Polyethylene glycol-microwave assisted almond protein extraction method

A technology of polyethylene glycol and almond protein, applied in protein food ingredients, protein composition of vegetable seeds, food science, etc., can solve the impact of protein nutritional value and food safety, protein emulsification and foaming functional reduction, Long extraction time and other problems, to achieve the effect of improving leaching efficiency, shortening extraction time, and shortening extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] With 100g defatted sweet almond powder as raw material, the method for polyethylene glycol-microwave-assisted extraction of almond protein comprises the steps:

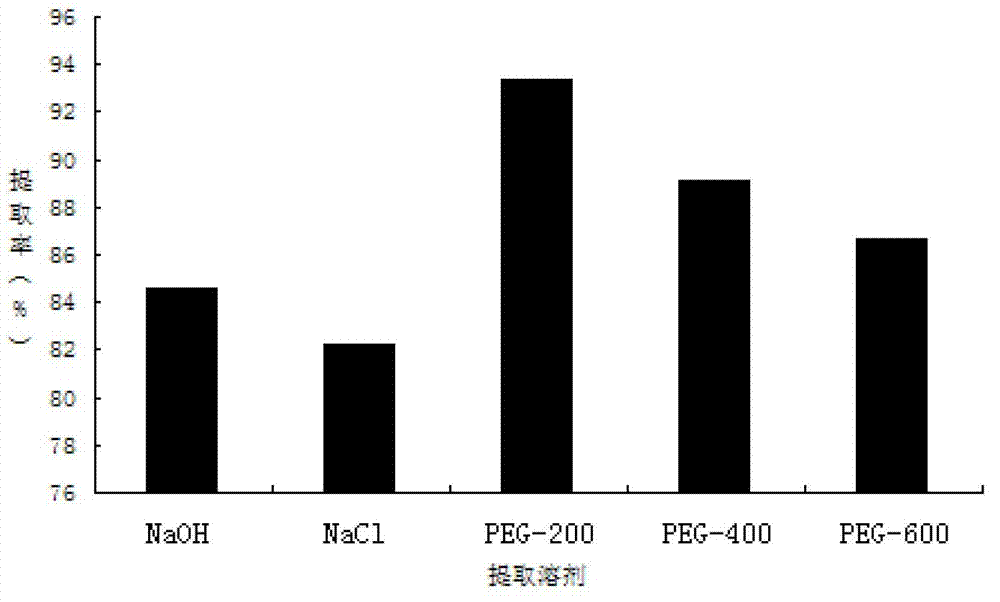

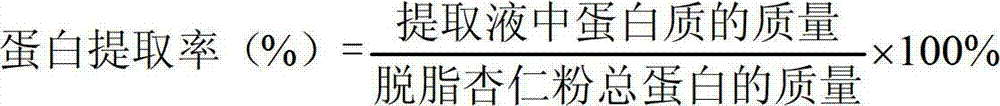

[0024] (1) Pass 100g of defatted sweet almond powder through a 70-mesh sieve, add 2200mL of polyethylene glycol 200 solution with a volume fraction of 25% to prepare a mixed solution with a material-liquid ratio of 1:22g / mL, and extract with 120w microwave at 45°C 4 minutes, under the condition of 9000 rpm, centrifuge for 9 minutes, take the supernatant, the extraction rate is 93.35%.

[0025] (2) Add 550 mL of ethanol to the supernatant of step (1), the volume ratio of the supernatant to ethanol is 1:0.25, stir and mix well, adjust the pH value to 4.5 with 1.0mol / L hydrochloric acid, and let stand for 4 Minutes to precipitate the protein, centrifuge for 6 minutes, discard the supernatant, wash the precipitate with water with a pH value of 4.5 for 3 times, and obtain the almond protein precipitate, and the prec...

Embodiment 2

[0029] With 100g defatted sweet almond powder as raw material, the method for polyethylene glycol-microwave-assisted extraction of almond protein comprises the steps:

[0030] (1) Pass 100g of defatted sweet almond powder through a 70-mesh sieve, add 2000mL of polyethylene glycol 200 solution with a volume fraction of 25% to prepare a mixed solution with a material-liquid ratio of 1:20g / mL, and extract with 120w microwave at 45°C 4 minutes, under the condition of 9000 rpm, centrifuge for 9 minutes, take the supernatant, the extraction rate is 91.65%.

[0031] (2) Add 480mL of ethanol to the supernatant of step (1), the volume ratio of the supernatant to ethanol is 1:0.24, stir and mix well, adjust the pH value to 4.5 with 1.0mol / L hydrochloric acid, and let stand for 4 Minute precipitation, centrifuged for 6 minutes, discarded the supernatant, and washed the precipitate 3 times with water with a pH value of 4.5 to obtain almond protein precipitation, and the precipitation rate...

Embodiment 3

[0034] With 100g defatted sweet almond powder as raw material, the method for polyethylene glycol-microwave-assisted extraction of almond protein comprises the steps:

[0035] (1) Pass 100g of defatted sweet almond powder through a 70-mesh sieve, add 2500mL of polyethylene glycol 200 solution with a volume fraction of 25% to prepare a mixed solution with a material-liquid ratio of 1:25g / mL, and extract with 120w microwave at 45°C 4 minutes, under the condition of 9000 rpm, centrifuge for 9 minutes, take the supernatant, the extraction rate is 92.14%.

[0036] (2) Add 675 mL of ethanol to the supernatant of step (1), the volume ratio of the supernatant to ethanol is 1:0.27, stir and mix well, adjust the pH value to 4.5 with 1.0mol / L hydrochloric acid, and let stand for 4 Minutes to precipitate, centrifuged for 6 minutes, discarded the supernatant, washed the precipitate with water with a pH value of 4.5 for 3 times, and obtained the almond protein precipitate, and the precipita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com