Patents

Literature

82results about How to "Increase sedimentation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

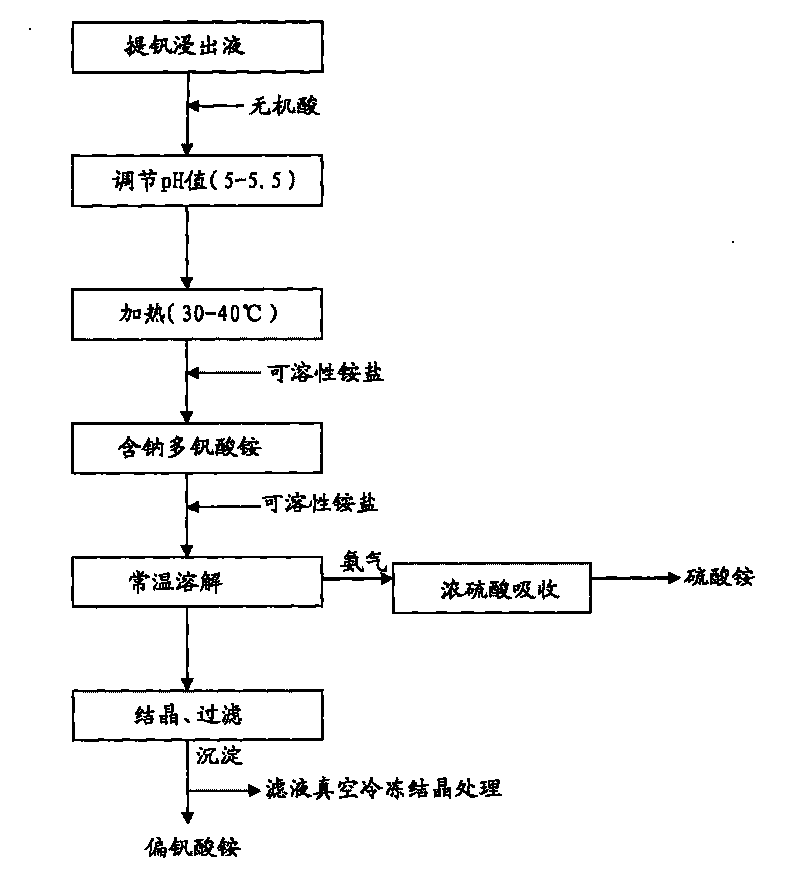

Method for preparing ammonium metavanadate from vanadium extraction leaching solution

InactiveCN101748297AIncrease sedimentation rateIncrease productivityVanadium compoundsRoom temperatureAmmonium metavanadate

The invention discloses a method for preparing ammonium metavanadate from a vanadium extraction leaching solution, comprising the following steps of: adjusting the pH value of the vanadium extraction leaching solution to 5-5.5 by using inorganic acid, then heating to the temperature of 30-40 DEG C, subsequently adding a soluble ammonium salt into the solution according to the mass ratio of NH4+:V=2.0-3.0, fully and uniformly stirring, and obtaining ammonium polyvanadate containing sodium after the reaction is finished; putting the obtained ammonium polyvanadate containing sodium into a sealed reactor, adding the soluble ammonium salt into the reactor according to the mol ratio of NH4+:V=3.0-5.0, slowly, uniformly stirring under the room temperature by controlling the pH value in the range of 7.5-8.5 and filtering the obtained solution after the reaction is finished to obtain an ammonium metavanadate solid.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM +1

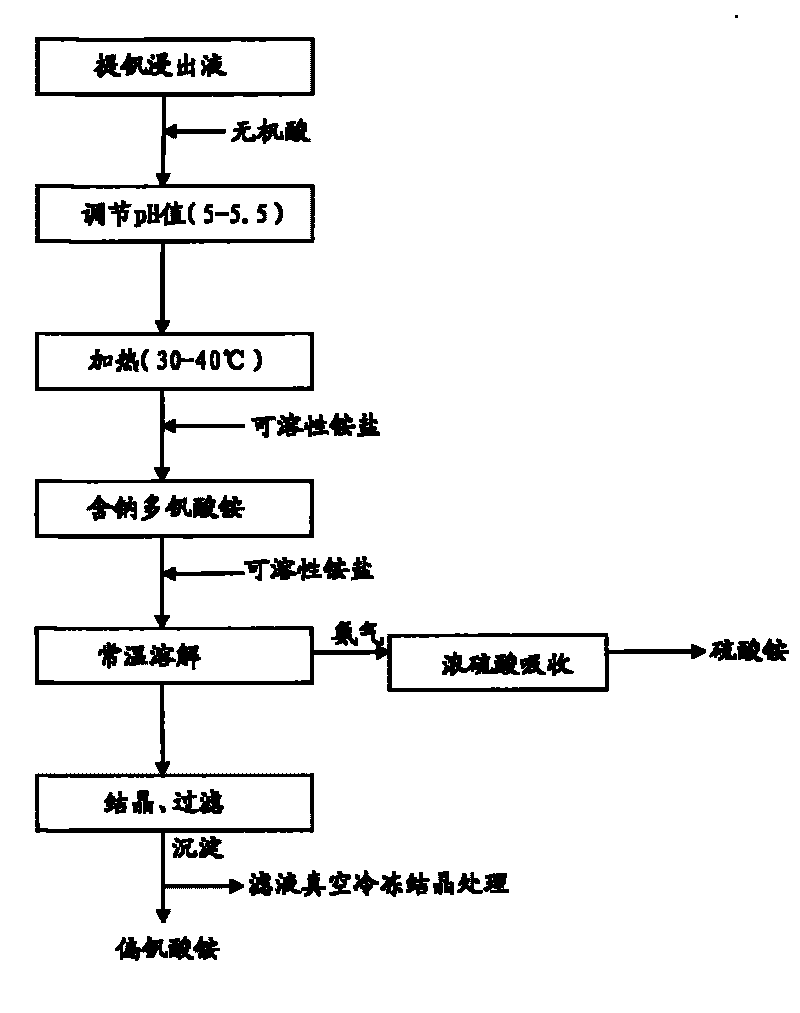

Method for separating arsenic and selenium from copper anode slime alkaline leach liquor

ActiveCN104911358ANo need to adjust pHRealize separation and enrichmentProcess efficiency improvementElemental selenium/telluriumPregnant leach solutionBarium salt

The invention discloses a method for separating arsenic and selenium from copper anode slime alkaline leach liquor. The method comprises the following steps: 1) oxidation, namely adding an oxidizing agent or introducing oxidizing gas into the copper anode slime alkaline leach liquor, so that oxidized copper anode slime alkaline leach liquor is obtained; 2) arsenic precipitation, namely adding a calcium salt into the oxidized copper anode slime alkaline leach liquor, stirring the obtained mixture so as to produce a precipitate, and carrying out filtration and separation on the precipitate so as to obtain a calcium arsenate precipitate and arsenic post-precipitation liquid; and 3) selenium precipitation, namely adding a barium salt into the arsenic post-precipitation liquid obtained in the step 2), stirring the obtained mixture so as to produce a precipitate, carrying out filtration and separation on the precipitate so as to obtain a barium selenate precipitate and selenium post-precipitation liquid, and carrying out evaporative crystallization on the selenium post-precipitation liquid so as to recycle alkali, or directly returning to a leaching process. The method disclosed by the invention is short in technological process, less in equipment and simple in operation, and can be used for realizing the separation and enrichment of arsenic and selenium, the precipitation rate of arsenic is higher than 96%, and the precipitation rate of selenium is higher than 99%; by virtue of carrying out evaporative crystallization on a solution for recycling or directly returning the solution to a leaching process, the recovery of alkali is realized.

Owner:CENT SOUTH UNIV

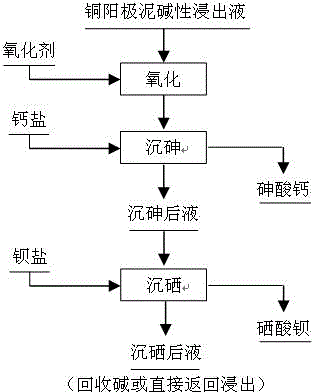

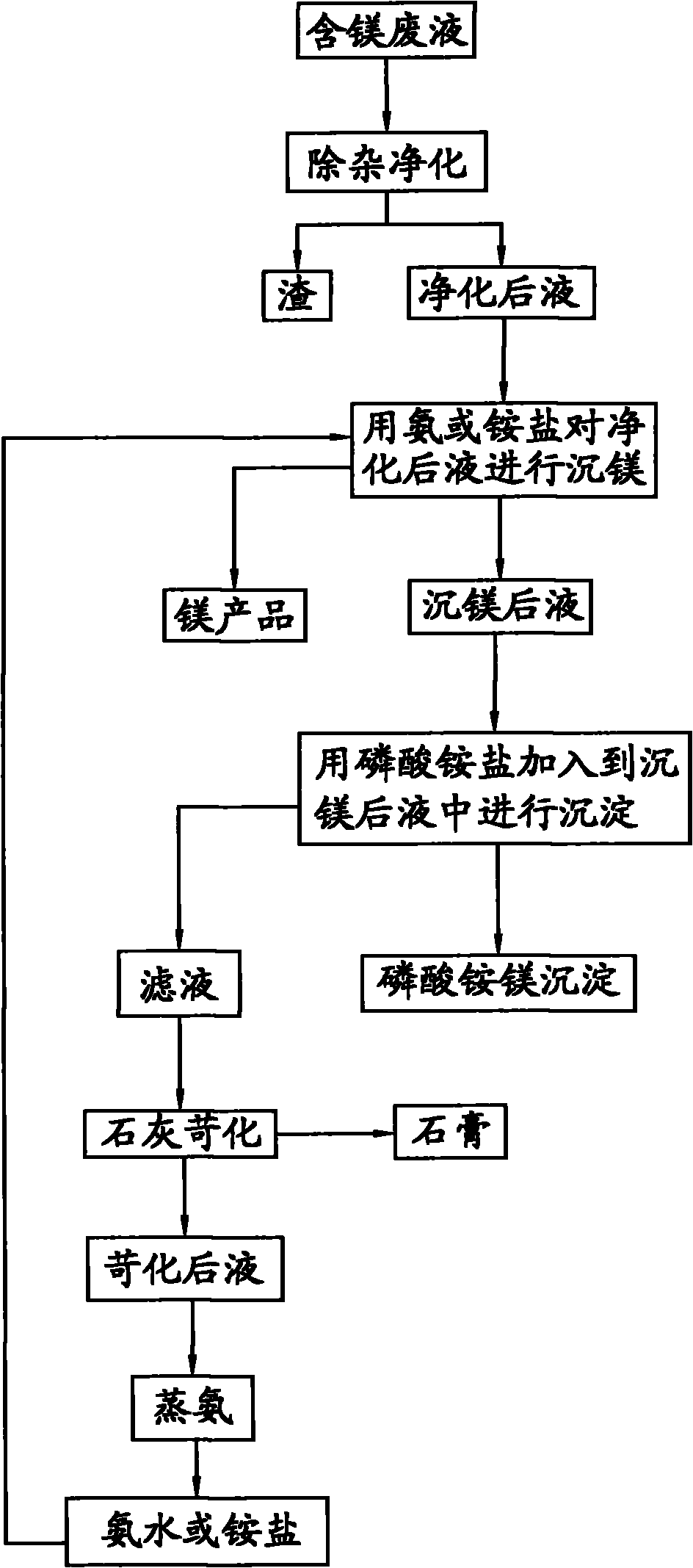

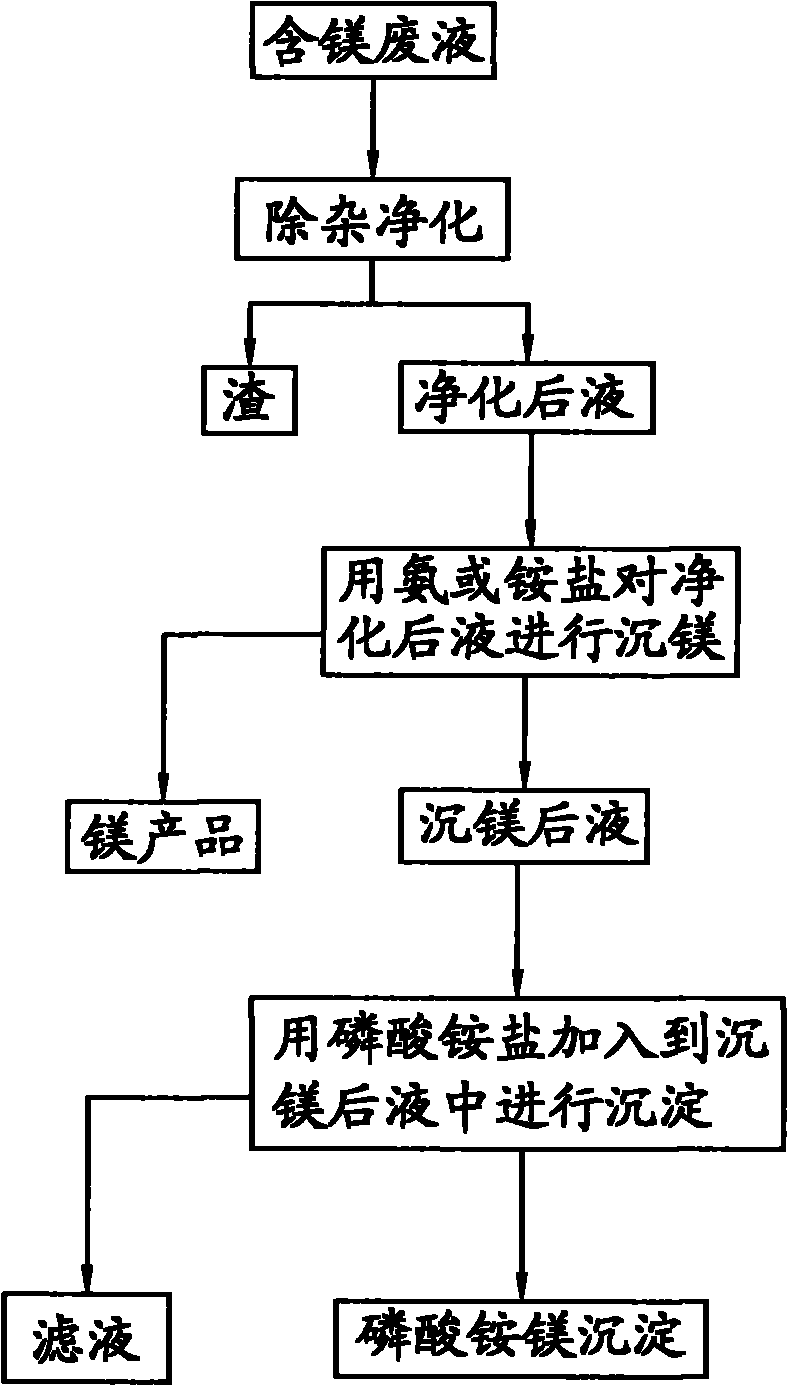

Method for treating waste liquid containing magnesium

ActiveCN101870461ASimple processEasy to controlCalcium/strontium/barium sulfatesPhosphorus compoundsMagnesium ammonium phosphateGypsum

The invention discloses a method for treating waste liquid containing magnesium. The method comprises the following steps of: performing impurity removal and purification on waste liquid containing magnesium to obtain dregs and purified liquid; performing magnesium precipitating on the purified liquid by using ammonia or ammonium salt to obtain magnesium product precipitate and magnesium precipitation liquid; and adding ammonium phosphate into the magnesium precipitation liquid for precipitation and filtration to obtain magnesium ammonium phosphate precipitate and filtrate. According to the method for treating waste liquid containing magnesium, magnesium ions which do not participate in the reaction can be thoroughly precipitated to obtain the high-quality magnesium ammonium phosphate used as a slow release fertilizer as the magnesium precipitation liquid is further treated by adopting the ammonium phosphate, thereby the full utilization of magnesium in the waste liquid is realized. In addition, the full precipitation of the magnesium in the waste liquid can avoid the lower gypsum purity caused by the formation of magnesium hydroxide when the gypsum is produced by using the magnesium precipitation liquid. By utilizing the method, the precipitation ratio of the magnesium ion in the waste liquid containing magnesium can reach more than 99 percent; and the method has simple process, easy control and low cost.

Owner:CHINA ENFI ENGINEERING CORPORATION

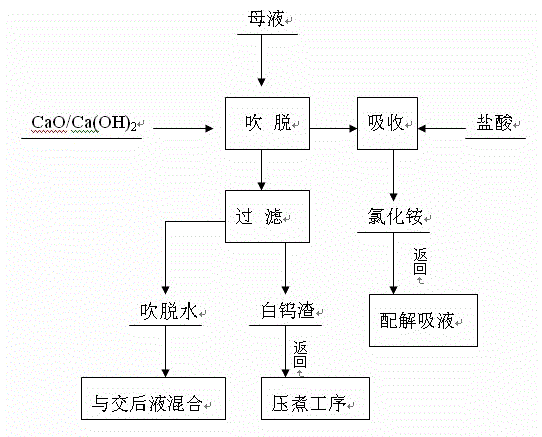

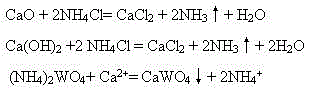

Method for recycling tungsten and ammonia in one step from ammonium paratungstate crystallization mother solution smelt through tungsten

InactiveCN102910648ALow costMature smelting technologyTungsten oxides/hydroxidesAmmonia preparation/separationBoiling processSlag

The invention discloses a method for recycling tungsten and ammonia in one step from an ammonium paratungstate crystallization mother solution smelt through tungsten. After the ammonium paratungstate (APT) is subjected to evaporative crystallization, a mother solution is pumped into a reaction kettle for stripping treatment, calcium oxide with content above 90% or calcium hydroxide with content above 95% are added into the mother solution, a stripping process which is commonly used in the crystallization mother solution in the APT preparation process is utilized to recycle the ammonia, the reaction temperature is in a range from 25 DEG C to 90 DEG C, when the ammonia is subjected to gas-liquid separation through condensation concentration, the ammonia is sprayed with a hydrochloric acid to prepare ammonium chloride to return to a main process to prepare an analytical solution, white tungsten slag returns to a pressure boiling process, when a potential of hydrogen (pH) value of a reaction system is maintained in a range from 9 to 11 and concentration of ammonia nitrogen in water is reduced to about 30mg / L, the reaction is finished, and a waste liquid free of the ammonia nitrogen is subjected to a mixing treatment with an ion exchange post-liquid which is generated in the main process working procedure. The method has the advantages that the process procedures are greatly simplified, the tungsten deposition rate is high, the process is simple, the operation is easy, and the treating cost is slightly low.

Owner:ZHONGXIANG TUNGSTEN IND

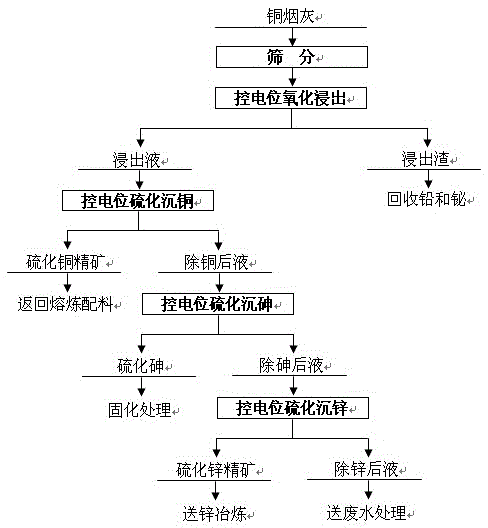

Method for potential controlled selection separation of copper refinery ash

InactiveCN105567984AIncrease sedimentation rateEasy to separateProcess efficiency improvementSlurryCopper sulfide

The invention relates to a method for potential controlled selection separation of copper refinery ash. The copper refinery ash is screened and then subjected to oxidizing leaching in a sulfuric acid system. An oxidizing agent is added to control the metal ion mixed potential of slurry, copper, arsenic, zinc and other metal are dissolved into a solution, and lead, bismuth and other metal precipitate and enter leaching residues. The metal ion mixed potential and the pH value of a leachate are simultaneously controlled, so that copper sulfide concentrate is produced through precipitation. The metal ion mixed potential and the pH value of copper-removed liquid are simultaneously controlled, so that arsenic sulfide products are produced through precipitation. The metal ion mixed potential and the pH value of arsenic-removed liquid are simultaneously controlled, so that zinc sulfide concentrate is produced through precipitation. Zinc-removed liquid is subjected to wastewater treatment and then discharged after reaching the standard. According to the method, the potential controlled oxidizing leaching and potential controlled sulfide precipitation ways are simultaneously adopted for recovering valuable metal step by step, the selection separation effect, which cannot be achieved by independently using the ways, of the valuable metal in the copper refinery ash is achieved, and the leaching rates of copper, arsenic and zinc are larger than 98.0%.

Owner:CENT SOUTH UNIV

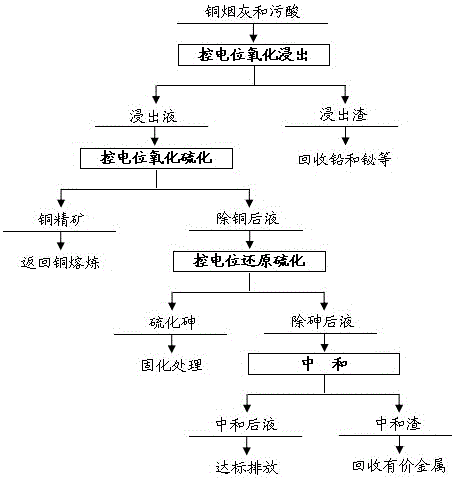

Combined treatment method for copper smelting soot and polluted acid

InactiveCN105950874AEasy to separateAvoid consumptionProcess efficiency improvementCopper sulfideSoot

The invention discloses a combined treatment method for copper smelting soot and polluted acid. The method includes the steps that after the copper smelting soot and the polluted acid are mixed for pulp conditioning, an oxidizing agent is added for controlled-potential oxidization leaching, so that copper, arsenic, zinc and other metal in the copper soot are dissolved to enter leachate, and lead, bismuth and other metal are precipitated to enter a reaching residue; then an oxidizing agent is added into the leachate so that As(III) in the solution can be completely oxidized into As(V); afterwards, sodium sulphide is added, so that the copper in the solution is precipitated in the form of copper sulphide to produce copper concentrate, and a reducing agent is added into the copper-removed solution so that the As(V) in the solution can be completely reduced into As (III); then sodium sulphide is added so that the arsenic in the solution can be precipitated in the form of arsenic sulfide; and finally the arsenic-removed solution is neutralized with alkaline and then is discharged after reaching the standard. By the adoption of the combined treatment method, controlled-potential oxidization leaching, controlled-potential oxidization sulfurization and reduction sulfurization are simultaneously combined to be used for step-by-step separation and recovery of valuable metal in the copper smelting soot and polluted acid, and therefore waste in the system can be recycled, and the purpose of using waste to treat waste is achieved.

Owner:CENT SOUTH UNIV

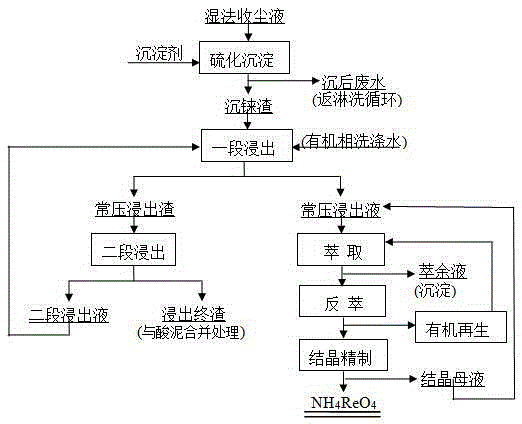

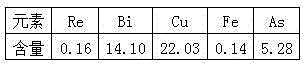

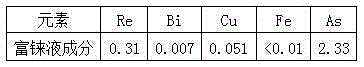

Method for extracting rhenium from copper smelting flue gas wet dust collecting liquid

InactiveCN105274348AIncrease sedimentation rateIncrease concentrationProcess efficiency improvementRheniumSlag

The invention provides a method for extracting rhenium from a copper smelting flue gas wet dust collecting liquid and relates to a method for selectively leaching rhenium by selectively enriching rhenium-rhenium precipitation slag from the copper smelting flue gas wet dust collecting liquid. The method comprises the following processing steps: firstly, the wet dust collecting waste liquid is put into a stirring tank, and a sodium thiosulfate solution is added to precipitate rhenate ions, wherein in the precipitation process, the generation of hydrogen sulfide can be effectively avoided, and the copper and the rhenium are selectively precipitated, while arsenic is less precipitated; secondly, the rhenium precipitation slag obtained through filtration after the precipitation reaction is subject to two-stage normal-pressure selective rhenium leaching, and the produced leachate is rich in rhenium and relatively low in impurity content; an amine extracting agent can be adopted for direct extraction to separate rhenium and for back extraction to obtain an ammonium rhenate solution high in concentration and purity. The method for extracting the rhenium from the wet dust collecting liquid is good in operating environment, simple in process and low in cost.

Owner:JINCHUAN GROUP LIMITED

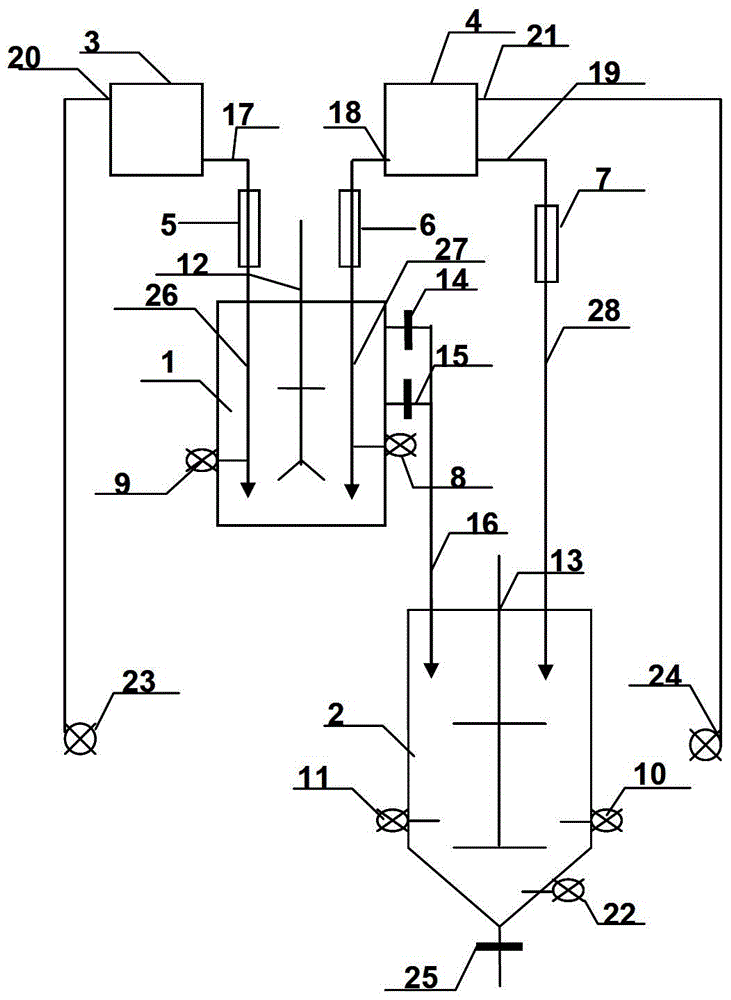

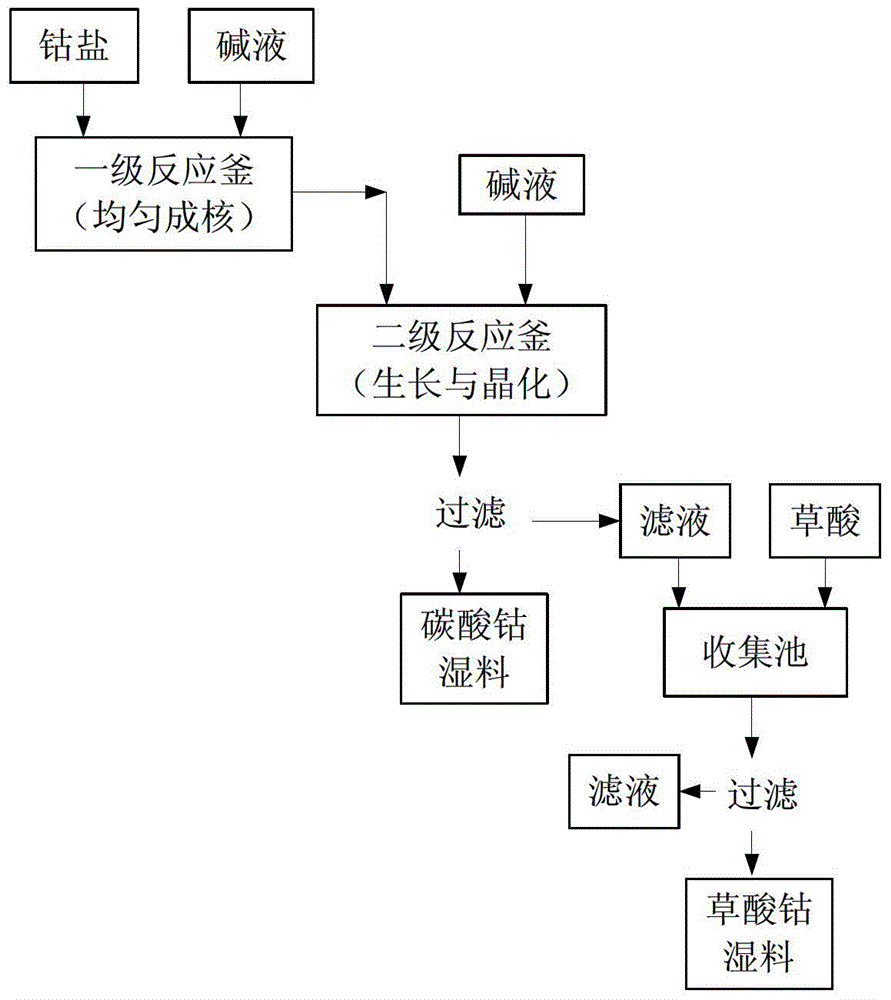

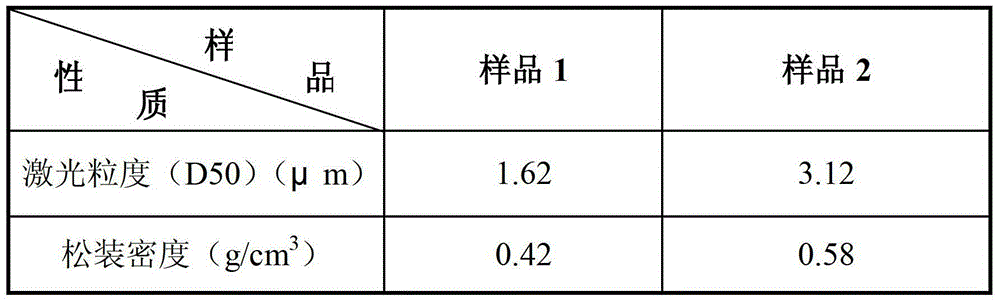

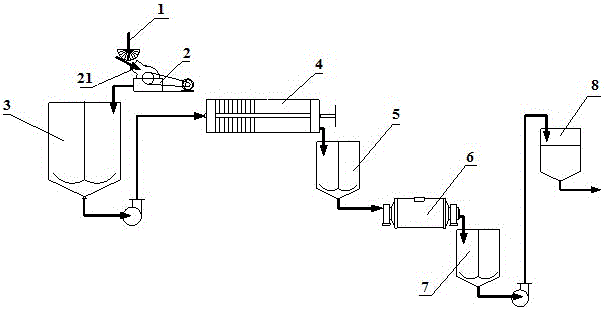

Process and device for continuous production of superfine cobalt carbonate powder

ActiveCN104418388AIncrease sedimentation rateHigh purityCobalt carbonatesFiltrationFirst-order reaction

The invention discloses a process for continuous production of superfine cobalt carbonate powder, the process includes two stages: first order reaction is homogeneous nucleation, the temperature is controlled at 15 to 30 DEG C, the pH value is 5.8-6.8, the vortex stirring speed is 800-1200R / min; and second stage reaction is growth and crystallization, the reaction temperature is controlled at 40 to 55 DEG C, the pH value is 6.8-7.2, the advection stirring speed is 200-400R / min, and a wet material is obtained by filtration of a precipitation material. The characteristics of the process are that: nucleation and growth processes are effectively separated, controllable cobalt carbonate powder particle size and morphology can be ensured, the co precipitation of impurity ions can be effectively avoided due to low pH value, and the product purity is improved. The invention also provides a device for the continuous production of the superfine cobalt carbonate powder, the characteristics are that: the device includes two stages of reactors, the process parameters can be independently set to facilitate independent performing of the nucleation and growth process.

Owner:JINGMEN GEM NEW MATERIAL

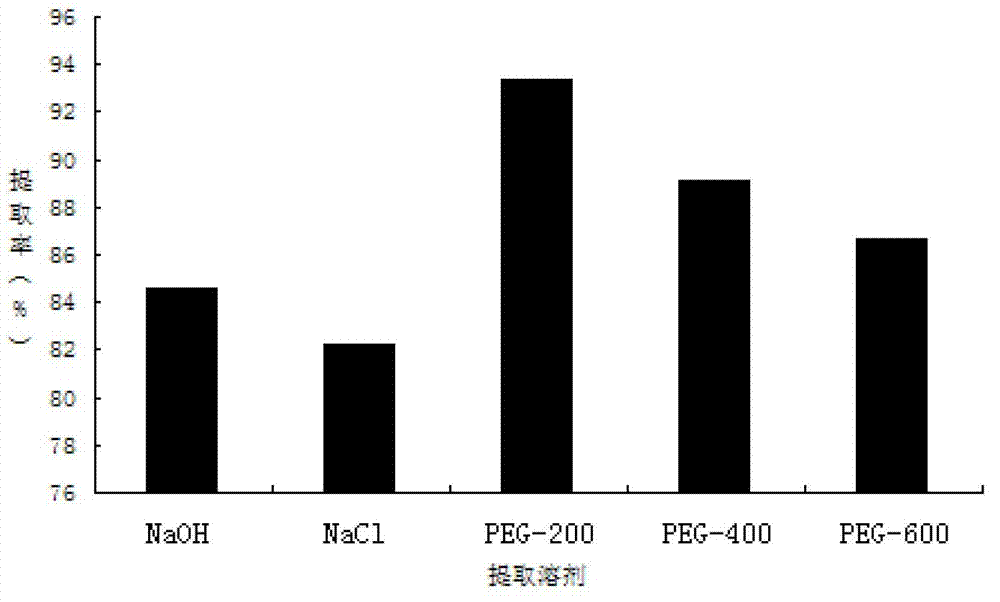

Polyethylene glycol-microwave assisted almond protein extraction method

InactiveCN102845585AHigh purityIncrease sedimentation rateProtein composition from vegetable seedsFreeze-dryingAdditive ingredient

The invention relates to a polyethylene glycol-microwave assisted almond protein extraction method, which adopts degreased almond powder as a raw material, and makes use of polyethylene glycol-microwave assisted extraction, isoelectric point-ethanol co-precipitation and vacuum freeze-drying to extract almond protein. Polyethylene glycol is a novel green solvent, has a solubilization effect on effective ingredients of almond protein, can improve the leaching efficiency and the extraction rate, and has no toxicity. Microwave-assisted extraction has the characteristics of high thermal efficiency, rapid and uniform temperature rising, greatly improved almond protein extraction efficiency, as well as shortened extraction time. Moreover, the almond protein has the advantages of high purity, high precipitation rate, simple extraction method, short extraction time, and environmental friendliness.

Owner:SHAANXI NORMAL UNIV

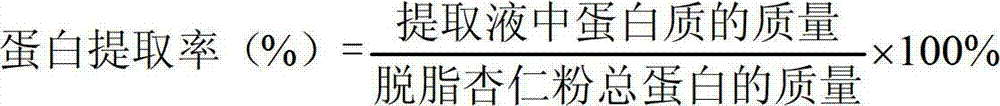

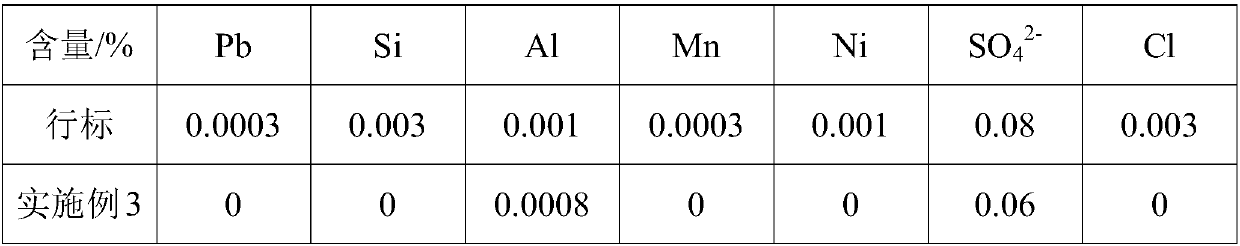

Method for selectively separating lithium from leaching solution of cathode material for waste lithium-ion batteries

ActiveCN109439914AImplement extractionRealize Adsorption SeparationProcess efficiency improvementOrganic solventElectrical battery

The invention discloses a method for selectively separating lithium from a leaching solution of a cathode material for waste lithium-ion batteries, and belongs to the field of regeneration of useful components of waste batteries. A crown ether compound which has the selective recognition action to lithium-ion is adopted as an adsorbent to dissolve in a certain organic solvent to extract the lithium-ion, and selective separation of the lithium-ion is realized; the lithium-ion can be separated from cobalt, nickel and manganese, steel and other organic solvent, the recovery ratio is high, the selectivity is high, and the extraction organic phase can be reused after stripping.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

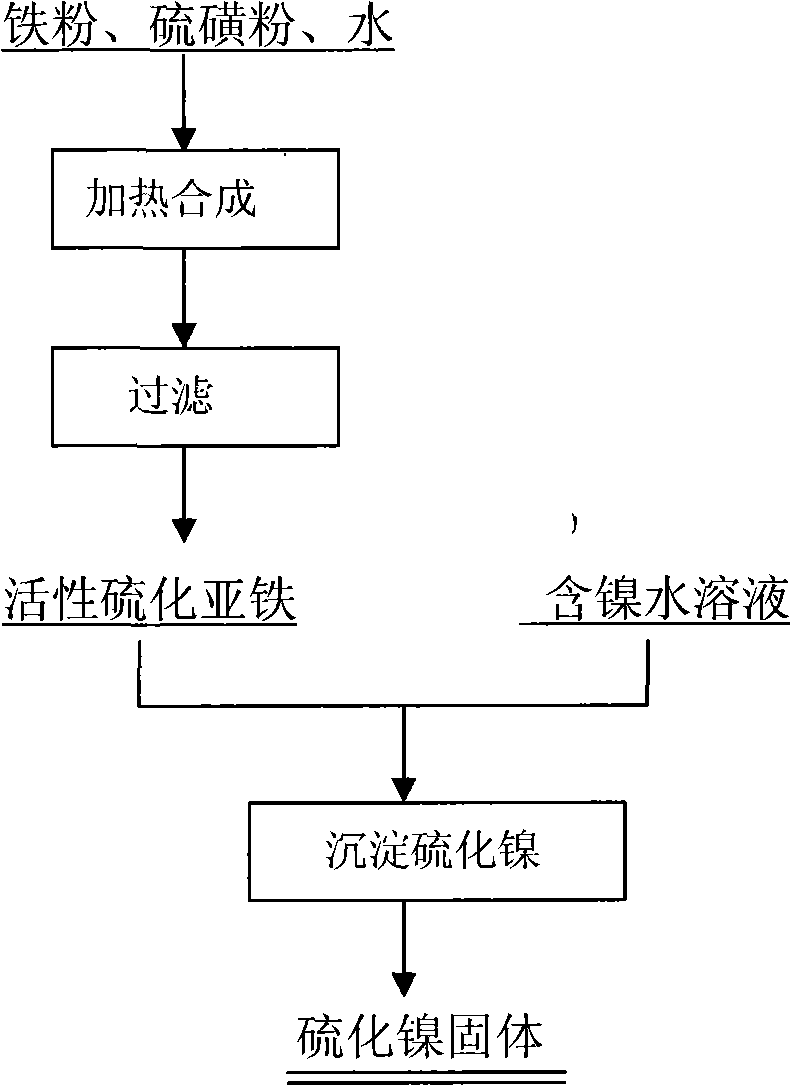

Synthesis of active ferrous sulphide and uses thereof

InactiveCN101508469AIncrease productivityIncrease sedimentation rateProcess efficiency improvementIron sulfidesNickel saltNickel sulfide

The invention provides a method for synthesizing active ferrous sulfide and application thereof. The invention belongs to the field of non-ferrous metallurgy, and relates to the synthesis of the active ferrous sulfide and application by using the active ferrous sulfide to precipitate nickel sulfide from a nickel-containing water solution. The method comprises that: the iron powder or / and nickel-iron powder is mixed with sulfur powder according to the mol ratio of metal iron to sulfur in the iron powder of 1:1-1.5, added with water for wetting, placed in a stirring reactor for heat-stirring reaction, cooled down, filtered to obtain the active ferrous sulfide, of which the main content of FeS reaches 75 percent and the average particle diameter is between 5 and 20mu m; and the active ferrous sulfide is added to a water solution of nickel-containing sulfate or chloride and subjected to heat-stirring reaction so as to precipitate the nickel sulfide. The active ferrous sulfide synthesized by the method has the advantages of high chemical activity, simple synthetic process and high production efficiency, and can be used to produce nickel salt or electronic nickel; and the method is an effective method for separating and recovering nickel from the nickel-containing solution.

Owner:YUNNAN TIN GROUP HLDG

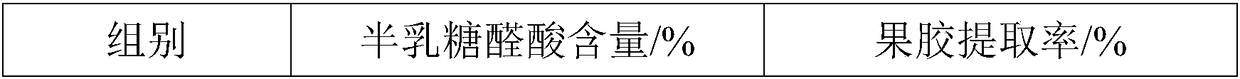

Process of extracting high-purity pectin from apple pomace

The invention discloses a process of extracting high-purity pectin from apple pomace, and relates to the technical field of pectin extraction. The process comprises the following steps: (1) rinsing for impurity removal; (2) powdering; (3) acid extraction; (4) decoloration; (5) concentration; (6) pectin settlement; (7) purification; (8) drying and powdering. According to the process, soluble sugarand part of pigments are removed from the apple pomace through rinsing operation; the apple pomace is granulated through the powdering operation to promote rapid leaching of the pectin during subsequent acid extraction; the pigments in a pectin extracting solution are effectively removed through the decoloration operation; by use of a pectin settling agent, the pectin settling rate and the pectinpurity are improved, so that the content of galacturonic acid in the prepared finished pectin is up to 85 percent or above, and the pectin extraction rate is up to 90 percent or above.

Owner:DANGSHAN HAISHENG PECTIN

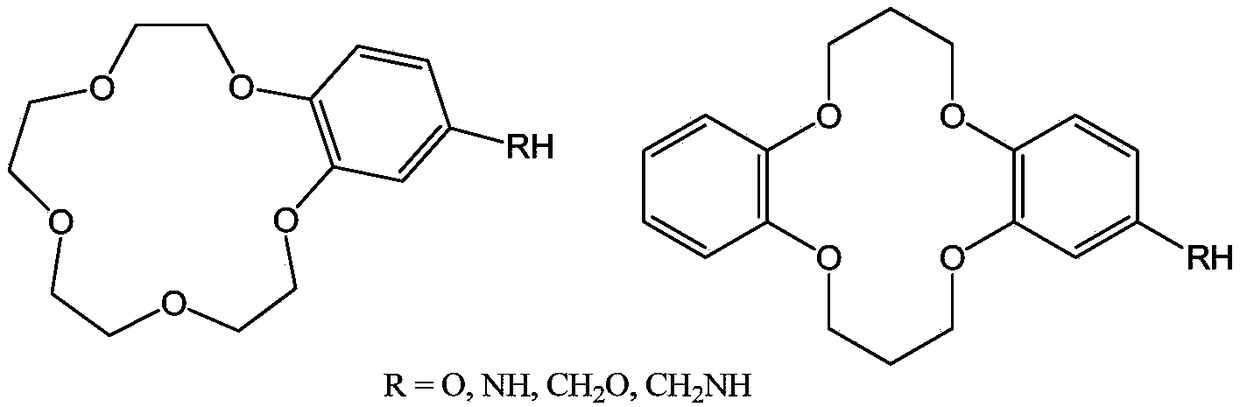

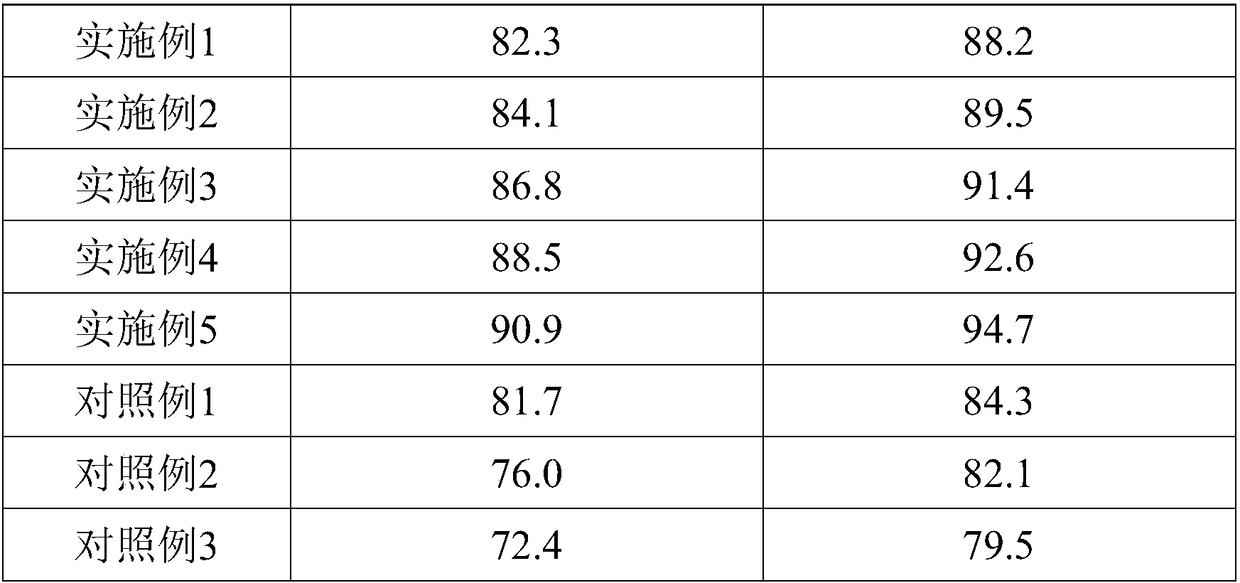

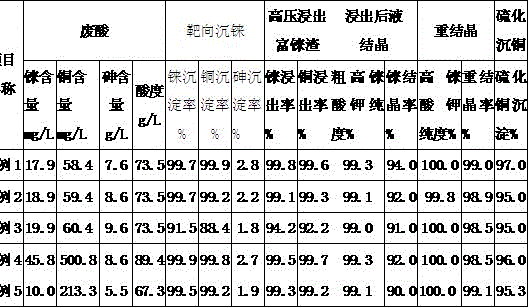

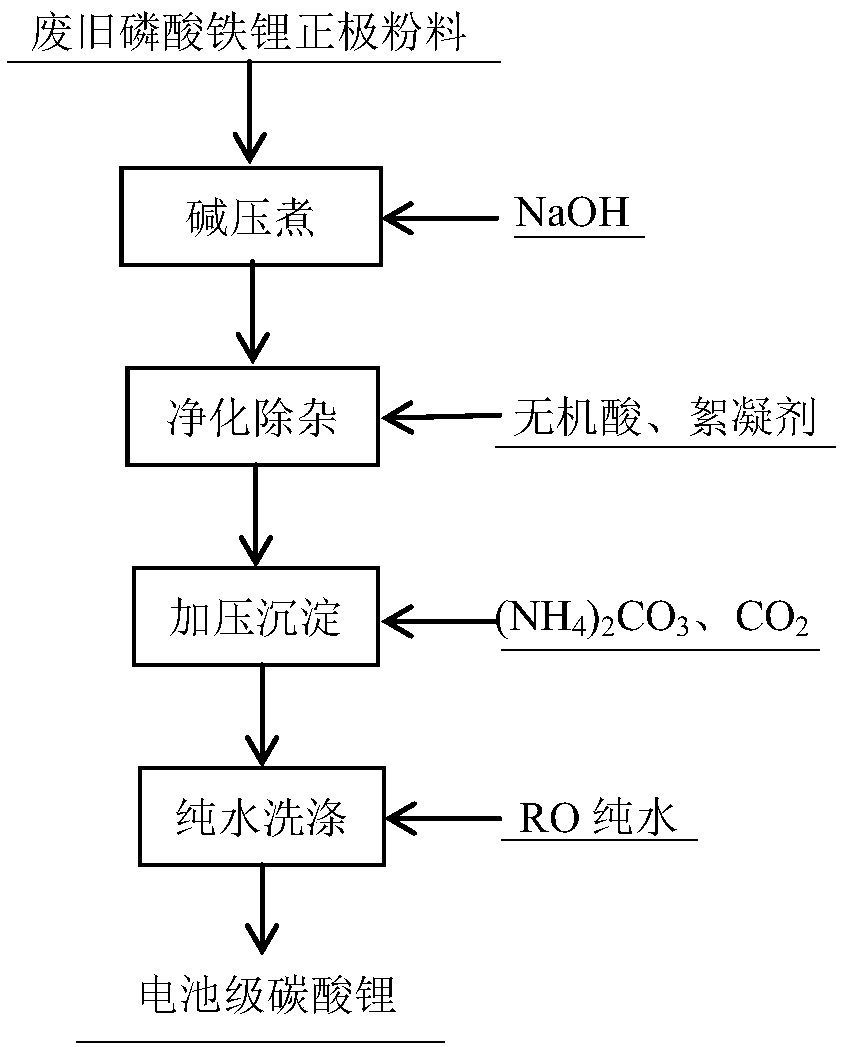

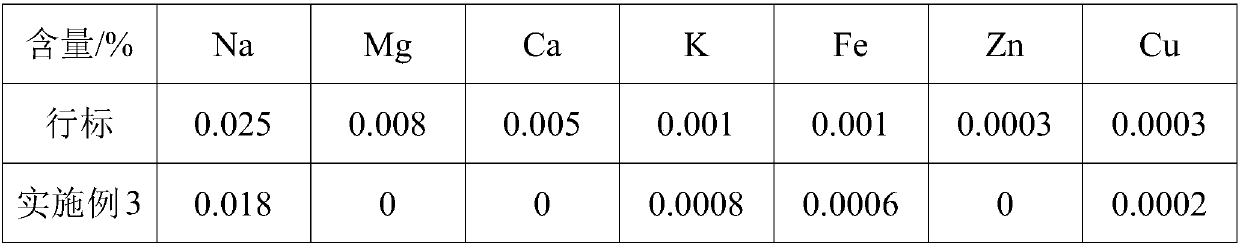

Method for recycling battery-grade lithium carbonate from anode powder of waste lithium iron phosphate battery

ActiveCN107540004AImprove leaching rateIncrease sedimentation rateLithium carbonates/bicarbonatesLithium iron phosphateLithium carbonate

The invention discloses a method for recycling battery-grade lithium carbonate from anode powder of a waste lithium iron phosphate battery. According to the method, anode powder of the waste lithium iron phosphate battery is studied, a vacuum boiling leaching mode is adopted, the leaching rate of lithium is greatly increased, influence of impurity metals is greatly reduced, and convenience is brought to later decontamination; in the presence of CO2, lithium carbonate is prepared from ammonium carbonate through vacuum precipitation, influence of sodium ions to impurity is avoided, the recyclingeffect of lithium is improved, thermal washing is implemented with RO (Reverse Osmosis) pure water, and the battery-grade lithium carbonate can be prepared. The method is a novel process route whichis short in process, high in lithium recycling rate, high in lithium carbonate purity, large in product additional value and capable of recycling waste lithium iron phosphate anode powder, and has great social values and considerable economic benefits.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

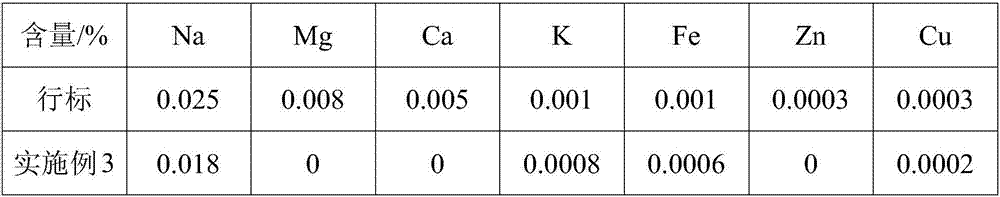

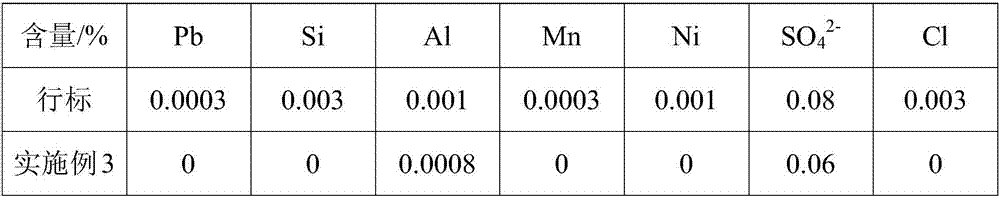

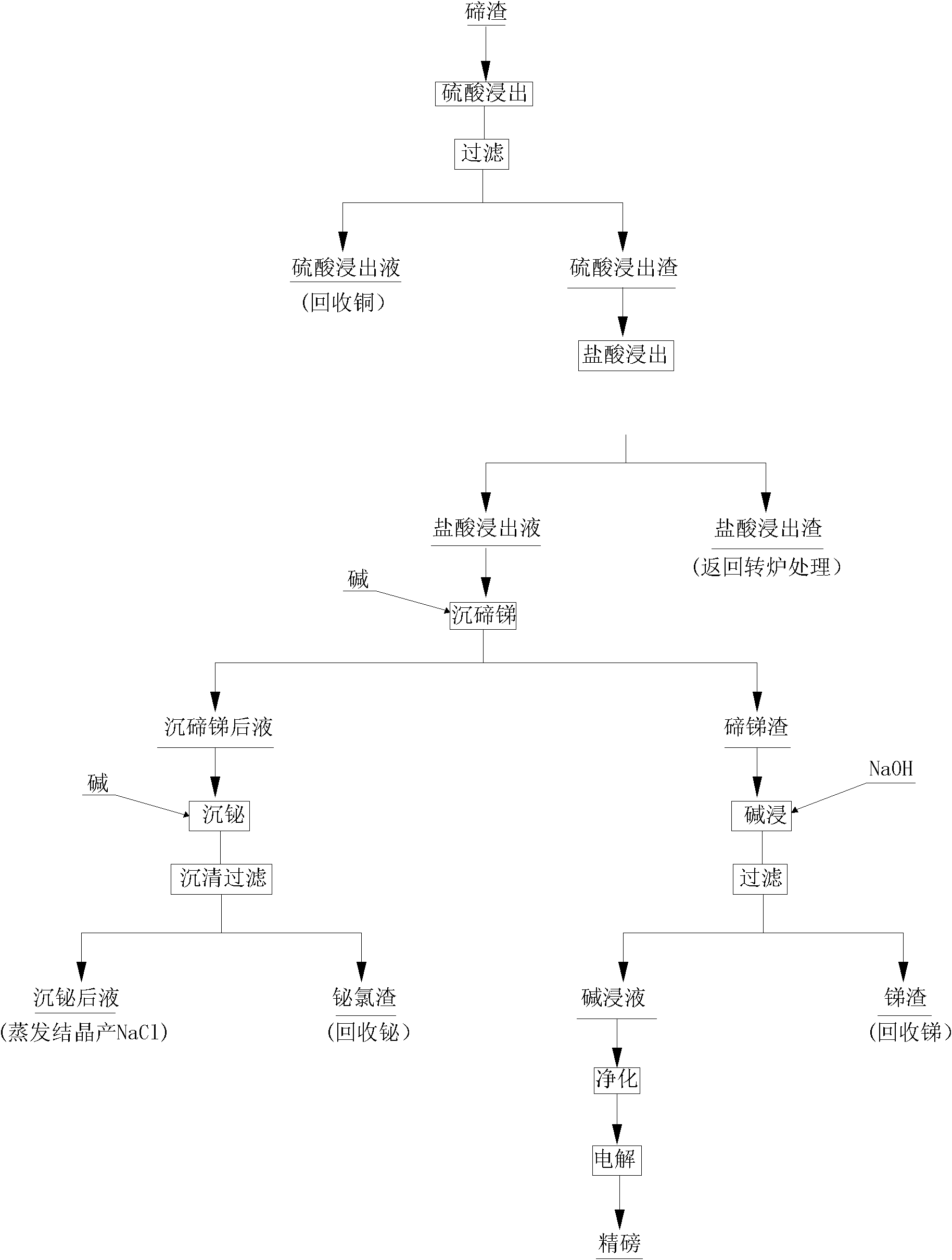

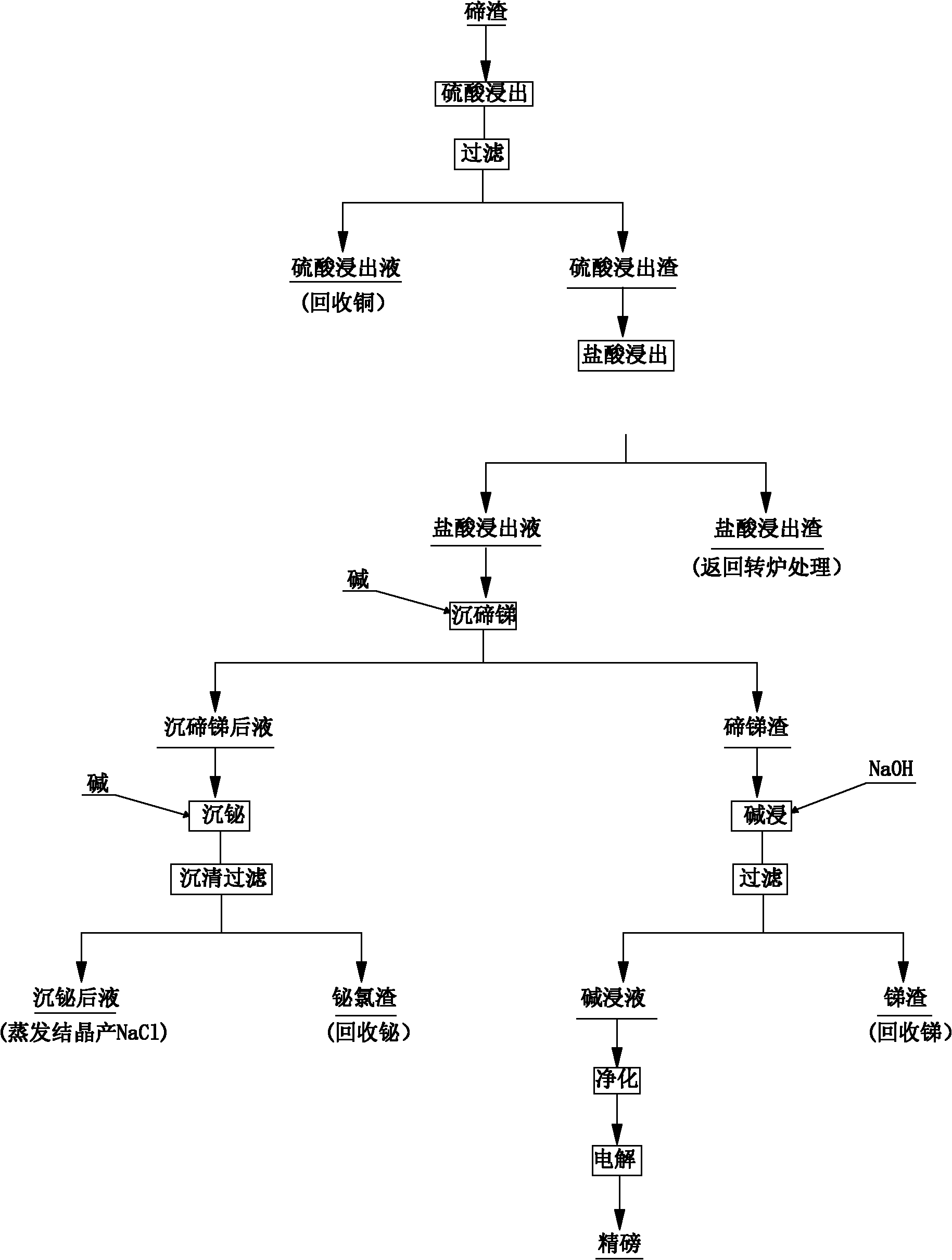

Method for comprehensively recovering valuable metals from low-grade tellurium slag

ActiveCN102002597AImprove direct yieldIncrease sedimentation rateSelenium/tellurium compundsProcess efficiency improvementSlagMaterials science

The invention discloses a method for comprehensively recovering valuable metals from low-grade tellurium slag, and aims to provide the method for comprehensively recovering the valuable metals from the low-grade tellurium slag. The method is characterized by comprising the following steps of: A, crushing and grinding the tellurium slag until the tellurium slag is below 80 meshes, stirring and leaching with a sulfuric acid and filtering to obtain sulfuric acid leach liquor and sulfuric acid leach residue; B, stirring and leaching the sulfuric acid leach residue obtained in the step A with a hydrochloric acid, cooling and filtering to obtain hydrochloric acid leach liquor and hydrochloric acid leach residue; C, stirring the hydrochloric acid leach liquor obtained in the step B, and adding alkali to precipitate tellurium and antimony so as to obtain liquor obtained after tellurium and antimony precipitation and tellurium and antimony slag; D, leaching the tellurium and antimony slag obtained in the step C with sodium hydroxide for 2 to 4 hours and filtering to obtain alkaline leach liquor and antimony slag; and E, adding the alkali into the liquor obtained after tellurium and antimony precipitation obtained in the step C to precipitate bismuth, settling and filtering to obtain bismuth chloride slag and recovering the bismuth. The method is mainly used for comprehensively recovering the valuable metals such as copper, bismuth, antimony, tellurium and the like from the low-grade tellurium slag.

Owner:ZHUZHOU SMELTER GRP

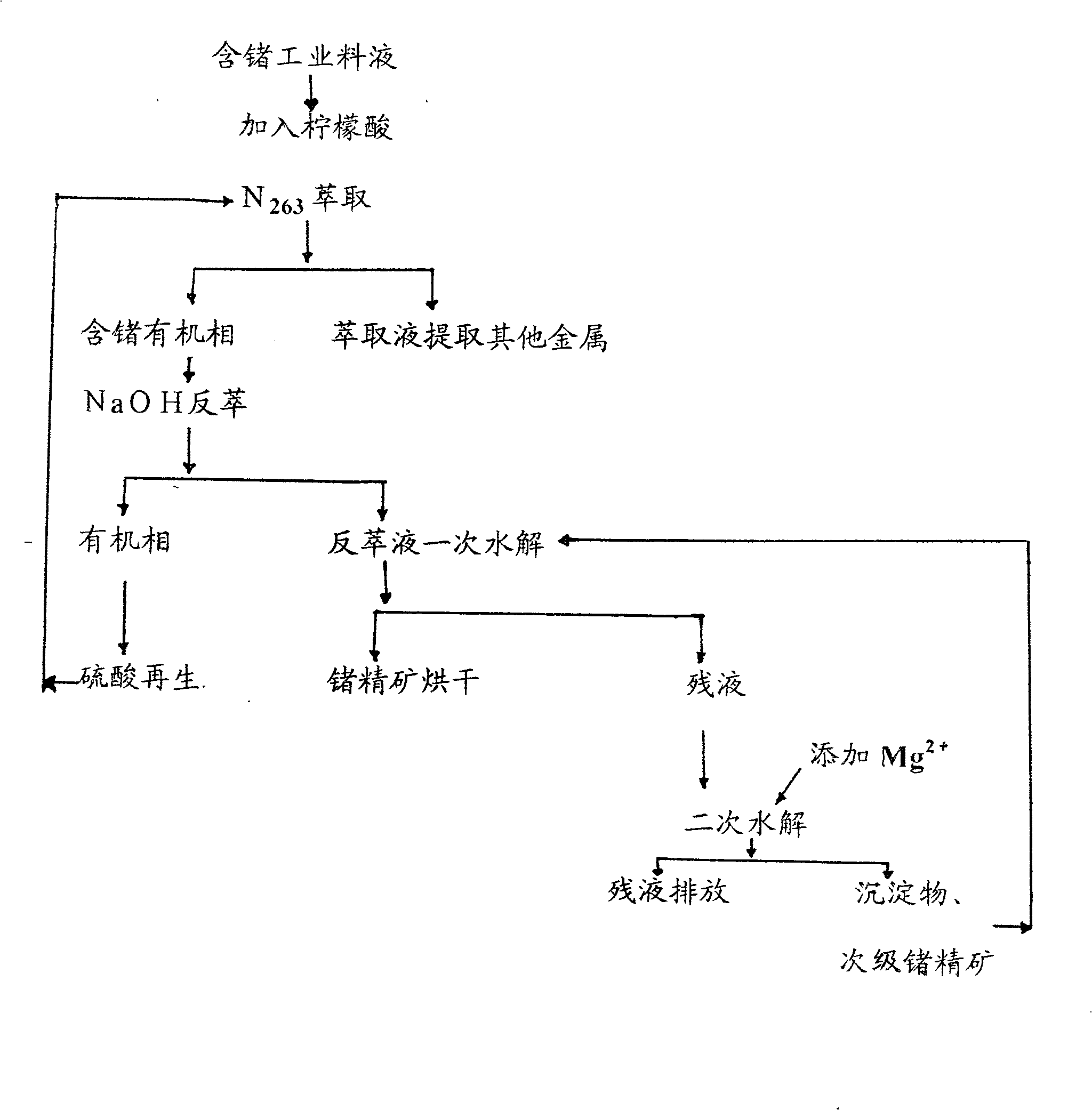

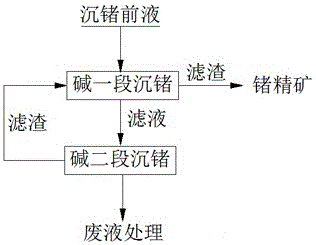

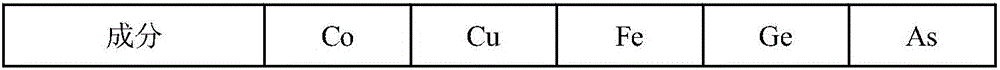

Method for producing germanium concentrated ore from germanium-containing industrial liquor

The invention relates to a method for producing germanium concentrated ore from germanium-containing industrial liquor, and belongs to the technical field of nonferrous metallurgy. The method comprises that: a, a germanium complexing agent is added into the germanium-containing industrial liquor of which pH is 0.5 to 3, wherein the complexing agent is organic acid containing hydroxyl or carboxyl or / and salt of the organic acid, and the weight ratio of the complexing agent to the germanium is 3-10:1; b, an organic reagent of quaternary ammonium with an R4N structure or tertiary amine with an R3N structure is used as an extracting agent to extract the germanium in the liquor obtained in step a, wherein R is hydrocarbyl or alkyl or fatty group, N is organic ammonium salt, and the extracting agent accounts for 10 to 50 percent of the extracted liquor by volume; c, NaOH water solution or Na2CO3 water solution of which the concentration in percentage by weight is 5 to 30 percent is used for reversely extracting the germanium-containing organic phase obtained in step b; and d, the pH of the obtained reverse extracted liquor is adjusted to 8 to 12 by acid, then the liquor is dehydrated twice and filtered, and the sediment is dried to form the germanium concentrated ore. The method can produce the germanium concentrated ore from various germanium industrial liquors, the extracting agent and the complexing agent are easily obtained, the extracting and reverse extracting effects are good, and the yield of the germanium is high.

Owner:YUNNAN WUXIN IND

Impurity removing method of vanadium solution

InactiveCN102888512AReduce lossesIncrease sedimentation rateProcess efficiency improvementCommon methodSulfuric acid

The invention discloses an impurity removing method of vanadium solution. The impurity removing method comprises steps as follows: a, adding an oxidant which is capable of respectively oxidizing Fe<2+> and V<4+> in the vanadium solution into Fe<3+> and V<5+> to the vanadium solution based on the contents of Fe<2+> and V<4+> in the vanadium solution, so as to remove impurities; b, adding a precipitating agent to the impurity-removed vanadium solution, and agitating so as to completely dissolve an impurity removing agent within 3 minutes; c, adjusting the pH (Potential Of Hydrogen) of the vanadium solution to reach 1.5-2.2 by virtue of sulfuric acid; d, heating the vanadium solution of which the pH is adjusted, and precipitating the vanadium solution for 60-150 minutes at 80-100 DEG C; and e, carrying out solid-liquid separation to the precipitated vanadium solution by virtue of common methods such as filtering, and then washing to obtain vanadate. With the adoption of the method disclosed by the invention, the impurity Fe2<+> which is disadvantageous for be precipitated can be removed from the vanadium solution, so that the precipitating rate in precipitating and producing process can be improved; and meanwhile, the tetravalent vanadium is reduced into pentavalent by virtue of the oxidant, so that the loss of the vanadium is decreased.

Owner:攀钢集团西昌钢钒有限公司

Arsenic-alkali slag treatment method and device

ActiveCN104120274BAddressing deficiencies in physical healthSmooth process operationProcess efficiency improvementPregnant leach solutionSlag

A method and device for treating arsenic-alkali slag. The method is to wet crush arsenic-alkali slag, add an oxidizing agent to perform the first leaching, and filter and separate to obtain the first leaching slag and the first leaching solution, and the first leaching slag Ball milling is carried out after pulping, adding an oxidizing agent after ball milling to perform second leaching and then filtering to obtain second leaching residue and second leaching solution. The present invention also includes an arsenic-alkali slag treatment device, which includes a water spray device, a crusher, a primary leaching unit, a primary leaching filter, a pulping unit, a grinding unit, a secondary leaching unit and a secondary leaching filter. The method and device of the present invention can achieve crushing and ball milling without raising dust, can minimize the pollution of harmful dust to the operating environment and the atmospheric environment, and can ensure >97.00% arsenic removal rate and >95.00% antimony incorporation while protecting the environment. The slag rate, crushing, ball milling and leaching are organically combined, not easy to block, and the process is smooth.

Owner:锡矿山闪星锑业有限责任公司

Method for quickly depositing lithium carbonate from lithium bicarbonate solution

ActiveCN101182012AIncrease sedimentation rateHigh recovery rateCarbonate preparationHydrogenOrganic solvent

The invention provides a method for rapidly precipitating lithium carbonate from lithium bicarbonate solution. The method adopts a heatable negative pressure device, uses water-soluble organic solvents such as ethanol, propanol, etc., controls the temperature at 80-180°C, and stirs under the condition of negative pressure in the container at 0.01-0.10MPa to carry out isovolumic reaction, so that bicarbonate Lithium decomposes, precipitates lithium carbonate, and the precipitated mother liquor can be recycled and reused. The present invention not only overcomes the problems of "wall-hanging effect" of precipitation and "concentration entrainment effect" of water-soluble impurity ions in the ordinary evaporation and precipitation process, but also accelerates the precipitation rate: the precipitation process only takes about 20 minutes, which is faster than the ordinary evaporation and precipitation method. 2 to 3 times; the precipitation rate of lithium is improved: the single precipitation rate of lithium carbonate reaches more than 87%, and the total lithium recovery rate reaches more than 94%.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

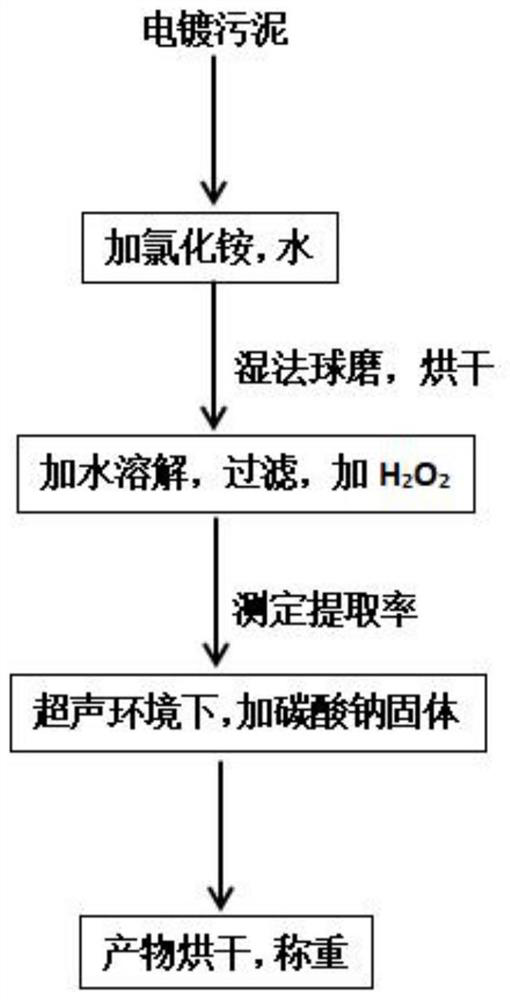

Method for selectively recovering heavy metals from electroplating sludge

InactiveCN111961864ARealize step-by-step precipitationIncrease sedimentation rateProcess efficiency improvementSludgeUltrasound assisted

The invention discloses a method for selectively recovering heavy metals from electroplating sludge. The method particularly comprises the steps that: step (1), the electroplating sludge, ammonium chloride and water are mixed in proportions, then wet milled with a ball mill and then taken out for drying; step (2), a product obtained in step (1) is dissolved in water, filtered with suction, and washed with deionized water; step (3), a certain amount of 30% hydrogen peroxide is added to a solution obtained in step (2), the concentration of each heavy metal element is determined after standing for a period of time, and the extraction rate is calculated; step (4), a solution in step (3) is taken and adjusted by ultrasonic under 80W-120W conditions and is added a precipitation agent to adjust the pH, so that the heavy metals in the electroplating sludge are precipitated step by step in the form of hydroxides. The method efficiently extracts the heavy metal elements in the electroplating sludge through wet ball milling, and uses the ultrasonic-assisted-step precipitation method to recover several heavy metal elements in the form of precipitation.

Owner:NANCHANG HANGKONG UNIVERSITY

Method for preparing lithium carbonate by using lithium aluminum-containing rock

ActiveCN107265486AAchieve separationEfficient separationPhosphatesAmmonium sulfatesFiltrationPhosphate

The invention discloses a method for preparing lithium carbonate by using lithium aluminum-containing rock. The method comprises the following steps: S1) the lithium aluminum-containing rock and a sulfur phosphor mixed acid leaching agent are mixed, a mixture is leached, the mixture is filtered to obtain a lithium-containing leachate; S2) hydrogen peroxide is added, then the materials are continuously stirred, an ammonium hydroxide solution is added for adjusting the pH value, water is added for dilution, the material is filtered to obtain a lithium-containing purified solution; S3) the lithium-containing purified solution is subjected to evaporative concentration to form a hot saturated solution, the hot saturated solution is cooled for crystallization, and mixed crystals of ammonium sulfate and ammonium biphosphate can be precipitated to obtain a lithium-containing concentrate; and S4) finally magnesium chloride is added, the pH value is adjusted by gradually adding a sodium hydroxide solution, the materials are stirred and reacted under normal temperature, filtration is carried after the reaction is finished, and the material can be filtered to obtain a phosphate-removing filtrate. and S5) the phosphate-removing filtrate is heated for concentration, solid sodium carbonate is added, after the reaction is finished, filtration is carried out while hot, the hot water is used for washing the precipitates, and the precipitates are dried to obtain the lithium carbonate. The method employs a chemical precipitation method, ammoniacal liquor is taken as a precipitating agent, magnesium salt is taken as a phosphor precipitating agent, lithium and aluminium separation is realized, lithium and phosphor separation is realized, and the lithium carbonate can be finally prepared.

Owner:GUIZHOU UNIV

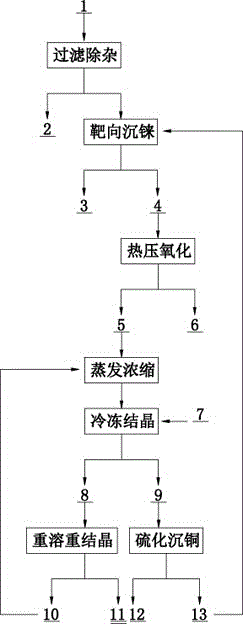

A method of comprehensively recovering rhenium and copper from copper smelting waste acid

ActiveCN105969985AIncrease sedimentation rateReduce dosageProcess efficiency improvementSlagPotassium

A method of comprehensively recovering rhenium and copper from copper smelting waste acid is disclosed. The method includes subjecting the copper smelting waste acid after being filtered to remove lead to targeted rhenium settling to obtain rhenium-rich slag, subjecting the rhenium-rich slag to hot-press oxidation leaching to obtain a rhenium-rich leachate, evaporating and concentrating to make the rhenium concentration 10-20 g / L, performing rhenium settling with KCl, and recrystallizing to obtain potassium perrhenate, and subjecting the liquid after rhenium settling to sulfuration copper settling. The objective of the method is to overcome complex processes, long treatment time, low recovery rates, and other disadvantages of processes recovering rhenium and copper from copper smelting waste acid through leaching at present, and to form a process which is low in investment, simple in operation, high in recovery rate, low in cost, low in pollution and convenient for industrial popularization and application, thus achieving high-value utilization of the rhenium resource in the copper smelting waste acid.

Owner:ZIJIN MINING GROUP

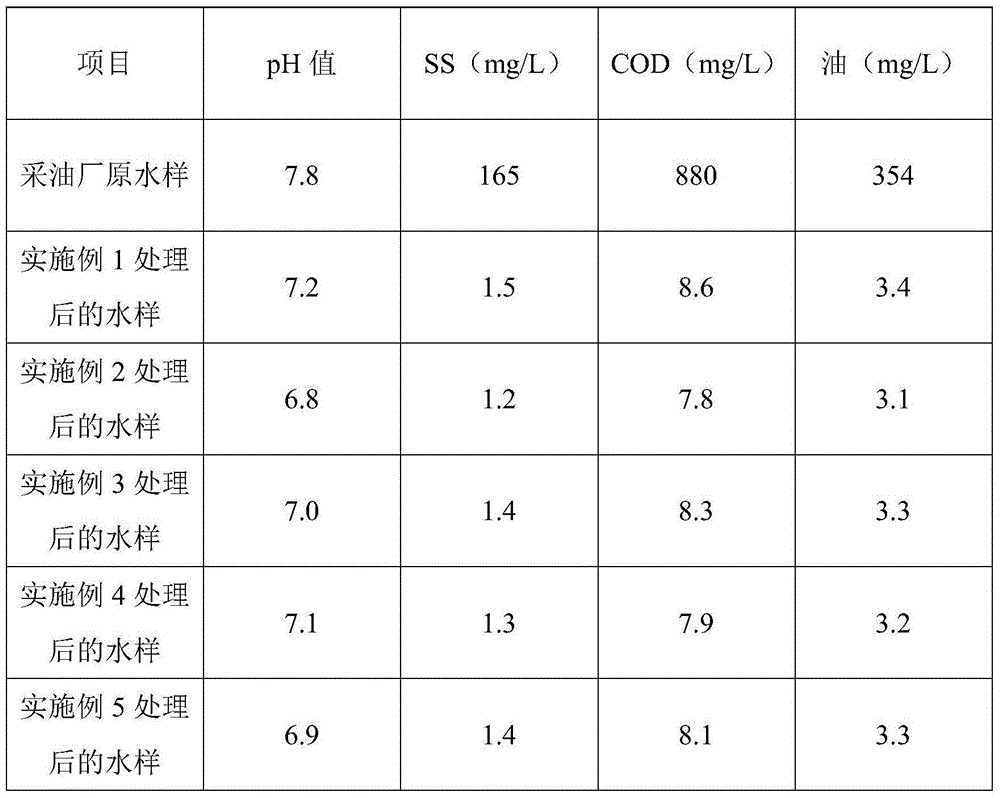

Sewage treatment agent for oil production plant

ActiveCN105198055AIncrease sedimentation rateImprove water qualityWater/sewage treatment by flocculation/precipitationWater qualityOil production

The invention discloses a sewage treatment agent for an oil production plant, belonging to the technical field of preparation of the sewage treatment agent. The sewage treatment agent for the oil production plant is prepared from the following raw materials in parts by weight: 40 to 80 parts of demulsifier, 30 to 60 parts of flocculant, 30 to 60 parts of foaming agent, 20 to 50 parts of flotation agent, 15 to 35 parts of fungicide, 10 to 20 parts of slow rot scale inhibitor, and 10 to 20 parts of deoxidant. The treatment agent provided by the invention for the oil production plant has the advantages of high deposition rate, good effluent quality, low treatment cost, no corrosive effect, nontoxicity, no pollution, safety in use, and the like; after oil production plant sewage is treated by adopting the treatment agent provided by the invention, the pH value basically reaches neutral pH, the SS removing rate can reach 99.09% to 99.27%, the COD removing rate can reach 99.02% to 99.11%, and the oil removing rate can reach 99.04% to 99.12%.

Owner:嘉兴沃特泰科环保科技股份有限公司

Preparation method of medium ferrovanadium

The invention provides a preparation method of medium ferrovanadium. The method comprises the following steps of: contacting a vanadium-extracting lixivium with a water-soluble ferric salt; controlling the pH value of a reaction system to be in a range of 1.8-2.8 through adding calcium hydroxide and / or calcium oxide in the contact process; carrying out solid-liquid separation on a product obtained after contact so as to obtain a solid containing ferric vanadate and calcium vanadate; calcining and dewatering the obtained solid and then evenly mixing the solid with aluminum powder, calcium oxide and magnesium oxide; and smelting the evenly mixed mixture in an induction furnace to obtain medium ferrovanadium. The method provided by the invention is a medium ferrovanadium preparation method which is simple in production process and low in cost.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

A method for recovering battery-grade lithium carbonate from waste lithium iron phosphate battery cathode powder

ActiveCN107540004BImprove leaching rateIncrease sedimentation rateLithium carbonates/bicarbonatesReverse osmosisDiammonium carbonate

The invention discloses a method for recycling battery-grade lithium carbonate from anode powder of a waste lithium iron phosphate battery. According to the method, anode powder of the waste lithium iron phosphate battery is studied, a vacuum boiling leaching mode is adopted, the leaching rate of lithium is greatly increased, influence of impurity metals is greatly reduced, and convenience is brought to later decontamination; in the presence of CO2, lithium carbonate is prepared from ammonium carbonate through vacuum precipitation, influence of sodium ions to impurity is avoided, the recyclingeffect of lithium is improved, thermal washing is implemented with RO (Reverse Osmosis) pure water, and the battery-grade lithium carbonate can be prepared. The method is a novel process route whichis short in process, high in lithium recycling rate, high in lithium carbonate purity, large in product additional value and capable of recycling waste lithium iron phosphate anode powder, and has great social values and considerable economic benefits.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

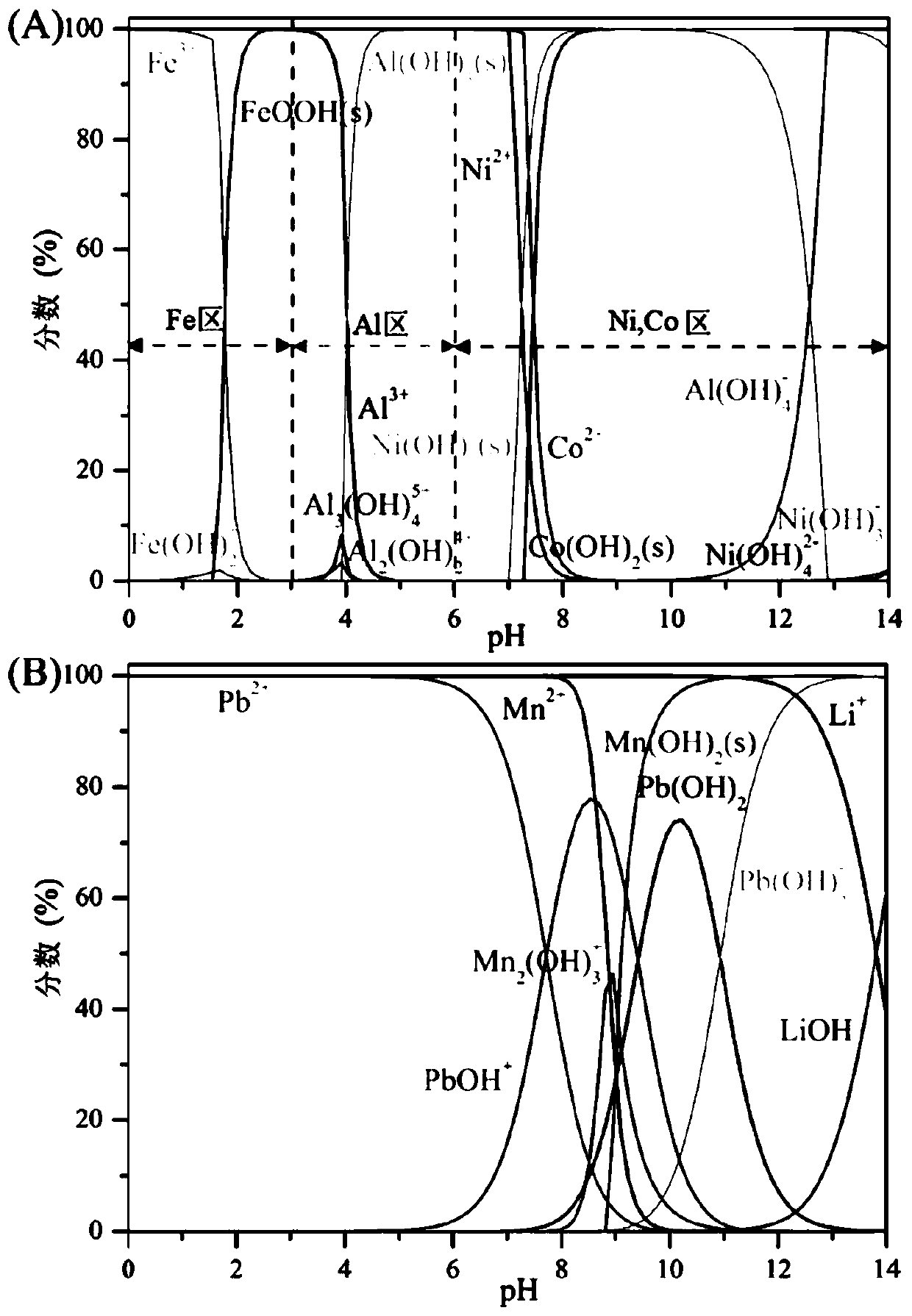

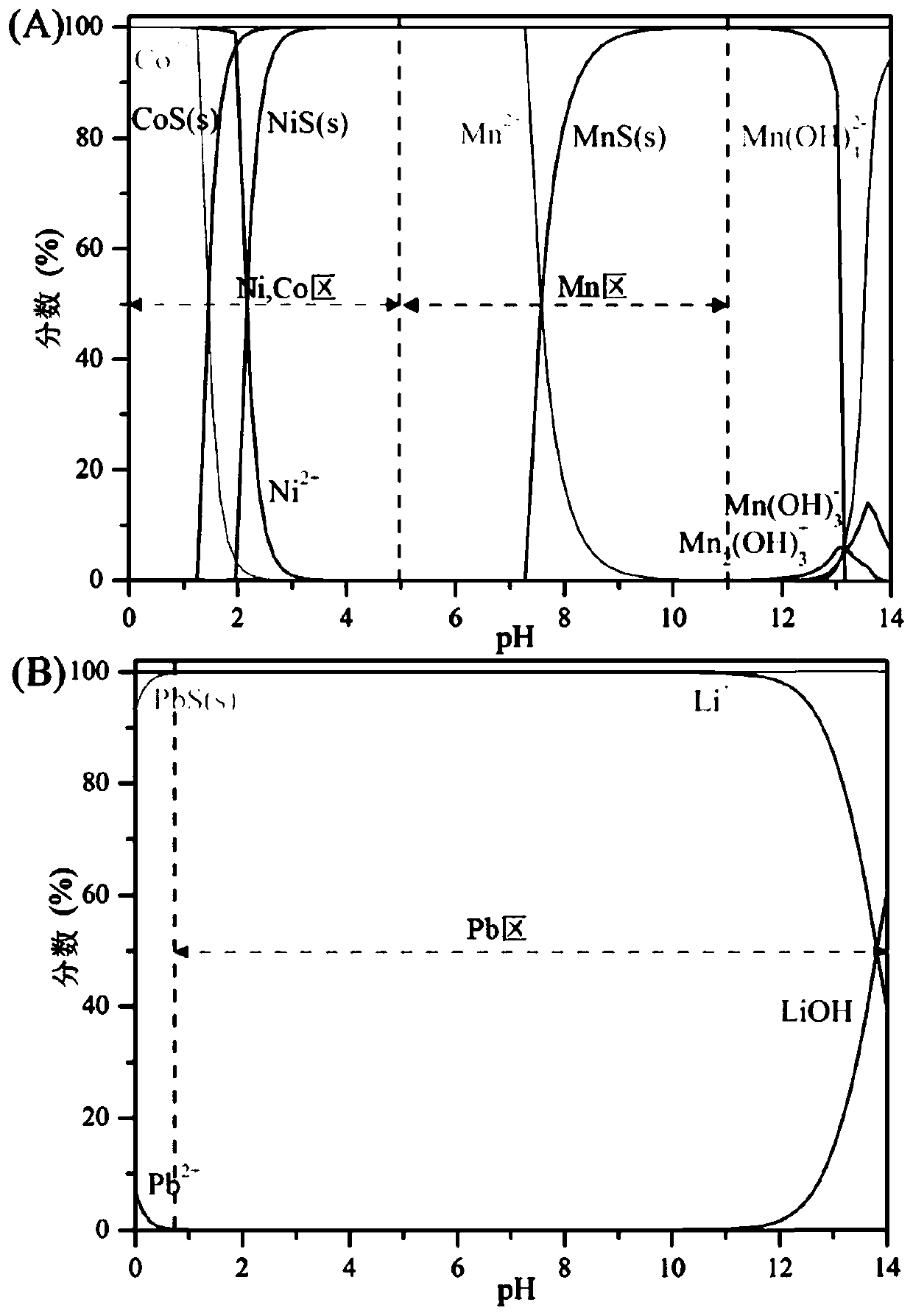

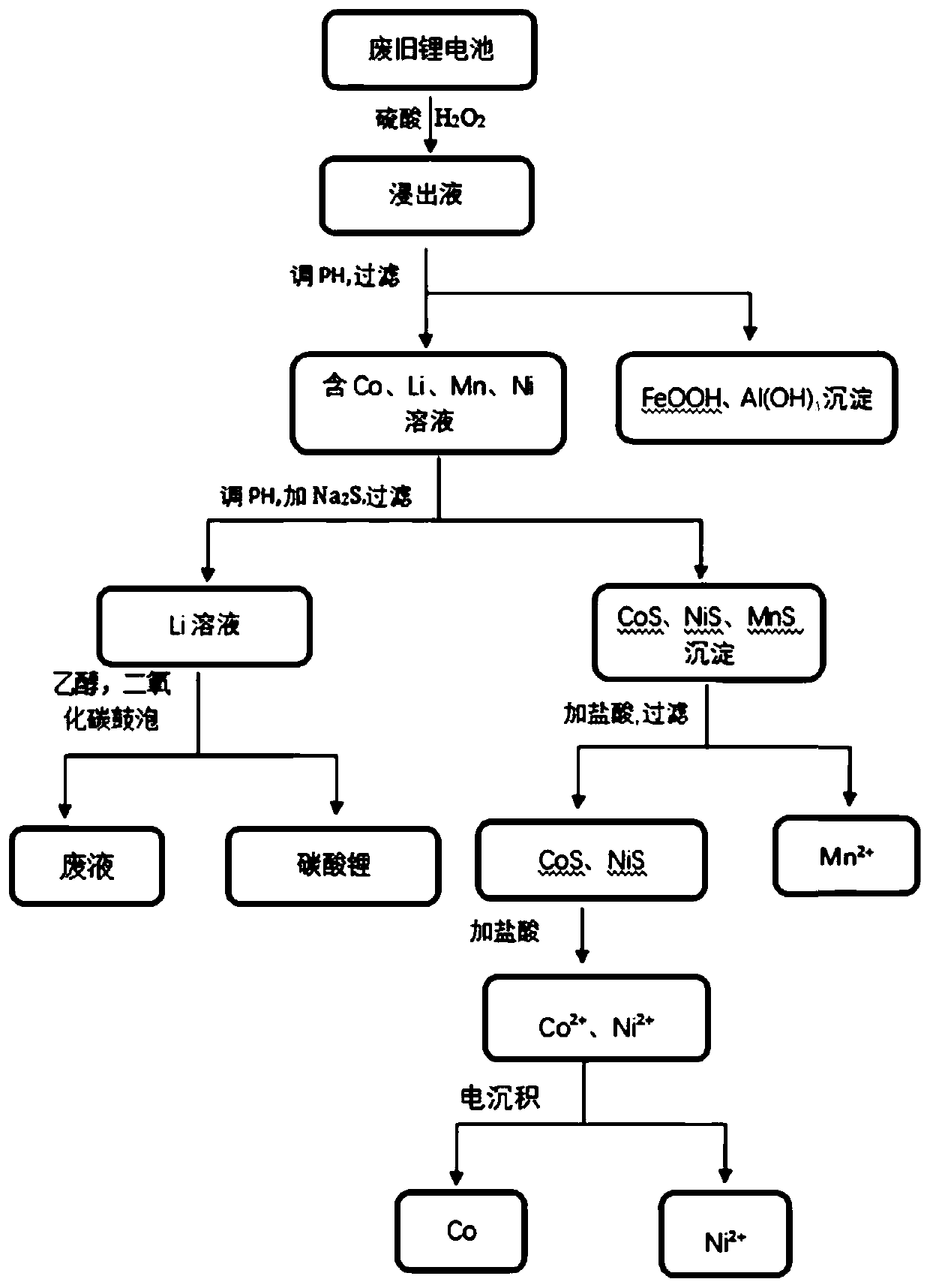

Method for efficiently recovering positive electrode material of mixed lithium ion battery

ActiveCN110233304AAvoid and minimize lossesReduce solubilityWaste accumulators reclaimingProcess efficiency improvementSolubilityRoom temperature

The invention discloses a method for efficiently recovering a positive electrode material of a mixed lithium ion battery. The method specifically comprises the steps of disassembling a waste lithium ion battery, and carrying out leaching with an acidic solution to obtain a leaching solution; precipitating Fe<3+> and Al<3+> by using an alkali solution, and carrying out precipitation separation; adjusting the pH value of the solution to be 9-10.5, adding Na2S to precipitate Mn<2+> and the like, and then filtering precipitates to obtain a lithium-containing solution; adding carbonate ions to carry out lithium precipitation to obtain Li2CO3 precipitates; and putting MnS, CoS and NiS precipitates into a hydrochloric acid solution with the pH value of 5.5-6.5 for enabling the MnS to be re-dissolved, carrying out filtering to separate out the Mn<2+>, dissolving the residual precipitates in the hydrochloric acid solution to release Co<2+> and Ni<2+>, and electrically depositing the Co<2+> intoCo. The solubility of the Li2CO3 at the room temperature is reduced by adding ethanol to participate in lithium ion precipitation, so that the recovery rate of Li and Co reaches more than 95%; meanwhile, other Fe<3+>, Al<3+>, Mn<2+> and Ni<2+> precipitates are recovered; and the method has the advantages of being low in cost, high in efficiency, high in recovery purity, capable of realizing valuable metal recovery and suitable for industrial application.

Owner:GUANGXI UNIV

Method for achieving germanium precipitation through metallic oxide

ActiveCN105907994AEasy to operateGood slag filtration performanceProcess efficiency improvementOxidePrecipitation

The invention relates to a treatment method for comprehensive resource recycling of dissipated metal germanium, in particular to a treatment method for carrying out precipitation recycling on germanium through metallic oxide. According to the treatment method, the metallic oxide is adopted as a neutral precipitation agent, a two-section neutralizing hydrolysis method is adopted, and the germanium is subjected to precipitation recycling from germanium containing material liquid. Compared with an existing germanium precipitation recycling process, the advantages of the method are remarkable, the metallic oxide is adopted as the neutral precipitation agent, and the two-section neutralizing hydrolysis method is adopted for treating germanium pre-precipitation liquid; operation is easy, the residue filtering performance is good, and the quantity of added auxiliary materials is small; and the total germanium precipitation rate can reach 98% or above, the grade of obtained germanium concentrates is about 6%-8%, and extraction and comprehensive recycling of the valuable metal germanium in the germanium containing material liquid can be achieved.

Owner:ZHEJIANG HUAYOU COBALT +1

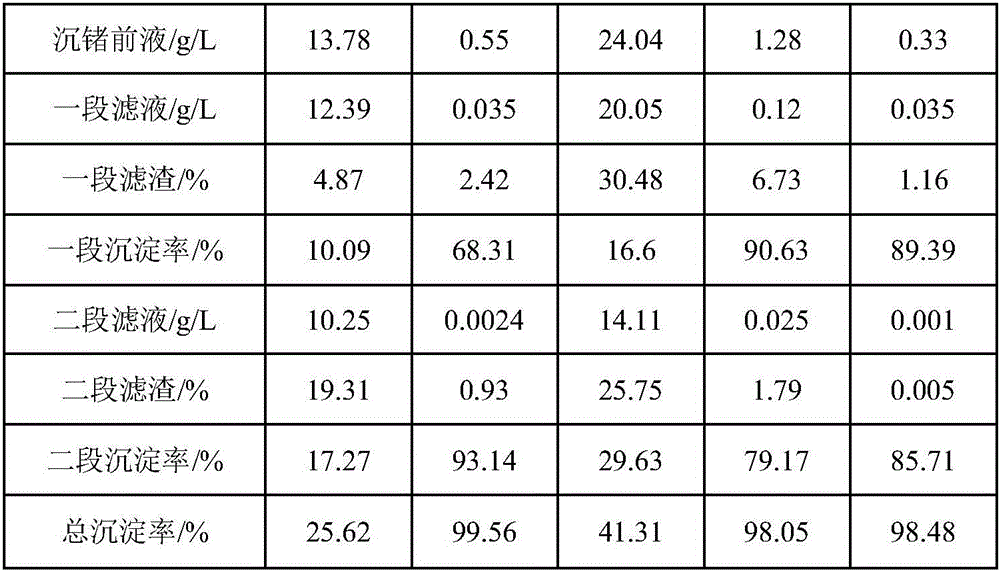

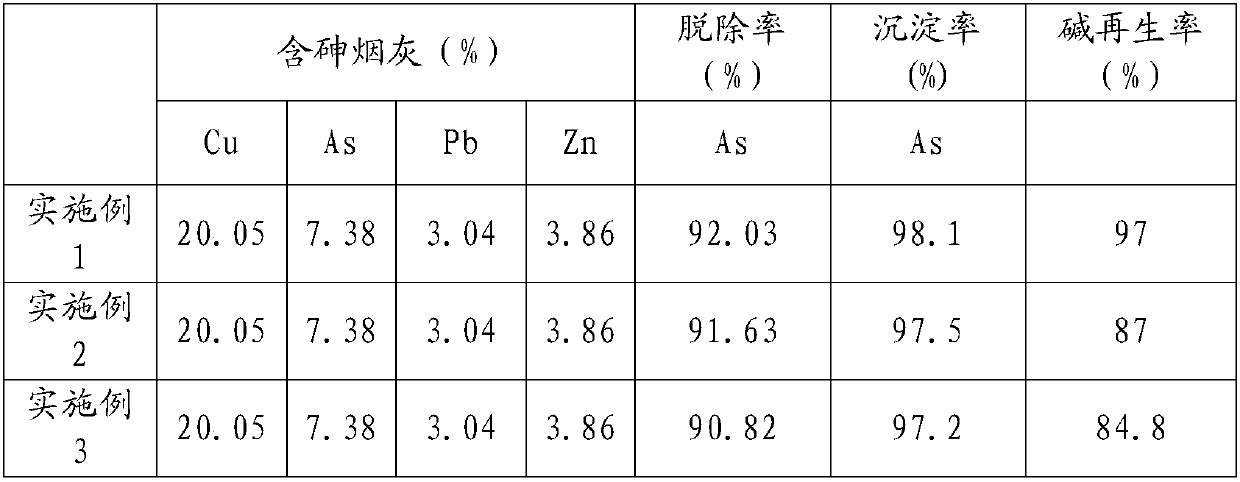

Method for low-cost dearsenification of copper smelting high-arsenic fume

ActiveCN107779607AReduce alkali consumptionEffective enrichment of arsenicPhotography auxillary processesProcess efficiency improvementPregnant leach solutionArsenic fumes

The invention discloses a method for low-cost dearsenification of copper smelting high-arsenic fume. The method comprises the following steps: A, performing neutral leaching on arsenic-containing fume, and after leaching is completed performing solid-liquid separation so as to obtain neutral leachate and natural leachate slag; B, performing primary normal-pressure alkali leaching on the natural leachate slag obtained in the step A, and after leaching is completed, performing solid-liquid separation so as to obtain primary leachate and primary leachate slag, wherein the final alkali concentration of the leachate is controlled to be less than 50g / L; C, performing secondary normal pressure alkali leaching on the primary leachate slag obtained in the step B, and after leaching is completed, performing solid-liquid separation so as to obtain secondary leachate and secondary leachate slag, wherein the NaOH concentration is 40-150g / L; D, performing rotational flow electrodeposition process copper removal by using the leachate obtained in the step A, wherein products are standard cathode copper and a copper removal after liquid; and E, performing lime causticization on the primary leachateobtained in the step B, and performing solid-liquid separation, thereby obtaining calcium arsenate and a causticization after liquid. The method is capable of low-cost high-efficiency dearsenification of c arsenic-containing fume and solving the influence of continuous increase of arsenic in copper concentrate to the copper smelting process, and has the advantages of environment protection, economy, energy conservation and resource utilization rates.

Owner:紫金铜业有限公司 +1

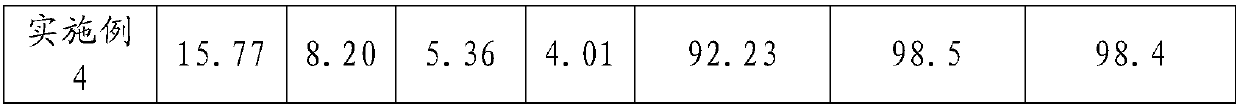

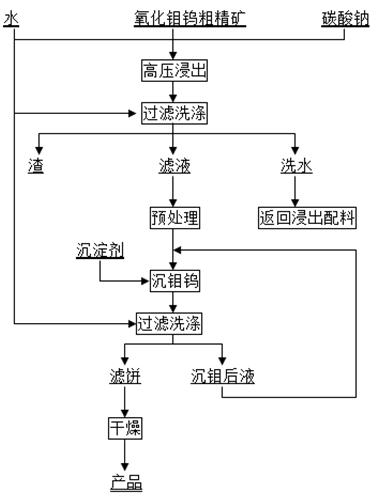

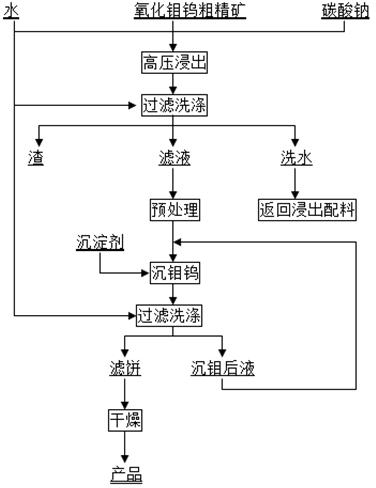

Wet-process treatment method of tungsten-containing molybdenum oxide rough concentrate

InactiveCN102205268AIncrease sedimentation rateLow molybdenum content in liquidWet separationMolybdateFiltration

The invention discloses a wet-process treatment method of tungsten-containing molybdenum oxide rough concentrate, which sequentially comprises the steps of: 1, carrying out sodium carbonate leaching on the tungsten-containing molybdenum oxide rough concentrate; 2, filtering and separating; 3, adding inorganic acid in filtrate obtained from filtration and separation to regulate the pH value to 3.5-6.5; 4, adding a settling agent in a solution subjected to pH regulation, carrying out molybdenum and tungsten settling reaction; and 5, filtering, washing and drying sediment obtained from filtration to obtain a mixture of calcium molybdate and calcium tungstate. The invention has the advantages of higher molybdenum settling rate and lower content of molybdenum in a settled solution, and does not need an ion exchange process.

Owner:中铁资源集团有限公司 +1

Method for removing aluminum ions in neodymium praseodymium chloride material liquid

ActiveCN110184460AIncrease sedimentation rateReduce sedimentation rateProcess efficiency improvementAluminum IonMineral Sources

The invention belongs to the technical field of rare-earth separation, and particularly relates to a method for removing aluminum ions in a neodymium praseodymium chloride material liquid. Due to diversity of mineral sources, non-rare earth impurities in a mixed rare earth chloride material liquid obtained through chemical leaching are difficult to remove. According to the method, another way is opened, the hydrolytic process of the aluminum ions in the neodymium praseodymium chloride material liquid subjected to extraction separation is explored, and optimal conditions of aluminum ion hydrolysis are found out by adding an additive and used for removing the aluminum ions in the neodymium praseodymium chloride material liquid. It is shown through the experimental result that the depositionrate of the aluminum ions in the neodymium praseodymium chloride material liquid reaches 93% or above, the deposition rate of rear earth is 1.5% or below, the deposition volume rate is small, and solid-liquid separation is facilitated.

Owner:SICHUAN PROVINCE LESHAN CITY RUIFENG METALLURGY CO LTD

Preparation process of fireproof and wear-resistant calcined basic zinc carbonate

PendingCN112520782AHigh cost of solutionLow costNanotechnologyZinc compoundsUltrasonic radiationFire retardant

The invention provides a preparation process of fireproof and wear-resistant calcined basic zinc carbonate, and the method comprises the following steps of: (1) preparation of a zinc sulfate solution:leaching and filtering zinc oxide ore to obtain the zinc sulfate solution; (2) preparation of a reaction solution: carrying out purification treatment of iron removal, copper removal and cadmium removal on the zinc sulfate solution to obtain a high-purity zinc sulfate solution; diluting the high-purity zinc sulfate solution to 0.8-1.0mol / L; dropwise adding a sodium carbonate solution in a constant-pressure dropping funnel into the solution until the pH value reaches 6.5-7.0, then raising the temperature to 60-70DEG C, carrying out ultrasonic radiation for 30-50min, and then performing ageingfor 1-1.5h to obtain a reaction solution; adding a fire retardant and a wear-resistant agent into the reaction solution; and (3) preparation of basic zinc carbonate. The preparation process of the fireproof and wear-resistant calcined basic zinc carbonate is simple and efficient, reasonable in formula design, high in production efficiency and low in comprehensive cost, the problems that a basic zinc carbonate product is single and low in additional value are solved, and the fireproof and wear-resistant calcined basic zinc carbonate is good in fire resistance and wear resistance and wide in application prospect.

Owner:太仓恒泽科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com