A method for recovering battery-grade lithium carbonate from waste lithium iron phosphate battery cathode powder

A lithium iron phosphate battery and lithium carbonate technology, applied in the direction of lithium carbonate;/acid carbonate, etc., can solve the problem of toxic and harmful gas and waste solid recovery, high sodium ion content of lithium carbonate products, unable to reach the battery Level and other issues, to achieve the effect of high added value of products, increase of lithium leaching rate, and strong social value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

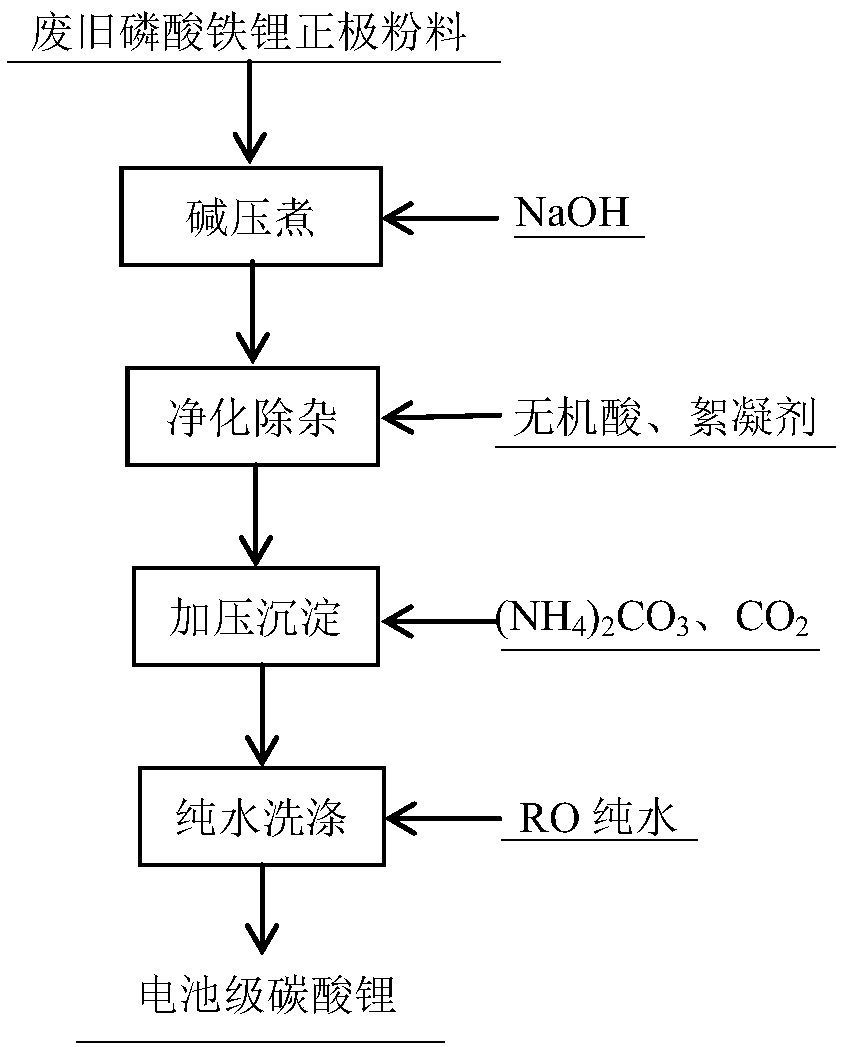

[0025] A method for reclaiming battery-grade lithium carbonate from waste lithium iron phosphate battery cathode powder, comprising the steps of:

[0026] S1. The positive electrode powder of the waste lithium iron phosphate battery is subjected to high temperature and high pressure alkali boiling, and the first material is obtained by filtering;

[0027] S2. Purifying and removing impurities from the first material to obtain the second material;

[0028] S3, adding ammonium carbonate to the second material, filling with carbon dioxide, performing high temperature and high pressure reaction, and filtering to obtain the third material;

[0029] S4, washing the third material to obtain battery grade lithium carbonate.

[0030] After the waste lithium iron phosphate battery was disassembled and crushed, positive electrode powder 1# and 2# were obtained after screening. The main element analysis is as follows:

[0031] content / %

Embodiment 2

[0033] A method for reclaiming battery-grade lithium carbonate from waste lithium iron phosphate battery cathode powder, comprising the steps of:

[0034] Put 500g of waste lithium iron phosphate battery positive electrode powder (1#) in an autoclave, add water according to the solid-to-liquid ratio of 1:3, add 75g of NaOH, heat up to 120°C and stir at a stirring speed of 600r / min, react for 5h, and filter to obtain The first material, its main element analysis is as follows (concentrations of metal ions such as Mg, Co, Ni, Fe are all less than 0.001g / L):

[0035] meal

[0036] Adjust the pH of the first material to 6 with sulfuric acid, add a flocculant obtained by mixing polyacrylamide and polyacrylic acid, the mass ratio of the flocculant to the aluminum element in the first material is 5:1000, and filter to remove aluminum to obtain the second material;

[0037] Put the second material in an autoclave, add ammonium carbonate according to 2.5 times the theoretical...

Embodiment 3

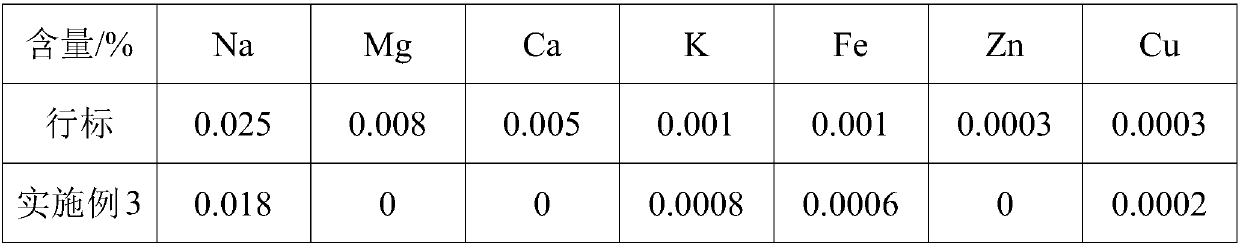

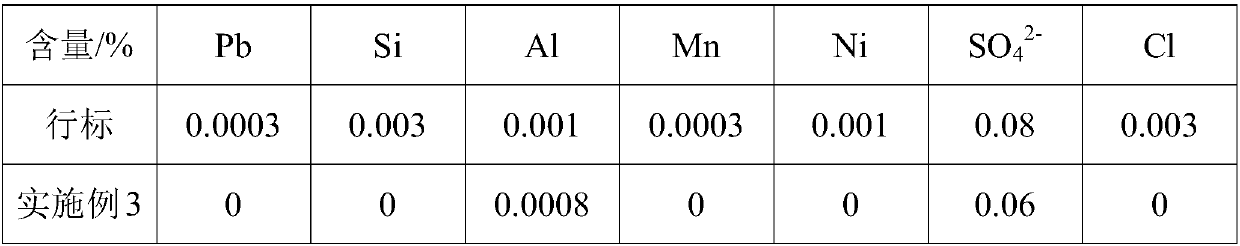

[0042] refer to figure 1 A method for reclaiming battery-grade lithium carbonate from waste lithium iron phosphate battery cathode powder, comprising the steps of:

[0043] Put 500g of waste lithium iron phosphate battery positive electrode powder (2#) in an autoclave, add water according to the solid-to-liquid ratio of 1:5, add 40g of NaOH, heat up to 150°C and stir at a stirring speed of 300r / min, react for 2h, and filter to obtain The first material, its main element analysis is as follows (Mg, Ca, Co, Cl and other ions are not detected in the raw material and the first material, and the concentrations of metal ions such as Ni and Fe are all less than 0.001g / L):

[0044] meal

F

Na

Al

S

K

Li

The first material, g / L

0.7

8.78

0.29

0.04

0.015

8.724

[0045] Adjust the pH of the first material to 4.5 with sulfuric acid, add methacrylic acid as a flocculant, the mass ratio of the flocculant to the aluminum element in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com