Method for producing germanium concentrated ore from germanium-containing industrial liquor

A germanium concentrate and industrial technology, applied in the field of non-ferrous metallurgy, can solve the problems of difficult filtration, large use restrictions, large alkali consumption and large extraction agent, and achieve good stripping effect, low cost, high germanium precipitation rate and recovery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

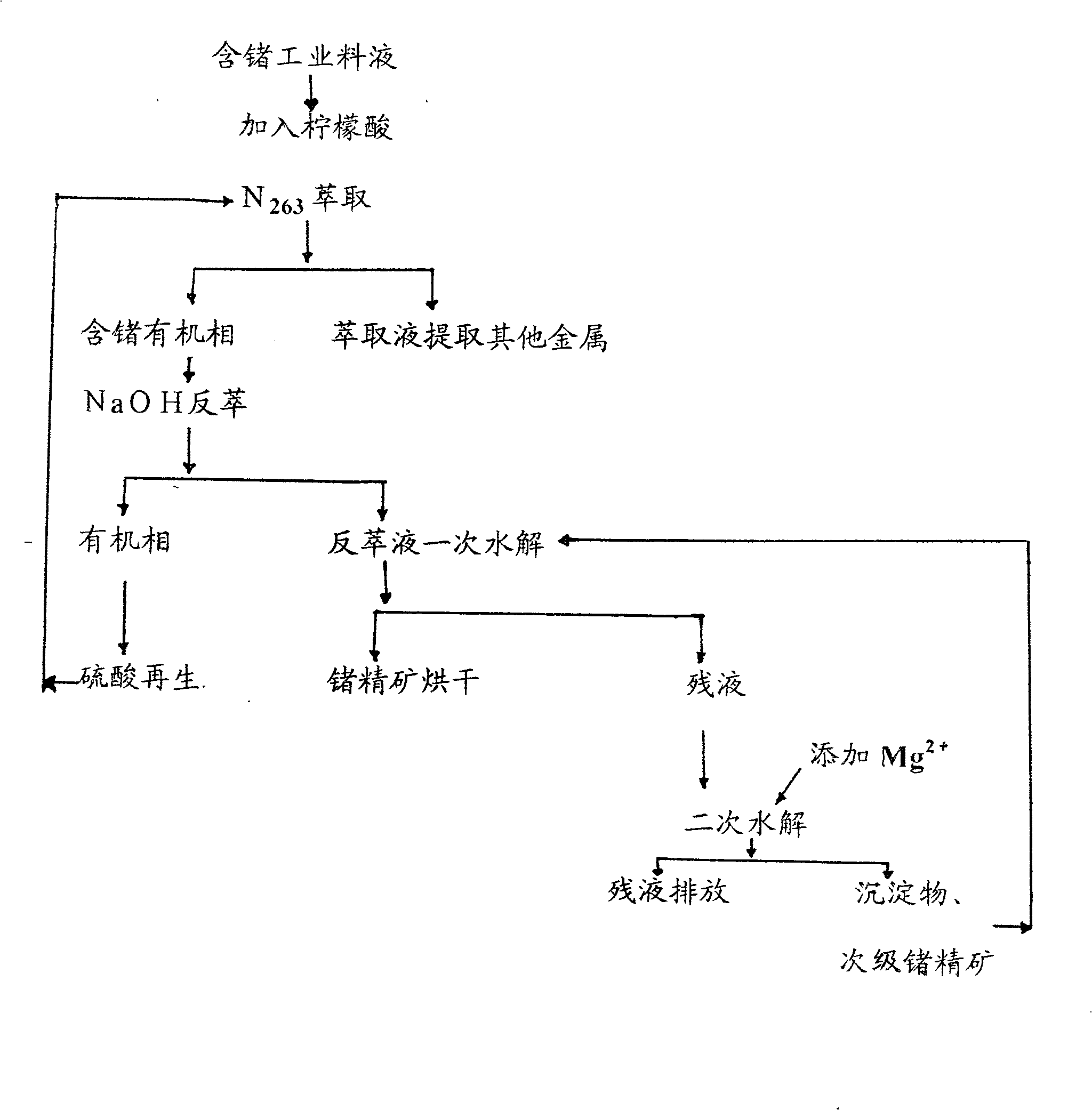

Image

Examples

Embodiment 1

[0012] Embodiment 1: The germanium-containing industrial feed solution is a sulfuric acid solution containing Ge 100-200 mg / L, In 10000±500 mg / L, and pH 0.5-1.5. Add citric acid at a weight ratio of citric acid: germanium = 4 to 5: 1, and dissolve at room temperature. Then use 30% volume percent N 263 (tetraalkylamine) kerosene solution extractant, carry out five-stage countercurrent extraction in the mixed sedimentation box-type extraction tank, use the NaOH aqueous solution of 20% to do three-stage countercurrent back extraction with the weight percent concentration, the sulfuric acid of weight percent concentration 10% Aqueous primary organic phase regeneration. The extraction rate of germanium is 98.5%, and the stripping rate is 99%. The NaOH back-extraction solution contains 19.78g / L of germanium, adjusts the pH to 8-10 with sulfuric acid for the first hydrolysis, heats and filters, and obtains a germanium concentrate containing 32.7% of germanium (weight ratio). After...

Embodiment 2

[0013] Embodiment 2: The germanium-containing industrial feed solution is a sulfuric acid solution containing Ge30-200mg / L, Zn2-3g / L, Fe61-200mg / L, pH2±0.5. Add tartaric acid by tartaric acid: germanium=8~10: 1 (weight ratio), then be 30% N with weight percentage concentration 235 (Trialkylamine) kerosene solution is used as the extraction agent, three countercurrent extractions are carried out in a box-type extraction tank, two-stage countercurrent back extraction is performed with a 30% NaOH aqueous solution, and the organic phase is regenerated with a 10% sulfuric acid aqueous solution. The extraction rate of germanium is 96.88%, and the stripping rate is 98.18%. Adjust the pH of the stripping solution to 9-11 with sulfuric acid, and add ZnSO at the same time 4 .7H 2 O is hydrolyzed according to Zn / Ge=4.5:1 (weight ratio), and the germanium concentrate contains 10.66% (weight ratio) of germanium. The equipment has been in operation for 1.5 months, processing 300 cubic me...

Embodiment 3

[0014] Example 3: Industrial feed liquid contains Ge 0.075g / L, Zn 80g / L, Fe1.3g / L, As0.9g / L, Cd 0.3g / L, In 0.011g / L, Cl - 0.56g / L,H 2 SO 4 5g / L, temperature 25°C. Potassium hydrogen tartrate is added according to potassium hydrogen tartrate: germanium=6.4:1 (weight ratio), or industrial citric acid is added according to citric acid: germanium=3:1 (weight ratio). Then use 30% volume percent N 263 (Tetraalkylamine) kerosene solution is the extractant, carries out five-stage extraction respectively in 2 escalating extractors, uses the NaOH aqueous solution of 25% to do two-stage back-extraction with weight percentage concentration, and 15% sulfuric acid aqueous solution primary organic phase regeneration. When potassium hydrogen tartrate is added, the extraction rate: Ge99.3%, In2.14%, Zn0.2%, Fe3.4%, As6.9%, Cd0.6%; the back extraction rate of Ge is 99.15%. When citric acid is added, the Ge extraction rate is 99%, and the stripping rate is 99%, and the Cl in the raffinate is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com