Method for selectively recovering heavy metals from electroplating sludge

A technology for electroplating sludge and heavy metals, applied in the direction of improving process efficiency, etc., can solve the problems of low chromium ion recovery rate, human health and environmental hazards, and large power consumption, and achieve the effect of increasing the precipitation rate of other ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

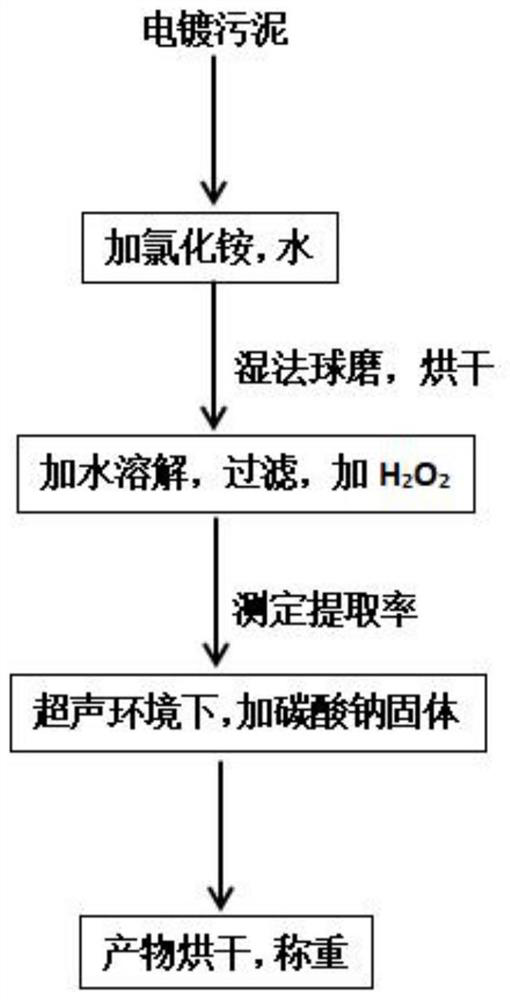

[0030] Such as figure 1 As shown, a method for selective recovery of heavy metals from electroplating sludge is as follows: (1) get 10g electroplating sludge, 12g ammonium chloride, 10ml deionized water (mixing ratio is 1:1.2:1), mix After wet grinding with a ball mill for 24 hours, take it out, dry it in an oven with the drying temperature set at 70°C, and take it out after 6 hours. (2) Suction filter after adding water to dissolve, wash with deionized water 3 times. (3) Add 5.4ml of hydrogen peroxide (6% of the volume of the solution in step 2). (4) prepare nickel, copper, iron standard solution, get the solution dilution certain multiple that gets suction filtration, use atomic absorption spectrometer to measure absorbance and draw concentration, according to formula R (i)=C i ×V / m×x i Calculate the extraction rate. (5) Repeat steps (1), (2), and (3) to take (3) filtrate and place it on a magnetic stirrer at a speed of 150r / min, place the probe of the ultrasonic breaker...

Embodiment 2

[0032] Such as figure 1 As shown, a method for selective recovery of heavy metals from electroplating sludge is as follows: (1) take 8g electroplating sludge, 12g ammonium chloride, 8ml deionized water (mixing ratio is 1:1.5:1), mix Finally, it was wet-milled with a ball mill for 27 hours, then taken out, and dried in an oven at a temperature of 80°C. The product was removed after 8h. (2) Suction filter after adding water to dissolve, wash with deionized water 3 times. (3) add 8.2ml hydrogen peroxide (10% of the solution volume for step 2) Concentration, according to the formula R(i)=C i ×V / m×x i Calculate the extraction rate. (5) Repeat steps (1), (2), (3) to take (3) filtrate and place it on a magnetic stirrer at a speed of 150r / min, place the probe of the ultrasonic breaker in the solution, adjust the power to 100W, and continuously Add solid sodium carbonate to adjust the pH to 3.40, let it stand for 10 minutes, and filter with suction to get iron hydroxide precipita...

Embodiment 3

[0034] Such as figure 1As shown, a method for selective recovery of heavy metals from electroplating sludge is as follows: (1) get 20g electroplating sludge, 26g ammonium chloride, 20ml deionized water (mixing ratio is 1:1.3:1), mix After wet grinding with a ball mill for 36 hours, take it out and dry it in an oven with the drying temperature set at 90°C. The product was removed after 9 h. (2) Suction filter after adding water to dissolve, wash with deionized water 3 times. (3) Add 15 ml of hydrogen peroxide (8% of the volume of the solution in step 2). (4) prepare nickel, copper, iron standard solution, get the solution dilution certain multiple that gets suction filtration, use atomic absorption spectrometer to measure absorbance and draw concentration, according to formula R (i)=C i ×V / m×x i Calculate the extraction rate. (5) Repeat steps (1), (2), and (3) to take (3) and place the filtrate on a magnetic stirrer at a speed of 150r / min, place the probe of the ultrasonic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com