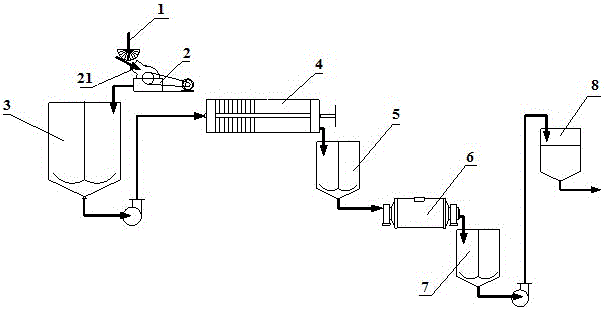

Arsenic-alkali slag treatment method and device

A treatment method and technology for arsenic-alkali slag, applied in the direction of improving process efficiency, can solve problems such as injury to the operator's body, secondary pollution, and contamination of the site, and achieve the effects of improving leaching efficiency, reducing separation costs, and reducing arsenic content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Weigh 5.0t of arsenic-alkali slag (Sb 5.01 wt%, As 1.02 wt%, total alkalinity 69.15%), turn on the feeder to evenly feed the material to the crusher, and then spray water to the hammer crusher inlet Water, control water spray volume 2.50m 3 (When crushing, spray water according to 0.5 tons of water / ton of arsenic-alkali slag), and crush to a particle size of ≤3mm; (2) The crushed material flows into the leaching tank, and 7.50m of water is added 3 (For the first leaching, add water at the rate of 1.5 tons of water / ton of arsenic-alkali slag), add 10.0kg of sodium chlorate at the same time, leaching temperature is 40-45°C, leaching time is 0.5h, and the stirring speed is 80 r / min for the first leaching; After leaching, filter with a plate and frame filter (filtering temperature is 40-45°C, pressure is 0.2-0.4Mpa) to obtain a leaching solution of 9.38m 3 (of which, Sb 0.81g / L, As 4.62g / L), the slag from primary leaching, converted into a dry weight of 1.44t (of which...

Embodiment 2

[0038] (1) Weigh 5.0t of arsenic-alkali slag (Sb 10.56 wt%, As 8.49 wt%, total alkalinity 53.49%), turn on the feeder to evenly feed the material to the crusher, and then spray water to the jaw crusher inlet Water, control water spray volume 4.0m 3 (When crushing, spray water according to 0.8 tons of water / ton of arsenic-alkali slag), and crush to a particle size of ≤3mm; (2) The crushed material flows into the leaching tank, supplemented with 10.0m of water 3 (For primary leaching, add water at the rate of 2.0 tons of water / ton of arsenic-alkali slag; among them, 9.65 m 3 Be the secondary leachate in embodiment 1, 0.35 m 3 tap water), and at the same time add 2.5kg of hydrogen peroxide (concentration 27.5wt%), leaching temperature 50-55°C, leaching time 0.8h, stirring speed 85 r / min for the first leaching; after leaching, use a plate and frame filter Filtration (filter temperature: 45-50°C, pressure: 0.2-0.4Mpa) to obtain primary leachate 12.83m 3 (of which, Sb 1.63g / L, As...

Embodiment 3

[0040] (1) Weigh 5.0t of arsenic-alkali slag (Sb 25.13 wt%, As 12.59 wt%, total alkalinity 35.19%), turn on the feeder to evenly feed the material to the crusher, and then spray water to the entrance of the hammer crusher Water, control water spray volume 5.0m 3 (When crushing, spray water according to 1.0 tons of water / ton of arsenic-alkali slag), crush to a particle size of ≤3mm; (2) The crushed material flows into the leaching tank, supplemented with 11.0m of water 3 (For primary leaching, add water at the rate of 2.2 tons of water / ton of arsenic-alkali slag; among them, 10.28 m 3 Be the secondary leachate in embodiment 2, 0.72 m 3 tap water), and at the same time add 2.5kg of chlorine gas, the leaching temperature is 60-65°C, the leaching time is 1.0h, and the stirring speed is 90 r / min for the first leaching; after leaching, filter with a plate and frame filter (filtering temperature is 45 ~50℃, pressure is 0.2~0.4Mpa), and the primary leachate is 14.33m 3 (Among them,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com