Patents

Literature

220 results about "Alkali activated slag" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alkali-Activated Slag,AAS is a hydraulic-cementing material (Slag and fly ash have potential activity), with dry granulated blast furnace Slag as the main raw material, with appropriate amount of silicate cement clinker, a small amount of dihydrate gypsum, and an appropriate amount of Alkali activator, consisting of 80%~85% Slag, 5%~10% Alkali ...

Composite tailing non-fired and non-steamed building block brick and preparation method thereof

InactiveCN102093004AHigh waste rateSolve the problem of excessive dosageSolid waste managementBrickSlag

The invention discloses a composite tailing non-fired and non-steamed building block brick and a preparation method thereof. The brick comprises the following raw materials in parts by weight or volume: 50-300 parts of tailing and 3-30 parts of cement; and at least two components are selected from the active wastes such as fly ash, coal gangue, shale slag, alkaline residue, carbide slag, chemical gypsum and the waste residue of metallurgical industry to be mixed with the raw materials. The preparation method comprises the following steps: mixing to stir, compressing and shaping, performing natural curing or utilizing the solar heaing hydrating maintenance to prepare the composite tailing building block brick. By adopting the preparation method of the invention, the single performances of the tailings and slags can be changed, thus the product can have higher strength and quality owning to the interaction of materials; the technology does not adopt firing and steaming, the cost is low; different sizes of solid bricks, perforated bricks, hollow blocks, floor tiles, grass planting bricks, roadside bricks and artistic rails can be prepared by changing the mould; and various harmful slags such as tailings can become good, the Chinese development direction of the comprehensive utilization of resources is satisfied and the brick of the invention has development and application prospect.

Owner:郭东京 +2

Preparation of composite high-expansion cementing material by using industrial slag and preparation technique thereof

The invention relates to a preparation process of using industrial slag to prepare composite cementing materials with high expansibility. The cementing materials consist of four components. The first component includes three parts: one or a plurality of combinations of fly ashes, slag, etc., which contain aluminosilicate; one or a plurality of combinations of phosphogysum, fluorine gypsum, etc., which contain calcium sulfate; one or a plurality of combinations of carbide, alkaline residue, quick lime or slaked lime. The second component includes: one or a plurality of combinations of alkaline composition, such as the quick lime or slaked lime, the carbide slag, etc.. The third component includes one or a plurality of combinations of the phosphogypsum, fluorine gypsum, etc., which contain the calcium sulfate. The preparation method is: firstly, to evenly mix the raw materials of the first component which are grinded to be with the surface area of 200-500m<2> / kg through the steam curing of four hours to ten days at 50-100 DEG C and the calcining of 0.5-24h at the high temperature of 400-1000 DEG C to obtain the first component; secondly, to dry and grind the raw materials of the second and the third component to be with the surface area of 200-500m<2> / kg to obtain the second and the third component; thirdly, to evenly mix the first, the second and the third component.

Owner:BEIHANG UNIV

Water-resisting high-strength gypsum-base concrete brick or building block, and producing method thereof

The invention relates to a waterproof high-strength gypsum-based concrete brick or building block and a production method thereof. The waterproof high-strength gypsum-based concrete brick or building block mainly contains gypsum-based composite binding agent, coagulation accelerator and filler. The weight proportions of the components are as follows: 10-100% of gypsum-based composite binding agent, 0-6% of coagulation accelerator, 0-90% of filler, 0-1% of early-strength agent, 0-1% of water-reducing agent, 0-6% of lime and 0-15% of gypsum hemihydrate. 80% of the raw materials of the high-strength gypsum-based concrete brick or building block are industrial byproducts, so that the invention reduces the production cost, realizes energy conservation and discharge reduction, avoids the land occupancy and water pollution caused by chemical gypsum, ore slag, coal ash, furnace slag, alkali waste and carbide slag, and protects the environment.

Owner:长沙归一新材料科技股份有限公司

Acetylene sludge aerated concrete block and preparation method thereof

ActiveCN102875070ALow bulk densityGood heat insulationSolid waste managementCeramicwareSODIUM METAPHOSPHATEParaffin wax

The invention provides an acetylene sludge aerated concrete block, which is prepared by processing the following raw materials in part by weight: 20-30 parts of acetylene sludge, 25-30 parts of coal ash, 5-10 parts of cement, 4-6 parts of modified attapulgite, 5-10 parts of water treatment sludge, 5-10 parts of soda residue, 5-10 parts of light calcium powder, 10-15 parts of lime, triethanolamine, 4-5 parts of gypse, 0.02-0.08 part of aluminium powder, oxidized paraffin wax soap, 0.01-0.02 part of calcium bicarbonate, 2-3 parts of chelky slag, 1-2 parts of lignocellulose, 0.3-0.5 part of water glass, 0.03-0.05 part of borax, 1-2 parts of sodium hexametaphosphate, 1-2 parts of hydroxy propyl methyl cellulose sodium and 1-2 parts of superfine polyvinyl alcohol, wherein the weight of the triethanolamine is 0.1-0.3 percent of that of the lime, and the weight of the oxidized paraffin wax soap is 3-5 percent of that of the aluminium powder. According to the invention, the acetylene sludge is added into the raw materials of the aerated concrete block, and meanwhile other conventional additives and modified nano additives are added; the aerated concrete block is prepared by adopting a proper technology and is low in cost and good in performance; the circulating economy effect of changing waste into valuable is realized; the pollution is reduced; and the prepared aerated concrete block has the characteristics of light volume weight, high thermal insulation performance, good sound absorption effect and high strength and can be used for non-bearing or bearing wall bodies.

Owner:广东合盛建筑工程有限公司

Alkali-activated slag powder geopolymer mortar for structure reinforcement and preparation method thereof

The invention discloses alkali-activated slag powder geopolymer mortar for structure reinforcement and a preparation method thereof. The alkali-activated slag powder geopolymer mortar for structure reinforcement is prepared from, by weight, 150-210 parts of slag powder, 0-60 parts of fly ash, 400-700 parts of sand, 190-240 parts of water glass and 25-50 parts of solid sodium hydroxide. The preparation method comprises the following steps that the slag powder, the fly ash and the sand are mixed to be uniform according to the proportions; solid sodium hydroxide particles are dissolved in the corresponding amount of the water glass according to the proportion; sodium hydroxide-dissolved water glass is added into well-mixed dry materials, and stirring is conducted continuously to be uniform; the well-stirred alkali-activated slag powder geopolymer mortar is used for building structure reinforcement; the alkali-activated slag powder geopolymer mortar has high compressive strength, good adhesive property with concrete and fiber cloth materials and a wide fluidity range and can adapt to the situation of reinforcing building structures through a fiber cloth bonding method or a grouting pouring method.

Owner:SHANGHAI JIUJIAN REINFORCEMENT TECH

Cement with high water-retaining property

ActiveCN104193202AThere is no decomposition failure problemSimple processCement productionCalcium hydroxideCement factory

The invention discloses cement with high water-retaining property. The cement with high water-retaining property consists of silicate cement clinker, a dechlorination caustic sludge mixture, a mixed material, gypsum and other auxiliaries. The water-retaining component dechlorination caustic sludge mixture of the cement is an inorganic material, so that the decomposition failure problem of organic materials is unavailable and the water-retaining rate of the cement is not lower than 90%; the cement can be produced by equipment in the existing cement plants so that the process is easy to realize; and the large solid waste such as caustic sludge and returned sand and rocks of the soda plants can be digested at the same time, and soda ash can be produced by using part of the calcium hydroxide.

Owner:SOUTH CHINA UNIV OF TECH

Alkaline residue processing method

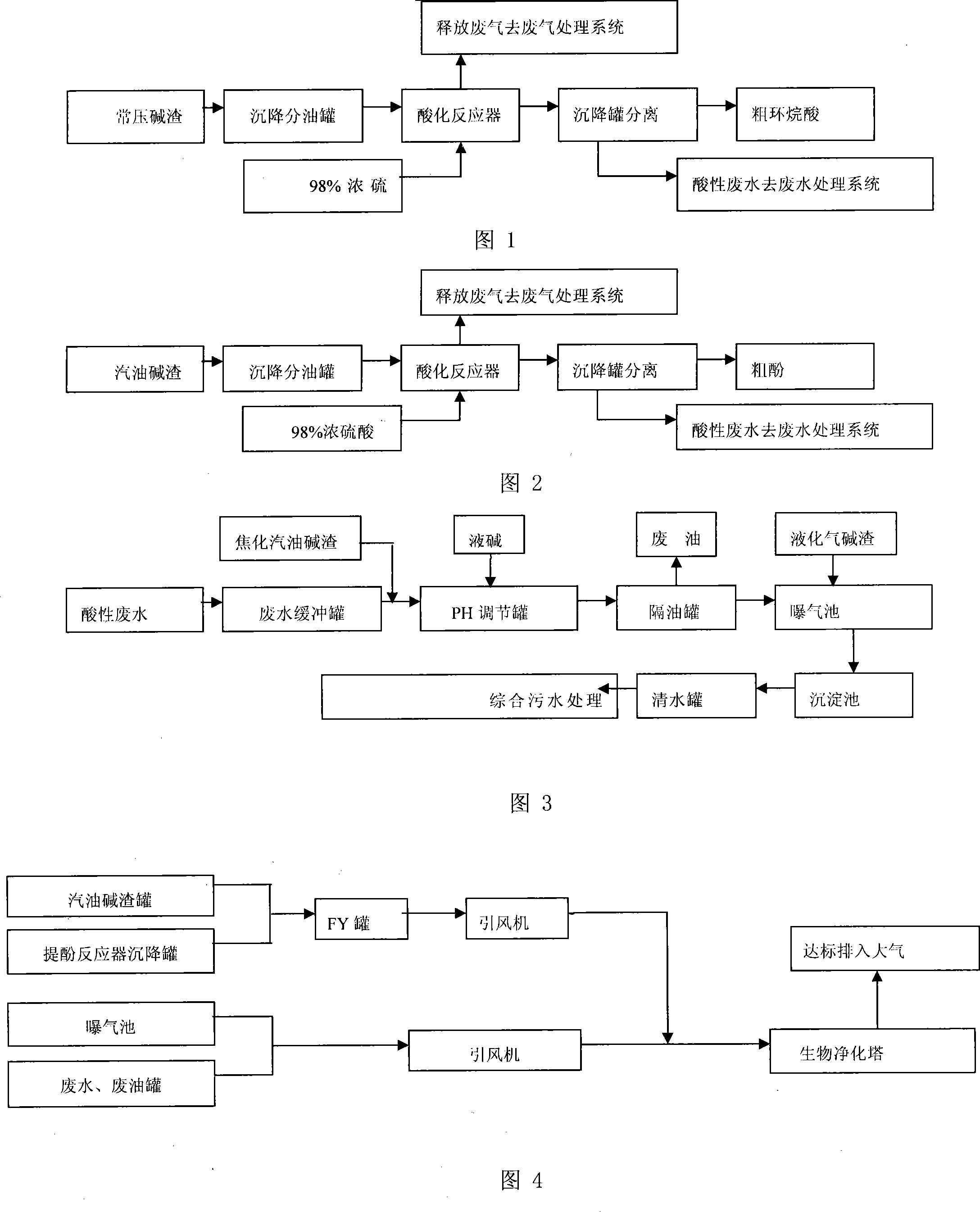

ActiveCN101172739AImprove impact performanceNo pollution in the processFatty/oily/floating substances removal devicesOrganic chemistryAlkali activated slagPollution

The invention provides an alkali dreg treatment method which includes the following steps: first, an alkali pretreatment system; second, a biological treatment system; and Third, a waste gas biological treatment system. Through the biological degradation, the organism in the waste gasis decomposed so as to eliminate the odor in the waste gas. The invention has the advantage that the highly efficient biological treatment process adopted by the comprehensive alkali treatment of the method has the characteristics of a little investment, low energy consumption, cheap treatment, safe and reliable performance, convenient operation and management, no pollution, friendliness to the environment, etc. The application of the method greatly reduces the attack to the sewage treatment field during the alkali dreg treatment and reduces the possible great amount of entrustment cost. On the one hand, the invention prevents the pollution of the alkali dreg to the environment, thereby protecting the environment, on the other hand, the invention makes full use of the potential value of the alkali dreg, thereby creating a new mode of benefit making through the circular economy. The invention conforms to the clean development of the enterprise, protects the natural environment and achieves the saving and sustainable development.

Owner:天津莱特化工有限公司

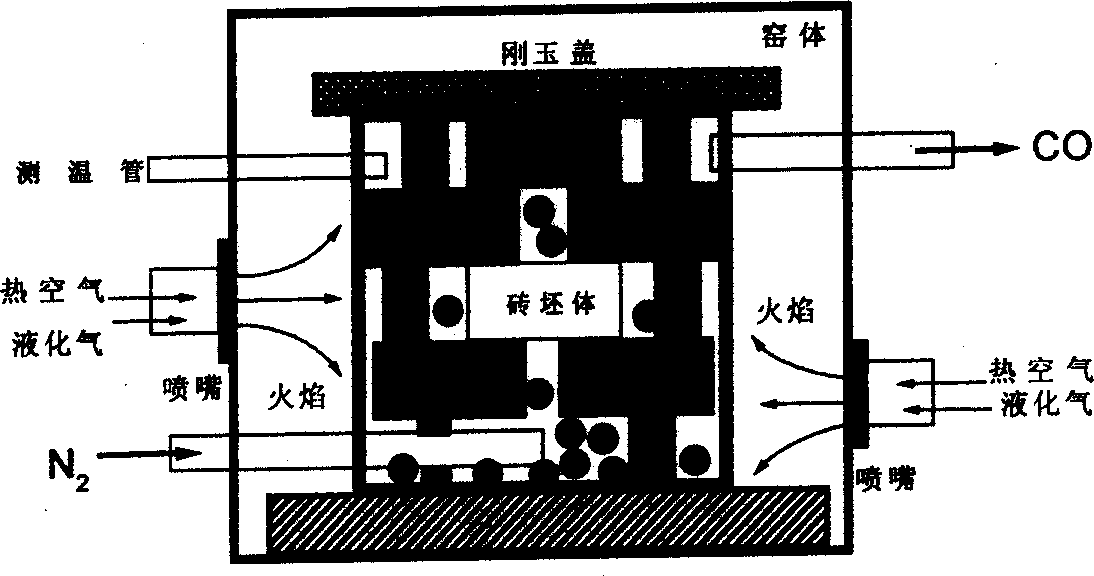

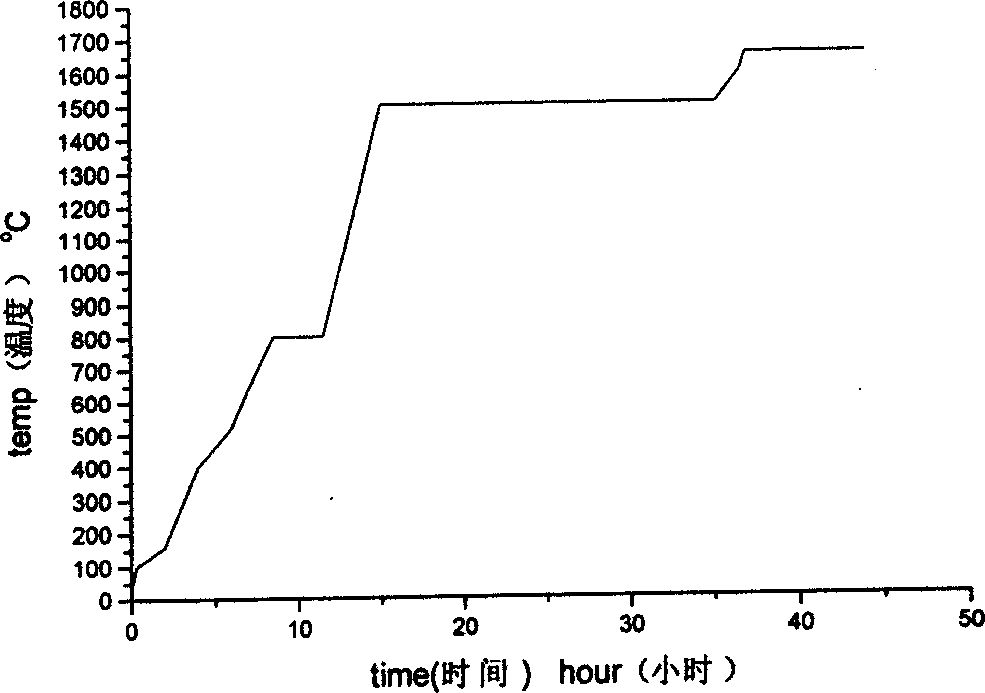

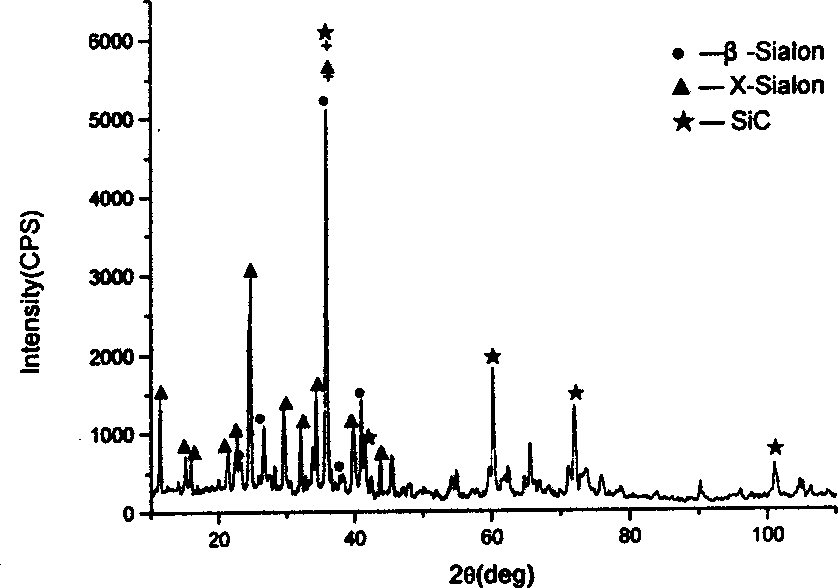

Process for preparing composition 'Sailong' from industrial waste dregs by in-situ synthesis

A process for in-situ preparing high-performance Sialon composition from powdered coal ash, coal gangue, clay, white corundum, and carbon (or silicon) powder includes such steps as die pressing, drying at 110 deg.C and nitrifying sinter segmentally. Its advantages include high conversion rate, no carbon, high compactness, mechanical performance and refractory nature, excellent resistance to alkaline slag corrosion, and low cost.

Owner:徐利华 +3

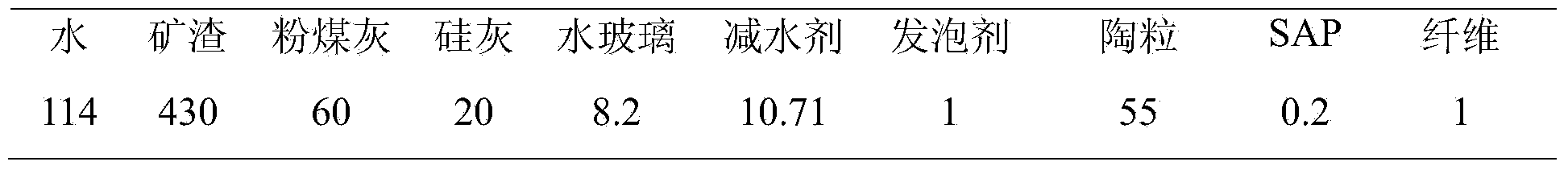

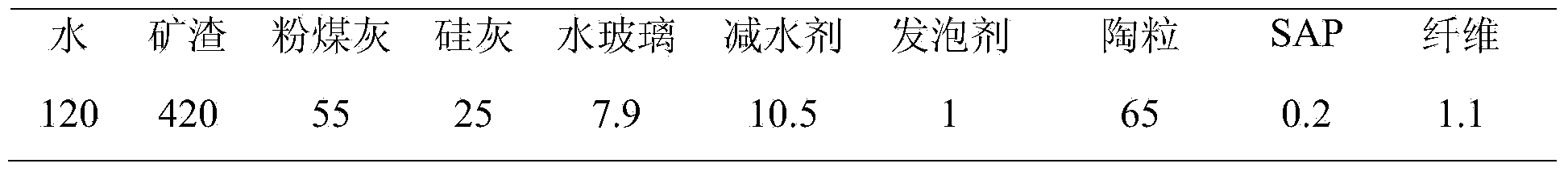

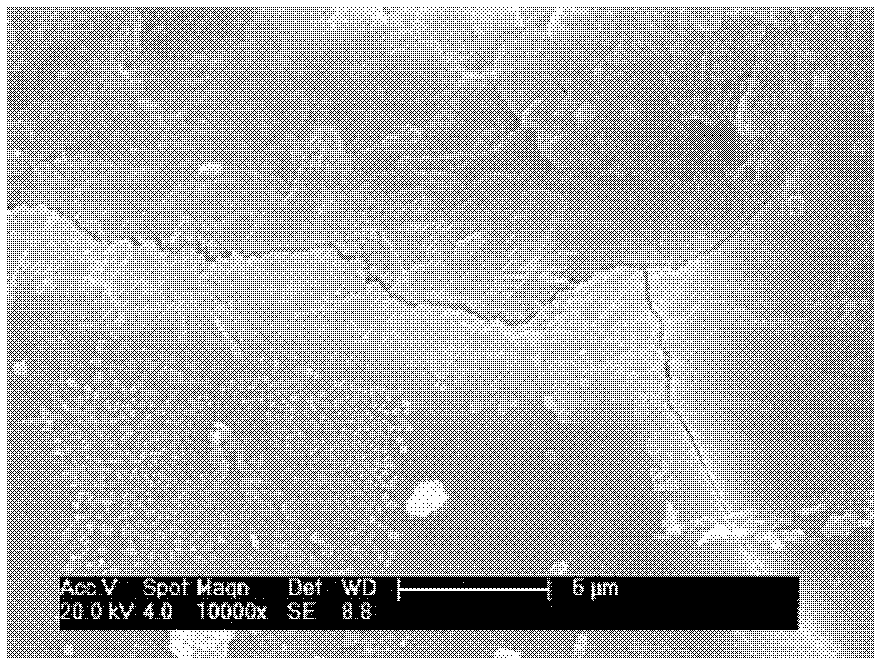

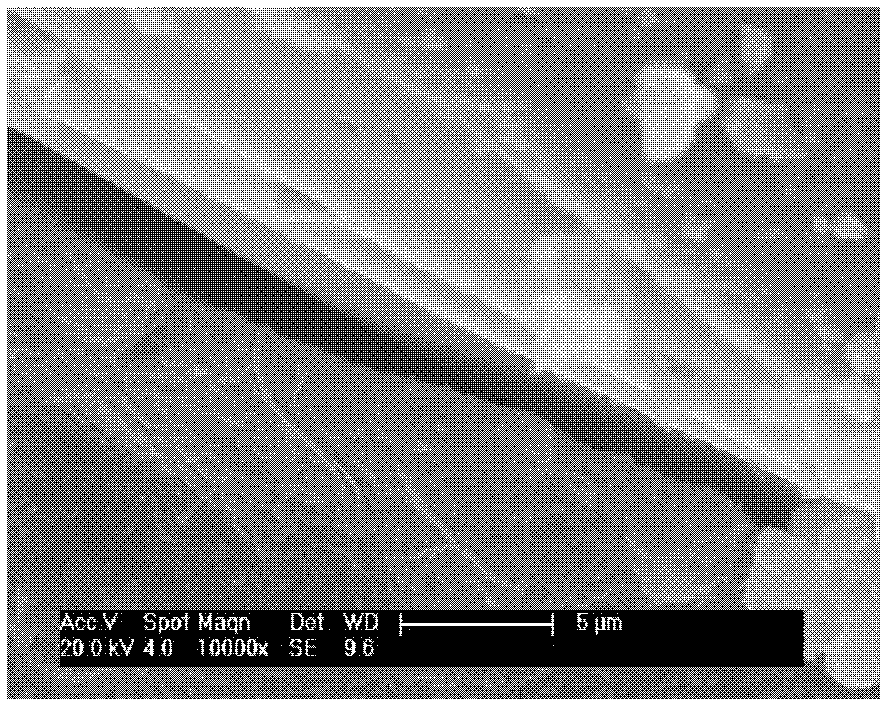

Low-shrinkage sludge ceramsite alkali-activated full-slag foam concrete plate and preparation method thereof

The invention discloses a low-shrinkage sludge ceramsite alkali-activated full-slag foam concrete plate and a preparation method thereof. The foam concrete plate is prepared from slag, silica fume, pulverized fuel ash, fibers, ceramsite, sodium polyacrylate SAP, water, a foaming agent, alkali activator and a water reducing agent. According to the method, cement is completely replaced by slag to prepare foam concrete, the shrinkage performance and heat conductivity coefficient of the foam concrete material can be reduced by doping ceramsite and sodium polyacrylate SAP, and the tensile strength of the foam concrete material can be guaranteed by utilizing an alkali-activated slag system and ceramsite. The prepared foam concrete plate has excellent mechanical performance and low-shrinkage self-insulation performance and is capable of solving the problems that a traditional autoclaved aerated concrete material needs high-temperature steaming and a prefabricated part made from the traditional autoclaved aerated concrete material easily cracks; in addition, the invention effectively realizes recycling of slag and other industrial wastes, saves energy, protects the environment and therefore has an important application value in the field of heat insulation of walls and the like.

Owner:WUHAN UNIV OF TECH

Alkali-activated slag mortar

The invention discloses alkali-activated slag mortar. The alkali-activated slag mortar consists of the following components in part by weight: 100 parts of mineral powder, 100 to 300 parts of water slag, 4 to 15 parts of alkali activator and 30 to 60 parts of water. The alkali-activated slag mortar can improve carbonization resistance, freeze-thaw cycle resistance, chloride ion penetration resistance and interface compactness of the mortar, provides a new route of water slag utilization and increases the utilization ratio of wastes.

Owner:SOUTHEAST UNIV

Alkali-activated slag geopolymer concrete and preparing method thereof

The invention provides alkali-activated slag geopolymer concrete. The geopolymer concrete is a compound powder cementing material is formed by slag powder and construction waste renewable micro powder under the priming action of a water glass solution of sodium hydroxide. The alkali-activated slag geopolymer concrete is prepared from, by weight, 150-210 parts of slag powder, 20-60 parts of construction waste renewable micro powder, 190-240 parts of water glass, 25-50 parts of solid sodium hydroxide, 400-700 parts of sand and 0-1600 parts of coarse aggregate. Being prepared from slag powder, construction waste renewable micro powder, water glass, solid sodium hydroxide, sand and coarse aggregate, the alkali-activated slag geopolymer concrete has the advantages of being high in early strength, high in durability, high temperature resistance, corrosion resistance and heat-insulating property and low in production energy consumption and is green building material low in cost and high in performance.

Owner:上海德滨环保科技有限公司

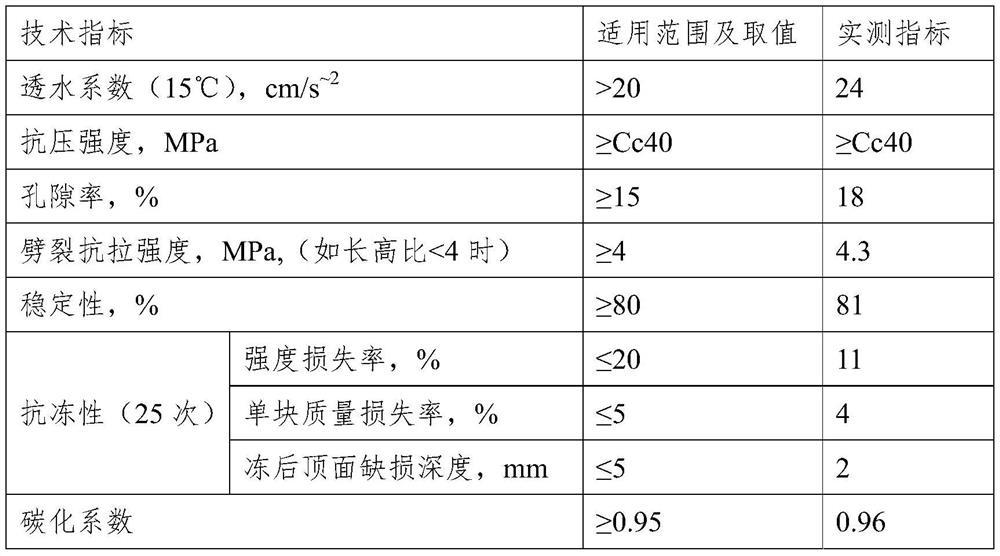

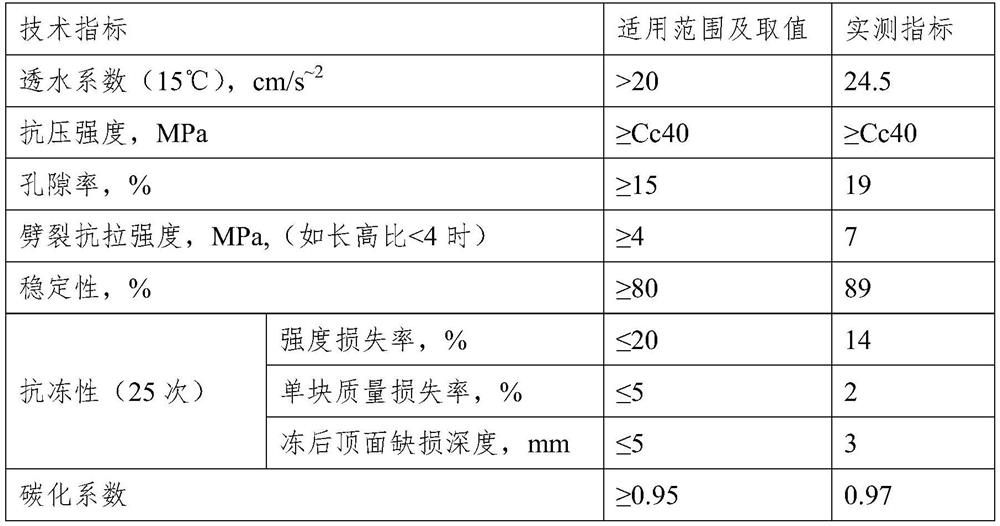

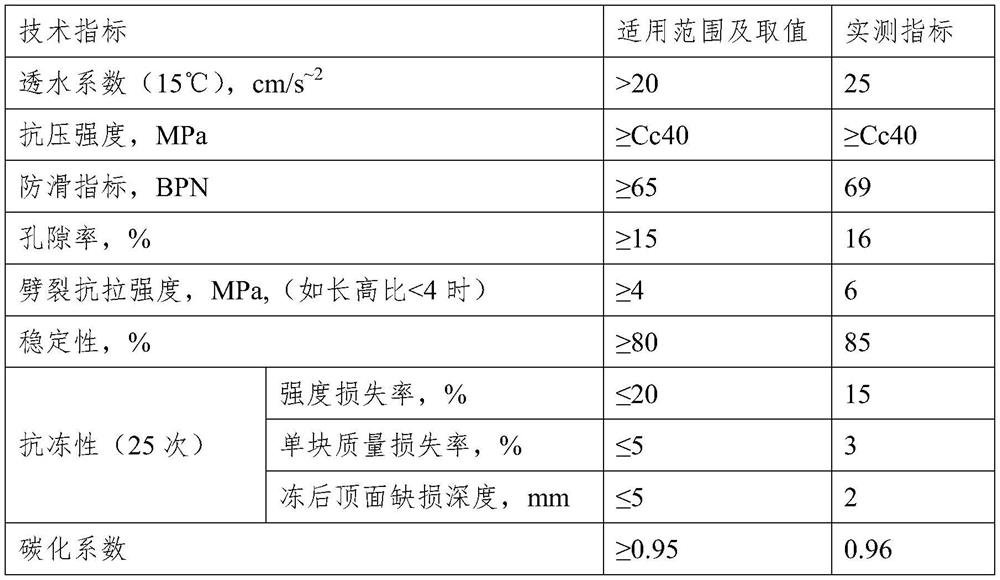

Red mud-based solid waste pervious concrete as well as preparation method and application thereof

ActiveCN111847995APermeablePermeable concrete material is breathable and hasIn situ pavingsSlagPhysical chemistry

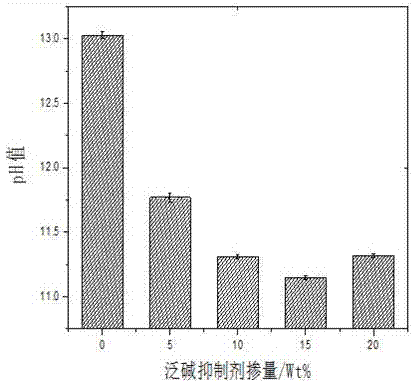

The invention relates to the technical field of pervious concrete, in particular to red mud-based solid waste pervious concrete as well as a preparation method and application thereof. The pervious concrete is prepared from the following raw materials in parts by weight: 55-75 parts of red mud, 5-20 parts of blast furnace slag, 0-30 parts of carbide slag, 0-25 parts of alkaline residue, 1-5 partsof a saltpetering inhibitor, 1-9 parts of a cementing agent, 0.5-1 part of a water reducing agent, 0.1-1 part of a reinforcing agent and 30-50 parts of aggregate. The red mud cooperates with various solid wastes such as the slag, the carbide slag and the alkaline residues, so that the prepared red mud-based pervious concrete material has excellent properties such as air permeability, water permeability, light weight, high bearing capacity, high heat dissipation and wear resistance. Besides, the alkaline components (Na and Ca) are fixed by the saltpetering inhibitor in a chemical bonding manner, so that leaching of the alkaline components in the red mud-based pervious concrete can be effectively controlled, and the problem that the red mud-based solid waste pervious concrete is prone to saltpetering and weathering is solved.

Owner:SHANDONG HI SPEED GRP CO LTD +1

Magnesite slag aerating brick and preparation method thereof

ActiveCN102875188ALow bulk densityGood heat insulationSolid waste managementCeramicwareSODIUM METAPHOSPHATECellulose

The invention provides a magnesite slag aerating brick. The magnesite slag aerating brick is processed and manufactured by the following raw materials in parts by weight: 20 to 30 parts of magnesite slag, 25 to 30 parts of fly ash, 5 to 10 parts of cement, 4 to 6 parts of modified kaolin, 5 to 10 parts of sewage treatment sludge, 5 to 10 parts of caustic sludge, 5 to 10 parts of calcium carbonate powder, 10 to 15 parts of lime, 0.1 to 0.3% of triethanolamine based on weight of lime, 4 to 5 parts of gypsum, 0.02 to 0.08 part of aluminum powder, 3 to 5% of oxyparaffin soap based on weight of aluminum powder, 0.01 to 0.02 part of calcium bicarbonate, 2 to 3 parts of expanded vermiculite, 1 to 2 parts of lignocellulose, 0.3 to 0.5 part of water glass, 0.03 to 0.05 part of sodium borate, 1 to 2 parts of sodium hexametaphosphate, 1 to 2 parts of hydroxypropyl methyl cellulose sodium and 1 to 2 parts of superfine polyvinyl alcohol. According to the magnesite slag aerating brick and the preparation method provided by the invention, the magnesite slag is added to the raw material of the aerating brick, and other common assistants and modified nanometer additives are synchronously added; the aerating brick processed by a proper technology is low in cost and high in performance, the circulating economic benefit of turning waste into wealth is achieved, and the pollution is reduced; the processed aerating brick has the characteristics of being light in unit weight, high in heat insulating performance, high in effect of sound absorbing and high in strength; and the aerating brick can be used as the non-bearing wall or bearing wall.

Owner:中山市中南机电安装工程有限公司

Dry-mixed pre-mixed mortar prepared by alkali activated slag cement, and preparation method thereof

Owner:JIANGSU NIGAO SCI & TECH +1

Bitumen mixture anti-stripping agent

InactiveCN103086628ASpeed up fusionEasy to integrateSolid waste managementAluminateAlkali activated slag

The invention discloses a bitumen mixture anti-stripping agent which consists of the following components in parts by weight: 30-50 parts of construction waste micropowder, 10-25 parts of alkali residue micropowder, 10-15 parts of coal gangue incinerator ash and 1-3 parts of additive, wherein the construction waste micropowder is formed by grinding construction waste (basically consisting of 20 percent of waste concrete and 80 percent of waste tiles) in which organic matters are removed; the coal gangue incinerator ash is coal gangue incinerator ash which is activated by keeping the temperature at 750-900 DEG C for 2.5-3 hours; and the additive is one or more of sulfoaluminate, silicate cement clinker and triethanolamine. Compared with like products in the prior art, the bitumen mixture anti-stripping agent has the advantages that the harm of chlorine salt and water to bitumen can be prevented, the anti-stripping agent is prevented from being decomposed due to heating, the environmental harm is avoided, and the price is low.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Phase-change thermal insulation putty

InactiveCN103214893AReduce waste burdenAchieve energy saving and emission reductionFilling pastesThermal insulationSlag

The invention discloses a phase-change thermal insulation putty consisting of the following substances in percentage by weight: 30-40% of activated and regenerated concrete fine powder, 5-10% of ground limestone, 3-5% of talcum powder, 15-25% of quartz sand, 1-3% of alkaline mud, 3-5% of washing slurry, 3-5% of silicate cement clinker, 1-3% of aluminum slag, 8-12% of a phase-change material, 2-5% of expanded perlite powder and 0.5-1.5% of an additive. The phase-change thermal insulation putty disclosed by the invention has the characteristics of remitting the environmental pressure from urban construction and alkaline production enterprises and the pressure of the resource shortage of building material enterprises, realizing energy conservation and emission reduction of buildings, reducing the waste burden of enterprises, increasing the income and improving the ecological environment.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

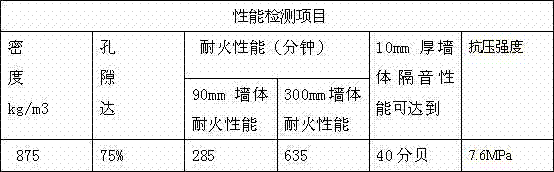

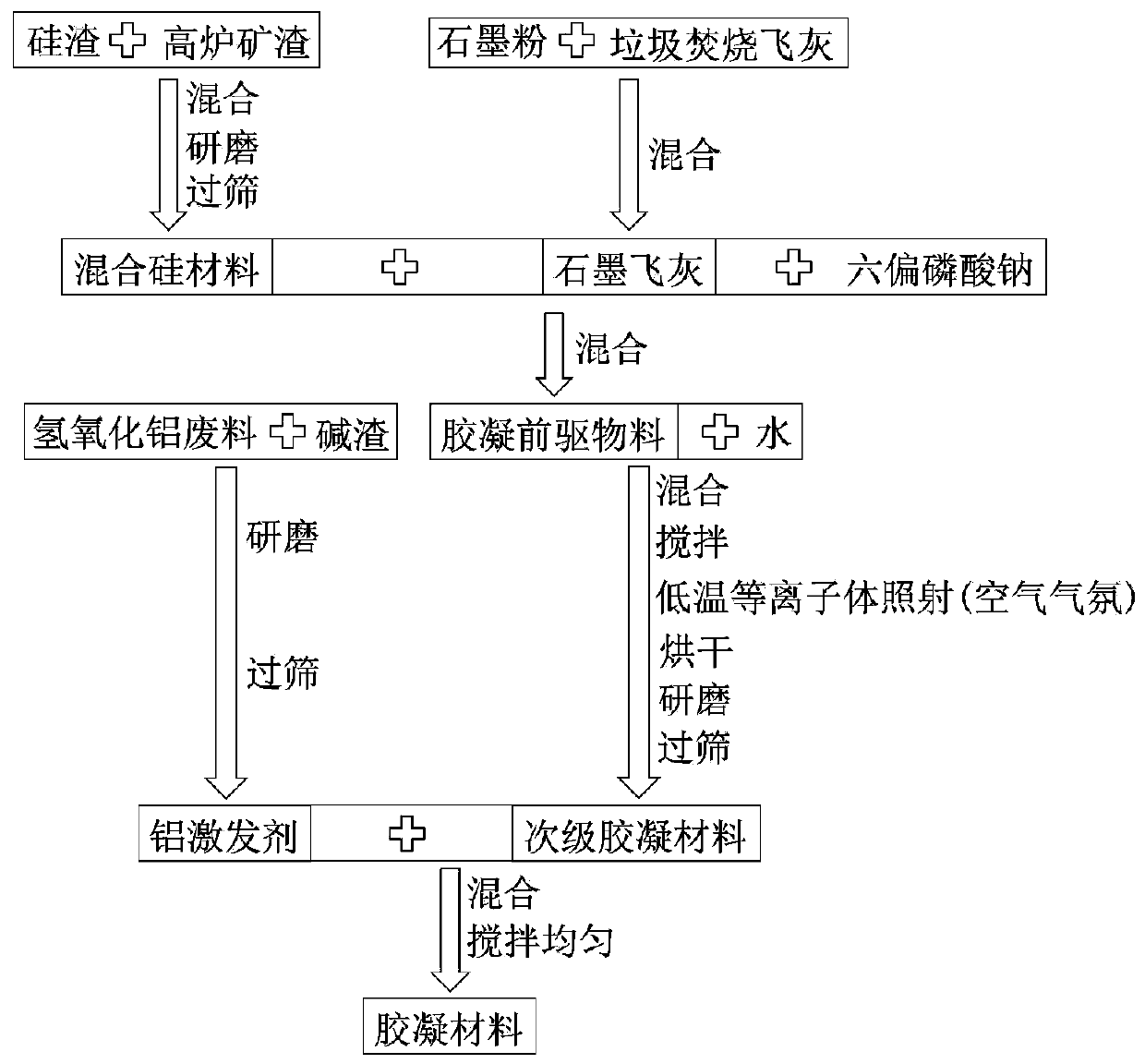

Method for preparing sintering-free cementing material from waste incineration fly ash

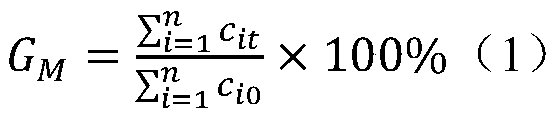

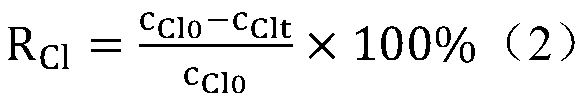

The invention discloses a method for preparing a sintering-free cementing material from waste incineration fly ash. The method comprises the following steps: (1) mixing silicon slag and blast furnaceslag, grinding, sieving to obtain a mixed silicon material, and mixing graphite powder and waste incineration fly ash to obtain graphite fly ash; (2) mixing sodium hexametaphosphate, the mixed siliconmaterial and graphite fly ash to obtain a gel precursor material; (3) dissolving the gelling precursor material in water, stirring while performing low-temperature plasma irradiation, drying, grinding and sieving to obtain a secondary cementing material; (4) mixing aluminum hydroxide waste and alkaline residues, grinding, and sieving to obtain an aluminum activator; and (5) uniformly mixing the aluminum activator and the secondary cementing material to obtain the cementing material. High-temperature sintering is not needed in the preparation process, so that process energy consumption is greatly reduced; the cementing material can achieve the highest heavy metal curing rate of 99.24%, the highest chlorine removal rate of 98.75% and the highest dioxin substance removal rate of 98.37%; andthe uniaxial compressive strength of a prepared mortar test block is as high as 50.68 MPa.

Owner:浙江慧科环保科技有限公司

No-baking and no-steaming environment protection solid fly ash-cinder brick

InactiveCN1931772AImprove early strengthGood compatibilitySolid waste managementCooking & bakingFly ash brick

The present invention relates to green building material, and features that the no-braking and no-steaming green brick is produced with cementing industrial waste, small amount of cement, aggregate and admixture. Cementing industrial waste, such as fly ash, calcium carbide slime, etc, cement, aggregate and admixture in certain weight proportion are produced into the no-braking and no-steaming green brick through mixing, forming, curing, stocking, naturally curing and inspection. The brick meets the requirement of fly ash brick, and has the features of saving clay resource, no need of steam curing, simple production and low cost.

Owner:HENAN POLYTECHNIC UNIV

Alkali activated slag foamed cement product and its preparation method

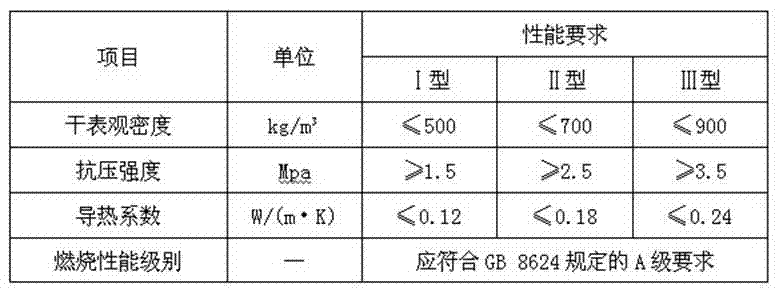

The invention provides an alkali activated slag foamed cement product and its preparation method. The product is prepared from the following raw materials by weight: 60 to 75% of an alkali slag cementing material, 0.5 to 1% of a composite admixture, 8 to 15% of foam and 16 to 25% of water. The alkali slag cementing material is prepared from the following raw materials by weight: 93.0 to 96.0% of slag powder, 1.0 to 2.0% of a water reducing agent and 2.0 to 5.0% of alkali powder particles. According to the invention, in a formula, the slag powder and the alkali powder particles which are generally used as industrial wastes are utilized as the cementing material for the foamed cement; the product has excellent early-strength mechanical performance and thermal insulation performance, stable and uniform foam and a short setting time; cost is reduced while production efficiency is improved. The product provided in the invention can be processed and molded in a factory or directly casted after mixing on the spot and is applicable to a non-load-bearing wall building block, a floor heating insulation layer and a roof insulation layer of a building or to preparation of various insulation materials.

Owner:王建国

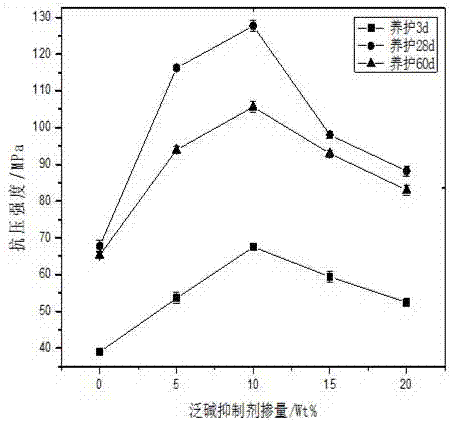

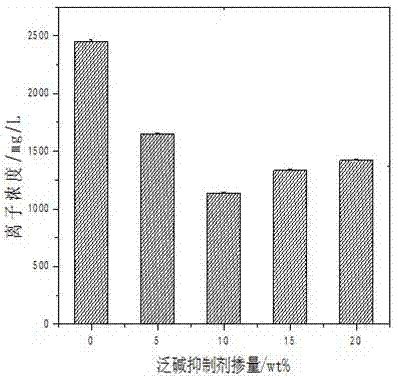

Alkali-activated slag cement efflorescence inhibitor and preparation method thereof

The invention relates to the technical field of building materials, in particular to an inhibitor capable of inhibiting efflorescence of alkali-activated slag cement and adjusting the performance of the alkali-activated slag cement, and a preparation method of the inhibitor. The alkali-activated slag cement efflorescence inhibitor is characterized by being prepared from the following raw materials by mass percent: 10-30% of zeolite, 10-20% of silica fume, 20-30% of pulverized fuel ash, 5-15% of boric acid and 5-55% of superfine slag powder. The alkali-activated slag cement efflorescence inhibitor provided by the invention is simple to prepare and use, and has a certain retarding effect; after the efflorescence inhibitor is added into alkali-activated slag cement concrete and mortar, the working performance of the alkali-activated slag cement concrete and mortar can be improved, the engineering quality is improved after construction, the early strength and later strength of the alkali-activated slag cement concrete can be increased by 15-20%, the efflorescence probability of the alkali-activated slag cement concrete is greatly reduced, and the reduction magnitude reaches up to 80%; the alkali-activated slag cement efflorescence inhibitor can inhibit the efflorescence phenomenon of the alkali-activated slag cement after construction, and has an inhibiting effect on the efflorescence phenomenon of the building materials after construction.

Owner:UNIV OF JINAN

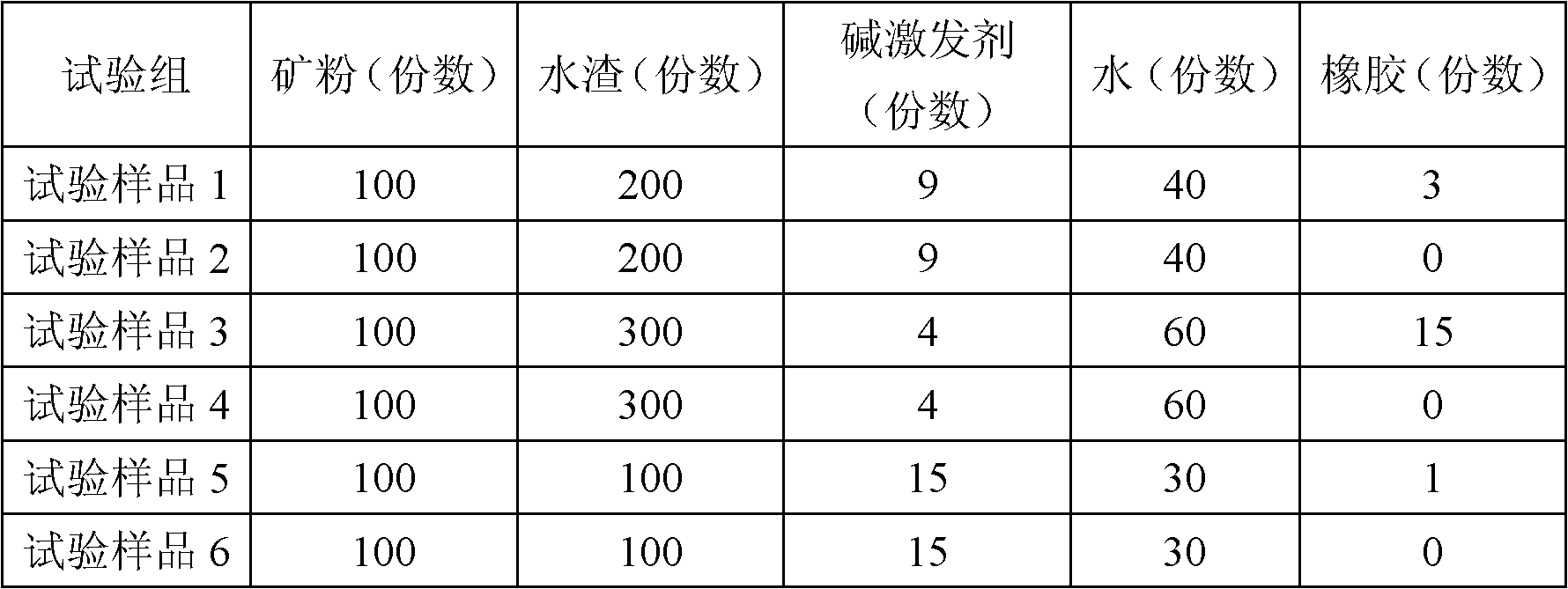

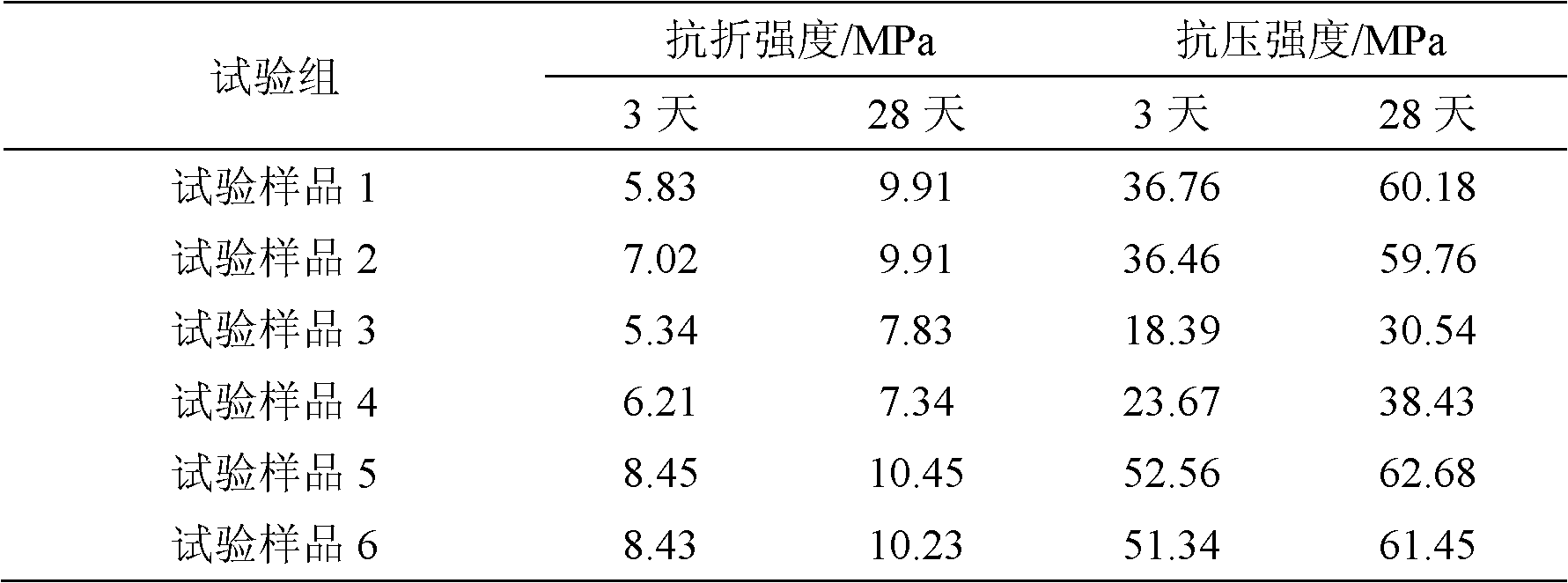

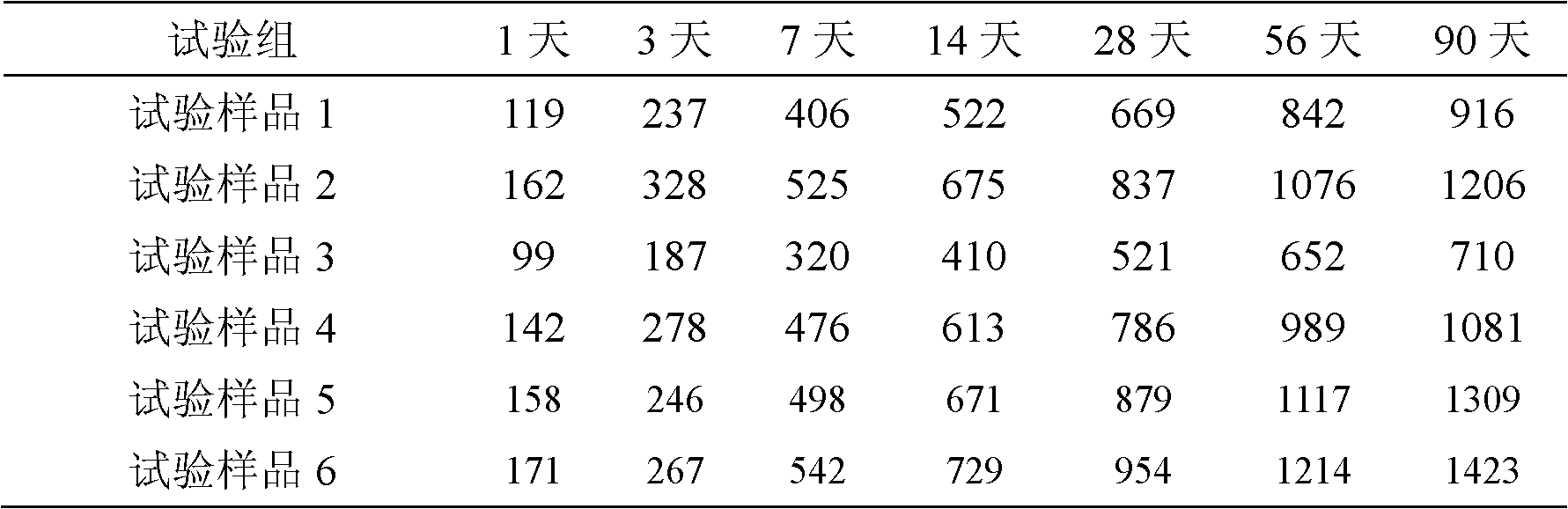

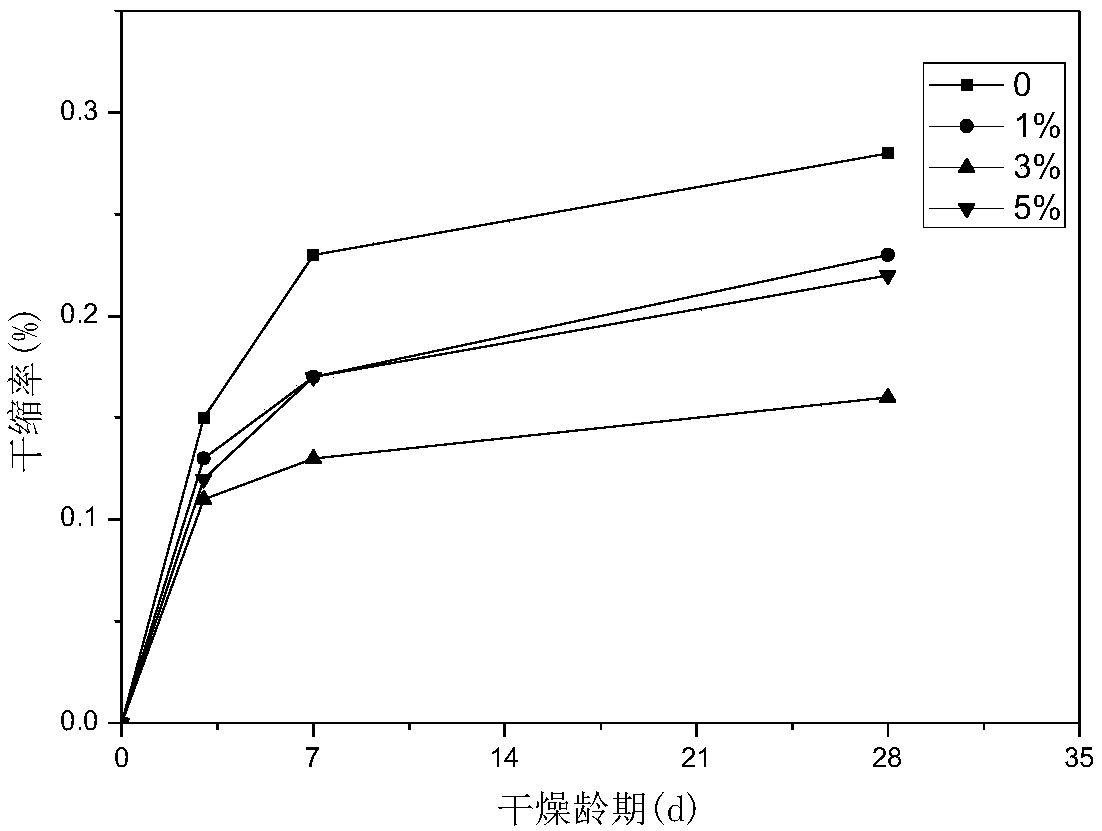

Alkali-activated slag mortar capable of reducing drying shrinkage and plastic cracking

ActiveCN102557505AReduce intensityImprove adhesionSolid waste managementPolymer scienceAlkali activated

The invention discloses an alkali-activated slag mortar capable of reducing drying shrinkage and plastic cracking, and the alkali-activated slag mortar comprises the following components in parts by weight: 100 parts of mineral powder, 100-300 parts of water granulated slag, 4-15 parts of alkali-activated agent, 30-60 parts of water and 1-15 parts of rubber, wherein the rubber is rubber particlesor rubber powder. The mechanical strength of the alkali-activated slag mortar prepared by the components can be maintained at the existing level, and the drying shrinkage and the plastic cracking areobviously reduced.

Owner:SOUTHEAST UNIV

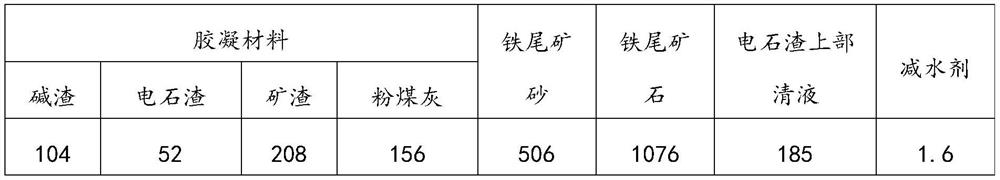

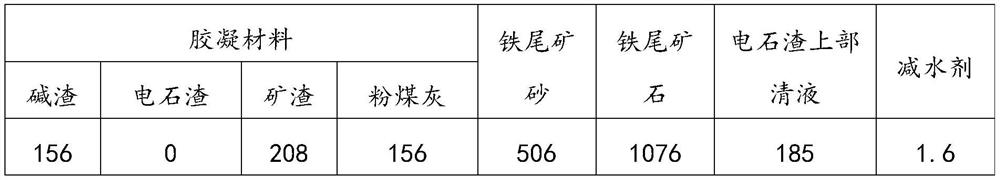

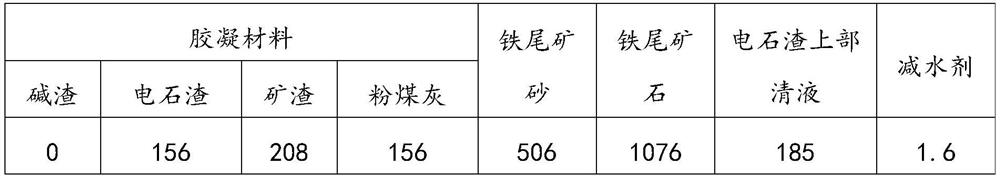

C30-grade all-solid-waste concrete and preparation method thereof

ActiveCN112125633AReduce manufacturing costTake advantage ofSolid waste managementSlagMining engineering

The invention provides a C30-grade all-solid-waste concrete and a preparation method thereof. Alkali residue carbide slag is utilized to synergistically excite a slag and fly ash composite cementing material to replace cement, and iron tailing sandstone is utilized to replace traditional sandstone. The all-solid-waste concrete is prepared from the following components in parts by weight: 52 to 156parts of alkaline residue, 26 to 78 parts of carbide slag, 182 to 234 parts of slag, 104 to 208 parts of fly ash, 170 to 190 parts of water, 460 to 510 parts of iron tailing sand, 1030 to 1150 partsof iron tailing ore and 1 to 3 parts of polycarboxylate superplasticizer. The new all-solid-waste concrete is prepared from various industrial solid waste residues, the 28d strength reaches 30 MPa orabove, waste is turned into wealth, the environment is protected, and meanwhile the production cost is reduced.

Owner:YANSHAN UNIV +1

Stable broken stone structure layer prepared form industrial waste alkaline residue and cement, and construction method thereof

ActiveCN103664107ASolve bottlenecksSolve the secondary effective useSolid waste managementChipsealStructure of the Earth

The invention discloses a stable broken stone structure layer prepared from industrial waste alkaline residue and cement, and a construction method thereof. The structure layer is composed of the following raw materials in parts by weight: 100 parts of aggregate, 4 to 10 parts of water, 1 to 10 parts of cement, and 1 to 10 parts of alkaline residue. The construction method comprises the following steps: processing a raw road surface, preparing a side mould, mixing, paving, pressing, curing, and quality inspecting; and finally builds an industrial waste alkaline residue and cement stable broken stone structure layer with a thickness of 180 to 220 mm. It has been proved by a lot of indoor researches and tests that the pavement performance indicators of the structure layer totally meet the standards issued by the ministry of communications, and the structure layer has the characteristics of strong anti-scouring performance and prominent shrinkage fracture resistant performance. Furthermore, the preparation method of the structure layer can effectively utilize industrial alkaline residue, has the advantages of good pavement performance, convenient construction, and low cost, is energy-saving and environment-friendly, is beneficial for the continuous development of economy and society, and can be widely applied to basic layers or basic bottom layers of airport roads, city roads, highways, and each classified highway.

Owner:CHINA RAILWAY NO 5 ENG GRP +1

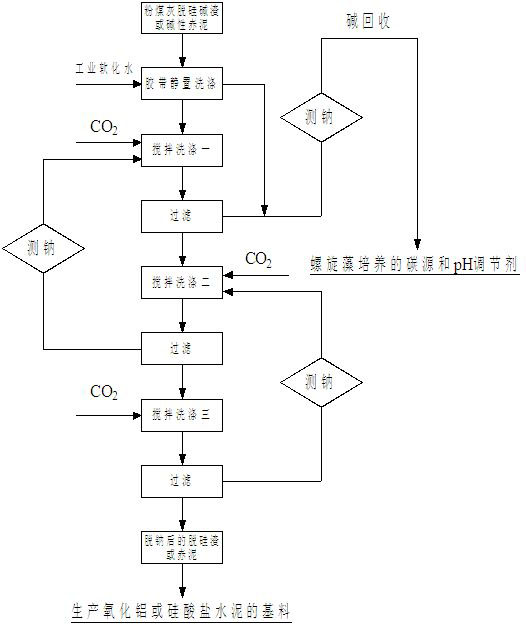

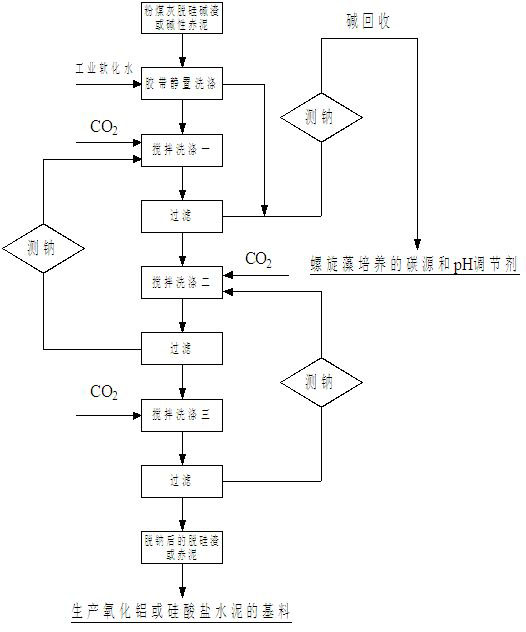

Method for washing carbon for removing sodium from silicon-removed alkaline residues of coal ash or basic red mud after process of extracting Al2O3

The invention discloses a method for washing carbon for removing sodium from silicon-removed alkaline residues of coal ash or basic red mud after a process of extracting Al2O3. The method is characterized by comprising the following step of: in a stirring and washing process, introducing desulfurated flue gas into a stirring and washing solution, wherein the washing temperature of the stirring and washing solution after introducing the desulfurated flue gas is 30-80 DEG C, the liquid / solid ratio L / S of the stirring and washing solution is 3-10, the introducing quantity of the flue gas is 0.5-2L / min, and the stirring and washing time is 1-3h. The method is simple and easy to apply, and the used stirring and washing solution can be used as a carbon source for cultivating spirulinas and a pH regulating agent; the silicon-removed alkaline residues after sodium removal can be used as a substrate for producing aluminum oxide by a lime sintering method; and the red mud after sodium removal is used as a substrate for producing silicate cement. The invention not only achieves the effects of waste gas emission reduction, waste liquid recycling and waste reduction, but also truly realizes a circulating economic model of the sustainable comprehensive recycling of three wastes (waste flue gas, sodium removal liquid and the red mud), and has obvious economic and social benefits.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

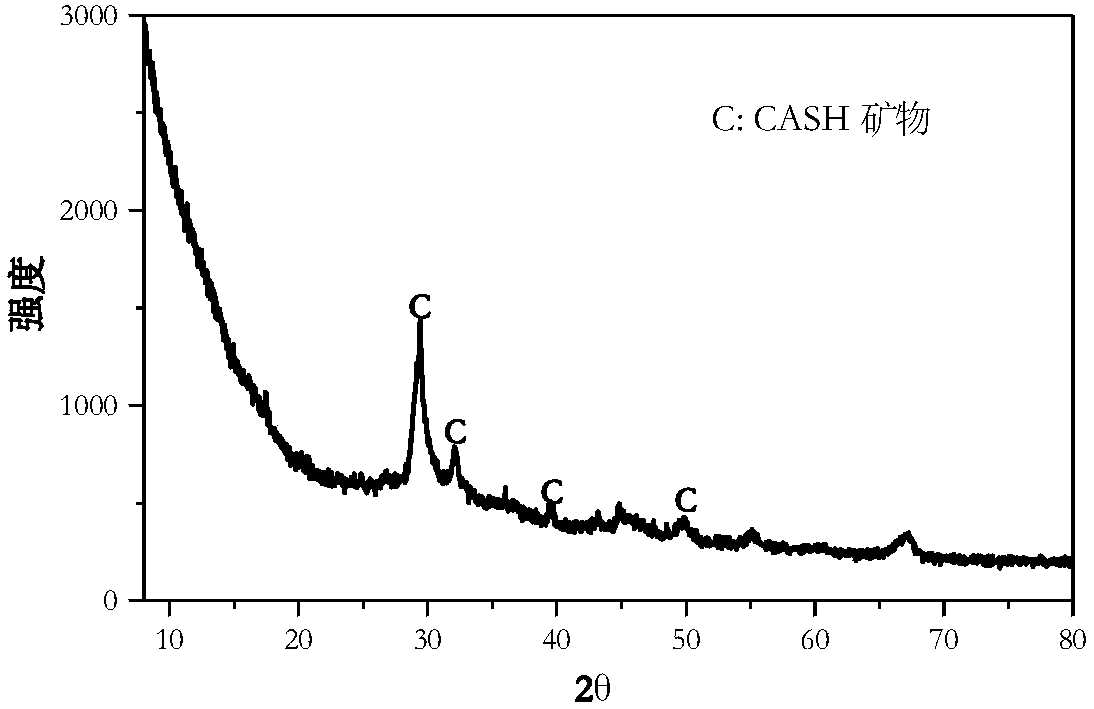

CASH mineral suitable for improving volume stability of alkali-activated slag system and preparation method thereof

The invention discloses a CASH mineral suitable for improving the volume stability of an alkali-activated slag system and a preparation method thereof. The prepared mineral can promote the hydration of alkali-activated slags and shorten the alkali-activated setting time. The preparation method comprises the following steps that (1), a calcareous material, an aluminum material, a siliceous materialand deionized water are accurately weighed, the aluminum material and the siliceous material are mixed with the deionized water in sequence and then dispersed, and then the calcareous material is added to obtain a mixture; (2), the mixture obtained in step (1) is heated in a water bath and stirred for reaction; (3), after the reaction is completed, the mixture is sealed in a polytetrafluoroethylene container, placed in a water bath and solidified to the age of 3-7 days. (4), after the solidification is completed, a product obtained in step (3) is washed with absolute ethanol and distilled water and then filtered for twice or more; (5), a product obtained in step (4) is dried in a vacuum drying oven until constant weight to obtain the CASH mineral.

Owner:NANJING UNIV OF TECH

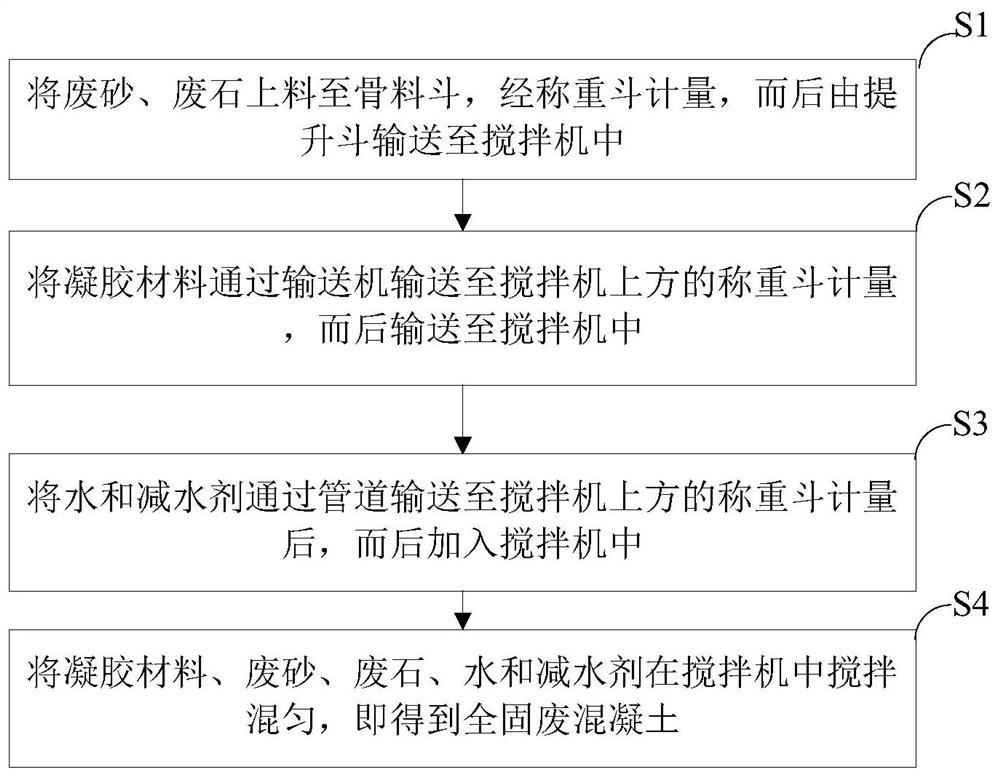

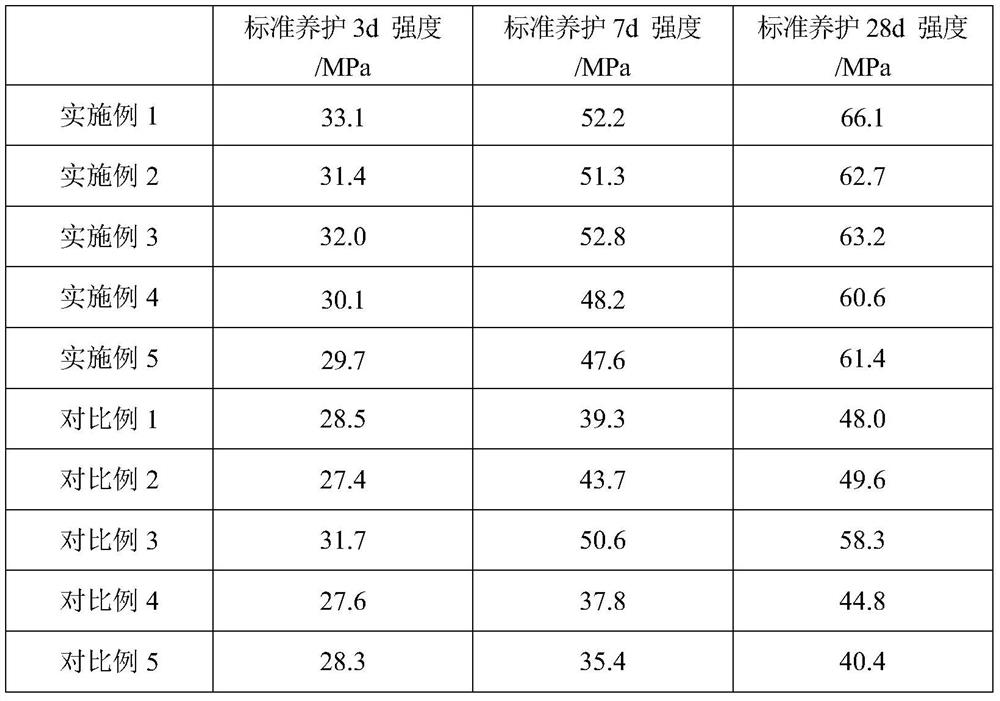

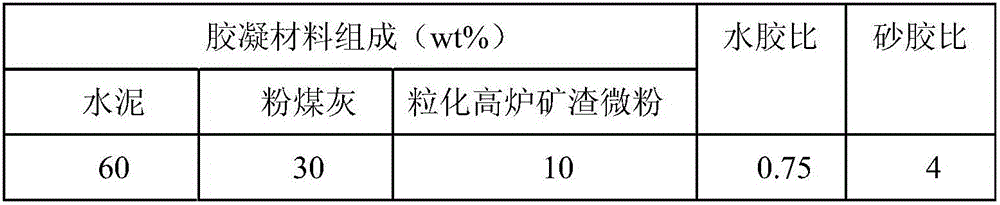

Cementing material, all-solid waste concrete and preparation method of all-solid waste concrete

The invention provides a cementing material, all-solid waste concrete and a preparation method thereof. The cementing material comprises the following components in percentage by mass: 25-35% of steel slag powder, 45-55% of slag powder, 10-15% of desulfurized gypsum powder and 5-10% of alkaline residue powder. According to the cementing material prepared by the preparation method disclosed by the invention, the potential hydraulic activity and "double salt effect" of silica tetrahedrons and alumina tetrahedrons in the slag powder are fully exerted by utilizing the mutual excitation effect among the alkaline residue powder, the steel slag powder, the slag powder and the desulfurized gypsum, and the cementing material capable of being hydrated and hardened is prepared. The cementing material is used for replacing cement and is mixed with waste sand, waste rock, water and a water reducing agent to prepare the all-solid waste concrete. According to the technology, 25-35% of raw material cost can be saved, the prepared concrete engineering material is excellent in mechanical property, and the compressive strength of the concrete engineering material can reach 60 MPa or above after standard curing for 28 days.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

Alkali activated slag cement concrete prefabricated inspection well lid and preparation process thereof

The invention discloses an alkali activated slag cement concrete prefabricated inspection well lid and a preparation process thereof. The inspection well lid is prepared from granulated blast-furnace slags, cement clinkers, retarders, sand, stone, steel fiber, water and sodium silicate. The preparation process comprises the following steps: in parts by weight, premixing granulated blast-furnace slags, cement clinkers, retarders, sand and stone in a mixer for 2-3 minutes; then, adding steel fiber by using a vibrating screen, and mixing the obtained mixture; adding water and sodium silicate by using a funnel; after mixing the obtained product, pouring the obtained product into an iron well-lid mould; after carrying out standing for 2-3 hours at room temperature, placing the obtained product into a steam curing chamber at a temperature of 75-85 DEG C to carry out curing for 2-3 days; and after carrying out natural cooling demoulding, carrying out watering and film covering on the obtained product to cure 7 for days. According to the invention, by using the excellent mechanical properties and durability properties of alkali activated slags, the impact-resistant and bending-resistant properties of the well lid are enhanced through mixing steel fibers with different lengths, and an alkali activated slag composite prefabricated round plate which is low in cost, light in weight and high in performance is prepared for replacing an iron inspection well lid, thereby solving the problem that an urban inspection well lid is stolen.

Owner:JIANGSU NIGAO SCI & TECH +1

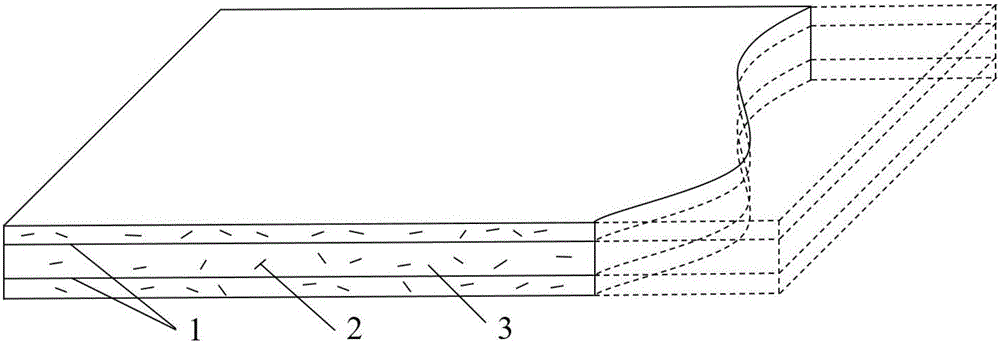

Composite reinforced alkali-activated slag mortar board and preparation method thereof

ActiveCN105859228AReasonable and effective resource utilizationEasy to getCeramic shaping apparatusFiberPolymer science

The invention relates to a composite reinforced alkali-activated slag mortar board and a preparation method thereof. The board is composed of continuous carbon fiber textile fabric, a chopped fiber composite reinforced material and alkali-activated slag mortar, wherein the continuous carbon fiber textile fabric and chopped fiber are reinforcing materials; and the alkali-activated slag mortar filled between the textile fabric and the fiber is a matrix material. The preparation method for the composite reinforced alkali-activated slag mortar board provided by the invention is simple, adopts a normal-temperature and normal-pressure curing preparation process without the need for heating and pressurization, has low unit energy consumption, does not discharge three wastes, and is a green preparation process. The composite reinforced alkali-activated slag mortar board prepared by using the above-mentioned preparation method has excellent bending property and strong impact resistance and freeze-thaw resistance.

Owner:SOUTHEAST UNIV

Alkali slag water-retaining agent and preparation method and application thereof

The invention discloses an alkali slag water-retaining agent and a preparation method and application thereof. The alkali slag water-retaining agent is composed of dechlorination alkali slag and a mixed material. The method for preparing the alkali slag water-retaining agent comprises the steps of evenly mixing the dechlorination alkali slag and the mixed material by mass percentage, adding the dechlorination alkali slag and the mixed material into a grinding device, performing grinding treatment to mixed powder with 0.30 mm residue on sieve smaller than 10 wt%, and obtaining the alkali slag water-retaining agent. The alkali slag water-retaining agent is good in water-retaining property, can be used for improving water-retaining property of mortar and contractibility of concrete, and is economical and environmentally friendly.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com