Alkali-activated slag mortar capable of reducing drying shrinkage and plastic cracking

A technology of alkali excitation and slag sand, which is applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of reducing the drying shrinkage of mortar and the compatibility of high-cost shrinkage reducing agents, so as to reduce drying shrinkage, Reduce and plastic cracking, reduce the effect of plastic cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

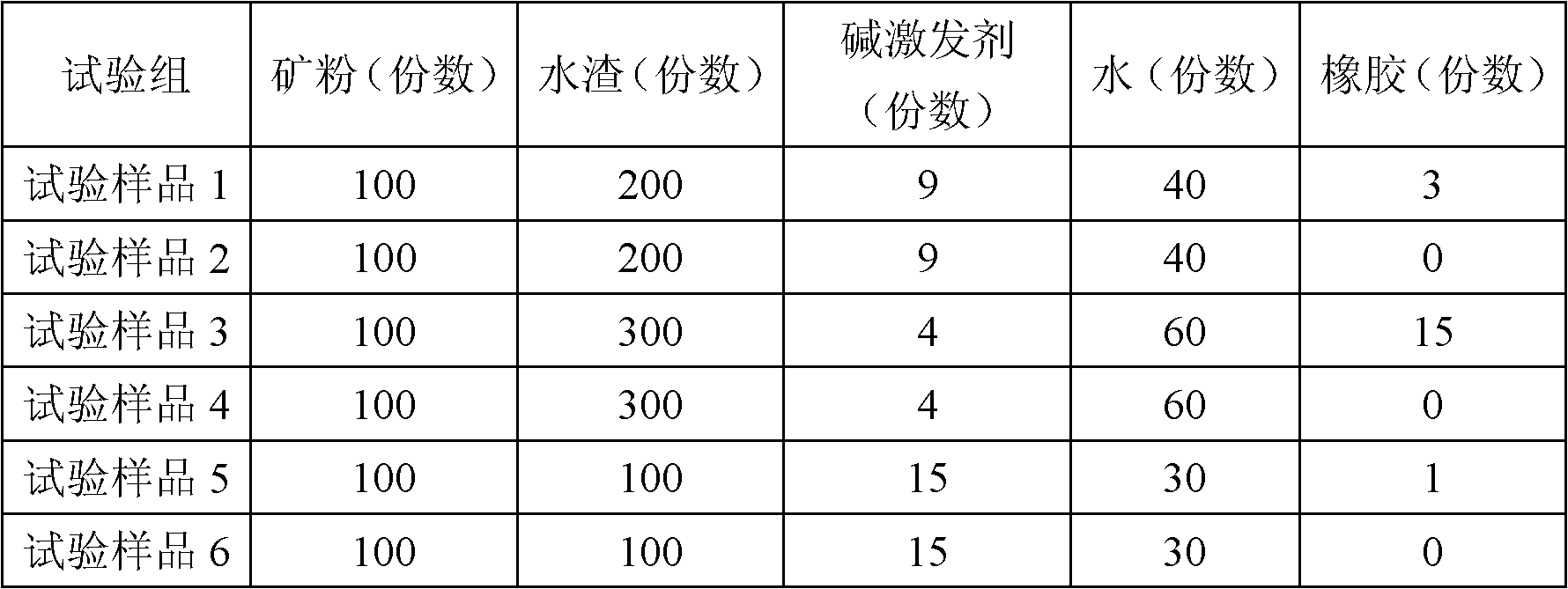

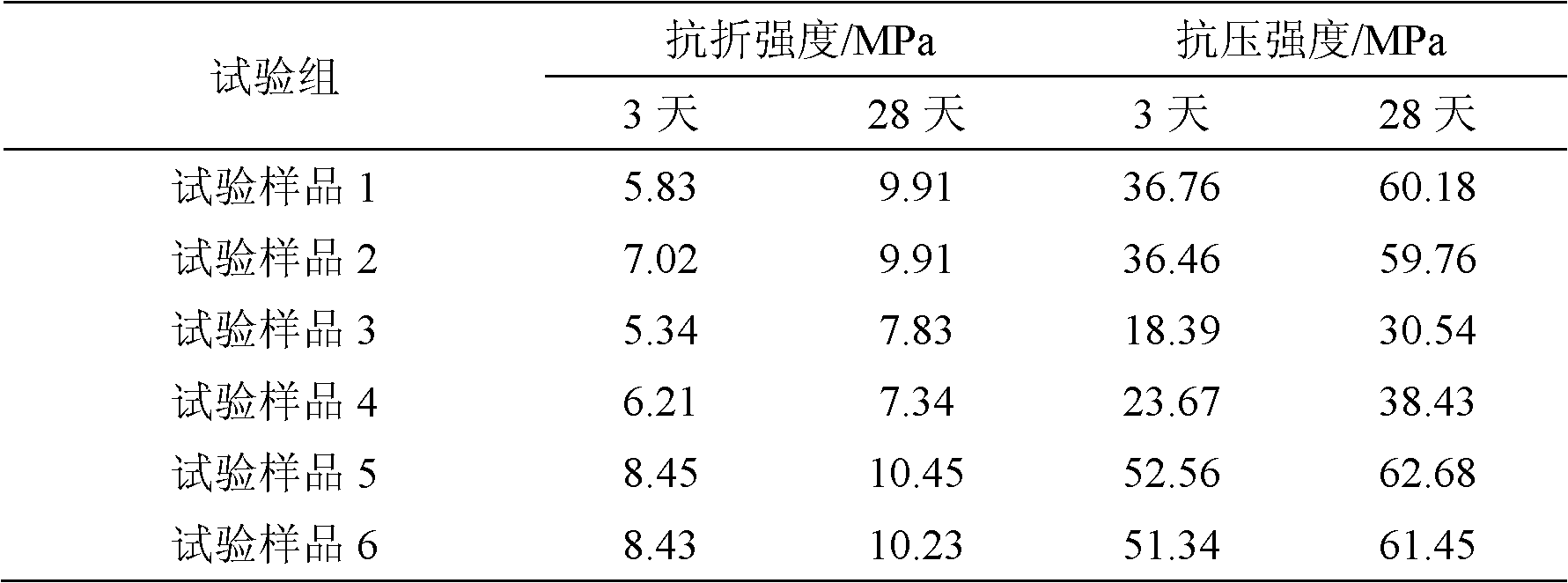

[0037] The strength performance test of the mortar is carried out: for the alkali-activated slag mortar prepared from the test sample 1 to the test sample 6, the strength performance test of the mortar is carried out according to the standard GB / T 17671-1999 of "Cement Mortar Strength Test Method". The test results are shown in Table 2.

[0038] Table 2 Flexural strength and compressive strength of alkali-activated slag mortar

[0039]

[0040]As can be seen from Table 2, comparing test sample 1 and sample sample 2, in 3 days, the flexural strength of test sample 1 was less than the flexural strength of sample sample 2, but also only poor 1.19Mpa, the compressive strength of test sample 1 Greater than the compressive strength of sample sample 2, the difference is only 0.3Mpa; at 28 days, the flexural strength of test sample 1 is equal to that of sample sample 2, and the compressive strength of test sample 1 is greater than that of sample sample 2 of compressive strength. ...

Embodiment 2

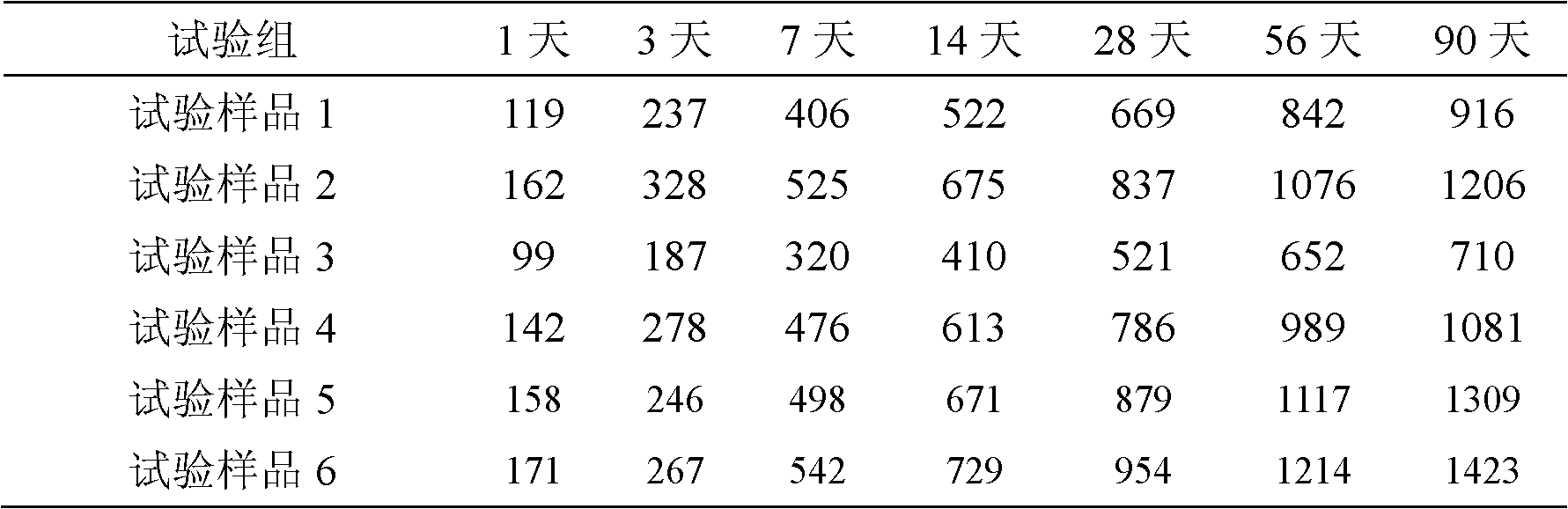

[0043] Drying shrinkage performance test of mortar: For the alkali-activated slag mortar prepared from test sample 1 to test sample 6, the drying shrinkage performance test of mortar was carried out according to the standard JGJ / T70-2009 of "Basic Performance Test Methods of Building Mortar". The test results are shown in Table 3.

[0044] Table 3 Alkali-induced slag mortar drying shrinkage test results / 10-6

[0045]

[0046] As can be seen from Table 3, for the test sample 1 and the test sample 2, the drying shrinkage of the test sample 1 is reduced compared with the test sample 2. Taking the 90-day drying shrinkage value as an example, the drying shrinkage of the test sample 1 is 24% lower than that of the test sample 2. %; For test sample 3 and test sample 4, test sample 3 has reduced drying shrinkage than test sample 4, taking 90 days drying shrinkage value as example, the drying shrinkage of test sample 3 has reduced 34% than test test sample 4; For For test sample ...

Embodiment 3

[0049] Conduct the plastic cracking performance test of the mortar: for the alkali-activated slag mortar prepared from the test sample 1 to the test sample 6, the plastic cracking performance test of the mortar was carried out according to the standard JC / T951-2005 of "Test Method for Cracking Resistance of Cement Mortar". The test results are shown in Table 4.

[0050] Table 4 Mortar plastic cracking resistance test results

[0051]

[0052] It can be seen from Table 4 that the cracking index of sample 1 is 260mm, and the maximum crack width is 0.9mm. The crack index of test sample 2 was 729 mm, and the maximum crack width was 1.7 mm. Whether it is the cracking index or the maximum crack width, the test sample 1 is obviously smaller than the test sample 2. That is to say, the plastic cracking resistance of Test Sample 1 is better than that of Test Sample 2. The cracking index of test piece sample 3 was 832 mm, and the maximum crack width was 1.5 mm. The crack index of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com