Low-shrinkage sludge ceramsite alkali-activated full-slag foam concrete plate and preparation method thereof

A technology of foam concrete and sludge ceramsite, which is applied in the field of building materials, can solve the problems of reducing strength, reducing the thermal conductivity of foam concrete, and increasing the porosity of products, so as to ensure the compressive strength, help protect the environment, and reduce engineering costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

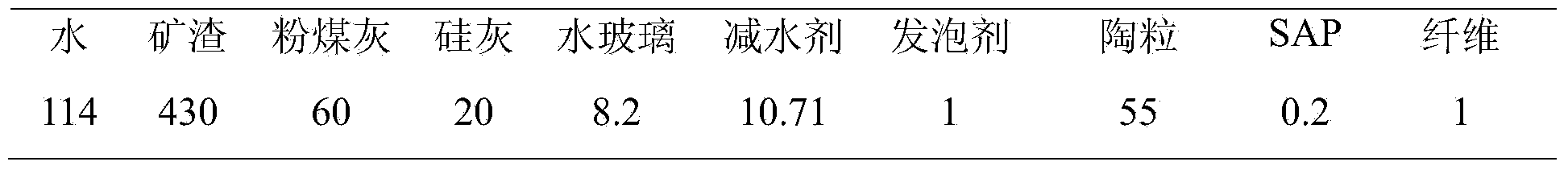

[0038] A low-shrinkage sludge ceramsite alkali-activated all-slag foam concrete slab, the contents of each component are shown in Table 1.

[0039] The raw material mixing ratio (kg / m3) of table 1 embodiment 1

[0040]

[0041] Weigh the raw materials according to the ratio of raw materials in Table 1 (among them, the amount of superplasticizer is 2.1% of the total mass of slag, silica fume and fly ash), soak the ceramsite in pre-wet for 24 hours and then lose water freely for 4-5 hours , and mix the ceramsite in the ceramsite heap evenly 1 hour before mixing, and measure its moisture content to be about 12%; absorb water of polyacrylic acid sodium salt SAP 150-200 times; mix slag, silicon powder, fly ash and The polypropylene fiber is dry mixed for 30-60s, so that the slag, silicon powder and fly ash as the cementing material are fully mixed with the fiber agent, and the water, water reducer, water Mix the glass, pre-wetted ceramsite (that is, ceramsite that has been satu...

Embodiment 2

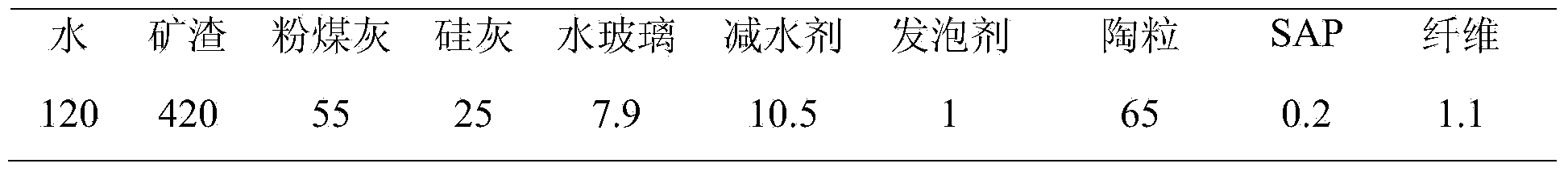

[0043] A low-shrinkage sludge ceramsite alkali-activated all-slag foam concrete slab, the contents of each component are shown in Table 2.

[0044] The raw material ratio (kg / m) of table 2 embodiment 2 3 )

[0045]

[0046] Weigh the raw materials according to the ratio of raw materials in Table 2 (among them, the amount of superplasticizer is 2.1% of the total mass of slag, silica fume and fly ash), soak the ceramsite in pre-wet for 24 hours, and then lose water freely for 4-5 hours , and mix the ceramsite in the ceramsite heap evenly 1 hour before mixing, and measure its moisture content to be about 12%; absorb water of polyacrylic acid sodium salt SAP 150-200 times; mix slag, silicon powder, fly ash and The polypropylene fiber is dry-mixed for 30-60s, so that the slag, silica fume and fly ash as the cementitious material are fully mixed with the fiber agent, and then water, water reducer, water reducing agent, Water glass, pre-wetted ceramsite (that is, ceramsite that ...

Embodiment 3

[0048] A low-shrinkage sludge ceramsite alkali-activated all-slag foam concrete slab, the contents of each component are shown in Table 3.

[0049] The raw material ratio (kg / m) of table 3 embodiment 3 3 )

[0050]

[0051] Weigh the raw materials according to the ratio of raw materials in Table 3 (among them, the amount of superplasticizer is 2.1% of the total mass of slag, silica fume and fly ash), pre-wet the ceramsite for 24 hours and then freely lose water for 4-5 hours , and mix the ceramsite in the ceramsite heap evenly 1 hour before mixing, and measure its moisture content to be about 12%; absorb water of polyacrylic acid sodium salt SAP 150-200 times; mix slag, silicon powder, fly ash and The polypropylene fiber is dry mixed for 30-60s, so that the slag, silicon powder and fly ash as the cementitious material are fully mixed with the fiber agent, and then water is added (deducting the water absorbed by the sludge ultra-light ceramsite and polyacrylic acid sodium s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com