CASH mineral suitable for improving volume stability of alkali-activated slag system and preparation method thereof

A technology of volume stability and alkali excitation, which is applied in the direction of aluminum silicate and silicate, can solve the problems of high preparation environment requirements and complicated preparation steps, and achieve the effect of simple preparation process, simple preparation method and reduced porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

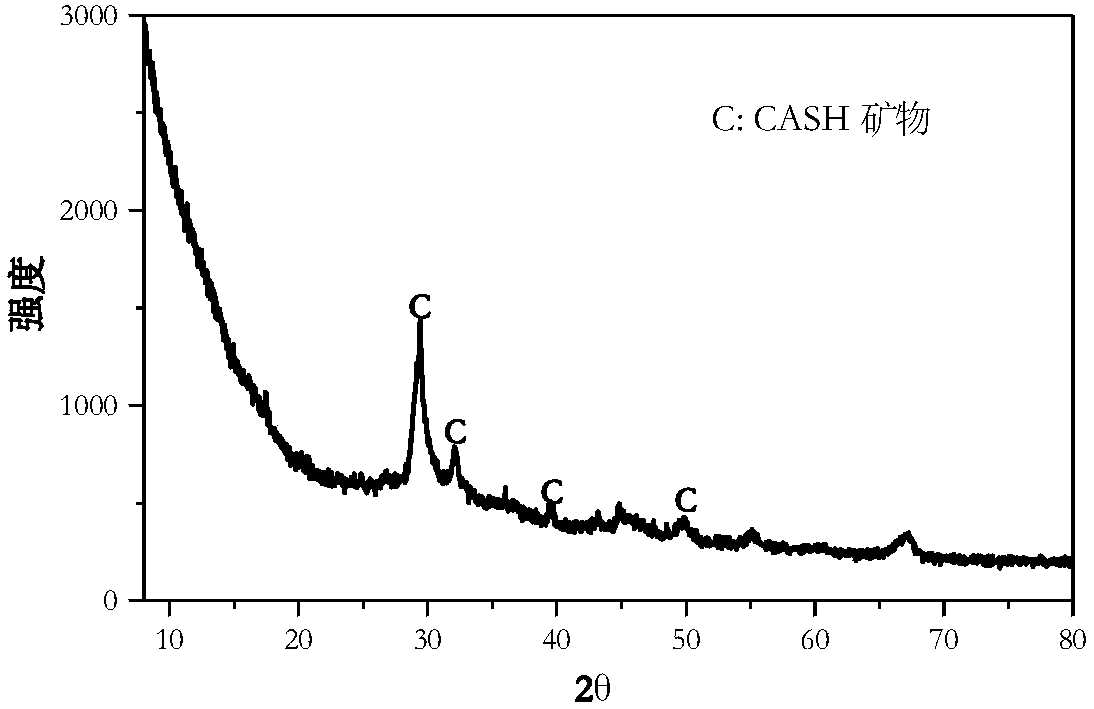

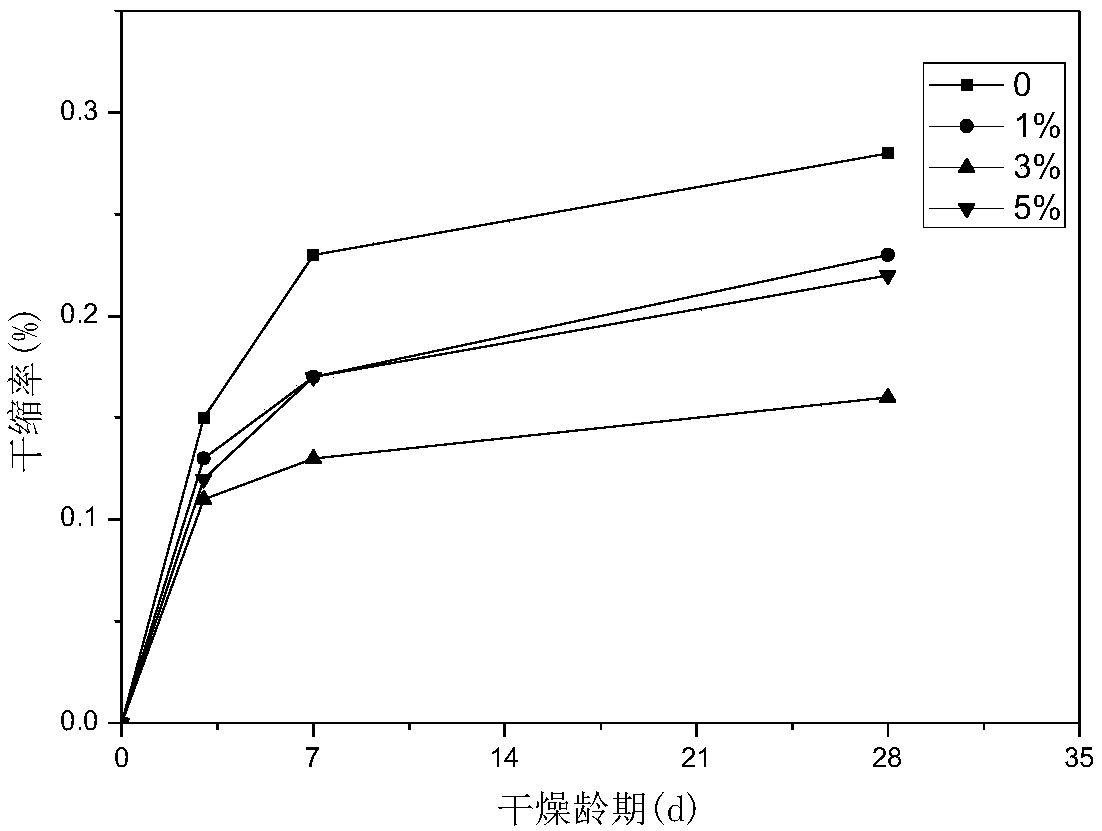

[0034] Using nano-alumina, nano-silicon dioxide, calcium hydroxide, and deionized water as raw materials, the calcium-silicon ratio is 0.5, the silicon-aluminum ratio is 2.0, the water-solid ratio is 1, the reaction temperature is 60°C, and the reaction time is 90 minutes. 3d age. The mass ratios of the raw materials are respectively: 32g of calcium hydroxide, 22.1g of nano-alumina, 25.9g of nano-silicon dioxide, and 640g of deionized water. Prepare according to the steps described in the summary of the invention to obtain the product (referred to as CASH). The mass ratio of slag powder to standard sand (mortar ratio) is 1:3, and the dosage of activator water glass with a modulus of 1.8 is Na 2 O equivalent (accounting for 5% of the mass of cementitious slag powder), without adding CASH, using 0.5 water (including the water introduced by water glass) to prepare mortar, without adding CASH, forming and curing, and measuring dryness of different ages Shrinkage, dry shrinkage t...

Embodiment 2

[0036] Using nano-alumina, nano-silicon dioxide, calcium hydroxide, and deionized water as raw materials, the calcium-silicon ratio is 0.5, the silicon-aluminum ratio is 2.0, the water-solid ratio is 1, the reaction temperature is 60°C, and the reaction time is 90 minutes. 3d age. The mass ratios of the raw materials are respectively: 32g of calcium hydroxide, 22.1g of nano-alumina, 25.9g of nano-silicon dioxide, and 640g of deionized water. Prepare according to the steps described in the summary of the invention to obtain the product (referred to as CASH). The mass ratio of slag powder to standard sand (mortar ratio) is 1:3, and the dosage of activator water glass with a modulus of 1.8 is Na 2O equivalent (accounting for 5% of the mass of cementitious material slag powder, i.e. the amount of alkali), mixed with 4.5g CASH (according to 1% of the mass fraction of slag), made it graded and dry mixed with slag, using 0.5% water (including the introduction of water glass) Prepar...

Embodiment 3

[0038] Using nano-alumina, nano-silicon dioxide, calcium hydroxide, and deionized water as raw materials, the calcium-silicon ratio is 0.5, the silicon-aluminum ratio is 2.0, the water-solid ratio is 1, the reaction temperature is 60°C, and the reaction time is 90 minutes. 3d age. The mass ratios of the raw materials are respectively: 32g of calcium hydroxide, 22.1g of nano-alumina, 25.9g of nano-silicon dioxide, and 640g of deionized water. Prepare according to the steps described in the summary of the invention to obtain the product (referred to as CASH). The mass ratio of slag powder to standard sand (mortar ratio) is 1:3, and the dosage of activator water glass with a modulus of 1.8 is Na 2 O equivalent (accounting for 5% of the mass of cementitious material slag powder, i.e. the amount of alkali), mixed with 13.5g CASH (3% according to the mass fraction of slag), made it graded and dry mixed with slag, using 0.5% water (including the introduction of water glass) Prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com