Red mud-based solid waste pervious concrete as well as preparation method and application thereof

A technology of permeable concrete and red mud, which can be applied to coagulating pavements, roads, buildings and other directions laid on site, and can solve the problems of difficult dehydration, insufficient application rate and high alkalinity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

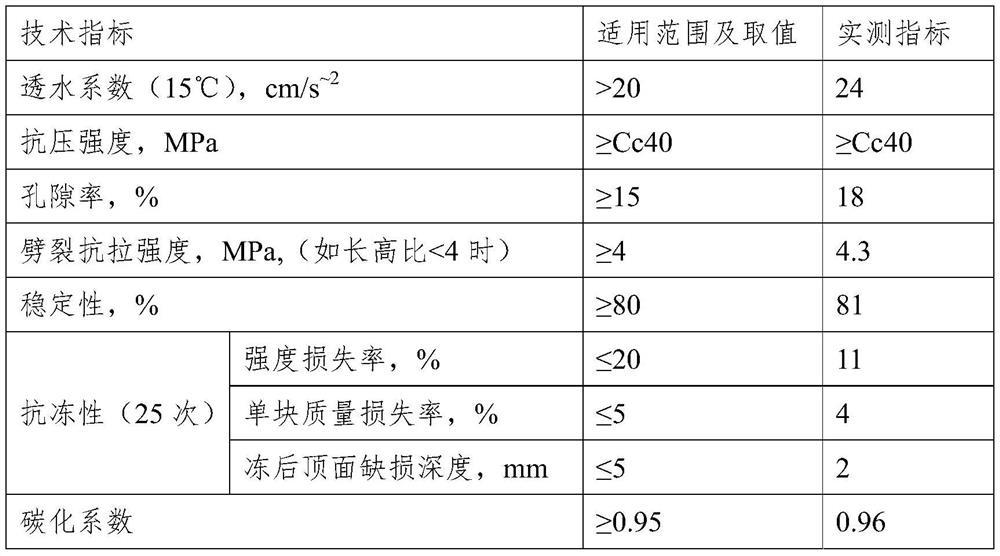

no. 1 example

[0031] The preparation of red mud-based solid waste permeable concrete includes the following steps:

[0032] A. Dry the red mud, blast furnace slag, calcium carbide slag, and alkali slag and sieving (the specific surface area is 360-420m 2 / kg), weigh the following solid wastes in proportion: 55 parts by weight of red mud, 15 parts by weight of blast furnace slag, 15 parts by weight of calcium carbide slag, and 5 parts by weight of alkali slag, for use.

[0033] B. Weigh the red mud, blast furnace slag, calcium carbide slag, alkali slag and 5 parts by weight of sodium silicate, 3 parts by weight of gelatin, 1 part by weight of polycarboxylic acid water-reducing agent, and 1 part by weight of silica fume in proportion Mix, get mixed powder, set aside.

[0034] C. Select 40 parts by weight of coal gangue with a particle size of 9-13mm, infiltrate with 10 parts of water, and then add the mixed powder of step B with a water-binder ratio of 0.15, pour and cure it to form a red mud-based ...

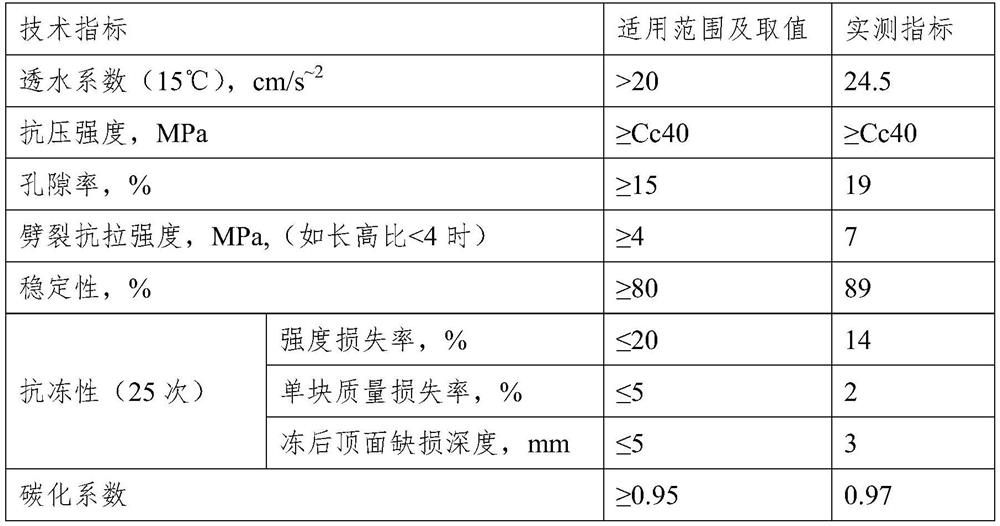

no. 2 example

[0038] The preparation of red mud-based solid waste permeable concrete includes the following steps:

[0039] A. Dry the red mud, blast furnace slag, calcium carbide slag and alkali slag and sieving (360-420m 2 / kg), weigh the following solid wastes in proportion: 65 parts by weight of red mud, 5 parts by weight of blast furnace slag, 5 parts by weight of calcium carbide slag, and 15 parts by weight of alkali slag for use.

[0040] B. Weigh the red mud, blast furnace slag, calcium carbide slag, alkali slag, 1 part by weight of sodium hydroxide, 1 part by weight of xanthan gum, 0.5 part by weight of naphthalene-based water reducing agent, and 0.5 part by weight of calcium carbonate whiskers that have been weighed in step A The parts are mixed in proportion to obtain the mixed powder and set aside.

[0041] C. Select 30 parts by weight of 9-13mm limestone tailings, add 10 parts of water to infiltrate, then add the mixed powder of step B, add water to a water-to-binder ratio of 0.2, pou...

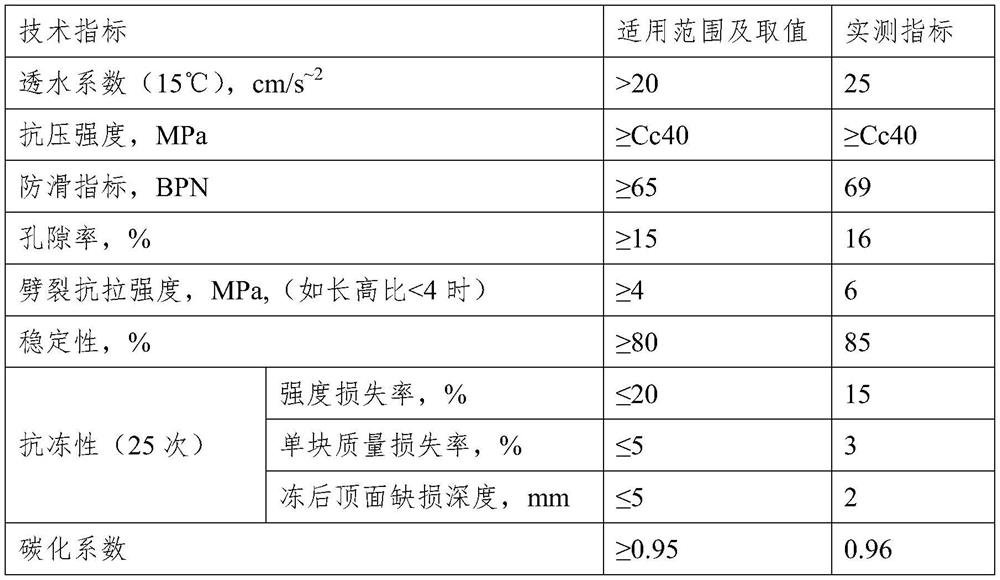

no. 3 example

[0045] The preparation of red mud-based solid waste permeable concrete includes the following steps:

[0046] A. Dry red mud, blast furnace slag, calcium carbide slag, alkali slag, and sieving (360-420m 2 / kg), weigh the following solid wastes in proportion: 75 parts by weight of red mud, 20 parts by weight of blast furnace slag, 30 parts by weight of calcium carbide slag, and 25 parts by weight of alkali slag, for use.

[0047] B. Weigh the red mud, blast furnace slag, calcium carbide slag, alkali slag, 9 parts by weight of sodium metaaluminate, 5 parts by weight of guar gum, 0.8 parts by weight of aliphatic water reducing agent, and 0.1 parts by weight of aluminum ash. The parts are mixed in proportion to obtain the mixed powder and set aside.

[0048] C. Choose 50 parts by weight of 9-13mm crushed stone, infiltrate it with 10 parts of water, then add the mixed powder of step B, add water to a water-to-binder ratio of 0.3, pour and cure it to obtain solid waste-based permeable conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com