Method for washing carbon for removing sodium from silicon-removed alkaline residues of coal ash or basic red mud after process of extracting Al2O3

A fly ash and desiliconization technology, which is applied in the field of alkaline red mud washing and desalination, and alkaline red mud washing and desalination process, can solve the problems of high operating temperature, rising process cost, poor economy, etc., and achieve water conservation , significant economic and social benefits, and the effect of reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

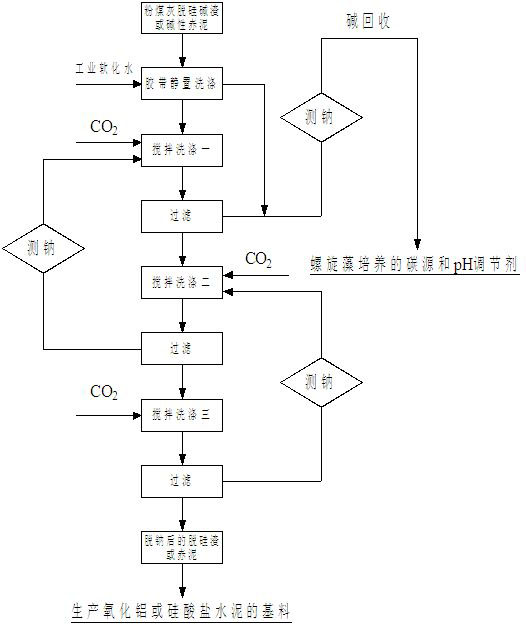

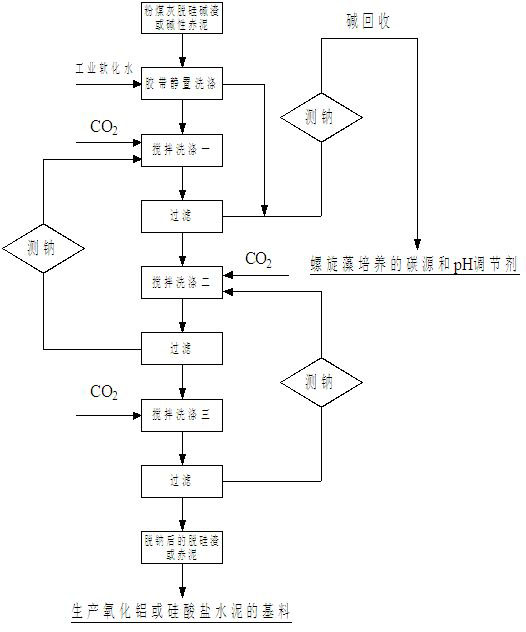

[0038] see figure 1 In this example, the silicon extracted from alkali-soluble fly ash is prepared into white carbon black and the residue is desodiumized, including static washing and stirring washing, and the flue gas after desulfurization is added to the stirring washing liquid three times. The ventilation rate is 1.5L / min, the liquid-solid ratio L / S=8, the washing temperature is controlled at 40°C, and the stirring washing time is 1h.

[0039] Follow the steps below to remove sodium:

[0040] (1) Stand and wash with 1.2 normal temperature industrial demineralized water on the belt filter machine based on the dry basis of fly ash extraction of silicon and alkali slag to elute the attached alkali.

[0041] (2) The alkaline red mud after static washing is sent to the stirring and washing reactor at a liquid-solid ratio of L / S=8 for stirring and washing. During the stirring and washing, the flue gas after desulfurization is intermittently introduced into the flue gas after de...

Embodiment 2

[0049] see figure 1 , the present embodiment extracts Al from fly ash 2 o 3 After the process, the alkaline red mud is desodiumized, including static washing and stirring washing, adding desulfurized flue gas to the stirring washing liquid three times, controlling the stirring washing temperature to 60°C, and the liquid-solid ratio L / S=3, The ventilation rate of the flue gas after desulfurization is 1L / min, and the stirring and washing time is 2h.

[0050] Follow the steps below to remove sodium:

[0051] (1) Stand and wash with 1 room temperature industrial demineralized water based on fly ash alkaline red mud dry base on the belt filter to elute the attached alkali.

[0052] (2) The alkaline red mud after static washing is sent to the stirring washing reactor at the liquid-solid ratio L / S=5 for stirring and washing. During the stirring and washing, the flue gas after desulfurization is intermittently introduced into the flue gas after desulfurization. The flue gas is eve...

Embodiment 3

[0060] see figure 1 , the present embodiment extracts Al from fly ash 2 o 3 After the process, the alkaline red mud is desodiumized, including static washing and stirring washing, and the flue gas after desulfurization is added to the stirring washing liquid three times, the ventilation rate is 0.5L / min, and the liquid-solid ratio L / S=3 , the washing temperature is 50°C, and the stirring and washing time is 3h.

[0061] Follow the steps below to remove sodium:

[0062] (1) Stand and wash with 1.5 normal temperature industrial demineralized water based on the dry base of fly ash alkaline red mud on the belt filter to elute the attached alkali.

[0063] (2) The alkaline red mud after static washing is sent to the stirring and washing reactor at a liquid-solid ratio of L / S=3 for stirring and washing. During the stirring and washing, the desulfurized flue gas is intermittently introduced into the flue gas three times. The flue gas is evenly dispersed in a three-phase reactor a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com