Patents

Literature

497 results about "Belt filter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The belt filter (sometimes called a belt press filter, or belt filter press) is an industrial machine, used for solid/liquid separation processes, particularly the dewatering of sludges in the chemical industry, mining and water treatment. Belt filter presses are also used in the production of apple juice, cider and winemaking. The process of filtration is primarily obtained by passing a pair of filtering cloths and belts through a system of rollers. The system takes a sludge or slurry as a feed, and separates it into a filtrate and a solid cake.

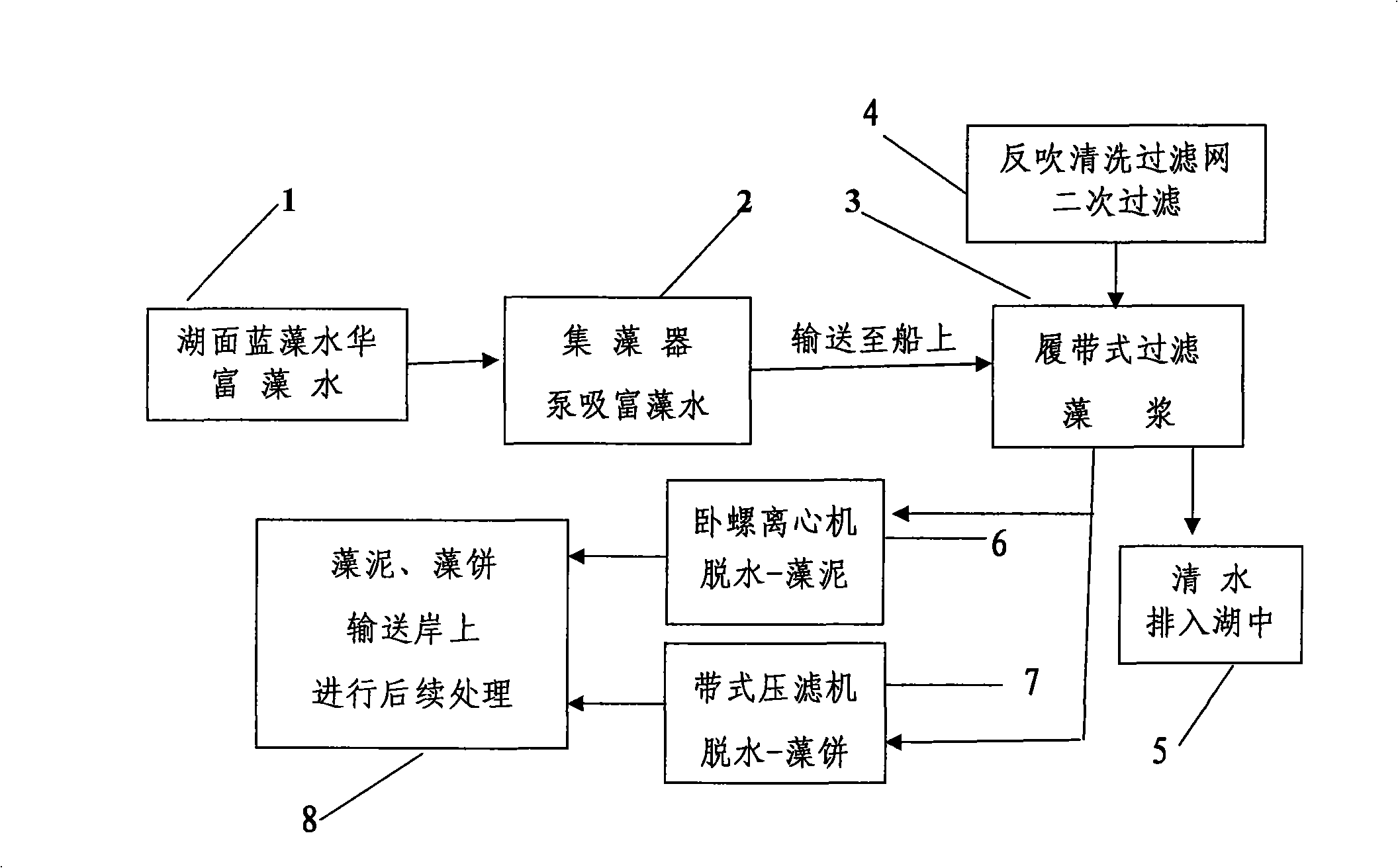

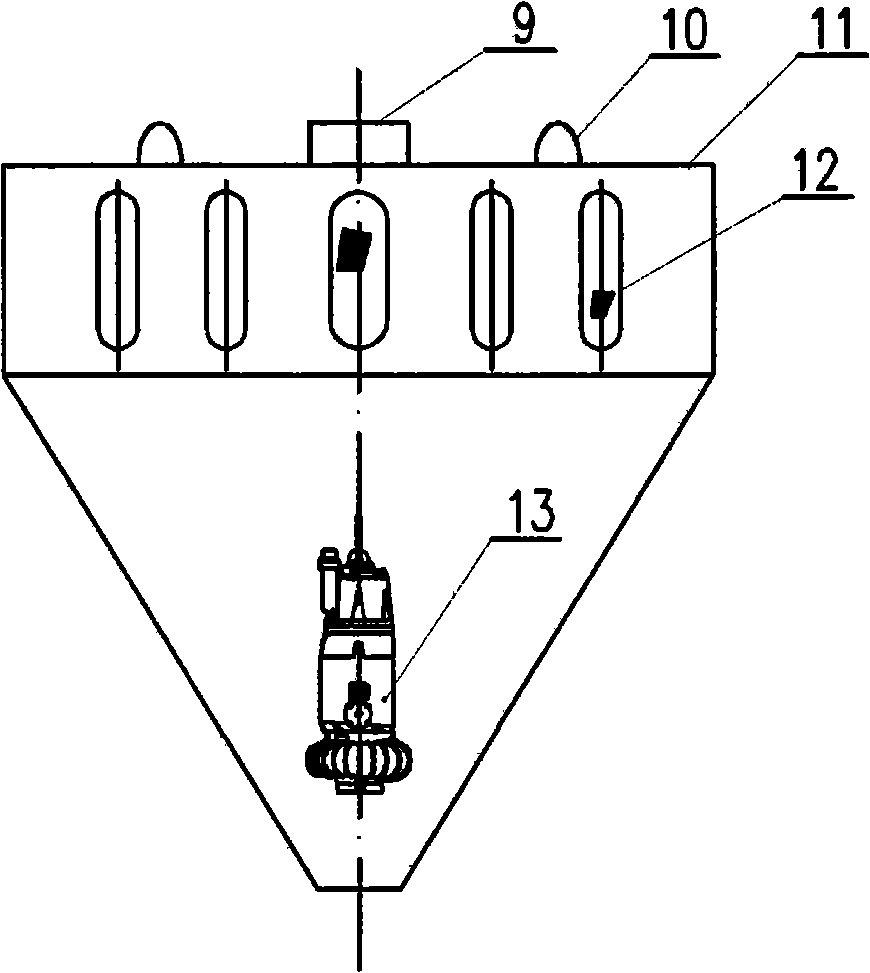

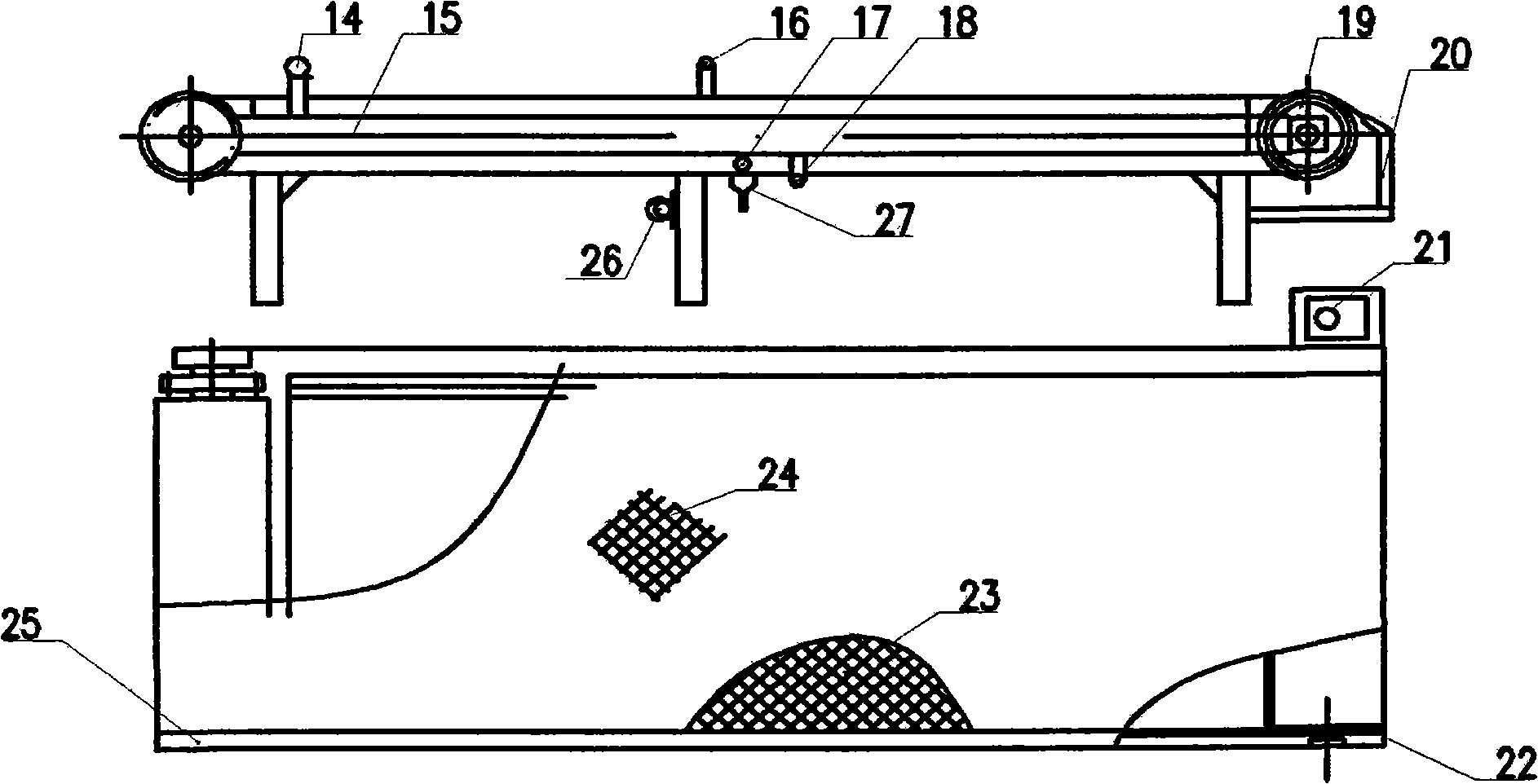

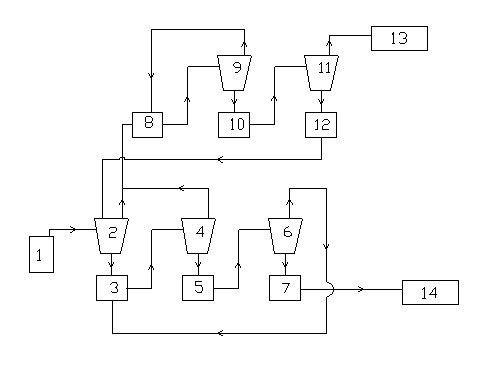

Method and apparatus for harvesting water bloom blue algae

InactiveCN101318714ASimple methodSimple and fast operationWater cleaningWater/sewage treatmentPhylum CyanobacteriaFiltration

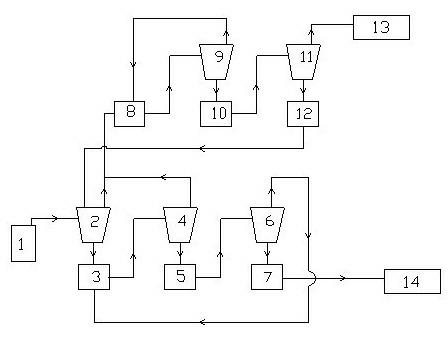

The invention discloses a method and a device for harvesting water-blooming cyanobacteria. The method comprises the following steps that: A. the water-blooming cyanobacteria is enriched into algae-rich water on water surfaces of lakes, reservoirs and riverways; B. an algae sucker pump is used to suck the algae-rich water; C. the algae-rich water is conveyed to a filtering system of a caterpillar system on a ship and is filtered into algae pulp; D. the algae pulp is subject to reverse purging and then secondary filtration; and E. the algae pulp is concentrated and dehydrated into algal biscuits or algae mud through a belt filter press or a horizontal screw decanter. The device for harvesting the water-blooming cyanobacteria comprises an algae sucker, a caterpillar algae-laden water filtering device, the belt filter press and the horizontal screw decanter, wherein, the fore of the ship is provided with the algae sucker, a non-clogging pump or a membrane pump is arranged in the algae sucker, the upper end of the algae sucker is provided with an impurity prevention net, and a cover plate is provided with a hoisting ring; and the caterpillar filtering device is fixed on a main frame body, and a stainless steel foraminous conveyer is arranged below a filter screen. The method is easy to operate, saves the energy, has low cost, a simple structure and convenient use, and effectively solves the problems of harvesting, concentration and dehydration of the water-blooming cyanobacteria accumulated in the lakes, reservoirs and riverways.

Owner:INST OF AQUATIC LIFE ACAD SINICA

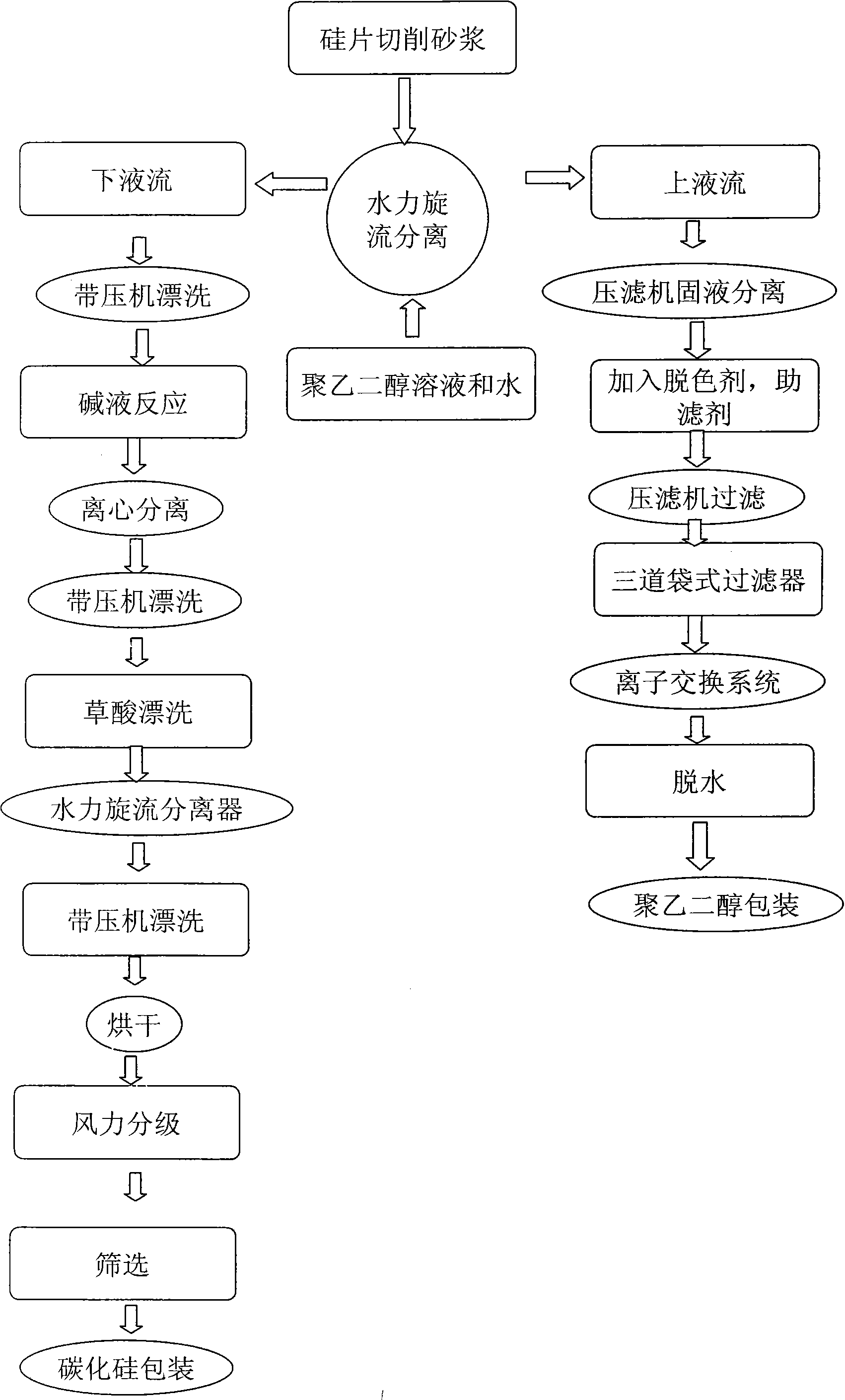

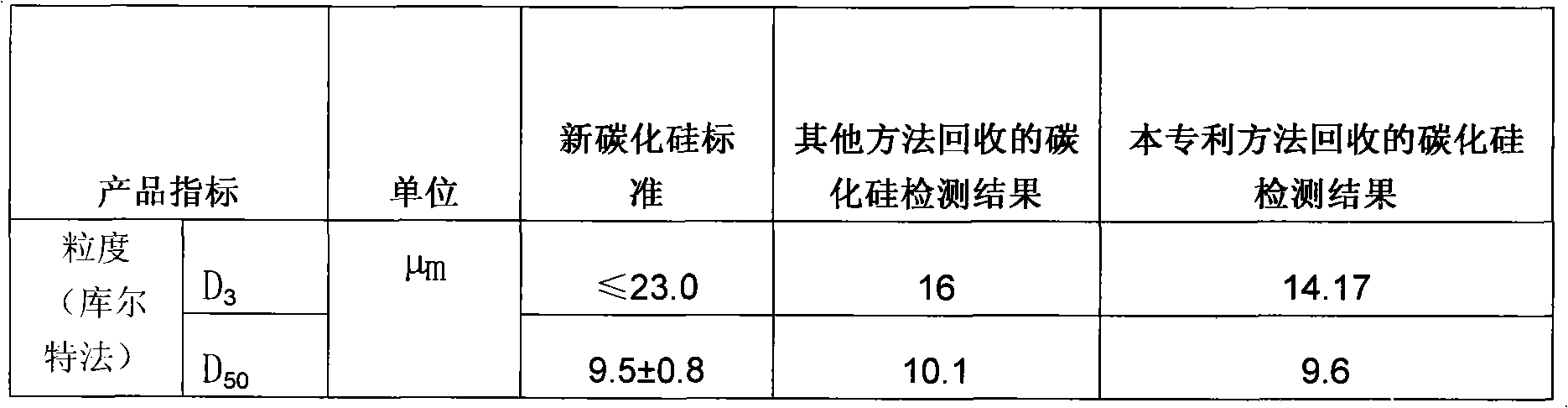

Method for recovering and recycling silicon slice cutting waste mortar

The invention relates to a method for recovering and recycling silicon slice cutting waste mortar. The method is characterized by comprising the following steps of: 1, pre-treating: uniformly stirring raw mortar and water and performing solid-liquid separation by using a plate and frame type filter press; 2, recovering polyethylene glycol (PEG): adding a decoloring agent into filtered liquid, and performing plate and frame filtering; treating obtained filtrate by using ion exchange resin or a multiple-effect distiller; and performing reduced pressure distillation, rectification and fine filtering to obtain a PEG finished product; and 3, recovering silicon carbide: mixing filtered filter cakes and water according to a proportion of 1:(3-4), stirring to form mortar; separating the mortar by using a multi-stage cyclone; performing acid washing; separating by using the cyclone; filtering by using a belt filter; and drying to obtain the silicon carbide finished product. By the method, the separation amount is large, recovery rate is high, recovered PEG and silicon carbide have high quality, and the method saves energy and is environmentally-friendly.

Owner:JIANGSU HAOBO NEW MATERIALS CO LTD

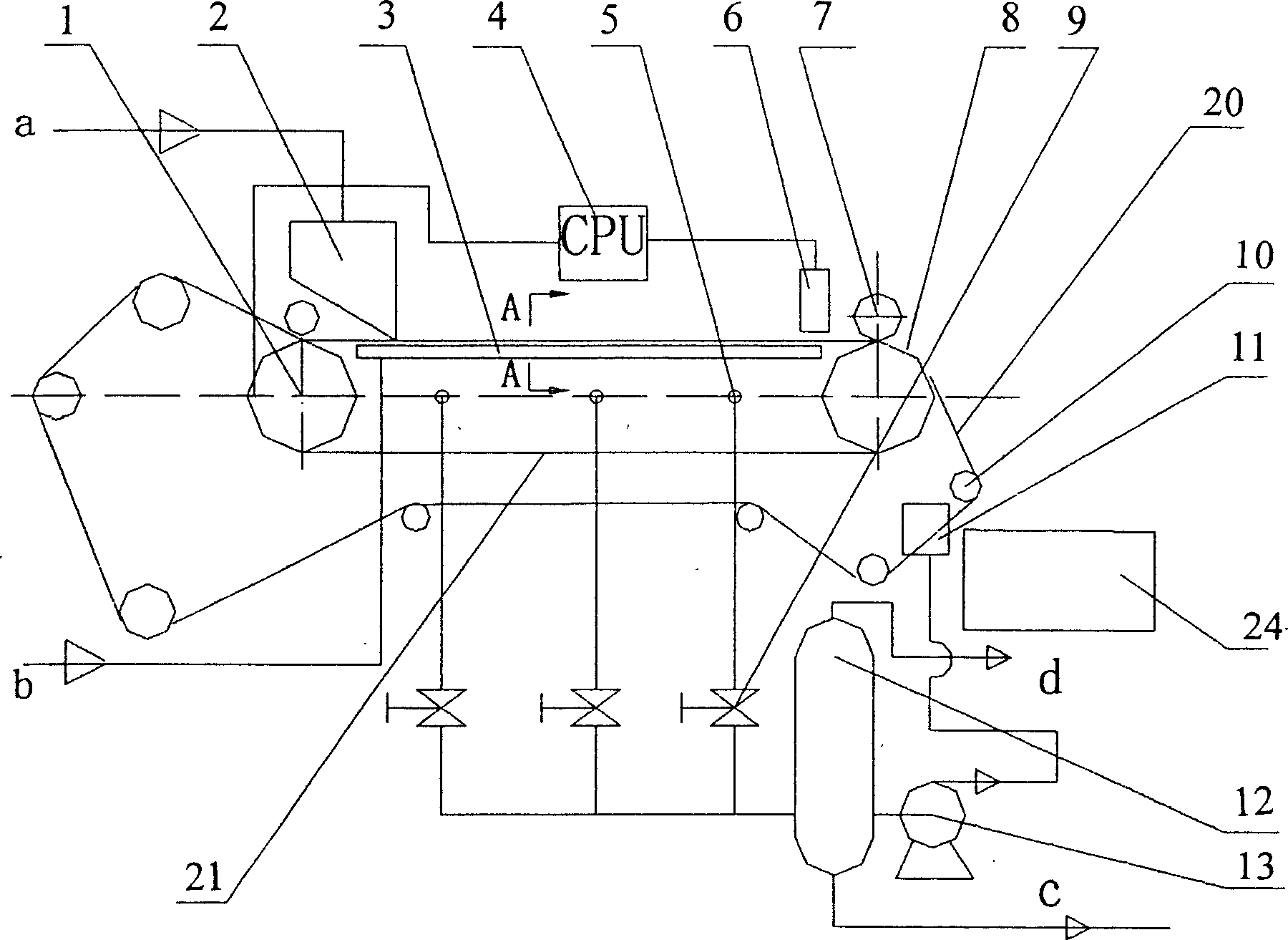

Electrolytic system and method for filtering an aqueous particulate suspension

ActiveUS20120091000A1Clogging of filter is minimized and eliminatedSludge treatmentVolume/mass flow measurementSuspended particlesFiltration

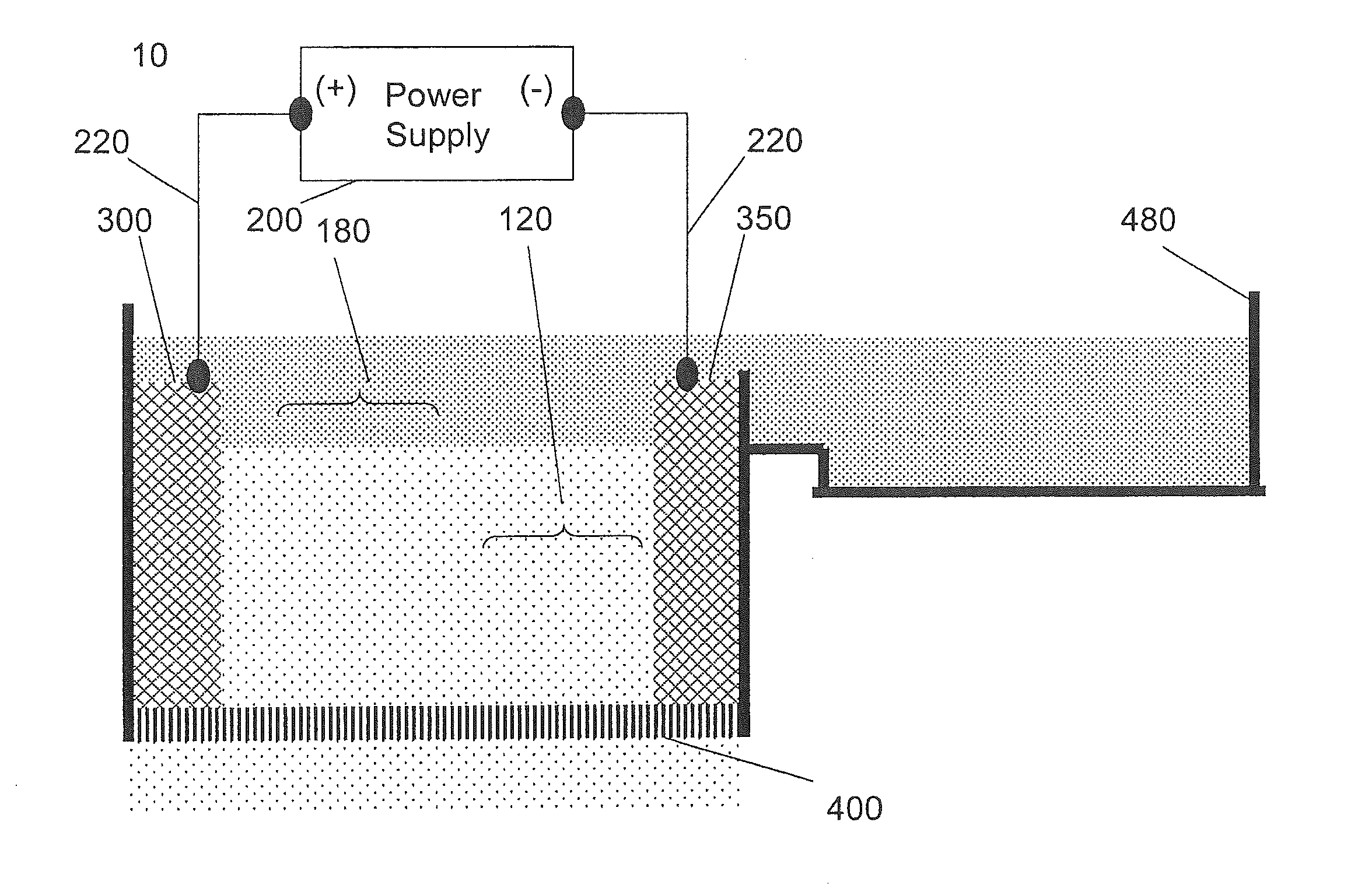

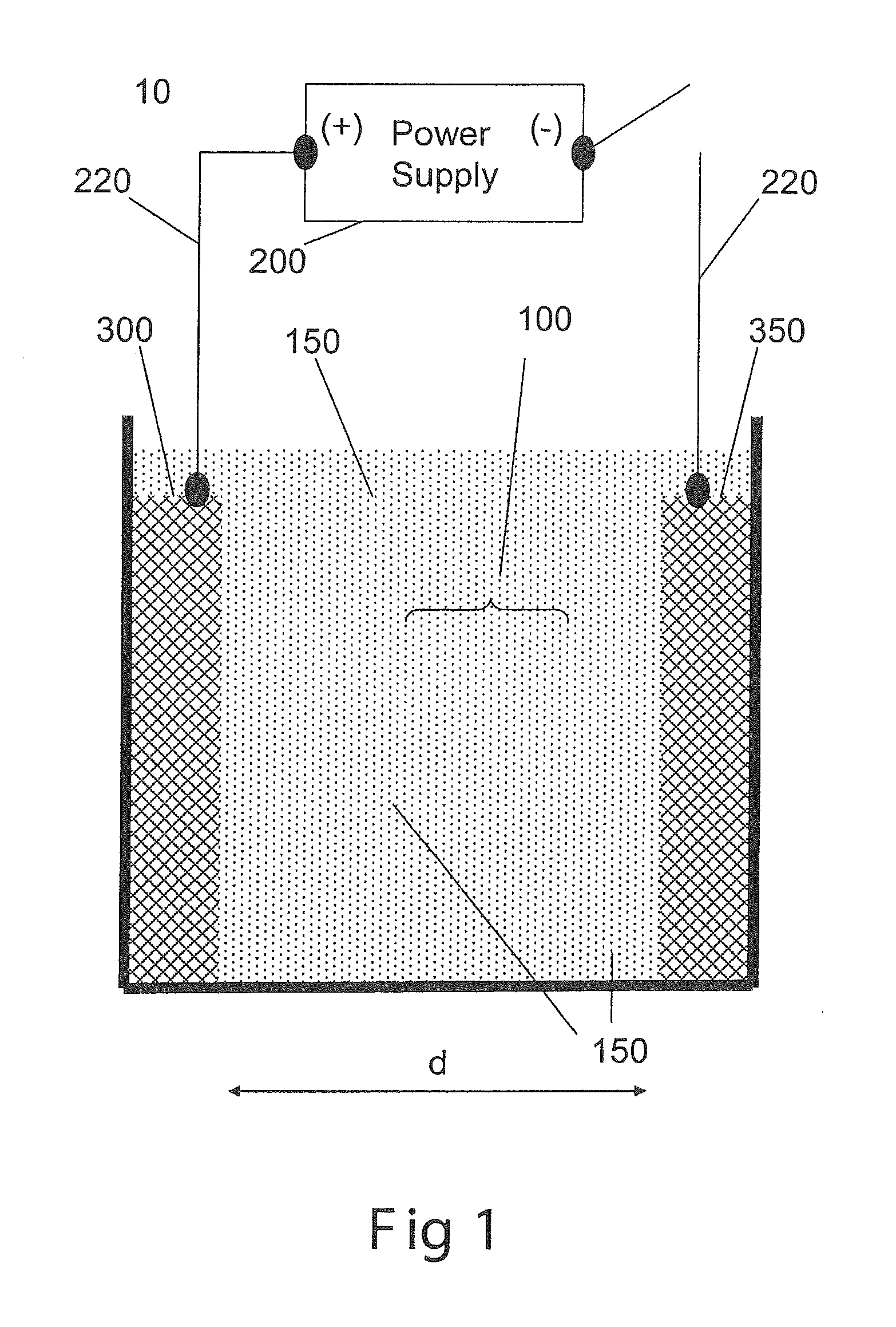

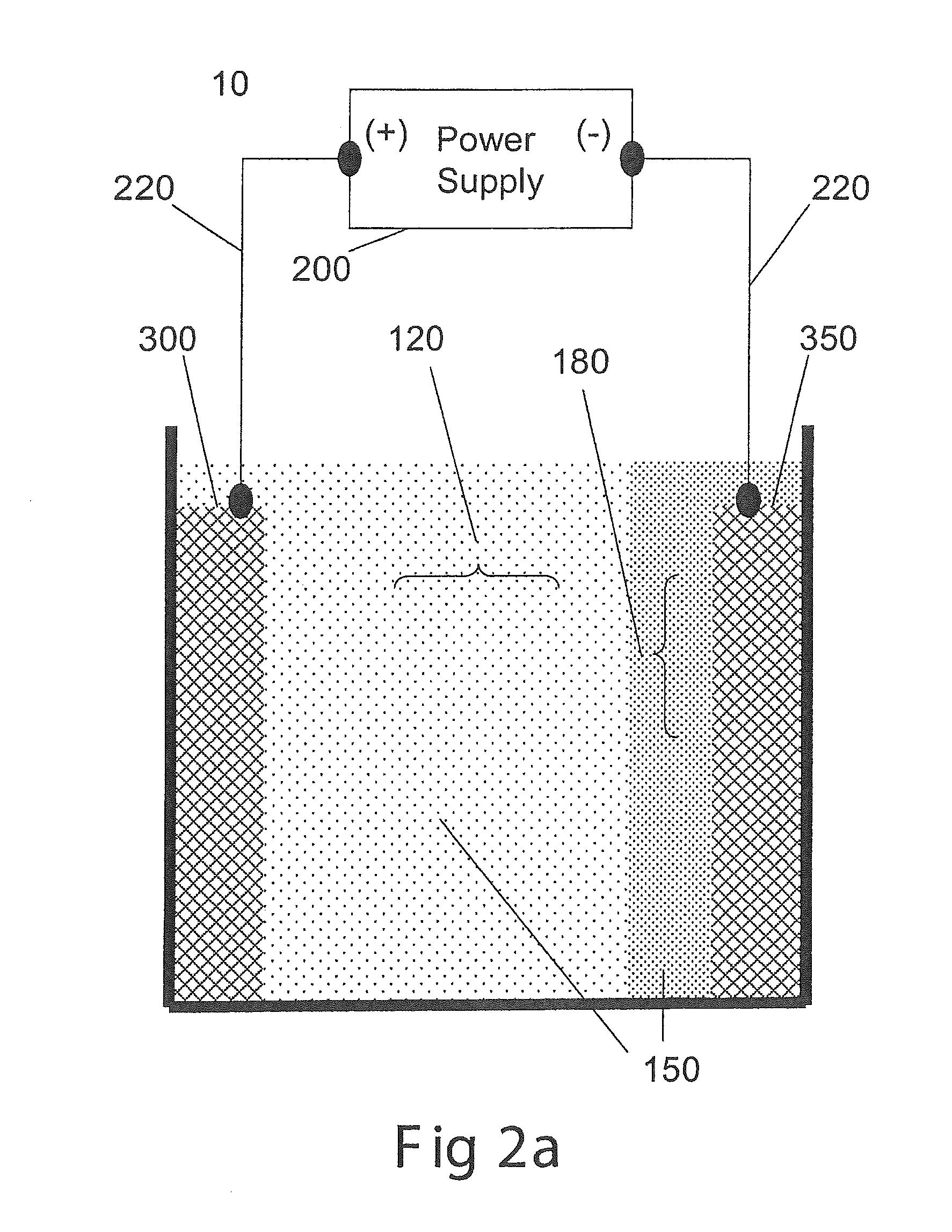

An electrolytic filtration method and apparatus for the concentration and collection of suspended particulates from aqueous solutions is disclosed. The electrolytic cell contains at least an anode and a cathode, and in one embodiment contains a plurality of anodes and cathodes. The electrolytic cell also contains a filter, and in one embodiment the filter is a moving belt filter. While not bound by theory, the electrolytic filtration method and apparatus is based on the electrophoretic movement of algae particles suspended in an aqueous solution away from the filter under the influence of an electric field. In one embodiment the electric field is a pulsed waveform with unidirectional voltage or current pulses. In another embodiment, the electric field is a pulsed waveform with bidirectional voltage or current pulses.

Owner:PHYSICAL SCI +1

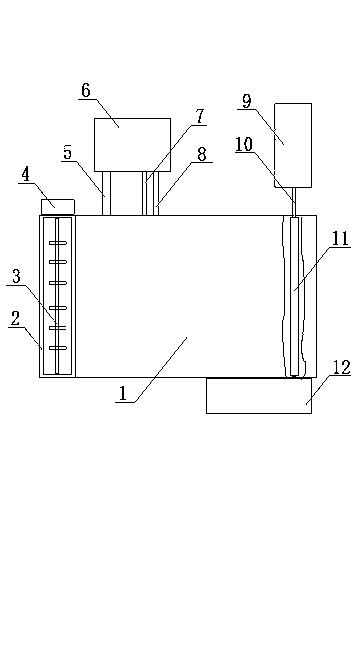

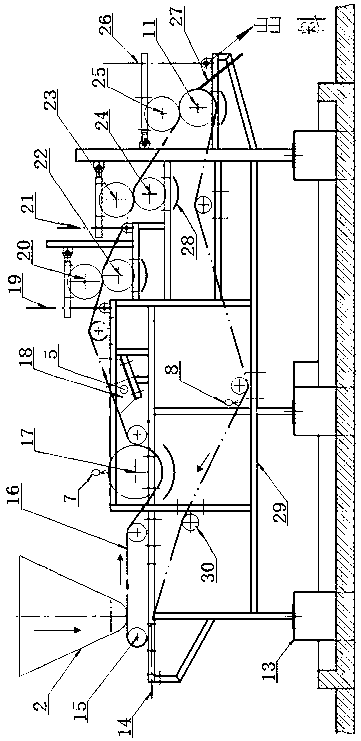

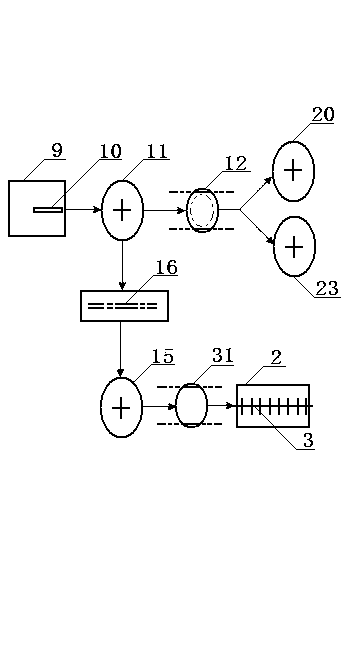

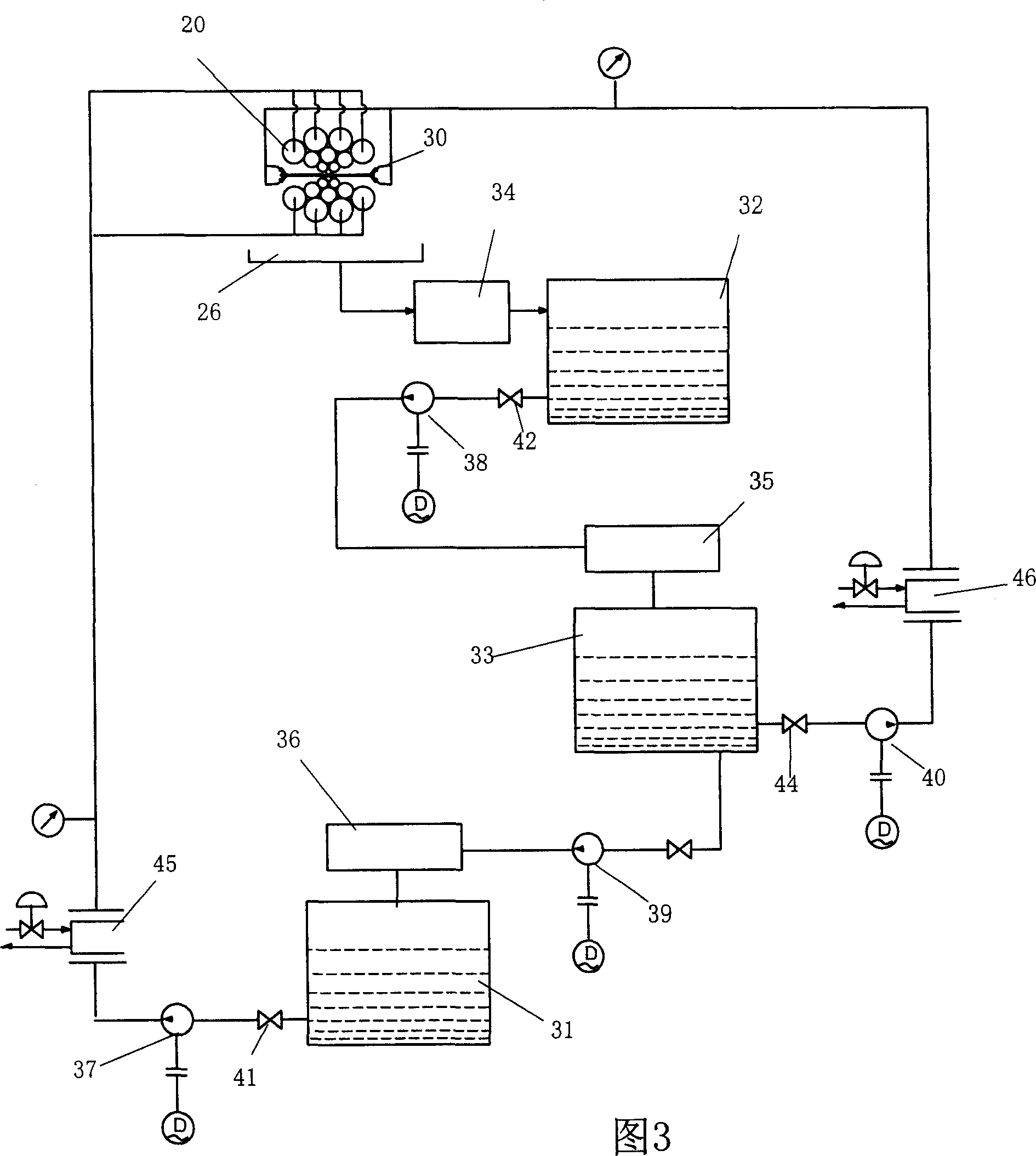

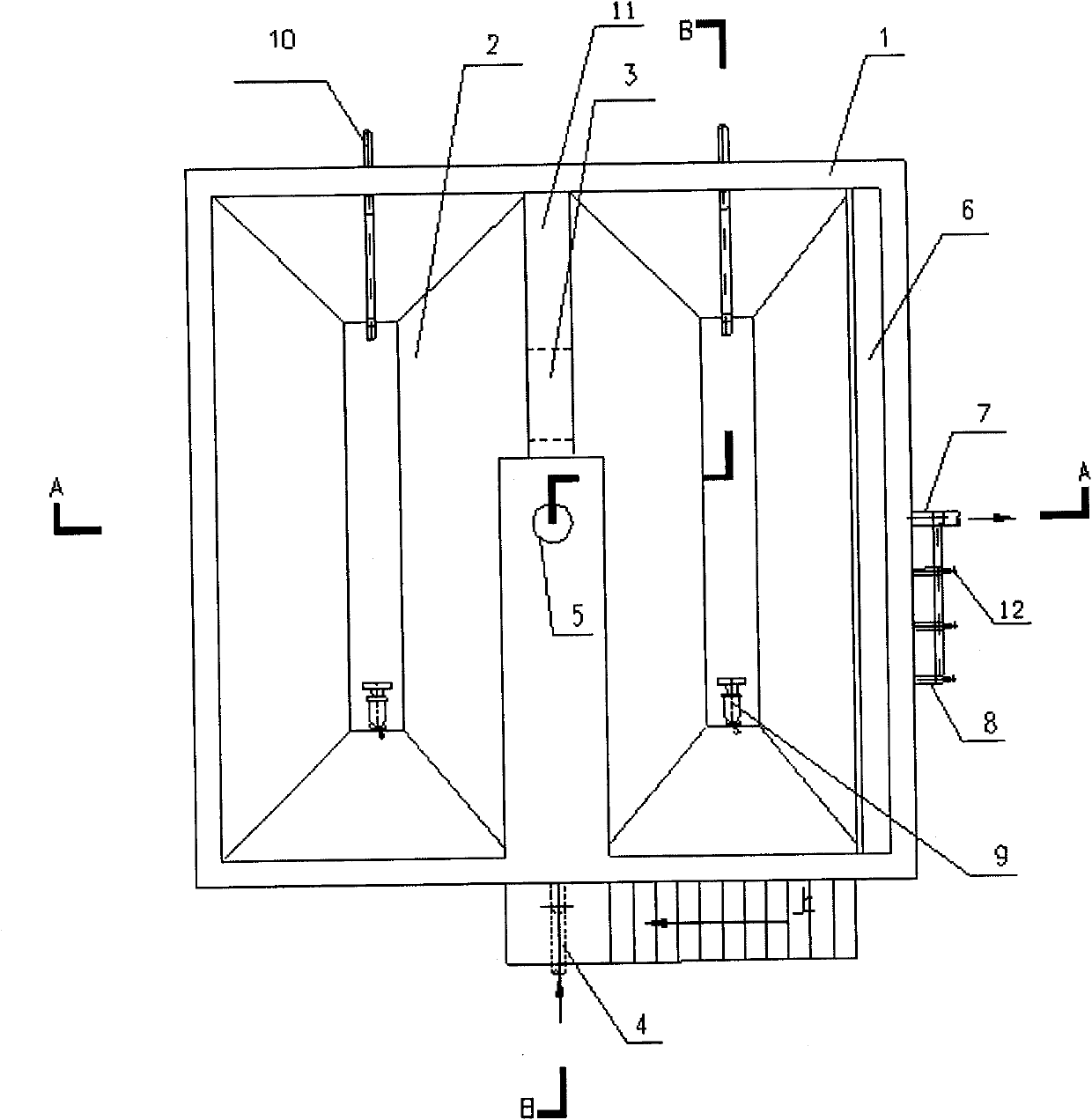

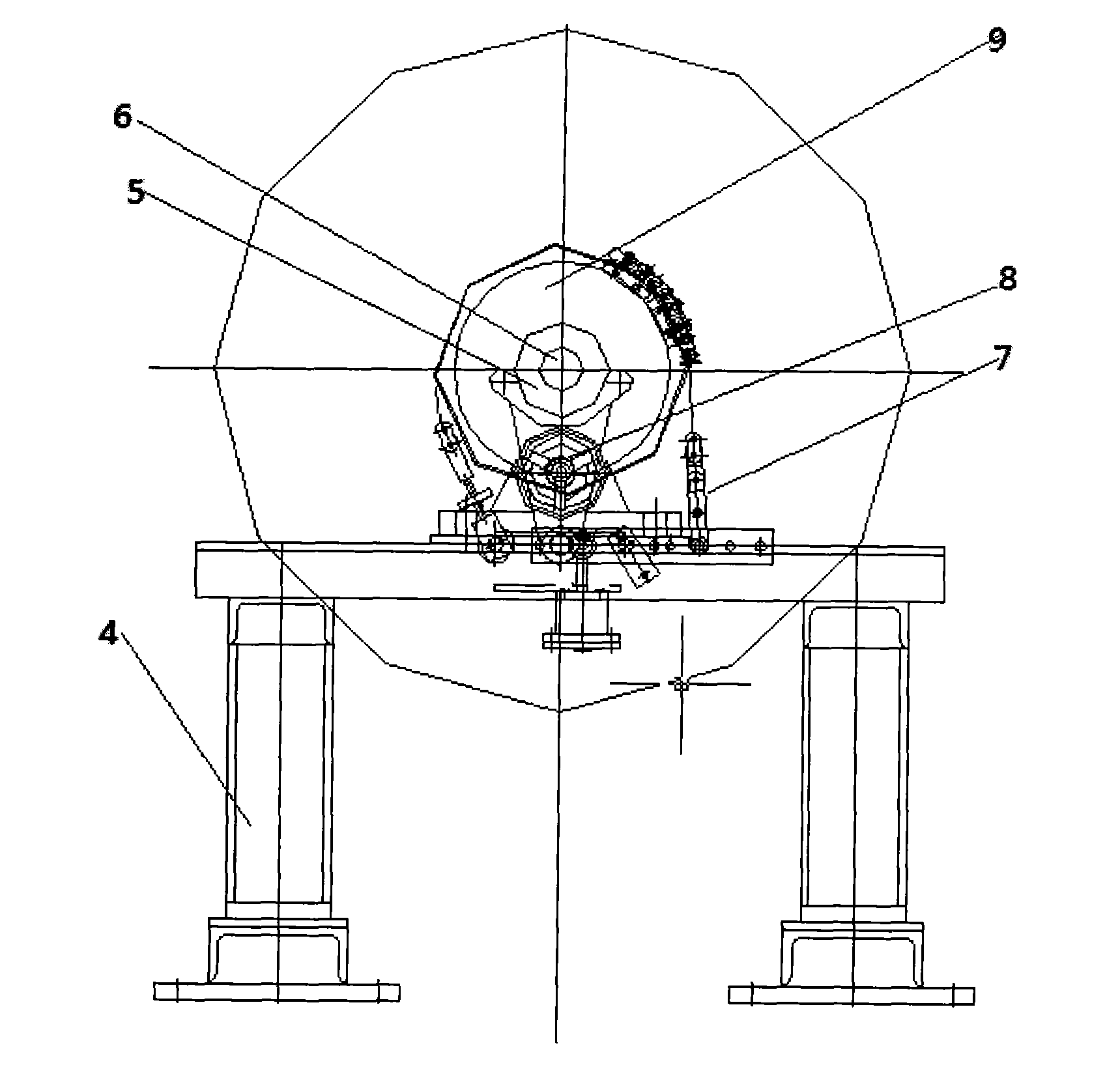

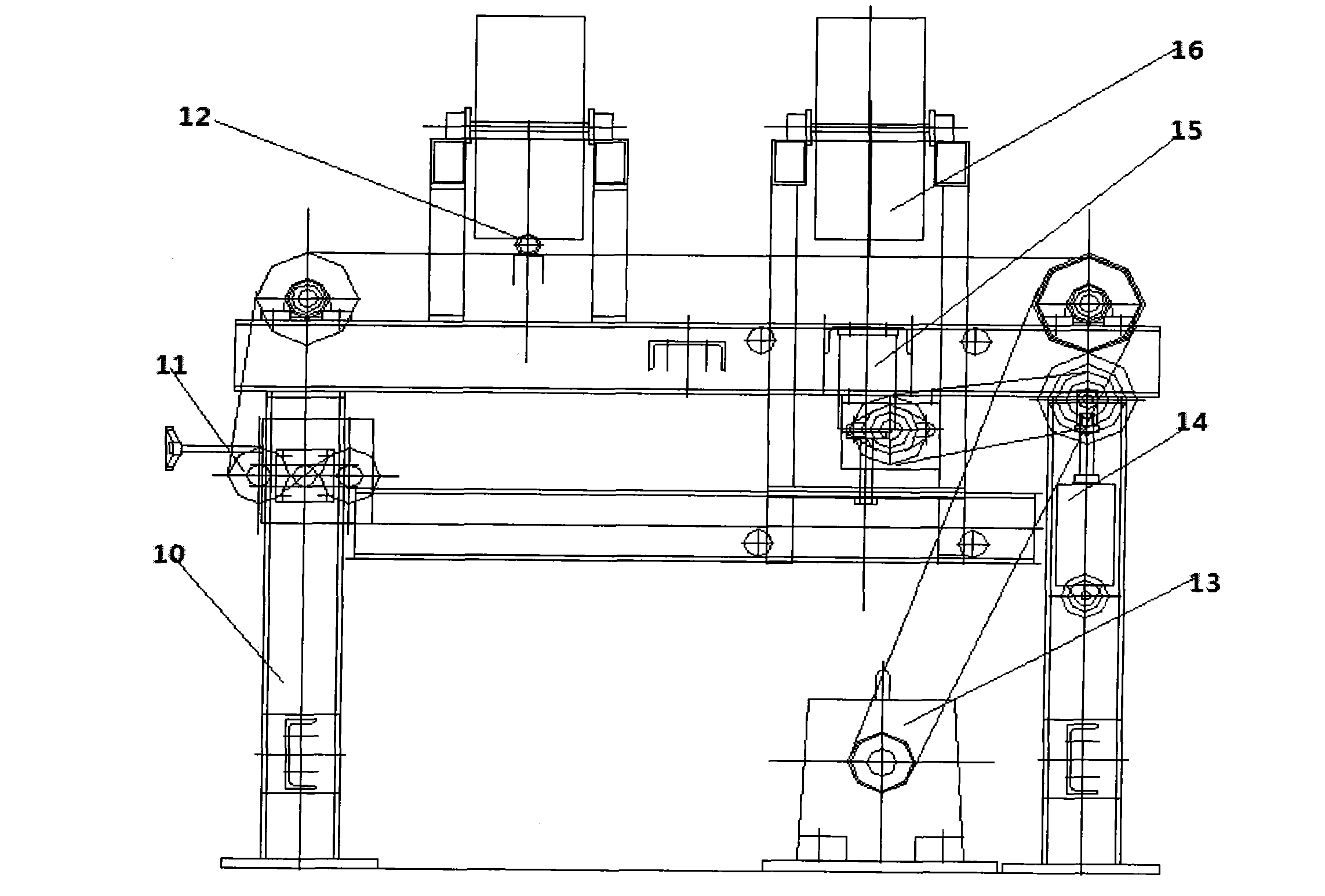

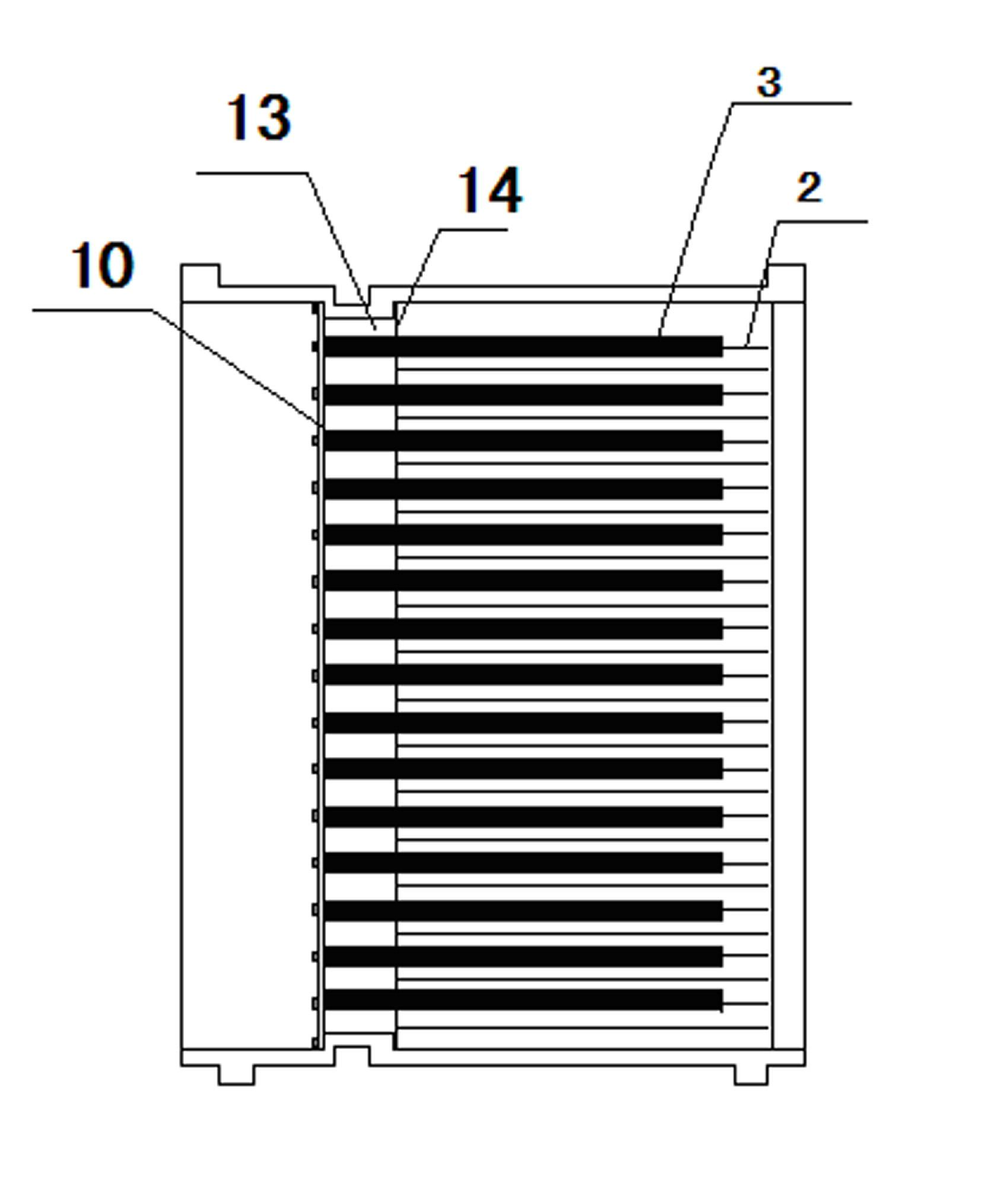

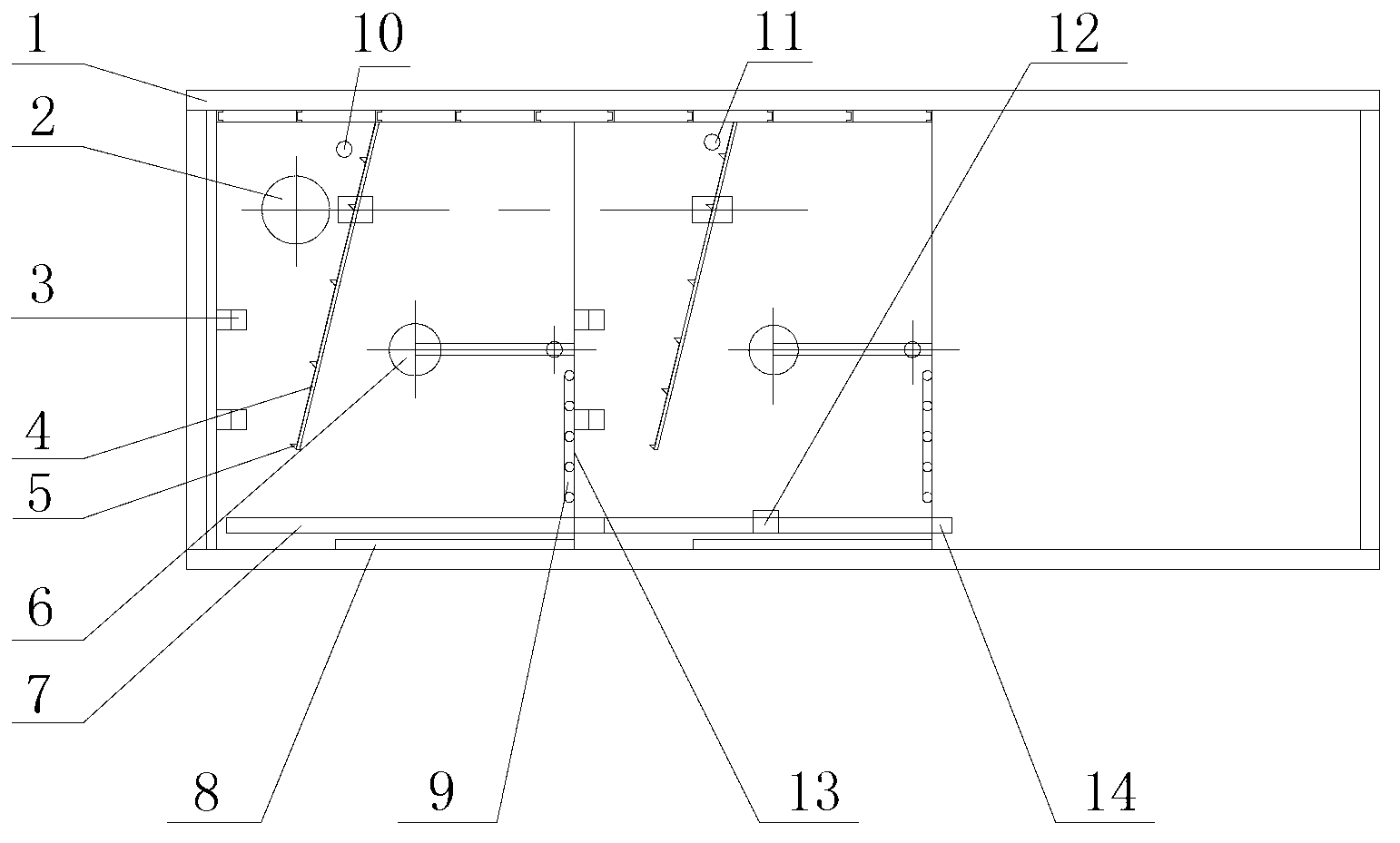

High-efficiency energy-saving belt filter press

InactiveCN103007614ANot easy to runSolve slipperyChemical industryMoving filtering element filtersChemical industrySlag

The invention discloses a high-efficiency energy-saving belt filter press which comprises a frame, a filter press belt, a hopper and a motor, and is characterized in that a material equalizing regulation device is arranged at a discharging end of the frame; the filter press belt is a double-layer filter cloth belt; a four-stage press filtering mechanism is arranged on the discharged filter press belt at intervals; a vacuum suction filtration disc for vacuumizing by utilizing a vacuum pump is arranged below the filter press belt behind a mesh cage roller; a tail gas cleaning mesh-cleaning roller and a filter press belt gas ejector pipe are respectively arranged on the mesh cage roller and on a belt return part of the filter press belt. The machine is uniform in feeding, long in service life, stable in performance, good in dewatering effect and high in yield, and the filter belt is difficult to block; the slag adhered to the mesh cage roller and the filter press belt is subjected to air injection cleaning by utilizing the vacuum pump tail gas, and water and electric energy are saved; and the machine is suitable for squeezing and dewatering manioc waste, cassava residues, bean dregs and distillers grains and water-containing raw materials in the industries such as municipal sludge, chemical industry, oil refining, papermaking and sugar refining.

Owner:陆汉克

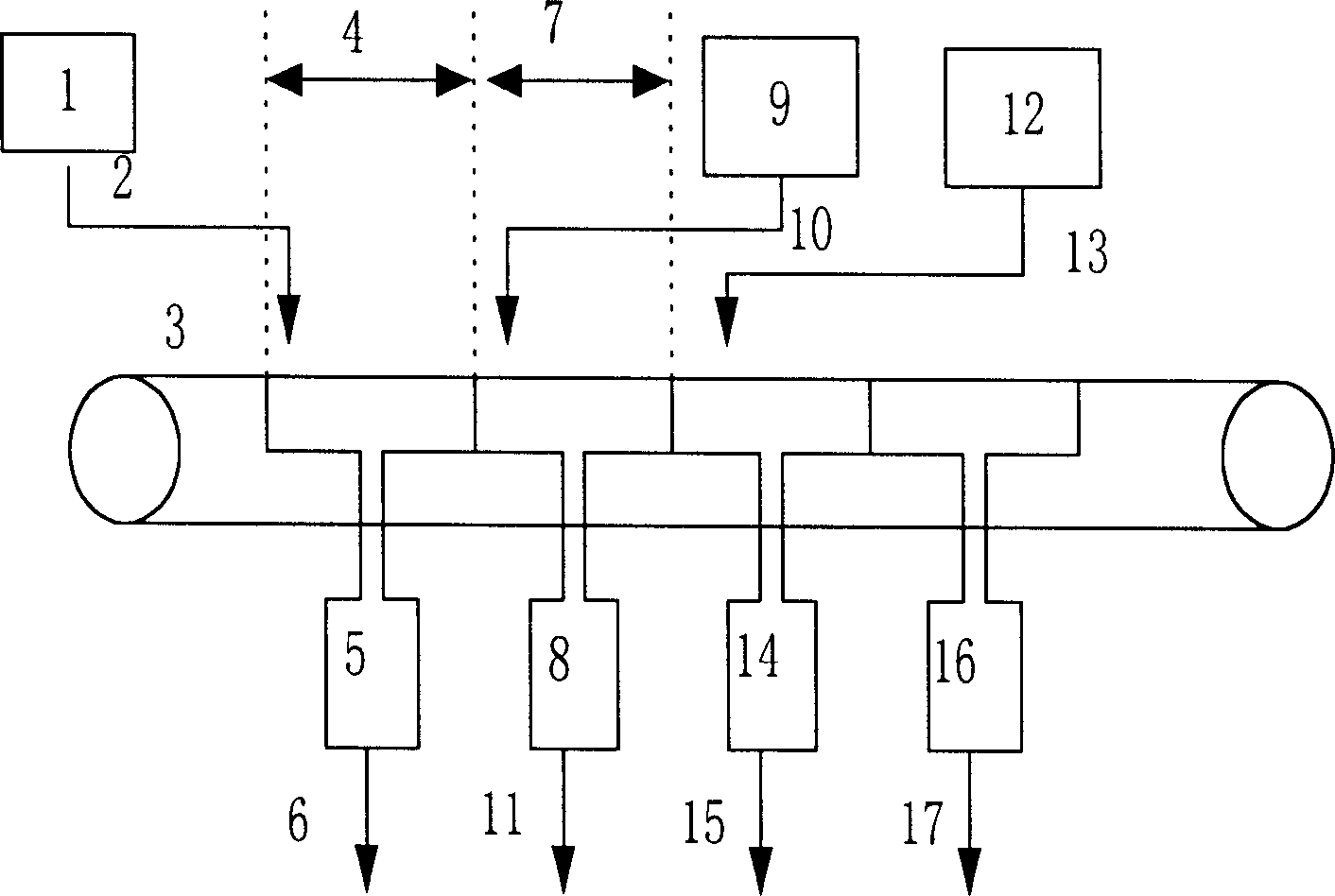

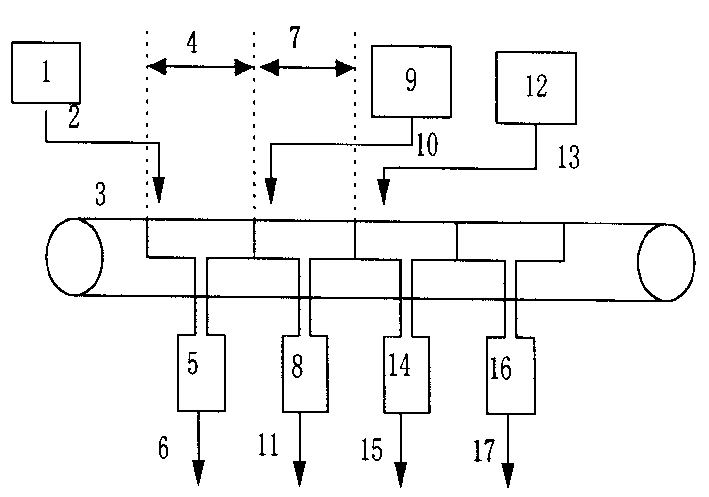

Automatic chemical dosing jet flow mixing and water pump stirring sewage treatment system

InactiveCN101559335APlay a stirring roleEffective monitoringFlow mixersMixer accessoriesElectricityJet flow

Owner:何荣灿

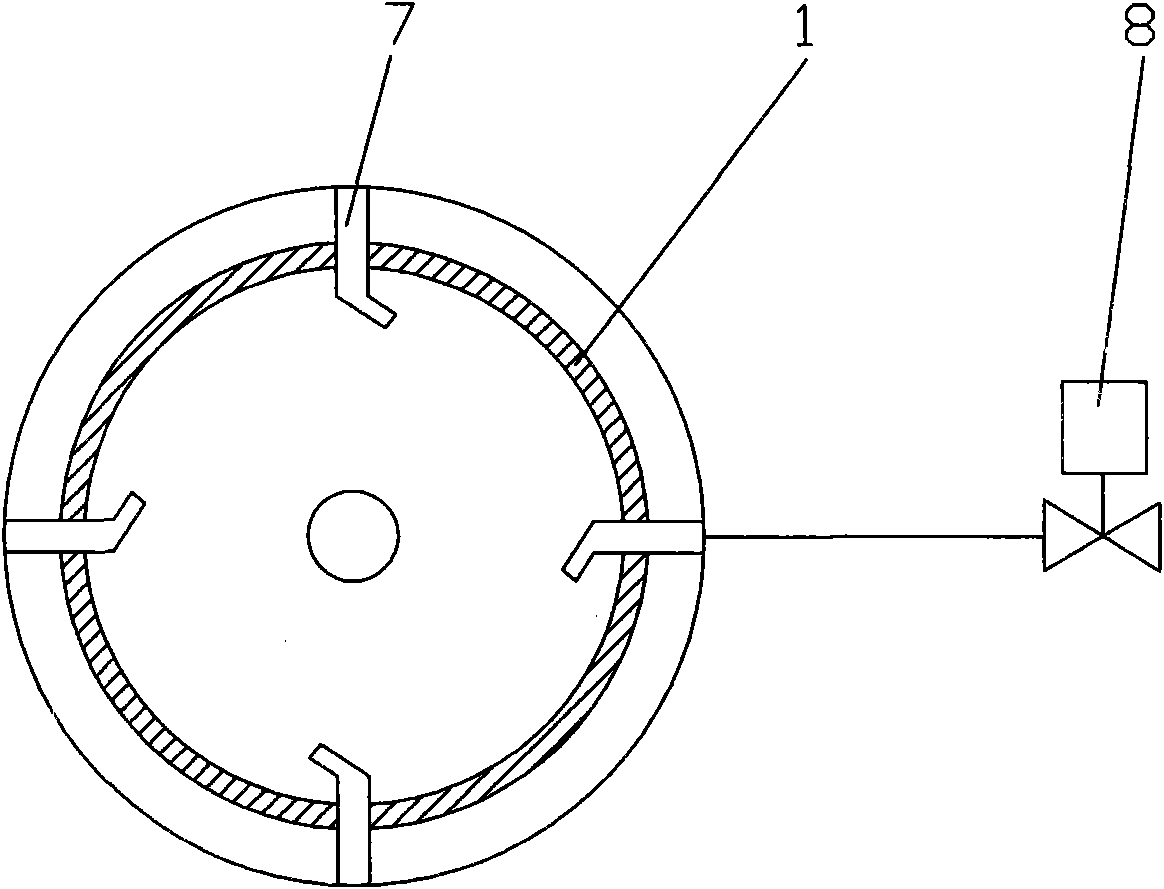

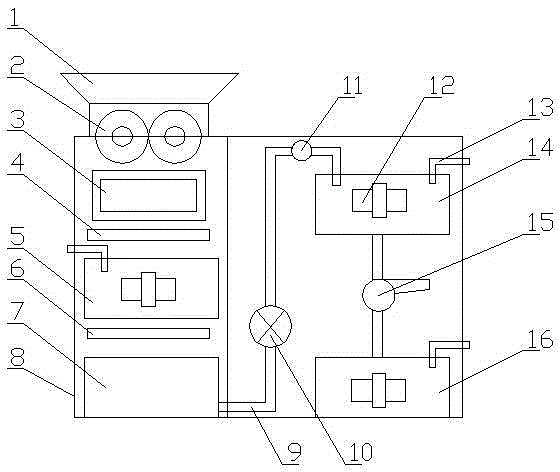

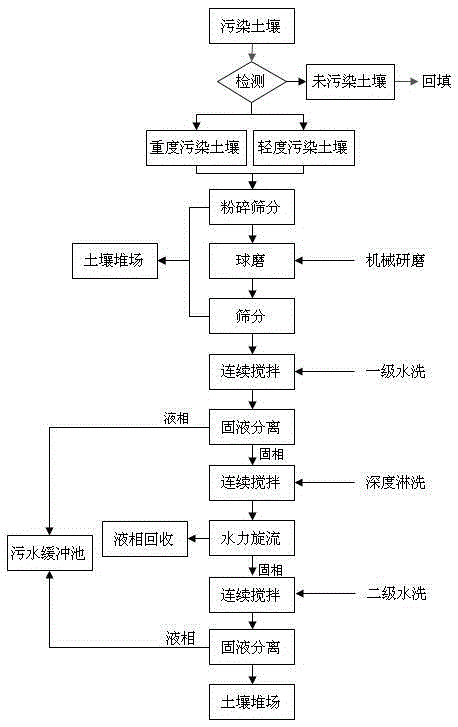

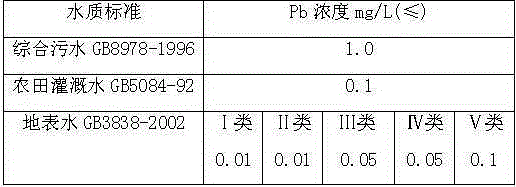

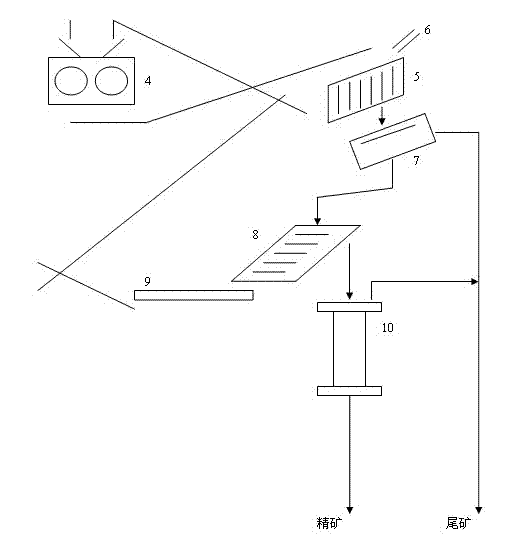

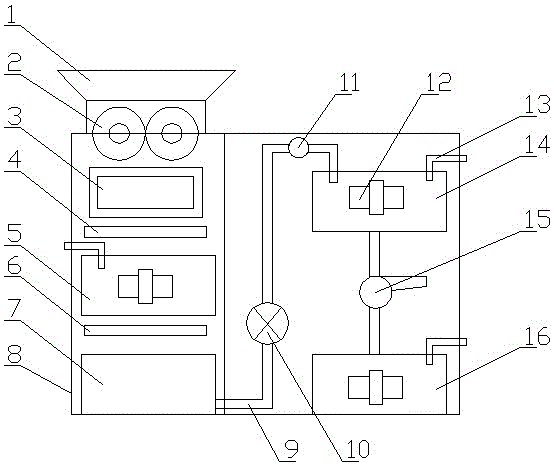

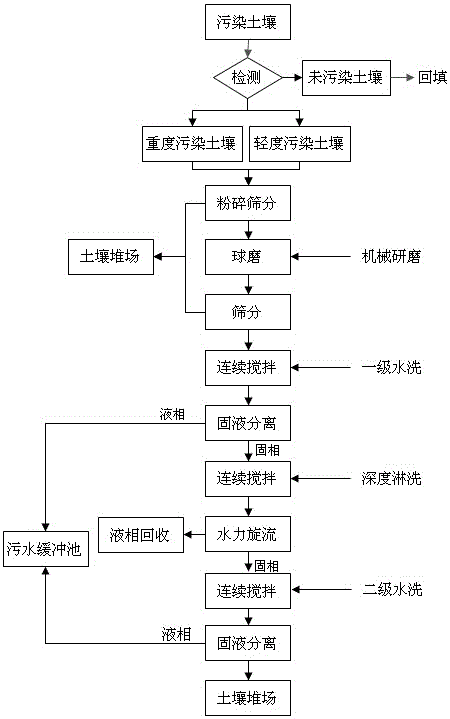

Heavy metal contaminated soil remediation equipment and remediation process thereof

ActiveCN105268737AOverall small sizeSmall footprintContaminated soil reclamationSoil scienceSoil remediation

The invention relates to heavy metal contaminated soil remediation equipment. The heavy metal contaminated soil remediation equipment comprises a machine frame, a feeding hopper, grinding rollers, a ball mill, a screen sieve, a first-level rinsing pool, a linear vibrating screen, a slurry buffer pool, a slurry pump, a centrifugal machine, a deep leaching pool, a belt filter press and a second-level rinsing pool. Contaminated soil is subjected to mechanical grinding, first-level rinsing, first-level solid-liquid separation, deep leaching, second-level rinsing and second-level solid-liquid separation to be remedied. The heavy metal contaminated soil remediation equipment is advanced in process, good in treatment effect, high in working efficiency and high in automation degree.

Owner:GUANGZHOU FIRST MUNICIPAL ENG CO LTD

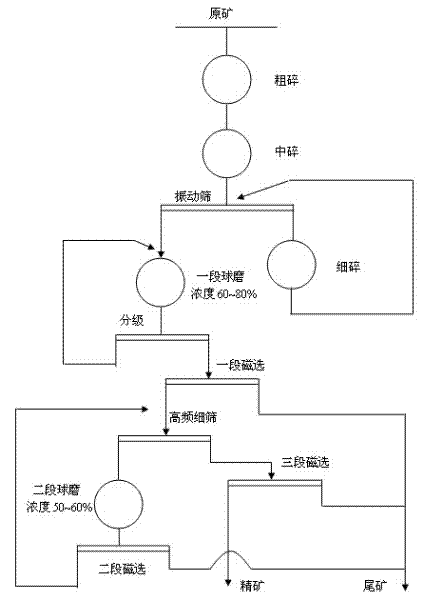

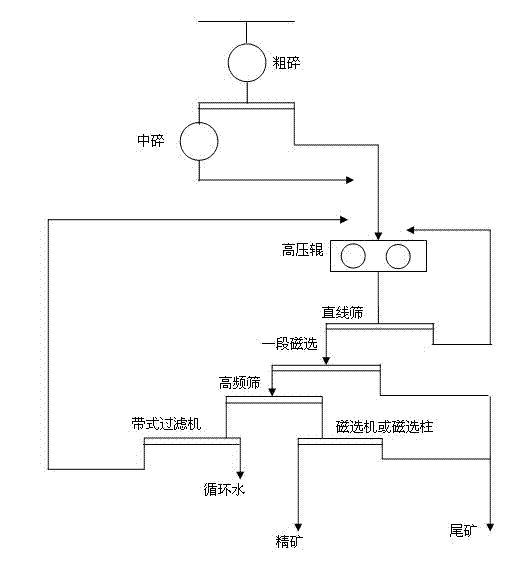

Wet-type magnetic separation method of magnetite

InactiveCN102240587AReduce power consumptionReduce steel consumptionMagnetic separationGrain treatmentsMagnetiteHigh pressure

The invention discloses a wet-type magnetic separation method of magnetite. Magnet crude ores are fed into a crusher to be subjected to coarse crushing, the crushed crude ores are fed into a vibrating screen to be screened, a sieve pore is controlled to be 35-75mm, an oversize product is fed into the crusher to be crushed, and the crushed oversize product and screen underflow are fed into a high pressure roller mill to be subjected to fine crushing; the finely crushed ores are fed into a wet-type linear vibrating screen to be screened, the oversize product returns to the high pressure roller mill to be subjected to fine crushing, the screen underflow is subjected to wet-type magnetic separation, and the magnetic field intensity is controlled to be 120-300mT; and the ores subjected to wet-type magnetic separation is fed into a high frequency vibrating fine screen, the size of a sieve pore is controlled to be 0.10-0.5mm, the oversize product is dehydrated by virtue of a vacuum belt filter and returns to the high pressure roller mill to be subjected to fine crushing, and the screen underflow is fed into a magnetic separator or a magnetic separation column to be subjected to magnetic separation, thus a concentrate product is obtained. By adopting the wet-type magnetic separation method provided by the invention, the power consumption and steel consumption are low, and the production cost is low.

Owner:CHENGDU LEEJUN IND

Method for recovering silicon carbide and polyglycol cutting solution from silicon slice cutting waste mortar

InactiveCN102031193ANo pollution in the processSame qualityLubricant compositionThree levelIon exchange

The invention relates to a method for recovering silicon carbide and polyglycol cutting solution from a silicon slice cutting waste mortar. The method comprises the following steps of: stirring the mortar at normal temperature, and then performing solid-liquid separation to obtain a lower liquid stream and an upper liquid stream; putting the lower liquid stream into a belt filter to obtain cleaned silicon carbide; rinsing the silicon carbide by using alkali liquor, and driving the silicon carbide into a centrifuge; cleaning the silicon carbide through the belt filter, then rinsing the silicon carbide by using oxalic acid, and driving the silicon carbide into a three-level hydrocyclone to obtain a lower liquid stream of the silicon carbide; putting the lower liquid stream of the silicon carbide into a third belt filter; conveying the cleaned silicon carbide into a drying machine through a conveyor belt; grading the dried silicon carbide by wind force, screening large granular impurities by using a vibrating screen to ensure that the silicon carbide can be packaged; performing solid-liquid separation on the liquid part obtained after separating the mortar; adding a decolorant and a filter aid into the liquid; putting the mixture into a press filter; putting the separated liquid into an ion exchange system after the separated liquid passes through a bag filter; and dehydrating the separated liquid through an evaporator to obtain polyglycol. By the method, the pollution to the environment caused by the direct emission of the mortar is avoided, and the production cost during silicon slice cutting is effectively reduced.

Owner:钱丽君

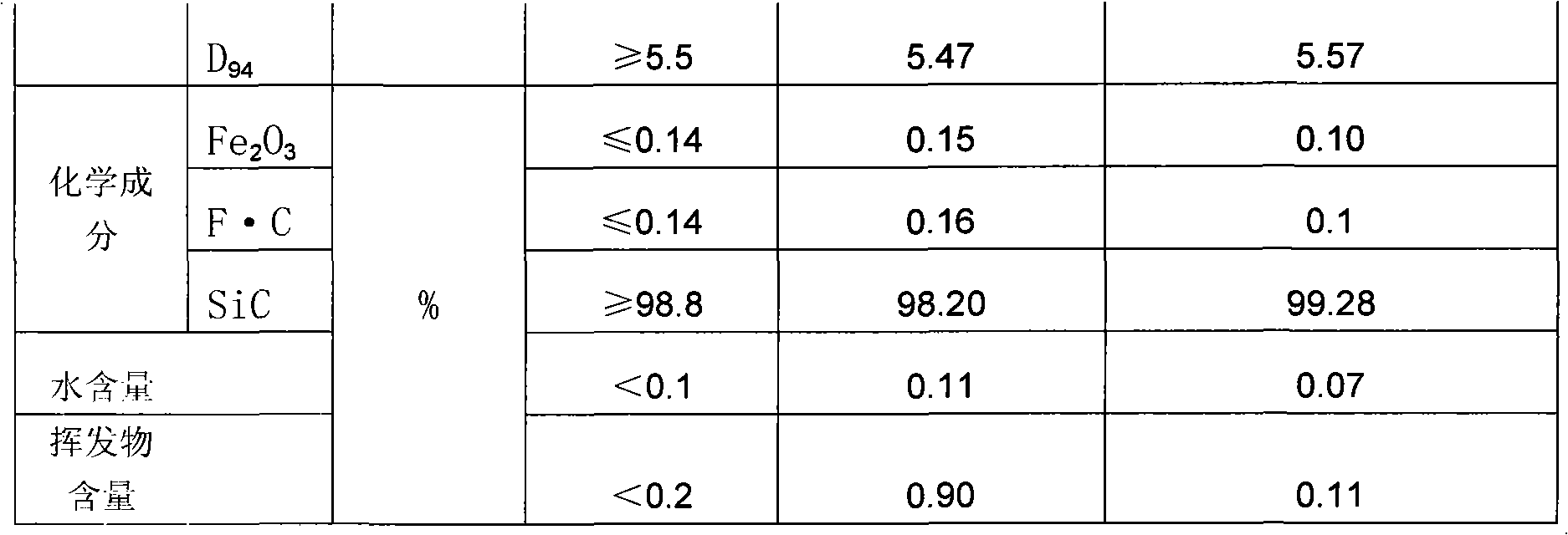

Bearing lubricating and cooling method and device

ActiveCN1931459AImprove the lubrication effectImprove cooling effectRolling equipment maintainenceWork treatment devicesEmulsionBelt filter

The present invention is bearing lubricating and cooling method and device, and features utilizing emulsion as lubricating and cooling medium and adopting an emulsion circulating device to provide the bearing, roller and the rolled plate with emulsion. The present invention can meet different lubricating and cooling requirements of rolling process in a two-stage paper belt filtering mode and has the pressure, flow rate, temperature, concentration and other parameters of the emulsion separately adjustable. The present invention can cool bearing, roller and the rolled plate effectively, save lubricating and cooling medium, improve rolled plate quality, prolong the service life of the bearing and make best use of the rolling machine.

Owner:BEIJING WEISHIJIE HYDRAULIC EQUIP +1

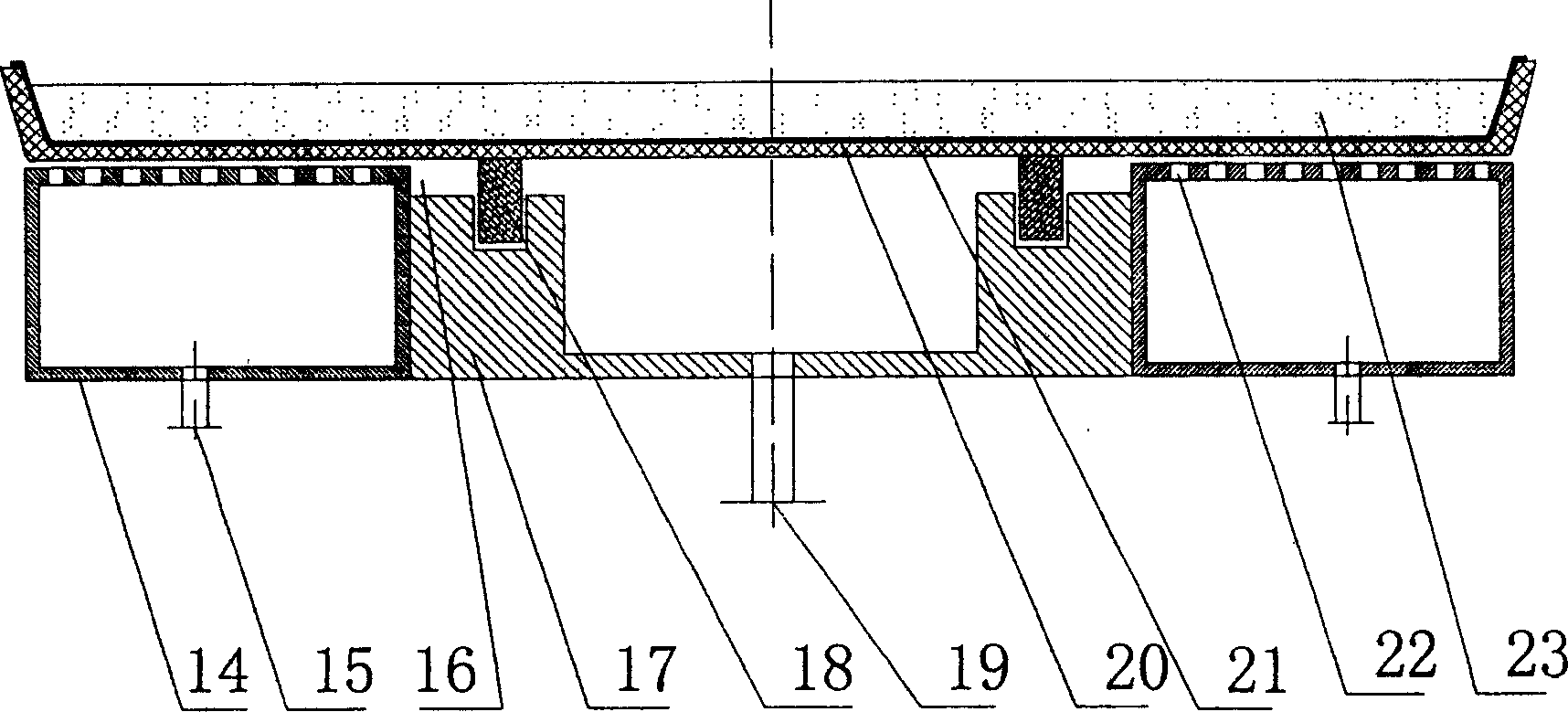

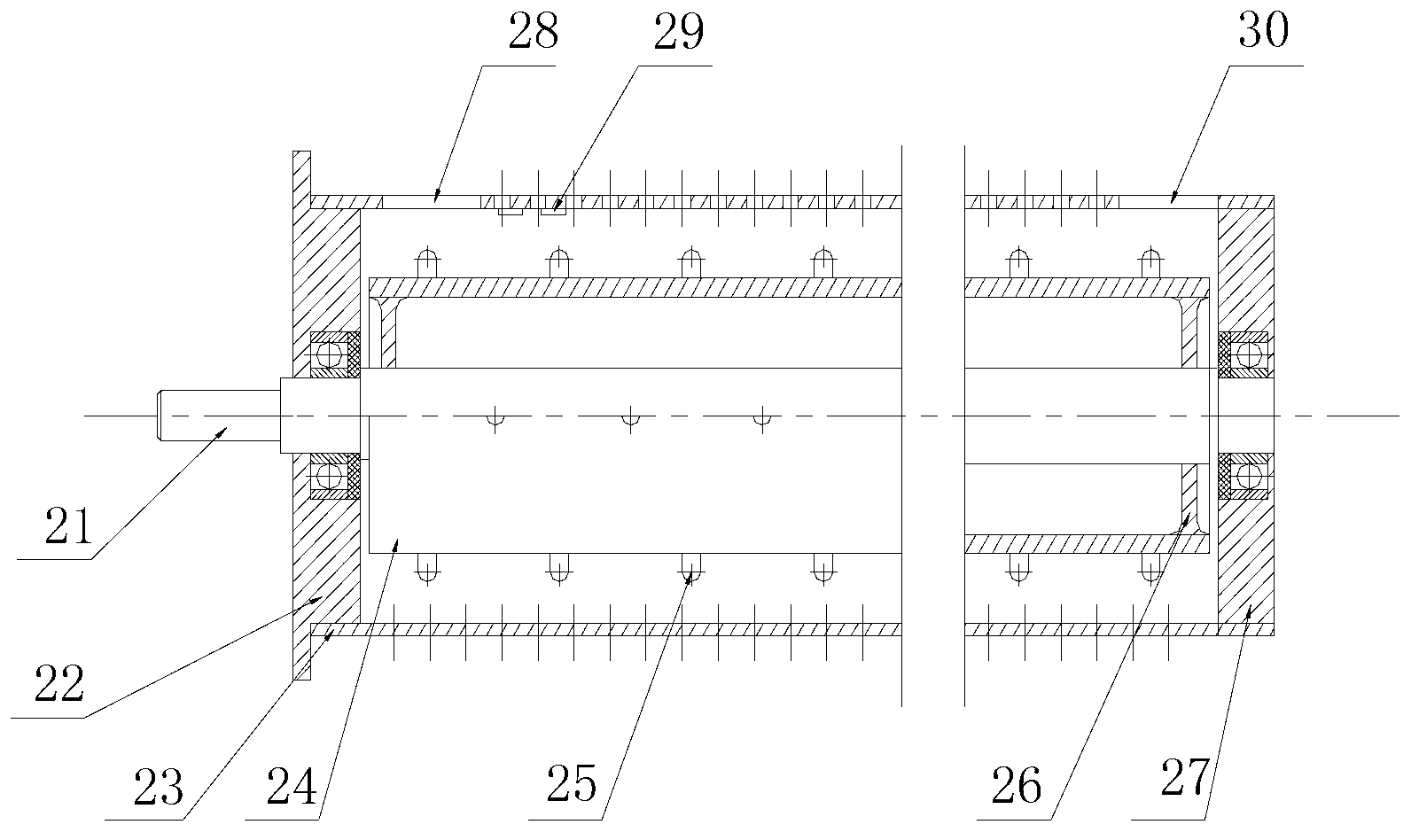

Vacuum belt type filter and dehydration machine

InactiveCN1843559AReduce frictionSmall power configurationMoving filtering element filtersFriction reductionLow demand

The invention discloses a vacuum belt filter dewaterer. Wherein, the filter belt is adhered on the rubber belt of ripple groove that driven by the drive motor as the rubber belt to step for the same direction; the rubber belt ripple groove is connected to the vacuum room; the rubber belt is supported by two lubricative support blocks and sealed by water, while said two support blocks and rubber belt form the vacuum room; the rubber belt outside the vacuum room is aerial via the compressed air when in working to reduce the friction resistance; the filter cake is compressed and dewatered at the front of outlet to attain drier filter cake and reduce the energy for following drying; the filter screen can execute filtration after regeneration. The invention has the advantages that: it uses vacuum filtration, with large filter drive power; the filter cake is mechanically compressed with lower moisture percentage; it can automatically detect the thickness of filter cake, via which to control the speed of filter belt to confirm the uniformity of filter cake; it has lower demand for the solid content of filter liquid; and it can realize continuous operation with high automatic degree and better economic benefit.

Owner:ZHEJIANG UNIV

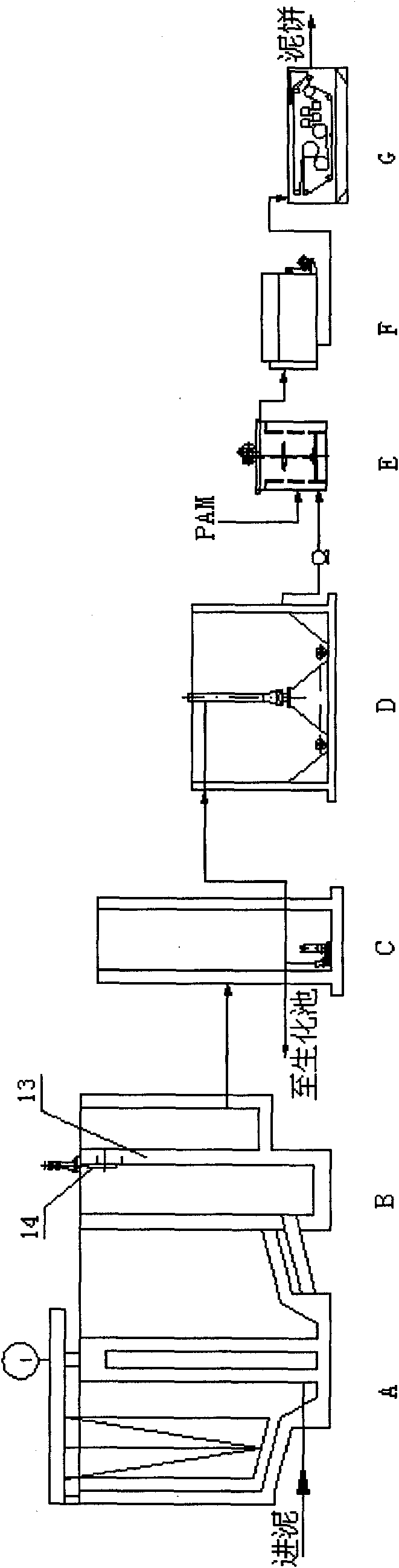

Sludge dehydration treatment technology

ActiveCN101767922AConform to the internal relationship of concentration progressionImprove concentrationSludge treatment by de-watering/drying/thickeningSludge cakeFiltration

The invention relates to a sludge dehydration treatment technology which includes the steps as follows: residual active sludge is treated for concentration sequentially in a continuous gravity concentration tank and an intermittent sludge concentration tank, then put in a chemical conditioning tank and guided into a tumbling centrifugal concentrator for further concentration after being chemically conditioned, and finally put into a belt filter press to be dehydrated to become sludge cake. The sludge dehydration treatment technology of the invention aims at the residual active sludge property characteristics to strengthen the concentration effect before mechanical dehydration and has the advantages of little addition dosage in dehydration, sludge cake chickening, low moisture content in sludge cake, easy washing of filtration fabric not stuck by sludge, low solid content in separation medium, and high solid recovery rate.

Owner:四川蓉信开工程设计有限公司

Sludge dewatering method for urban sewage plant

InactiveCN102674657AImprove dehydration and drying methodsIncrease the solid content of raw sludgeSludge treatment by de-watering/drying/thickeningBelt filterMunicipal sewage

The invention discloses a sludge dewatering method used for an urban sewage plant. The method comprises the following steps of: putting original sludge of the urban sewage plant in a container, wherein the moisture content of the sludge is more than 90 percent, and stirring fully and uniformly; adding mixed coagulant aids of dolomite and quick lime into the obtained sludge and uniformly stirring; adding inorganic flocculant, stirring uniformly, adding a polyacrylamide (PAM) flocculating agent, and stirring uniformly; and feeding the obtained sludge into a plate-and-frame filter press, squeezing and dewatering the sludge, keeping pressure for 5 to 30 minutes, and decompressing and discharging. The sludge of the urban sewage plant is conditioned and flocculated further, and then is filtered, squeezed and dewatered, so that moisture in the original sludge in the sewage plant, which is not dewatered by a belt filter press, can be dewatered effectively, the treatment process of the sludge dewatering method is simple, and the sludge dewatering method is low in treatment cost.

Owner:中节能国祯环保科技股份有限公司

Molecular sieve RE ion exchange method

InactiveCN1416951AReduce water consumptionImprove efficiencyMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveBelt filter

The RE ion exchange method for molecular sieve includes pulping molecular sieve with water, feeding the obtained slurry to filtering cloth of horizontal vacuum belt filter continuously, passing the slurry successively through a filter cake forming area and an ion exchange area with vacuum acceptors below the filtering cloth to wash and sucking dry the filter cake, and unloading the filter cake. The molecular sieve is Y-type molecular sieve, and some acid and / or salt in the amount of 0.1-5 wt% of molecular sieve are added to the slurry. Some solution containing RE ion is added to the filter cake over the ion exchange area with the weight ratio between the RE oxide and the molecular sieve being 0.01-0.5.

Owner:CHINA PETROLEUM & CHEM CORP +1

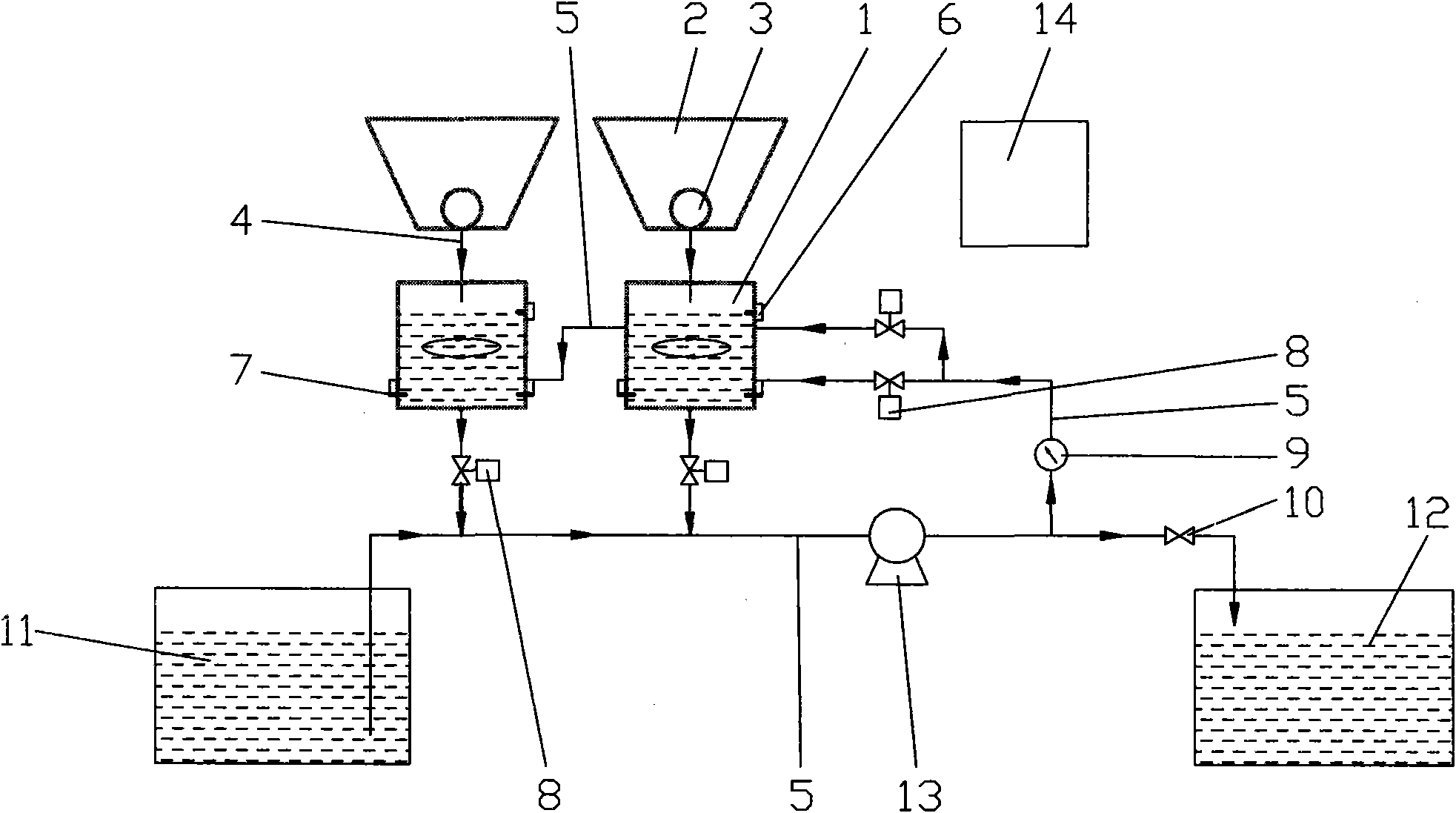

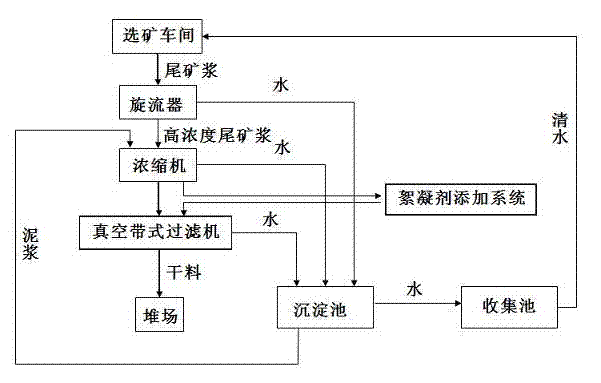

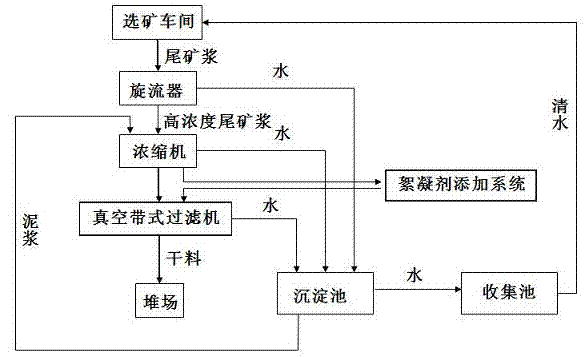

Dehydration method and device of tailings

ActiveCN102228762AEliminate the risk of dehydrationAvoid accidentsFiltration circuitsCycloneTailings dam

The invention relates to a dehydration method and a dehydration device of tailings. The dehydration device mainly comprises a cyclone, a thickener, a vacuum belt filter and a sedimentation basin. A tailing slurry discharged from an ore dressing workshop go through the cyclone, the thickener and the vacuum belt filter in order to form dry materials which are placed in a stock dump. And a flocculating agent adding system is installed between the thickener and the vacuum belt filter. The sedimentation basin is connected to a collection basin used for collecting the clear water overflowing from the sedimentation basin, and then the clear water come into the ore dressing workshop for recycling. With the dehydration method and dehydration device of tailings, risks from dehydration with a tailing dam can be eliminated, so that accidents are effectively avoided. Meanwhile, the device of the invention has low investment, low running cost and high dehydration rate.

Owner:YUNNAN DAHONGSHAN PIPELINE

Treatment device for heavy metal polluted soil and treatment process thereof

InactiveCN106077060AOverall small sizeSmall footprintContaminated soil reclamationBelt filterElution

The invention relates to a treatment device for heavy metal polluted soil. The treatment device comprises a machine frame, a feeding hopper, crushing rollers, a ball grinder, a separation screen, a first-stage water washing pool, a linear vibration screen, a slurry buffering pool, a slurry pump, a centrifugal machine, a deep elution pool, a belt filter press and a second-stage water washing pool. The polluted soil is remedied through mechanical grinding, first-stage water washing, first-stage solid-liquid separation, deep elution, second-stage water washing and second-stage solid-liquid separation. The process is advanced, the treatment effect is good, the work efficiency is high, and the automation degree is high.

Owner:杰瑞环境工程技术有限公司

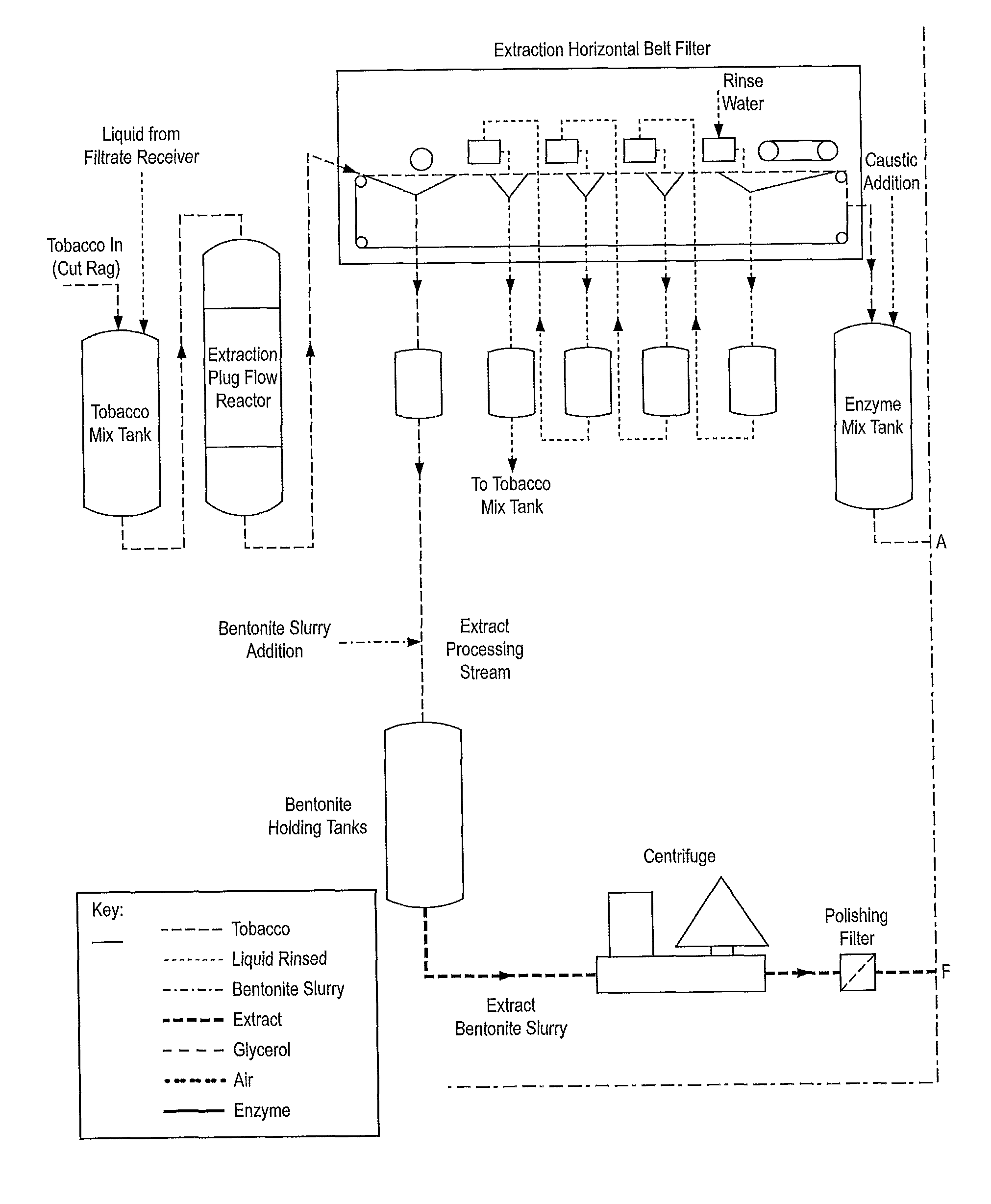

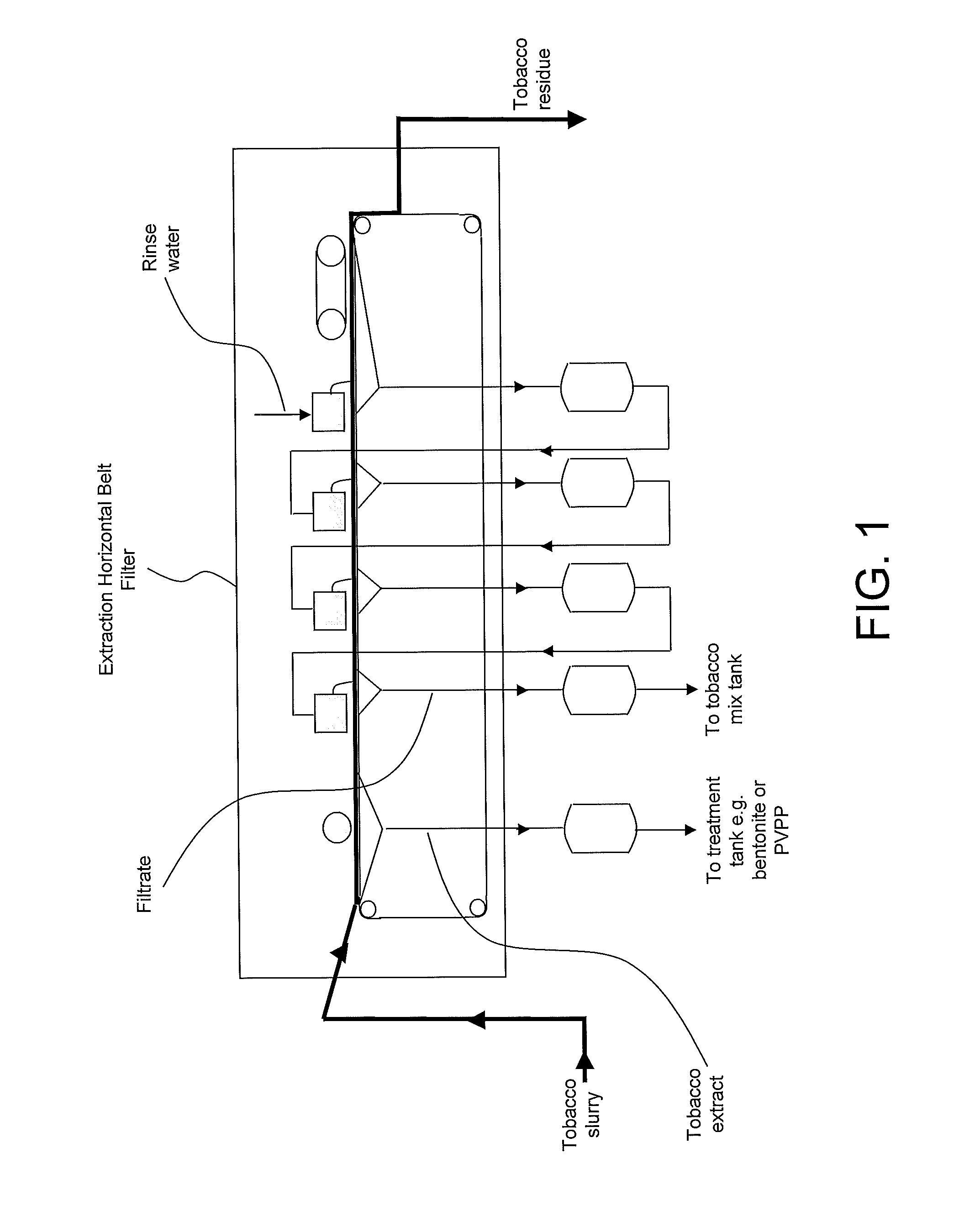

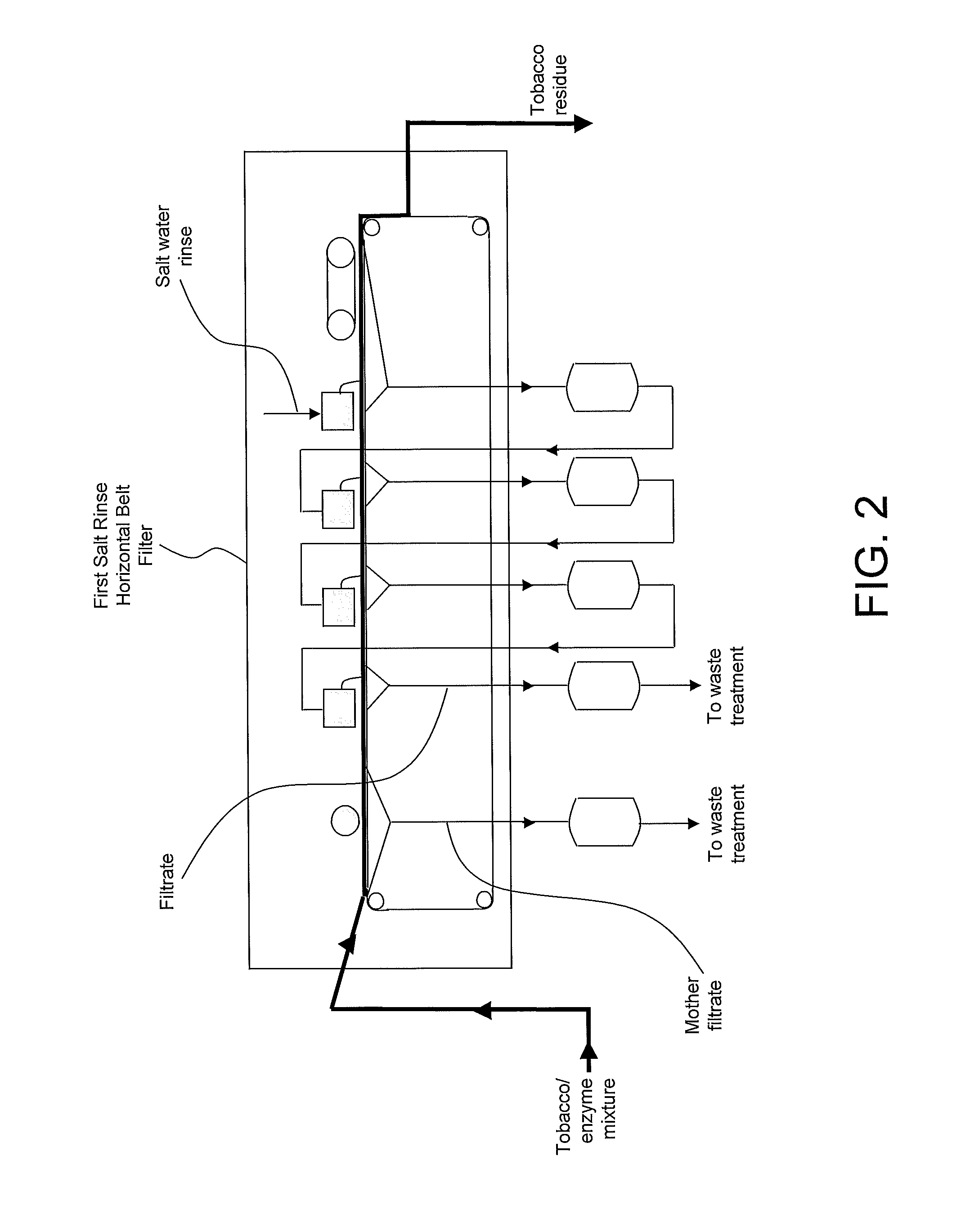

Tobacco Treatment

This invention provides a method for removing undesirable constituents from tobacco which includes extracting tobacco material in an aqueous or organic solvent and filtering the product of the extraction using a horizontal belt filter. The extract and insoluble tobacco residue may be further treated enzymically, chemically or otherwise to remove a complement of undesirable constituents. The extract and insoluble tobacco residue are recombined to form a regenerated tobacco material that is less harmful when combusted than the original material.

Owner:BRITISH AMERICAN TOBACCO (INVESTMENTS) LTD

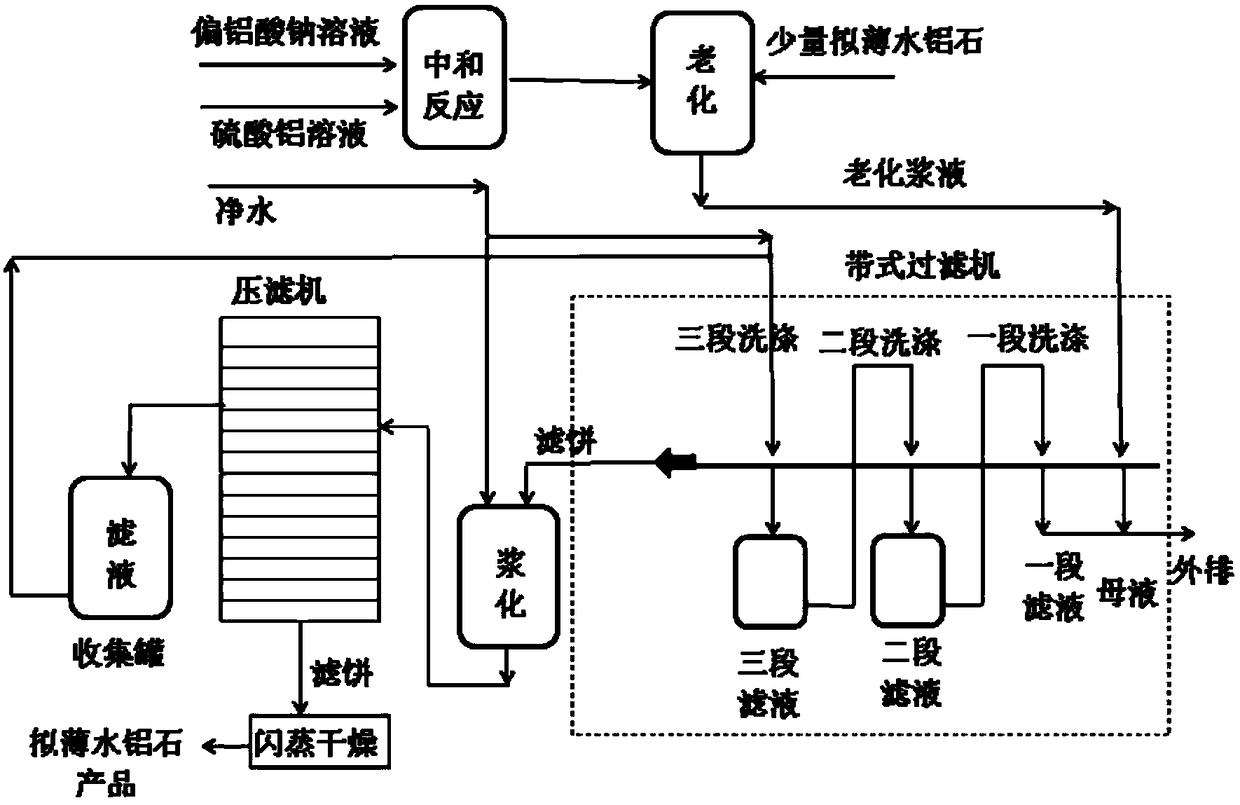

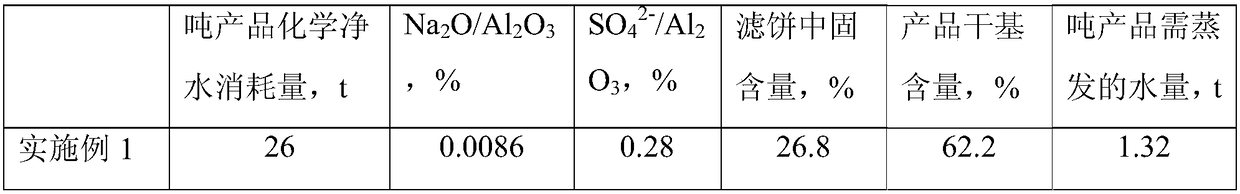

Preparation method of pseudoboehmite

ActiveCN108910925AGood water permeabilityReduce dosageAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationPseudoboehmiteEvaporation

The invention discloses a preparation method of pseudoboehmite. The whole process consists of neutralization, aging, washing and drying steps. The process is characterized in that: 0.5%-5% of dried pseudoboehmite is added at the end of aging, the washing process adopts a continuous belt filter and intermittent filter press two-stage combination process, the washing water amount is 10-30 times thatof the pseudoboehmite product, the solid content of a pseudoboehmite filter cake is in the range of 26.0%-35.0%, the washing water amount is reduced by 50% or more, the amount of water needing evaporation for unit product is reduced by 40% or more, and the energy consumption for drying is reduced by 40% or more. The process saves the washing water amount, reduces the energy consumption for dryingand makes the product quality more stable.

Owner:ZIBO QIMAO CATALYST

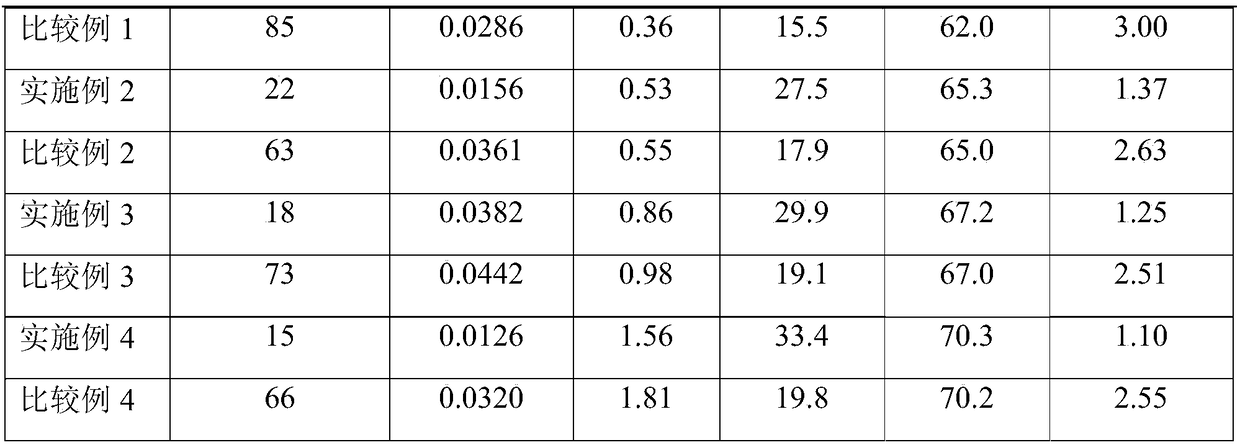

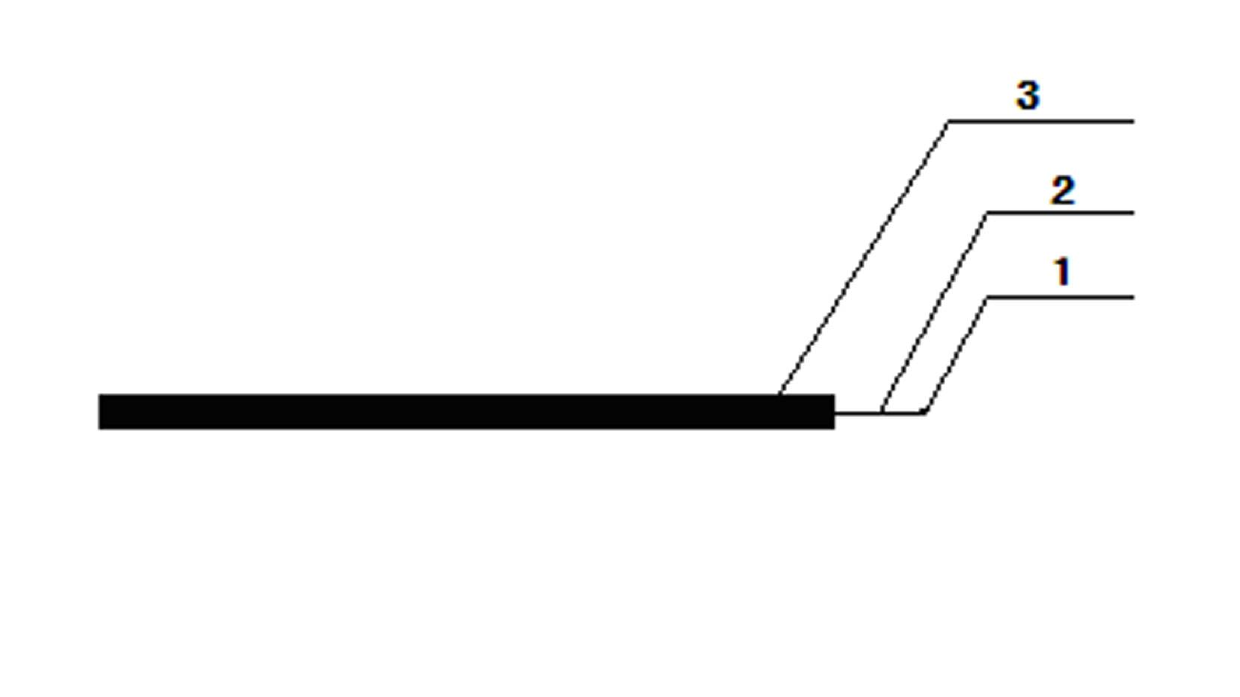

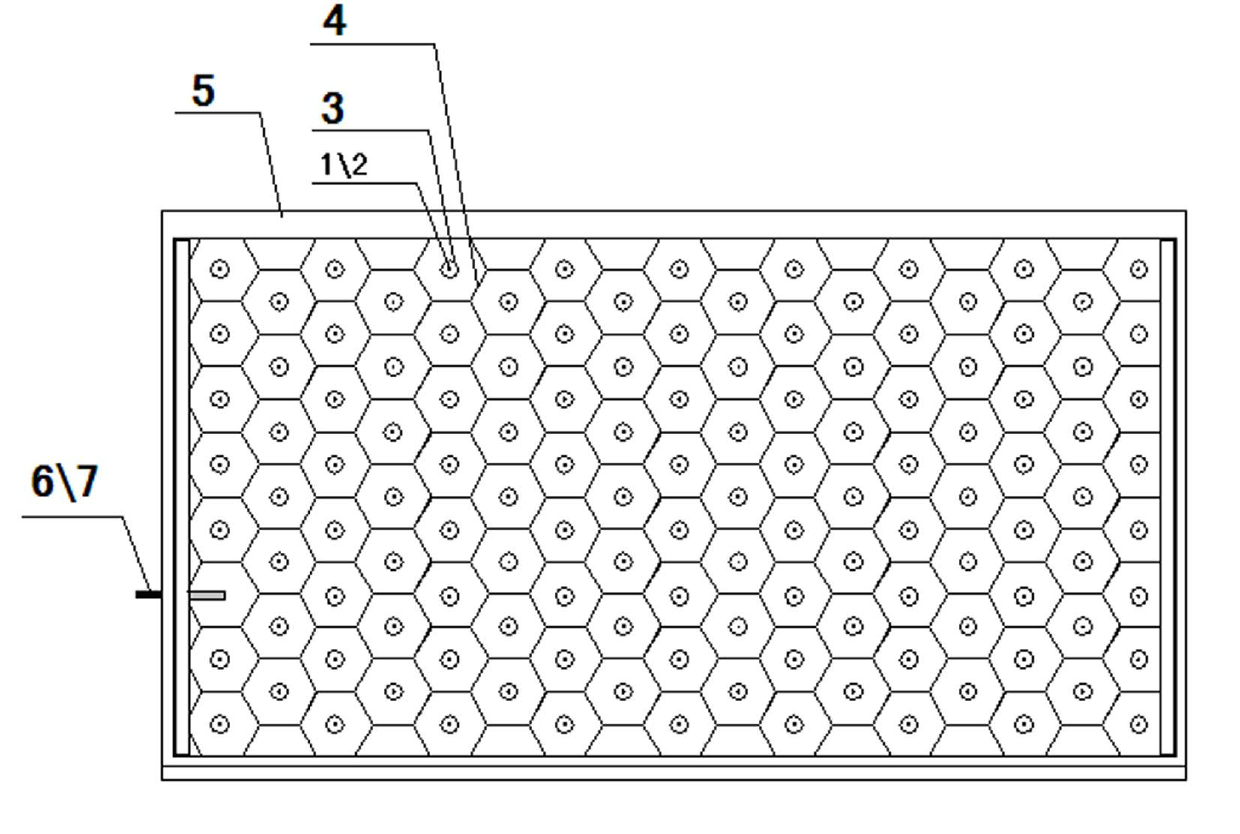

Extremely wide type breadth shortening forming cutting machine

The invention relates to an extremely wide type breadth shortening forming cutting machine used for the length fixing and breadth fixing of formed high-density fabric of terylene and polypropylene fiber, and providing qualified cloth used for industrial filtration for a belt filter. According to the invention, the overall structure is composed of a shaft bracket, a length fixing and breadth fixing cutter, a winding device, and the like; a yardage roll is unwound on the shaft bracket freely and then enters into a length fixing and breadth fixing cutting area; a variable frequency motor actively drives to-be-cut filter cloth in the breadth fixing cutting area, and a pressure cutting wheel pneumatically controlled by hot melting of 2-3 ultrasonic waves is fixed on a horizontal guide rail according to the size of the breadth for breadth fixing cutting; a winding mechanism is controlled by the variable frequency motor, when the wound yardage roll reaches a set length, the cut filtering cloth stops operation, and is controlled to operate by a heating resistor hot melting cutter along the horizontal guide rail through the variable frequency motor, so as to conduct fixed length cutting.

Owner:YANCHENG INST OF IND TECH

Method for producing citric acid by carrying out slag removal and fermentation on cassava

InactiveCN101698860AImprove filtration yieldEfficient use ofMicroorganismsFood processingSlagFiltration

The invention discloses a method for producing citric acid by carrying out slag removal and fermentation on cassava, and the method comprises the following steps: cutting the cassava into small pieces, smashing, adding water in well smashed cassava powder and mixing for preparing pulp, then liquefying the cassava powder by the continuous spray liquefaction technology, filtering liquefied solution by adopting a belt filter or a plate-and-frame filter after completing the liquefaction, leading filtrate after the filtration into a fermentation device, then adding an organic nitrogen source which accounts for 0.3-15% of the total fermentation volume for carrying out the fermentation, and finally adopting the calcium salt method for extracting the citric acid from fermentation broth. The method can not only greatly reduce the viscosity of the fermentation broth, well improve the dissolved oxygen during the fermentation process and reduce the fermentation cycle, but also increase the utilization rate of a fermentation tank and expand the production scale by increasing the initial total sugar concentration for the fermentation. The method can simultaneously solve the problem that grain resources are occupied during the production process of the citric acid.

Owner:YIXING UNION BIOCHEM

Electrostatic air conditioner cleaner and electric discharge device

ActiveCN102430479AImprove bindingIncrease discharge voltageExternal electric electrostatic seperatorElectrode constructionsElectric dischargeEngineering

The invention provides an electrostatic air conditioner cleaner for a central air-conditioning system and an electric discharge device arranged in the electrostatic air conditioner cleaner. The electrostatic air conditioner cleaner comprises a shell, an air inlet, an air outlet, an electric discharge assembly and an ionization dust collecting assembly, wherein the electric discharge assembly comprises an electric discharge anode assembly which is of an acicular structure and an electric discharge cathode assembly, the acicular structure is firm, can be used for improving an electric discharge voltage, can be washed without any chemical agent or a soaking process and can be directly flushed with a pressure water pistol, the electric discharge anode assembly passes through the center of the ionization dust collecting assembly and extends out of the tail end of the ionization dust collecting assembly, and the ionization dust collecting assembly consists of honeycomb six-wall type ionization dust connecting plates, thus the dust collecting space is increased and the overall size of the cleaner is reduced; and the overall performance of the cleaner is improved, and the cleaning period is prolonged. Compared with a medium-efficiency band filter, the cleaner has the advantages that the production of nondegradable solid pollutants can be reduced and the effects of environmental friendliness, energy conservation and emission reduction are achieved truly.

Owner:杨全辉

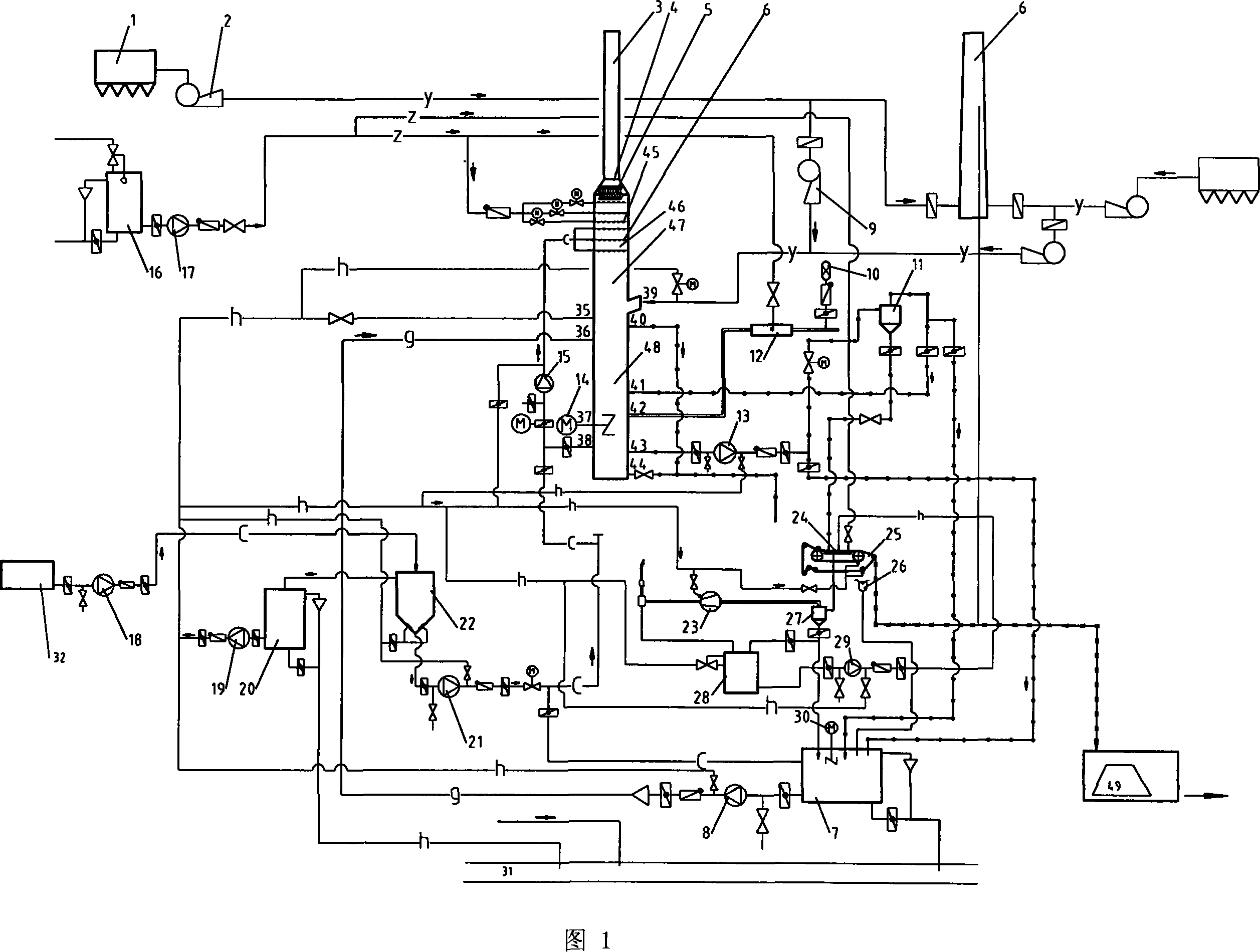

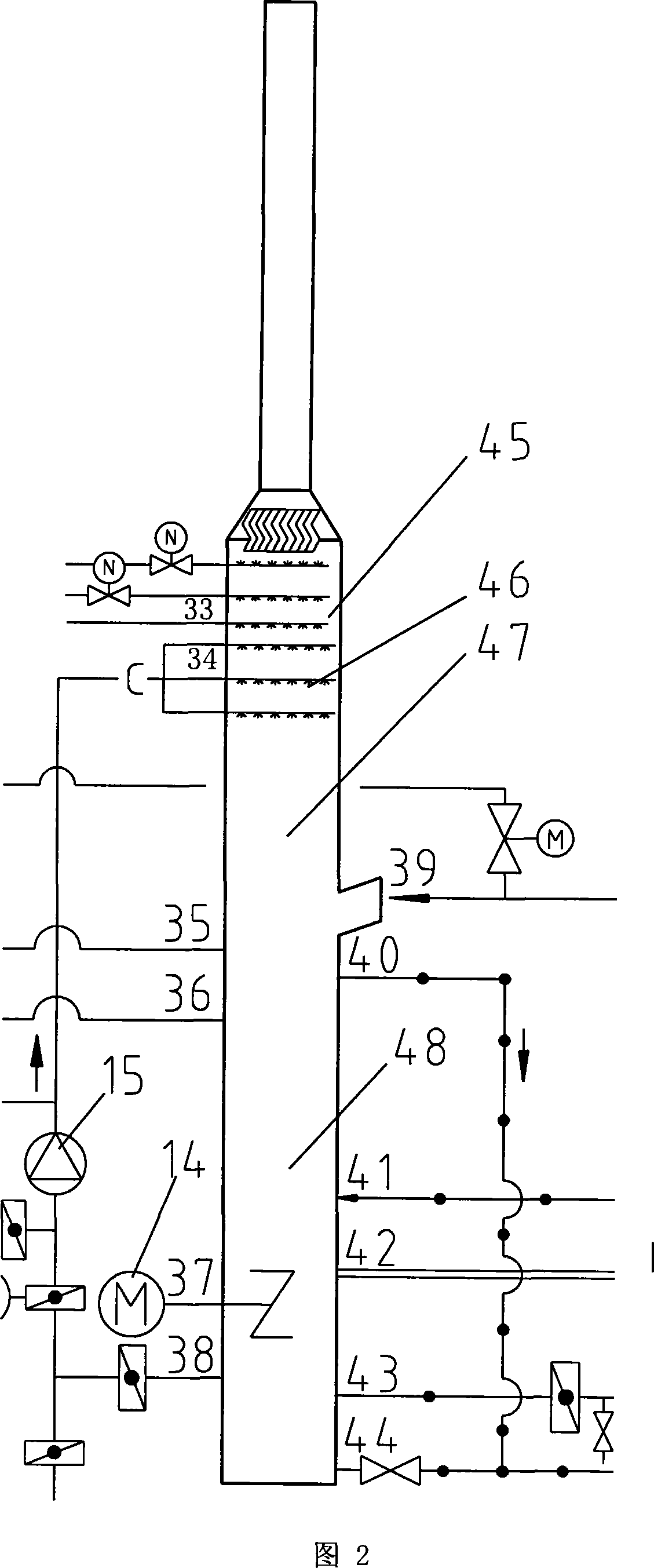

High-efficiency desulfurization dust separation system for coal-fired boiler flue gas

InactiveCN101219331ALow running costEliminate secondary pollutionLighting and heating apparatusUsing liquid separation agentCycloneFiltration

The invention relates to a high-effective desulfuration dedusting purification system of coal boiler flue gas, in particular to a purification equipment of industrial waste gas. The invention provides the highly effective desulfuration dedusting purification system with good desulfuration dedusting effect. The system is provided with a deduster, a draft fan, a booster fan, an absorption tower, a process water pump, a process water tank, an oxidation air blower, a hydraulic cyclone, a slurry pump, a stirrer, a recycle pump, a slurry transfer pump, a clarified water pump, a clarified water tank, a dispensing pump, a concentration groove, a water-ring vacuum pump, a belt filter press, a gas-water separator, a filtration fabric flushing pump, a filtration fabric flushing water tank, a filtrate water pump, a filtrate neutralization box, An electric butterfly valve, an electromagnetic valve, an intercepting valve, a regulating valve, a check valve, etc. The coal boiler flue gas is desulfurized and dedusted through dedusting before desulfuration, lime-spraying desulfuration, liquid absorption, air blowing oxidation, defogging purification, neutral liquid circulation, cyclone separated lime latex, gas water separation, mechanical filtration, etc., thus reaching the emission standard; the water and lye can be recycled, the invention has low cost for operating the system and no secondary pollution.

Owner:QUANZHOU TIANLONG ENVIRONMENTAL ENG

Lime milk neutralization method acid dipping-extraction vanadium extraction technology

The invention relates to a technology for extracting vanadium pentoxide from stone coal vanadium ore, comprising a lime milk neutralization method acid dipping-extraction vanadium extraction technology adopting a thickener production line and a lime milk neutralization method acid dipping-extraction vanadium extraction technology adopting a belt filter production line. The first technology adopts the working procedures of raw material pulverization, ball milling, sulfuric acid leaching, five-stage thickening washing separation, overflowing lime milk neutralization, single-stage thickening solid-liquid separation, overflowing reduction, pH value adjustment, extraction, reverse extraction, vanadium-contained solution oxidation, ammonia water precipitation, pyrogenation, and the like to obtain the vanadium pentoxide finished products, and the second technology adopts the working procedures of raw material pulverization, ball milling, sulfuric acid leaching, ore pulp lime milk neutralization, filtration washing, filtrate clarification washing, pH value adjustment, extraction, reverse extraction, vanadium-contained solution oxidation, ammonia water precipitation, pyrogenation, and the like to obtain the vanadium pentoxide finished products. The invention solves the problems of above-norm tailing wastewater NH3-N existing in the prior acid dipping-extraction vanadium extraction and has the advantages of high vanadium recovery rate, low production cost, good economic benefits and environment-friendly effect, and the like.

Owner:SHAANXI WUZHOU MINING +1

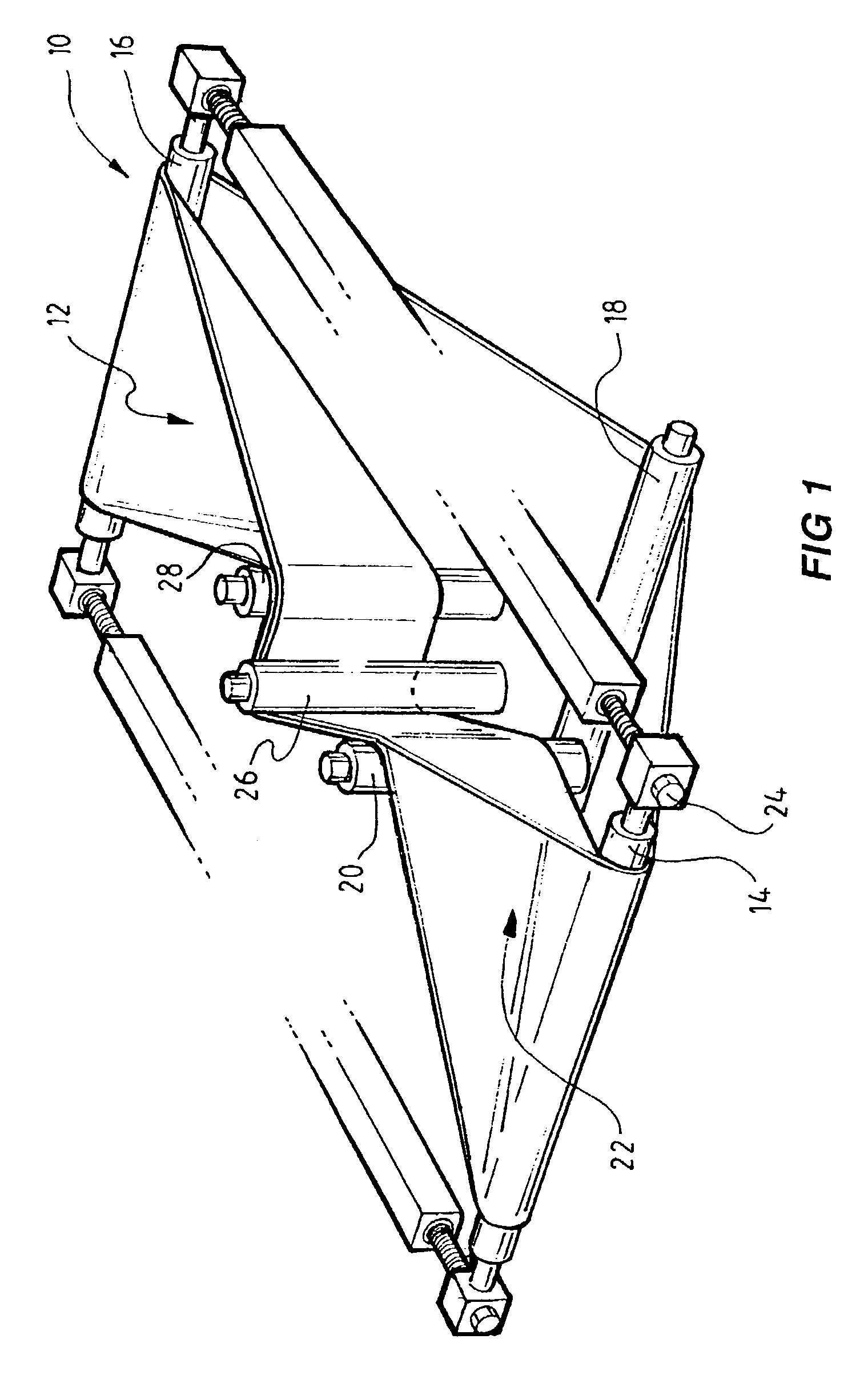

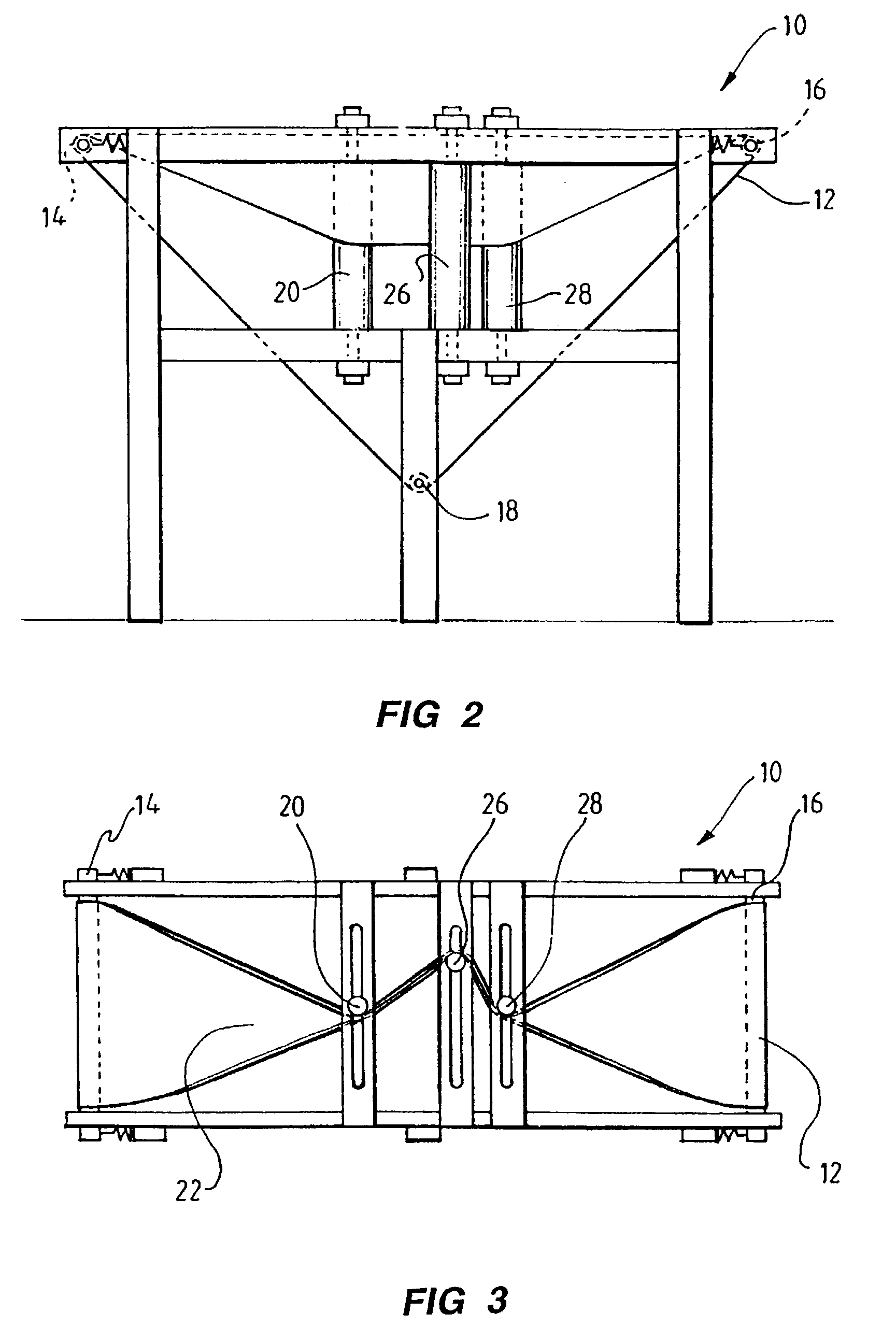

Folding belt filter

A belt filter for effecting separation of liquid from solids where, at the collection zone, a filter belt or belts is changed shape so as to provide a supporting shape to bold liquid, which is then fed into a nipping zone. In an embodiment there is a single belt used which is folded in a middle portion to provide the supporting shape.

Owner:LASERRAVE

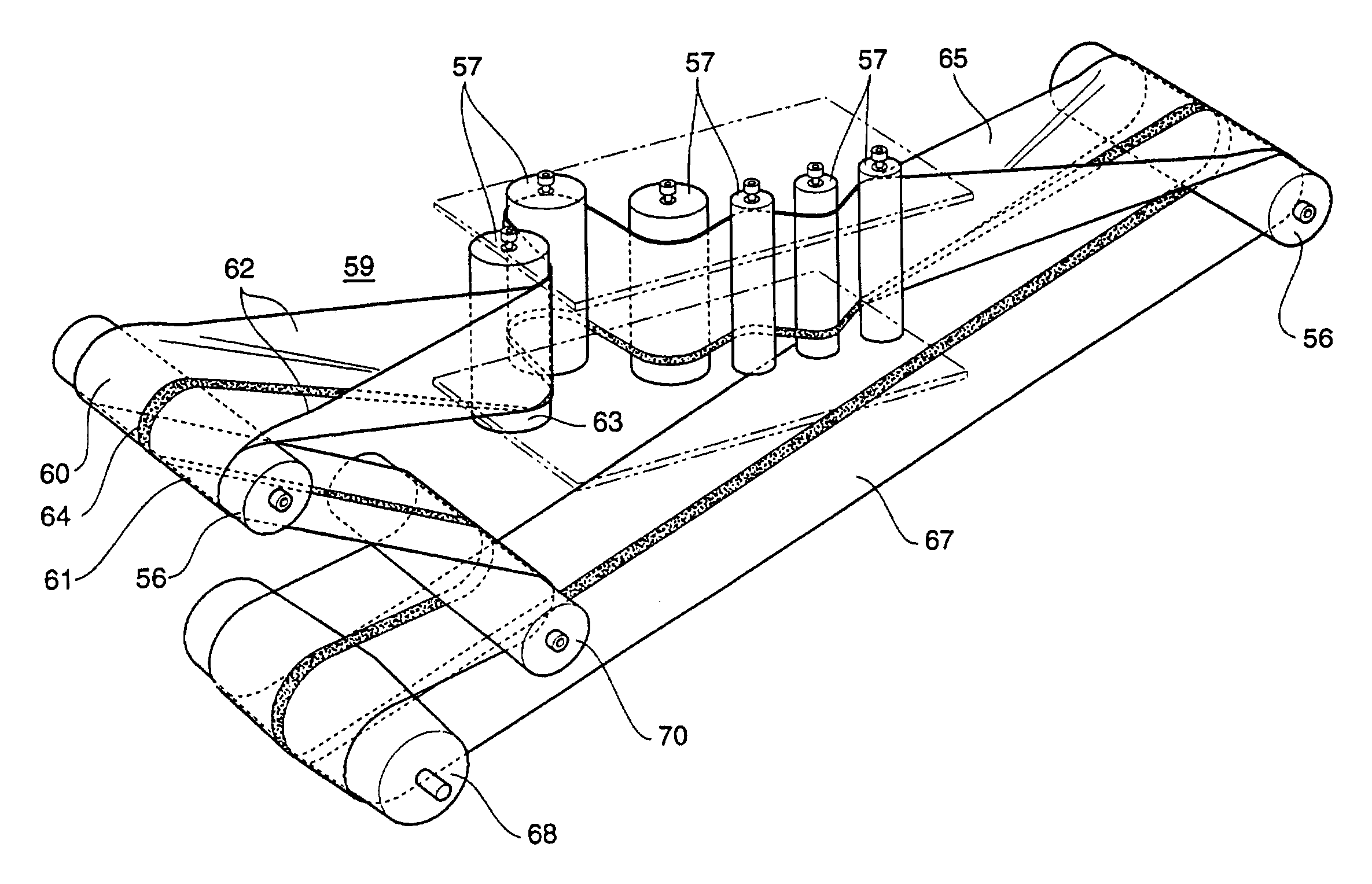

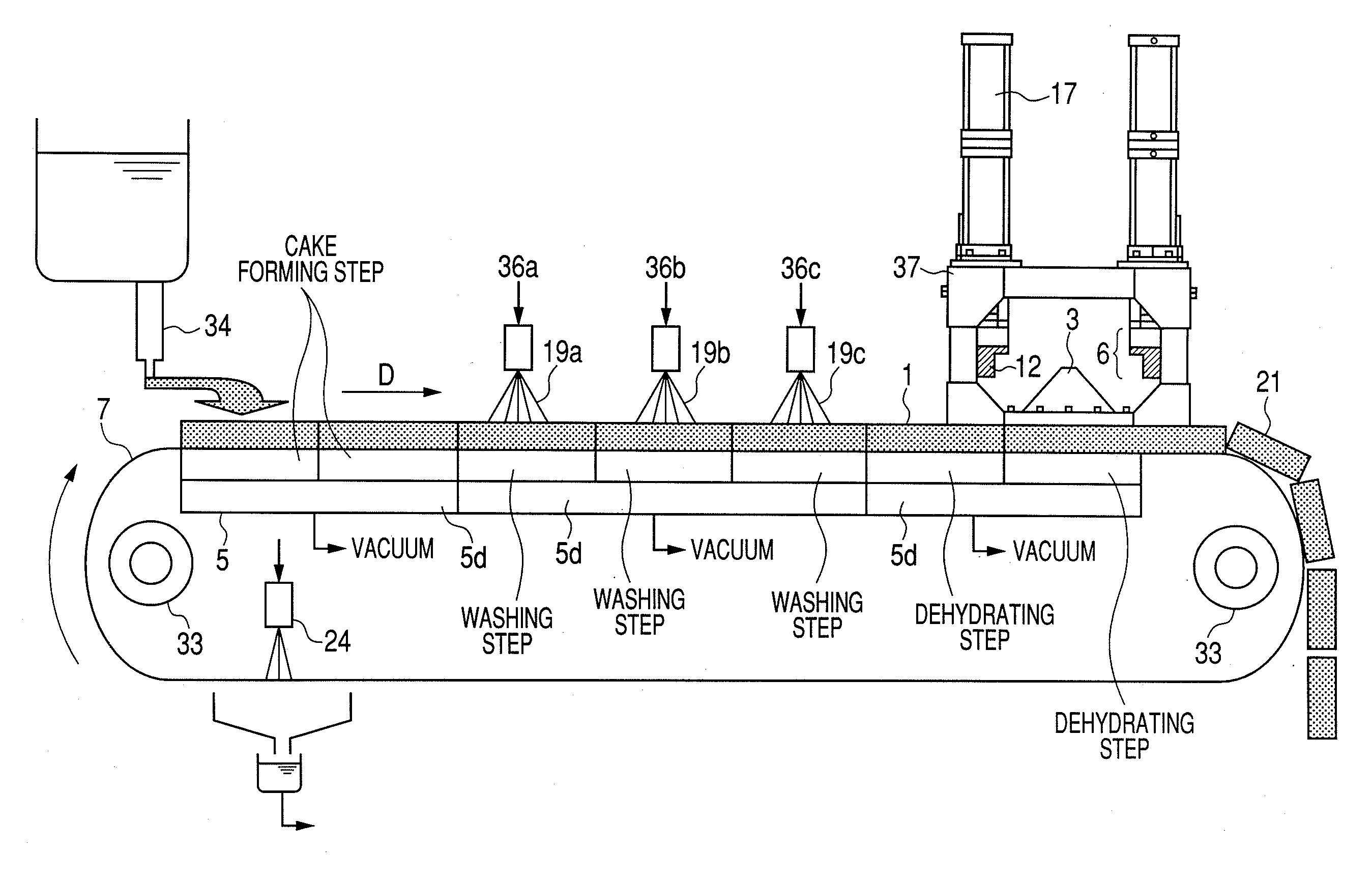

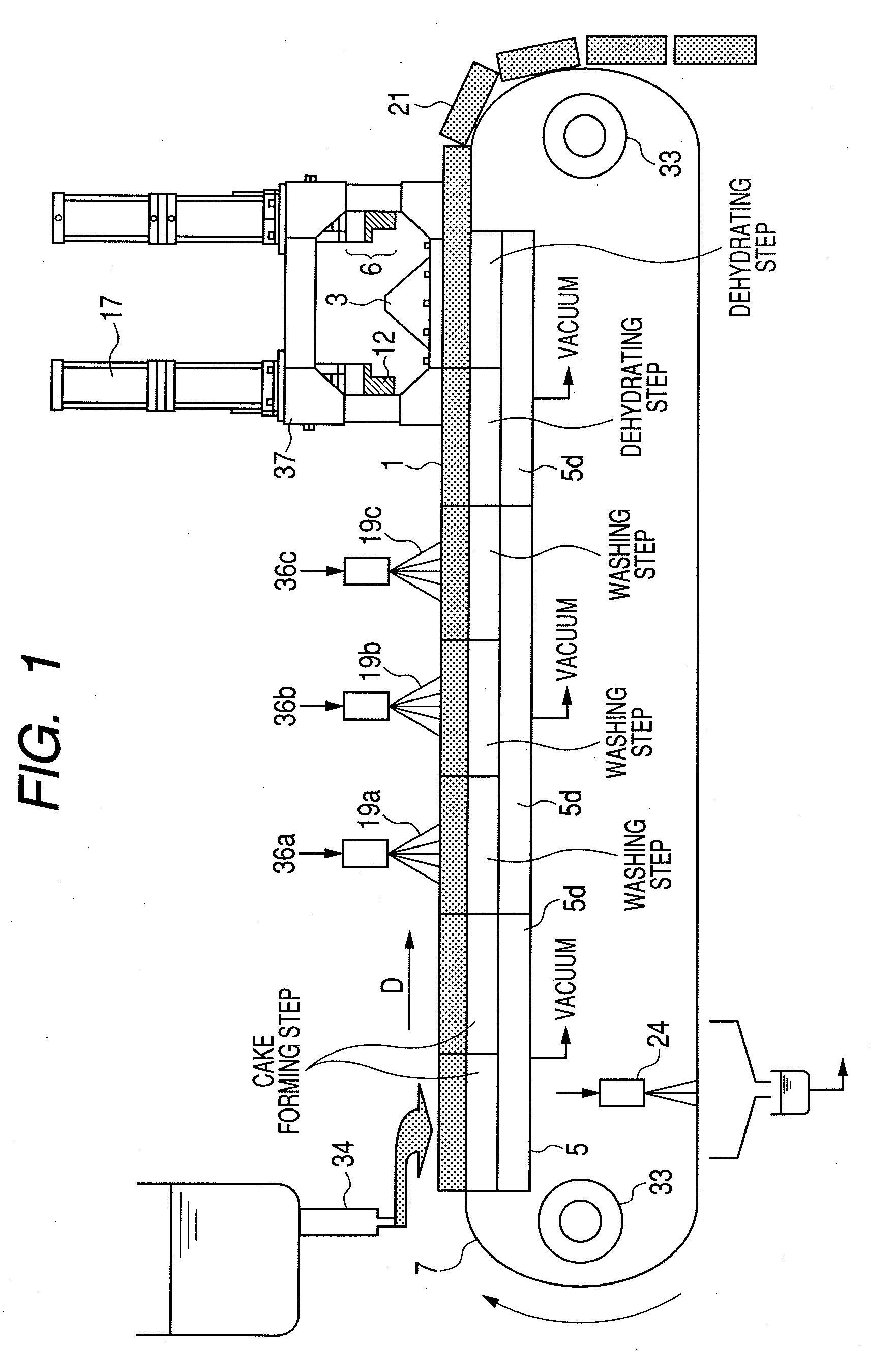

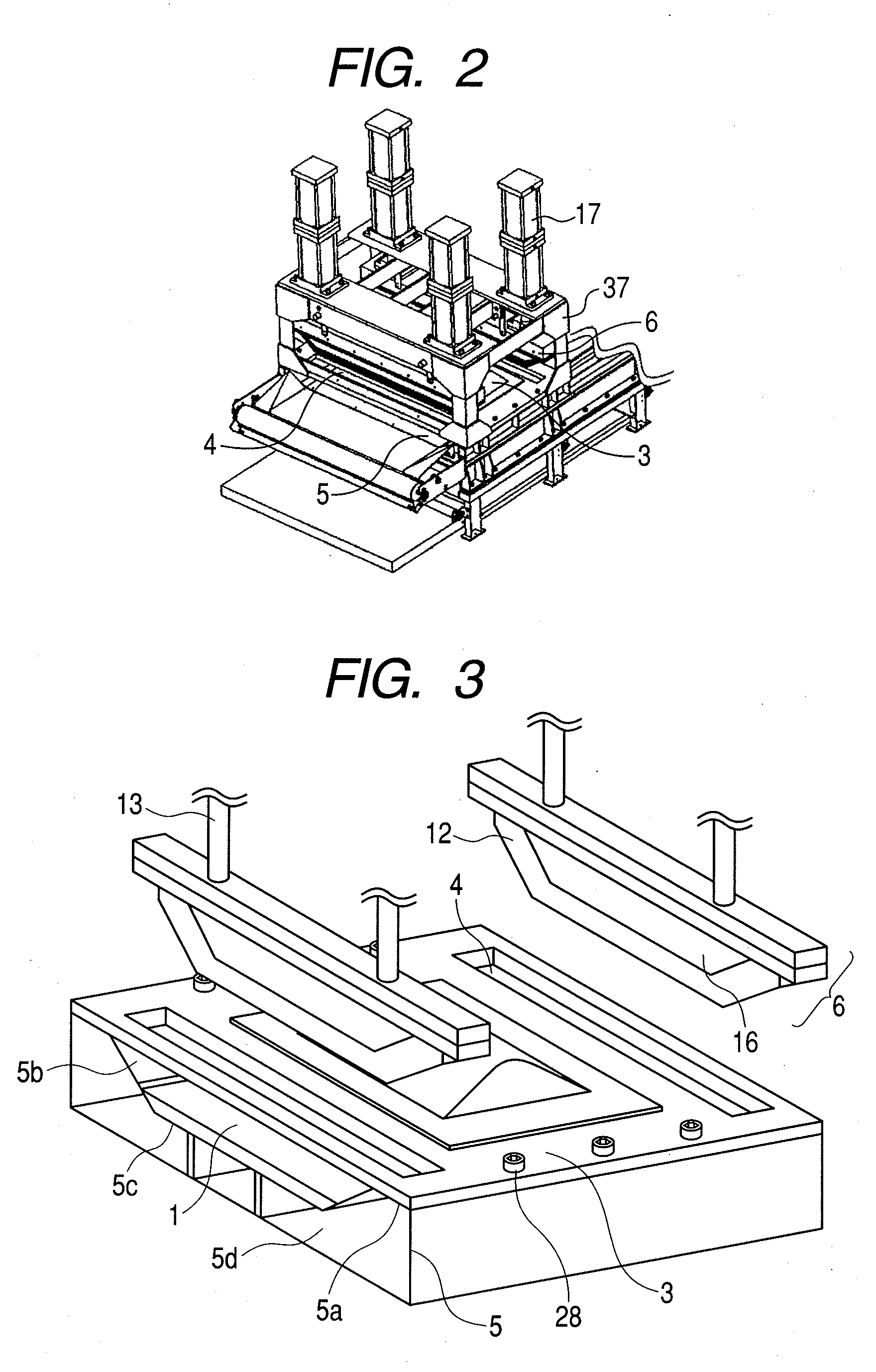

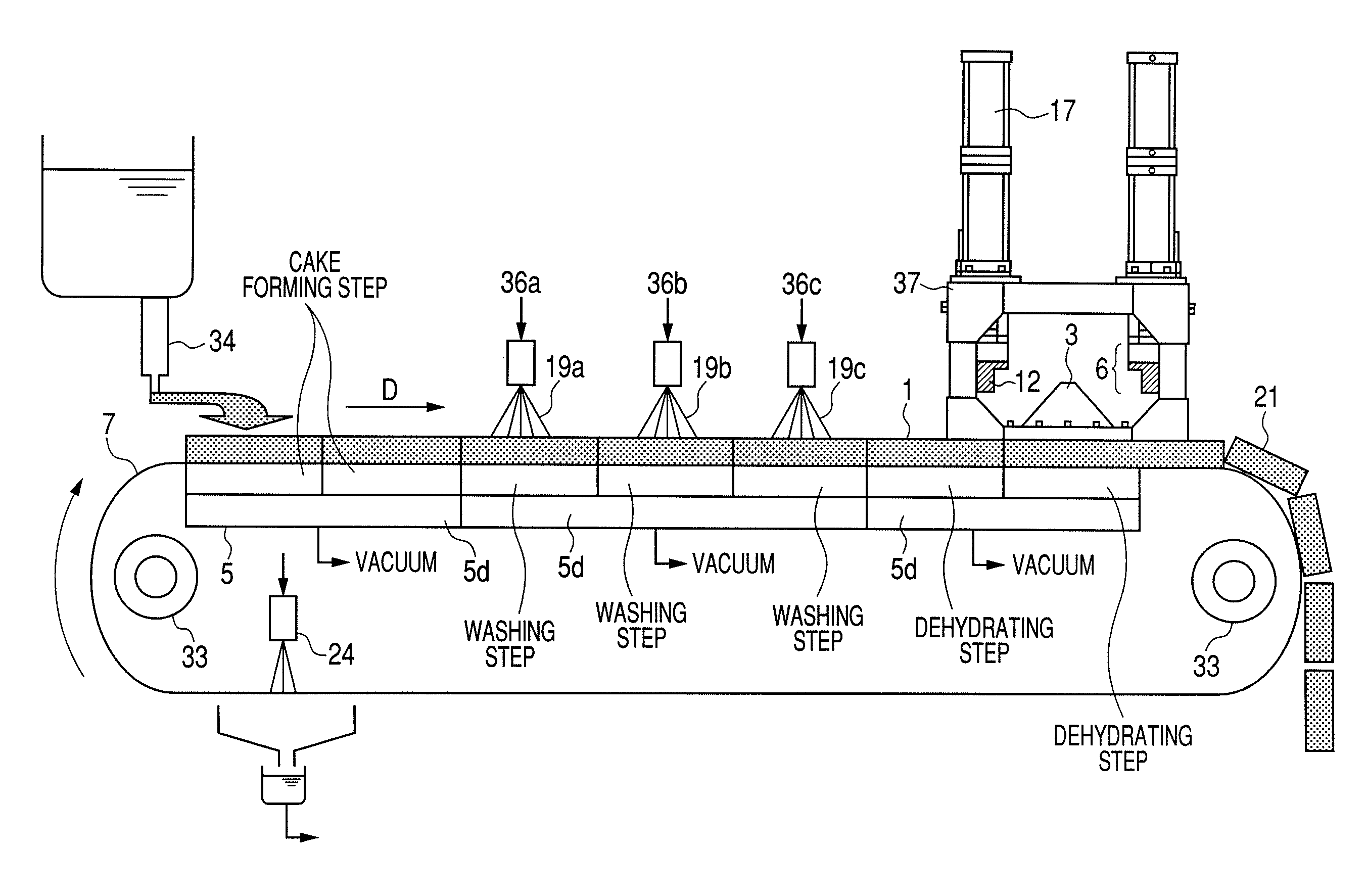

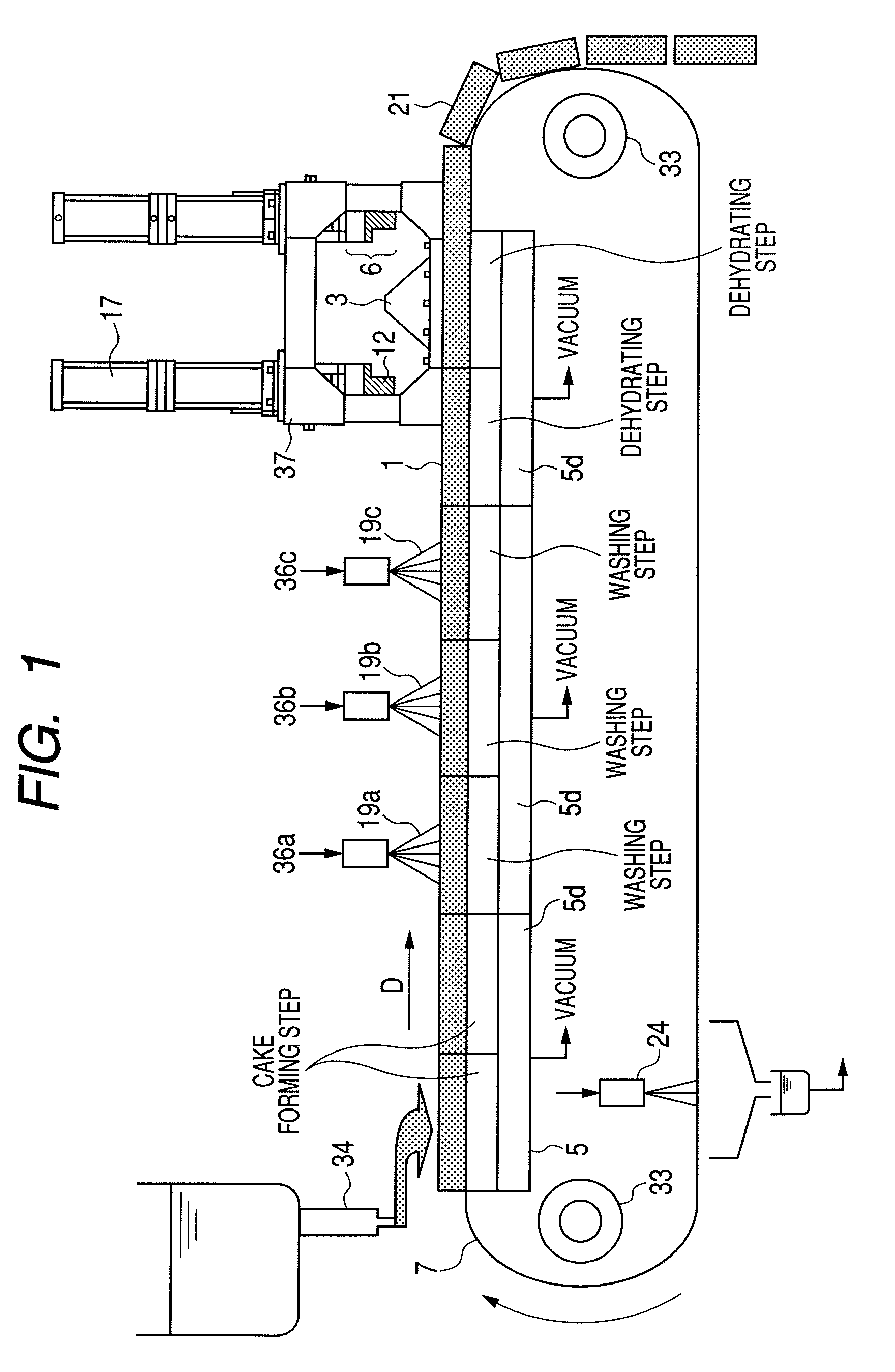

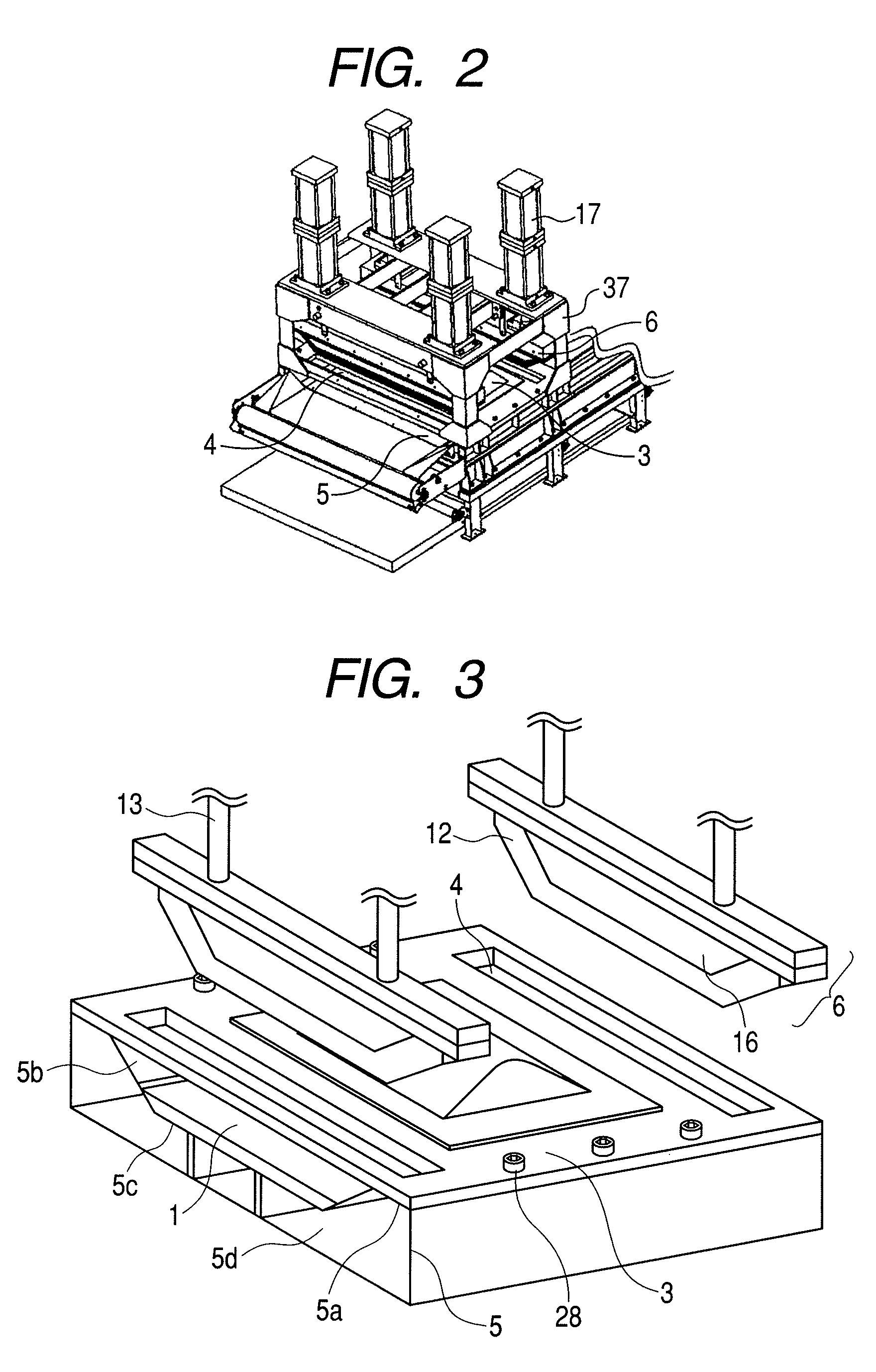

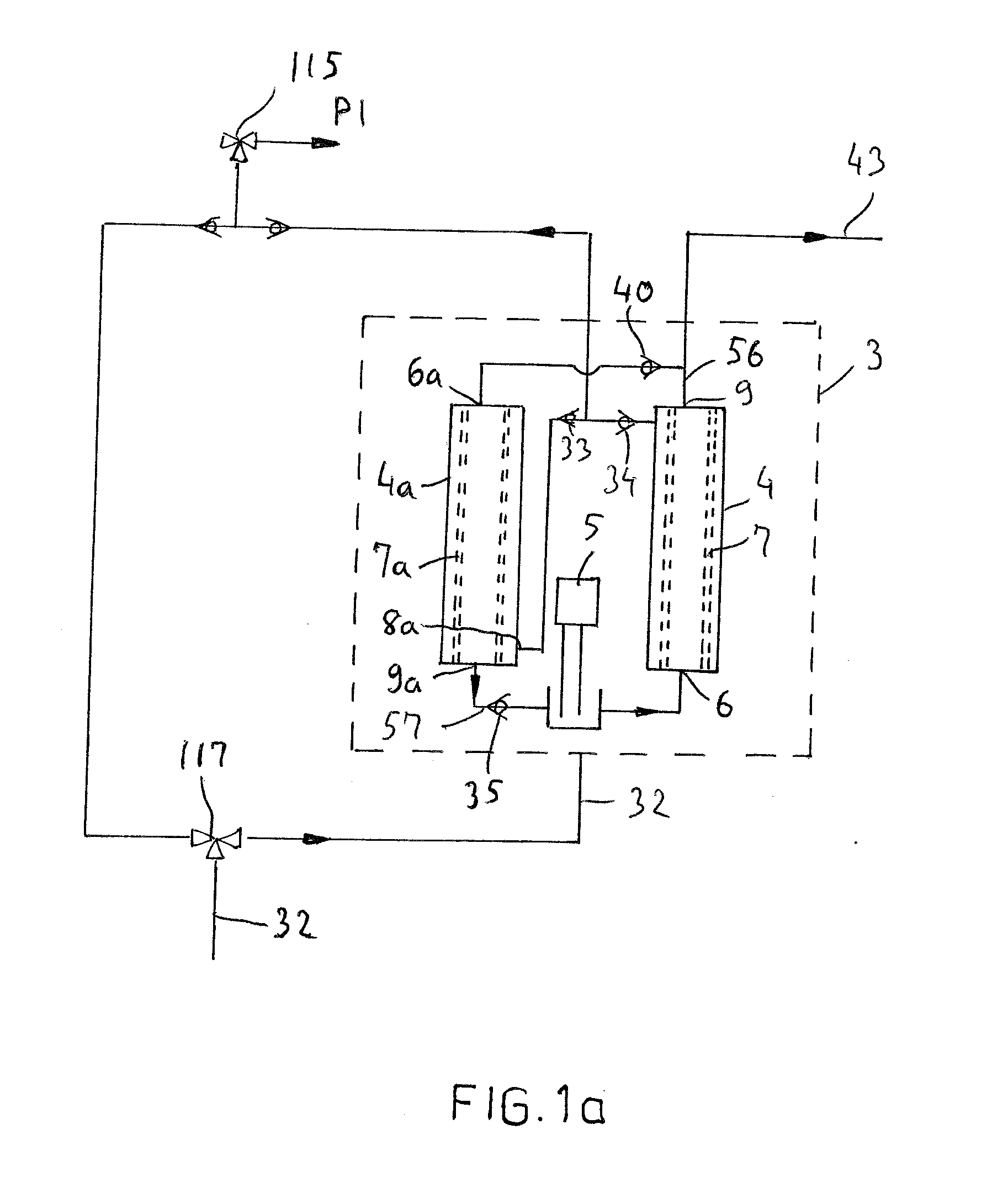

Filter cloth traveling type belt filter and production method of toner particles

ActiveUS20090226840A1Improve sealingWater contentConveyorsWater/sewage treatmentBelt filterEngineering

A production apparatus and a production method of toner particles are provided which efficiently and stably reduce the water content of the wet toner particle cake obtained by separating and washing toner particles from toner particle dispersion in a production apparatus of toner particles granulated in a wet process. A wet toner particle cake 1 formed on a belt filter is aerated and dehydrated with air, and at the same time, sealing units provided on the upstream and downstream sides of the aeration unit 3 can be operated to efficiently seal aeration air.

Owner:CANON KK

Filter cloth traveling type belt filter and production method of toner particles

A production apparatus and a production method of toner particles are provided which efficiently and stably reduce the water content of the wet toner particle cake obtained by separating and washing toner particles from toner particle dispersion in a production apparatus of toner particles granulated in a wet process. A wet toner particle cake 1 formed on a belt filter is aerated and dehydrated with air, and at the same time, sealing units 6 provided on the upstream and downstream sides of the aeration unit 3 can be operated to efficiently seal aeration air.

Owner:CANON KK

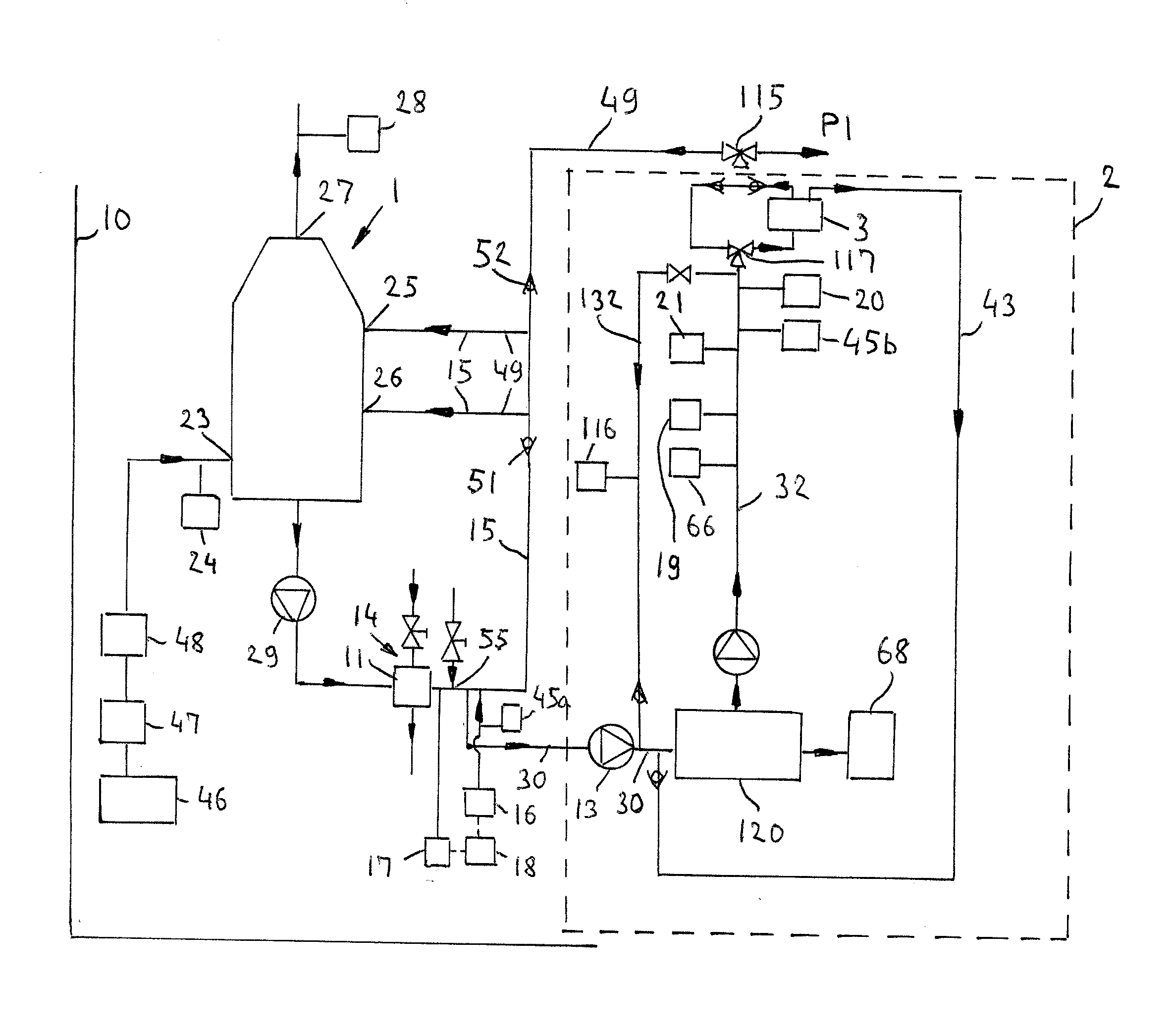

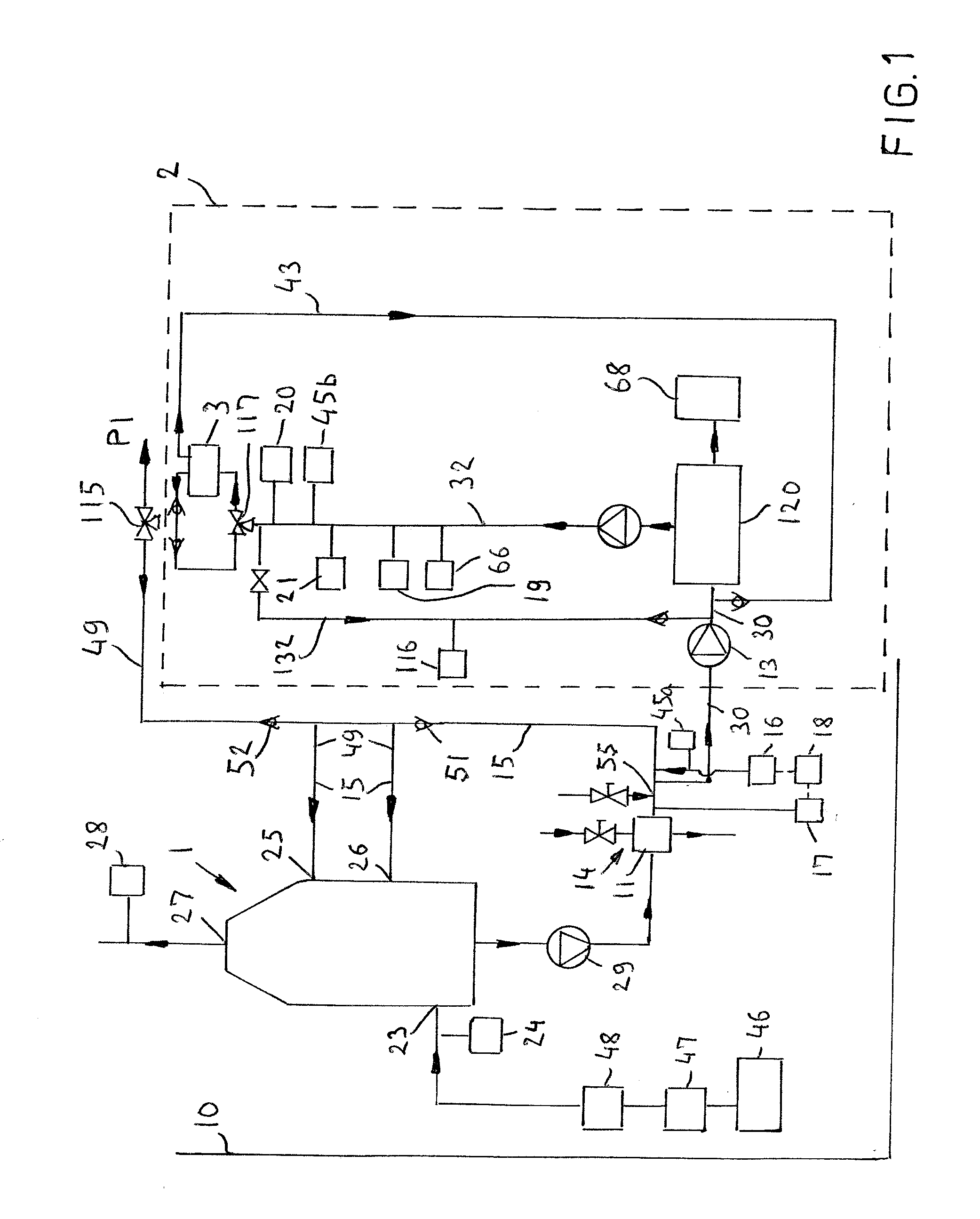

Method for treating impurities contained in exhaust gases of ships, ship with a scrubber, and purification unit

ActiveUS20150182905A1Small volumeEasy transferInternal combustion piston enginesUsing liquid separation agentWash waterBelt filter

A method for treating impurities contained in exhaust gases of ships to reduce sulphur oxide and other emissions, includes scrubbing the exhaust gases in an exhaust gas scrubber and supplying wash water effluent exiting from the scrubber and containing impurities to a purification unit onboard a ship. In order for the method to purify wash water exiting the scrubber sufficiently enough to be discharged directly to sea, the purification unit includes a moving filter band, whereby an aqueous fluid containing impurities originating from the effluent is together with a precipitating agent fed to a surface of the inclined filter band and filtered there through to concentrate impurities onto the surface of the band filter as a precipitate. When necessary, the pH of the purified effluent is adjusted so that it is at least 6.5 before discharging the purified effluent into the sea or returning it to the exhaust gas scrubber.

Owner:OY LANGH SHIP AB

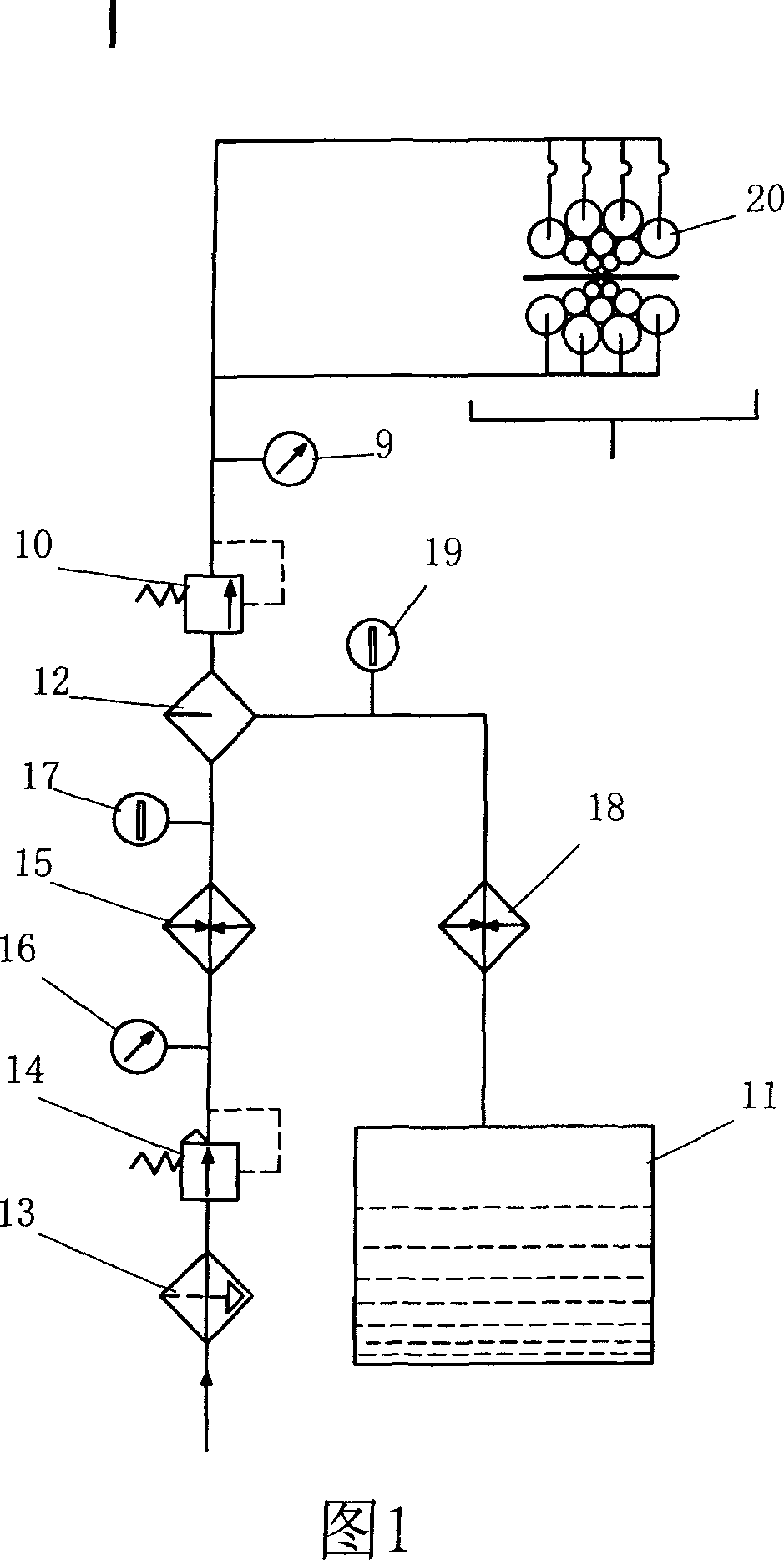

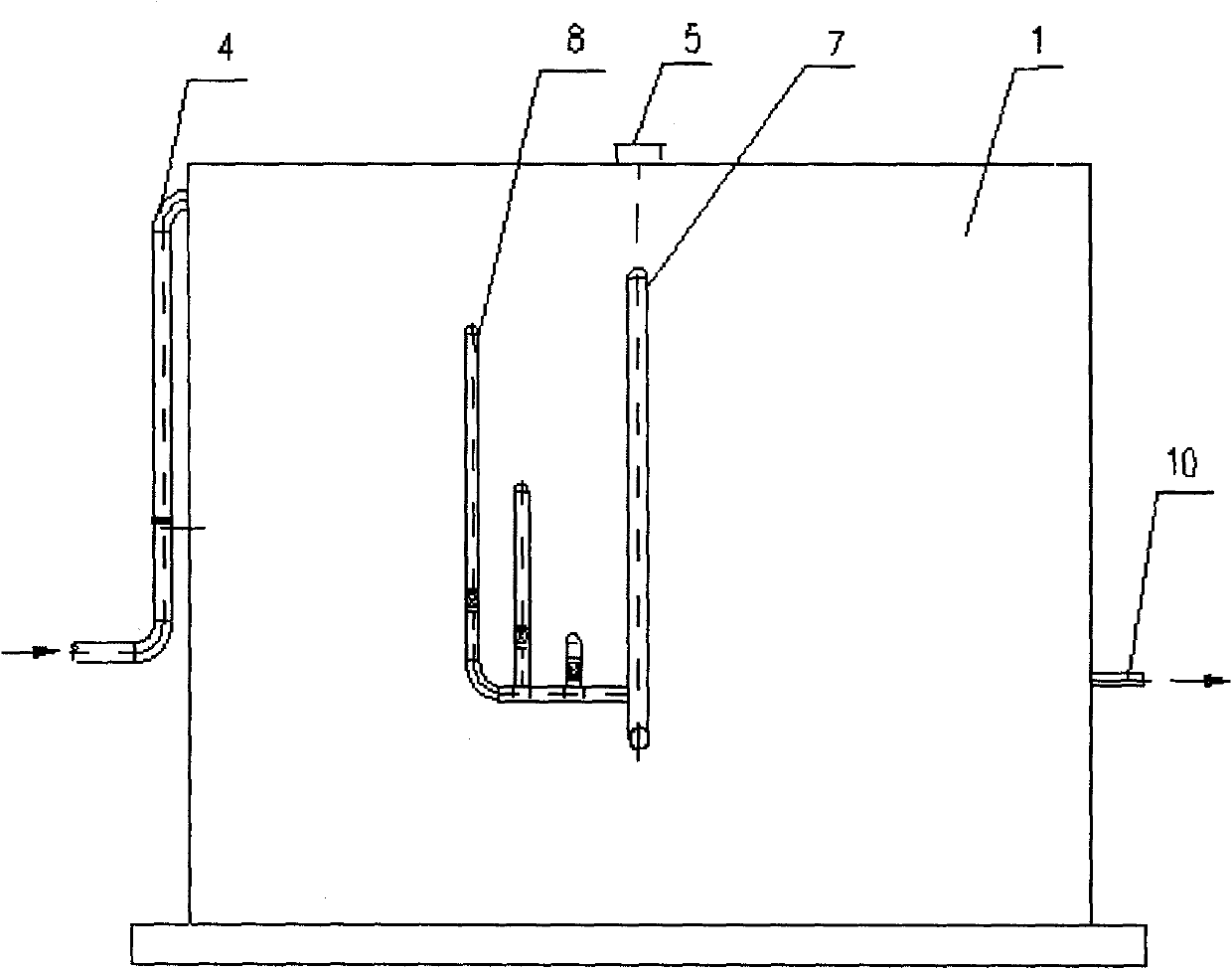

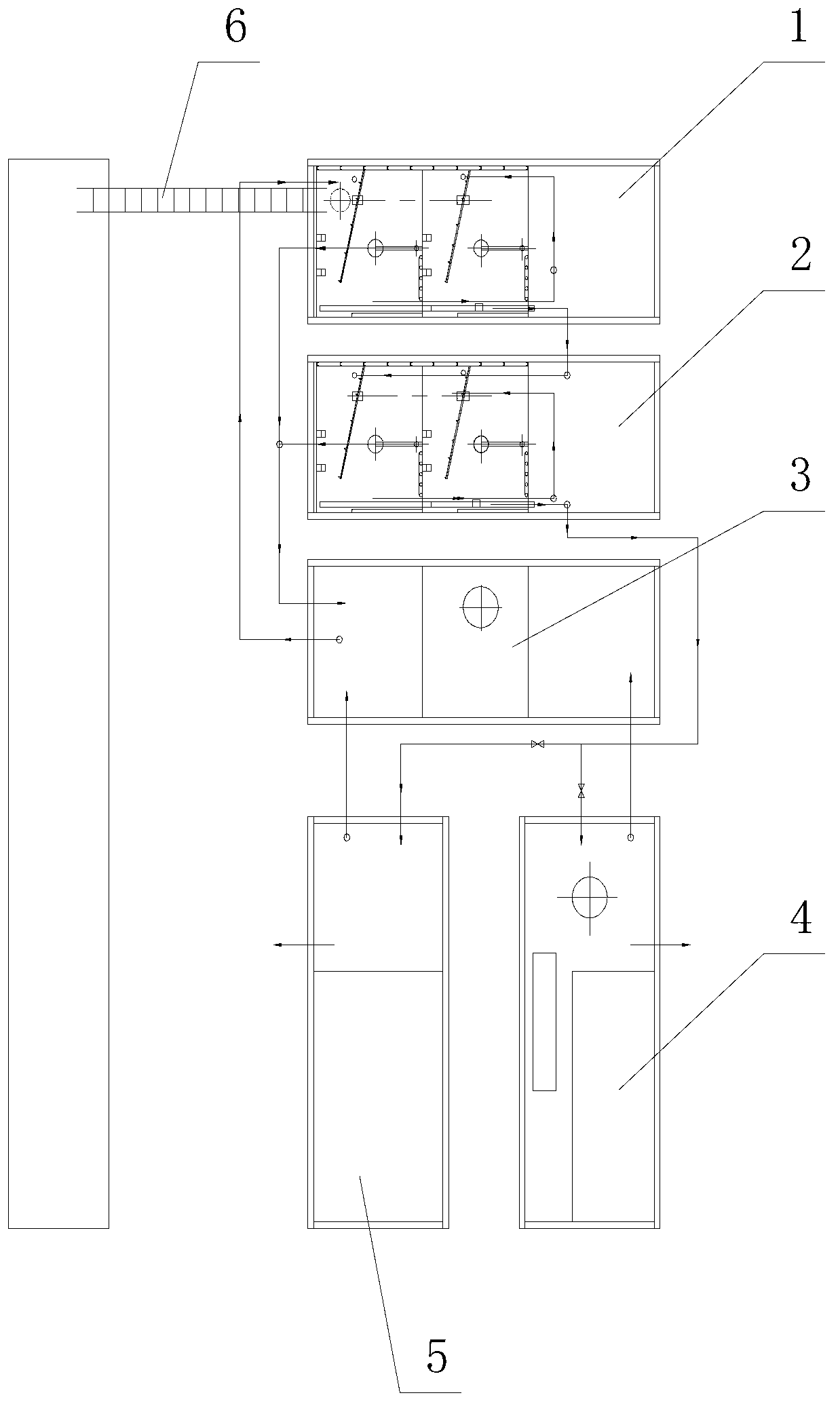

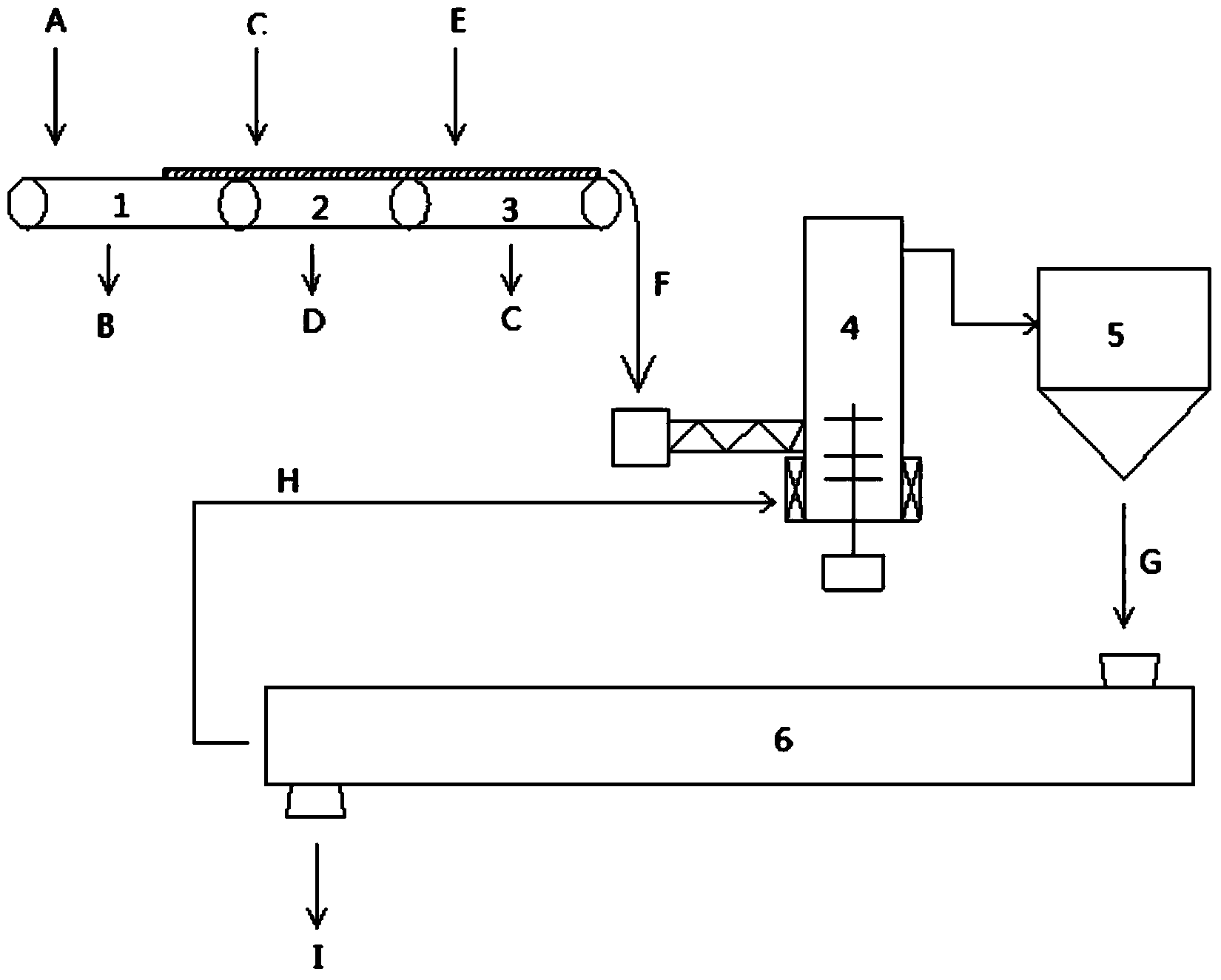

Portable oilfield oil sludge purifying treatment and recovery device and method

ActiveCN103159387ASolve pollutionSuitable for emergency treatmentSludge treatmentBelt filterOil sludge

The invention relates to a portable oilfield oil sludge purifying treatment and recovery device and method. The invention mainly solves the problems of large occupied area, high transportation cost and environment pollution in the existing oilfield oil sludge piled storage. The invention is characterized in that the device comprises a pretreatment tank (1), an advanced treatment tank (2), an oil water tank jimmy (3), a centrifugal machine (4) and a belt filter (5), wherein a first feed pipe (1-10) of the pretreatment tank (1) is connected with a hopper-type sludge lifter (6); the outlet of an oil collector (1-6) is connected with an oil tank in the oil water tank jimmy (3); a second discharge pipe (1-4) is connected with the advanced treatment tank (2); and the discharge port of the advanced treatment tank (2) is respectively connected with the centrifugal machine (4) and the belt filter (5) through pipelines. After the oil sludge is treated by the device and method, water can be recycled, silt can be covered on soil and returned to the field, and crude oil can be recovered, thereby thoroughly solving the problem of pollution caused by oilfield oil sludge.

Owner:珠海海啸生物科技有限公司

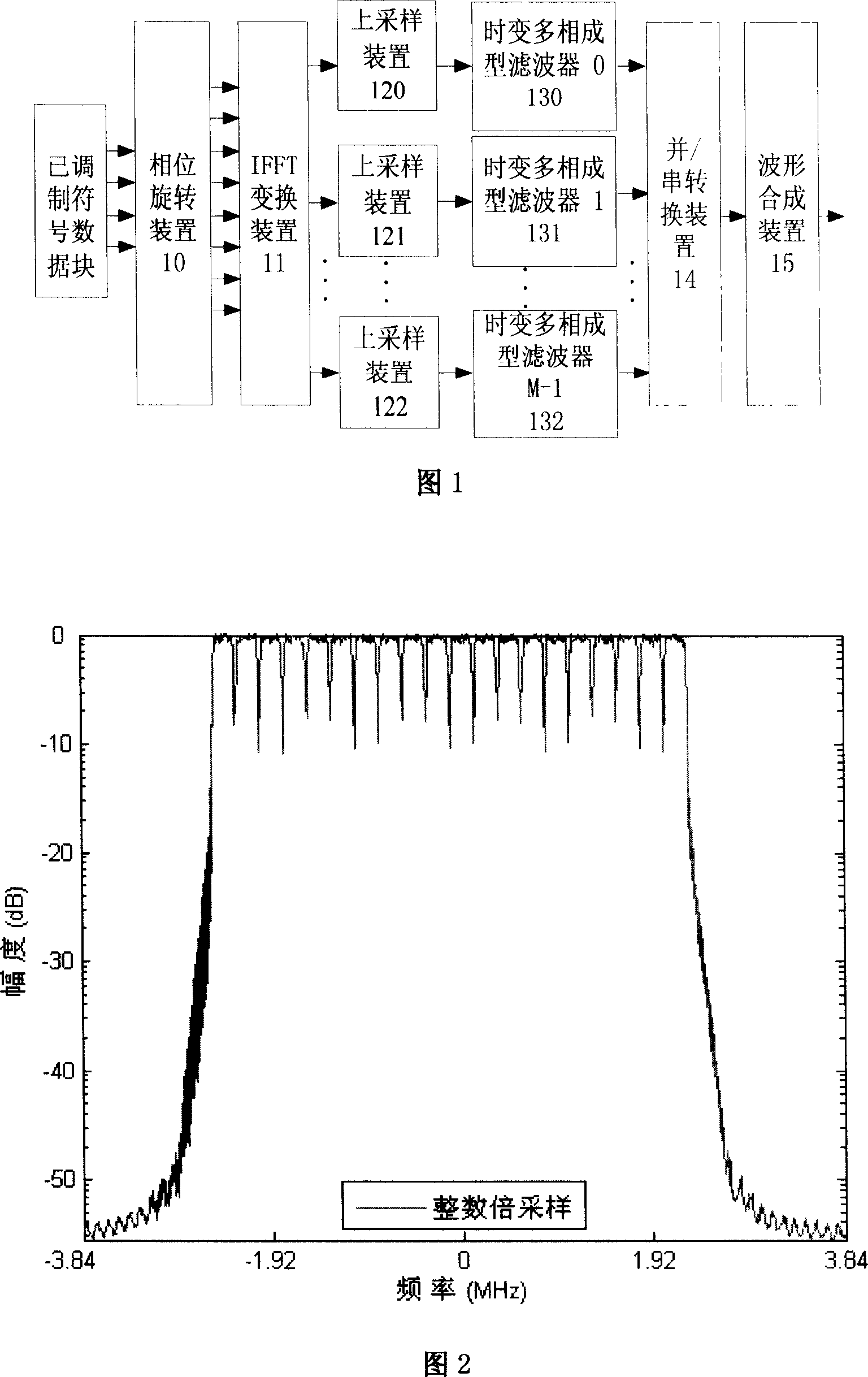

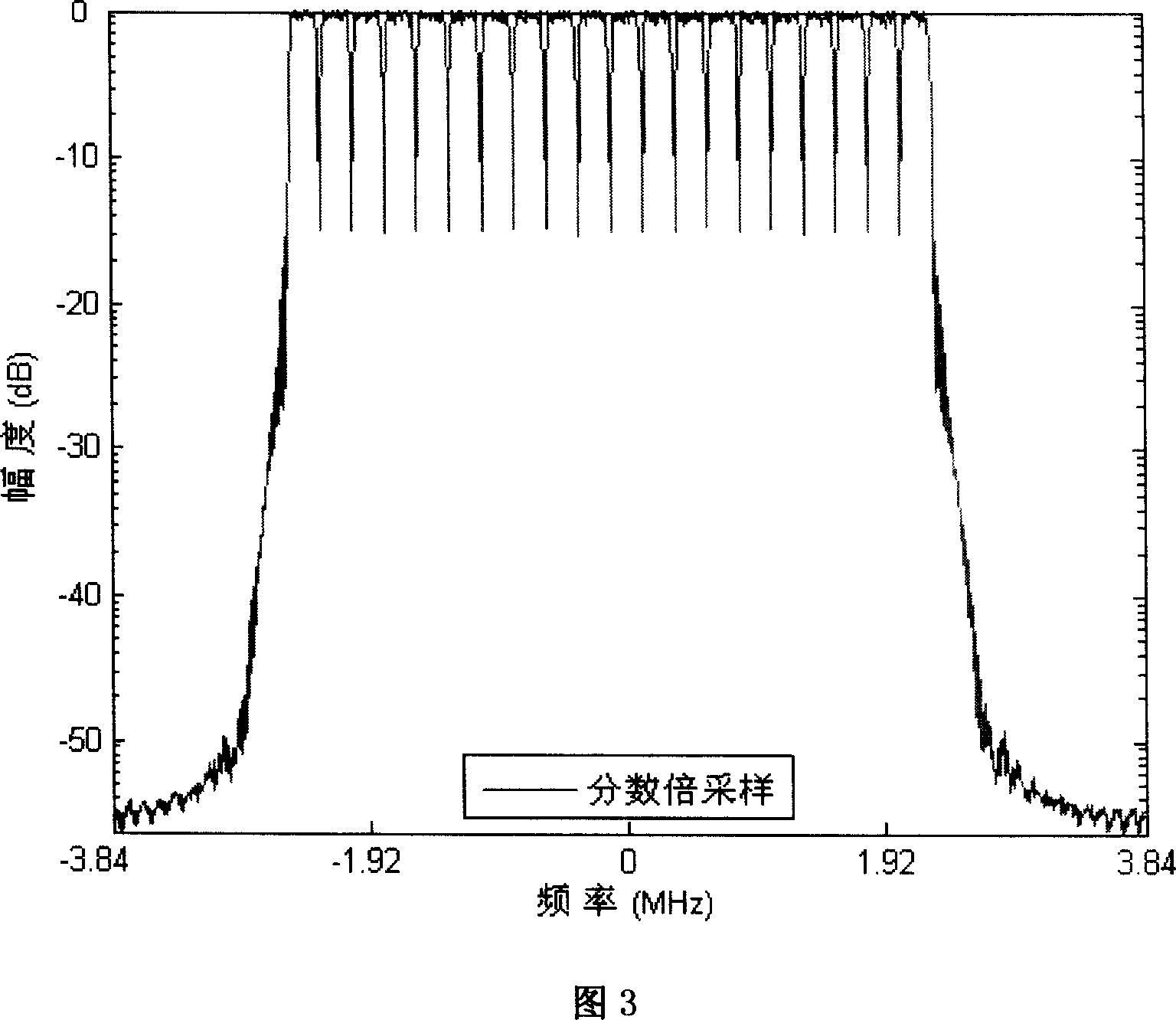

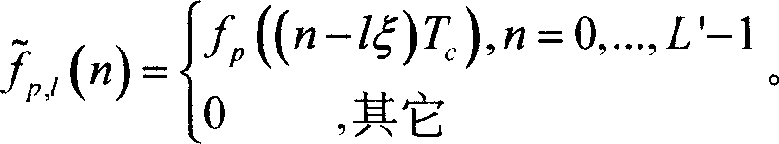

Fraction time sampling based filter group and filtering method

InactiveCN101083639AIncrease guard intervalReduce distractionsMulti-frequency code systemsTransmitter/receiver shaping networksTransport systemFilter bank

The invention supplies filter bank and filtering method based on fraction times sampling. For the M belt filter bank, adjusted symbol data block is processed time change phase rotation, M point IFFT change, R times upper sampling, time change poly-phase filtering, parallel serial convert, motion superpose, then output. The signal is discrete sampling sequence. The transmission system adopts fraction times sampling filter bank. The receiver frequency domain balanced size can be 2-th power. Thus frequency domain balance can adopt effective FFT operation to realize. Meanwhile, the receiver frequency domain balanced size is integral multiple of the sub-band sum M to ensure each sub-band frequency domain balanced point same.

Owner:SHANGHAI RES CENT FOR WIRELESS COMM

Post-treatment method for washing, drying and calcining SAPO (silicoaluminophosphate) molecular sieve

InactiveCN103723742ANo pollution in the processTake advantage ofMolecular sieve catalystsMolecular-sieve and base-exchange phosphatesCalcinationStock solution

The invention discloses a post-treatment process for washing, drying and calcining an SAPO (silicoaluminophosphate) molecular sieve. The process is characterized in that aiming at the production characteristics of an SAPO molecular sieve, a crystalized molecular sieve stock solution is filtered by a primary section of a belt filter, and is washed twice by secondary and tertiary sections of the belt filter, and is formed into a filter cake at the tail end of the belt filter; the filter cake is dried by using a spin flash drying device to form dried fine powder; and the dried fine powder is collected by a cloth envelope collector, and is calcined by using a rotary kiln to complete removing an organic amine template agent in a molecular sieve channel, so that the SAPO molecular sieve product with catalytic activity can be obtained. Meanwhile, high-temperature tail gas generated in calcination of the rotary kiln can be used as a heat source and returned to the spin flash drying device. The process has the characteristics of continuous operation, high automatic degree, sufficient utilization of high-temperature heat source, low comprehensive energy consumption, and no dust pollution because dust is operated in closed equipment or pipeline.

Owner:CHINA TIANCHEN ENG +1

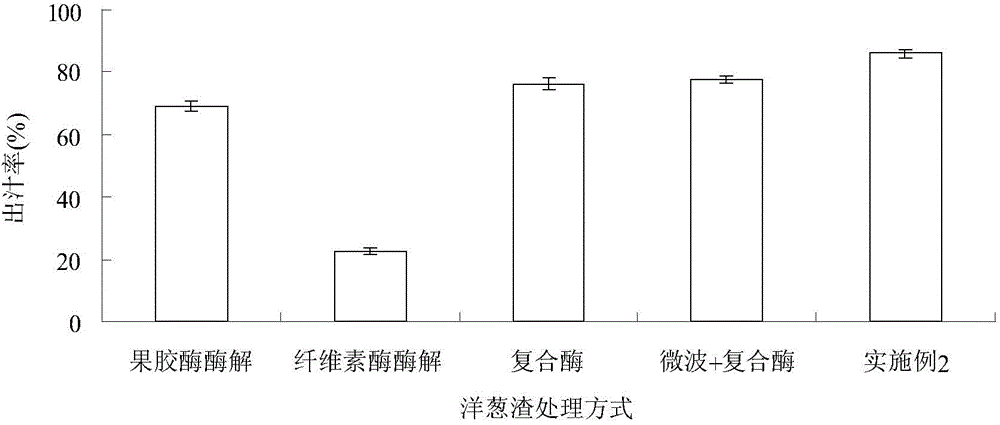

Method for processing onion juice by ultrasonic-assisted biological enzymolysis technology

InactiveCN103598545AIncrease the juice yieldImprove efficiencyFood preparationFlavorUltrasonic assisted

The invention relates to a method for processing onion juice by an ultrasonic-assisted biological enzymolysis technology. The method comprises the steps of crushing a raw material, carrying out filter pressing by using a belt filter press, separating the filtered juice at high speed, carrying out ultrasonic enzymolysis on filter residue, concentrating and sterilizing. According to the method, in the processing process, ultrasonic treatment and composite enzyme system enzymolysis are carried out on the filter residue, so that the processing rate is increased by 10-15%. The onion juice processed by the method is good in flavor and high in content of physiological activators, the emission of waste residue is reduced, and the production cost is greatly lowered.

Owner:海通食品徐州有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com