Vacuum belt type filter and dehydration machine

A vacuum belt filter and dehydrator technology, applied in the direction of filtration separation, mobile filter element filter, separation method, etc., can solve the problems of poor adaptability to different solid content rates, large contact area, large power consumption, etc., and achieve low water content efficiency, reduce friction, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

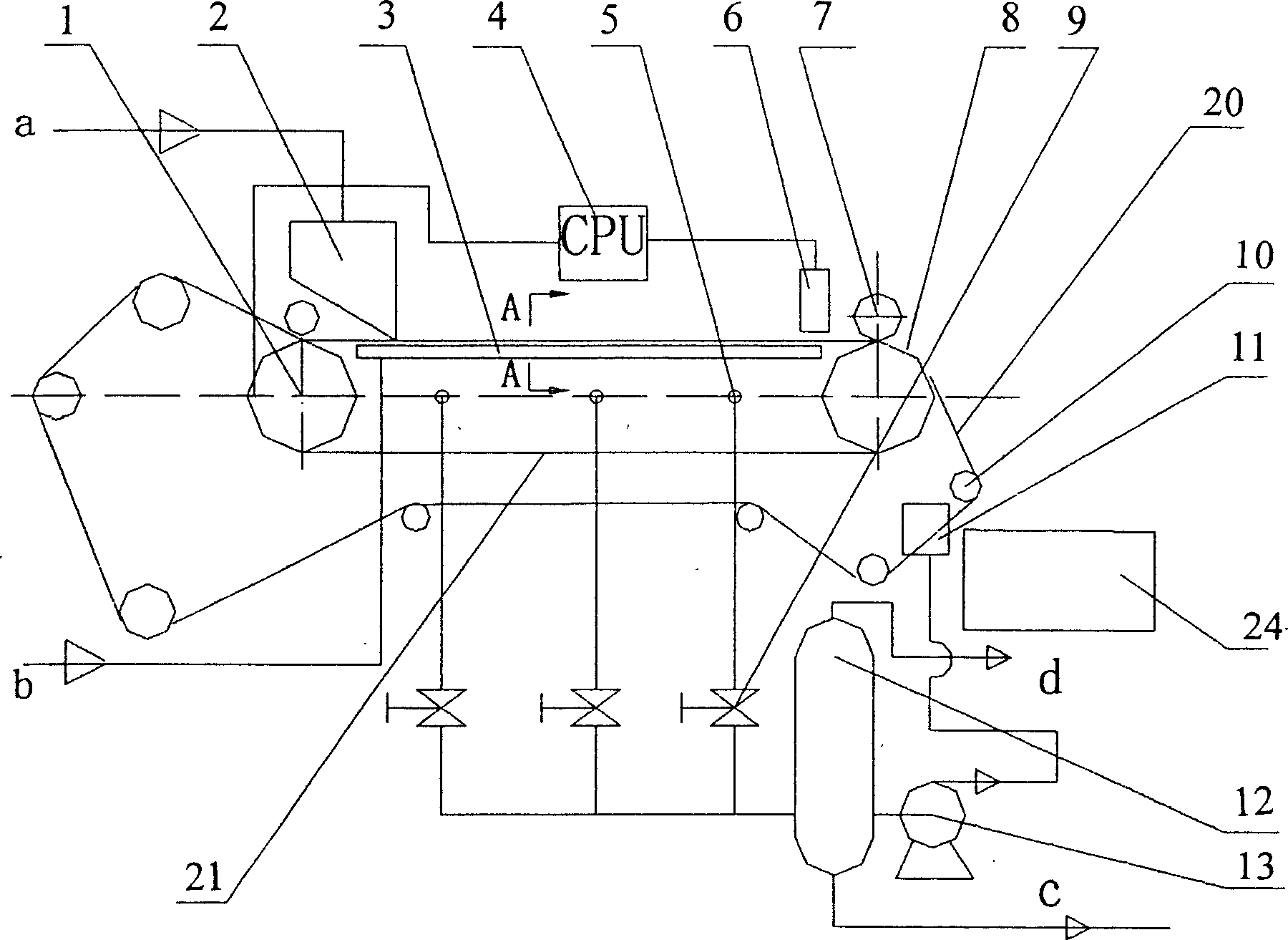

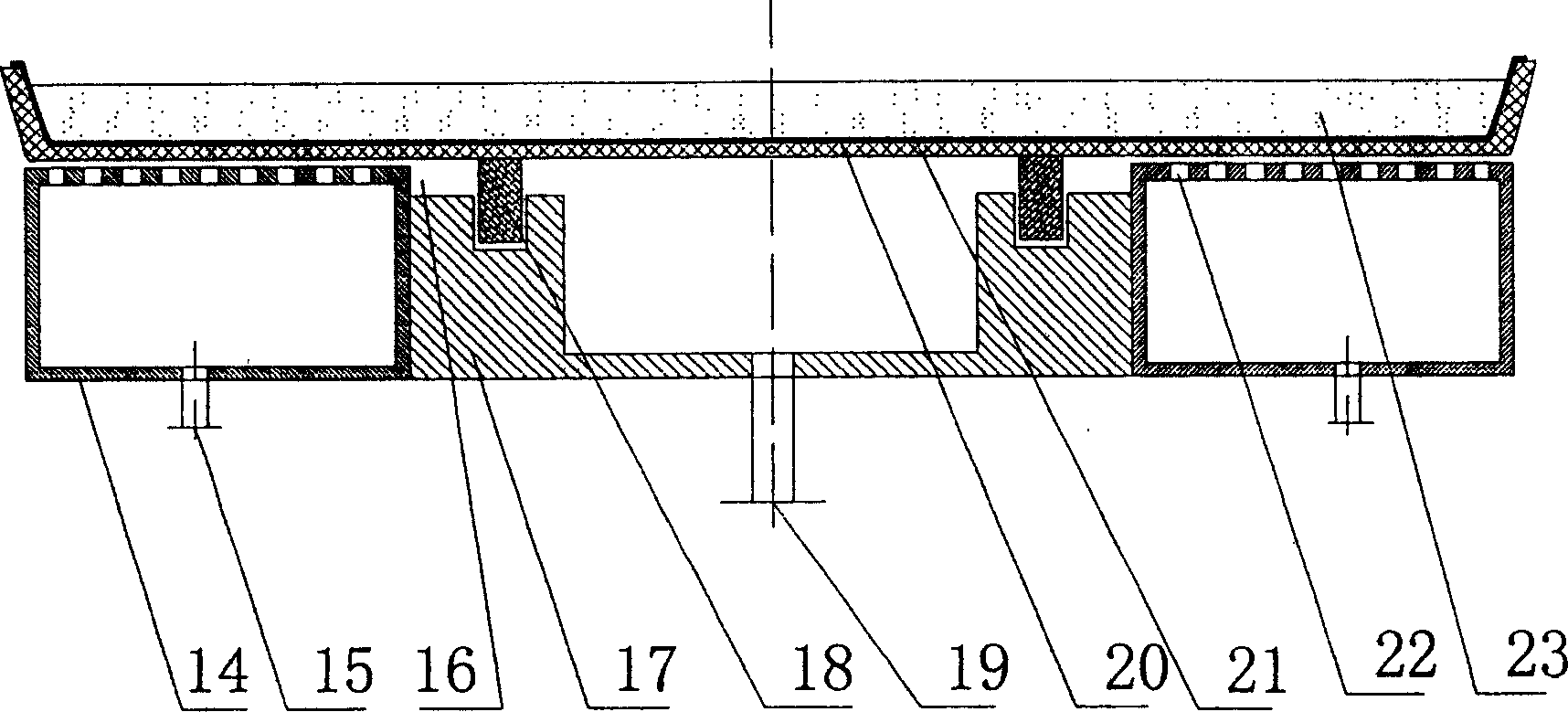

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

[0013] like figure 1 , figure 2 As shown, the present invention includes: the filter belt 20 is closely attached to the rubber belt 21 with corrugated grooves, the stock solution distributor 2 is installed above the filter belt 20, and 23 is the stock solution, and the filter belt is installed below the rubber belt 21 with corrugated grooves. The support system 3, the filter belt support system 3 is composed of a vacuum chamber 17 and a compressed air chamber 14 with a compressed air through hole 22 on the upper end. The two compressed air chambers 14 are respectively located on both sides of the vacuum chamber 17; the compressed air The inlet b is connected to the compressed air chamber 14 through the valve and the compressed air inlet 15, the steam-water separation tank 12 is connected to the vacuum chamber 17 through another valve 9 and the vacuum suction pipe 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com