Patents

Literature

30results about How to "Not easy to run" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

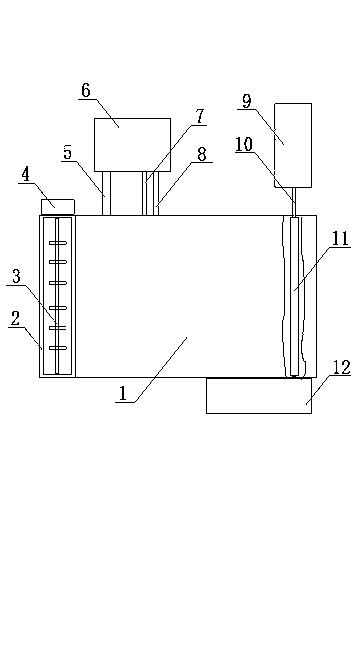

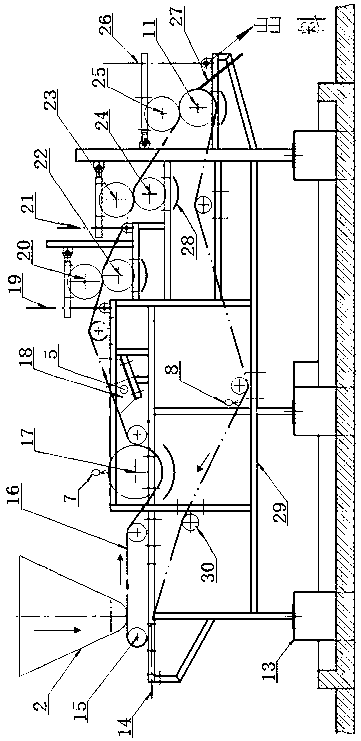

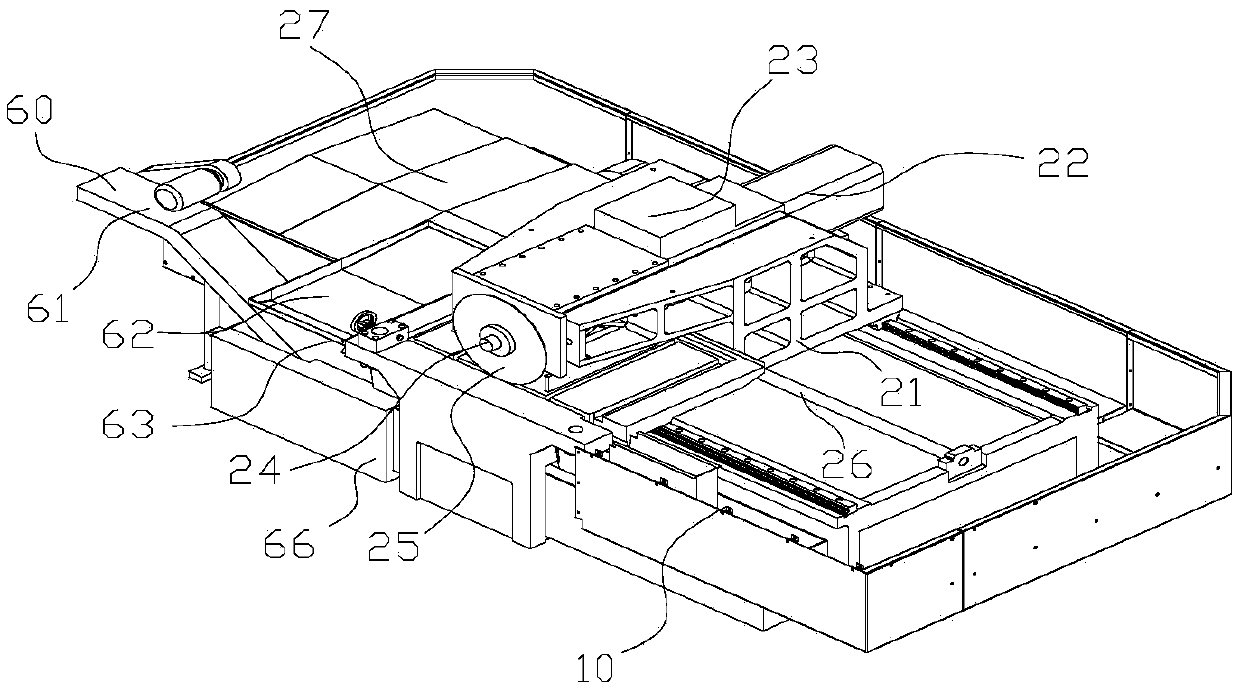

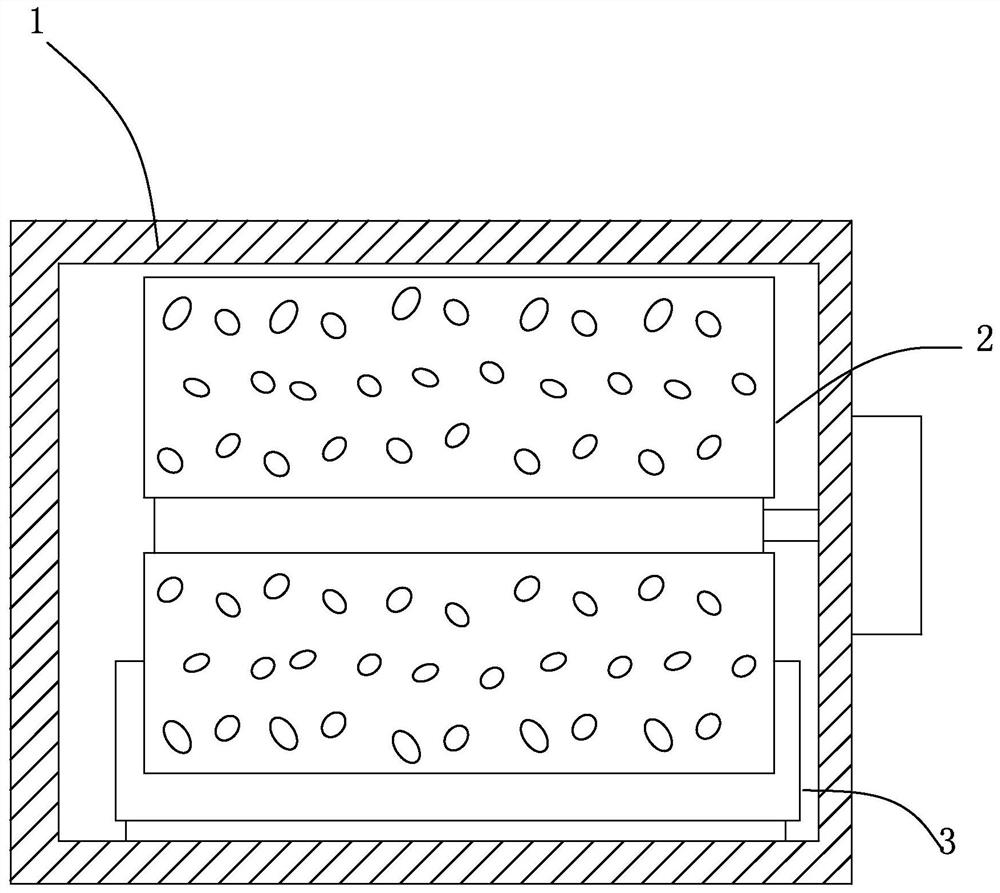

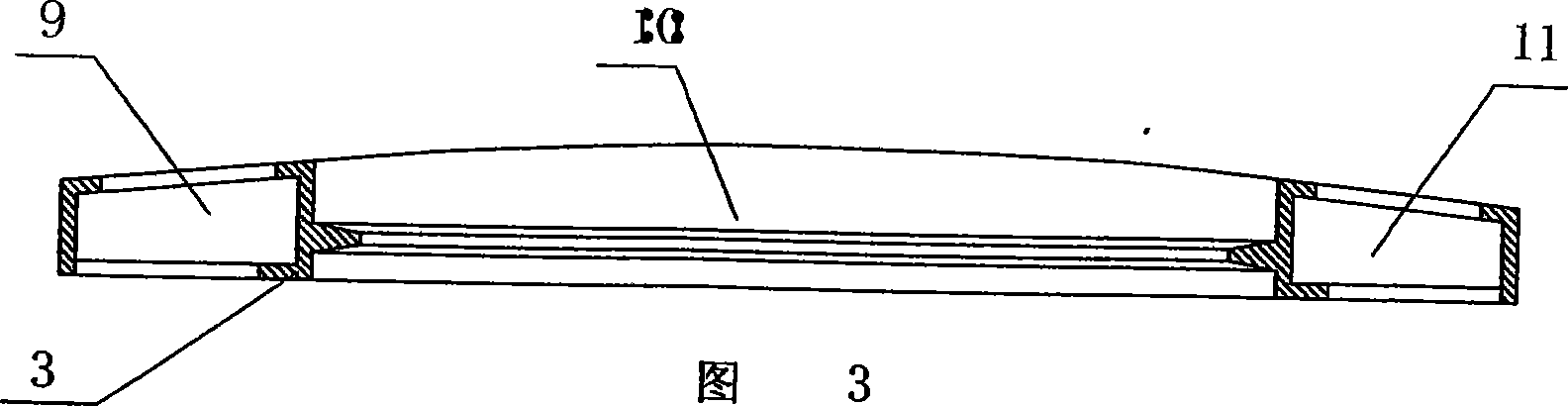

High-efficiency energy-saving belt filter press

InactiveCN103007614ANot easy to runSolve slipperyChemical industryMoving filtering element filtersChemical industrySlag

The invention discloses a high-efficiency energy-saving belt filter press which comprises a frame, a filter press belt, a hopper and a motor, and is characterized in that a material equalizing regulation device is arranged at a discharging end of the frame; the filter press belt is a double-layer filter cloth belt; a four-stage press filtering mechanism is arranged on the discharged filter press belt at intervals; a vacuum suction filtration disc for vacuumizing by utilizing a vacuum pump is arranged below the filter press belt behind a mesh cage roller; a tail gas cleaning mesh-cleaning roller and a filter press belt gas ejector pipe are respectively arranged on the mesh cage roller and on a belt return part of the filter press belt. The machine is uniform in feeding, long in service life, stable in performance, good in dewatering effect and high in yield, and the filter belt is difficult to block; the slag adhered to the mesh cage roller and the filter press belt is subjected to air injection cleaning by utilizing the vacuum pump tail gas, and water and electric energy are saved; and the machine is suitable for squeezing and dewatering manioc waste, cassava residues, bean dregs and distillers grains and water-containing raw materials in the industries such as municipal sludge, chemical industry, oil refining, papermaking and sugar refining.

Owner:陆汉克

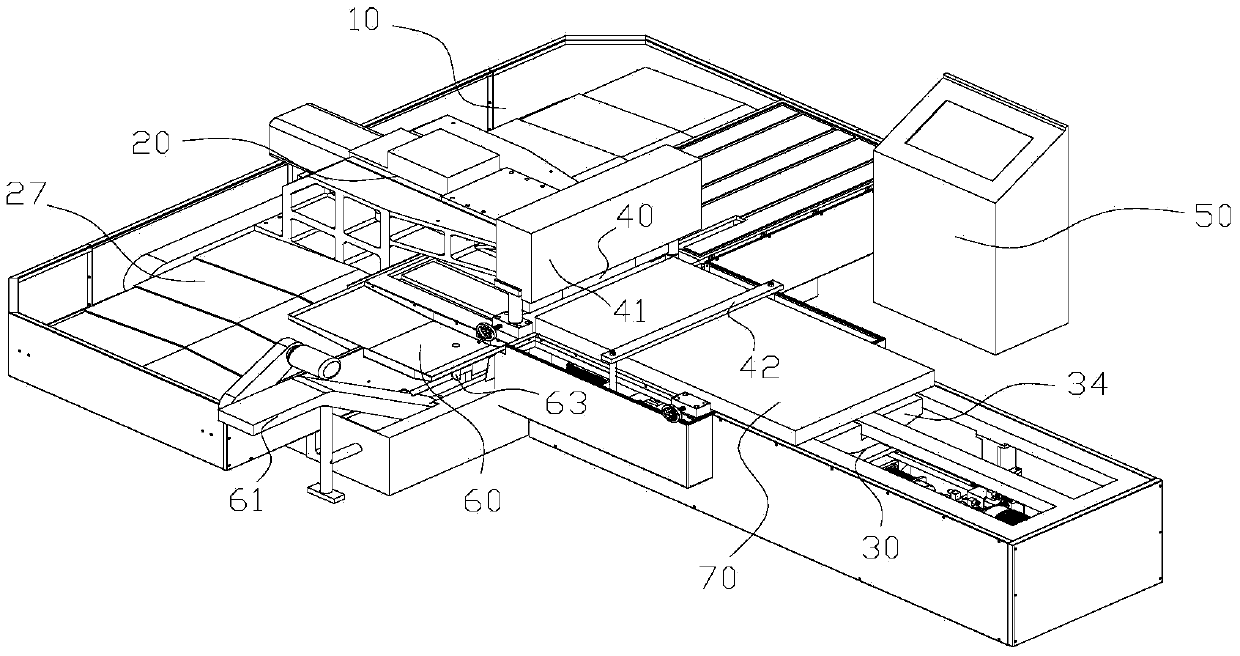

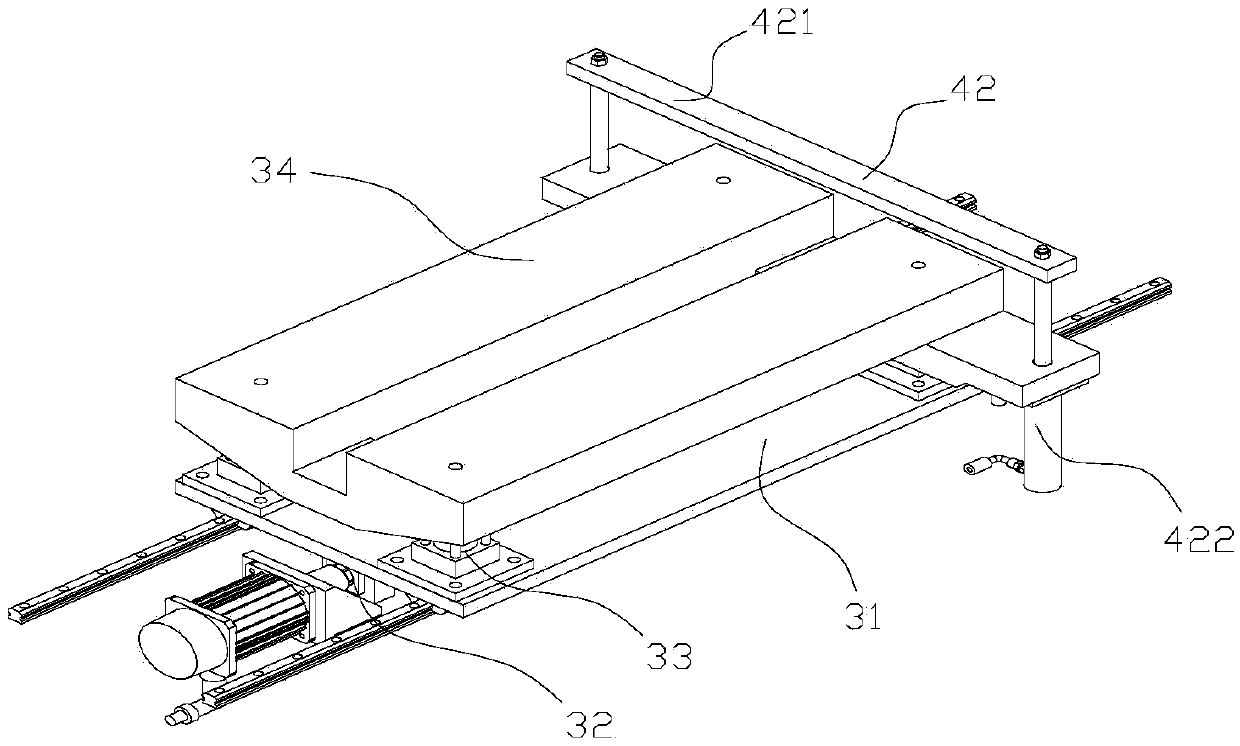

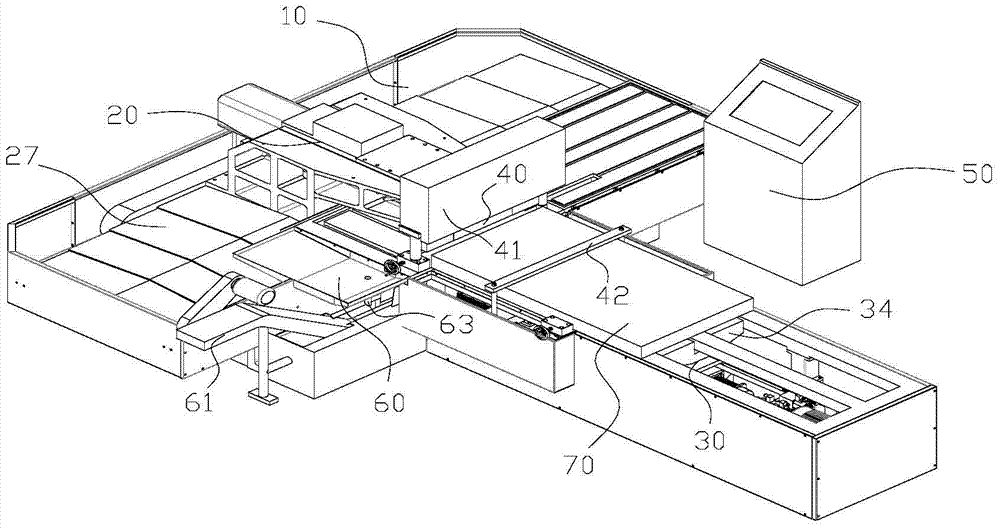

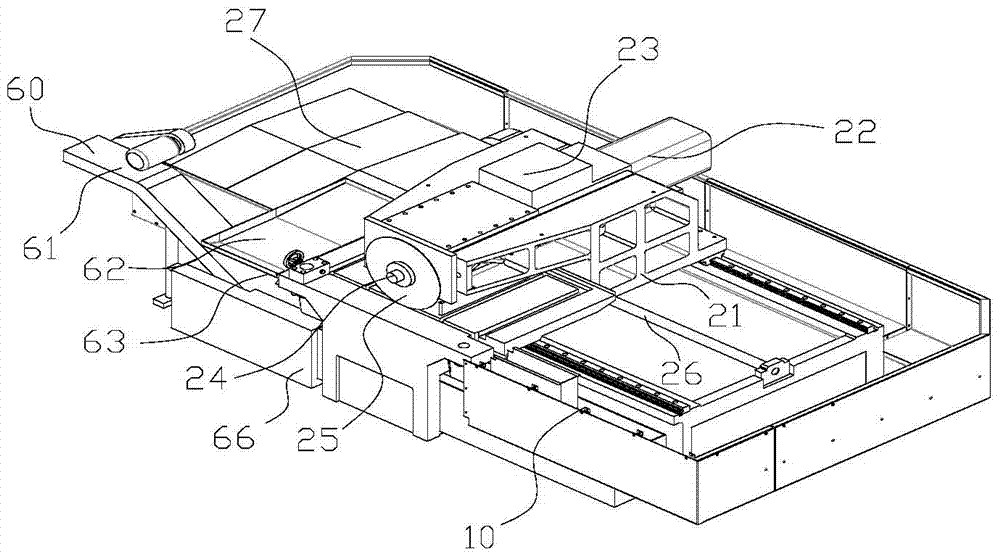

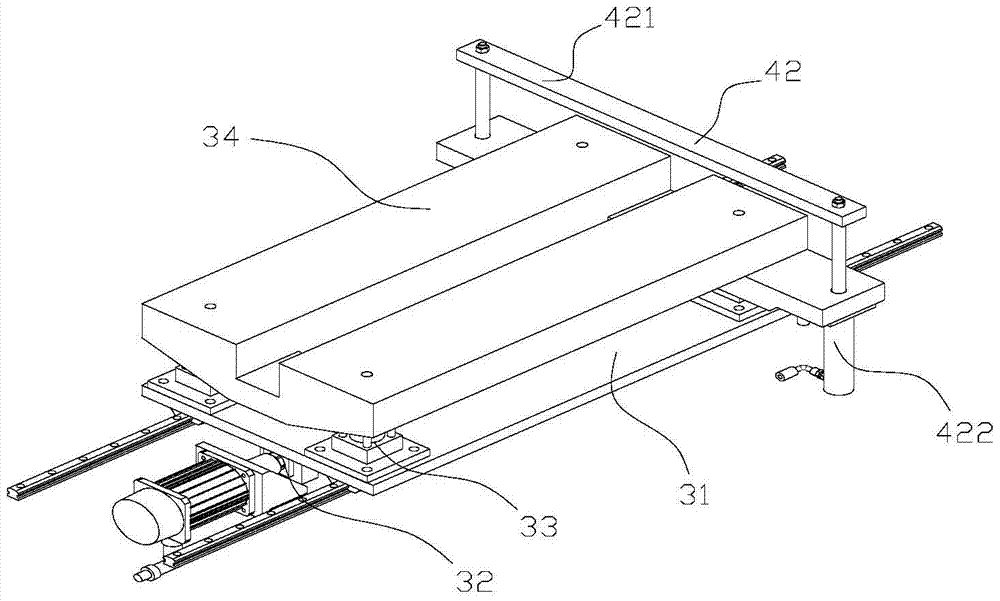

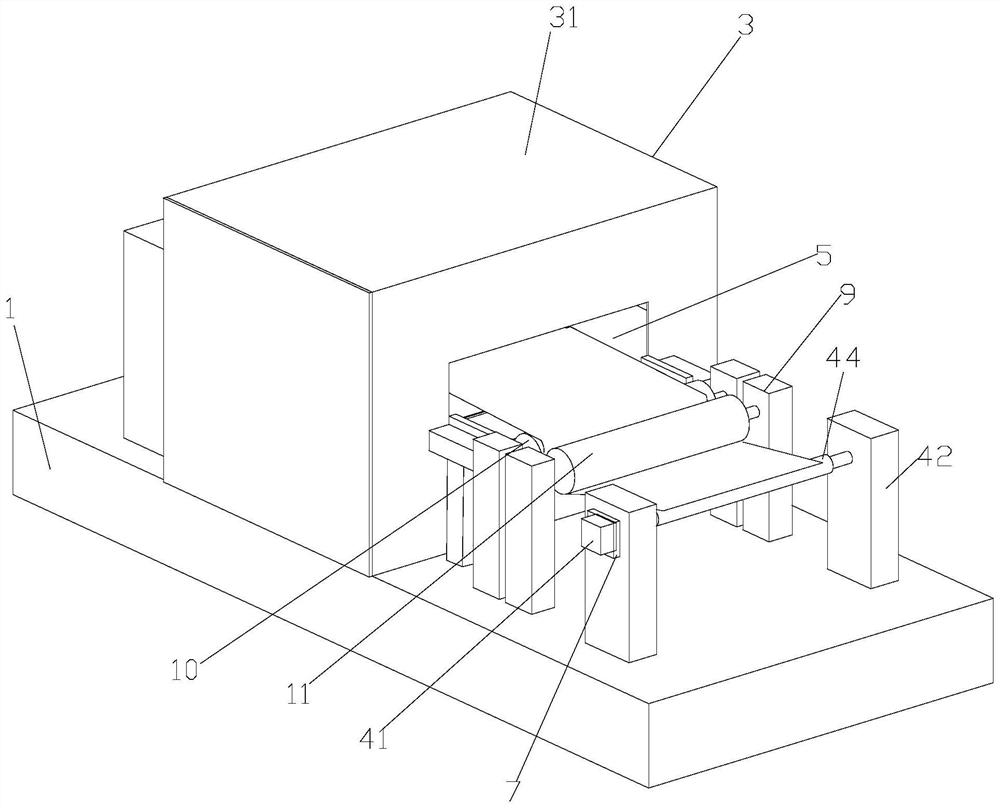

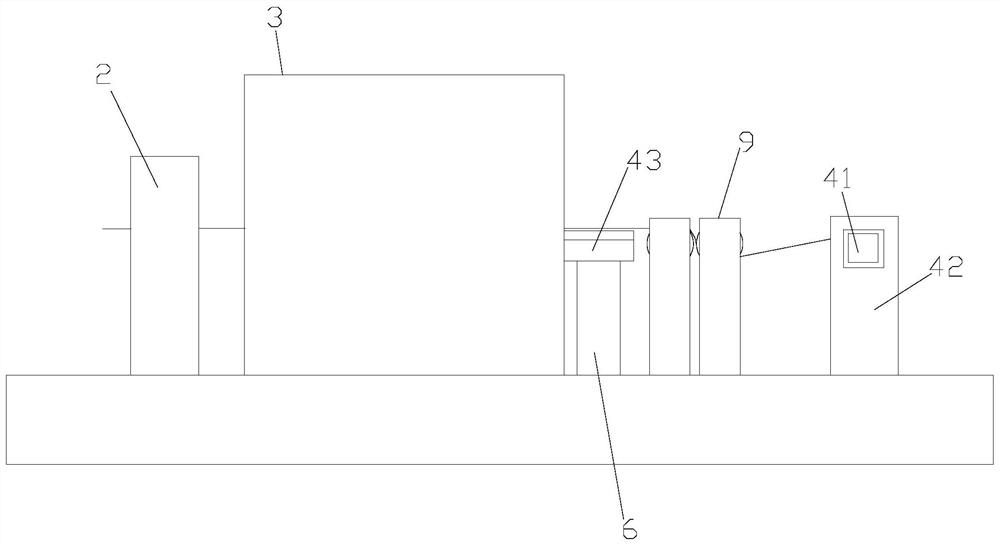

Circular sawing machine for steel plate cutting

ActiveCN105364174AHigh degree of automationImprove processing efficiencyMetal sawing devicesMetal sawing accessoriesSheet steelControl system

The invention discloses a circular sawing machine for steel plate cutting. The circular sawing machine for steel plate cutting comprises a rack, a cutting device, a moving assembly, a pressing assembly and a control system, wherein the cutting device is mounted on the rack, and the moving assembly is used for conveying a workpiece. The moving assembly comprises a moving plate, a screw rod component, a telescopic component and a supporting plate, wherein the screw rod component is mounted on one side of the moving plate, the telescopic component is mounted on the other side of the moving plate, and the supporting plate is fixedly connected to an output shaft of the telescopic component. The pressing assembly comprises a main pressing component and an auxiliary pressing component. The main pressing component is pressed on the rack and faces the cutting device, and the auxiliary pressing component is mounted on the supporting plate. The workpiece is placed on the supporting plate. The control system controls the screw rod component to drive the moving plate to move and enables the pressing assembly to press the workpiece. The workpiece is cut by the cutting device. The circular sawing machine for steel plate cutting has the characteristics of being high in cutting efficiency and cutting precision.

Owner:江苏宁兴恒力智能设备有限公司

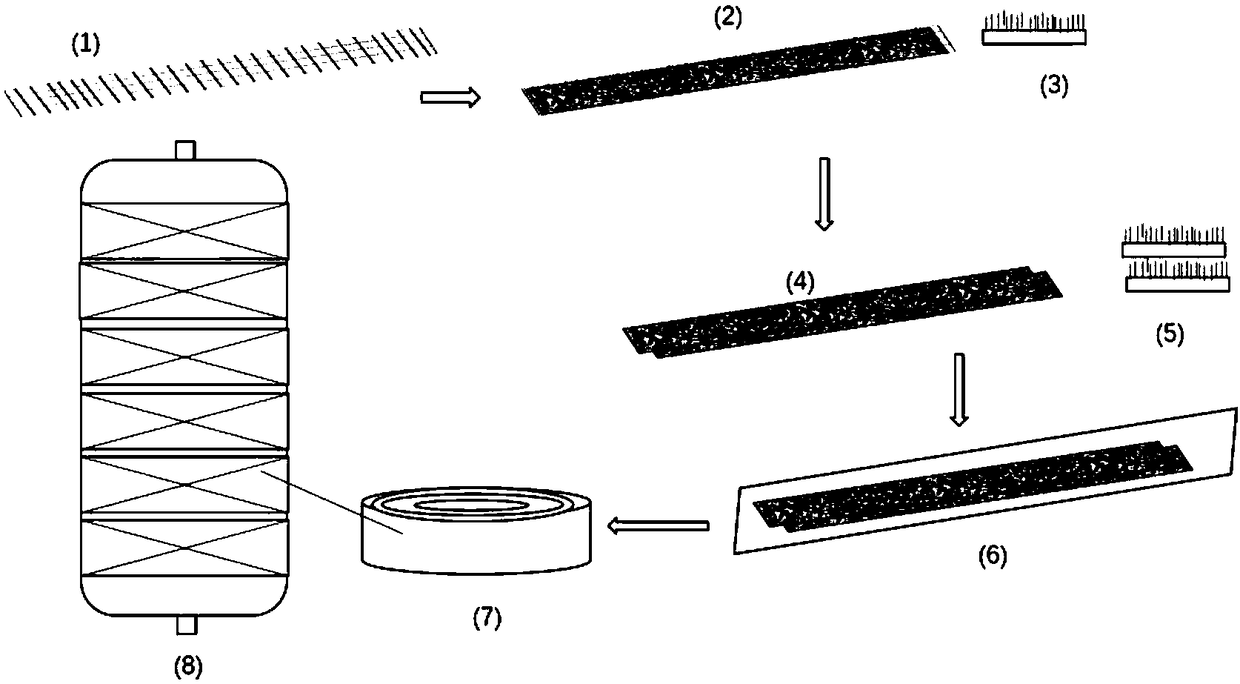

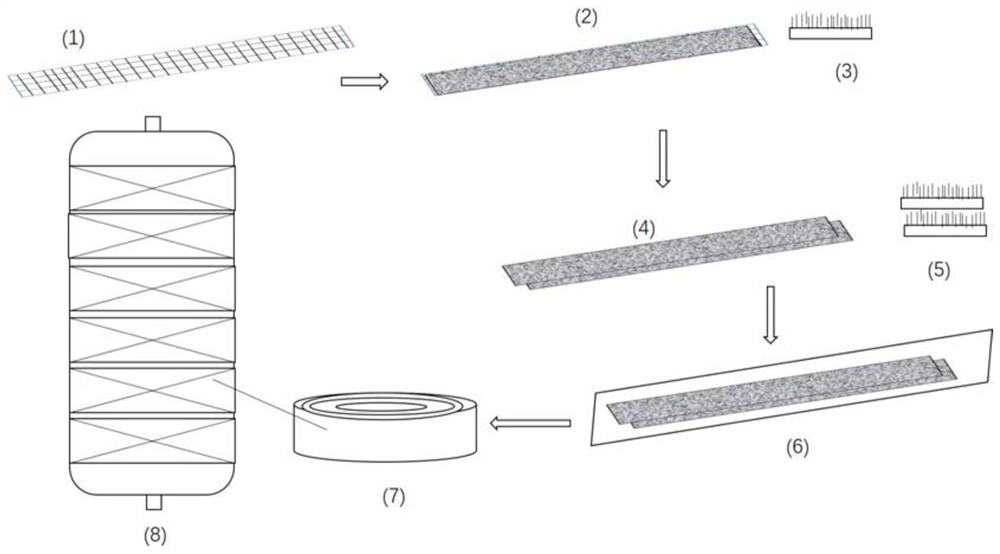

Carbon nannotube adsorption component as well as preparation method and application of carbon nannotube adsorption component

ActiveCN108262013AEasy to replaceLow costCarbon compoundsOther chemical processesDiameter ratioWastewater

The invention discloses a carbon nannotube adsorption component as well as a preparation method and application of the carbon nannotube adsorption component. Carbon nanotubes of the carbon nannotube adsorption component grow at one side of each metal wire mesh belt, a strip-shaped structure is formed at the side by arranging the sides, not provided with carbon, of the metal wire mesh belts at intervals; upper and lower outer layers of the strip-shaped structure are packaged by using filter cloth, and the whole strip-shaped structure is strip-shaped and can be wound; when being wound to form acylindrical structure, the strip-shaped structure has the height-to-diameter ratio of 1:1 to 1:5; and a carbon nannotube adsorption device applying the carbon nannotube adsorption component is internally filled with the carbon nannotube adsorption component, the void ratio of a bed layer of the component is 70-95%, and no gas or liquid distribution devices are arranged in the device. The inventionfurther discloses a preparation method of the carbon nannotube adsorption component and a mounting method of the carbon nannotube adsorption device; it is not needed that the carbon nannotube adsorption device is additionally provided with an independent gas or liquid distribution device, and the carbon nannotube adsorption device can be used for adsorbing and rapidly desorbing organic matters inwastewater or gases; and the carbon nannotube adsorption component has the advantages such as firm structure, long service life, high throughput, low preparation cost and low treatment energy consumption.

Owner:TSINGHUA UNIV

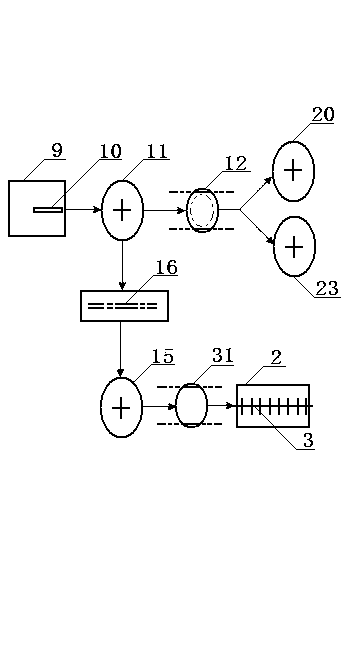

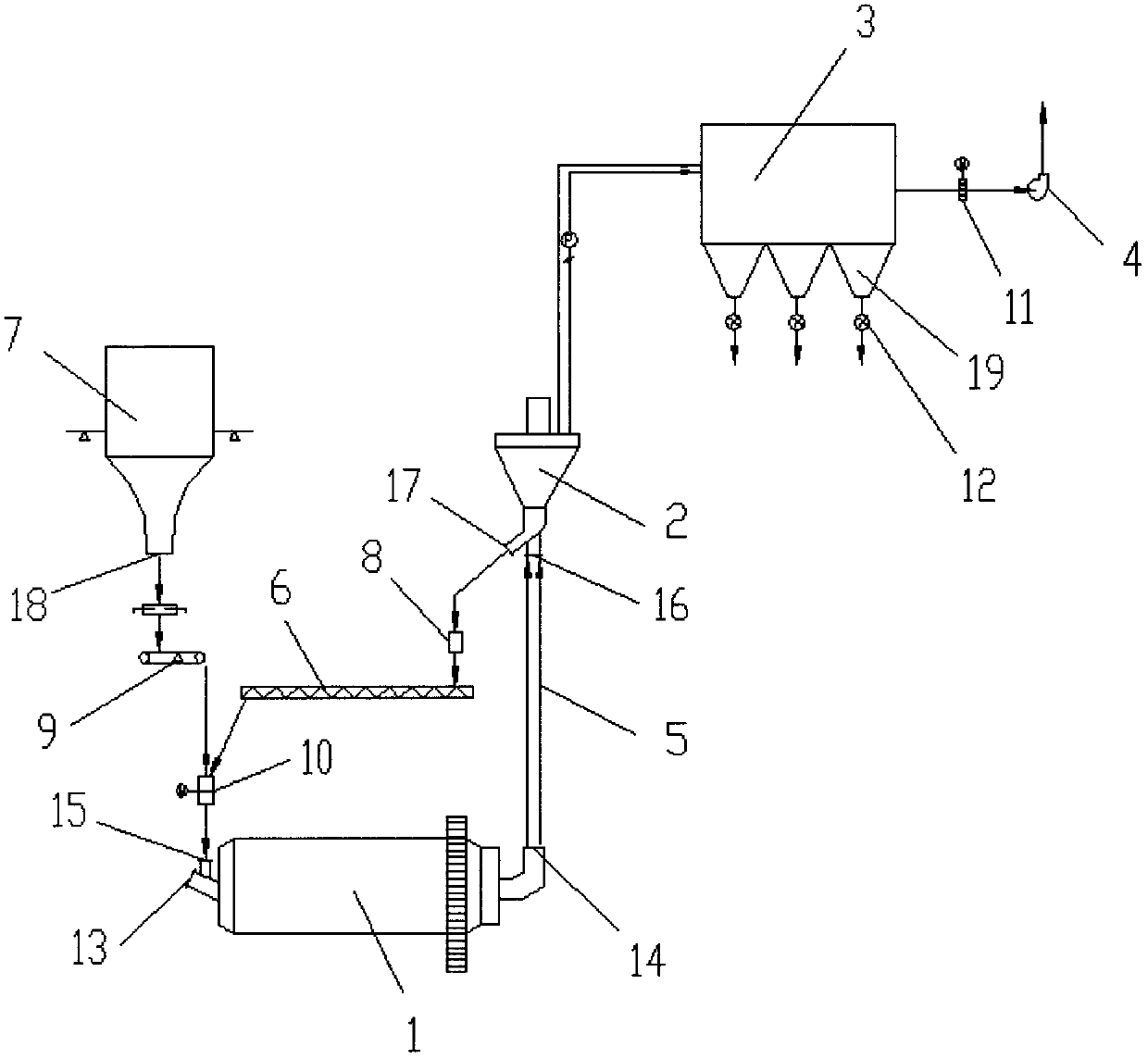

Negative pressure type ball mill coal grinding and powdering powder grinding system

The invention discloses a negative pressure type ball mill coal grinding and powdering powder grinding system. The negative pressure type ball mill coal grinding and powdering powder grinding system comprises a ball mill, a powder selecting machine, a bag type dust collector and a centrifugal draught fan; the ball mill is used for grinding raw coal materials; the ball mill is provided with an airinlet and an air outlet; the powder selecting machine screens ground coal powder; fine coal powder conforming to fineness is fed to the bag type dust collector; rough coal powder without conforming tofineness is fed back to the ball mill; the powder selecting machine is provided with an air sucking pipeline which is connected with the air outlet of the ball mill; the bag type dust collector is used for collecting fine powder fed in from the powder selecting machine; an air inlet of the centrifugal draught fan is connected with an air outlet of the bag type dust collector; and the ball mill, the power selecting machine and the dust collector are connected in series and form a closed negative pressure sucking system under the air draft effect of the centrifugal draught fan from inside to outside. Compared with the prior art, the negative pressure type ball mill coal grinding and powdering powder grinding system does not diffuse dust to the outside, it is avoided that dust-containing airflow runs to the outside, and using is more environment-friendly.

Owner:佛山市锠联重工科技有限公司

Carbon nanomaterial macro body, preparing method and particle adsorption filter properties

ActiveCN106582520AReduce consumptionLow costOther chemical processesWater contaminantsMacroscopic scaleParticle adsorption

The invention discloses a carbon nanomaterial macro body. The carbon nanomaterial macro body is characterized in that the macro body has three structures of a definite porous shell, an inner wall and an inside. The material of the porous shell is any one of carbon fiber, ceramic and metal. The inner wall of the macro body (namely the inner surface of the porous shell) has a carbon nanomaterial. The inside of the macro body is filled with the carbon nanomaterial. The porosity of the macro body reaches 60%-97%, and the ratio of the height to the diameter of the macro body is 0.001-1000. The invention further discloses a method for utilizing a chemical vapor deposition method to prepare the macro body. The macro body can be used for adsorbing organic matters in wastewater and filter particles or the organic matters in gases, and has the advantages of being long in service life, big in handling capacity and low in preparing cost.

Owner:TSINGHUA UNIV

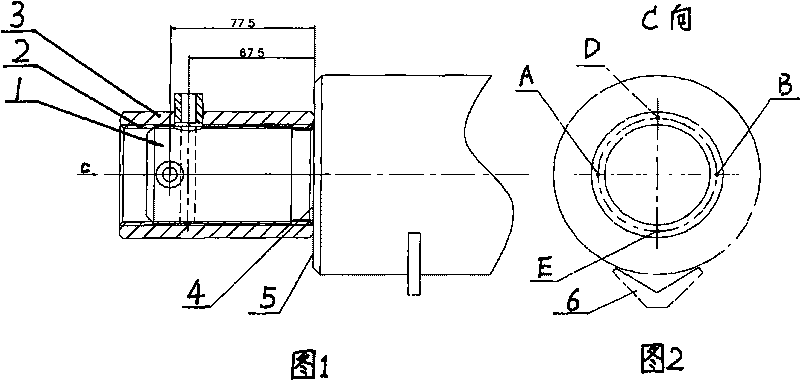

Method for fast and correctly drilling decussation hole of center pin

The invention discloses a method for fast and correctly drilling a decussation hole of a center pin, which is characterized in that a drill jig is firstly screwed on threads of the center pin, a drill sleeve is sleeved on the drill jig, and the end surface of the drill sleeve is tightly adhered to the step surface of the center pin; a cross line is scribed on the end surface of the drill jig, the center pin is rotated on a V-shaped iron, a scribing block is used for leveling, a work piece is clamped, and the hole is drilled; the center pin is rotated for 90 degrees on the V-shaped iron, the scribing block is used for leveling again, the work piece is clamped, and another hole is drilled. In the invention, because the hole is drilled on the drill sleeve and leveling is carried out by scribing the cross line and a drill bit is not easy to deviate, the accuracy of a part can be ensured and the production efficiency can also be enhanced.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

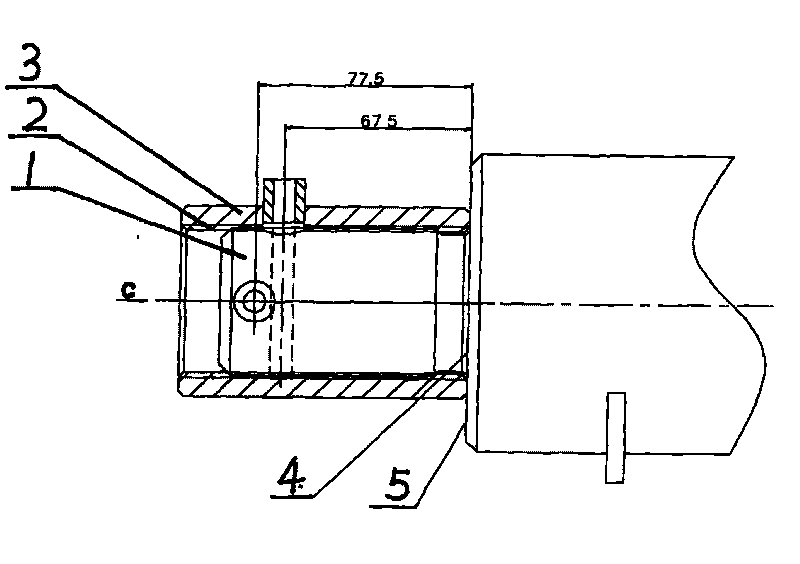

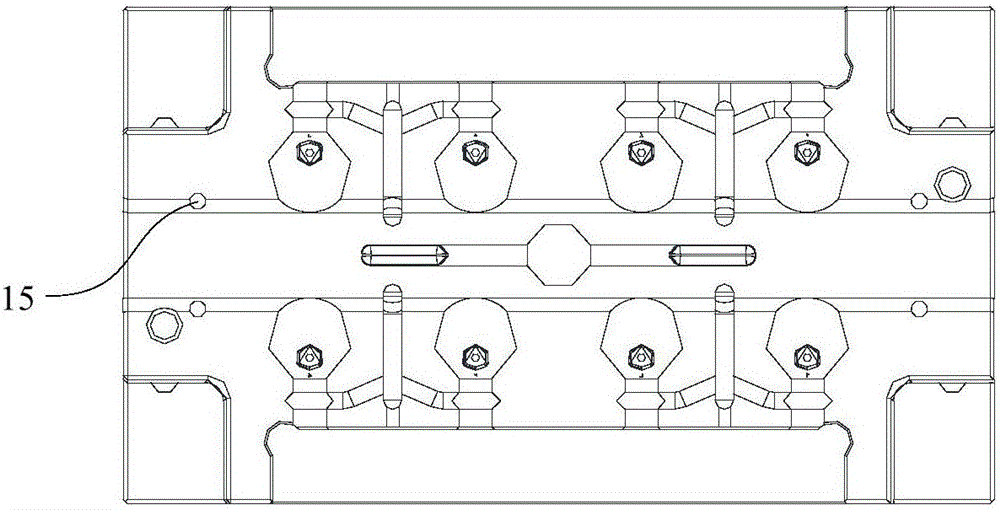

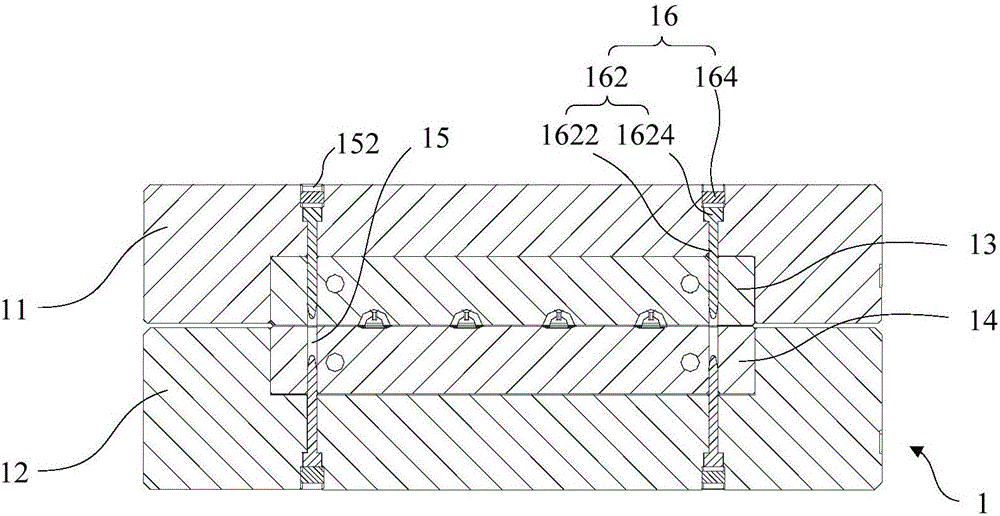

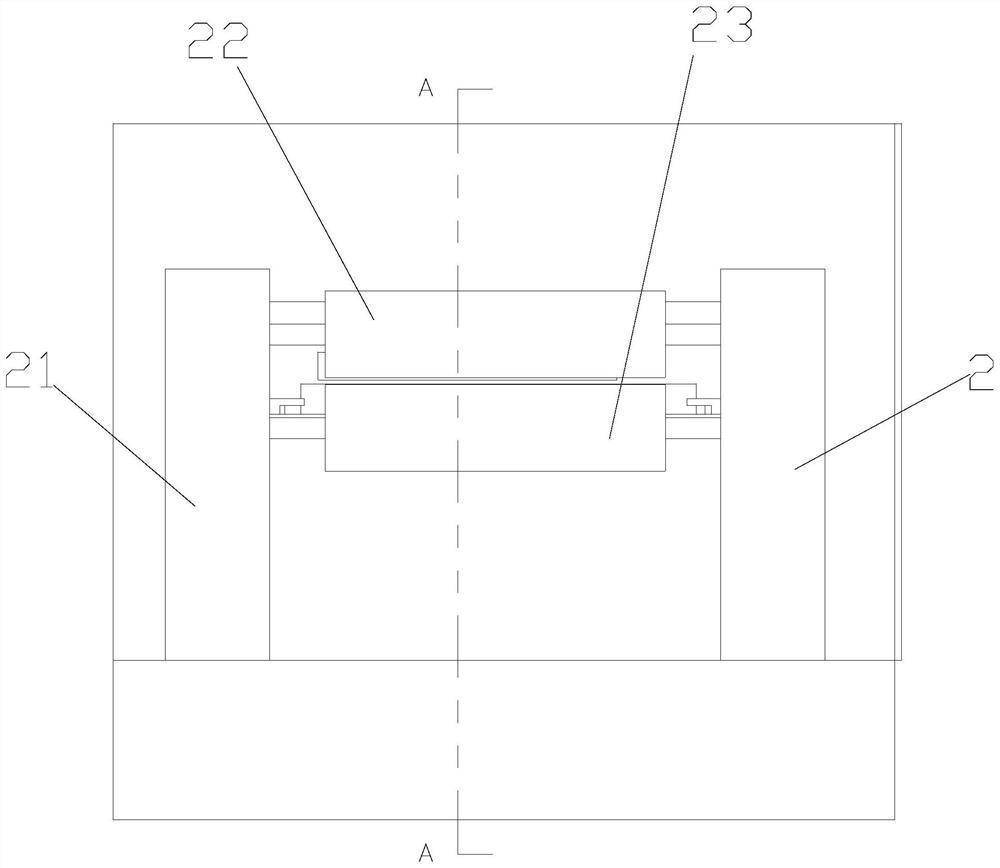

Injection mold and machining and assembling technology

The invention provides an injection mold and a machining and assembling technology. The injection mold comprises a fixed mold plate, a movable mold plate, a first inner mold, a second inner mold, at least one datum hole and locating pieces, wherein the first inner mold and the second inner mold are installed in the fixed mold plate and the movable mold plate correspondingly, each datum hole penetrates through the fixed mold plate, the first inner mold, the second inner mold and the movable mold plate at the same time, and the locating pieces are inserted into the datum holes. According to the injection mold, through the uniform datum, the inner mold of the injection mold is machined according to the uniform datum, the machining datum is also used as the assembling datum, and the precise locating effect is achieved; and in this way, the defects that the frame forming precision is low, the datum faces of the inner molds deviate, screw receding locating is ineffective and the datums are respectively independent are overcome, the machining precision is improved, and finally the problems of dislocation, segment gaps and flashes of products are solved. The products are made to reach the ideal state that the appearance and the hand feeling are both good. Meanwhile, zero-error one-time machining is ensured, repeated machining and the risk of scraping of the inner molds are avoided, the products produced through the mold discharging one product once or the mold discharging multiple products once are significantly improved, and the mold precision is also significantly improved.

Owner:FOSHAN CITY SHUNDE DISTRICT BAINIAN TECH CO LTD

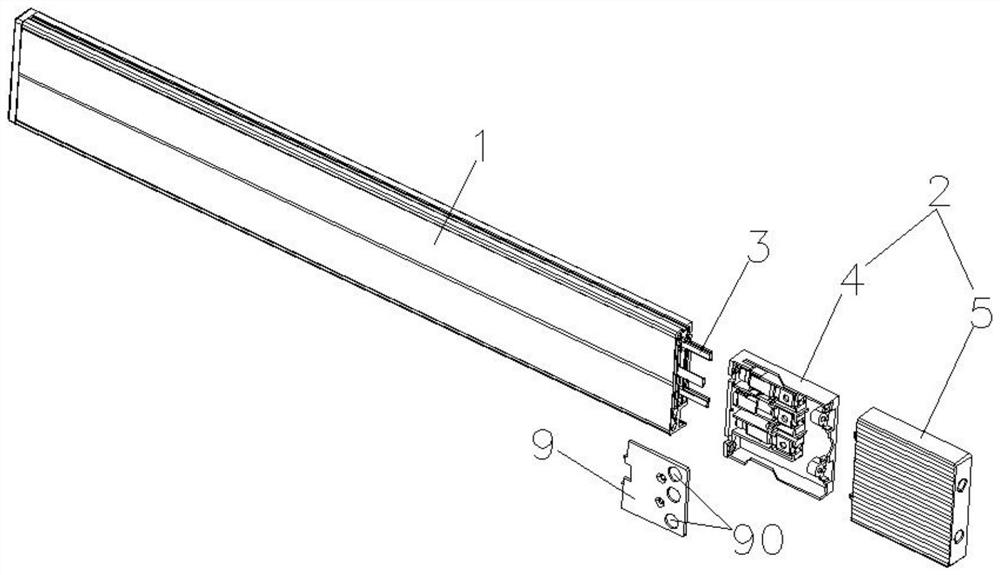

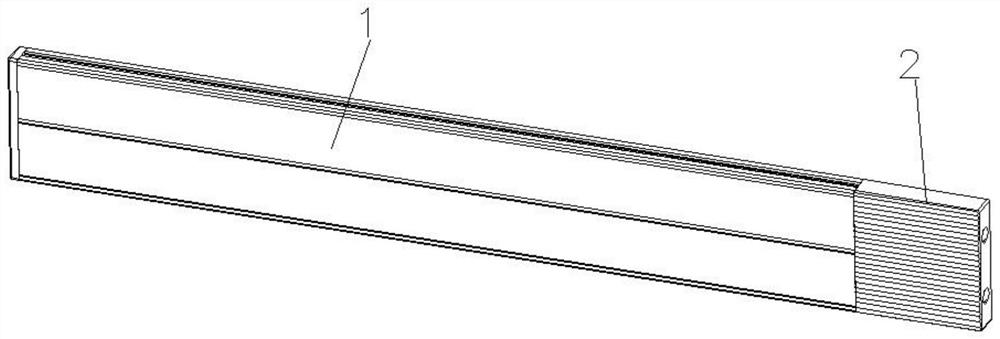

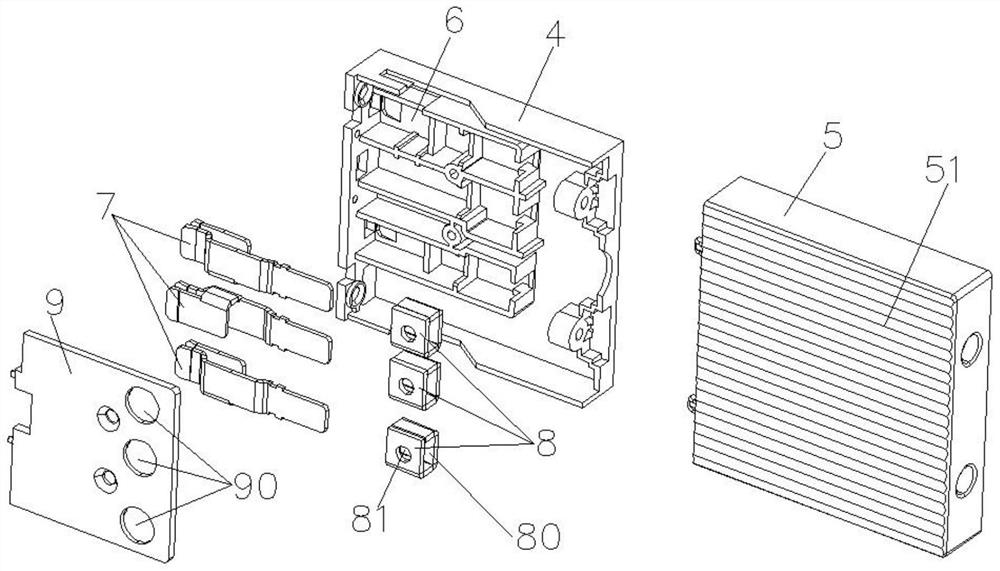

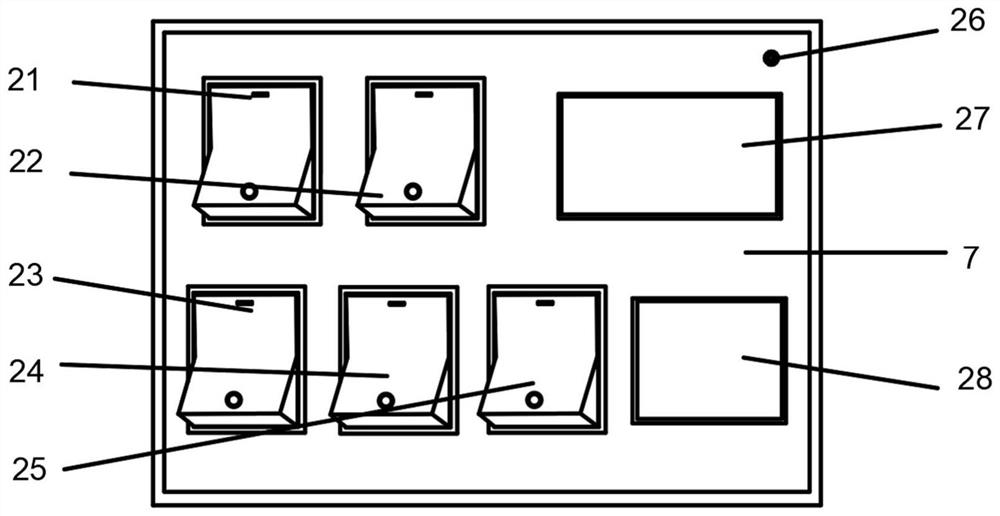

Anti-electric shock track socket

PendingCN114300899ANot easy to runNot easy to moveCoupling contact membersLive contact access preventionElectrical conductorElectrical connection

The invention discloses an anti-electric shock track socket, which comprises a track socket box and a power supply connecting seat, the track socket box is detachably connected and fixed with the power supply connecting seat, a conductor copper rod for taking electricity with an adapter is arranged in the track socket box, the power supply connecting seat comprises a base and a box body, and the base is detachably connected and fixed with the box body. The base is provided with a positioning groove used for fixing an electricity taking connecting piece, the electricity taking connecting piece detachably connected with the conductor copper rod is arranged in the positioning groove, and the electricity taking connecting piece is further sleeved with a wiring terminal used for fixing a wire to the electricity taking connecting piece. The power-taking connector is fixed in the space and is not easy to run or move, and then is fixed by the cover plate, so that the power-taking connector is installed more firmly and is not easy to displace, the connection firmness of a matched conductor copper rod is improved, the power-taking connector is not easy to loosen, the working stability of a power supply is ensured, the installation is simpler, and the operation is more convenient.

Owner:福建美沿科技有限公司

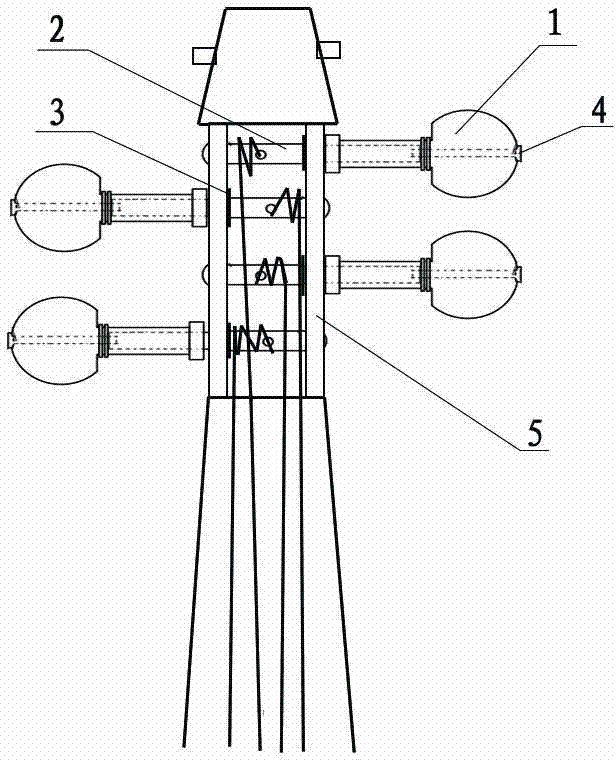

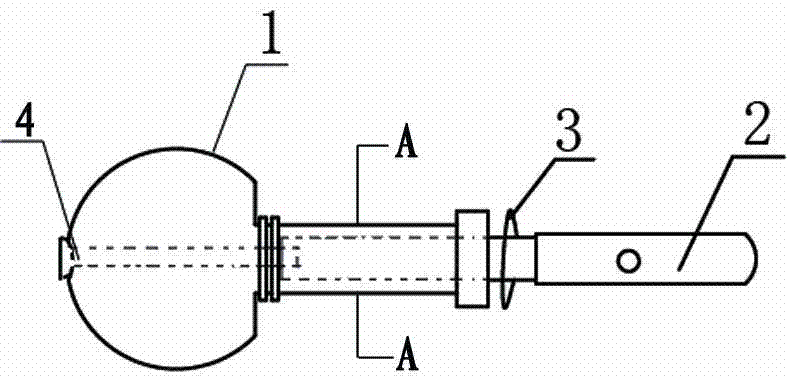

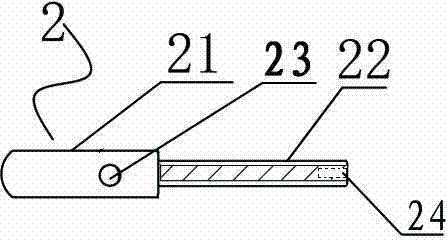

String adjustment device for violins

InactiveCN104751827AAvoid loose springbackExtended service lifeStringed musical instrumentsEngineeringViolin

Owner:河北金音乐器集团有限公司

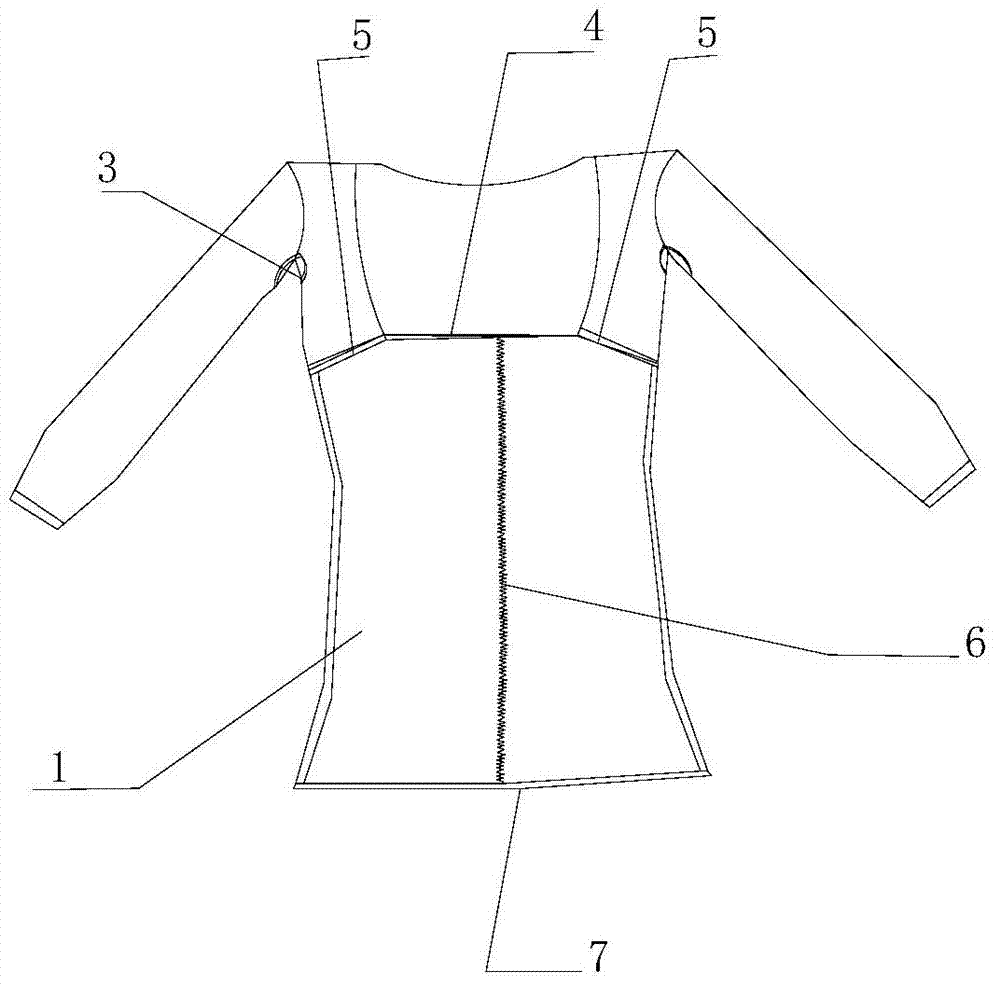

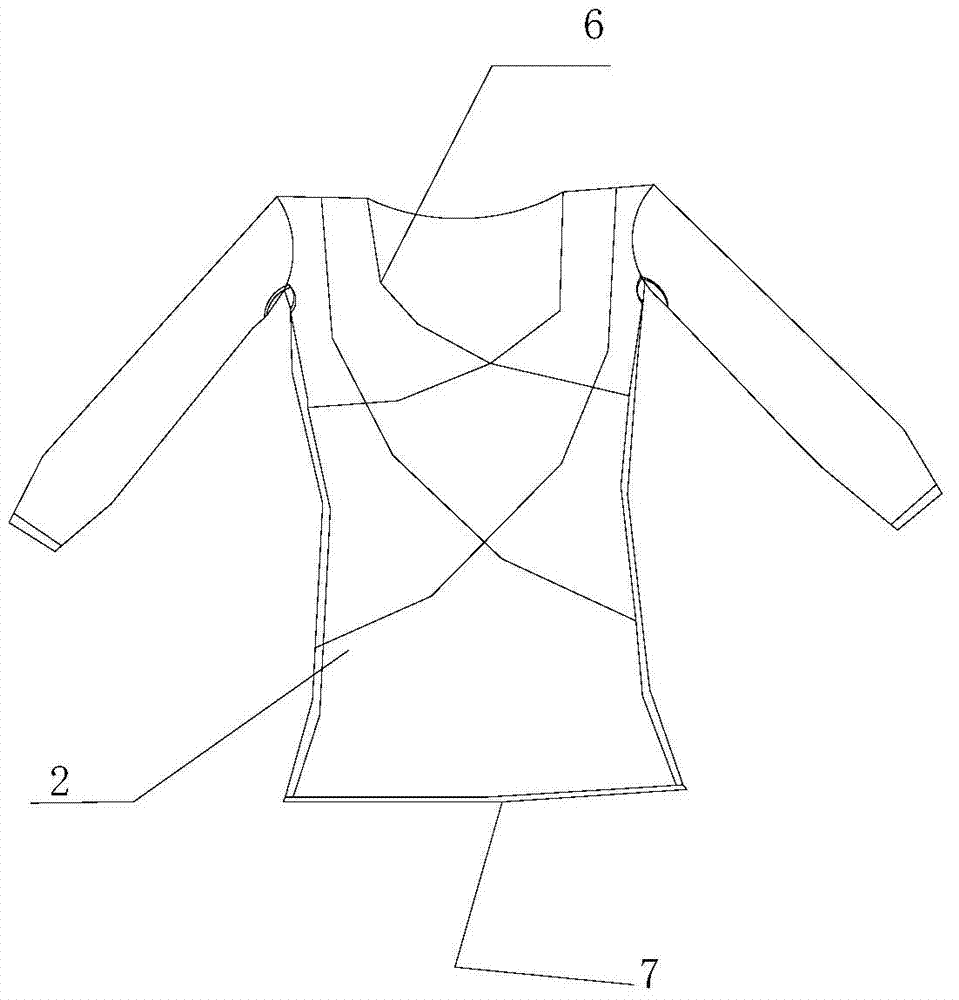

Shaping and warm keeping underwear capable of being worn outside

InactiveCN104705816AEfficient removalGood form stabilityProtective garmentSpecial outerwear garmentsMechanical engineeringAccessory breast

The invention discloses shaping and warm keeping underwear capable of being worn outside. The shaping and warm keeping underwear capable of being worn outside comprises a shaping and warm keeping underwear body which comprises a front piece and a back piece. A warm keeping woolen layer is arranged on the inner layer of the shaping and warm keeping underwear body and is made of thickened hot woolen fabrics. Openings are formed in the underarm parts of the shaping and warm keeping underwear body. A breast supporting device is arranged at the position, below the breast of a user, of the front piece, and accessory breast tightening devices are arranged at the ends of the breast supporting device along the underarm parts. The shaping and warm keeping underwear achieves shaping through elastic cloth. The openings in the underarm parts solve the problem of uplift of sleeves, the arms can move freely without the constraint feeling, and ventilating and sweat discharging are achieved; the breast supporting device and the accessory breast tightening devices can improve the shaping effect, and fat cannot deviate. The user can have a brand new feeling on the skin, warm keeping, body building and shaping are achieved, a proud chest line is enhanced, a waist curve is tightened, a back line is corrected, and warm keeping becomes fashionable.

Owner:CHANGZHOU LONGDAO E COMMERCE

Manufacturing process ofmachine washable silk quilt

ActiveCN113491419AExtended service lifeNot easy to runBlanketBed linenComposite materialHydrogen peroxide

Owner:JIAXING SHAOSHI HOME TEXTILE CO LTD

Circular sawing machine for steel plate cutting

ActiveCN105364174BHigh degree of automationImprove processing efficiencyMetal sawing devicesMetal sawing accessoriesControl systemCircular saw

The invention discloses a steel plate cutting circular sawing machine, which comprises a frame, a cutting device installed on the frame, a moving assembly for conveying workpieces, a pressing assembly, and a control system. The screw assembly on one side, the telescopic assembly installed on the other side of the moving plate and the support plate fixedly connected to the output shaft of the telescopic assembly, the pressing assembly includes a main pressing assembly and an auxiliary pressing assembly, the main pressing assembly The pressing assembly is pressed on the frame and faces the cutting device, the auxiliary pressing assembly is installed on the support plate, the workpiece is placed on the supporting plate, the control system controls the screw assembly to drive the moving plate to move and the pressing assembly presses the workpiece, The cutting device cuts the workpiece. It has the characteristics of high cutting efficiency and high cutting precision.

Owner:江苏宁兴恒力智能设备有限公司

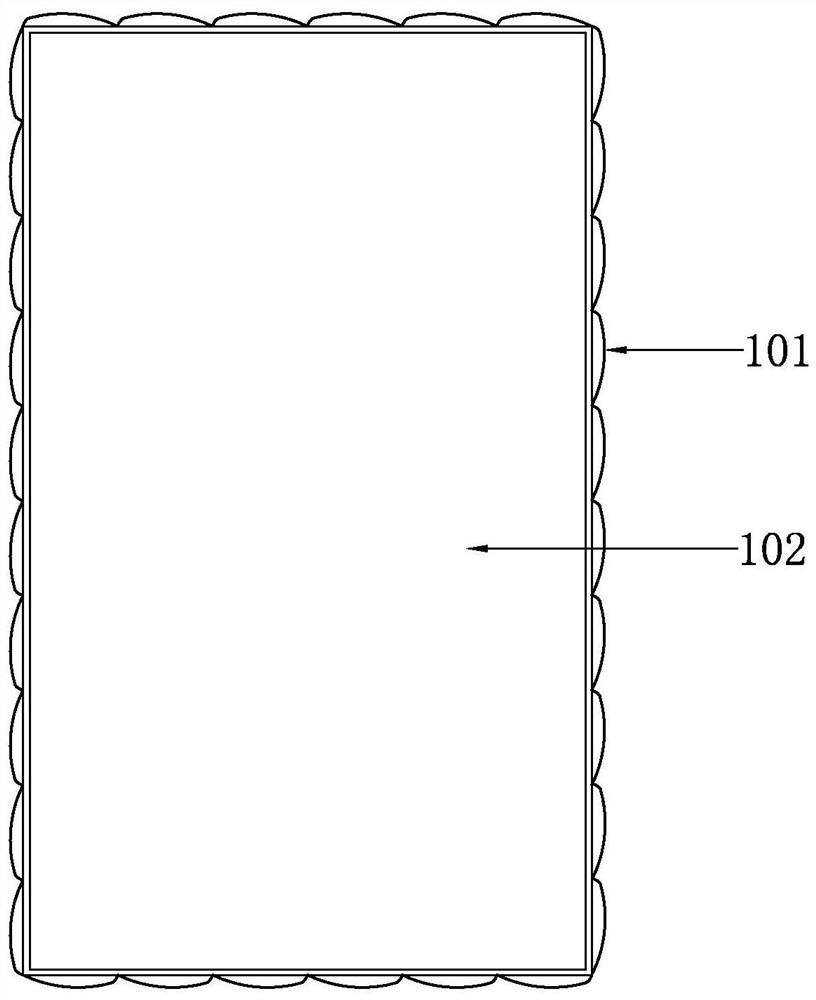

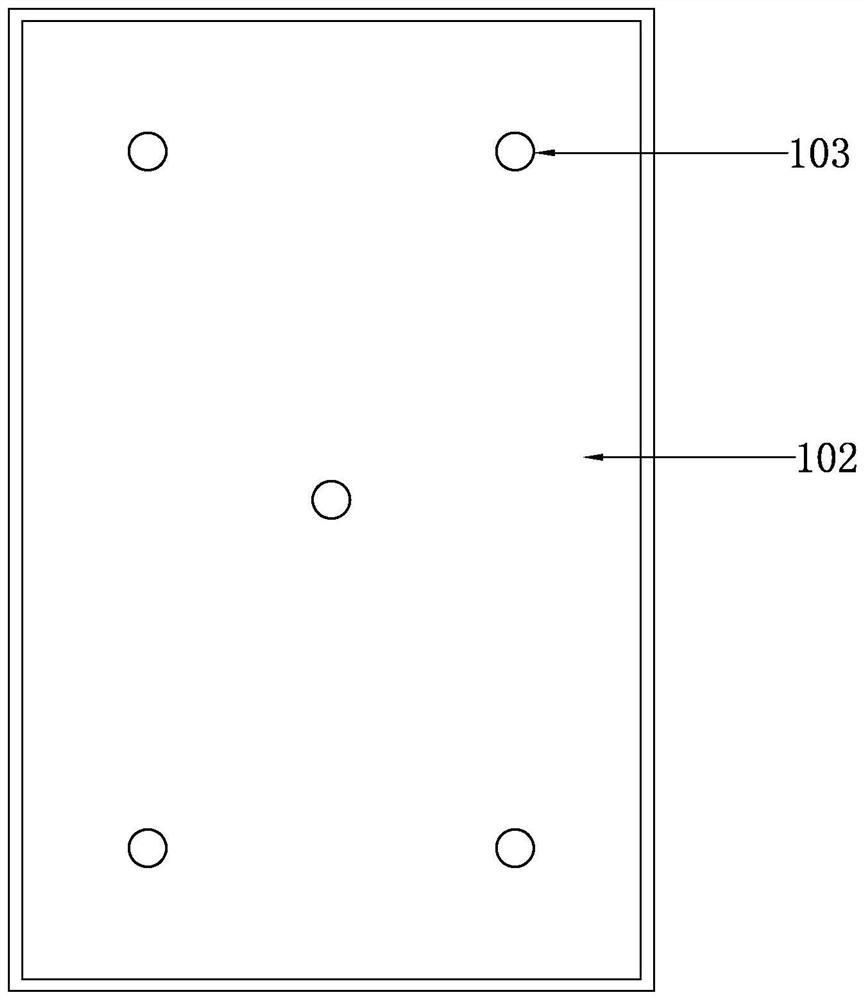

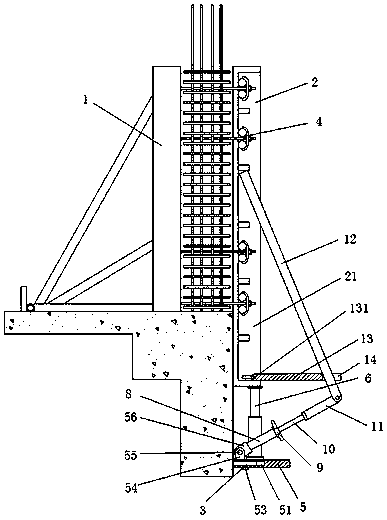

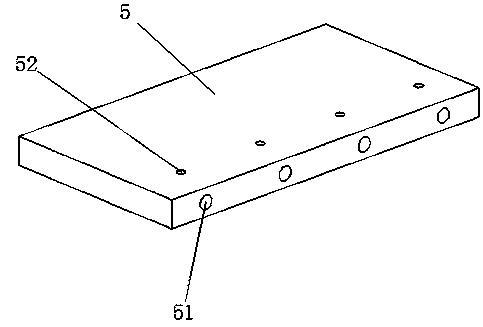

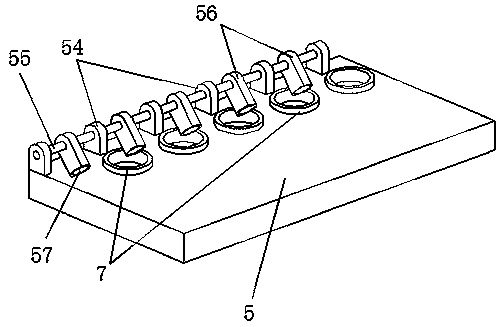

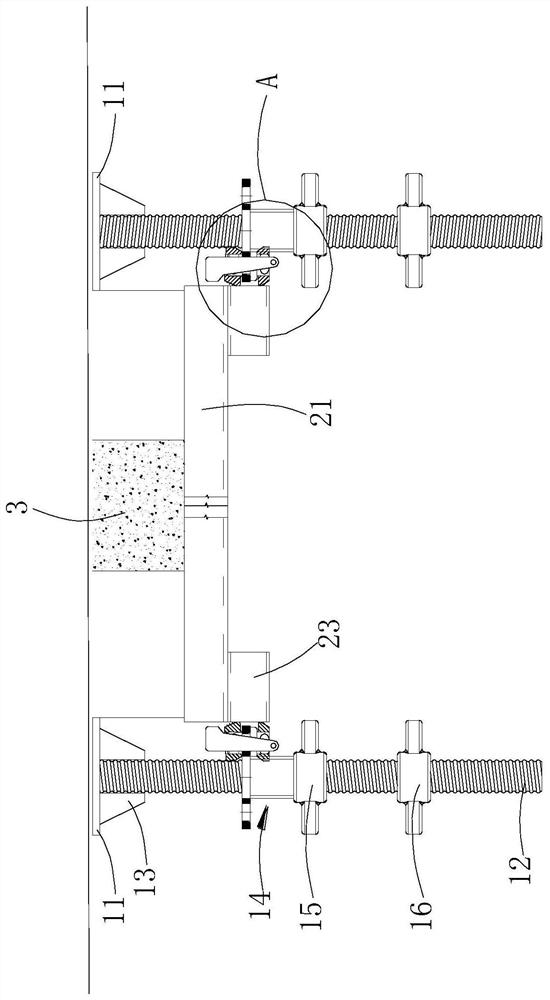

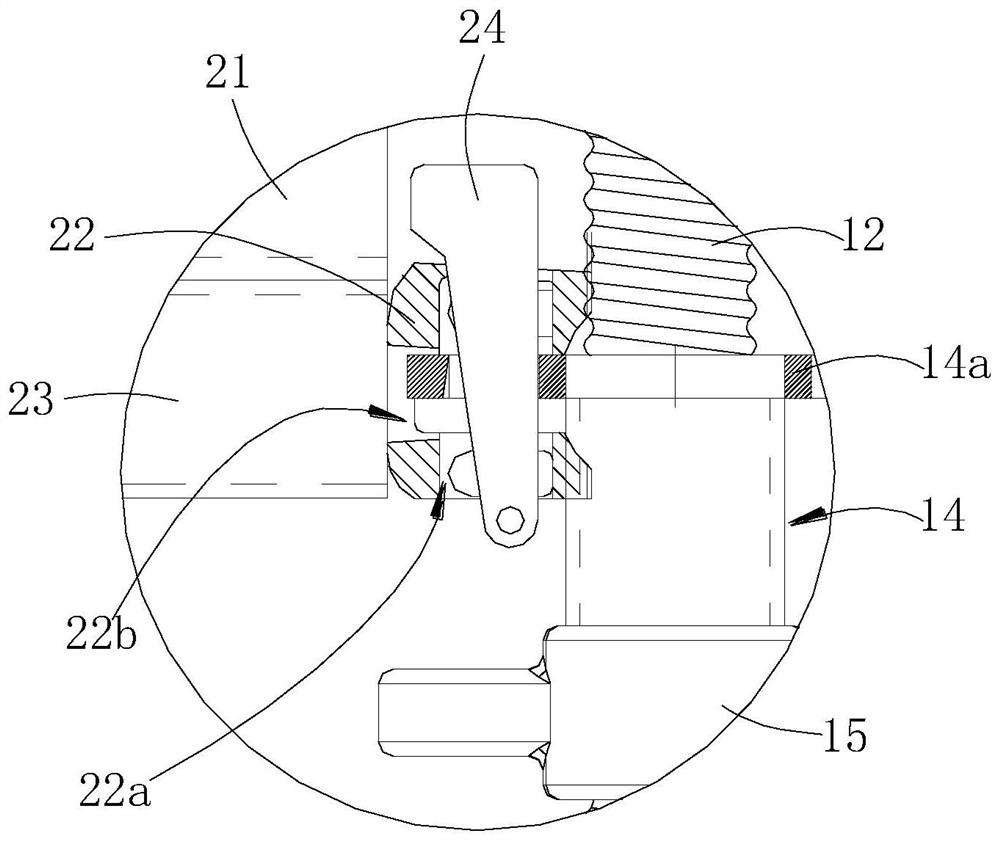

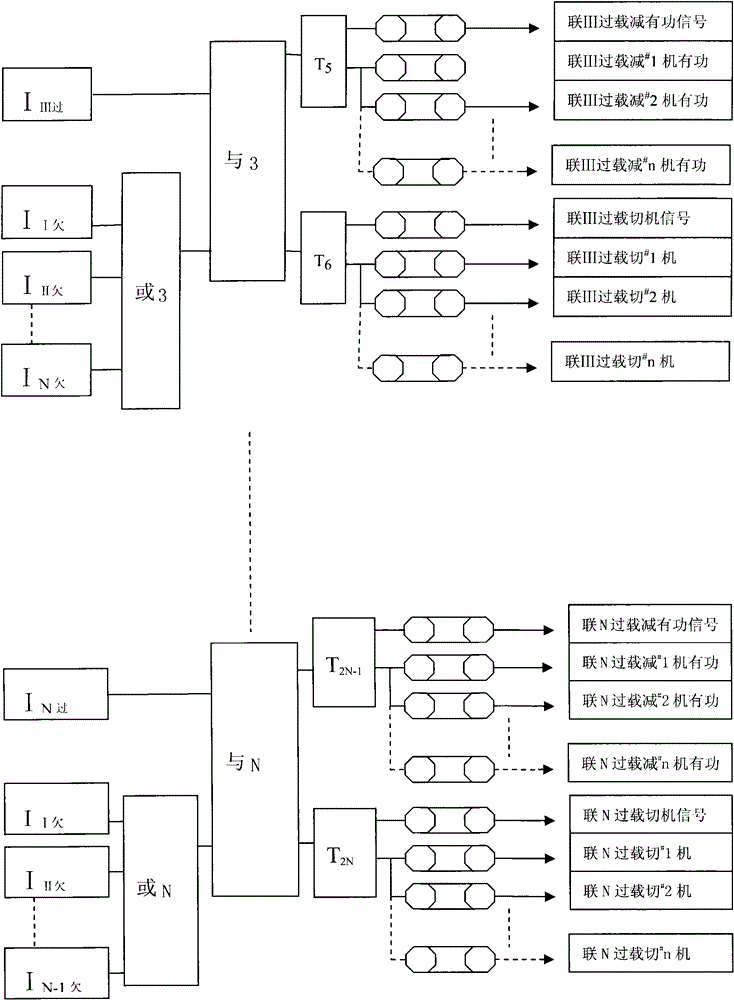

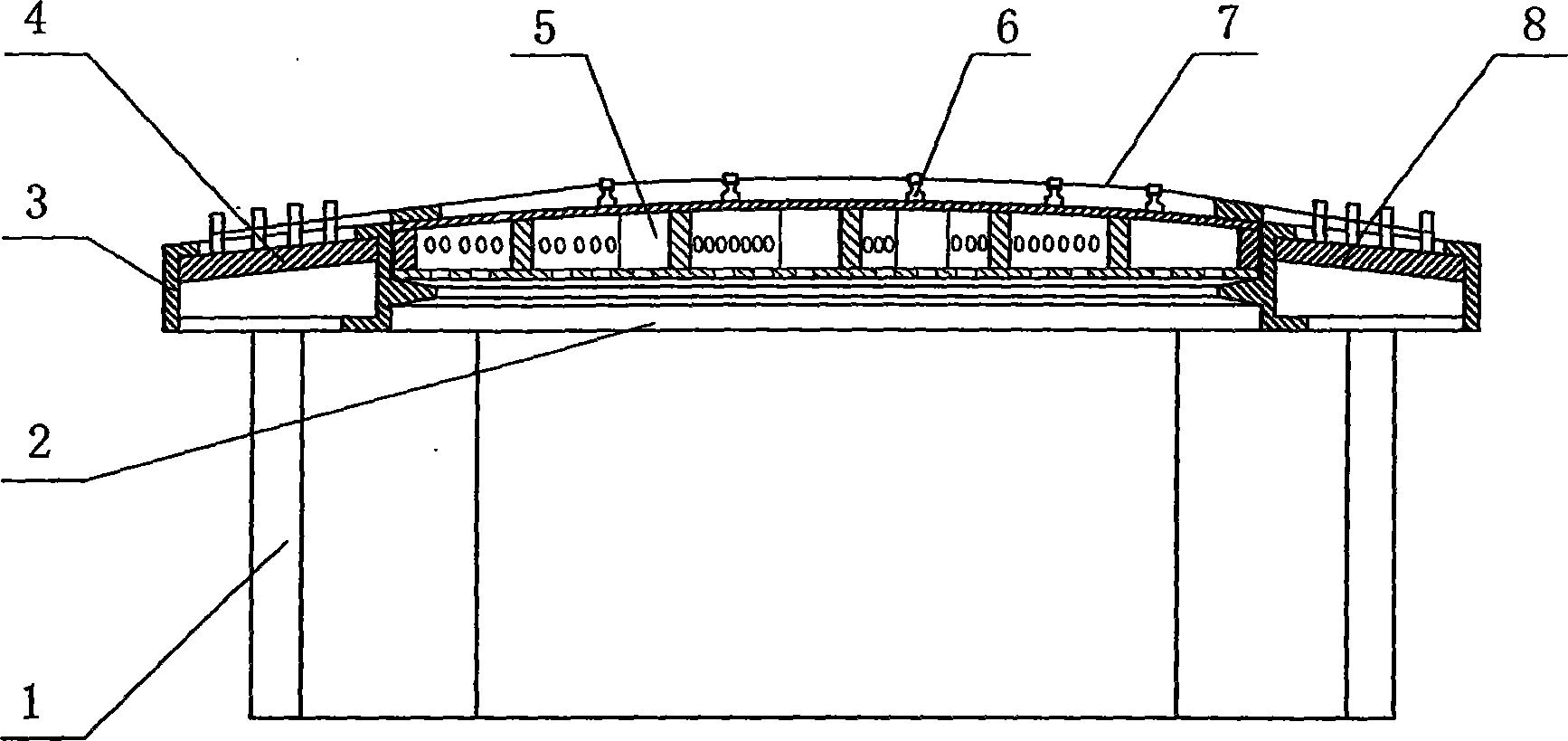

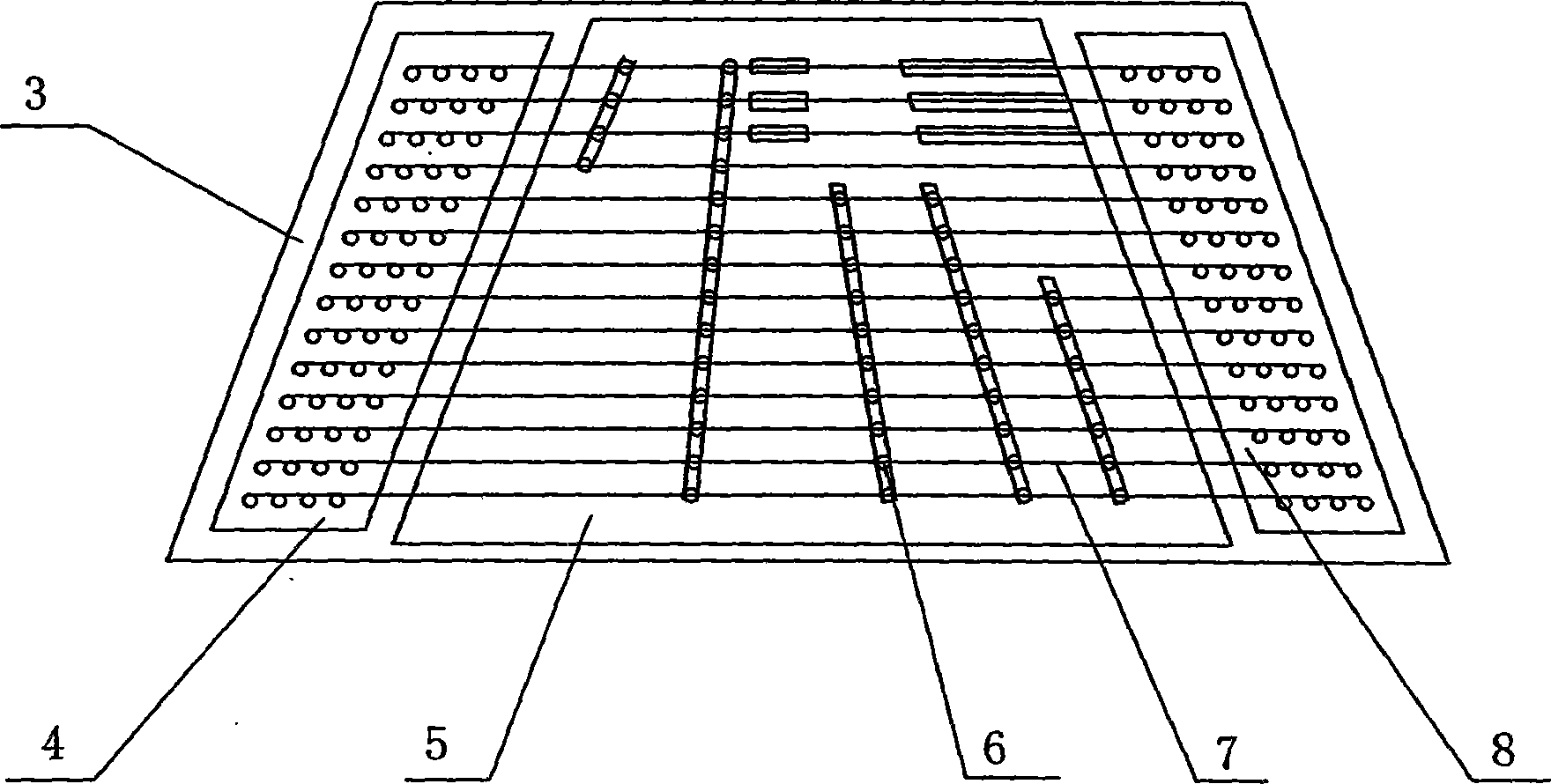

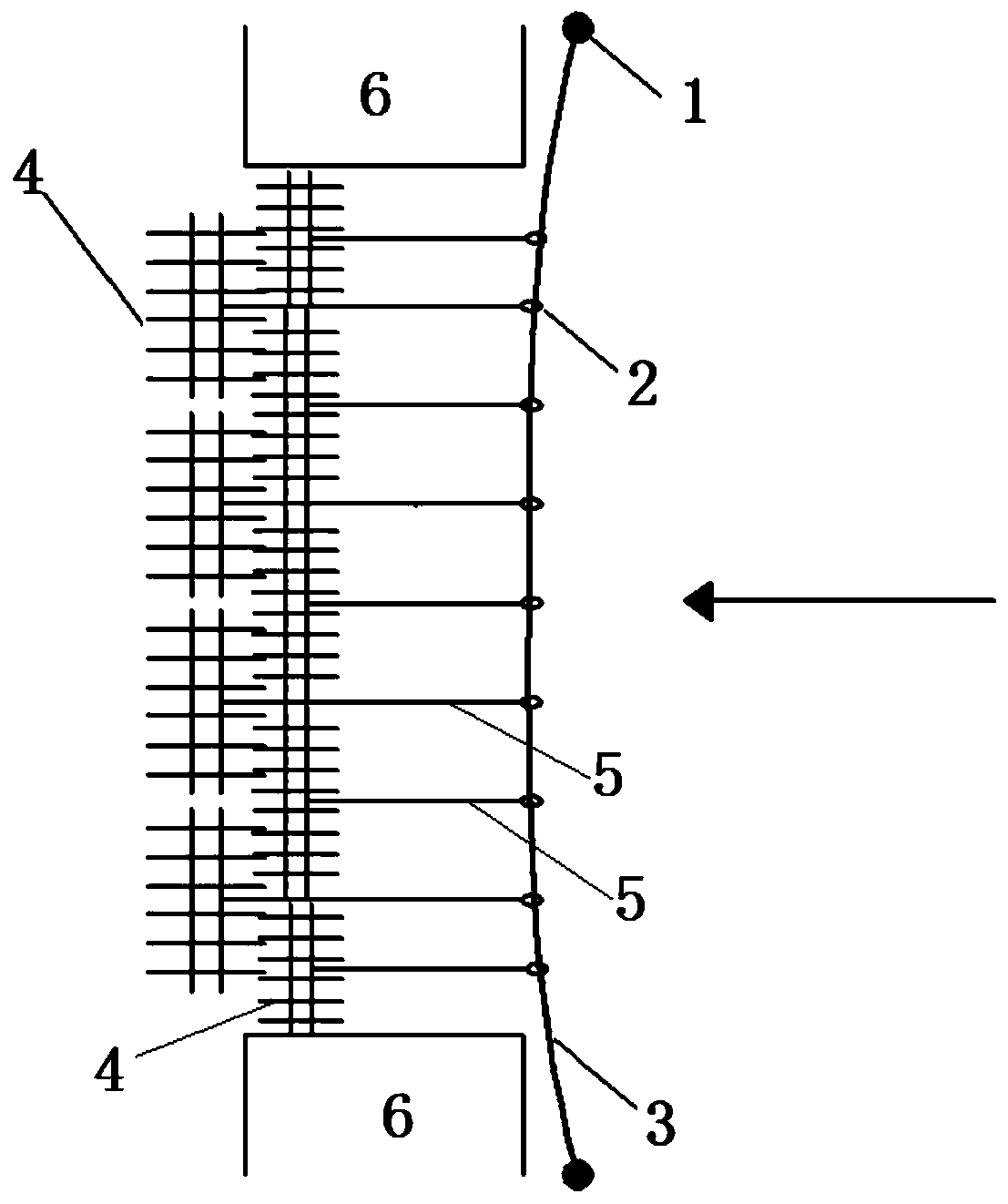

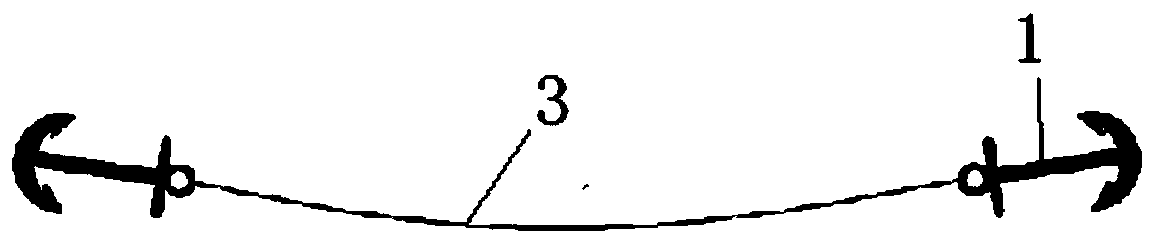

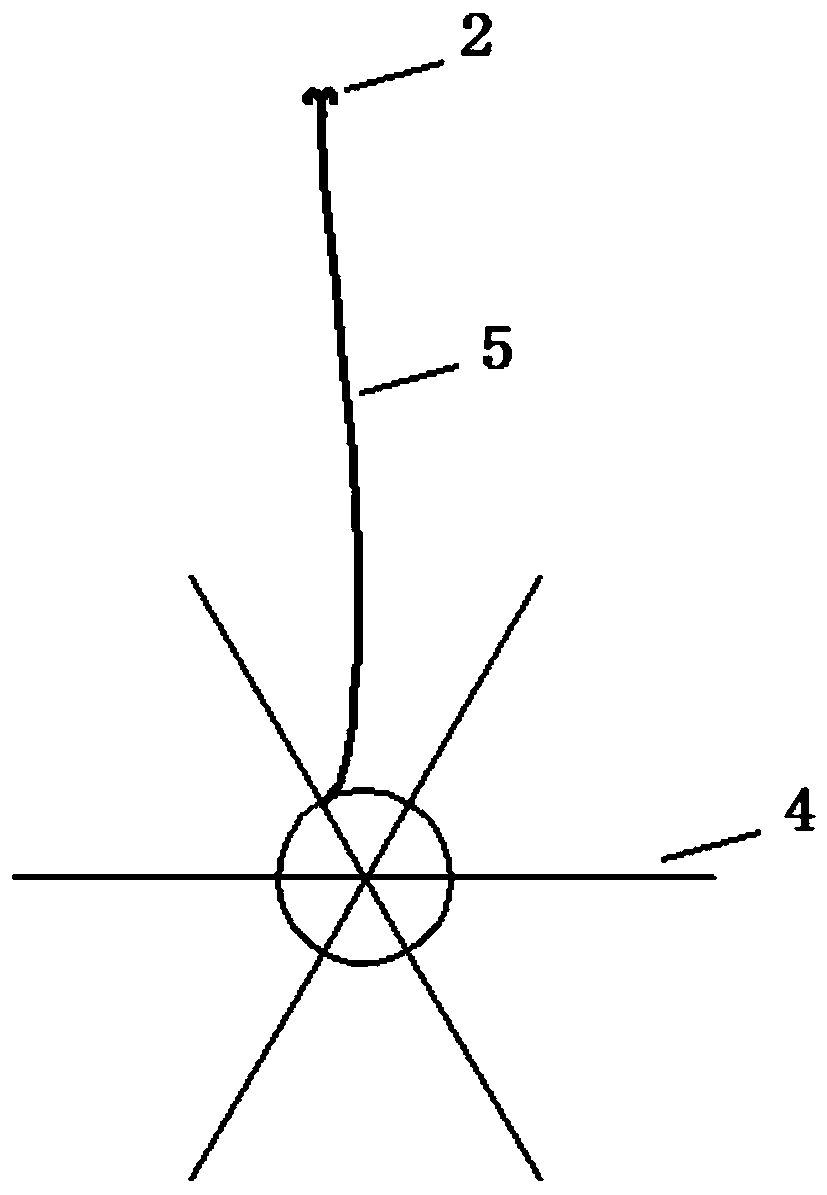

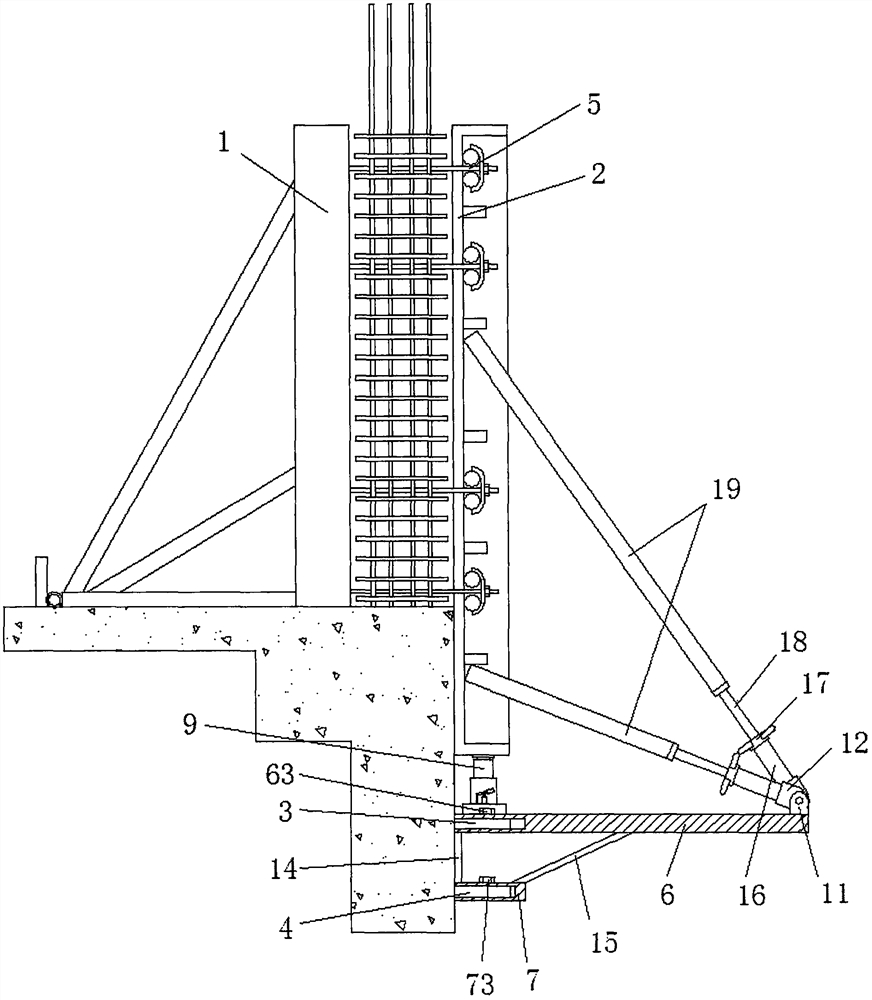

Reinforcing structure for shear wall formworks

PendingCN109184188AImprove stabilityNot easy to runForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksEngineeringRebar

The invention discloses a reinforcing structure for shear wall formworks. The reinforcing structure comprises an inner formwork (1) and an outer formwork (2) on the two sides of shear wall steer barswhich are well bound and are accepted by supervision, and a number of supporting steel bars (3) pre-implanted into a shear wall body. The inner formwork (1) and the outer formwork (2) are connected and fixed together by screw pull rods (4). A positioning plate (5) serving as a first operating platform is arranged on the outer side of the supporting steel bars (3). A number of positioning holes (51) for the supporting steel bars (3) to be inserted into at intervals are arranged inward in a side of the positioning plate (5). The reinforcing structure has a simple structure, and is convenient touse. As certain bracing support is provided for the outer formwork, the stability of the outer formwork is greatly improved. The correction method in the invention is different from the correction method of verticality adjustment through the screw pull rods, so that the verticality of the external wall of a formed shear wall is better, and the safety in the construction process is greatly improved.

Owner:SHANGHAI GREENLAND CONSTR GRP

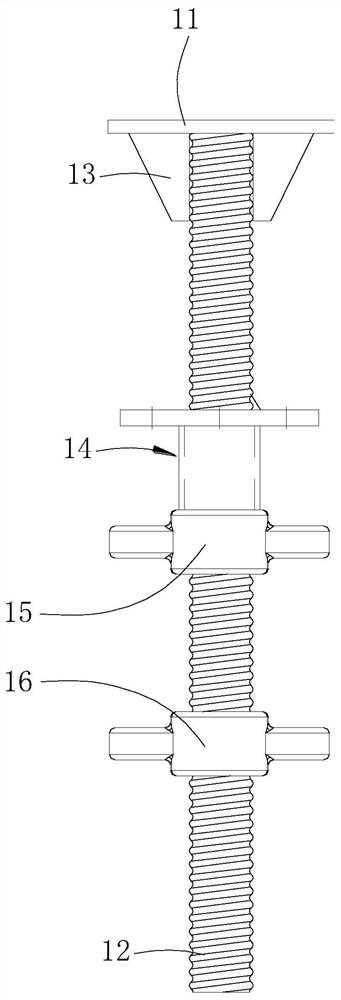

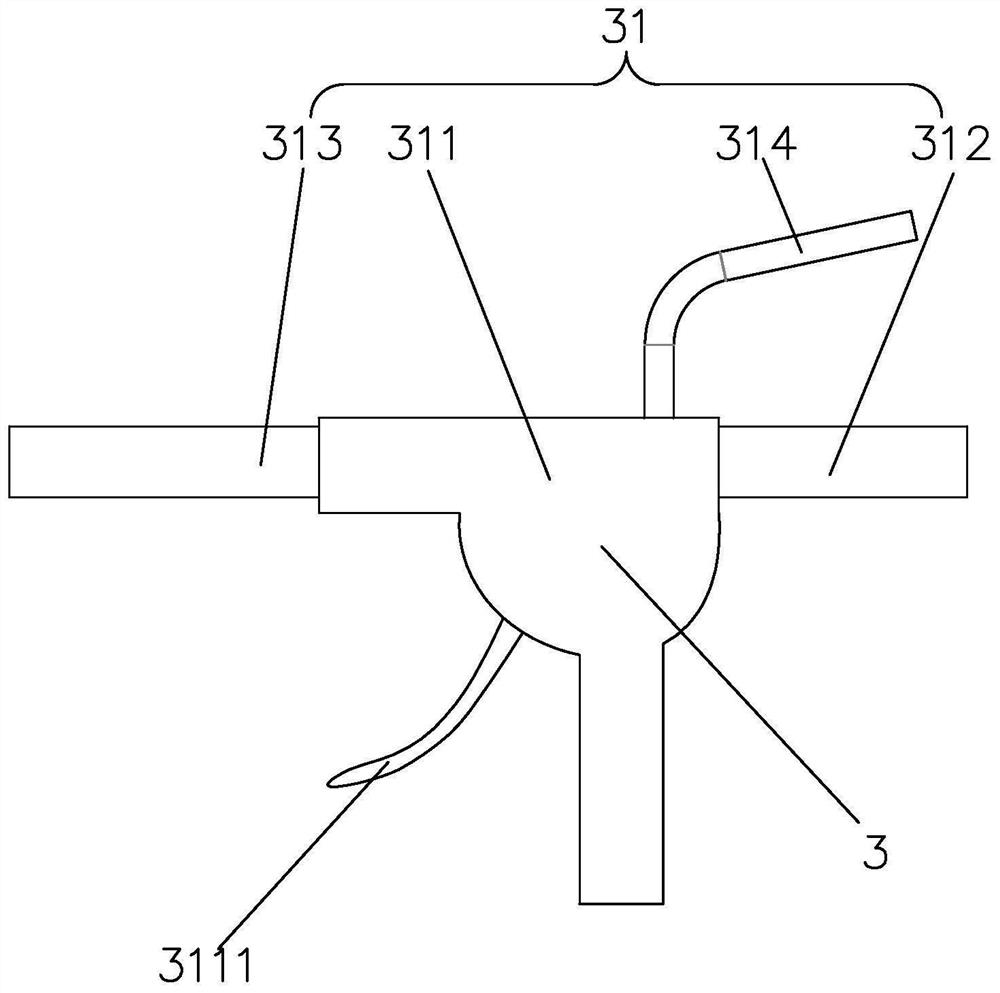

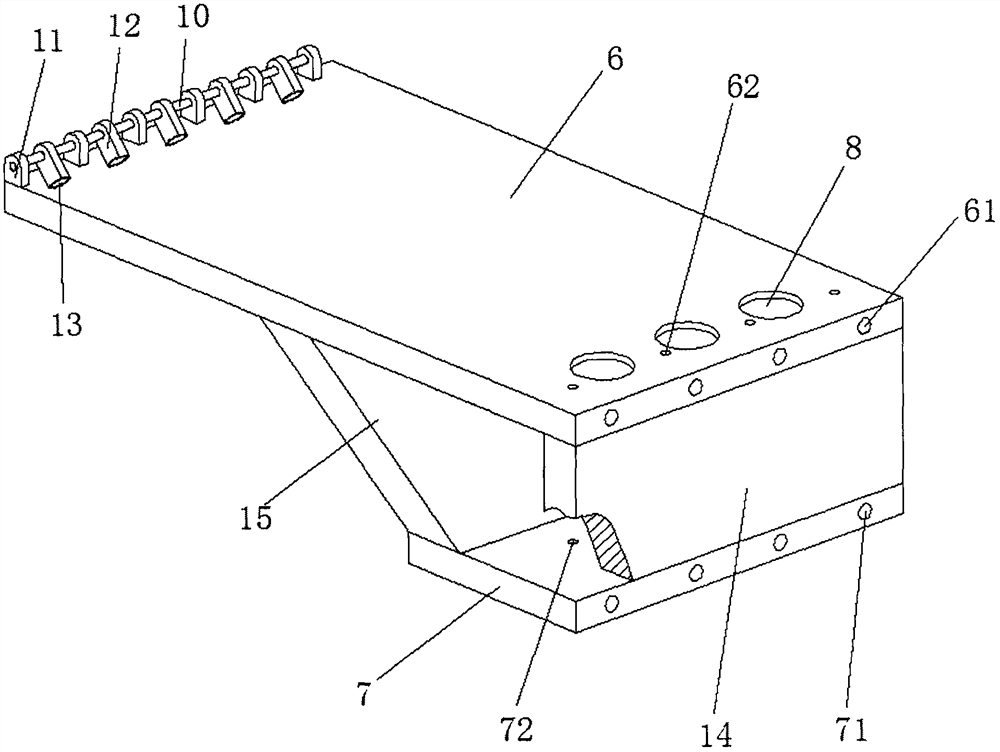

Beam plate lower cross beam supporting structure under disc buckle quick-release supporting system

PendingCN112538965AStable supportNot easy to runForms/shuttering/falseworksSupporting systemCircular disc

The invention provides a beam plate lower cross beam supporting structure under a disc buckle quick-release supporting system. The supporting structure comprises a cross rod supporting assembly and two supporting head assemblies; each supporting head assembly comprises a fixed top plate, a screw rod, a first nut, a second nut, and an adjusting supporting sliding block; the fixed top plates are fixed to the tops of the screw rods; the adjusting supporting sliding blocks sleeve the outer walls of the screw rods; connecting discs extend from the outer walls of the adjusting supporting sliding blocks; first pin holes are formed in the connecting discs; the first nuts and the second nuts are matched with the screw rods; the cross rod supporting assembly comprises a supporting transverse rod, two plugs, and two locking pin pieces; the plugs are fixed to the two ends of the supporting transverse rod; second pin holes are formed in the plugs; clamping grooves matched with the connecting discsare formed in the side walls of the plugs; and the locking pin pieces are matched with the second pin holes of the plugs and the first pin holes of the connecting discs. A beam body is reinforced through the beam plate lower cross beam supporting structure under the disc buckle quick-release supporting system, and the beam bottom is supported through the supporting transverse rod, so that the supporting effect is stable, and meanwhile the supporting height can be flexibly adjusted according to the size of the beam bottom.

Owner:安徽水利开发有限公司 +1

Processing method of multifunctional cotton like shirt fabric

InactiveCN103015019BGood moisture absorptionGood hygroscopicityWeft knittingBleaching apparatusPolymer scienceCarbon fibers

Owner:YANGZHOU JIYUAN TEXTILE

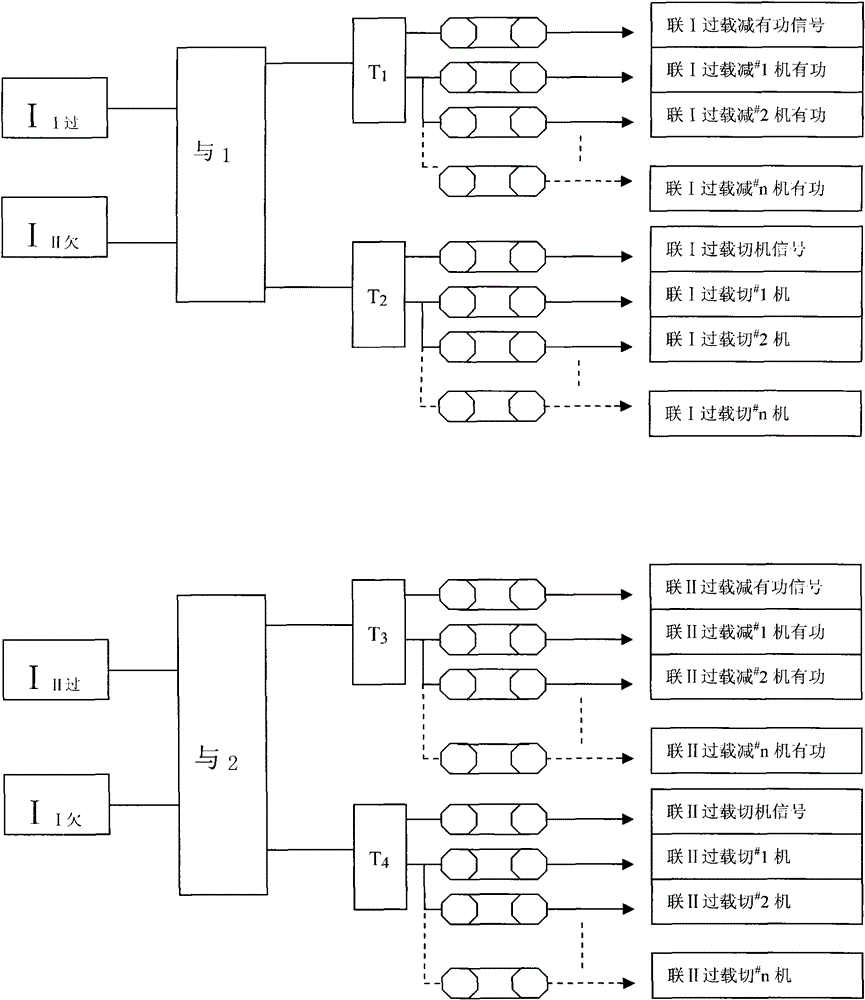

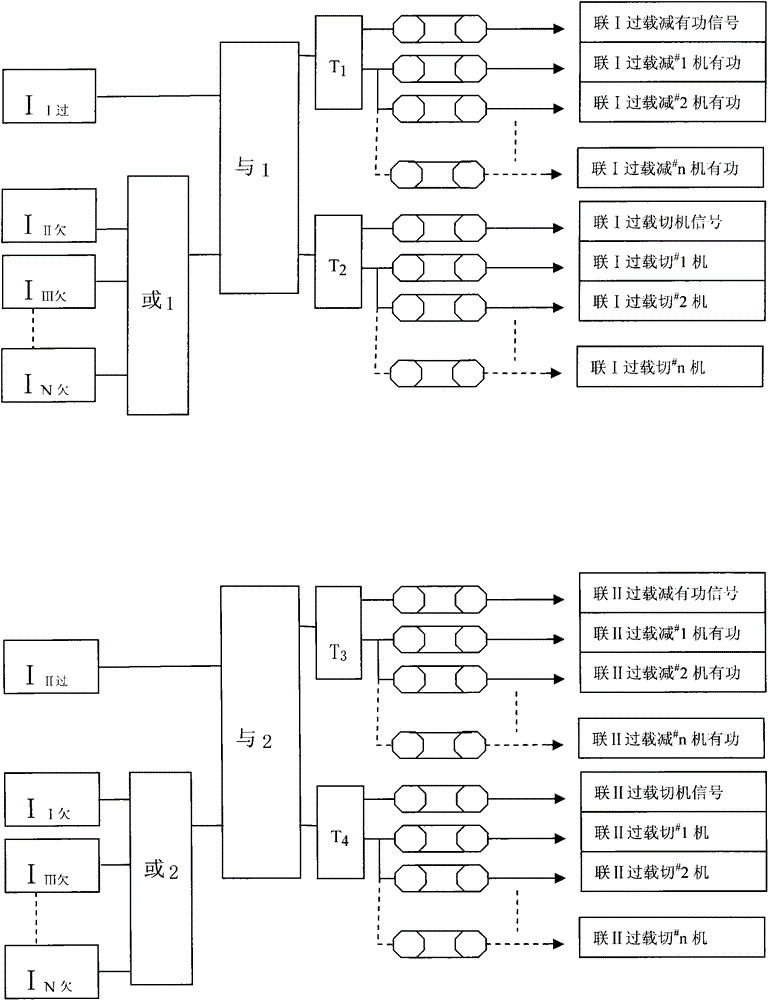

Generating set output reducing and generating set tripping device used in case of overload of contact outgoing lines of power plant

InactiveCN102751735BProtect safe operationNot easy to runSingle network parallel feeding arrangementsPower flowPower station

The invention provides a generating set output reducing and generating set tripping device used in the case of overload of contact outgoing lines of a power plant. When the contact outgoing lines of the power plant do not conform to the N-1 criterion of power supply security, in the case that any of the contact outgoing line trips out, firstly, the output of the generating sets engaged in operation is reduced automatically within the time limit allowed by the overload of the contact outgoing lines and then whether to trip the generating sets engaged in operation is determined according to the value of the current delivered by the contact outgoing lines after the output of the generating sets engaged in operation is reduced. The generating set output reducing and generating set tripping device is based on a clear principle and is simple in structure and can flexibly choose to reduce the output of the generating sets or trip out the generating sets. The generating set output reducing and generating set tripping device can be independently used as a high-reliability power grid automatic device.

Owner:巨争号

Carbon nanotube adsorption member, preparation method and application

ActiveCN108262013BReduce adsorptionNot easy to runCarbon compoundsOther chemical processesNanotubeWire mesh

The invention discloses a carbon nannotube adsorption component as well as a preparation method and application of the carbon nannotube adsorption component. Carbon nanotubes of the carbon nannotube adsorption component grow at one side of each metal wire mesh belt, a strip-shaped structure is formed at the side by arranging the sides, not provided with carbon, of the metal wire mesh belts at intervals; upper and lower outer layers of the strip-shaped structure are packaged by using filter cloth, and the whole strip-shaped structure is strip-shaped and can be wound; when being wound to form acylindrical structure, the strip-shaped structure has the height-to-diameter ratio of 1:1 to 1:5; and a carbon nannotube adsorption device applying the carbon nannotube adsorption component is internally filled with the carbon nannotube adsorption component, the void ratio of a bed layer of the component is 70-95%, and no gas or liquid distribution devices are arranged in the device. The inventionfurther discloses a preparation method of the carbon nannotube adsorption component and a mounting method of the carbon nannotube adsorption device; it is not needed that the carbon nannotube adsorption device is additionally provided with an independent gas or liquid distribution device, and the carbon nannotube adsorption device can be used for adsorbing and rapidly desorbing organic matters inwastewater or gases; and the carbon nannotube adsorption component has the advantages such as firm structure, long service life, high throughput, low preparation cost and low treatment energy consumption.

Owner:TSINGHUA UNIV

Stem production process

ActiveCN103750537BImprove fill rateQuality improvementTobacco preparationTobacco treatmentFilling ratePulp and paper industry

The invention discloses a cut stem production process which includes the steps of distributing, washing stems, dampening, storing the stems, shredding, drying cut tobaccos and the like. Mixed stems formed by 90% of Guizhou stems and 10% of Fujian stems or Yunnan stems are machined into the cut stems, advantages and disadvantages of tobacco stems in different production places can be balanced by the mode, so that the manufactured cut stems have quite high filling rate, suction resistance of cigarettes cannot be adversely affected, the water content of the stored tobacco stems is controlled by controlling the temperature of stem washing water and the water addition quantity of dampening by the aid of the process, the water content of the tobacco stems is reduced, the tobacco stems do not easily run when the tobacco stems are shredded, the tobacco stems are not easily plugged when the cut stems are dried, the expansion rate of the tobacco stems can be effectively increased, the quality of the cut stems is improved, and loss of the tobacco stems is reduced.

Owner:CHINA TOBACCO GUIZHOU IND

Anti-chord change endurable Yang musical instrument

InactiveCN101266780BHigh strengthExtended service lifeStringed musical instrumentsEngineeringAcoustic effect

Owner:李成文

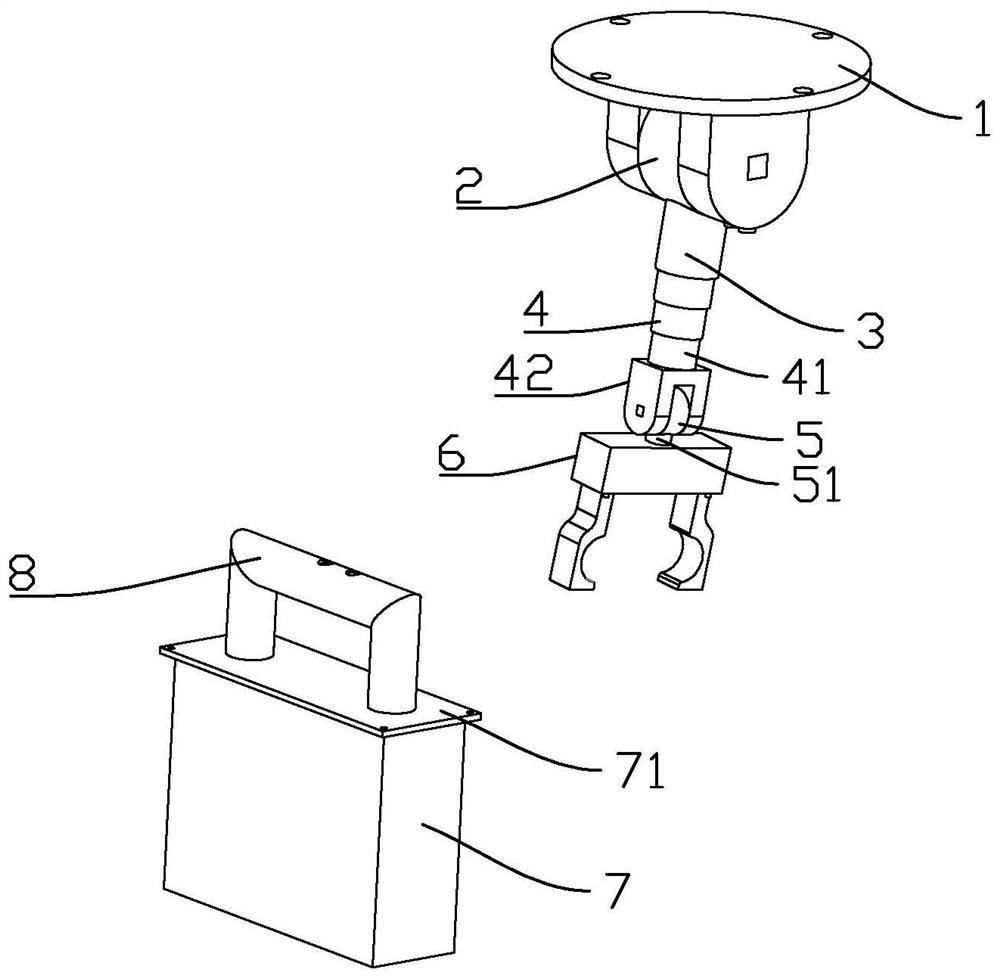

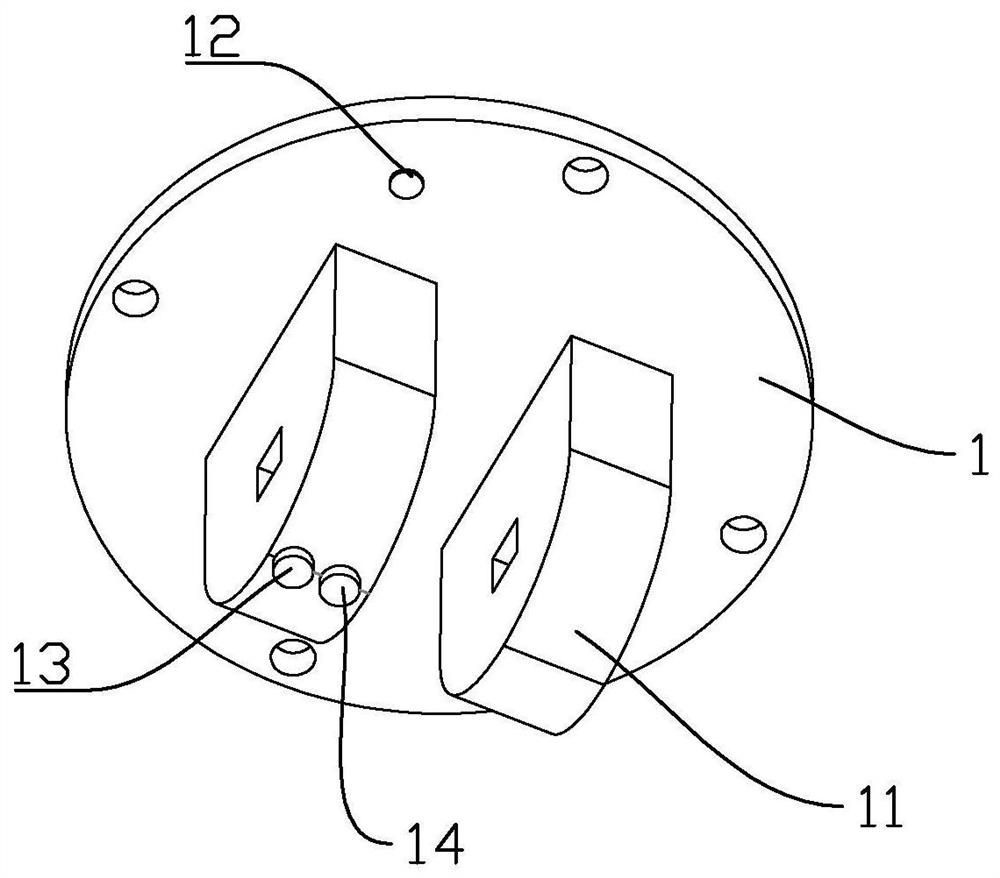

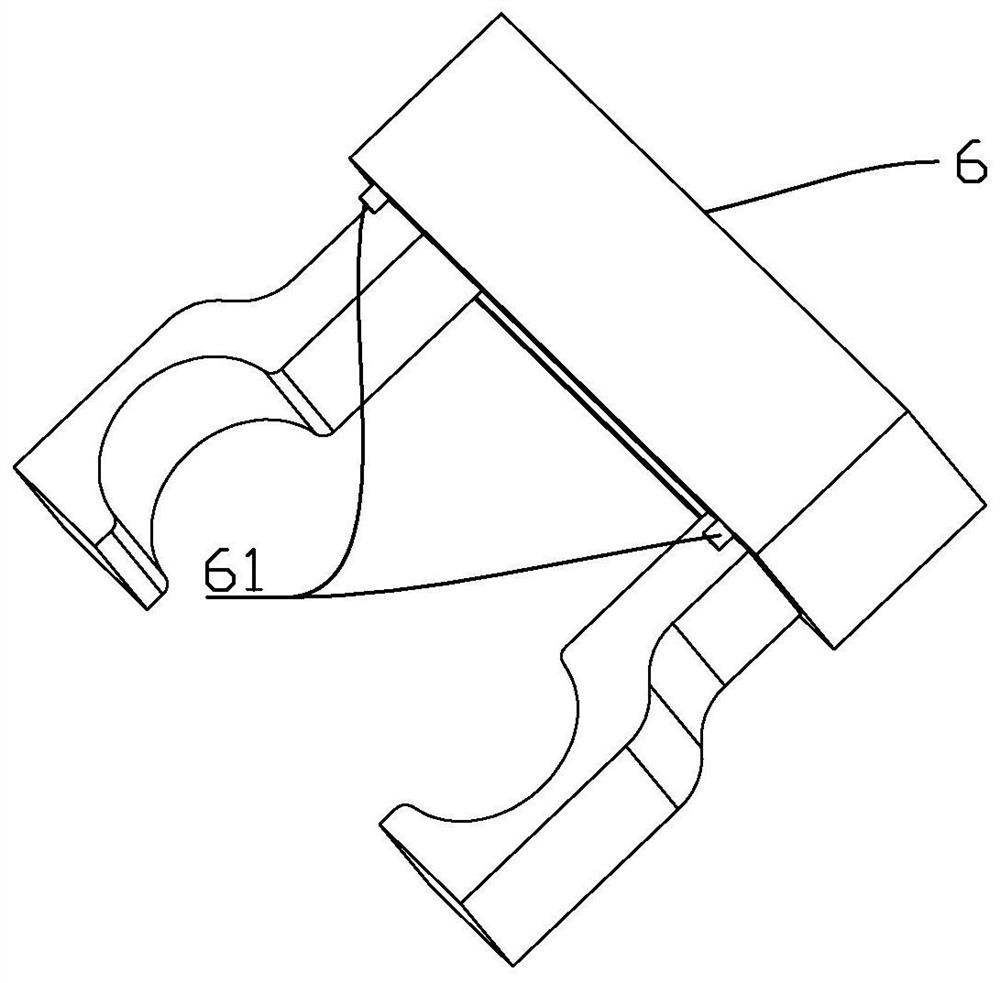

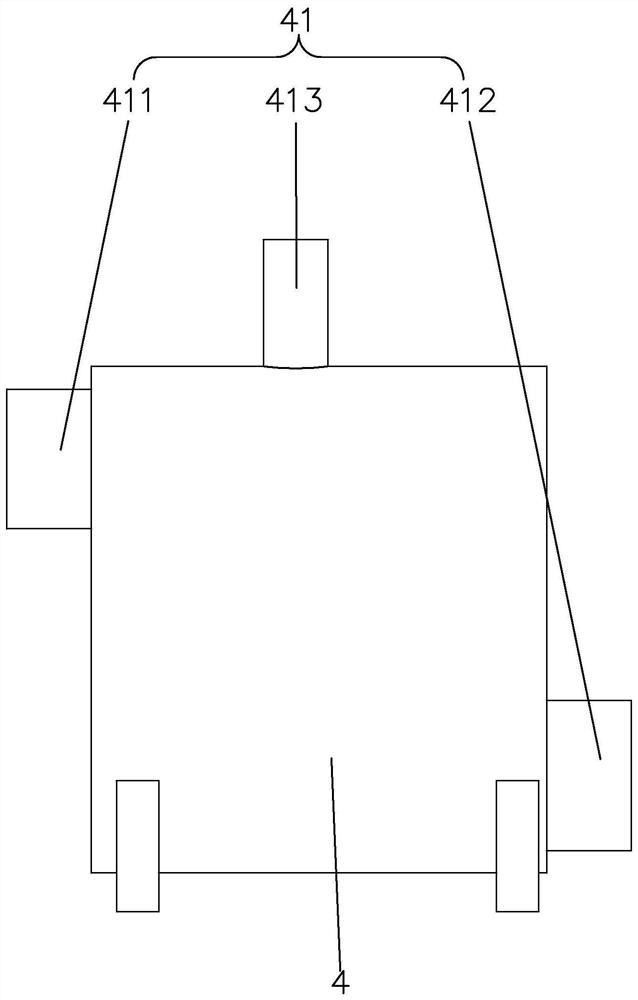

Device for preventing vehicle from being blown away and washed away

ActiveCN111645625ANot easy to blow awayNot easy to runTransmission systemsPedestrian/occupant safety arrangementParking spaceControl circuit

The invention discloses a device for preventing a vehicle from being blown away and washed away. The device comprises an upper connecting disc, a rotating mechanism a, a telescopic mechanism, a rotating mechanism b, a motor, a clamp, a positioning mechanism, a connecting rod, a box body, a lifting mechanism and the like. A groove with a downward opening is formed in the automobile chassis and usedfor containing the connecting disc, the rotating mechanism a, the telescopic mechanism, the rotating mechanism b, the motor and the clamp. The box body and the lifting mechanism are fixed in an outdoor parking space or in the ground at a proper position; the connecting rod is fixedly connected with the lifting mechanism; a vehicle is parked above the connecting rod; through a first wireless module a, a first wireless module b and two control circuit boards, the position of the connecting rod is lifted, the positions of the clamp and the connecting rod are determined through the positioning mechanism, the connecting rod is clamped by the clamp by continuously debugging the position of the clamp, in this way, it is equivalent that the vehicle is pulled by the ground, the vehicle is not prone to being blown away or rushed away no matter in strong wind or in heavy water, the vehicle cannot turn over, and therefore collision of the vehicle is reduced, and vehicle damage is reduced.

Owner:李知音

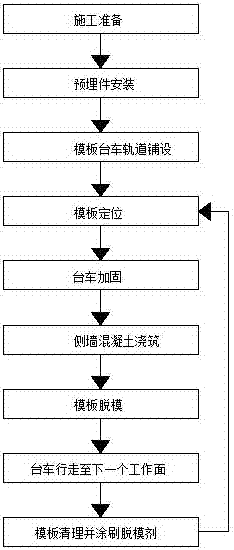

Construction method of metro station side wall self-walking type integral hydraulic formwork trolley

InactiveCN107143354ASimple processEasy to useUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention discloses a construction method of a metro station side wall self-walking type integral hydraulic formwork trolley. The method specifically includes the following construction steps of construction preparation, installation of embedded parts, laying of formwork trolley rails, assembling of a formwork trolley, positioning of a formwork, reinforcing of the trolley, side wall concrete casting, demolding of the formwork, displacement of the trolley, and cleaning of the formwork. Compared with the prior art and the traditional technology, the method is simple in process, convenient to use and suitable for large station straightway line production; by means of large steel formworks, after reinforcing measures are taken, the structure is stable, formwork explosion and formwork shifting can not easily occur, safety is high, and the overall construction quality is easy to guarantee; the method saves energy and is environmentally friendly, rapid in construction procedure and high in efficiency; by means of mechanical operation, manpower input is small, loss is small, and the repeated utilization rate is high.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP OF THE FIFTH ENG +1

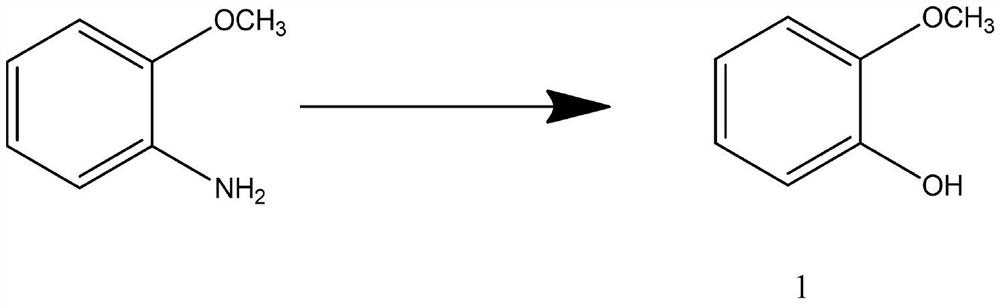

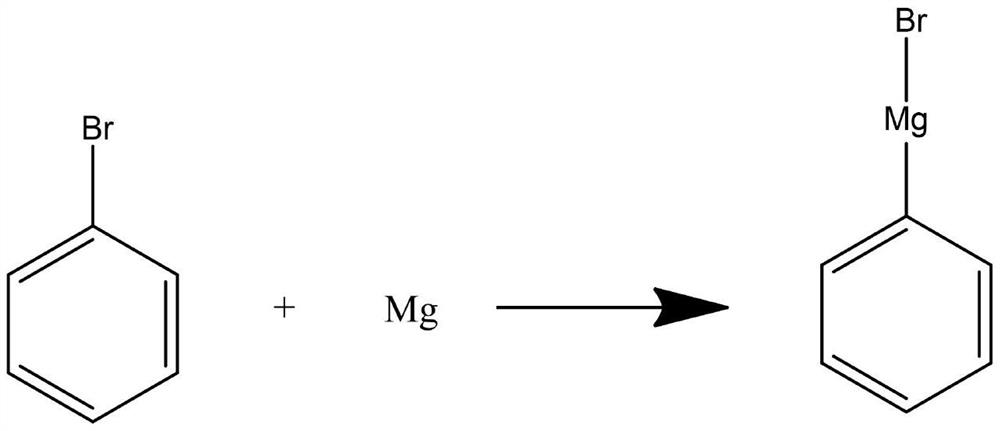

Mineral collecting agent

The invention provides a mineral collecting agent which comprises the following components in percentage by weight: 15%-20% of sodium ethyl xanthate, 15%-20% of sodium diethyl dithiophosphate, 15%-20%of cyanoethyl isopropyl xanthate, 10%-15% of thiamine ether ester, and 30%-40% of water. The mineral collecting agent can generate higher soluble performance, and is high in ore dressing recovery percentage and ore dressing enrichment ratio, useful minerals are used to generate hydrophobicity, and the probability of overflowing from a channel is low in the flotation operation.

Owner:天津市石广丰科技有限公司

A plugging method and device after a dike breach

ActiveCN106400740BImprove structural stabilityNot easy to runDamsClimate change adaptationWire ropeGeotechnical engineering

Owner:WUHAN UNIV

Flattening mechanism for PVC film calender

The invention discloses a flattening mechanism for a PVC film calender. The flattening mechanism is characterized in that an adjusting assembly is arranged above a base, a flattening assembly is arranged at the side edge of the adjusting assembly, and a collecting assembly is arranged at the side edge of the flattening assembly; the flattening assembly comprises a flattening box, supporting blocks, an air cylinder, an extending rod, an abutting block and a working plate; the flattening box is arranged above the base, and openings are formed in the two sides of the flattening box; the working plate is arranged in the flattening box, and the air cylinder is arranged in the flattening box; the number of the supporting blocks is two, and each supporting block is fixedly connected with the flattening box and located below the air cylinder; and one end of the extending rod is fixedly connected with the output end of the air cylinder, and the other end of the extending rod is fixedly connected with the abutting block and located above the working plate. Through the structural design, a PVC film is not prone to edge deviation, and wrinkles cannot be generated.

Owner:江苏海乐塑胶有限公司

Enameled diamond mold of high-speed large round wire horizontal enameling machine

ActiveCN113333756AImprove stabilityExtended service lifeFinal product manufactureCable/conductor manufactureGraphiteBall mill

The invention discloses an enamelled diamond mold of a high-speed large round wire horizontal enameling machine, and relates to the field of high-speed large round wire horizontal enamelling machine painting processes. Diamond is processed to form a mold core, nickel, zinc, cobalt, molybdenum, copper, tungsten and tin are mixed and stirred to obtain a mixed raw material, the mixed raw material and a grinding aid are added into a ball mill for ball milling to obtain sintered powder, a mold holder is fixed by a graphite mold sleeve, the mold core is placed in the mold holder, then the sintered powder is added between the mold holder and the mold core for sintering processing, the mold core is fixed to the center of the mold holder through hot pressing sintering by a powder metallurgy process, and the mold is obtained. According to the mold, the diamond mold core is arranged, the diamond mold core has the advantages of being good in stability, not prone to number shifting, long in service life and the like, a diamond mold core body is connected with the mold holder through a sintering body, the sintering body has high tensile strength, the diamond and the mold sleeve are welded into a whole, the situation that the mold core is stable can be effectively ensured, and gap paint leakage is permanently rejected.

Owner:TONGLING JINGLONG ELECTRIC MATERIAL

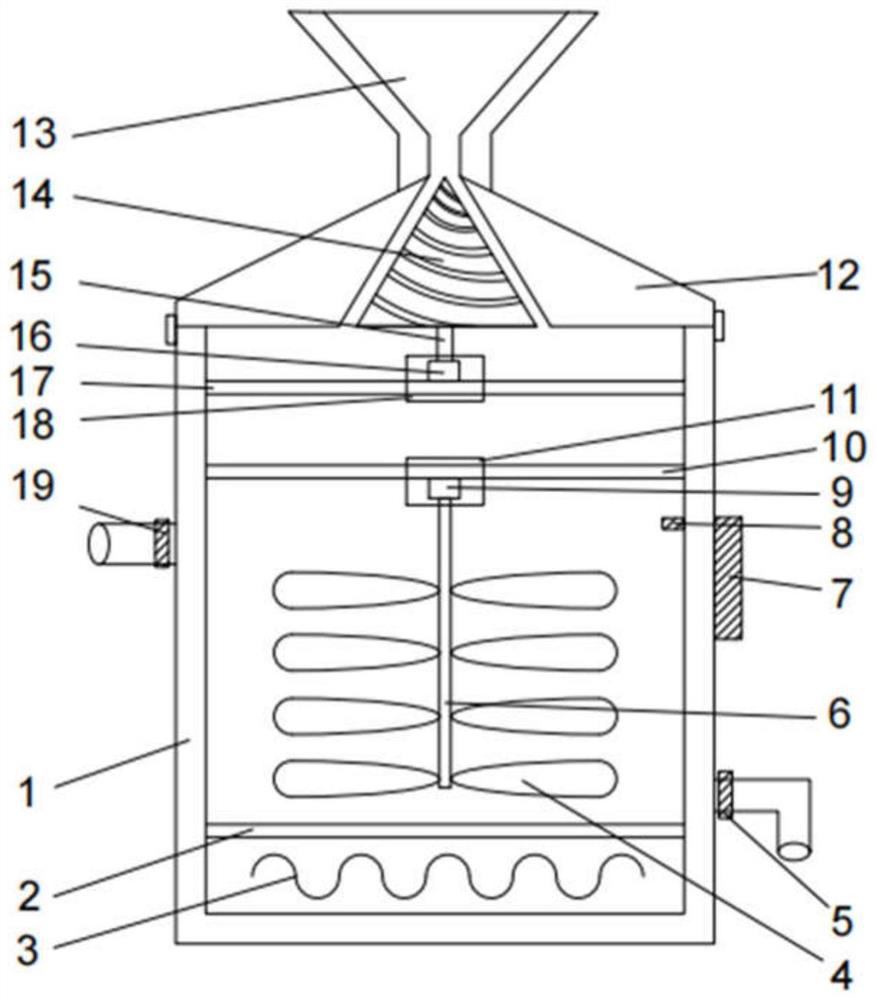

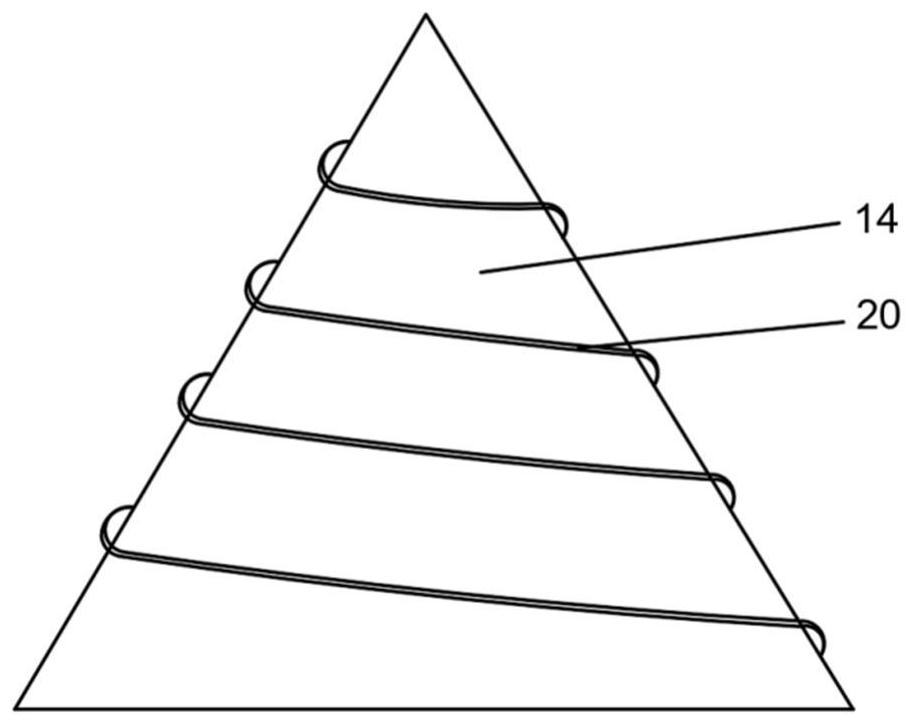

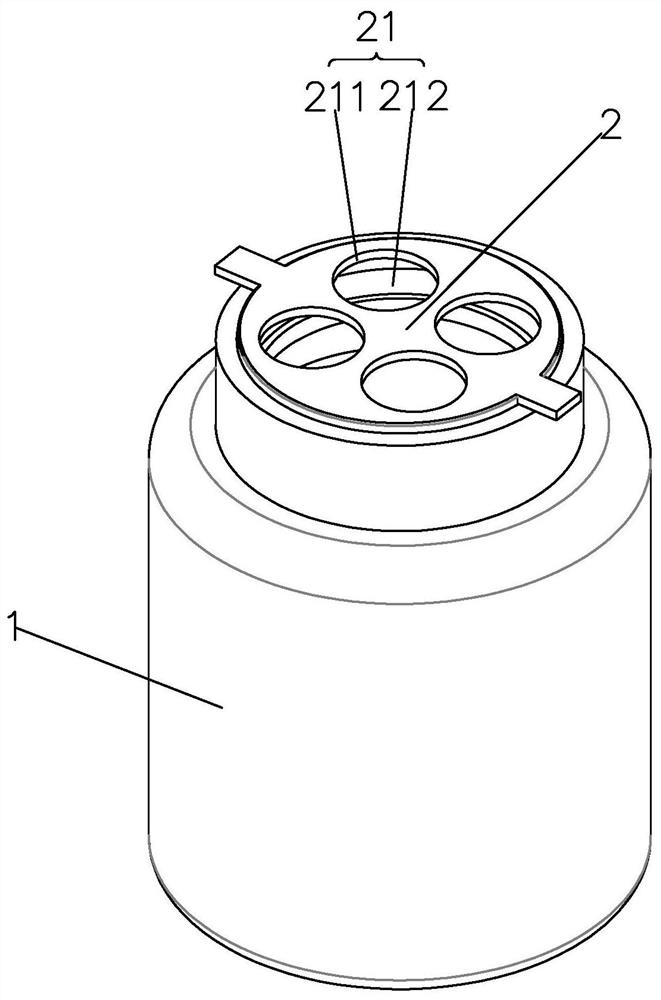

Device for efficiently preparing flocculant solution

PendingCN114471328AAvoid enteringAvoid destructionTransportation and packagingMixer accessoriesPhysical chemistryMacromolecule

According to the device for efficiently preparing the flocculating agent solution, a device body is composed of the barrel body and the barrel cover, the grinding device and the stirring device which are driven by the motor are designed in the barrel, flocculating agent particles can be ground into powder to be fully dissolved in water, the heating device is arranged at the bottom of the barrel, and the dissolving process of a polymeric flocculating agent can be accelerated; and the control panel is arranged, so that the concentration of the flocculating agent and the stirring time can be accurately controlled.

Owner:ZHEJIANG UNIV OF TECH

A kind of carbon nanomaterial macroscopic body, preparation method and adsorption and filtration particle performance

ActiveCN106582520BNot easy to runExtend the life cycleOther chemical processesWater contaminantsFiberPorosity

The invention discloses a carbon nanomaterial macro body. The carbon nanomaterial macro body is characterized in that the macro body has three structures of a definite porous shell, an inner wall and an inside. The material of the porous shell is any one of carbon fiber, ceramic and metal. The inner wall of the macro body (namely the inner surface of the porous shell) has a carbon nanomaterial. The inside of the macro body is filled with the carbon nanomaterial. The porosity of the macro body reaches 60%-97%, and the ratio of the height to the diameter of the macro body is 0.001-1000. The invention further discloses a method for utilizing a chemical vapor deposition method to prepare the macro body. The macro body can be used for adsorbing organic matters in wastewater and filter particles or the organic matters in gases, and has the advantages of being long in service life, big in handling capacity and low in preparing cost.

Owner:TSINGHUA UNIV

Excellent pleurotus geesteranus breeding method

InactiveCN112106646AImprove qualityImprove survival rateFungi productsLichen productsBiotechnologySporeling

The invention provides an excellent pleurotus geesteranus breeding method. The method comprises the following steps of (1) selecting an approved variety strain and a wild strain as parent strains; (2)performing breeding; (3) performing antagonism selection; (4) mixing a test strain with glutinous rice flour; (5) granulating a mixture of the test strain and the glutinous rice flour to form spore granular seeds; (6) inoculating the spore granular seeds into a cultivation container filled with a culture material; (7) feeding a cultivation container inoculated with the spore granular seeds into astrain cultivating chamber for strain cultivation; and (8) after hypha emerging, transferring the cultivation container into a fruiting room for fruiting. According to the pleurotus geesteranus breeding method, dominant strains are selected through the breeding process, the survival rate of pleurotus geesteranus is higher, a cultivation container is divided into a plurality of areas, the growth of the pleurotus geesteranus is not prone to extrusion, the growth of the pleurotus geesteranus is facilitated, inoculation operation is conducted through an inoculation device, and the inoculation efficiency is improved.

Owner:福建成发农业开发有限公司

A kind of reinforcement support structure of shear wall external formwork

ActiveCN109322483BImprove stabilityNot easy to runForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksClassical mechanicsEngineering

Owner:SHANGHAI GREENLAND CONSTR GRP

Automatic center adjusting polycrystalline die of high-speed vertical enameling machine

ActiveCN113421720AImprove stabilityHigh tensile strengthFinal product manufactureInsulating conductors/cablesPolycrystalline diamondNichrome

The invention discloses an automatic center adjusting polycrystalline die of a high-speed vertical enamelling machine, which relates to the field of high-speed vertical enamelling machine painting technology. A die core raw material is manufactured into a die core, electrolytic copper, zinc, cobalt, molybdenum, nickel, chromium and tin are uniformly mixed to obtain sintering powder, a die holder is then fixed through a graphite die sleeve, the die core is placed in the die holder, sintering powder is later added between the die holder and the die core, the die core is fixed to the center of the die holder in a hot pressing sintering mode through the powder metallurgy technology, and the automatic center adjusting polycrystalline die of the high-speed vertical enamelling machine is obtained. The die core is prepared from the diamond micro-powder, the intermediate 3 and the temperature-resistant filler, and under the synergistic effect of the intermediate 3 and the temperature-resistant filler, the high-temperature stability of the polycrystalline diamond prepared from the diamond micro-powder is effectively improved, so that flaws in the die core are avoided, the mechanical property of the die core is ensured, and the product quality is ensured; and the service life of the high-speed vertical enameling machine automatic adjustment center polycrystalline die is prolonged.

Owner:TONGLING JINGLONG ELECTRIC MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com