Beam plate lower cross beam supporting structure under disc buckle quick-release supporting system

A support system and support structure technology, applied in building construction, formwork/formwork/work frame, on-site preparation of building components, etc., can solve the problems of unqualified beam structure, labor and waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

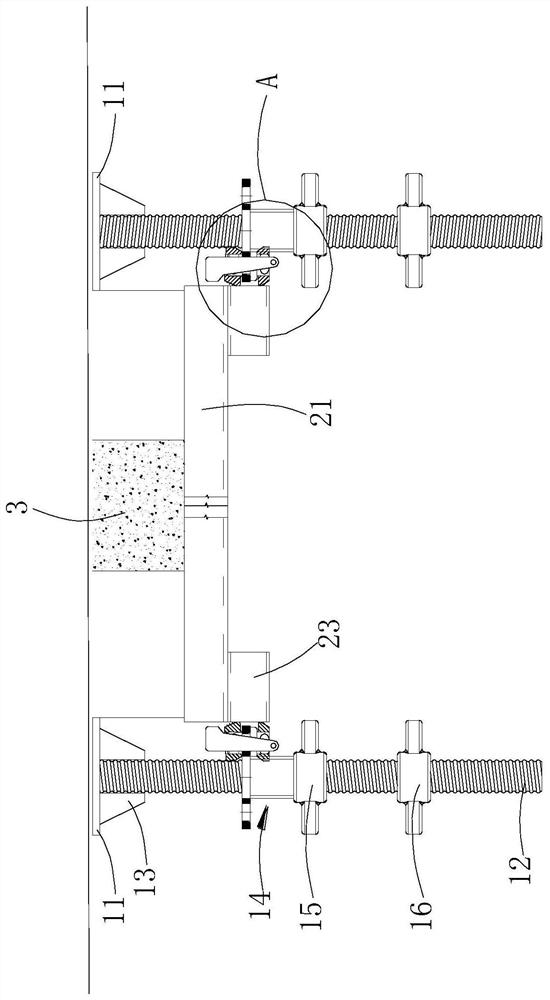

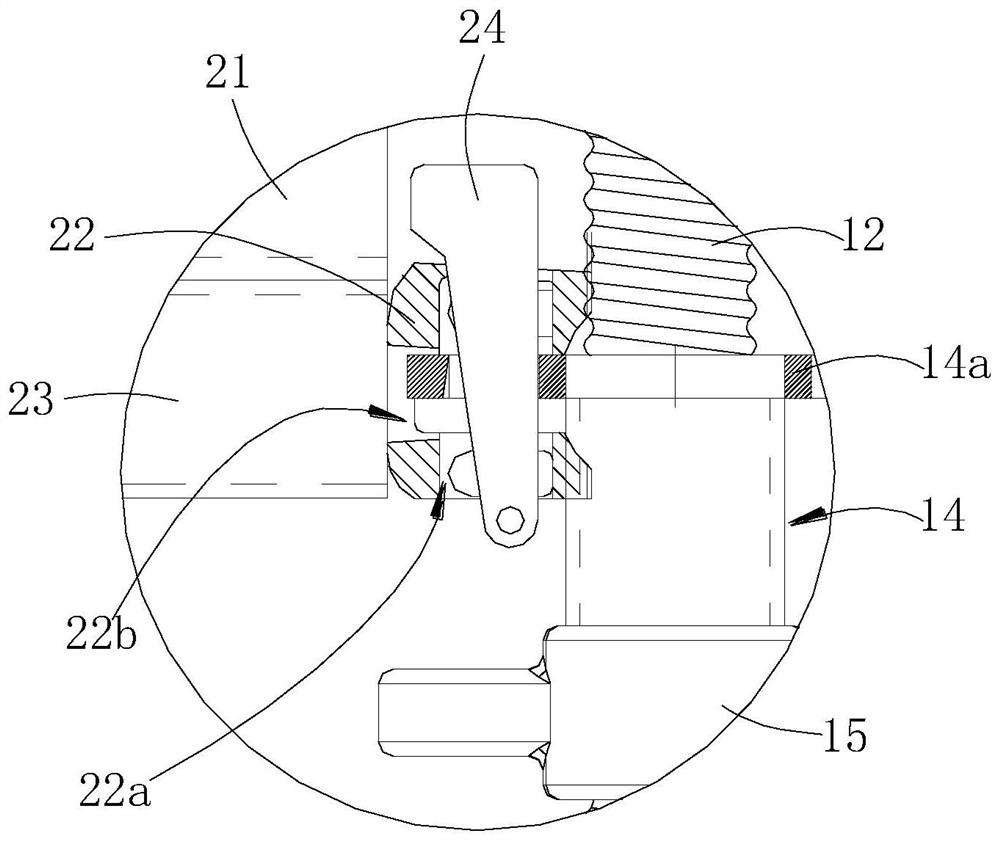

[0022] like Figures 1 to 6 shown

[0023] In this embodiment, a conventional pan buckle quick-release support system is first built on the lower side of the beam. The pan buckle quick-release support system includes multiple cross bars and multiple vertical bars, and multiple cross bars and multiple vertical bars are connected by multiple pan buckles. Fixing constitutes a supporting frame.

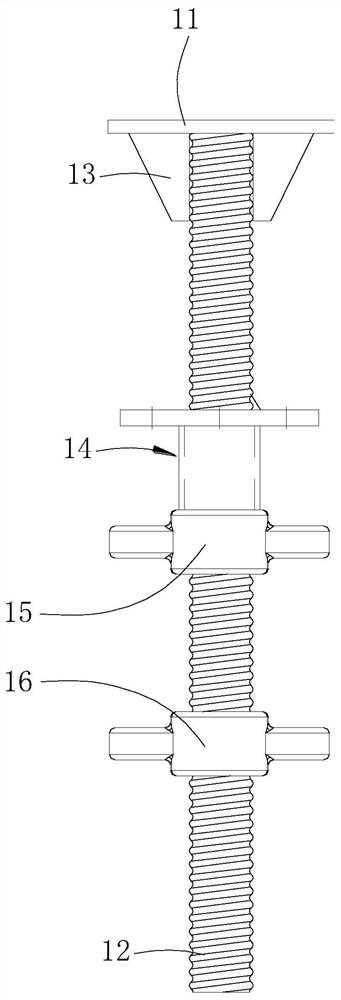

[0024] The lower beam support structure of the beam includes a cross bar support assembly and two support head assemblies.

[0025] The support head assembly includes a fixed top plate 11, a screw rod 12, a first nut 15, a second nut 16 and an adjustable support slider 14. The fixed top plate 11 is horizontally welded on the top of the screw rod 12, and two reinforcements are welded between the fixed top plate 11 and the screw rod 12. Rib 13, the adjustable support slider 14 is provided with an inner hole, the adjustable support slider 14 is sleeved on the outer wall of the screw rod 12...

Embodiment 2

[0030] like Figure 7 shown

[0031] The difference between this embodiment and Embodiment 1 is only that: after the installation of the support work for the laminated slab is completed, the lower beam support structure of the beam is installed under the pouring section, the square timber 4 is erected on the support cross bar 21, and then the formwork 5 is placed. At the same level as the bottom plate of the prefabricated laminated slab, the pouring belt is applied to install the reinforcement, and then the concrete is poured. After the strength reaches the form removal standard, the slide block 14 is lowered, the support cross bar 21 falls, the support cross bar 21 is removed, and the template 5 and the formwork are removed. side, turnaround into the next layer to use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com