Circular sawing machine for steel plate cutting

A circular saw and steel plate technology, applied in the field of steel plate cutting circular sawing machines, can solve the problems of at least several hours or even several days of waiting, the impact of sawing quality and productivity, and the impact on the production progress of the enterprise, achieving a high degree of automation, Long service life and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

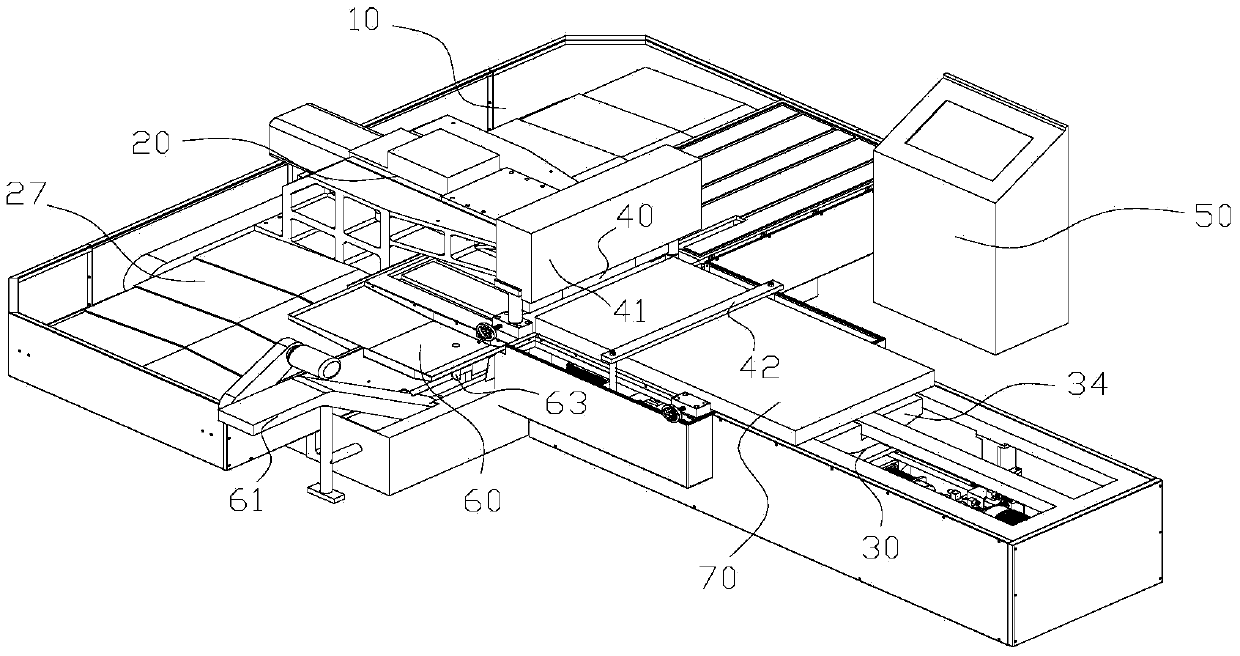

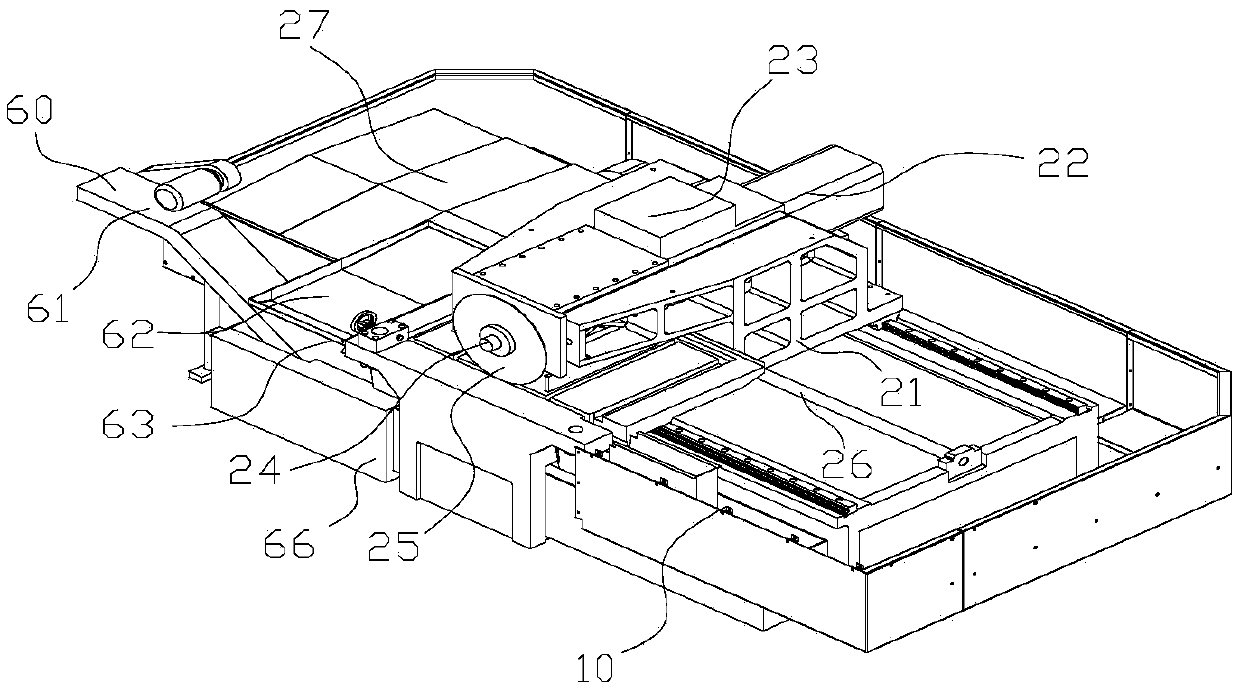

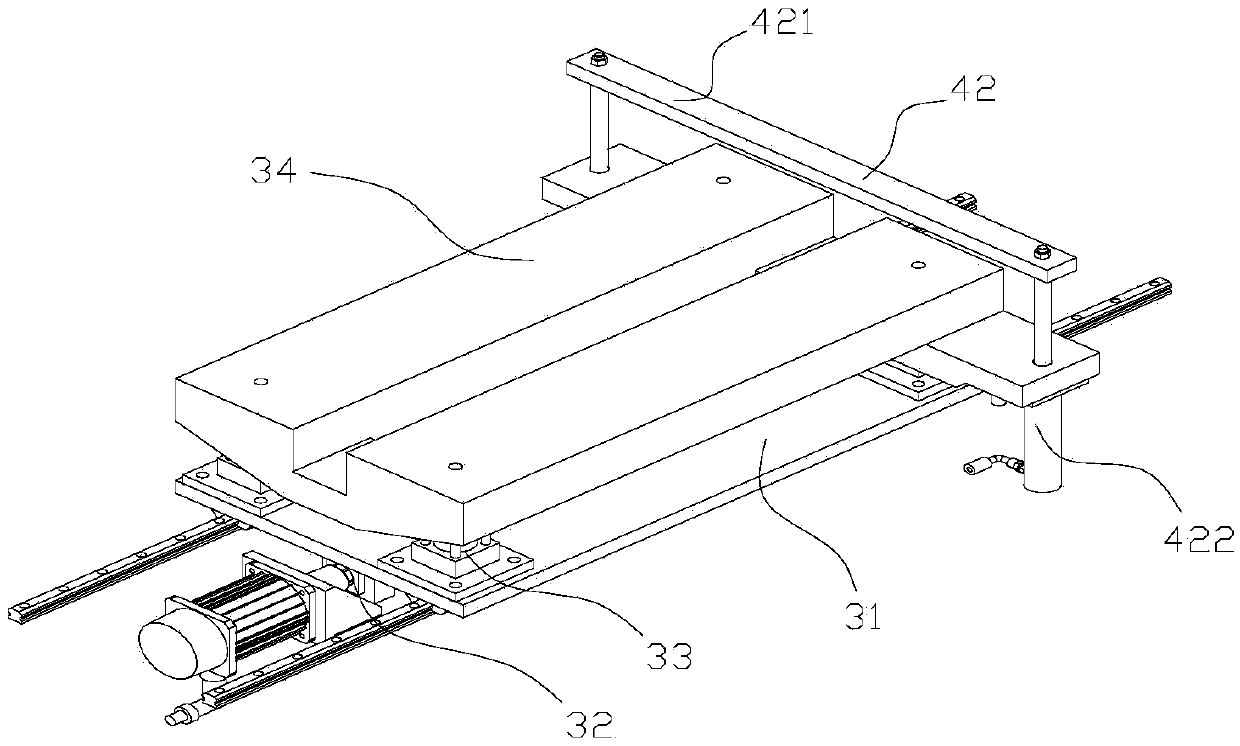

[0030] Examples, see Figure 1 to Figure 3 Shown: a steel plate cutting circular sawing machine, including a frame 10, a cutting device 20 installed on the frame 10, a moving assembly 30 for conveying a workpiece 70, a pressing assembly 40, and a control system 50, and the moving assembly 30 includes a moving plate 31 , the screw assembly 32 installed on one side of the moving plate 31, the telescopic assembly 33 installed on the other side of the moving plate 31 and the support plate 34 fixedly connected on the output shaft of the telescopic assembly 33, the pressing assembly 40 includes the main pressing Assembly 41 and auxiliary pressing assembly 42, the main pressing assembly 41 is pressed on the frame 10 and faces the cutting device 20, the auxiliary pressing assembly 42 is installed on the supporting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com