Patents

Literature

96results about How to "Seam smooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

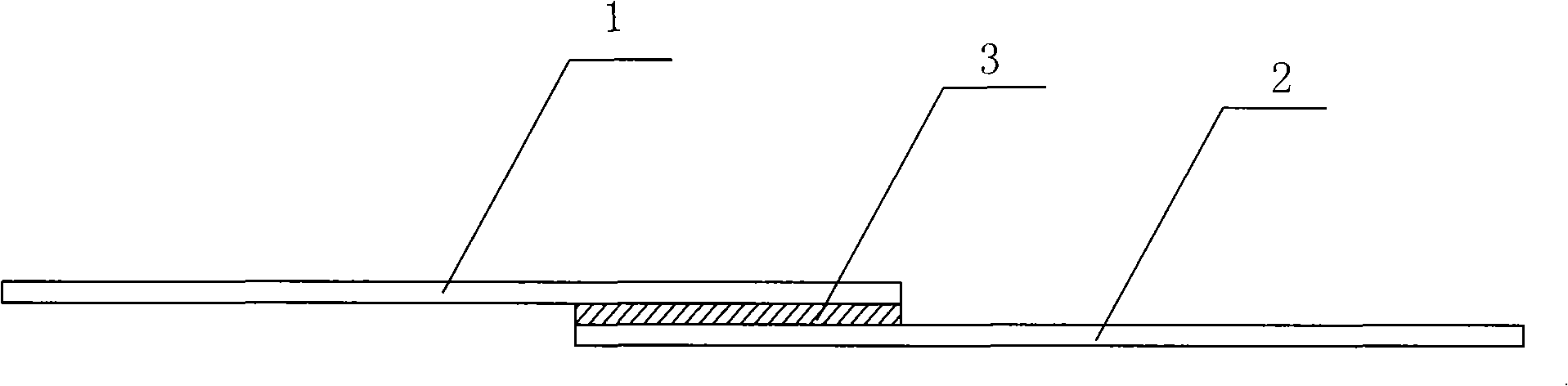

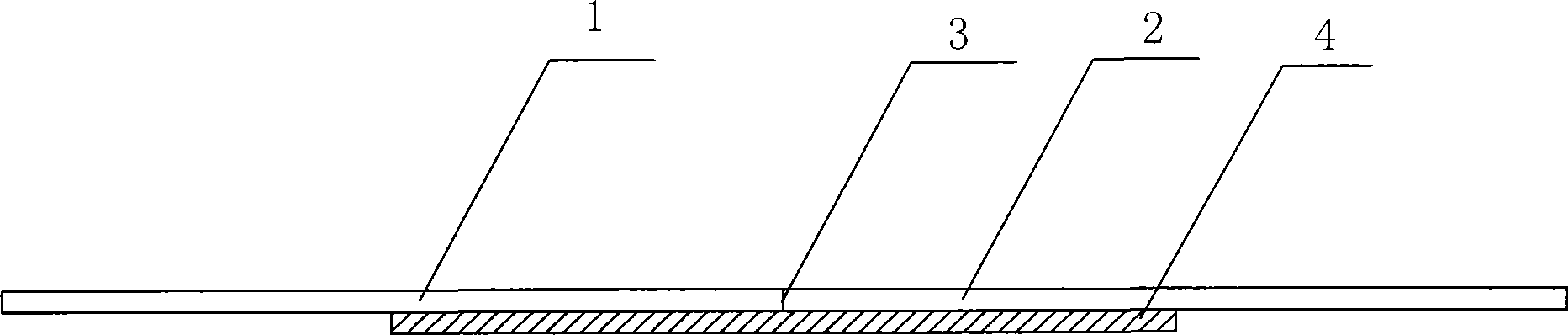

Clothing seamless splicing structure and splicing method thereof

InactiveCN101406331AImprove bonding fastnessEliminate voidsClothes making applicancesEngineeringMechanical engineering

The invention relates to a stitches free spicing structure for clothes, which comprises two pieces of fabrics to be spiced, the two pieces of the fabrics are overlapped at sliced position, and a double sticky tape joined with the fabrics by hot pressing is arranged between the two pieces of the fabrics positioned at the spiced position. The splicing process for the clothes stitches free spicing structure comprises the following steps: (1) cutting and shaping the two pieces of the fabrics to be spliced and the double sticky tape; and (2) sticking the double sticky tape on the splicing position of one piece of the fabric, and then fixing the other piece of the fabric by a hot pressing process. The clothes adopting the stitches free spicing structure has the characteristics of comfortable wearing, lightness, convenience, wind prevention, warmness maintenance, water resistance and so on.

Owner:杭州福星工贸有限公司

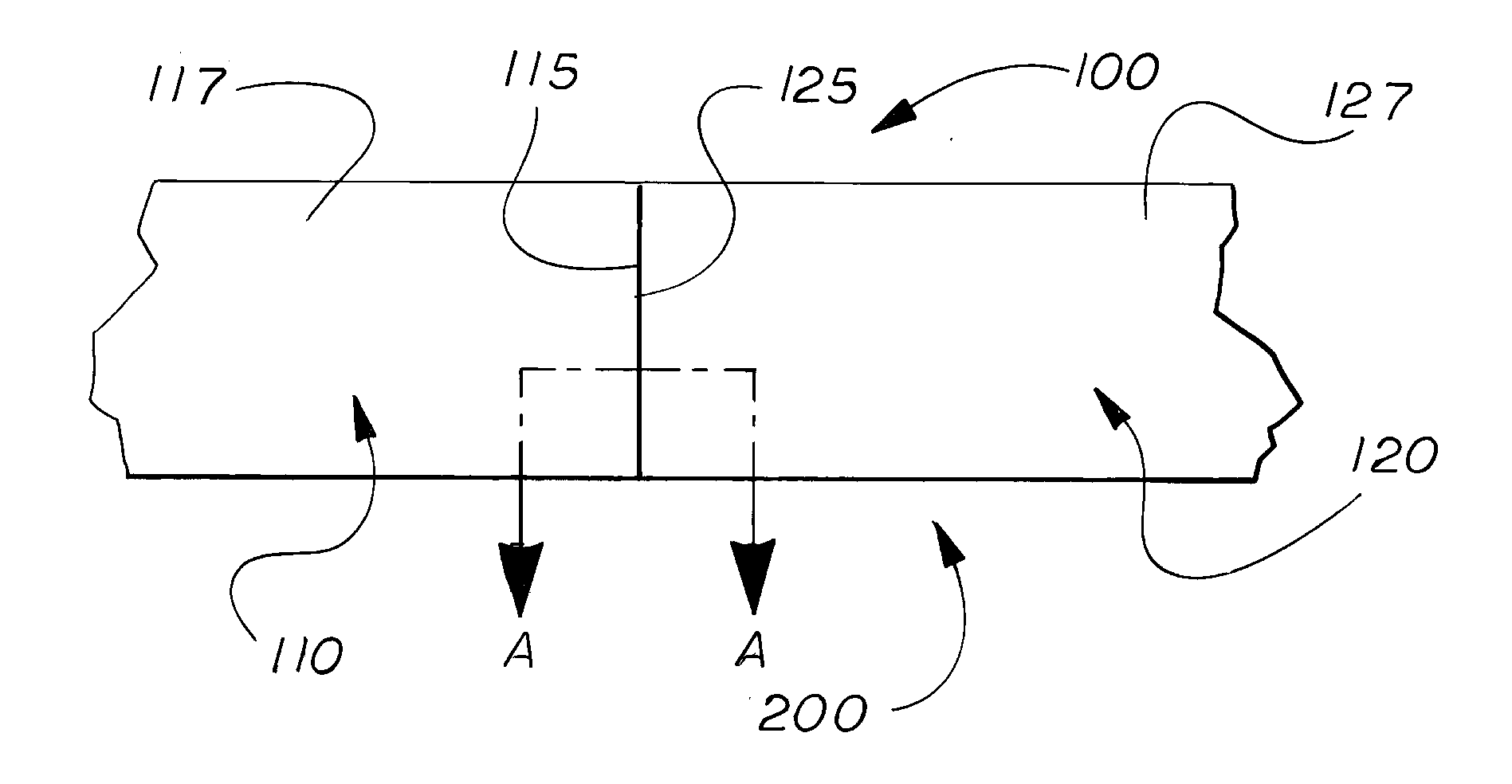

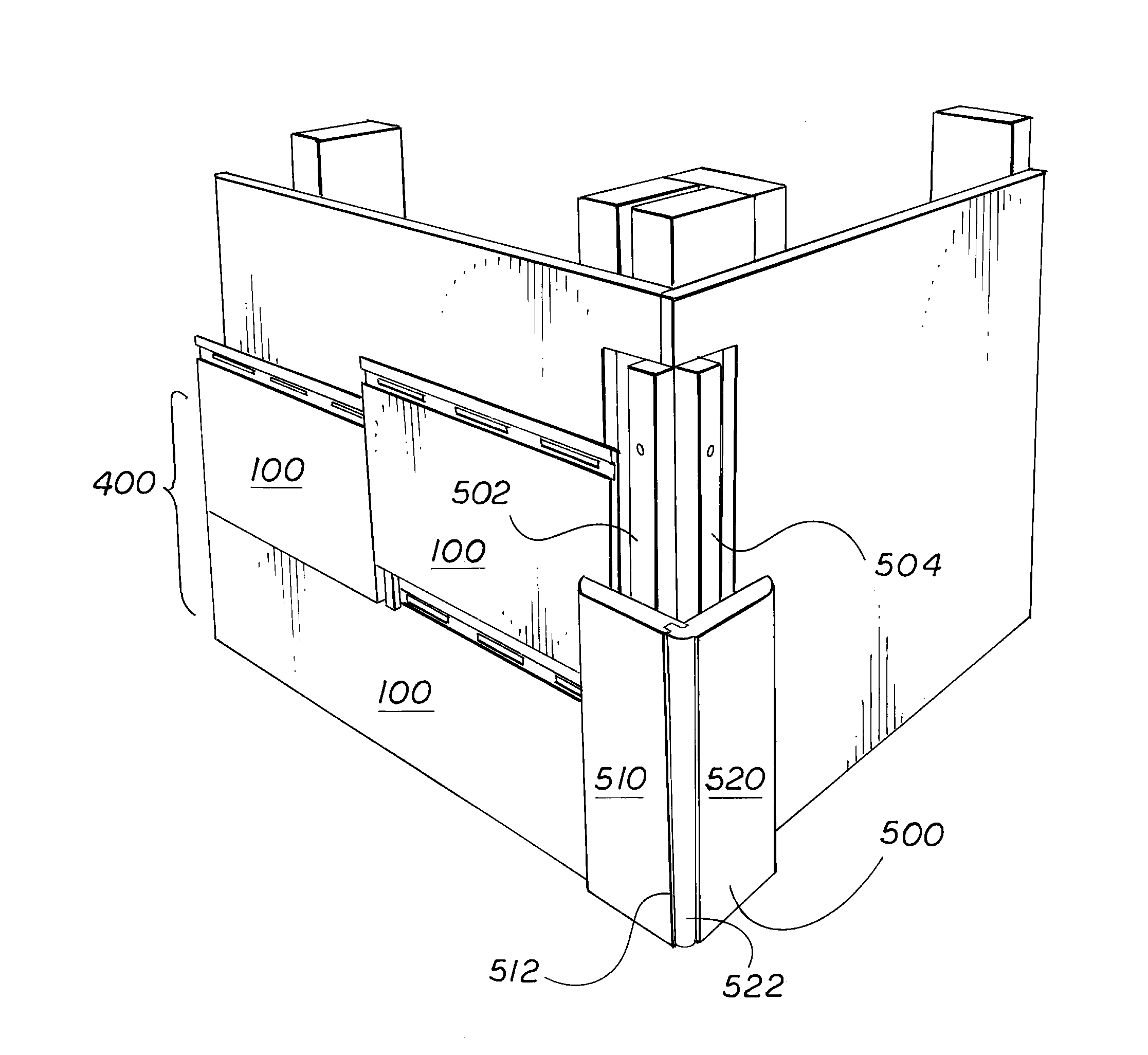

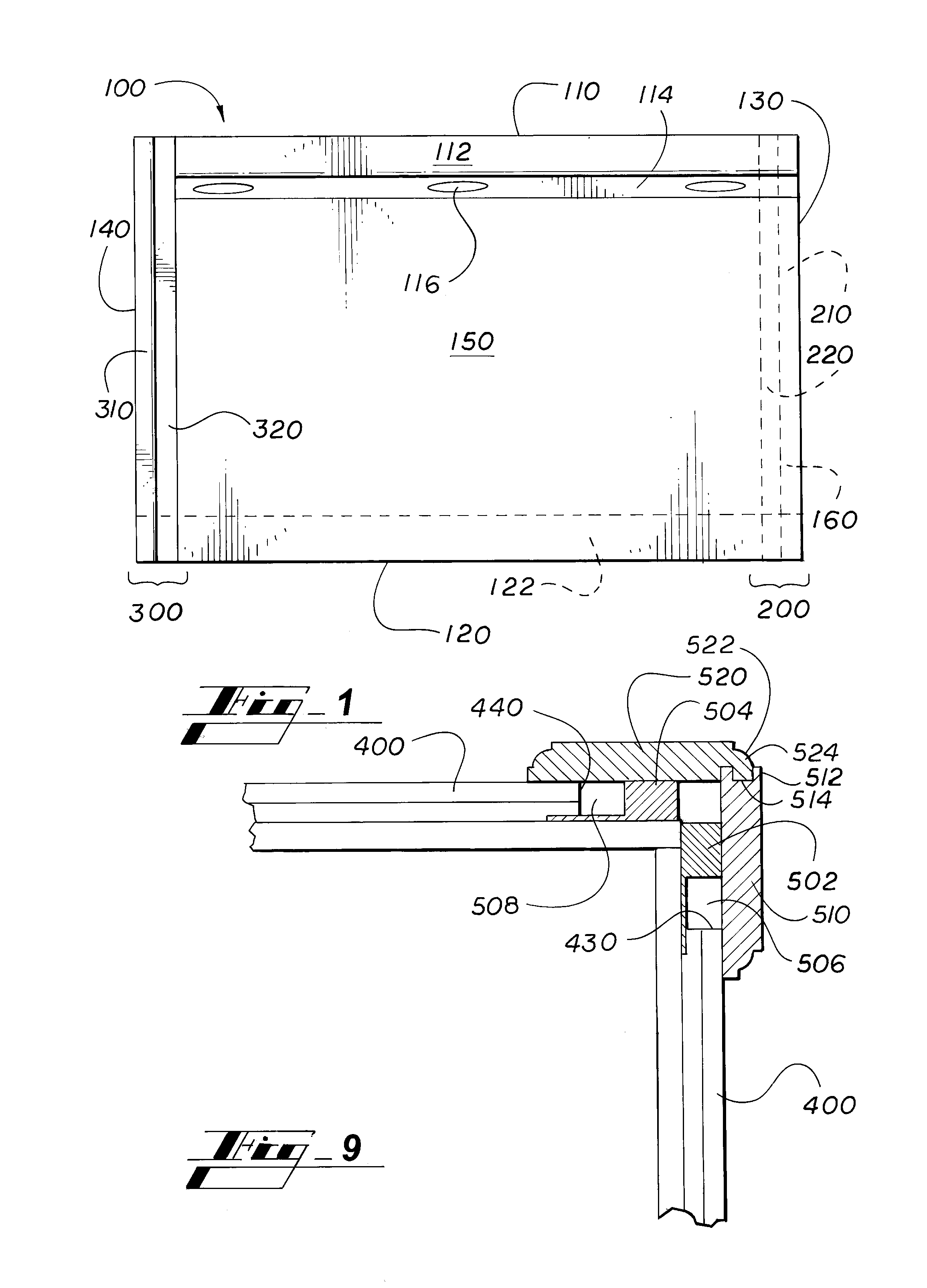

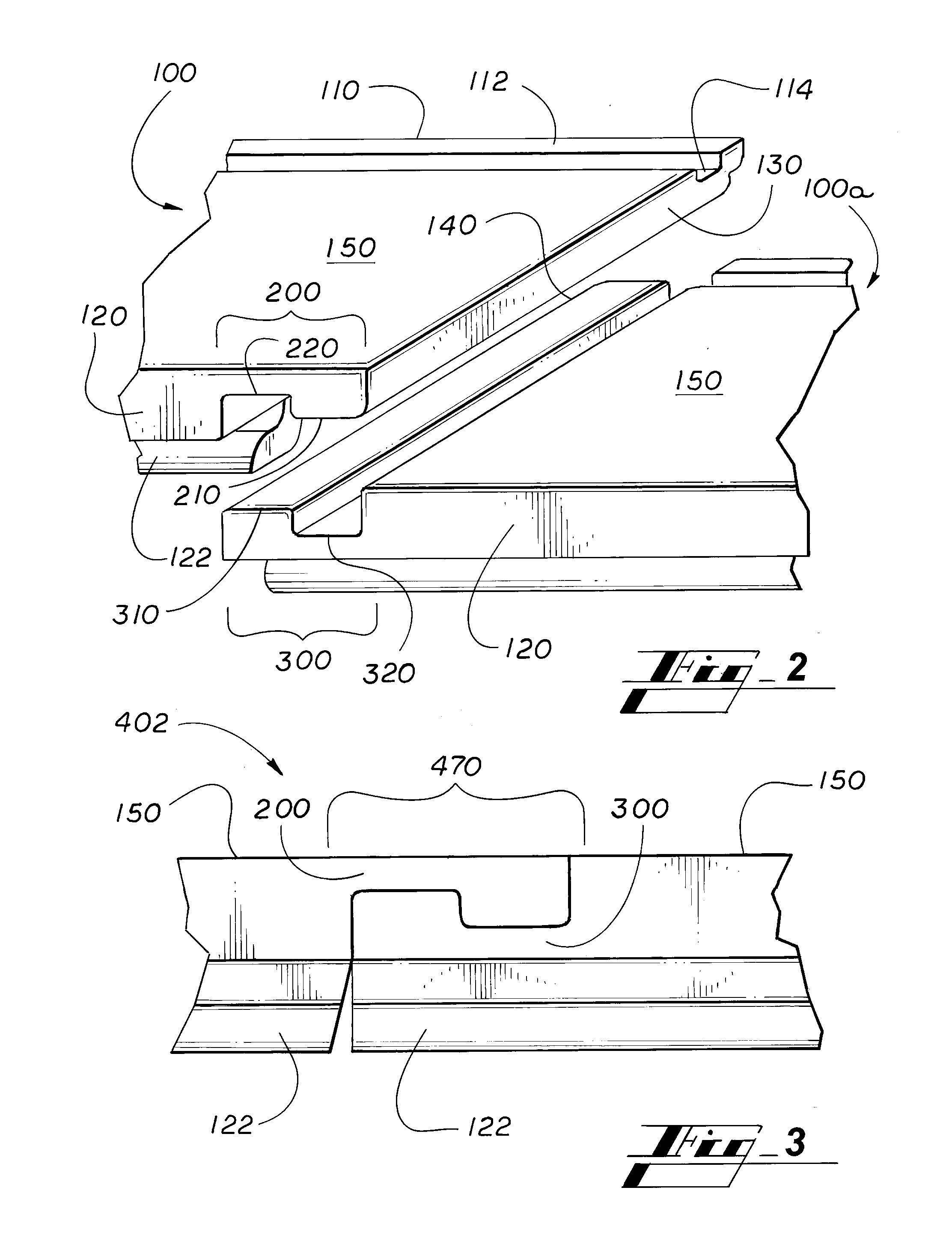

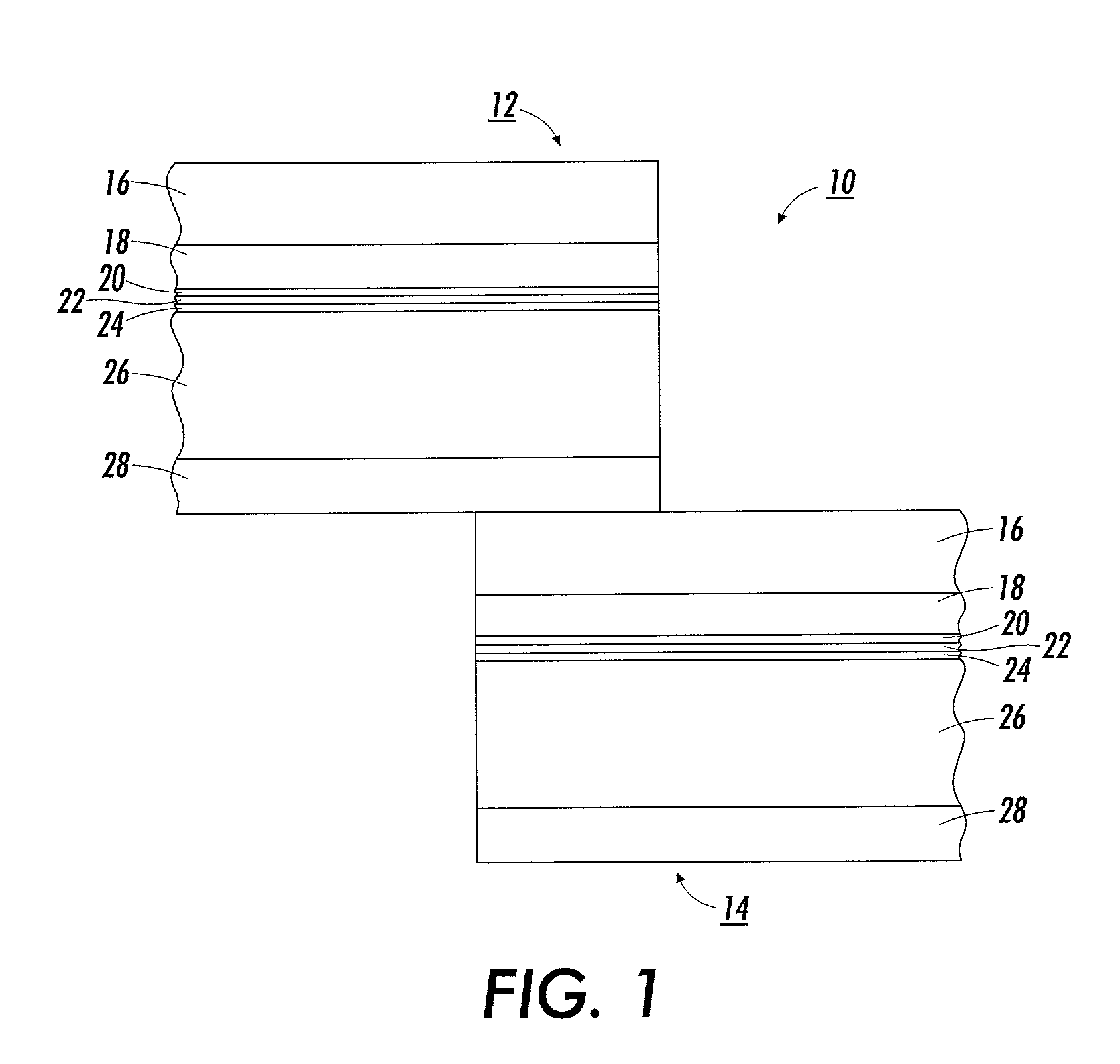

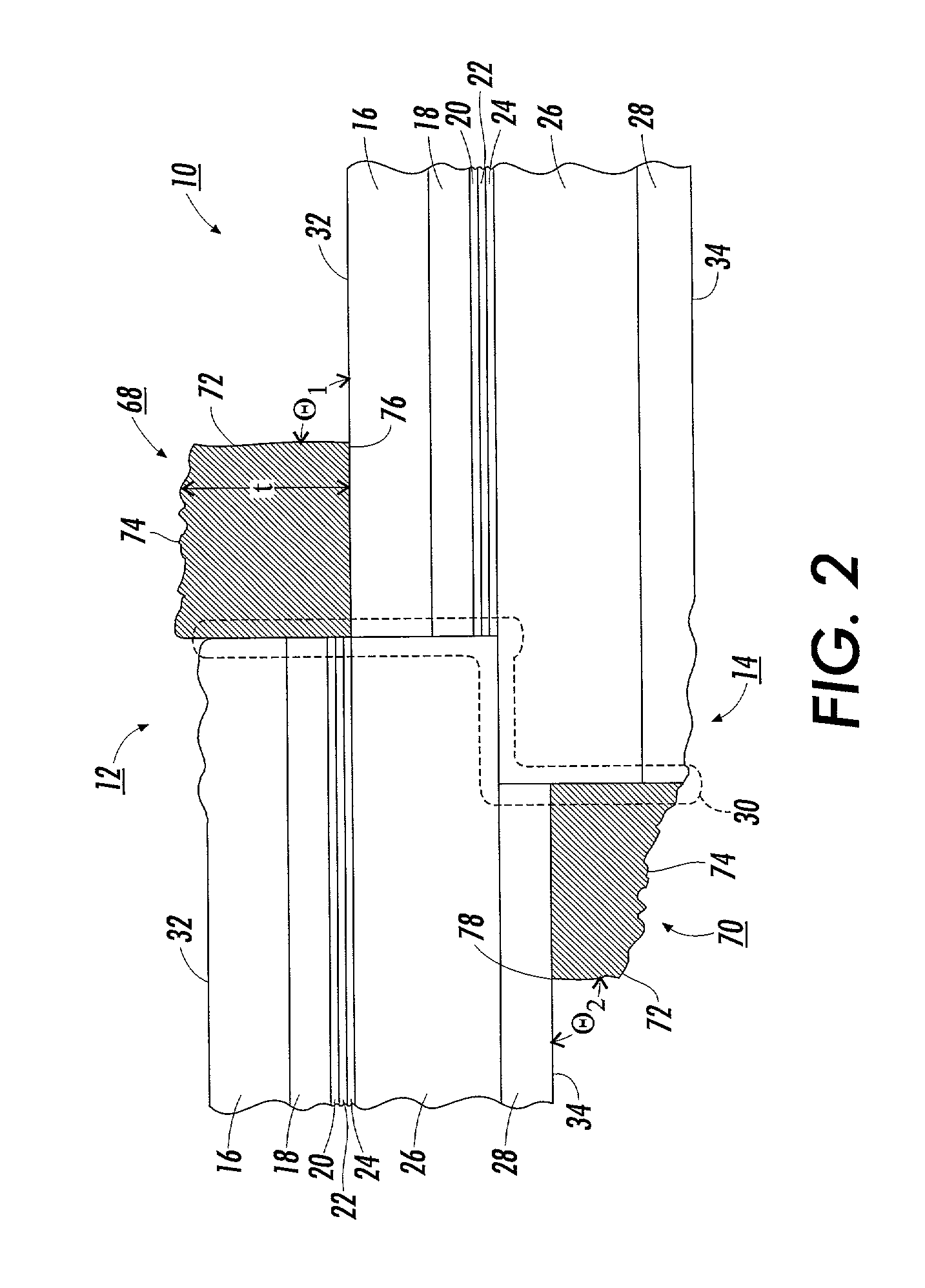

Siding joinery

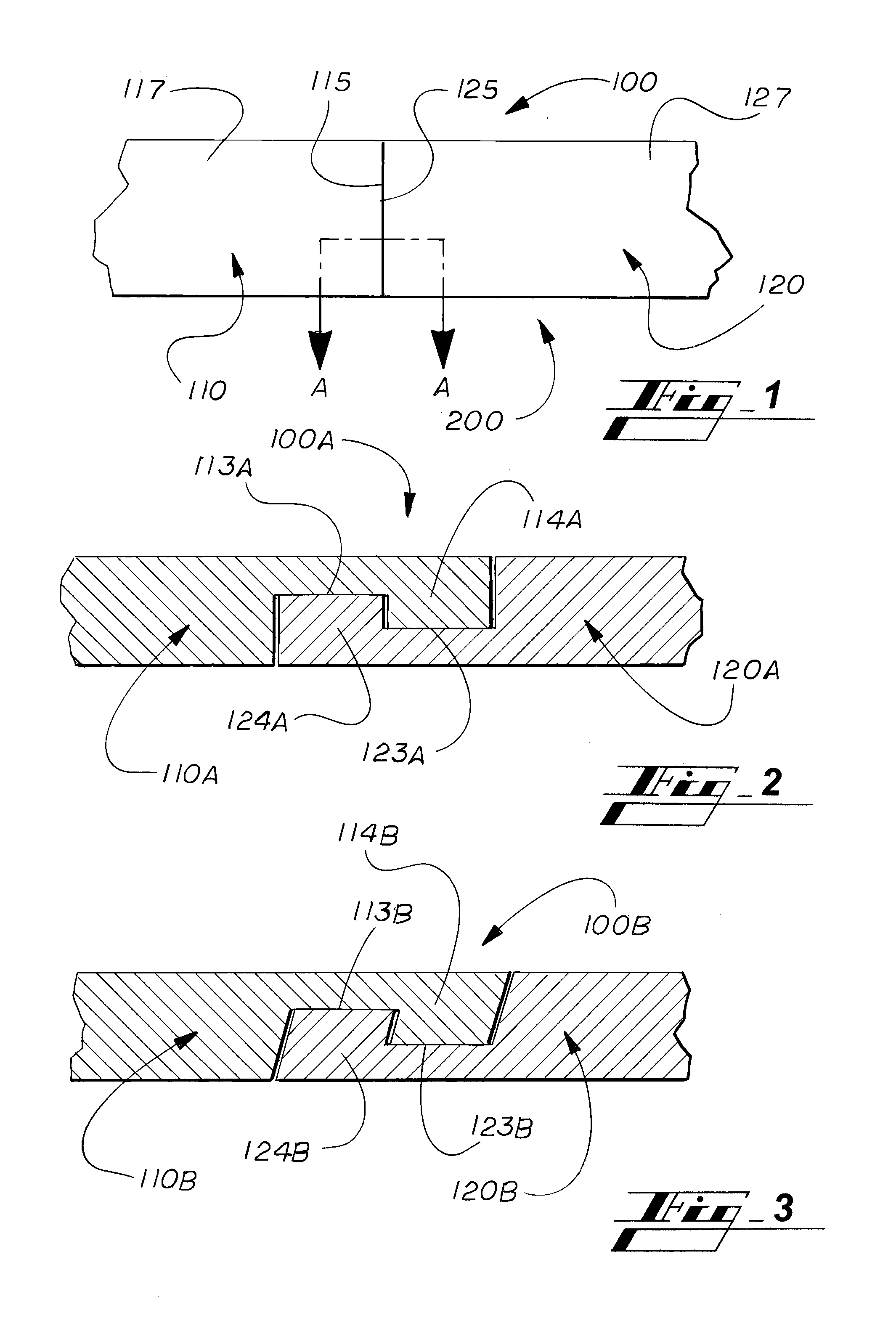

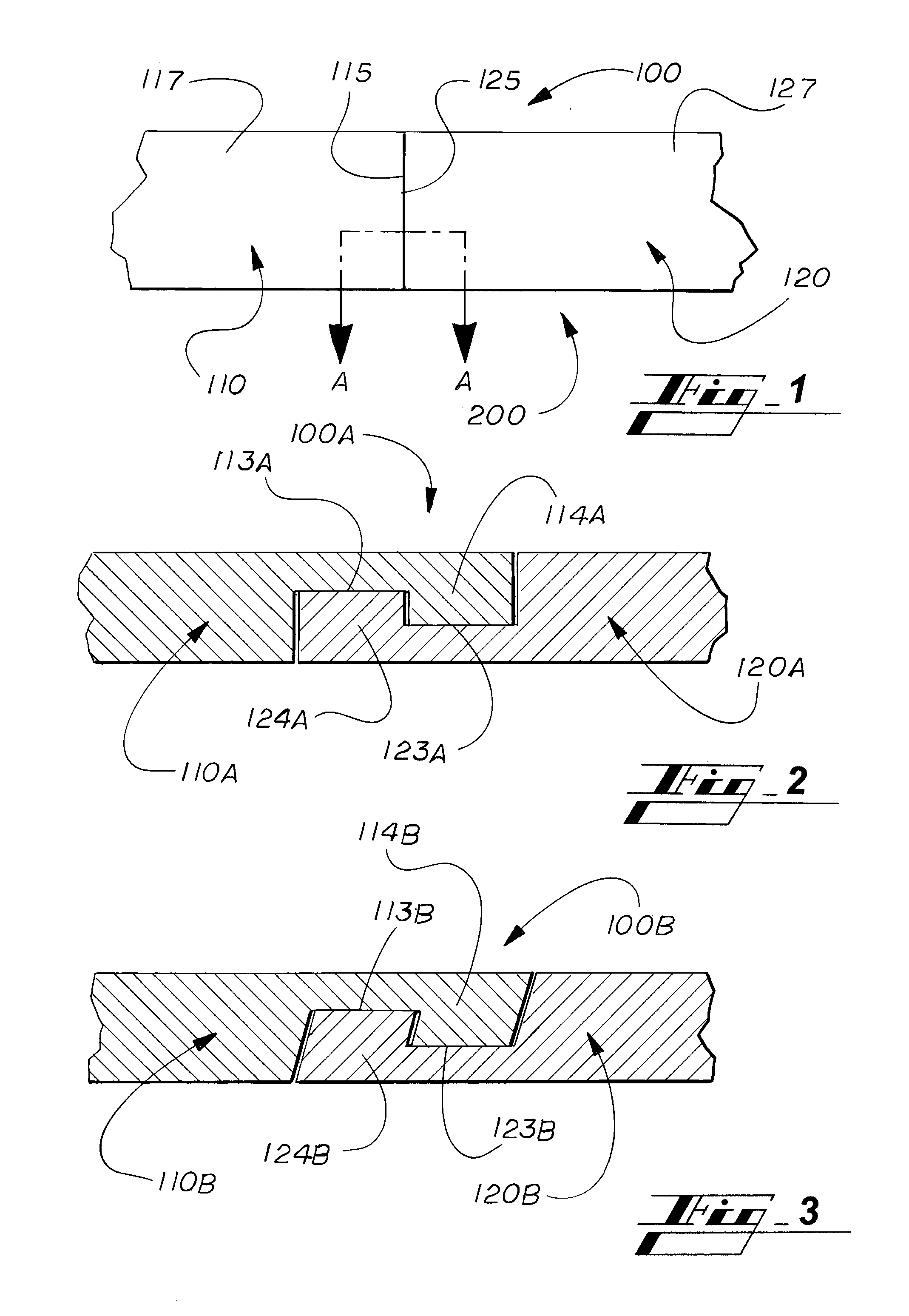

InactiveUS20130255174A1Seam smoothLess apparentRoof covering using tiles/slatesCovering/liningsWoodworkingEngineering

A panel system includes elongated panels coupled together at a seam portion with respective interlocking portions at corresponding vertical ends to provide a substantially planar surface. In siding panel systems, joined siding panels are provided in vertically arranged rows that further couple together along adjacent horizontal edges of the respective rows of siding panels.

Owner:GENERAL ELECTRIC CO ADMINISTATIVE AGENT AS SUCCESSOR BY MERGER

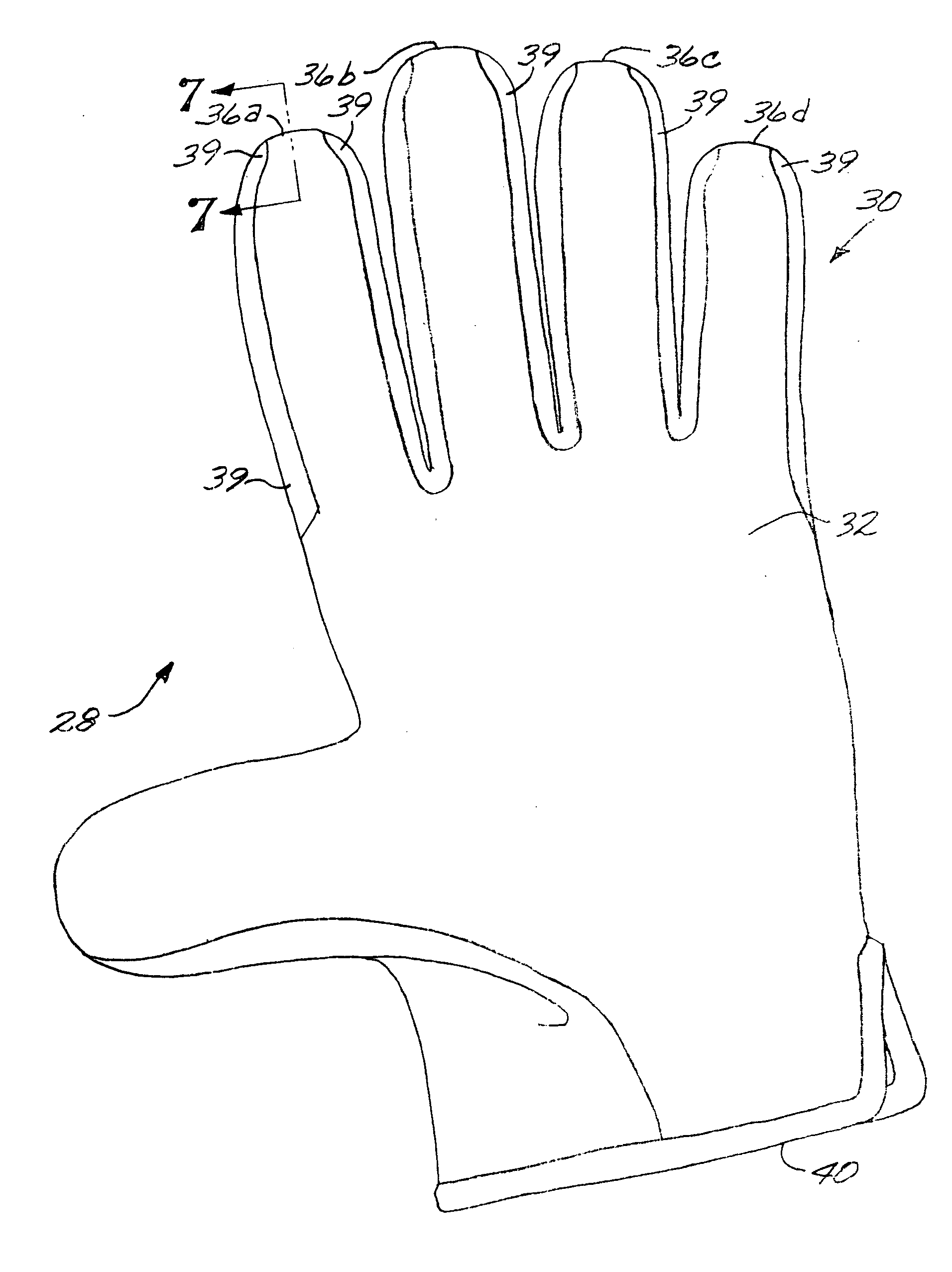

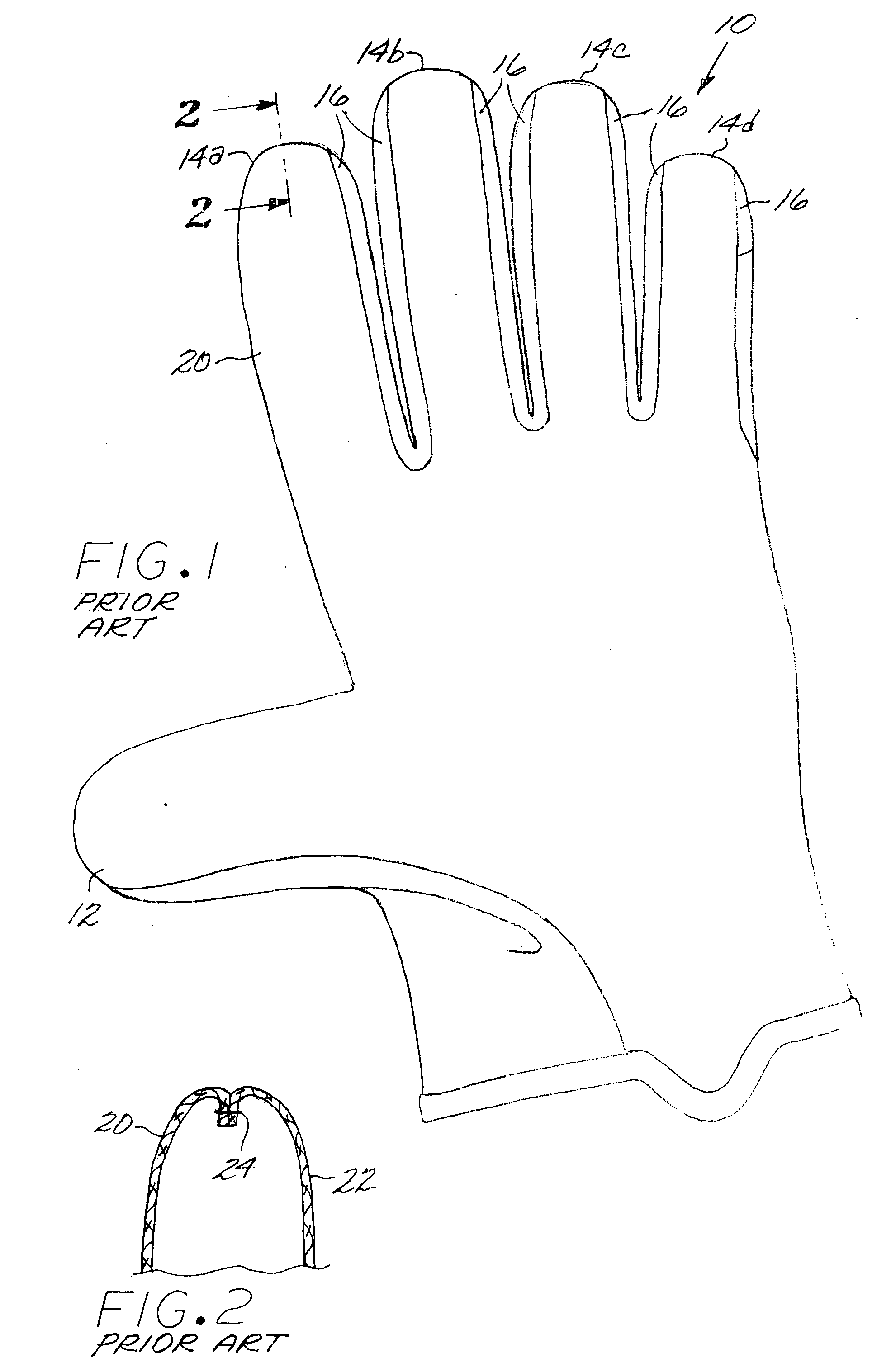

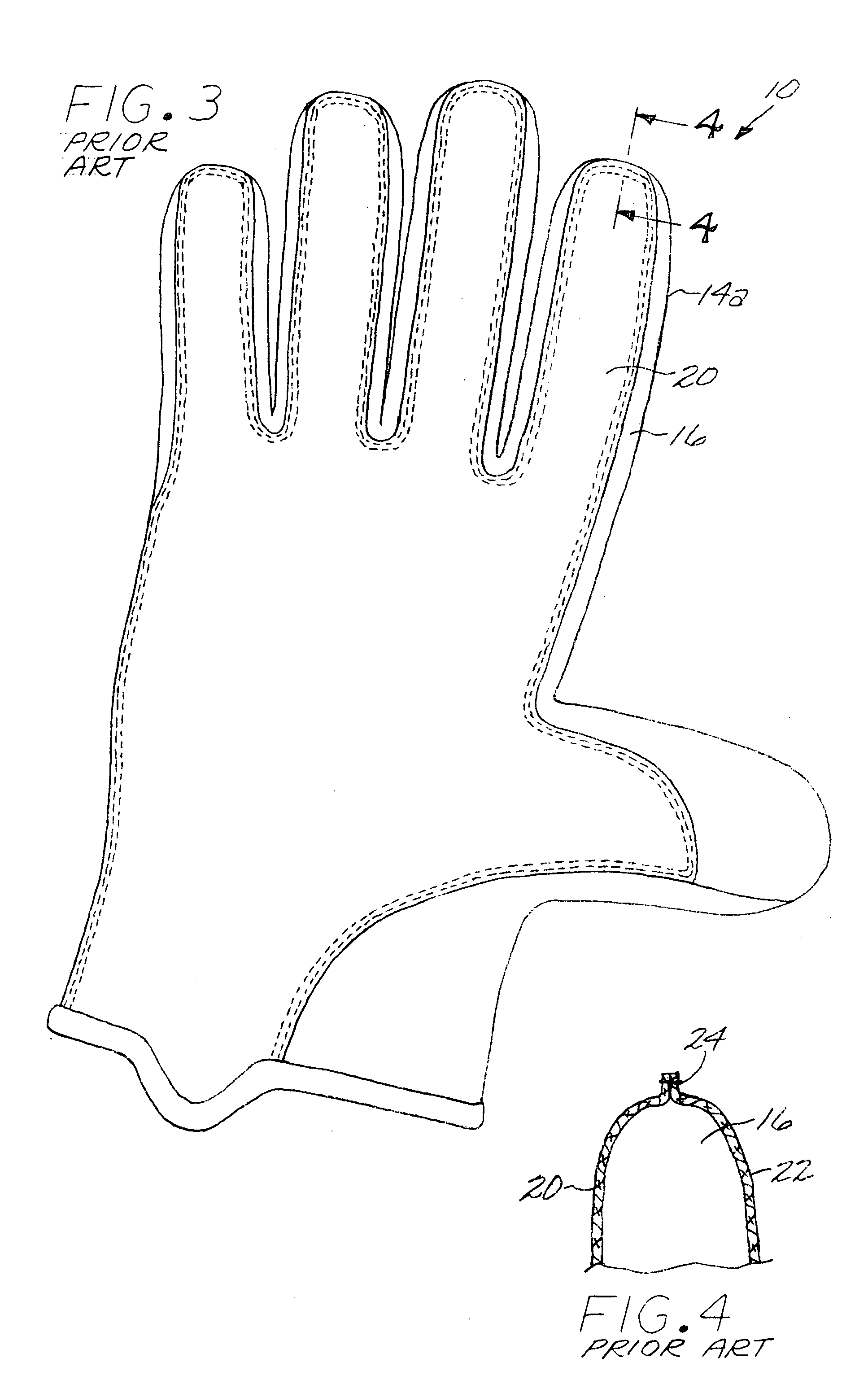

Glove construction wherein palm material rolls over fingertip

A glove structure that incorporates a palm piece having a portion that rolls over the fingertips and is sewn to the top portion of the back piece thus eliminating the conventional thick seam lines on the fingertips and resulting in a smooth seam of material over the entire fingertip and a substantial increase in finger tactility. The palm material narrows as it rolls over the fingertip and preferably has the shape of an hourglass.

Owner:BRIGHTON BEST INT INC

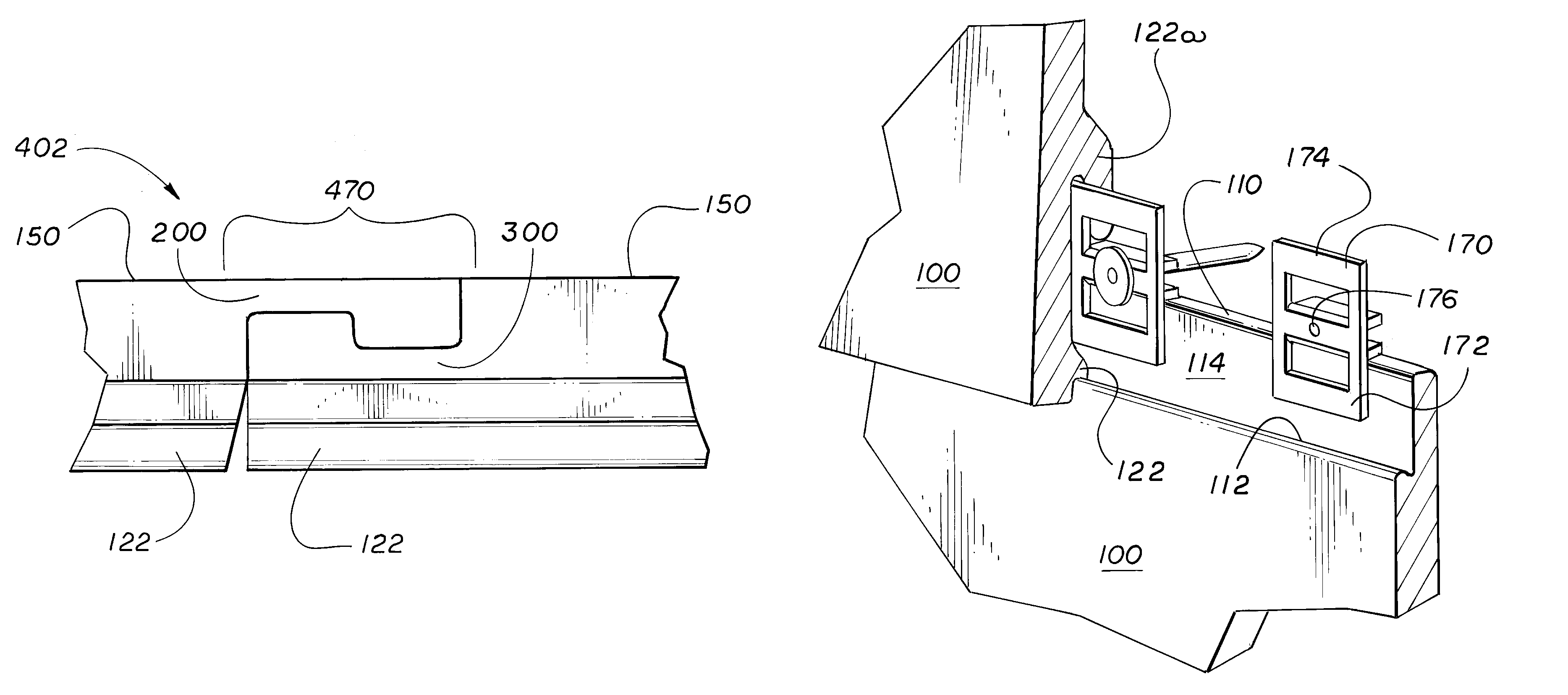

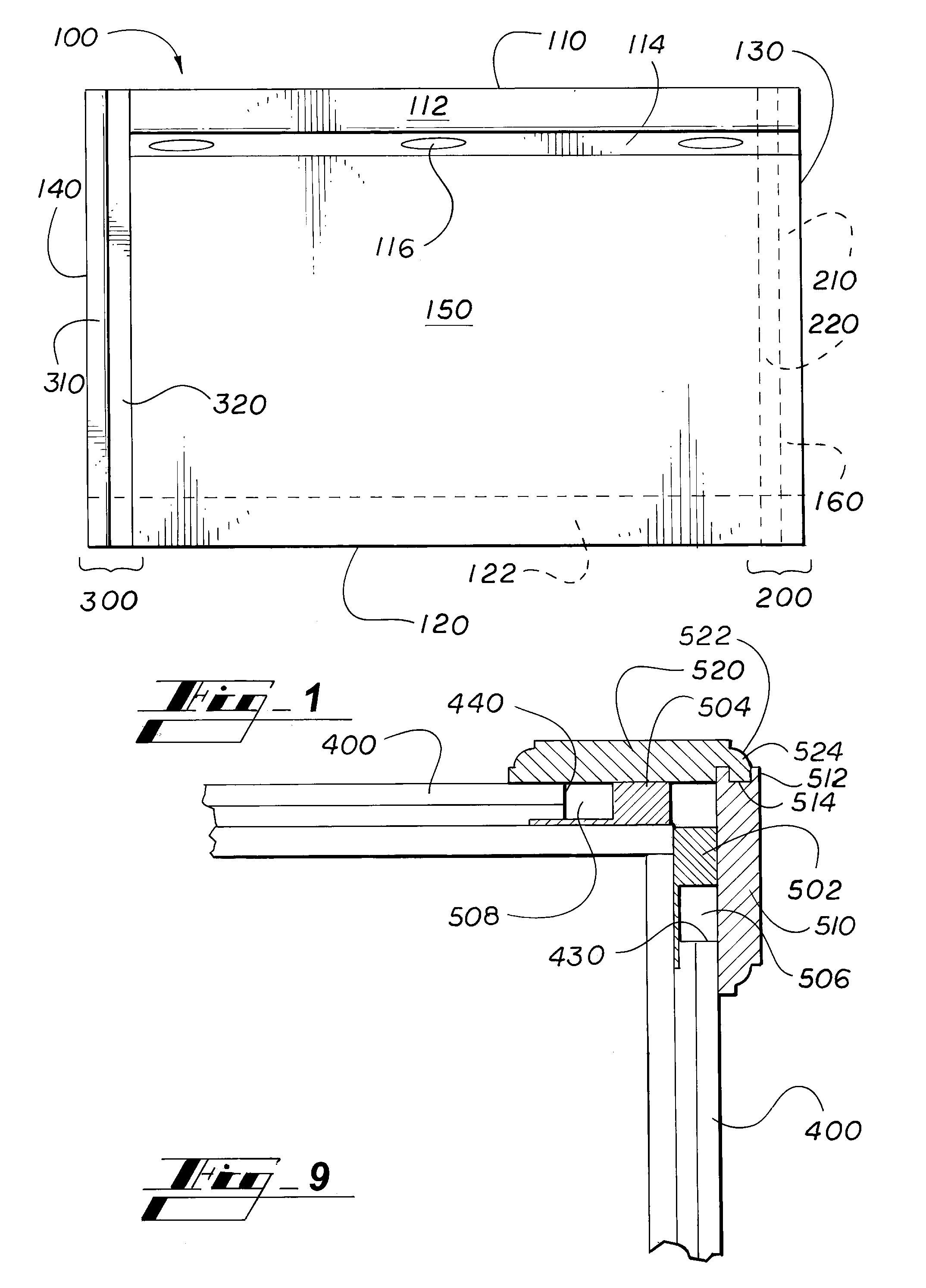

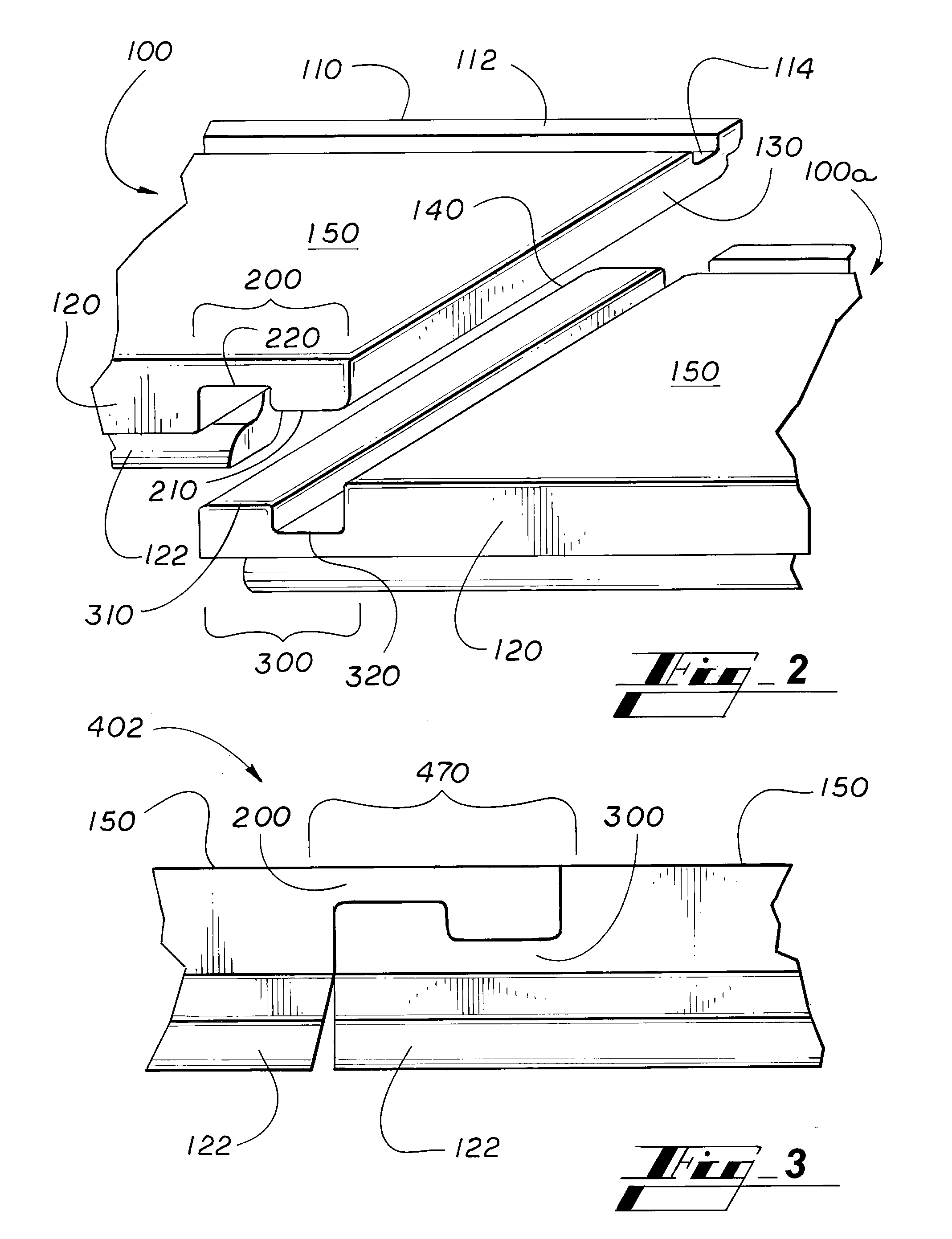

Interlocking panel system

ActiveUS8402707B2Seam smoothLess apparentConstruction materialRoof covering using tiles/slatesEngineeringMechanical engineering

A panel system includes elongated panels coupled together at a seam portion with respective interlocking portions at corresponding vertical ends to provide a substantially planar surface. In siding panel systems, joined siding panels are provided in vertically arranged rows that further couple together along adjacent horizontal edges of the respective rows of siding panels.

Owner:ROYAL GROUP

Interlocking panel system

ActiveUS20110185670A1Seam smoothLess apparentConstruction materialRoof covering using tiles/slatesEngineeringMechanical engineering

A panel system includes elongated panels coupled together at a seam portion with respective interlocking portions at corresponding vertical ends to provide a substantially planar surface. In siding panel systems, joined siding panels are provided in vertically arranged rows that further couple together along adjacent horizontal edges of the respective rows of siding panels.

Owner:ROYAL GROUP

High-strength electron beam welding process of titanium metal material and copper or copper alloy

InactiveCN102059443AEliminates brittle compoundsHigh strengthElectron beam welding apparatusWelding/soldering/cutting articlesTitanium metalVacuum chamber

The invention relates to a high-strength electron beam welding process of a titanium metal material and a copper or copper alloy, in particular to a welding process of a titanium metal material and a copper or copper alloy. The invention solves the problems of low joint strength and poor plasticity of because of brittle compounds existing in a welding joint of the titanium metal material and the copper or copper alloy. The process comprises the following steps of: filling the uniformly mixed powder of vanadium and copper powder in a specific die, carrying out chill pressing and forming the mixed powder under the action of a press punch so that the metal thickness of a pressed filling layer is 0.5-2.0 mm; putting the pressed and formed filling layer into a vacuum heating furnace for dispersion treatment, wherein the filling layer is a copper alloy layer; presetting a barium-copper alloy layer in a butt seam of the titanium metal material and the copper or copper alloy, fixing through TIG (Tungsten Inert Gas) spot welding, ultrasonically cleaning, carrying out acidic cleaning, drying and arranging in a vacuum chamber for vacuum electron beam welding; and welding by adopting an electron beam, wherein the beam current acting point is arranged on the barium-copper alloy layer in welding. The high-strength electron beam welding process is suitable for the welding of a titanium metal material and a copper or copper alloy.

Owner:HARBIN INST OF TECH

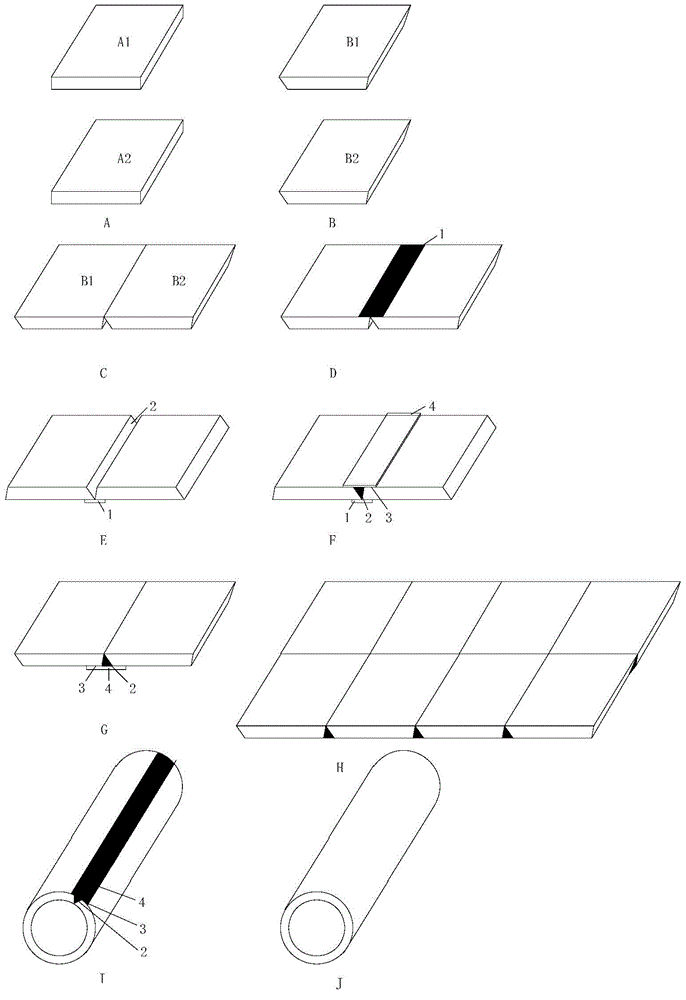

Seamless splicing method for circular metal mould tape with optical micro structure aggregate on surface

The invention discloses a seamless splicing method for a circular metal mould tape with an optical micro structure aggregate on the surface. The seamless splicing method for the circular metal mould tape with the optical micro structure aggregate on the surface is characterized in that a peelable adhesive tape is adopted for sealing and pasting a seam in the front, a room temperature cured A / B structure conductive adhesive is used for packing the back of the seam, and a method that the seam is fixed by metal sheet and two-component structural adhesive from the back is adopted for treating the seam; meanwhile, an electroforming process is combined, and finally a super large circular tape metal template is formed. The seamless splicing method for the circular metal mould tape with the optical micro structure aggregate on the surface has the advantages that the seam is smooth and ablation-free and mechanical strength can be guaranteed.

Owner:田武学 +1

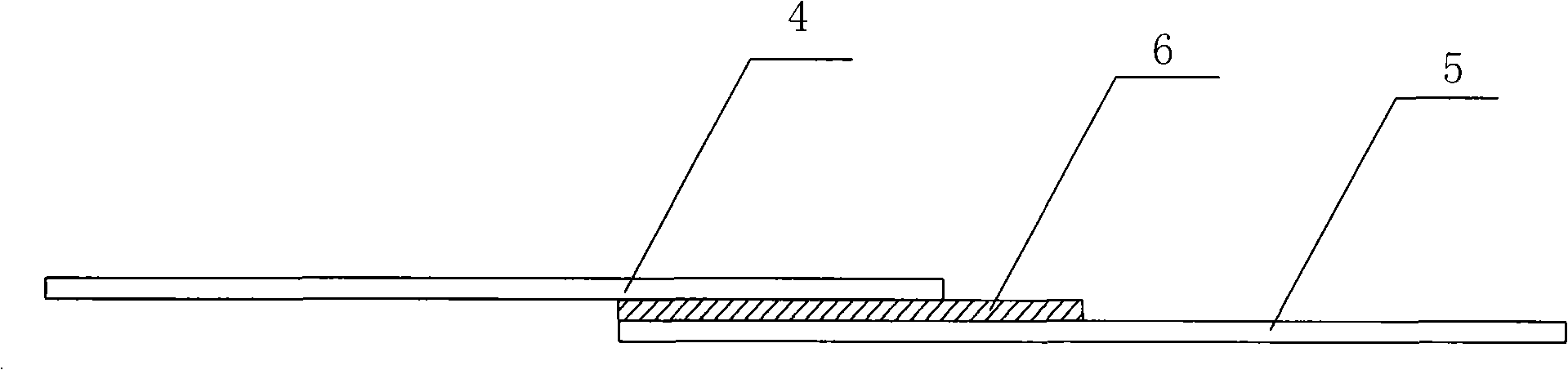

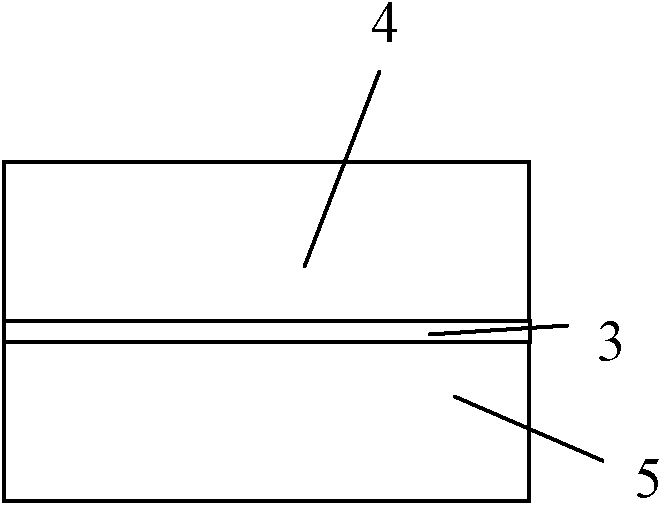

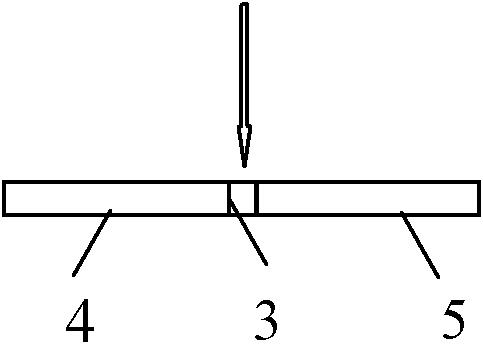

Seamless line split joint structure and split joint method for clothing

InactiveCN101427853AThe waterproof tape improves the wind resistance of the seamless seam-jointed structure of the garmentWaterproofClothes making applicancesEngineeringHot press

The invention relates to a seamless splicing structure of clothing, which comprises two pieces of fabric to be spliced, wherein the two pieces of fabric are molten at the spliced position and are connected with each other; and a one-side adhesive tape spun-bonded with the fabric is arranged on one side of the fabric at the spliced position. The splicing process of the seamless splicing structure comprises the following steps: (1) melting the two pieces of fabric to be spliced by ultrasonic thermal-melting process at the spliced position and connecting with each other; and (2) fixing a one-side adhesive tape on one side of the fabric by hot-press bonding process at the spliced position. The clothing with the seamless splicing structure has the advantages of wearing comfort, light weight, convenience, wind resistance, warmth retention, water tightness, etc.

Owner:杭州福星工贸有限公司

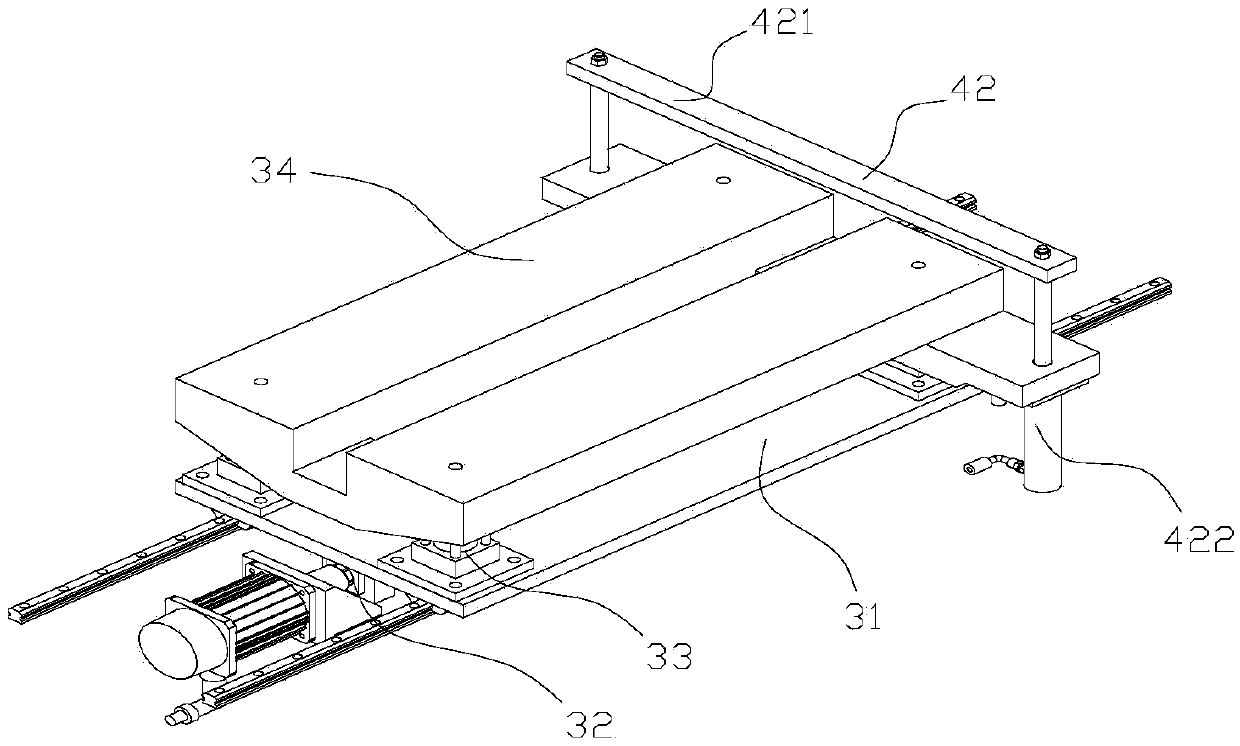

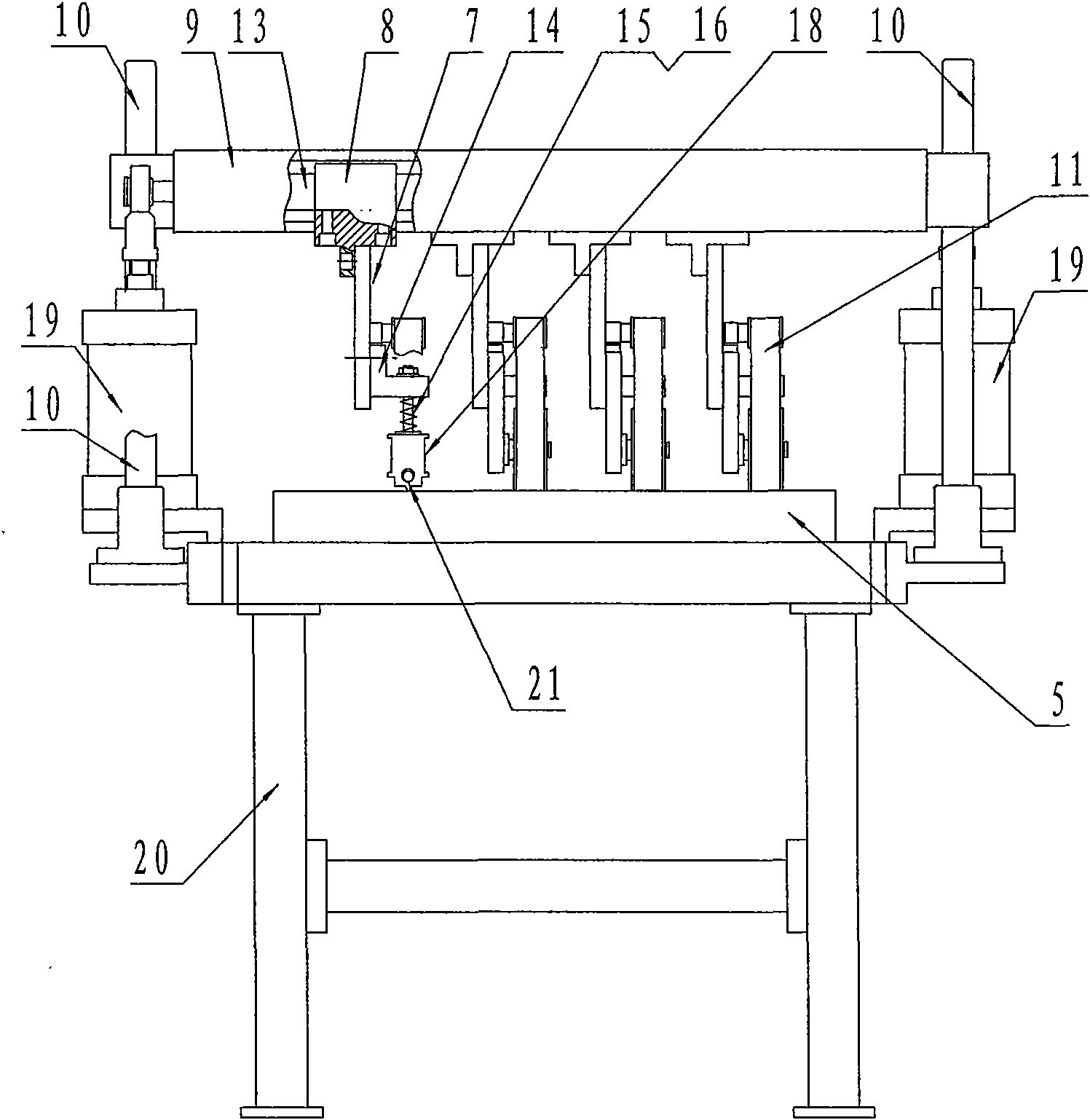

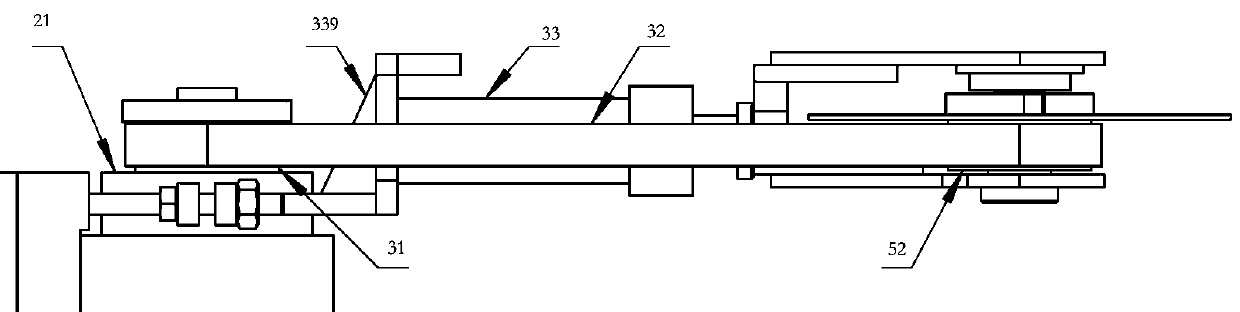

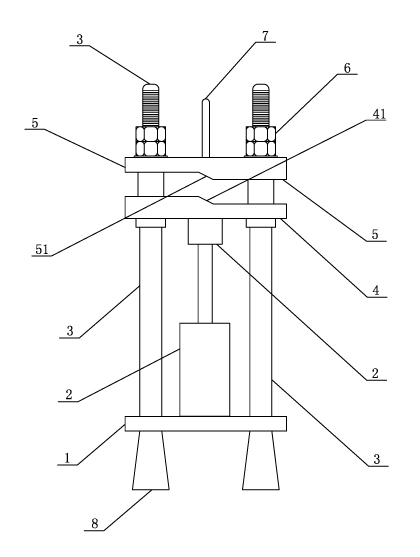

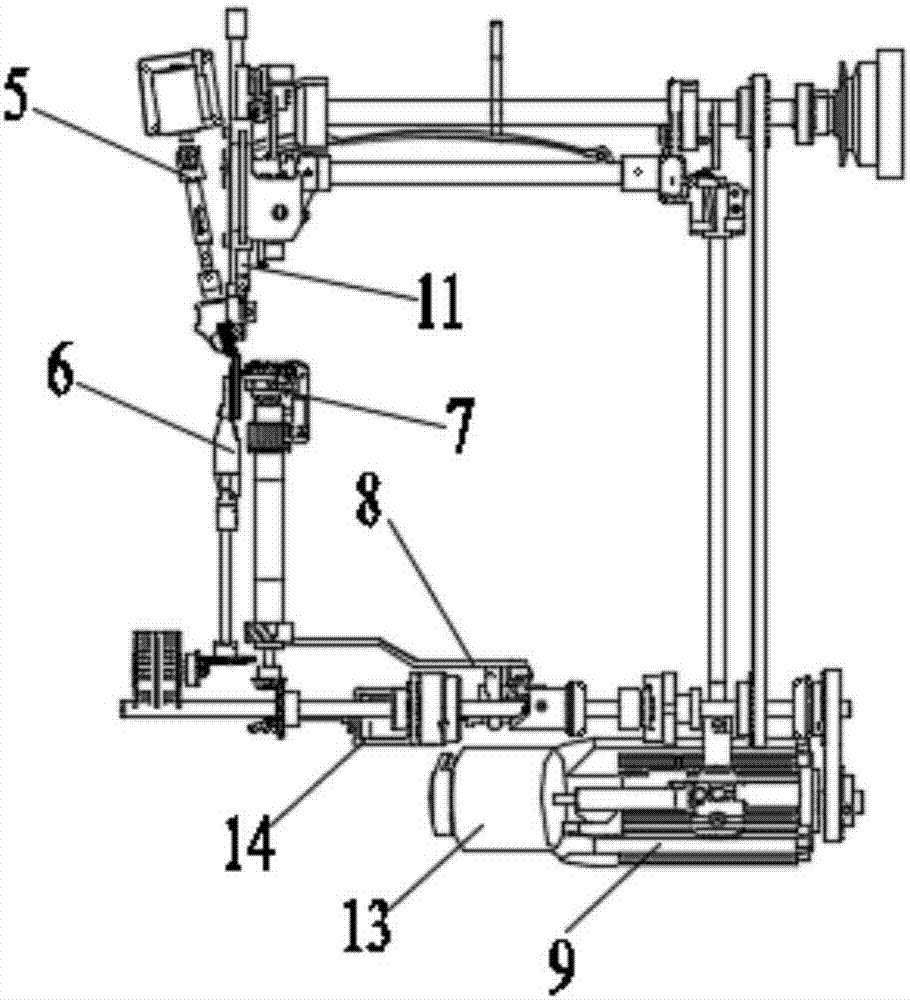

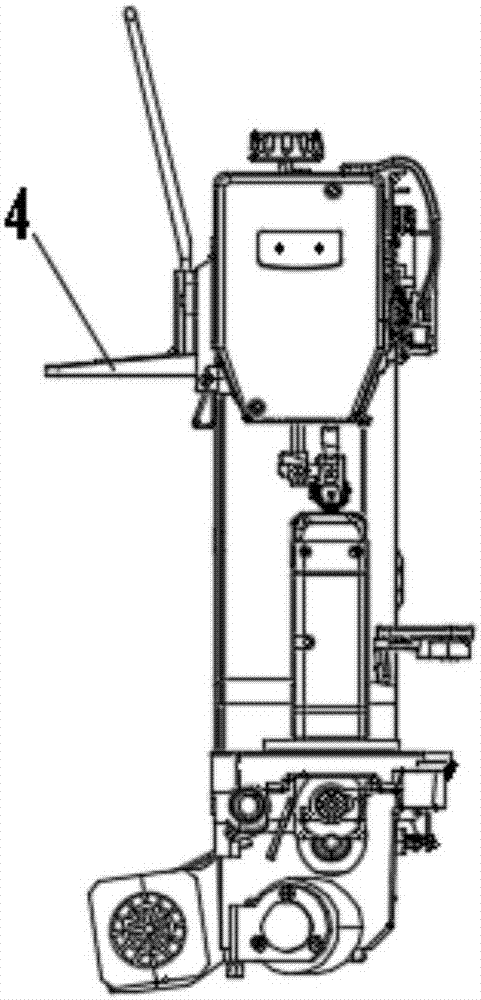

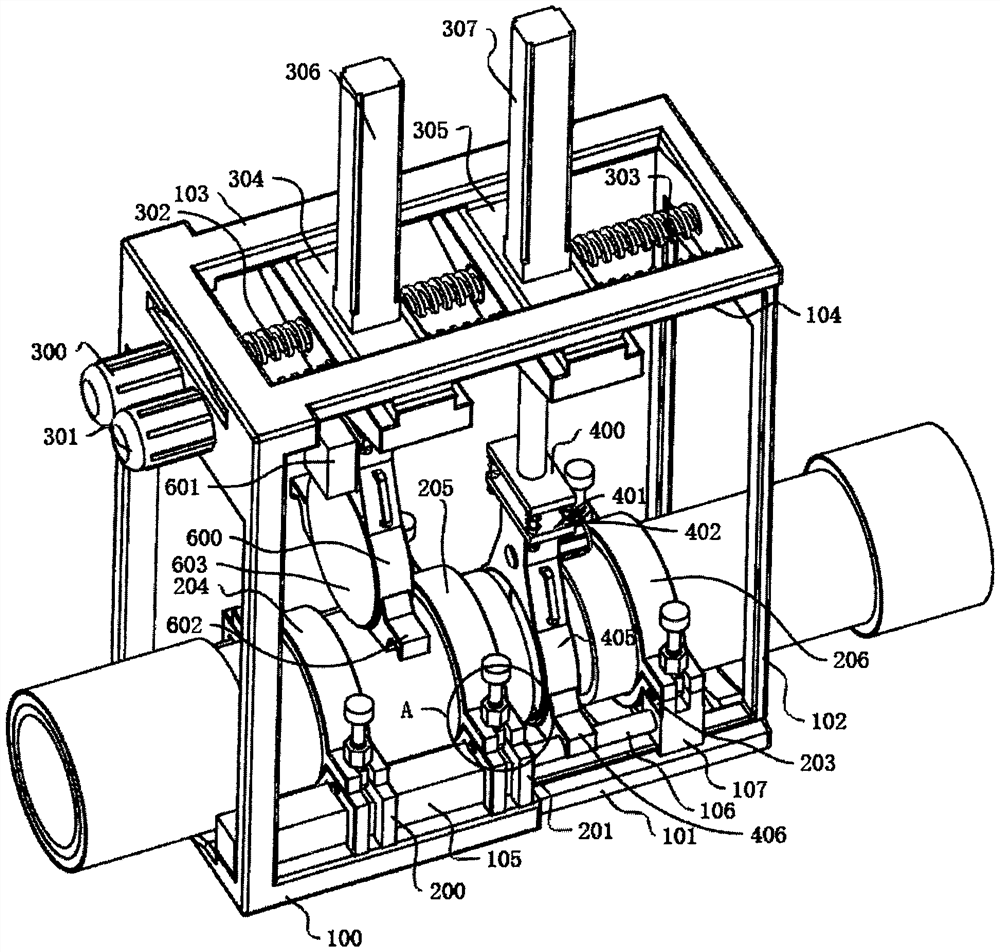

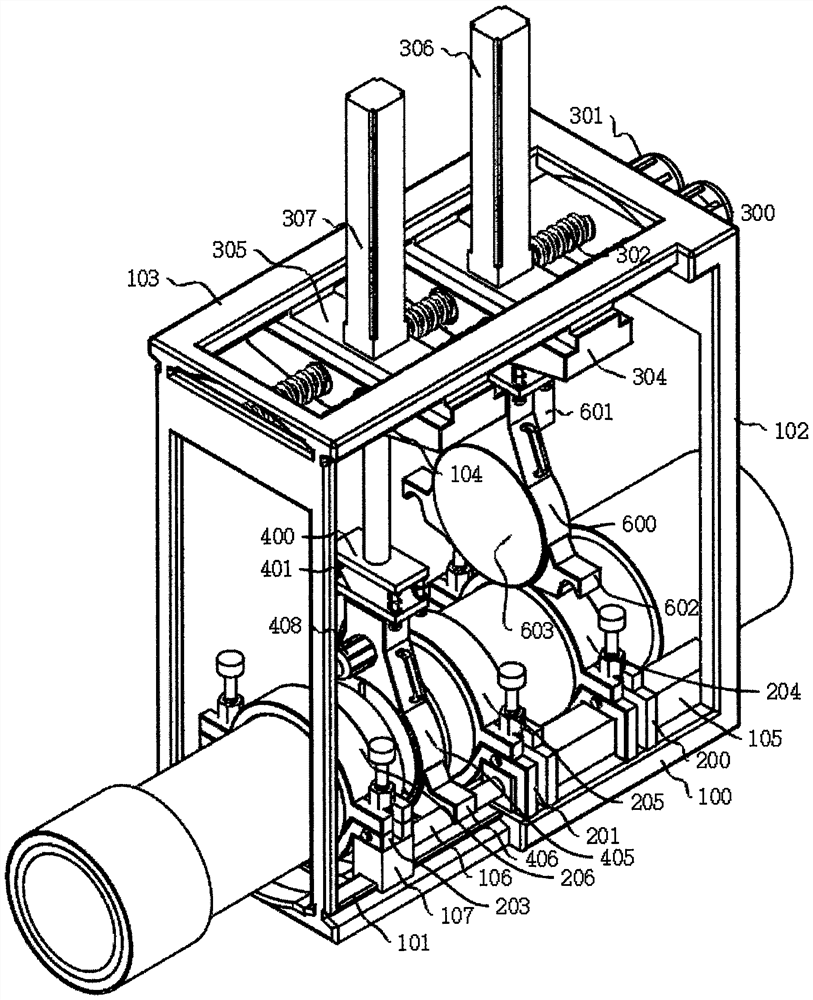

Circular sawing machine for steel plate cutting

ActiveCN105364174AHigh degree of automationImprove processing efficiencyMetal sawing devicesMetal sawing accessoriesSheet steelControl system

The invention discloses a circular sawing machine for steel plate cutting. The circular sawing machine for steel plate cutting comprises a rack, a cutting device, a moving assembly, a pressing assembly and a control system, wherein the cutting device is mounted on the rack, and the moving assembly is used for conveying a workpiece. The moving assembly comprises a moving plate, a screw rod component, a telescopic component and a supporting plate, wherein the screw rod component is mounted on one side of the moving plate, the telescopic component is mounted on the other side of the moving plate, and the supporting plate is fixedly connected to an output shaft of the telescopic component. The pressing assembly comprises a main pressing component and an auxiliary pressing component. The main pressing component is pressed on the rack and faces the cutting device, and the auxiliary pressing component is mounted on the supporting plate. The workpiece is placed on the supporting plate. The control system controls the screw rod component to drive the moving plate to move and enables the pressing assembly to press the workpiece. The workpiece is cut by the cutting device. The circular sawing machine for steel plate cutting has the characteristics of being high in cutting efficiency and cutting precision.

Owner:江苏宁兴恒力智能设备有限公司

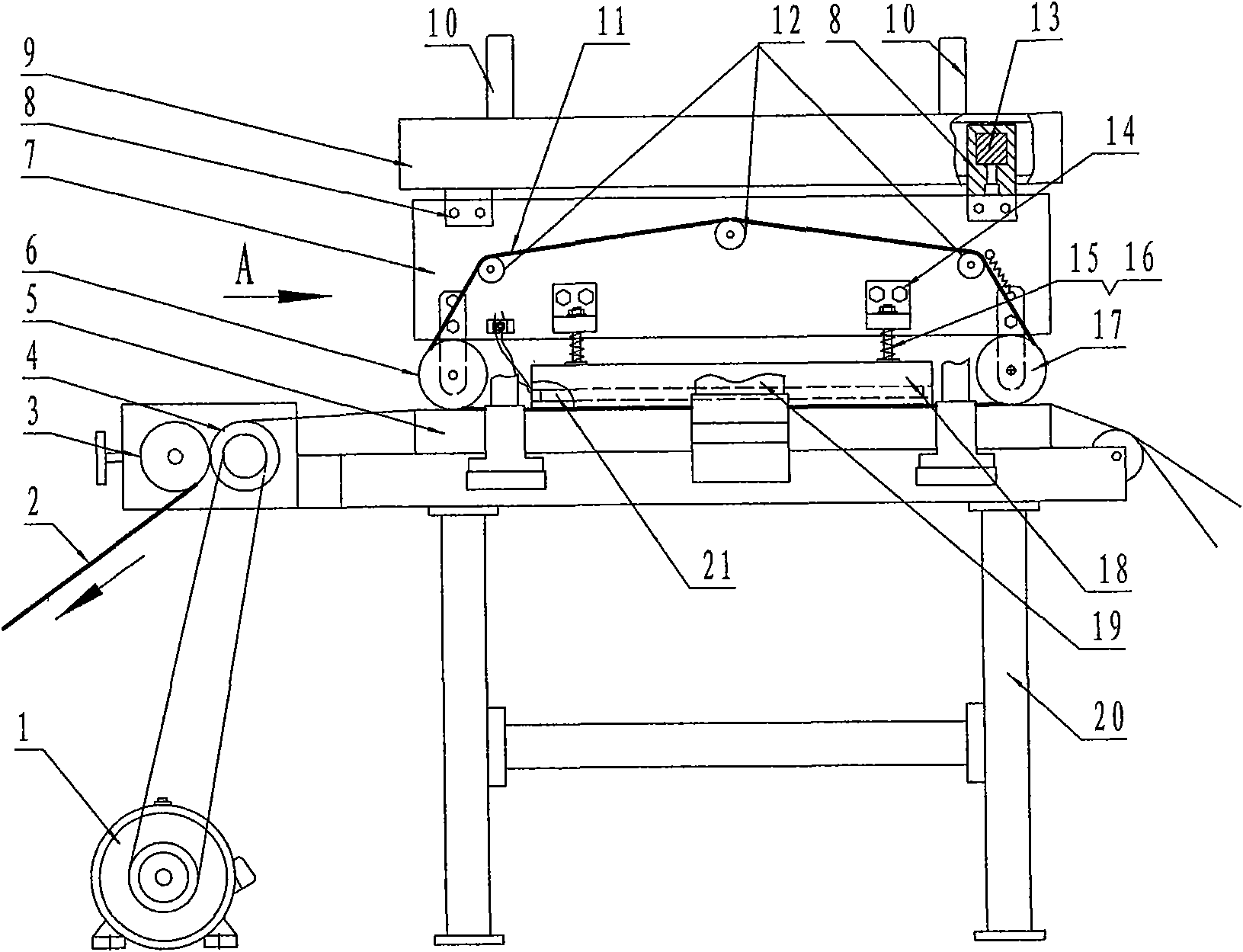

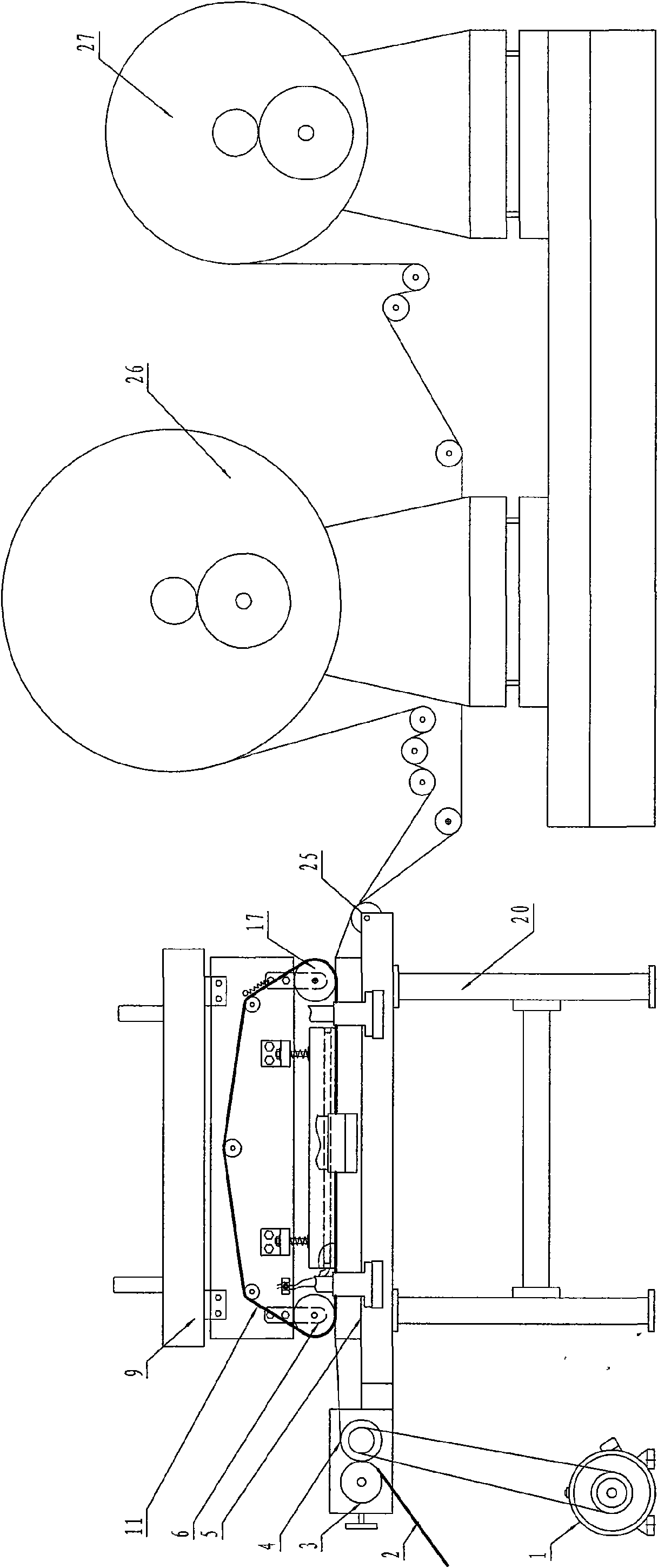

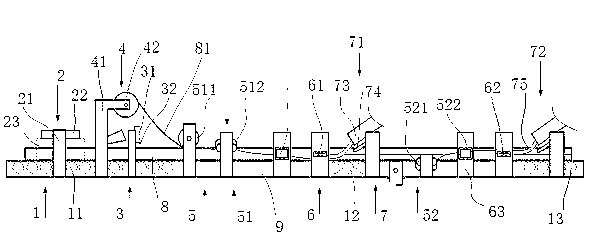

Continuous heat seal device of packing list envelop

ActiveCN101612817AStrong heat sealExtend heating timeBox making operationsPaper-makingHeater RodEngineering

The invention provides a continuous heat seal device of a packing list envelop which is used for improving processing efficiency and product quality of the packing list envelop. The technical proposal is as follows: the invention is composed of a rack, a worktable, an upper bracket, an iron conjunction part, an iron knife pressing and lifting mechanism and a traction part, wherein, the iron conjunction part comprises a longitudinal iron knife, an iron knife fixed plate, an iron belt, a front belt pulley, a rear belt pulley and propping belt pulleys; the iron knife fixed plate is connected with the upper bracket; the longitudinal iron knife is internally provided with a heating rod; the front belt pulley, the longitudinal iron knife and the rear belt pulley are arranged at the lower part of the longitudinal iron knife fixed plate in turn; the propping belt pulley is fixed on the iron knife fixed plate; the iron belt encircles the front and rear belt pulleys, the longitudinal iron knife and each propping belt pulley; and the bottom surface of the iron belt is contacted with the worktable. According to the material features of the packing list envelop, the invention specially designs a device which can realize continuous heat seal; the device can ensure stable processing technology of packing list envelop heat seal, obtain better product quality and higher product percent of pass and improve production efficiency greatly.

Owner:河北方大包装股份有限公司

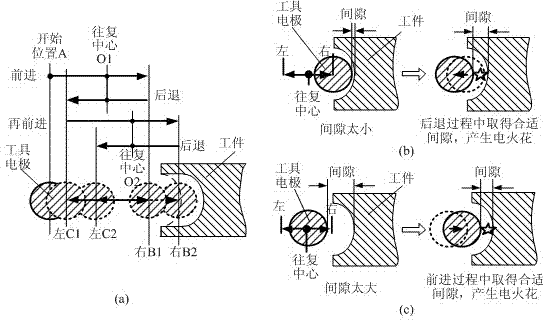

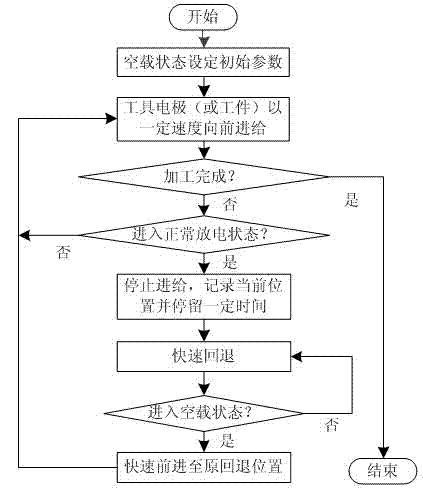

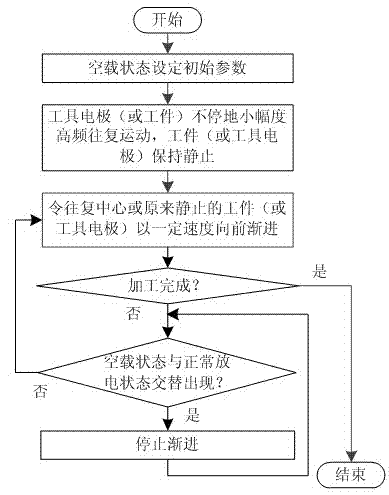

Reciprocating progressive self-adaptive feed control method for electrical spark machine tool

ActiveCN103752962AImplement automatic trackingAchieve holdElectric circuitsAdaptive controlSemiconductor materialsReciprocating motion

The invention discloses a reciprocating progressive self-adaptive feed control method for an electrical spark machine tool. A tool electrode in the electrical spark machine tool is controlled to perform a reciprocating progressive feed motion with a workpiece in an integral manner of reciprocating motion and progressive motion or in a separated manner of reciprocating motion and progressive motion so as to realize high-efficiency and high-quality electrical spark machining of a difficult-to machine material, particularly a semiconductor material, with a metal material. An appropriate discharge gap is automatically formed between the workpiece and the tool electrode, so that normal electrical spark discharge is promoted, continuous machining is ensured, and the method has the beneficial effects of quick chip removal and cooling, preventing the electrode from burning, improving the quality of machining surface, improving the machining efficiency, being wide in application range and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

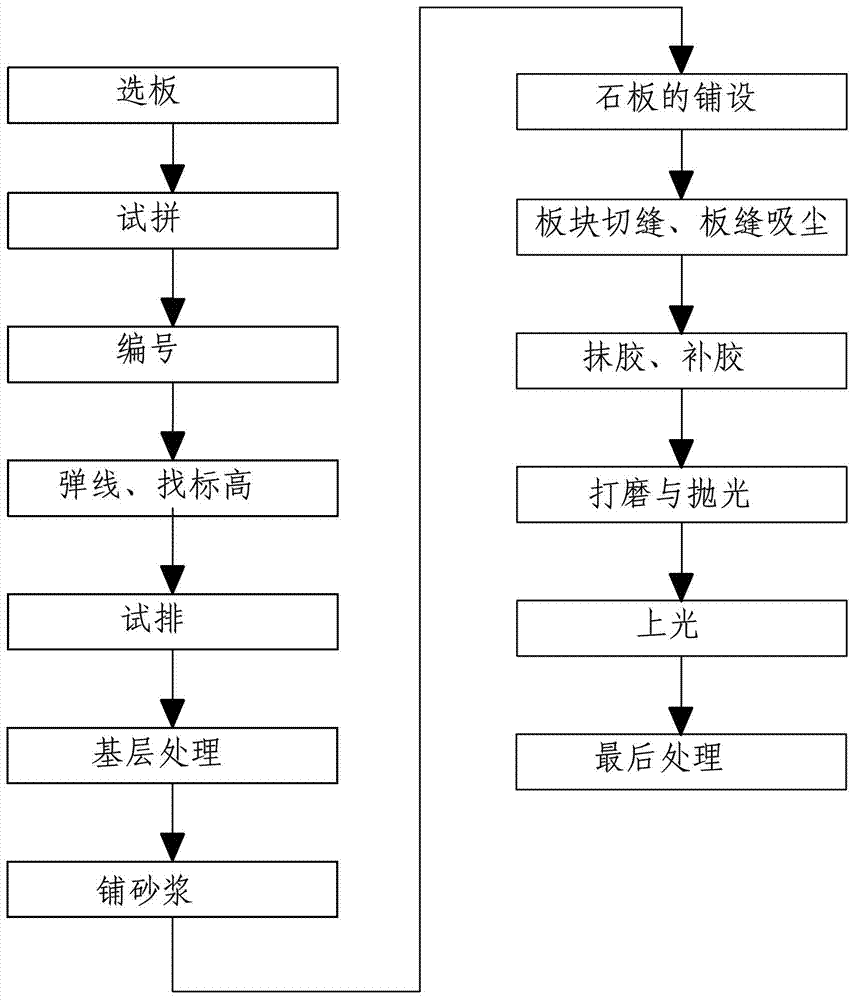

Stone material seamless polishing construction method

The invention belongs to the technical field of ground and wall surface decoration construction methods and relates to a stone material seamless polishing construction method. The stone material seamless polishing construction method comprises the steps of selecting plates, trying piecing the plates together, numbering, snapping lines on surrounding walls, finding a standard height, trying arranging stone materials, carrying out base treatment on a concrete pad layer or a cement slag pad layer after trying arranging the stone materials, and paving mortar. The following technological processes are carried out after paving the mortar: (1) paving the stone materials; (2) carrying out mechanical dust absorption on plate block cutting seams and plate seams; (3) gluing and compensating glue; (4) grinding and polishing; (5) varnishing; and (6) final processing. Surfaces of processed stone materials by means of the stone material seamless polishing construction method are clear in texture, uniform in seam and smooth in plate block connecting seam. Surface gloss of polished stone materials can reach 80-90 degrees. Besides, the stone material seamless polishing construction method has the advantages of being easy and convenient to operate, rapid in construction progress, short in construction period and suitable for paving of new materials and old materials on the ground and the wall surfaces.

Owner:BIAOLI CONSTR GROUP

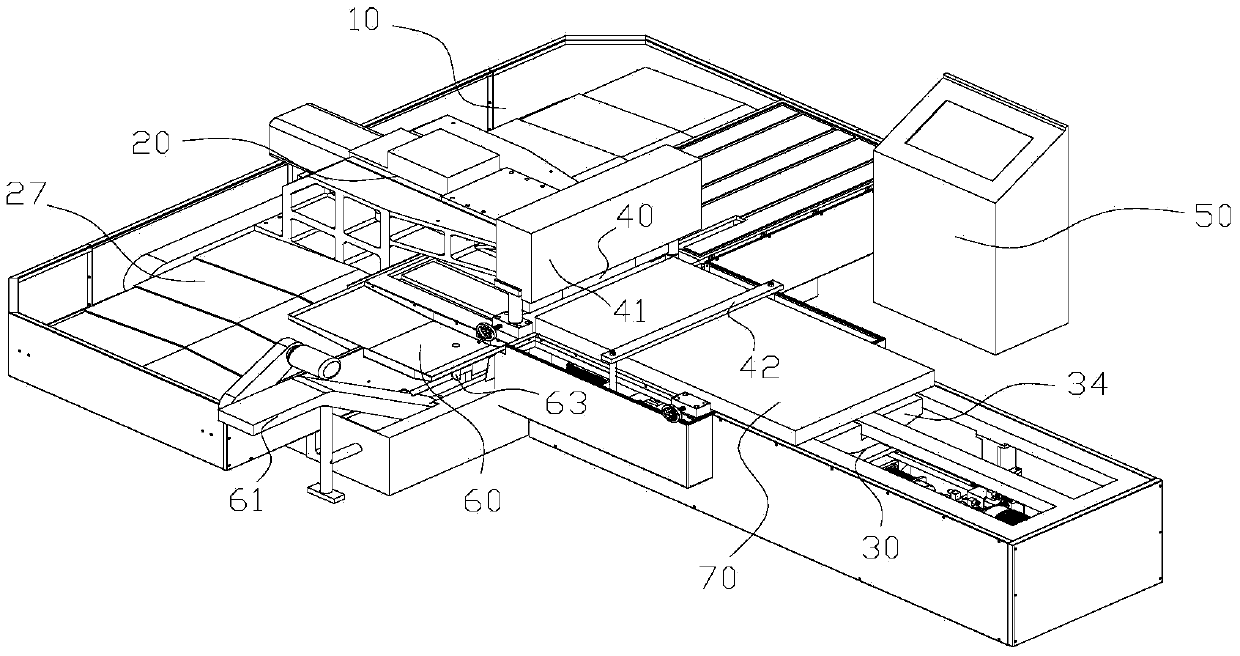

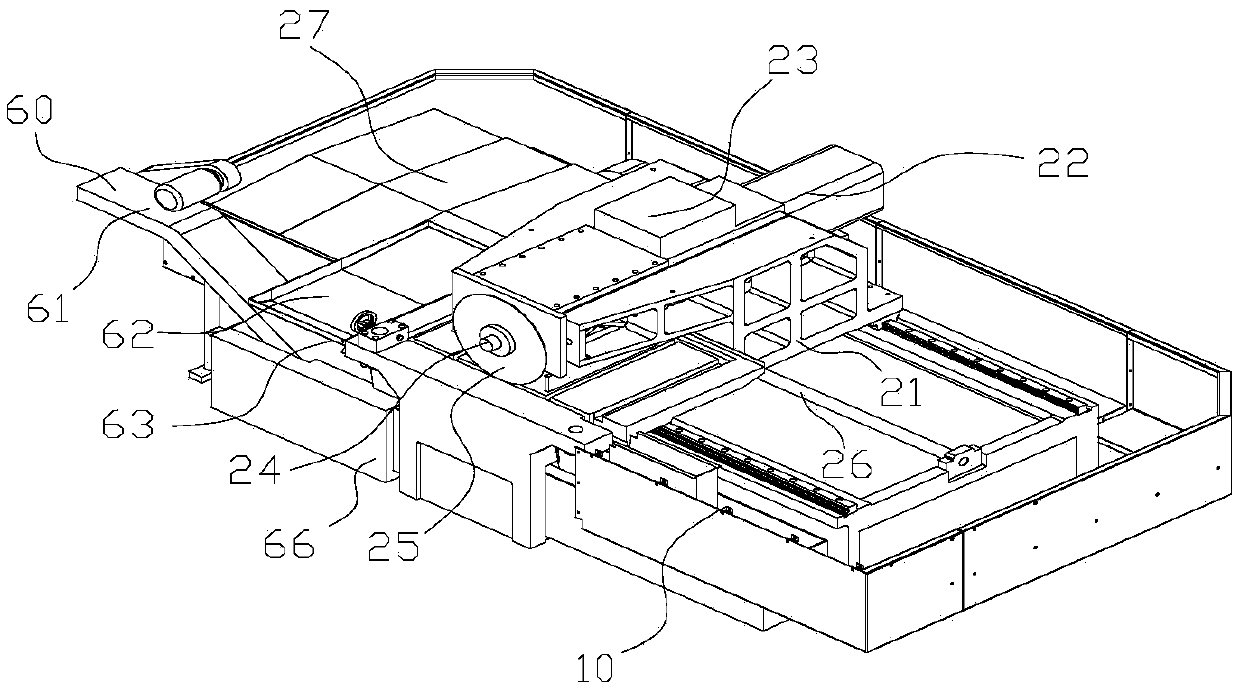

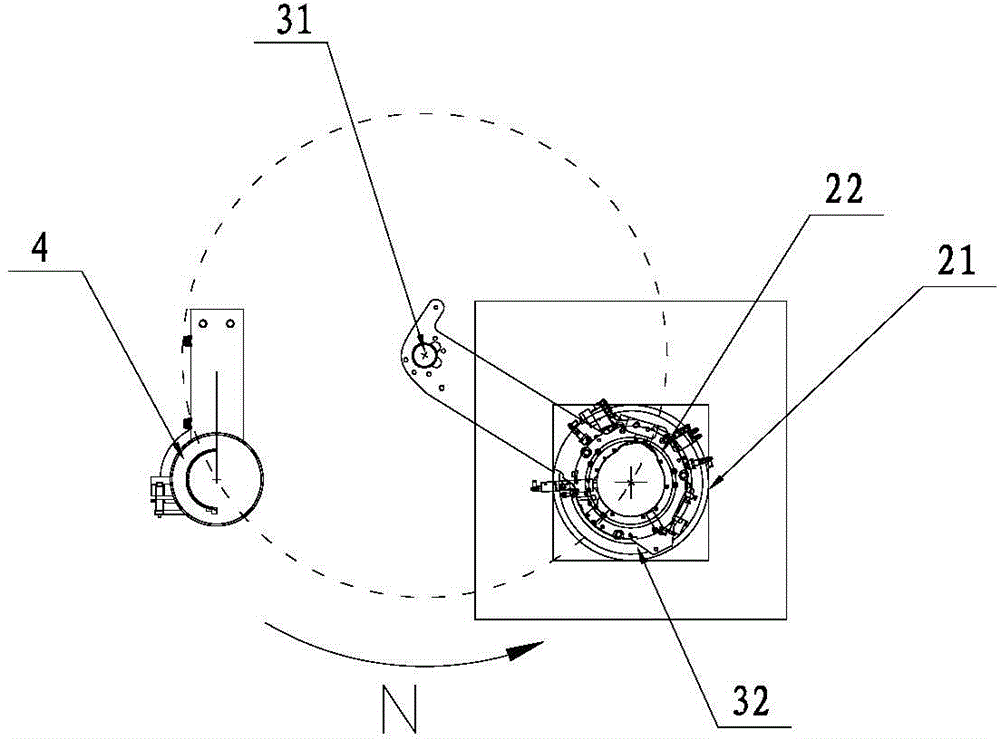

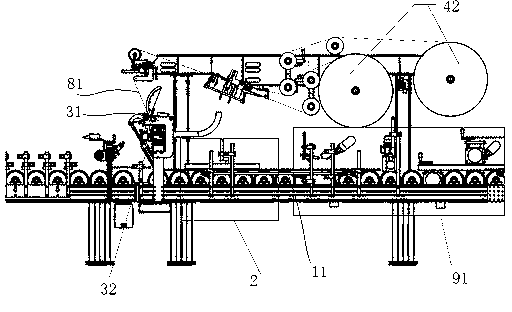

Full-fashioned hosiery production device and production technique

ActiveCN104818571AReduce workloadShorten production timeCircular knitting machinesProduction lineTransfer mechanism

The invention discloses a full-fashioned hosiery production device and production technique. The production device comprises a knitting mechanism, a transfer mechanism, a sewing mechanism, a delivery mechanism and a suction mechanism arranged on a production line in sequence and further comprises a control mechanism for controlling the whole production device to run. The full-fashioned hosiery production device and production technique can integrate the hosiery knitting, hosiery head winding transfer, hosiery transfer, hosiery turning, winding transfer after the hosiery head winding overlapping, head sewing, hosiery removing, hosiery turning, sucking, delivery and the like flow and run naturally, the product production time is greatly saved, the space is reasonably used, the workload on the worker is alleviated, the demand on manpower is reduced, and the safety production reliability is improved.

Owner:SHAOXING CITY YUEFA MACHINE

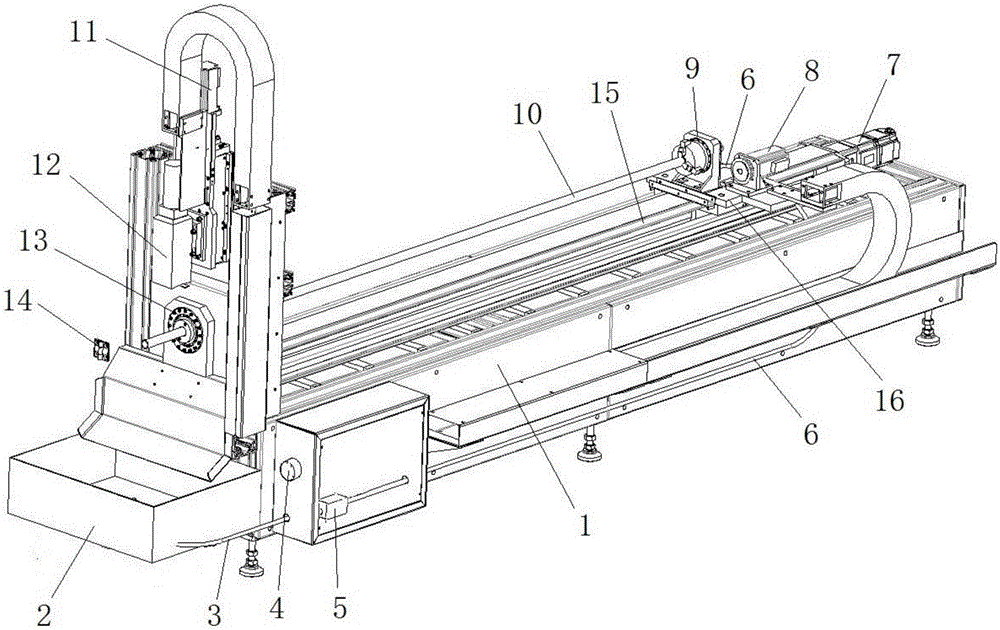

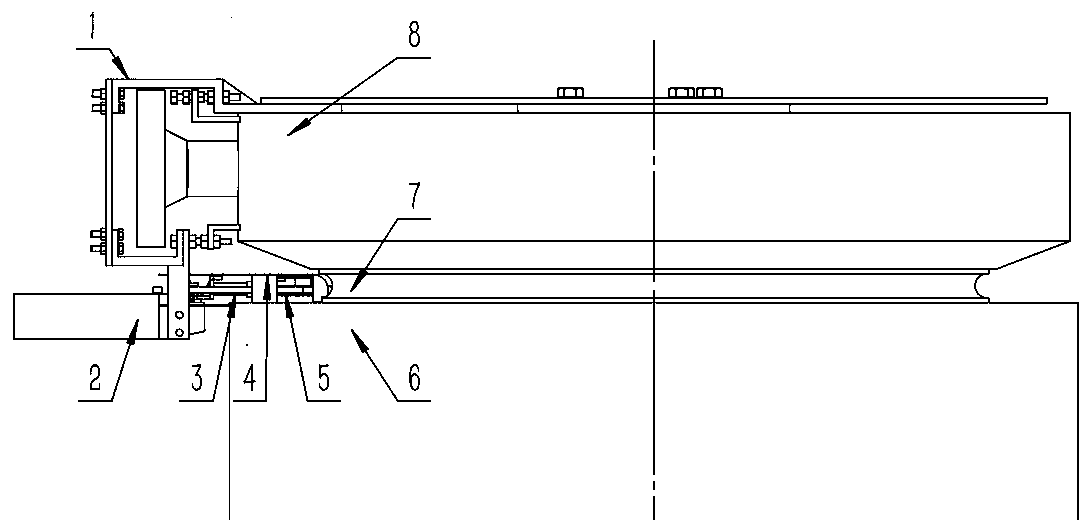

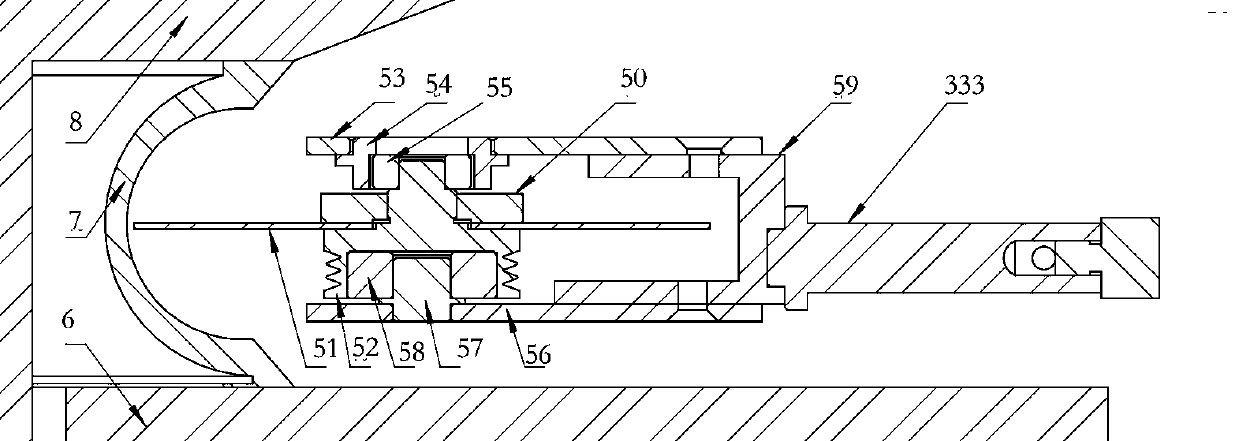

Laser cutting device for small-aperture pipelines

InactiveCN106735941AEnsure the original shapeSeam smoothLaser beam welding apparatusEngineeringLaser cutting

The invention relates to a laser cutting device for small-aperture pipelines. The laser cutting device for the small-aperture pipelines comprises a machine table, wherein a pipeline conveying mechanism is arranged above the machine table and used for controlling the translation and rotation of a pipeline; a laser cutting mechanism is arranged above the left side of the pipeline conveying mechanism; a material collecting water tank is arranged at the left side of the machine table and located below the laser cutting mechanism; the bottom of the material collecting water tank is provided with a water inlet pipe; the other end of the water inlet pipe is connected with a water inlet of a vacuum water pump arranged on the front of the machine table; a water outlet of the vacuum water pump is connected with a water outlet pipe; and the other end of the water outlet pipe is connected into the right end of the pipeline conveying mechanism and used for connecting an inner core at the right end of the pipeline. The laser cutting device for the small-aperture pipelines has the advantages that the precise machining of a product with any pipeline diameter in a region between 0.1mm and 20mm is realized, the kerf is neat, the fracture surface is smooth, high-temperature deformation produced during laser cutting is avoided, the initial shape of a machined material is ensured, the machining speed is raised, the structure is simple, and the manufacture cost is low.

Owner:SUZHOU TIANHONG LASER

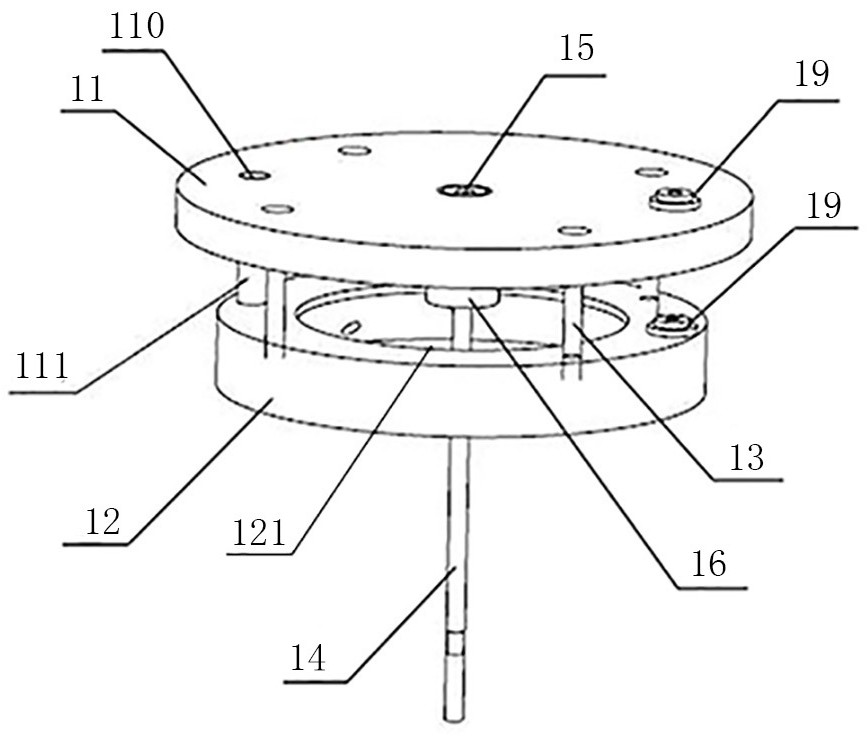

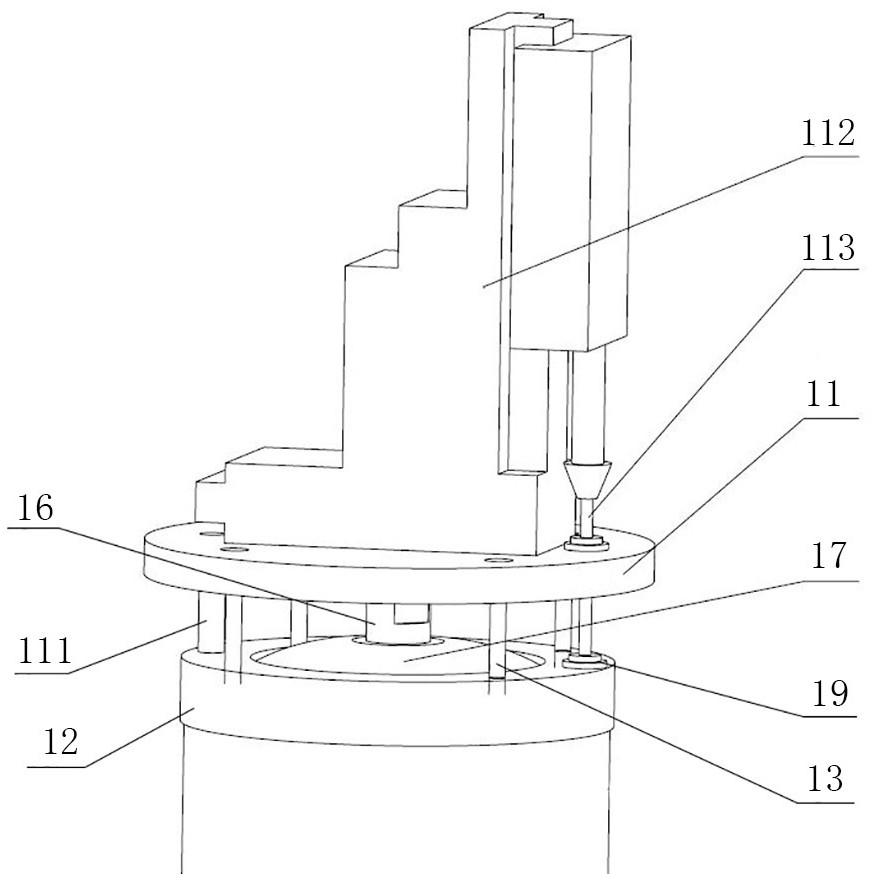

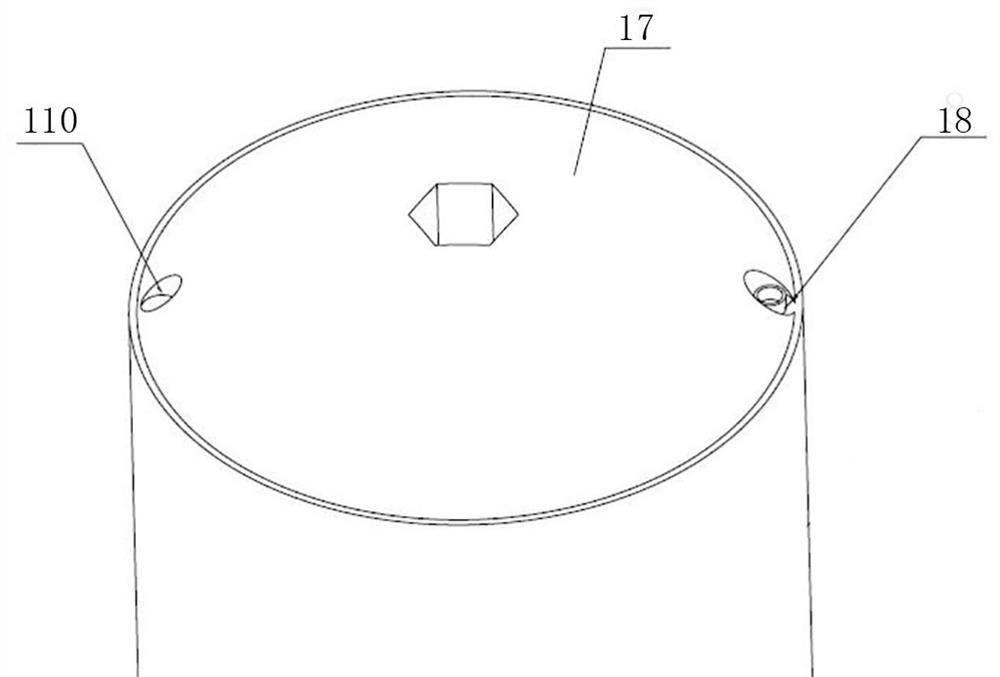

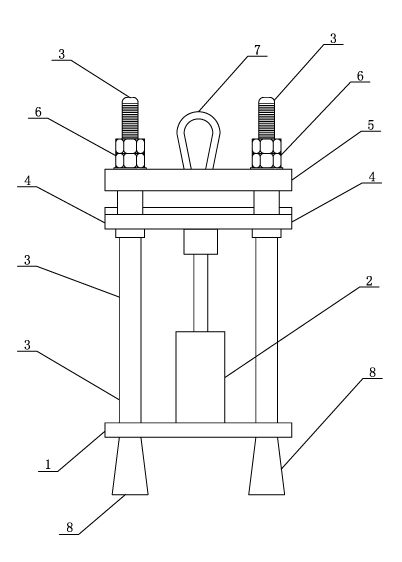

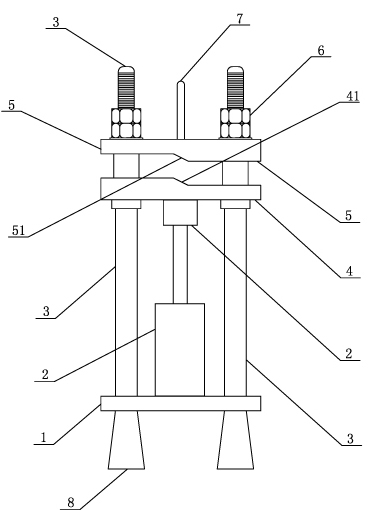

Nuclear power plant large shielded main pump lower portion C-ring cutting device

PendingCN110181379AEasy to cutImprove cutting accuracyGrinding machinesGrinding/polishing safety devicesForeign matterAngle grinder

The invention relates to a nuclear power plant large shielded main pump lower portion C-ring cutting device, and belongs to the technical field of maintenance of a nuclear power plant large shielded main pump. The device comprises a wall mounting assembly and a cutting assembly; the wall mounting assembly comprises a pressing plate and a wall hanging body; the pressing plate is fixed to the end surface of a lower end cover of the main pump, a gap is reserved between the pressing plate and the lower end cover of the main pump, and therefore a tongue portion of the wall hanging body can slide inthe gap; the cutting assembly includes an angle grinder head, a transmission mechanism and a cutting mechanism; the lower portion of the wall hanging body is connected to the angle grinder head, andthe angle grinder head is connected to the cutting mechanism extending into a space where a C ring of the main pump is located through the transmission mechanism. The nuclear power plant large shielded main pump lower portion C-ring cutting device is suitable for a narrow and deep cutting environment, can conduct online cutting, is high in efficiency, controllable in precision, smooth in cutting slit and controllable in foreign matter, and does not cause air radiation pollution.

Owner:SANMEN NUCLEAR POWER CO LTD

Door window welding process

InactiveCN104476141ASolve fit clearance problemsSolve the strength problemArc welding apparatusSurface oxidationAcid washing

The invention discloses a door window welding process which comprises the following steps: (1), performing cold-press moulding on a metal plate in a metal door window cold press, aligning the end parts of two edges of a door window section material, and performing fine adjustment on butt seams, wherein the tail end of the metal door window cold press is provided with a roller wheel mold with the thickness less than 2mm; (2) polishing the surface of a to-be-welded door window to remove a surface oxidation film; (3) cleaning a to-be-welded part with an acid-washing passivation solution. The invention provides the welding process of a door window which is excellent in heat-proof cycle performance, good in abrasion resistance and wearability performance, free from welded doorframe section material salient points and long in service life.

Owner:QINGDAO DUANYI METAL

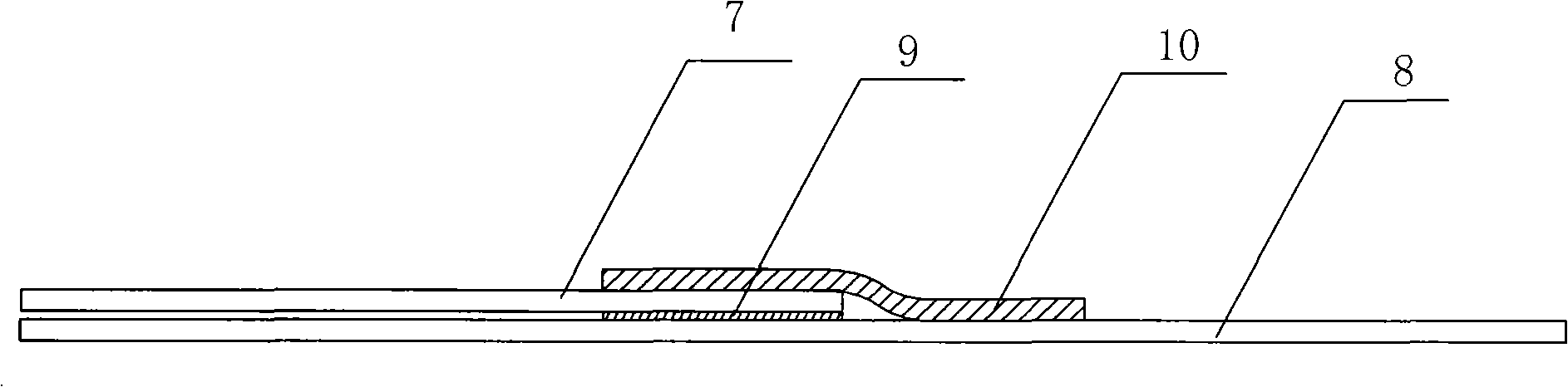

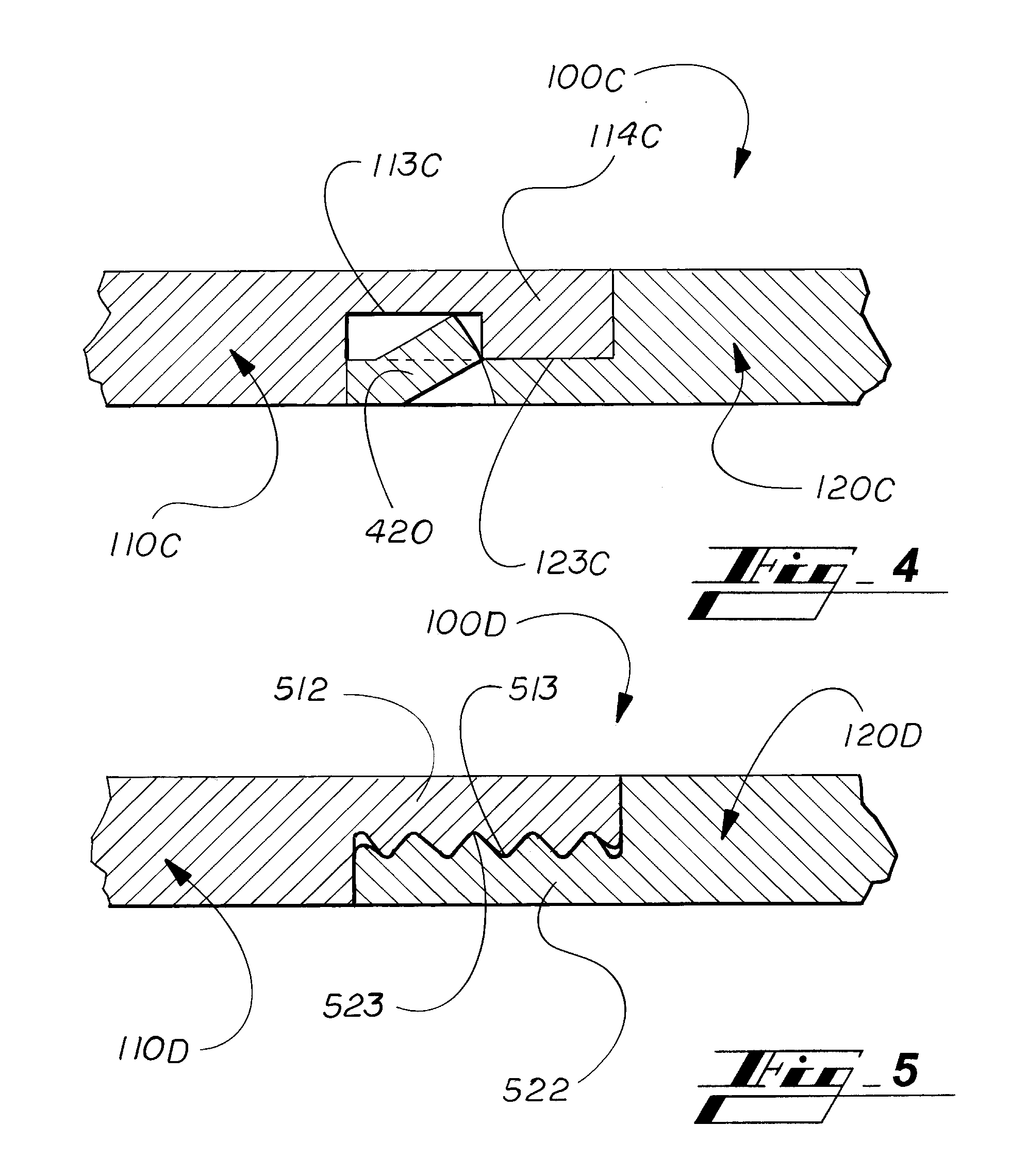

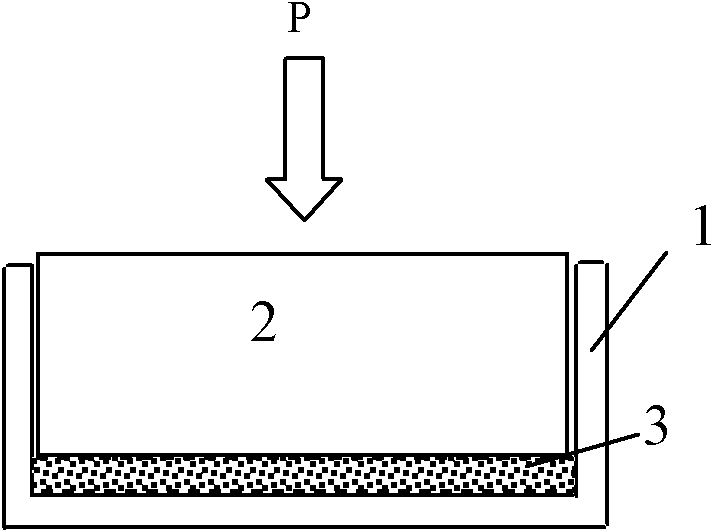

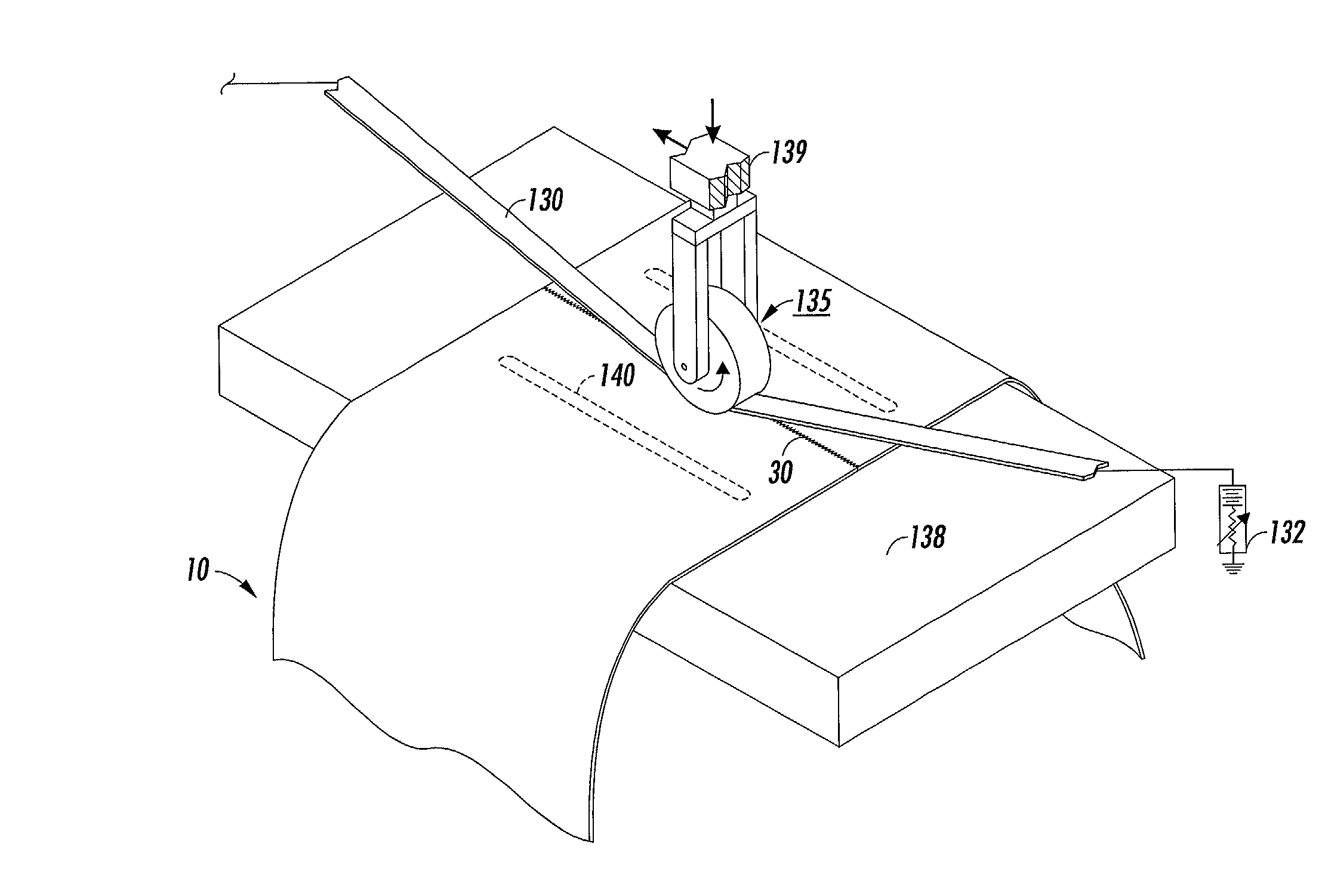

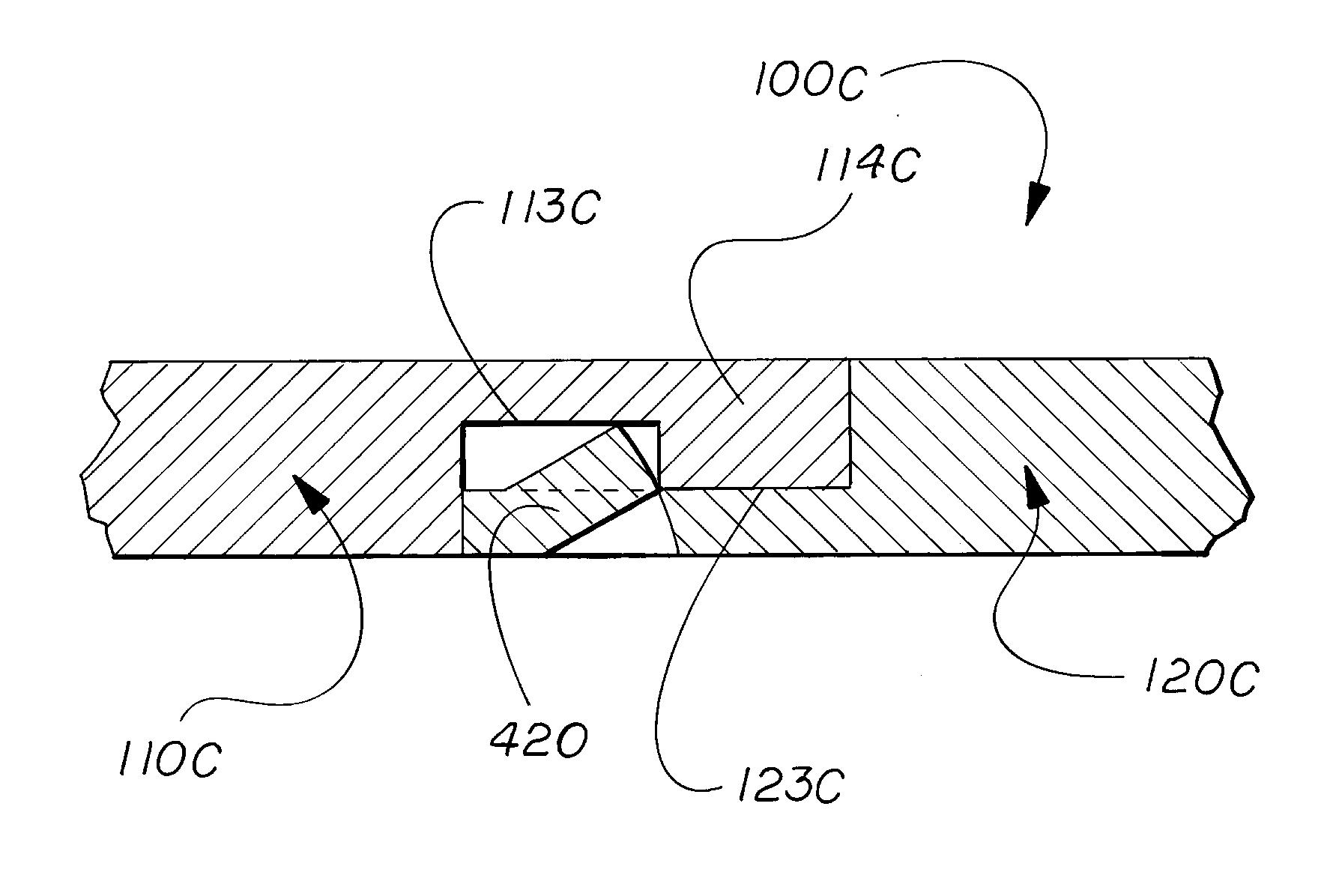

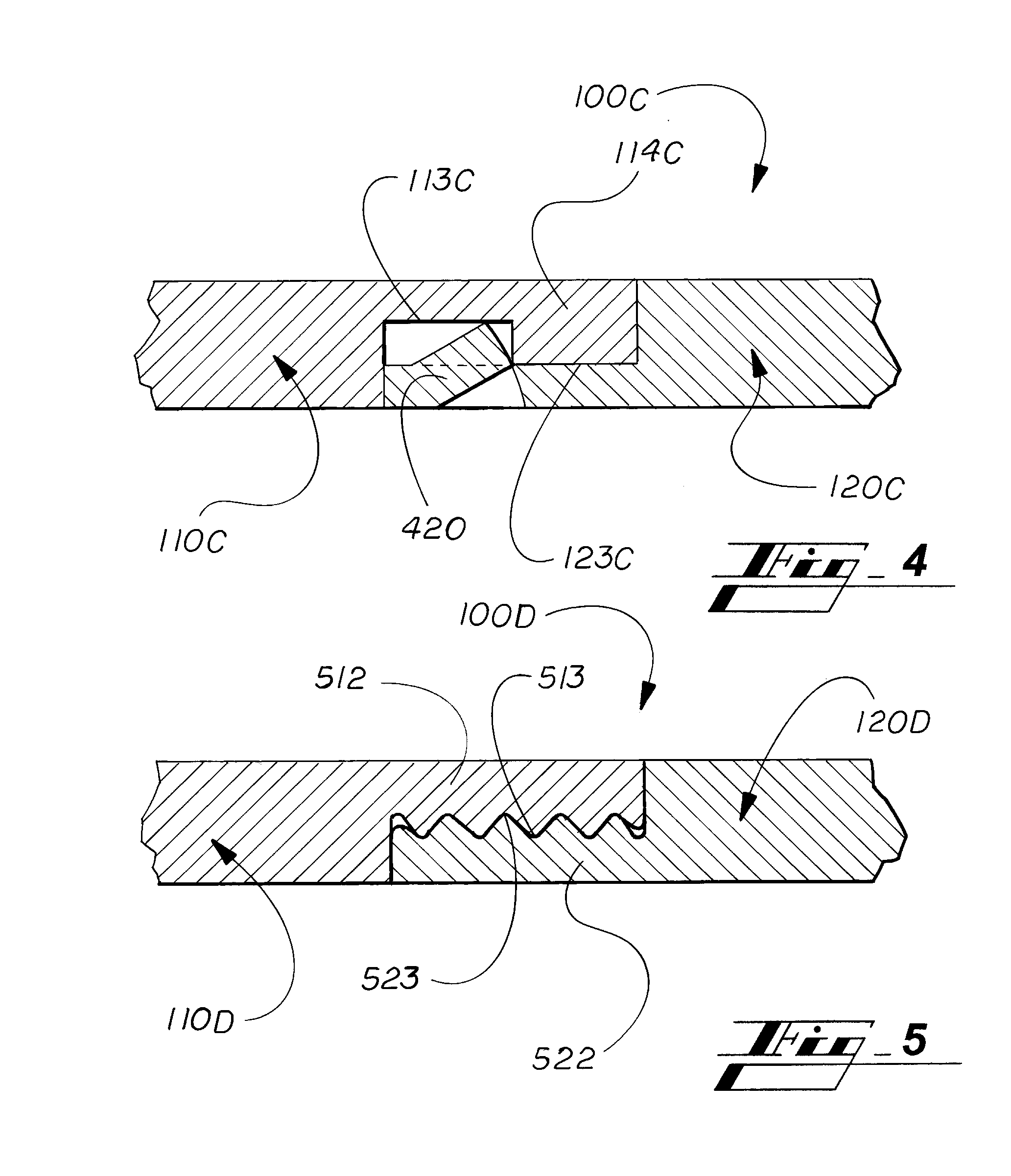

Flexible imaging member belt seam smoothing method

InactiveUS7094048B2Eliminate protrusion spotReduce seam region thicknessConfectionerySweetmeatsVitrificationEngineering

Apparatus comprising a support member having a flat surface adapted to receive and support a seam region of a flexible belt comprising thermoplastic polymer material having a predetermined glass transition temperature, a heatable member having a smooth heatable flat surface for compressing at least a portion of the seam region of a flexible belt placed on the smooth flat surface of the support member to heat the portion to at least the glass transition temperature of the thermoplastic polymer material, the smooth surface of the heatable member having a profile which is parallel to the smooth flat surface of the support member, and wherein the heatable flat surface comprises a low surface energy or abhesive material.

Owner:REFLEC USA CORP

Equipment for coating paper on square wood parts

ActiveCN103182828AAutomatic turningAutomatic compactionLaminationLamination apparatusIndustrial engineeringWaste paper

The invention discloses equipment for coating paper on square wood parts, which comprises a frame and a controller. A conveying unit, a heating unit, an adhesive dispensing unit, a paper feeding unit, a paper pressing unit, a paper cutting unit and a paper waste recovery unit are arranged on the frame. The conveying unit comprises input delivery rollers, middle delivery rollers and output delivery rollers. The heating unit comprises an infrared heater. The adhesive dispensing unit comprises an extrusion-type pre-melted adhesive device and an adhesive dispensing port formed below the extrusion-type pre-melted adhesive device. The paper feeding unit consists of a support and a paper winding drum, and the paper winding drum is positioned in front of a heating rack. The paper pressing unit comprises a first paper pressing unit and a second paper pressing unit; the first paper pressing unit is positioned above the middle of the input and middle delivery rollers and comprises paper pressing mechanisms facing to the upper bottom, the left side and the lower bottom of a square wood part; and the second paper pressing unit comprises a paper pressing mechanism facing to the right side of the square wood part. The paper cutting unit comprises a cutter height alignment and regulation mechanism on which a first cutter and a second cutter are arranged. The paper waste recovery unit comprises a connecting base and a sucker. The equipment has the advantages of close bonding effect and flat and step difference-free joint.

Owner:宁波捷丰现代家俱有限公司

Method for laser cutting of 0.5 mm stainless steel

InactiveCN112222639AImprove cleanlinessQuality improvementWelding/soldering/cutting articlesLaser beam welding apparatusLaser cuttingSS - Stainless steel

The invention relates to a method for laser cutting of a 0.5 mm stainless steel. The method comprises the following steps: (1) removing greasy dirt and dust on the surface of stainless steel, and keeping the surface of the stainless steel smooth; and (2) cutting a 0.5 mm stainless steel panel by a ProCutter laser cutting gun, wherein the technological parameters are as follows: the cutting speed is 14-16 m / min; the laser power is 1-2kW; the gas pressure is 1-2 MPa; the defocusing amount is -1-0 mm; the working distance is 0.6 to 1.0 mm; the diameter of a cutting nozzle is 0.8 to 1.2 mm; and the cutting gas is nitrogen. The method is stable in process, has repeatability, is safe, stable and reliable, and a kerf is smooth, level, free of adhering slag and good in quality.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

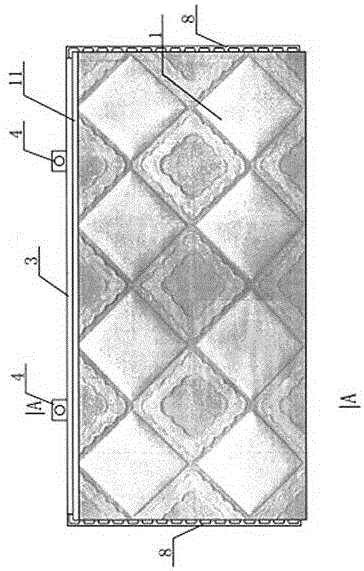

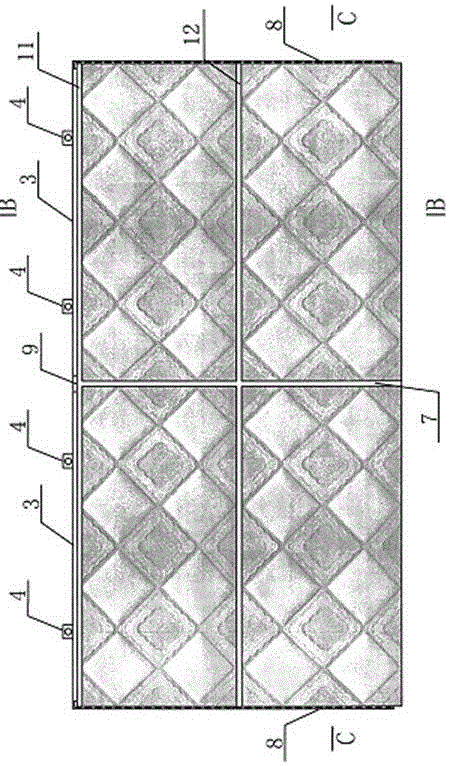

External thermal insulation cement decoration panel provided with concave edge and sunk key type joint and mounting and leveling method thereof

InactiveCN105735580AImprove flatnessAdapt to production process requirementsCovering/liningsThermal insulationPerforated metal

The invention relates to an external thermal insulation cement decoration panel provided with a concave edge and sunk key type joint and a mounting and leveling method thereof. The external thermal insulation cement decoration panel is characterized in that the cement decoration panel is internally provided with a metal or non-metal net; a three-dimensional decorative pattern is preformed on the outer side face of the cement decoration panel; the upper edge of the cement decoration panel is provided with a concave edge with an appropriate width and depth; the upper end face of the cement decoration panel is provided with a full-length convex key and metal hanging parts at certain intervals; and the two side end faces of the cement decoration panel are planes or the outer edges of the cement decoration panel are provided with convex edges with an appropriate height, and perforated metal plate strips are embedded in the two side end faces or the outer edges of the cement decoration panel. During construction and assembly of the cement decoration panel, horizontal joints serve as sunk key type joints, the concave edges form horizontal grid division joints, vertical joints serve as perforated metal plate strip coped joints, special mortar is embedded in the joints compactly in a filling mode, and vertical grid division joints with the same depth as the horizontal grid division joints are formed. The perforated metal plate strips are good in flatness, accurate in shape and size and capable of well meeting the requirements of the production process of the cement decoration panel. The perforated metal plate strip coped joints have good tensile strength and can effectively protect the mortar joints against cracking and leakage.

Owner:上海紫霓节能科技有限公司

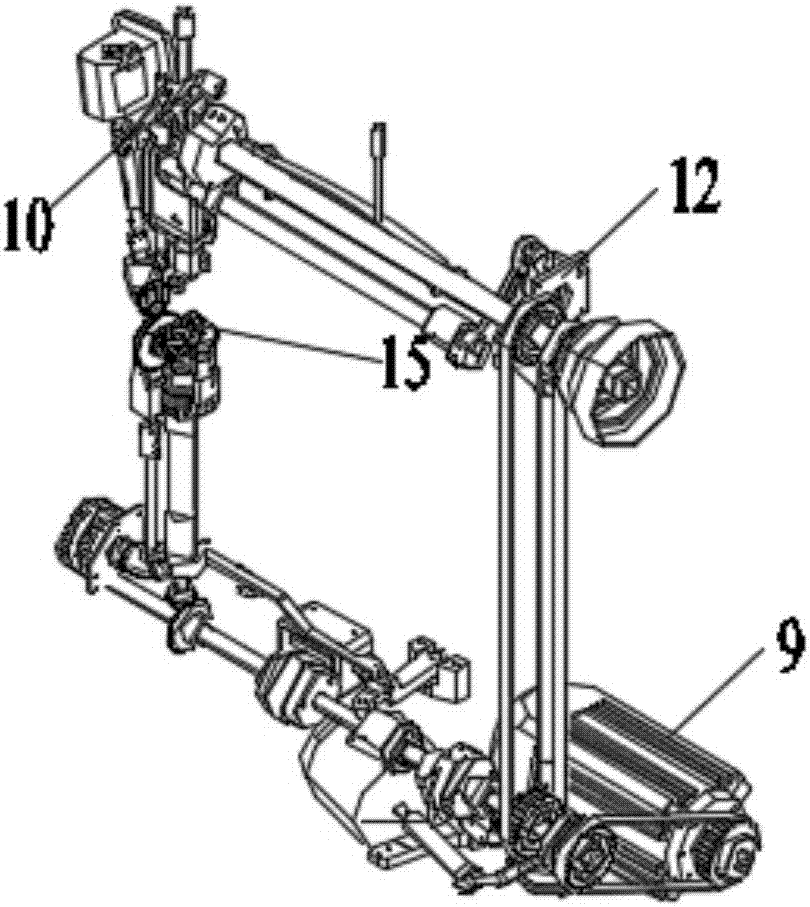

Disassembling device and disassembling process for large-sized shielding main pump in radioactive environment

ActiveCN111649007APrevent splashAvoid incomplete drilling of locking pinsPump componentsGrinding machinesImpellerNuclear power

The invention discloses a disassembling device and a disassembling process for a large-sized shielding main pump in a radioactive environment, and belongs to the technical field of nuclear power station large-sized shielding main pump maintenance. The disassembling device comprises an impeller nut locking pin dismounting assembly, a C-shaped ring cutting assembly and a lower radial bearing dismounting and rotor core-pulling assembly, and the impeller nut locking pin dismounting assembly comprises an upper plate, a lower plate, a connecting screw, a double-end lead screw, a fixing nut and an adjusting nut; the C-shaped ring cutting assembly comprises a wall-mounted assembly and a cutting assembly; the wall-mounted assembly comprises a pressing plate and a wall-mounted main body; the lower radial bearing dismounting and rotor core-pulling assembly comprises a foundation plate, a foundation plate support used for connecting the foundation plate and a pump body, a double-end lead screw used for connecting the foundation plate and a lower radial bearing, a nut connected to the double-end lead screw and a lifting lug arranged on the foundation plate, a rotor supporting tool and a cushionblock which are used for connecting the foundation plate and a pump shaft, and a main bolt used for connecting the foundation plate and the pump body. The disassembling method is easy to operate, anddisassembling of the large-sized shielding main pump can be completed safely and efficiently.

Owner:SANMEN NUCLEAR POWER CO LTD

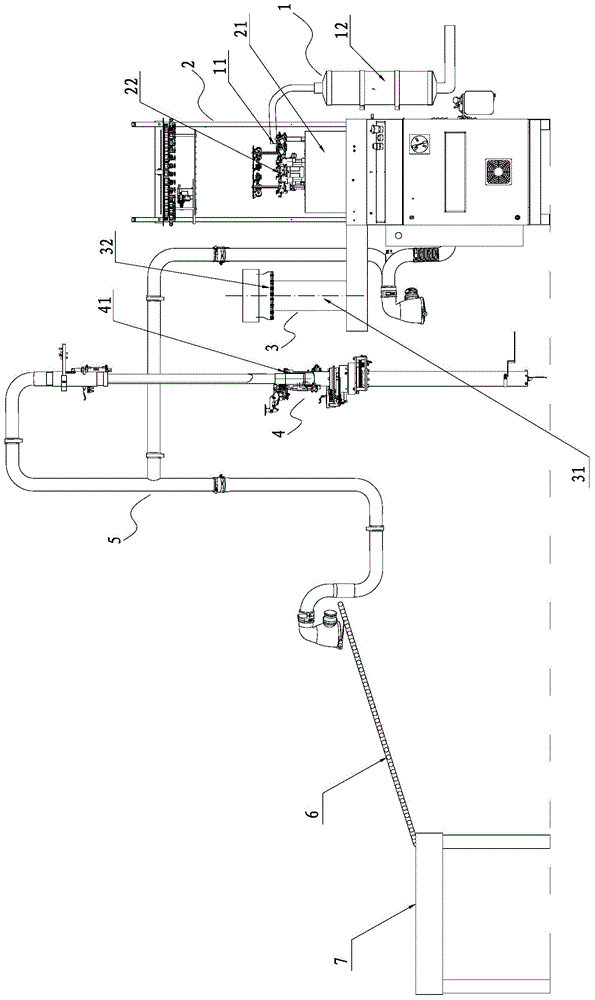

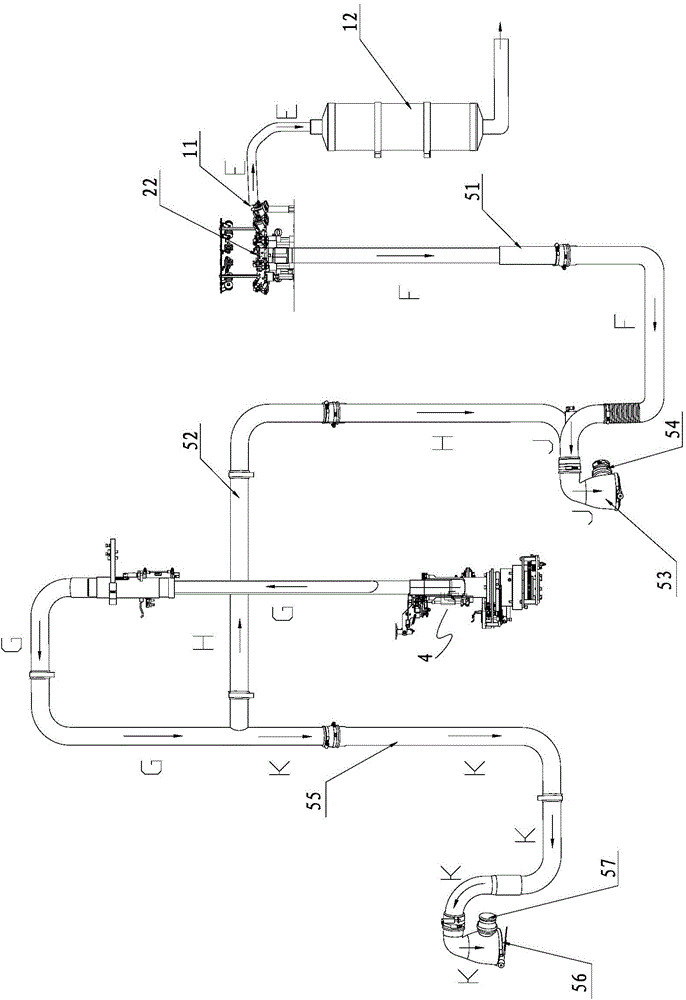

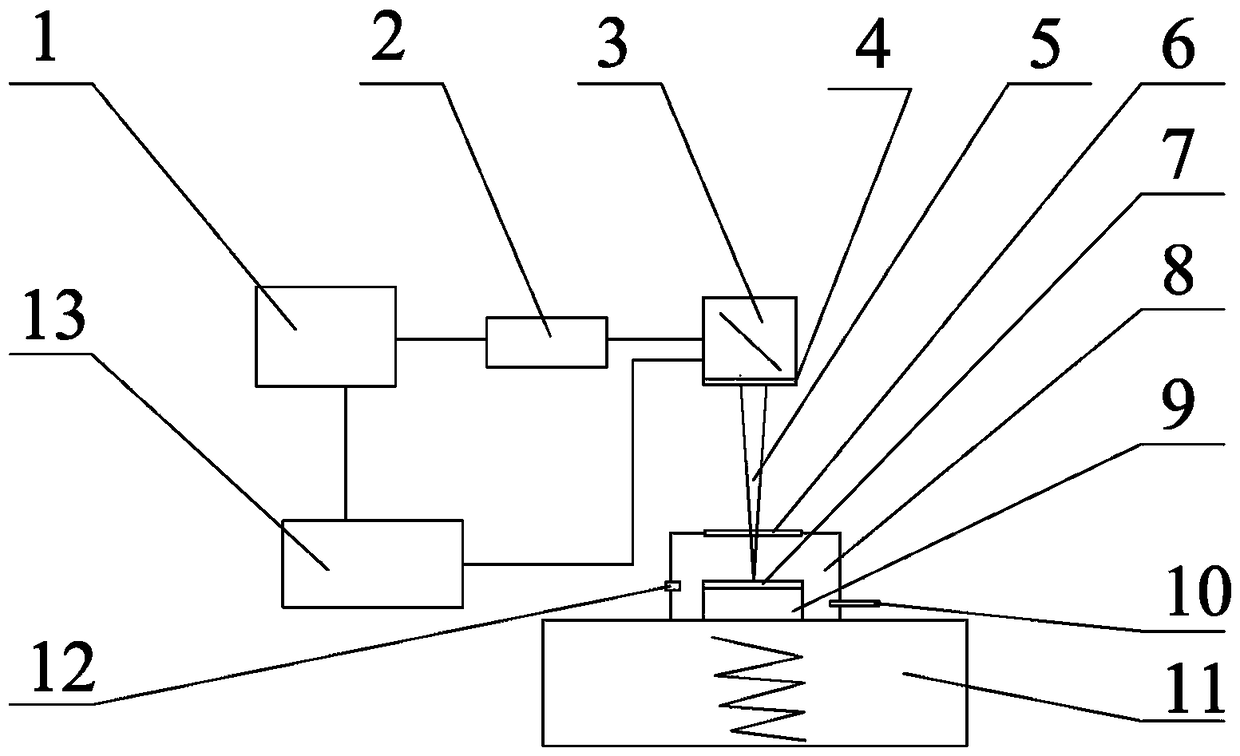

Laser cutting method and system used for amorphous thin belts

The invention discloses a laser cutting method and system used for amorphous thin belts. The cutting system comprises a pulse laser, a beam expansion collimating mirror, a scanning galvanometer, a focus lens, an industrial personal computer, an inflation chamber and a worktable, wherein the industrial personal computer is used for controlling the pulse laser and the scanning galvanometer; a clampused for fixing the amorphous thin belts is arranged on the worktable; a light-transmitting lens is arranged on a top surface of the inflation chamber; an inflation opening and an oxygen content measuring interface are arranged on a side surface of the inflation chamber; a pulse laser beam generated by the pulse laser is expanded by the beam expansion collimating mirror, then enters the scanning galvanometer, and is focused by the focus lens through deflection of the scanning galvanometer; and the laser beam enters the surface of the amorphous thin belt through the light-transmitting lens on the inflation chamber after being focused. By adopting the laser cutting method and system, the 0.01-0.05 mm-thick amorphous thin belt can be subjected to complicated-shape high-speed cutting; besides,cutting joints are smooth; and oxidation and slag adhering are avoided.

Owner:GUANGDONG PROVINCIAL INST OF WELDING TECH GUANGDONG PROVINCIAL ACADEMY OF UKRAINE

Device for producing S-shaped joint of rectangular busbar

Owner:STATE GRID CORP OF CHINA +2

Coating method for peach-blossom core fork bark veneer

InactiveCN102357925AAvoid crackingStable structureWood veneer joiningWood layered productsWood veneerEngineering

The invention discloses a coating method for a peach-blossom core fork bark veneer, which comprises the following steps of: A) using a bark-cutting machine to straightly cut a peach-blossom core fork bark and then using a bark-sewing machine to splice a plurality of slices into a whole peach bark; B) selecting a plank, coating a glue on the surface of the plank, and gluing the peach bark above the glue, thereby forming a plate; C) before the glue is dry, placing the plate into a hot-pressing machine, for hot-pressing; D) polishing the hot-pressed plate till the surface of the peach bark is smooth and free from burr; and E) painting the polished plate. Compared with the prior art, a product produced according to the method has the advantages of stable structure, smooth joint, beautiful appearance, capabilities of efficiently preventing bark from cracking and ensuring quality of the product under an adverse climatic environment, and wide industrial application prospect.

Owner:深圳市森源蒙玛家具有限公司

Method for laser cutting of 0.5 mm titanium alloy

InactiveCN112222640AExtended maintenance cycleCut nozzle long lifeWelding/soldering/cutting articlesLaser beam welding apparatusLaser cuttingTitanium alloy

The invention relates to a method for laser cutting of a 0.5 mm titanium alloy. The method comprises the steps: (1) removing greasy dirt and dust on the surface of the titanium alloy; and (2) cuttinga titanium alloy panel with the thickness of 0.5 mm by using a ProCutter laser cutting gun, wherein the technological parameters are as follows: the cutting speed is 14-16 m / min; the laser power is 1-2kW; the gas pressure is 1-1.5 MPa; the defocusing amount is -1-0 mm; the working distance is 0.8 to 1.2 mm; the diameter of a cutting nozzle is 0.8 to 1.2 mm; and cutting gas is argon. According to the method, the process stability can be guaranteed, and the method is repeatable, safe, stable and reliable, and a kerf is smooth, level, free of adhering slag and good in quality.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Door and window welding process

InactiveCN107931789ASolve fit clearance problemsTo satisfy the market's needsArc welding apparatusEngineeringWear resistance

The invention discloses a door and window welding process, which comprises the following steps: (1) forming a metal plate by cold pressing in a metal door and window cold pressing machine; the tail end of the metal door and window cold pressing machine is provided with a roller mold with a thickness less than 2mm ; Align the two edge ends of a door and window profile, and fine-tune the joint; (2) Polish the surface of the door and window to be welded to remove the surface oxide film; (3) Clean the part to be welded with pickling passivation solution. The invention provides a door and window welding process with excellent heat cycle resistance, good wear resistance and corrosion resistance, excellent mechanical properties, no bumps on welded door frame profiles and longer service life.

Owner:商亚锋

Intelligent sewing machine with independent motor feeding

InactiveCN107164881AAchieve the effect of wrinkle sewingRealize differential feedingProgramme-controlled sewing machinesWork-feeding meansElectric machineryEngineering

The invention discloses an intelligent sewing machine with independent motor feeding, and belongs to the technical field of sewing machine device design. The intelligent sewing machine with independent motor feeding comprises a lower feeding mechanism, a rotating shuttle mechanism, a wire shearing mechanism, a main transmission motor, a take-up-lever mechanism, a needle-rod mechanism, a needle swing feeding mechanism, an automatic presser foot lifting electromagnet, a wire shearing electromagnet and a wire shearing moving cutter, the needle-rod mechanism is further arranged above the rotating shuttle mechanism, the bottom of the lower feeding mechanism is provided with the wire shearing mechanism and the wire shearing electromagnet, the main transmission motor and the automatic presser foot lifting electromagnet are arranged at the right front portion of the wire shearing electromagnet, the needle swing feeding mechanism is arranged at the front portion of a wire disc in a machine shell set, the take-up-lever mechanism is connected with the top of the upper feeding mechanism, and the wire shearing moving cutter is arranged at the top end of the lower feeding mechanism. The intelligent sewing machine with independent motor feeding can freely conduct front-stitch and backstitch, achieve pattern sewing and differential feeding, and freely veer during machine sewing, the stitch line is smooth and uniform, the crease is not generated, the operation is convenient, and the sewing efficiency is high.

Owner:CHIZHOU XUHAO MACHINERY

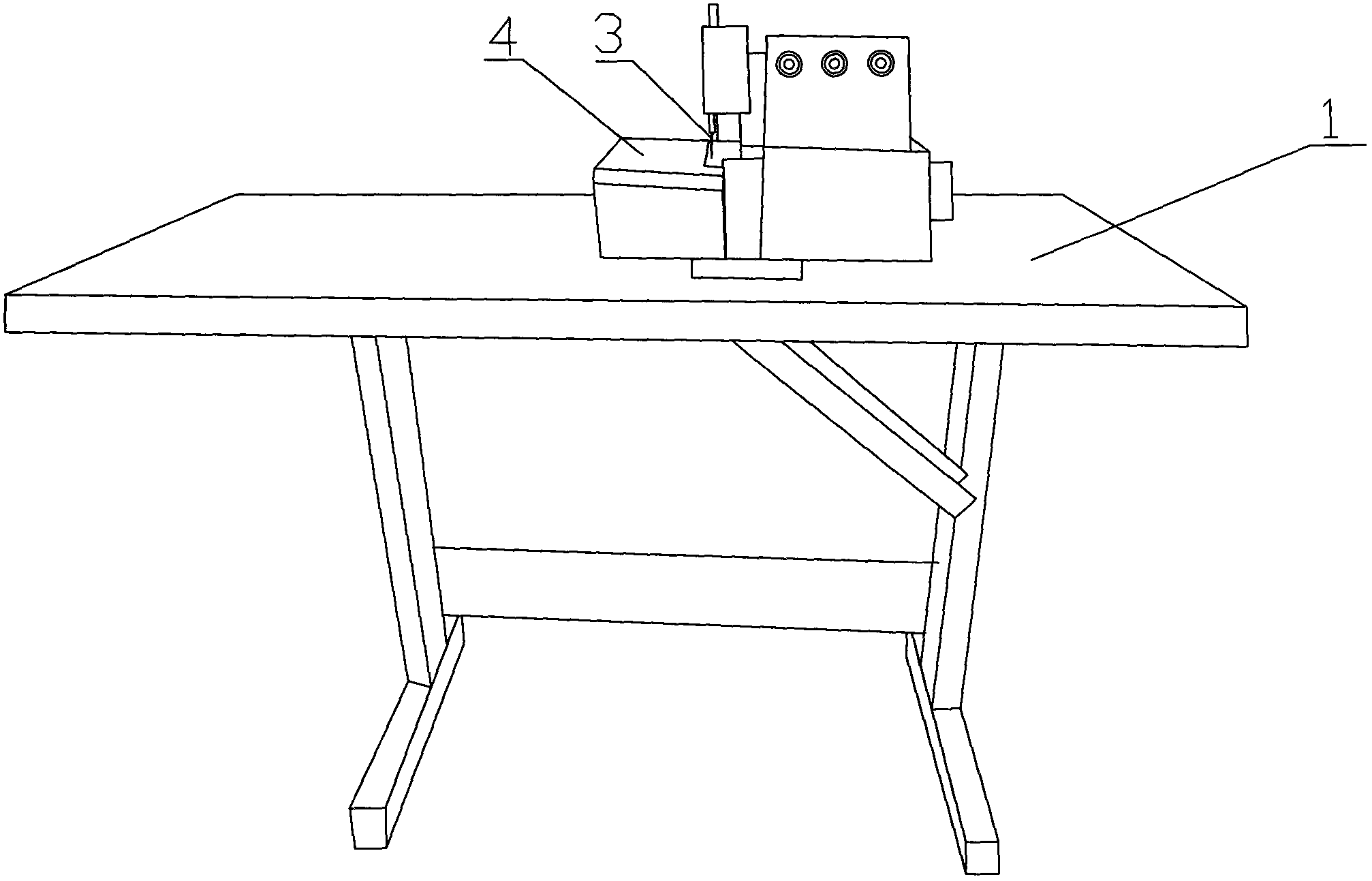

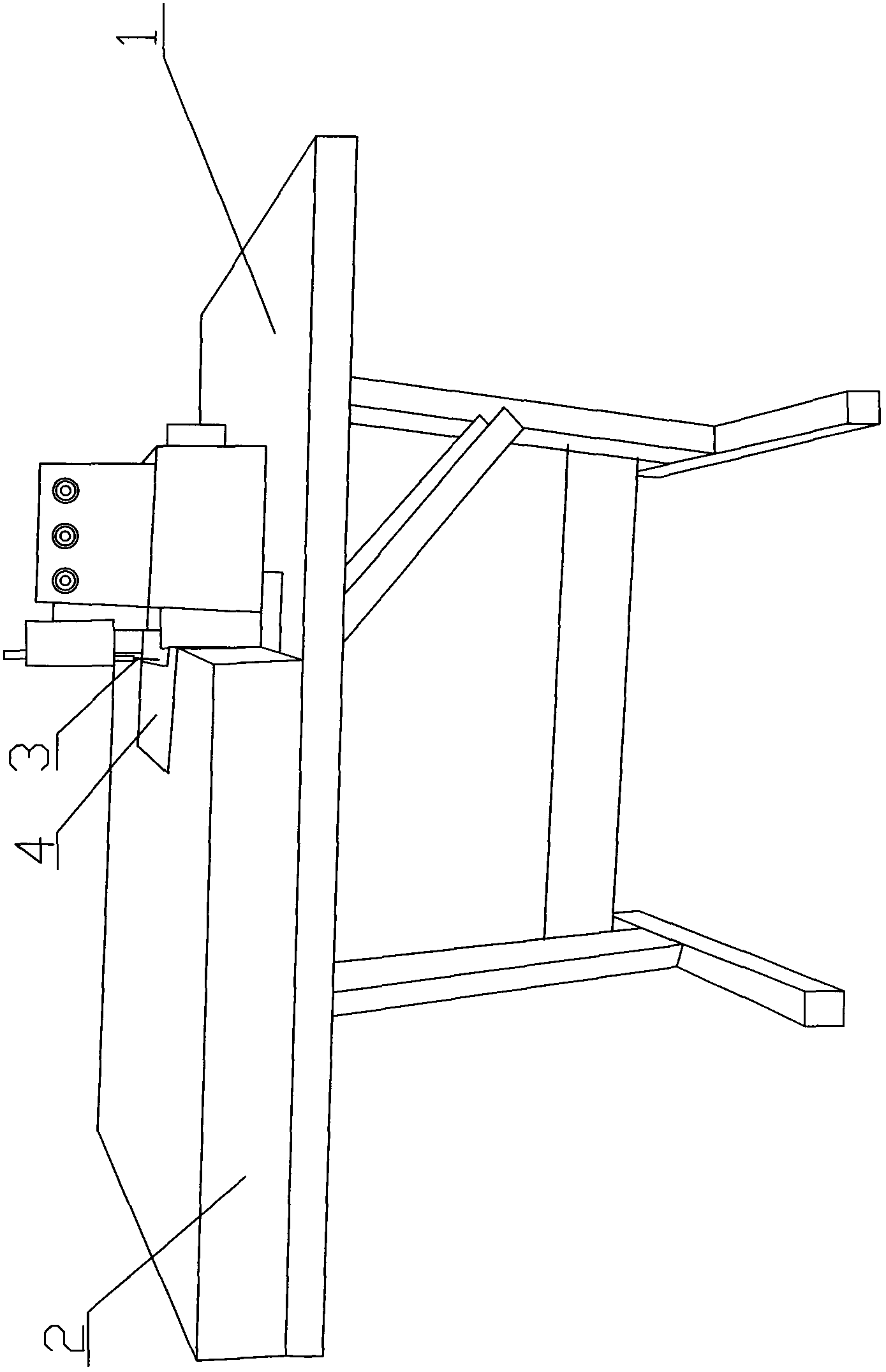

Novel worktable structure of overlocking machine

The invention relates to a novel worktable structure of an overlocking machine. The novel worktable structure of the overlocking machine comprises a planar worktable and a protruding part arranged on the planar worktable, wherein the protruding part is positioned on one side of the overlocking needle; the protruding part has the same height as a small platform on which the needle on the overlocking machine works. According to the novel worktable structure of eh overlocking machine disclosed by the invention, the overlocking needle and a bedplate on one side of the small platform on which the needle works are heightened to have equal height as the small platform, so that during the overlocking process, relatively heavy cloth does not fall down due to height difference of the small platform, relatively hard cloth is not tilted up any longer, the cloth is not required to be supported or pressed by a hand, stitches are uniform and smooth, and the quality of finished clothes is not affected by the process any more.

Owner:青岛酷特智能股份有限公司

Siding joinery with fastener

InactiveUS20160017612A1Seam smoothLess apparentCovering/liningsFlooringEngineeringElectrical and Electronics engineering

Owner:ROYAL GROUP

Prefabricated directly-buried thermal insulation pipe connecting device and process

The invention discloses a prefabricated directly-buried thermal insulation pipe connecting device which comprises a rack, and a first sliding rail is arranged on the rack; the telescopic part is installed on the rack, and the output end of the telescopic part is connected with a sliding block sliding on the first sliding rail; at least one first thermal insulation pipe fixing sleeve and a second thermal insulation pipe fixing sleeve are connected to the fixed section, located on the telescopic part, of the rack, and the second thermal insulation pipe fixing sleeve is located on the telescopic section of the telescopic part and fixed to the sliding block; the connecting device further comprises an end face cutting mechanism which is installed on the machine frame and can be arranged between the two heat preservation pipes to cut the end faces of the two heat preservation pipes. The end face thermoplastic mechanism is mounted on the rack and can be arranged between the two thermal insulation pipes to heat and soften the end faces of the thermal insulation pipes; after machining is completed, only the telescopic part needs to be shrunk, so that the two ends of the two thermal insulation pipes are attached under driving of the sliding blocks, the end faces of the thermal insulation pipes are conveniently machined, and the beneficial effects of being accurate in positioning, smooth in joint and the like are achieved.

Owner:DALIAN KAIYUAN PIPELINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com