Reciprocating progressive self-adaptive feed control method for electrical spark machine tool

A technology for feed control and machining of machine tools, applied in adaptive control, electric machining equipment, general control system, etc., can solve problems such as difficulty in distinguishing between normal discharge state and short circuit state, failure of feed control system, bending of electrode wire, etc. Achieve the effect of improving machining quality, improving machining surface quality, preventing over-feed and under-feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

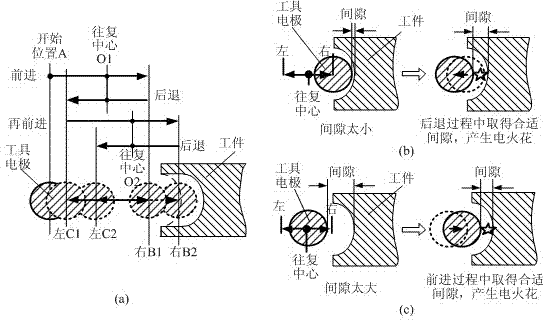

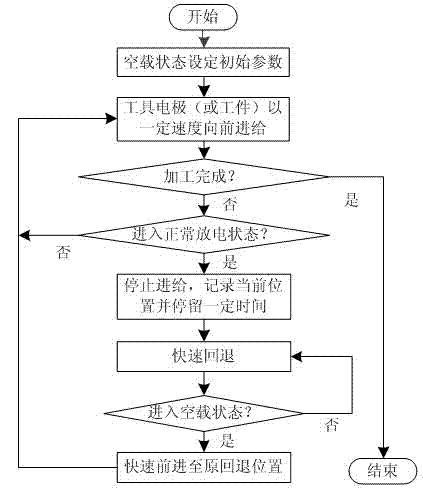

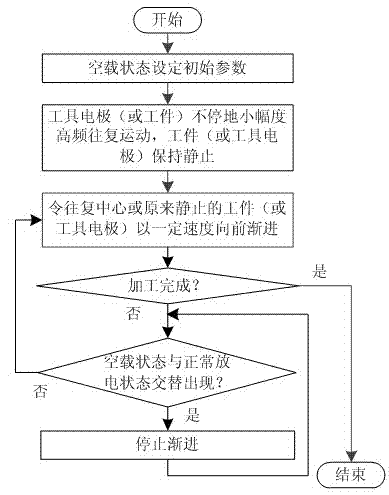

[0040] A reciprocating progressive adaptive feed control method for EDM machine tools, which realizes adaptive feed control by controlling the reciprocating progressive feed motion between the tool electrode and the workpiece, and utilizes that the short circuit state always occurs after the normal discharge state According to the law, the gradual movement is performed in the no-load state, and the gradual movement is stopped after the normal discharge state is recognized, so as to avoid the EDM from falling into a short circuit state, and at the same time, the retreat movement in the reciprocating movement is used to increase the gap between the electrode and the workpiece to accelerate Chip removal, improve discharge conditions. In this way, there is no need to detect the short-circuit state during the feed control, and only need to detect the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com