Patents

Literature

247results about How to "Implement automatic tracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

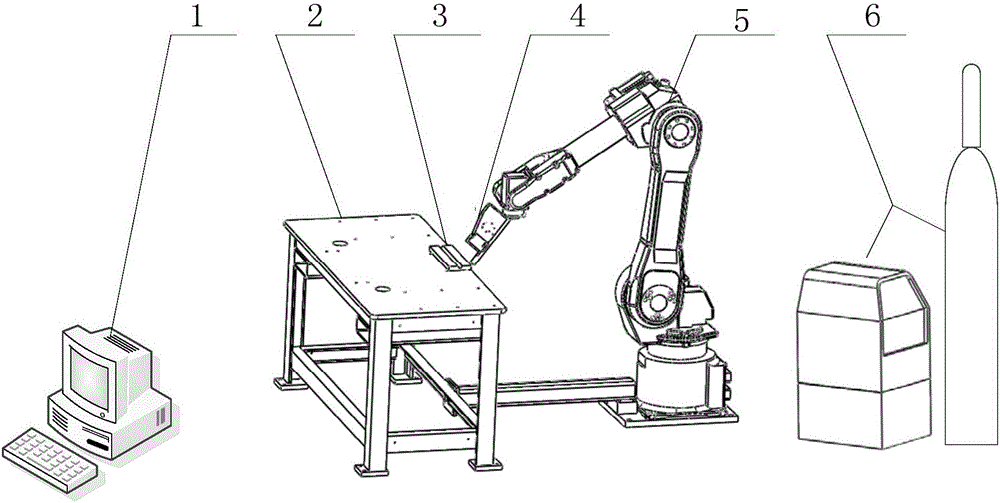

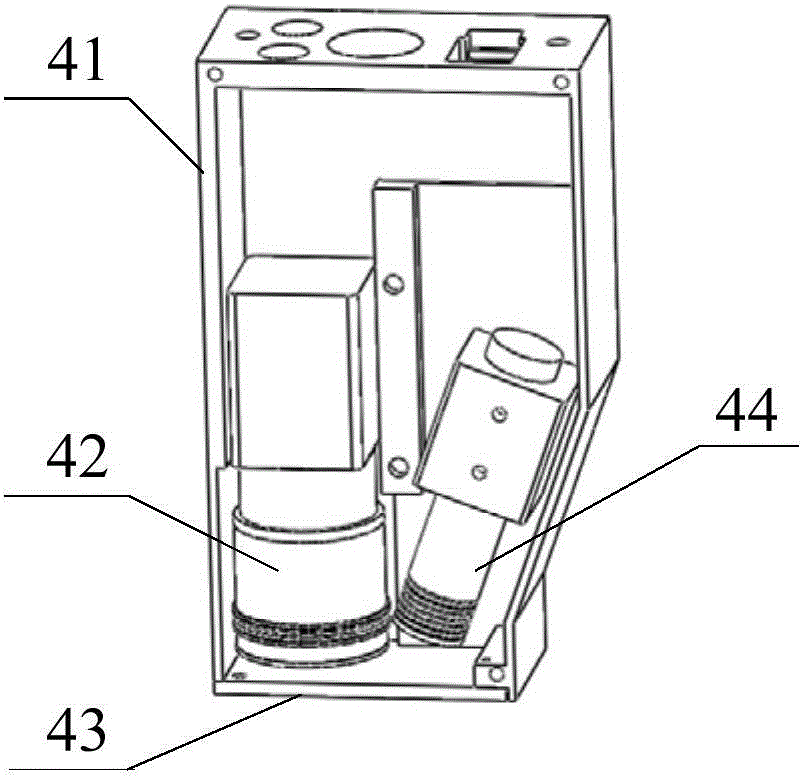

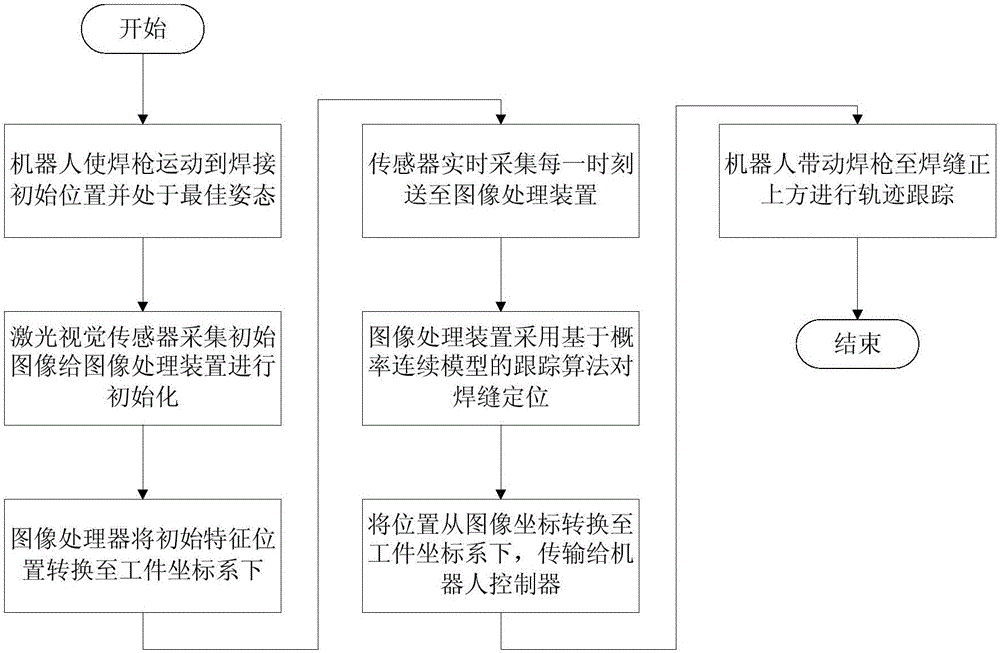

Laser vision guided automatic welding track tracking system and method

InactiveCN106312397ASimple structureImprove data processing efficiencyWelding/cutting auxillary devicesArc welding apparatusImaging processingLight irradiation

The invention discloses a laser vision guided automatic welding track tracking system which comprises an embedded type industrial personal computer with an image processing device, a laser vision sensor, a welding robot, matched welding equipment and a workpiece clamping workbench; the laser vision sensor is installed on a welding gun in an advanced parallel manner in the welding direction through a laser sensor fixing element; the welding gun is installed on a tail end flange disc of the welding robot through a welding gun fixing element; and the embedded type industrial personal computer is connected with the laser vision sensor through a circuit. The invention also discloses a laser vision guided automatic welding track tracking method. With adoption of the laser vision guided automatic welding track tracking system and method, without the process of teaching in advance, the welding production efficiency and the adaptive ability are improved through real-time detection and tracking; and meanwhile, the problem of tracking lag caused by advanced detection is prevented, and the problem that when a sensor is too near the welding gun, large noise of coupling feature images is caused by factors including strong arc light irradiation, high temperature and smoke dusts, thus the real time and the tracking accuracy of the system are restricted is solved.

Owner:SOUTH CHINA UNIV OF TECH

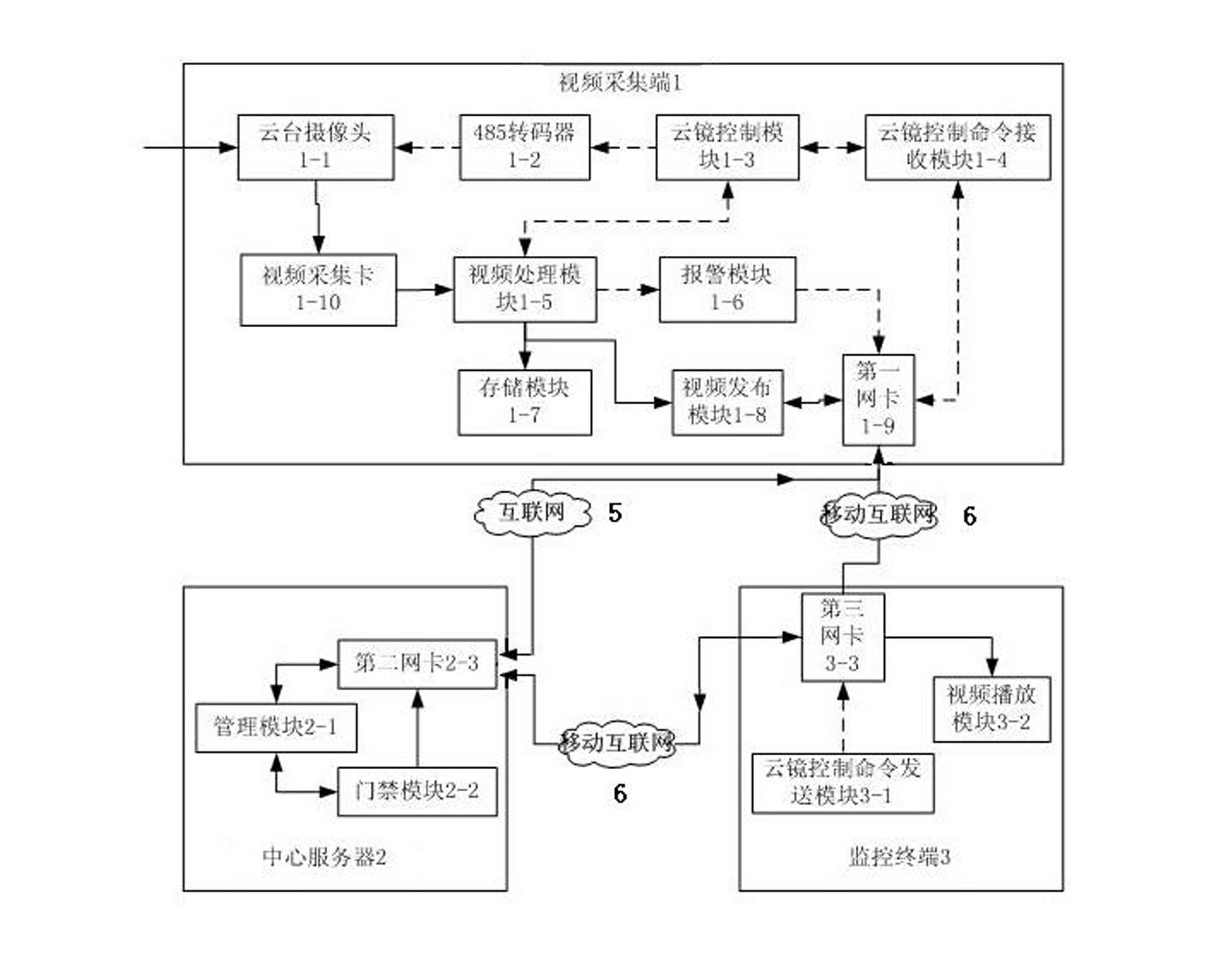

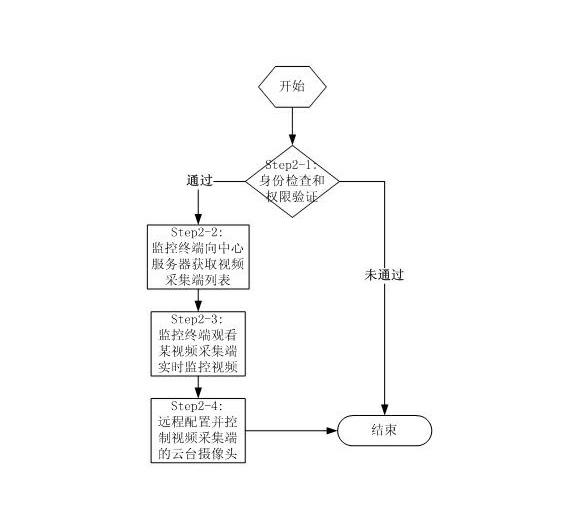

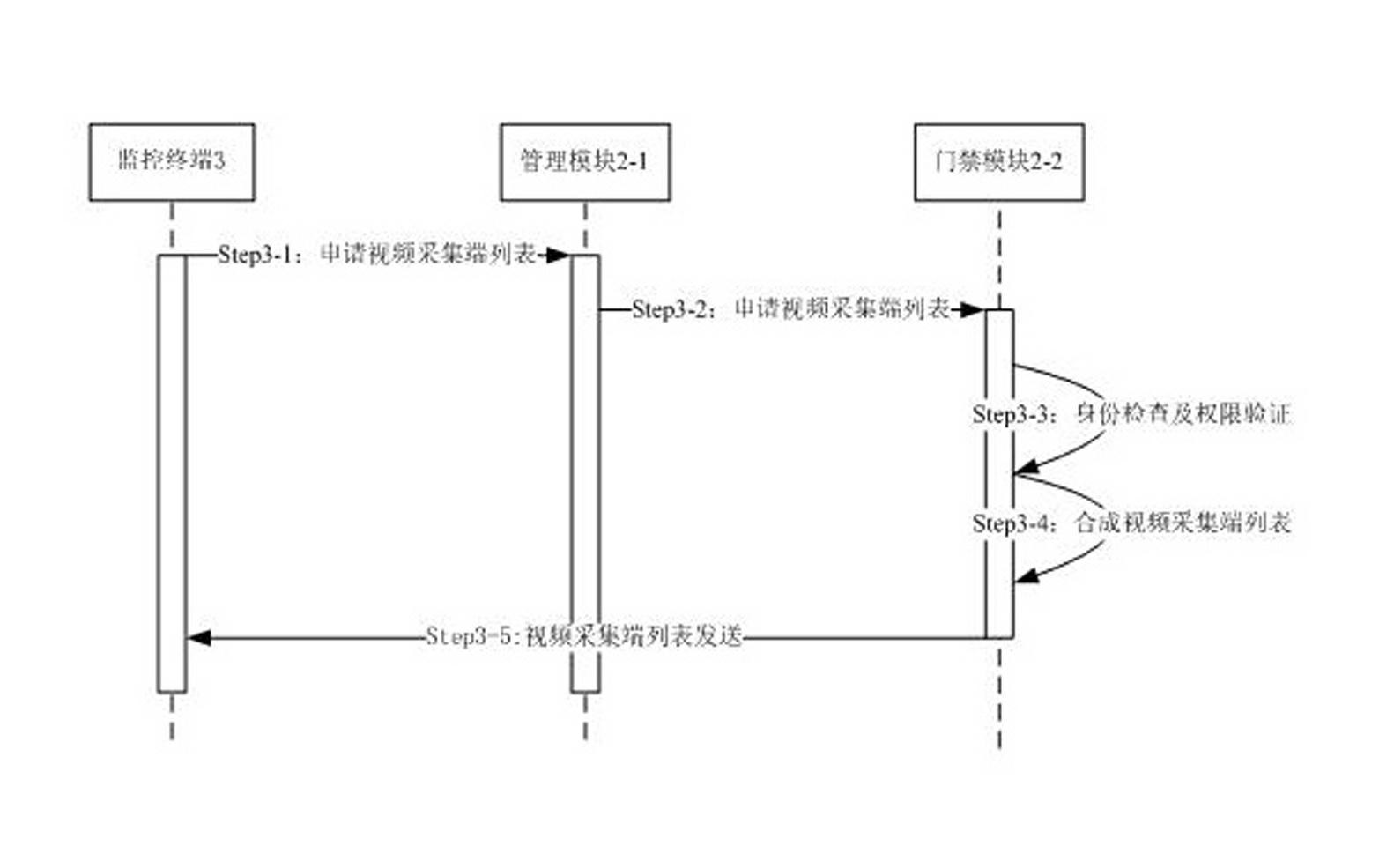

Mobile phone remote control intelligent video monitoring system and monitoring method thereof

InactiveCN102186056ASmooth real-time surveillance videoImprove the effect of remote monitoringTelephonic communicationClosed circuit television systemsVideo monitoringRemote control

The invention relates to a mobile phone remote control intelligent video monitoring system and a monitoring method thereof. The system comprises a video acquisition end, a central server and a monitoring terminal. The monitoring method comprises the following steps: the monitoring terminal obtains a video acquisition end list from the central server; the monitoring terminal watches real-time monitored video acquired by a cradle head camera of the video acquisition end; and the monitoring terminal remotely configures and controls the cradle head cameras of the video acquisition end. The systemand method provided by the invention can automatic track, alarm and store the cradle head cameras and have certain protection function for the cradle head cameras, improve the intelligence and stability of remote monitoring, and have the characteristics of high speed, safety and high efficiency.

Owner:HEBEI NORMAL UNIV

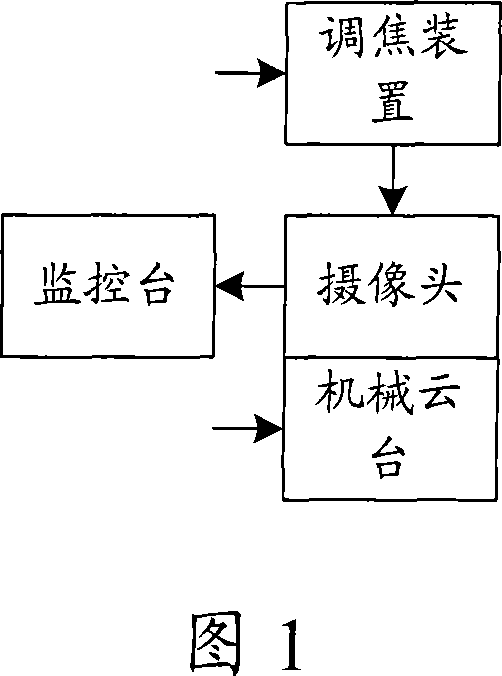

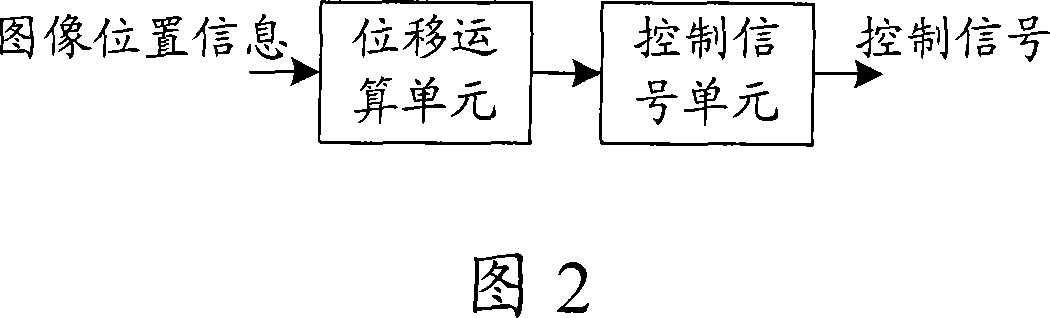

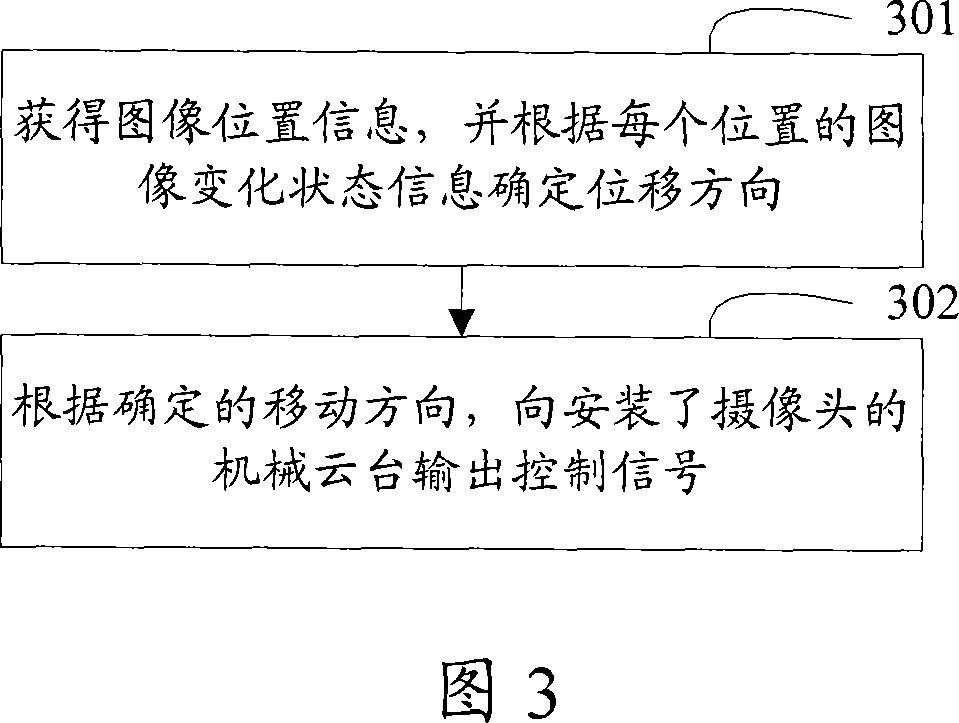

Automatically tracking and controlling method and control device in the video monitoring

InactiveCN101035273AImprove reliabilityImprove clarityTelevision system detailsColor television detailsDistinctness of imageHigh definition

The invention discloses an auto tracking control method and device in video monitoring. According to the obtained image position information, the invention judges the moving direction of the monitored object and controls mechanical platform to drive camera to track the moving monitored object and makes the monitored object all along able to be in the center of a monitoring picture, improving video monitoring reliability. At the same time of implementing automatic tracking, it can judge variation trend of image definition according to the image definition information and sends control signal to a camera focuser by this, so as to make the monitoring picture keep a higher definition all along, implementing automatic focusing and further improving video monitoring reliability.

Owner:WUXI ZGMICRO ELECTRONICS CO LTD

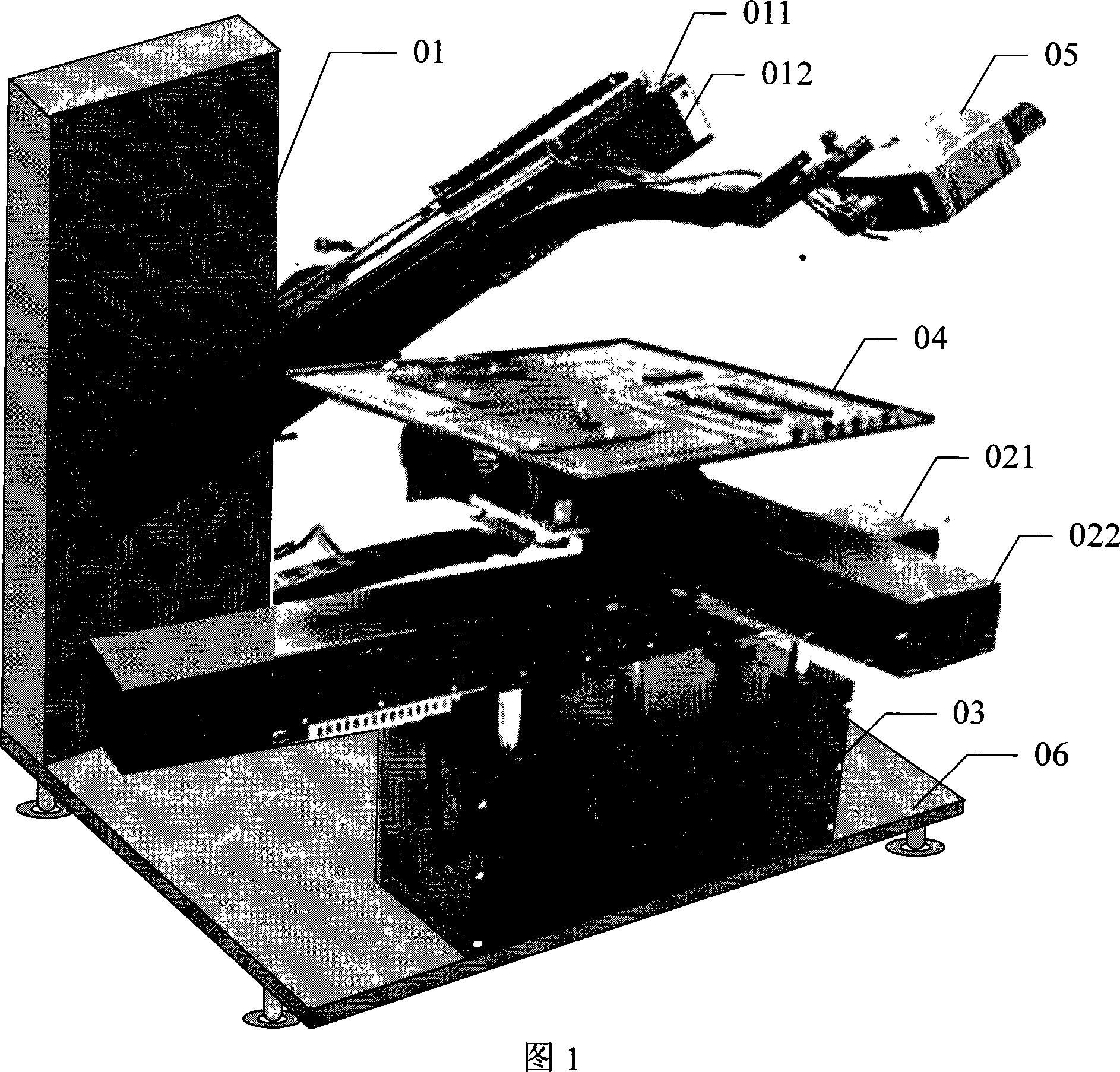

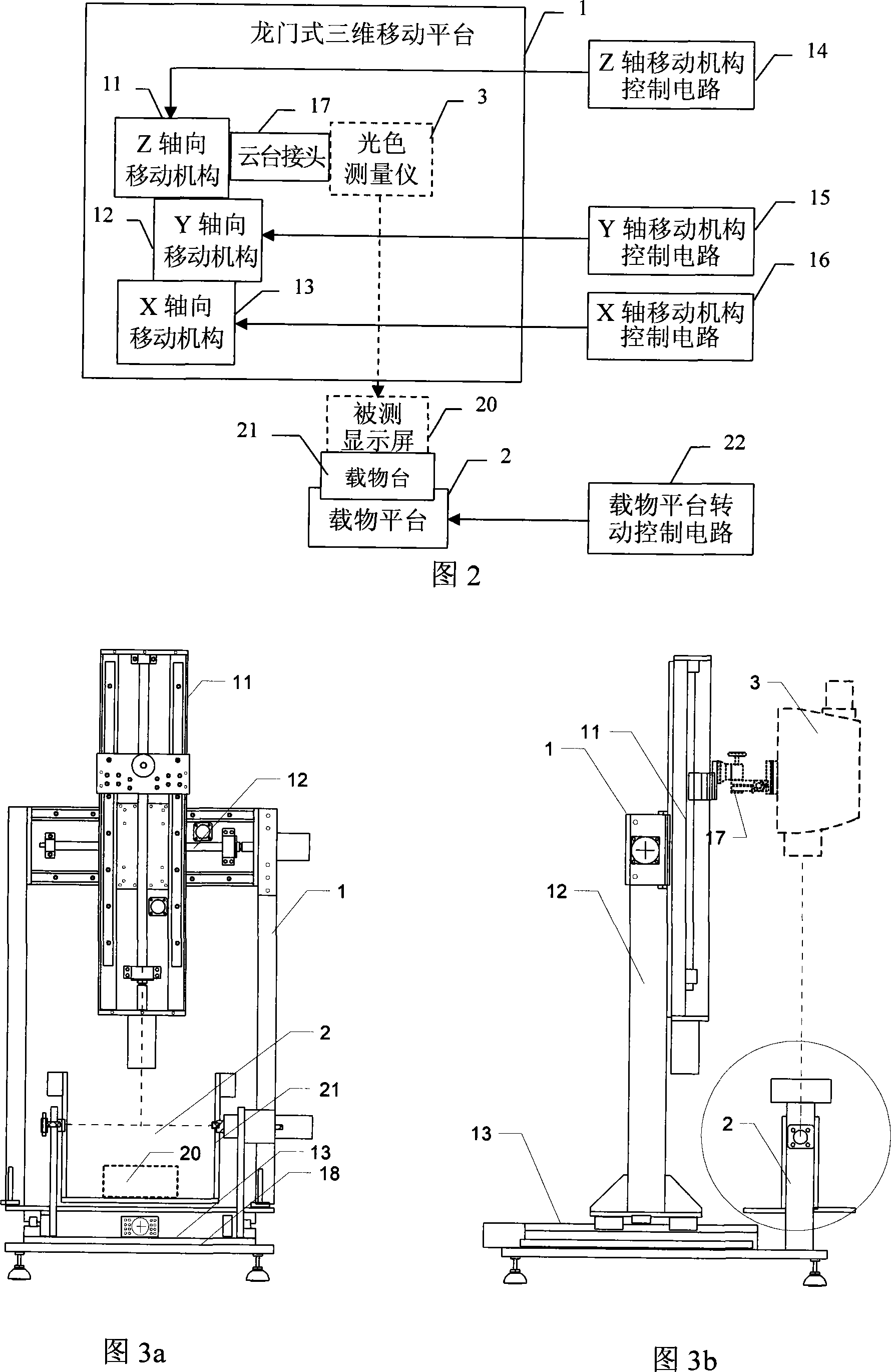

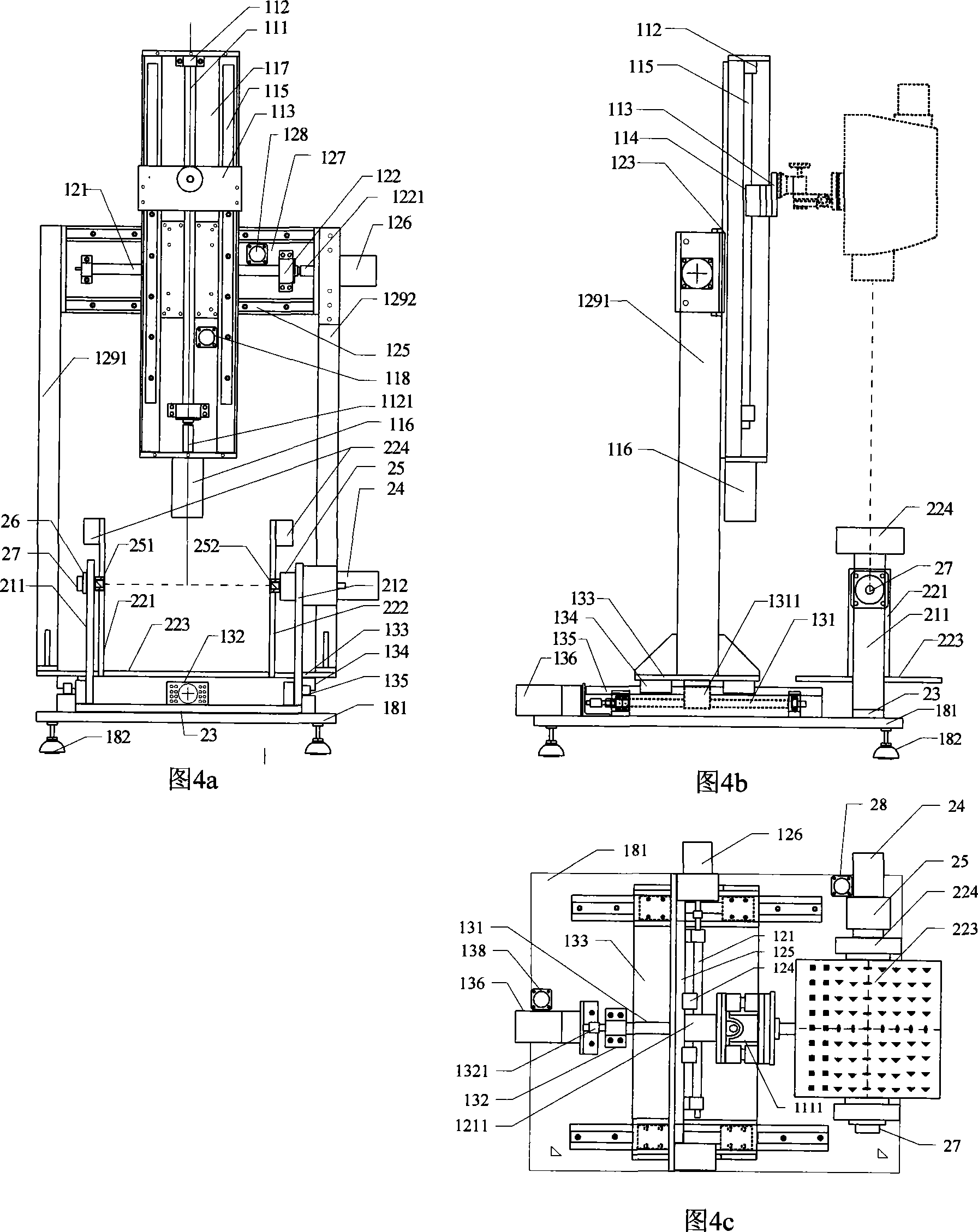

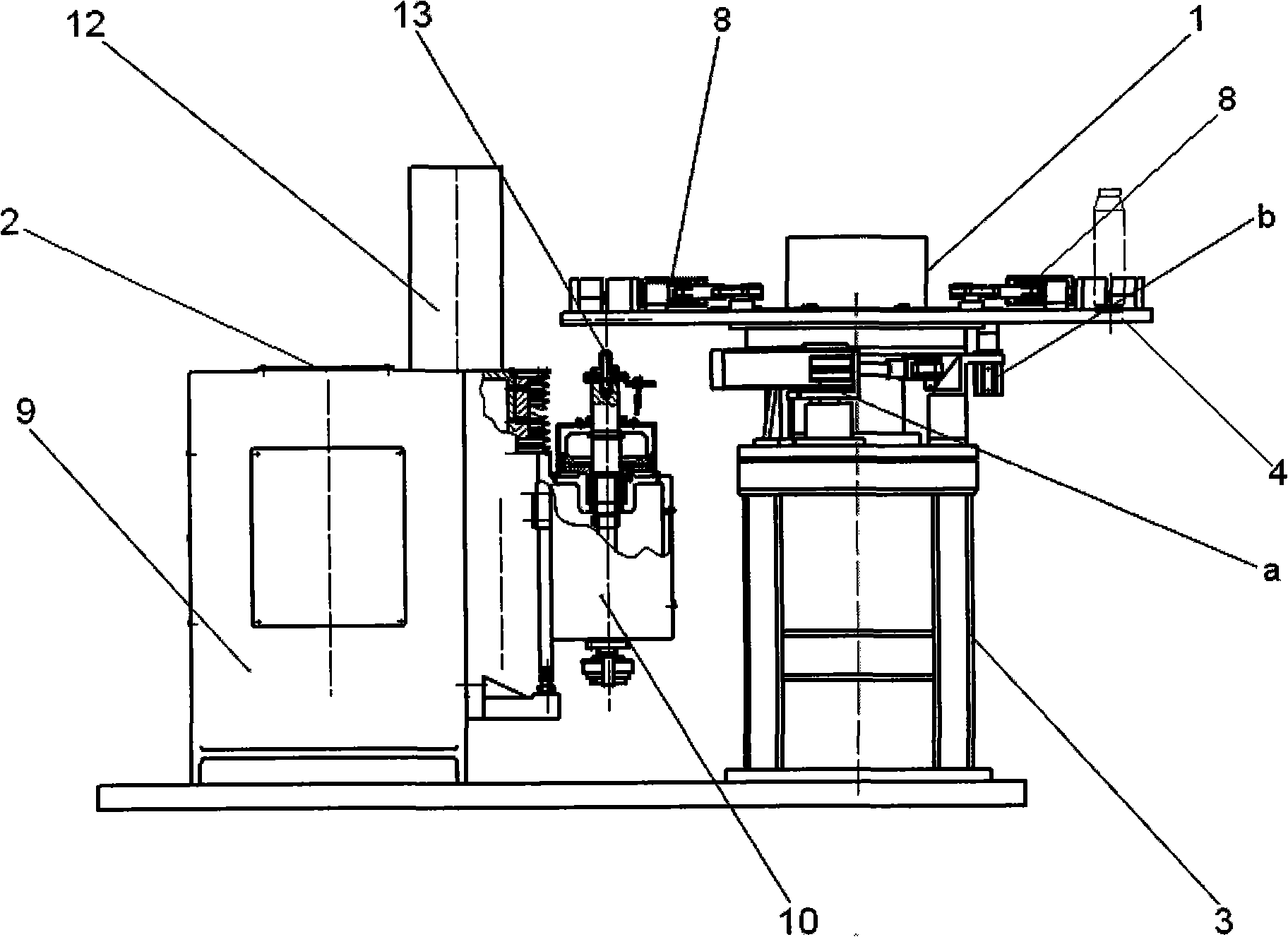

Gantry type four dimensional automatic measurement used for detecting display screen color performance

InactiveCN101118719AImprove stabilityReduce weightColor measuring devicesStatic indicating devicesMeasuring instrumentTelevision screen

The present invention discloses a composition method of a gantry four-dimensional automatic measurement platform for detecting photochromic performance of display screens and a gantry four-dimensional automatic measurement platform using the method. The present invention relates to the automatic measuring technology of the photochromic performance of display screens, and comprises a platform base, a gantry frame, an X-axis moving mechanism, a Y-axis moving mechanism, a Z-axis lifting mechanism, and a display screen-carrying rotating platform. By moving the mechanisms to control the circuit, the four-dimensional automatic measurement platform for detecting photochromic performance of display screens is flexibly controlled to accomplish the three-dimensional move of the photochromic measuring instrument and the accurate one-dimensional rotation of the display screen to be measured, the present invention is characterized in stable movement of the photochromic measuring instrument, small rotation radium of the display screen, novel structure, small driving power needed, small size, light weight, low cost, rapid measuring speed, high reliability and so on. The present invention can be widely applied to the photochromic automatic detecting system of LCD or LED television screen, display screen, or mobile phone screen and so on, and the present invention can precisely adjust the coordinate position of the test points and the angle of the display screen intelligently according to the detecting requirement of photochromic performance of the display screens under the computer management, and rapidly accomplish the detection of photochromic performance.

Owner:ZHEJIANG UNIV

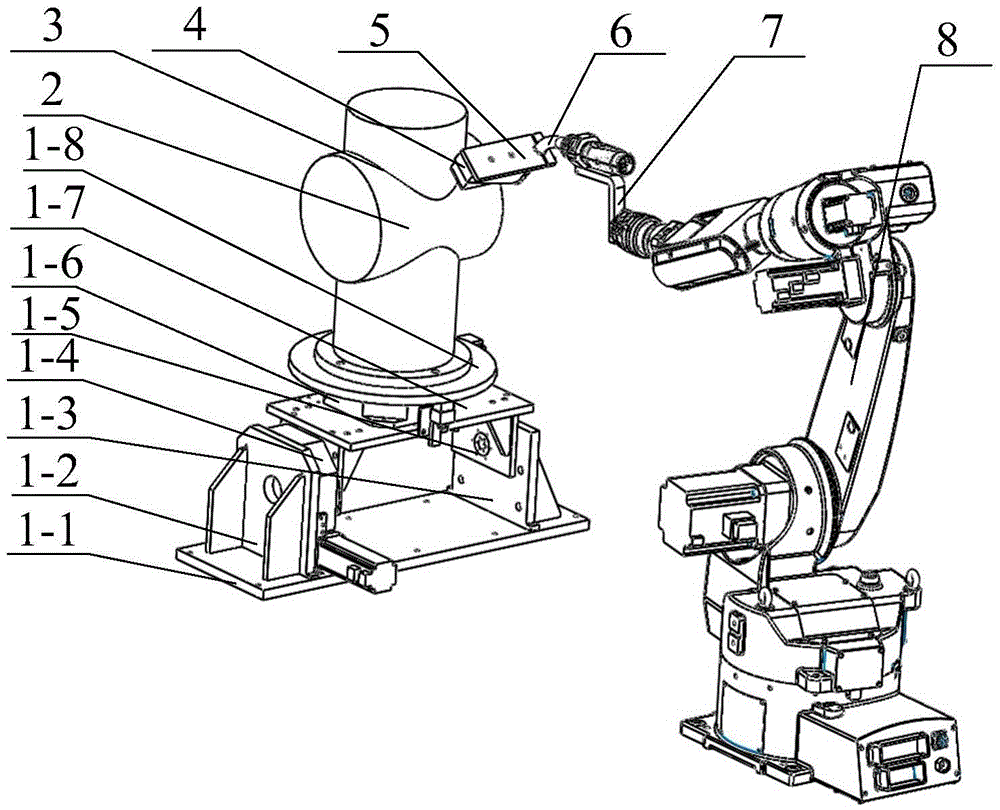

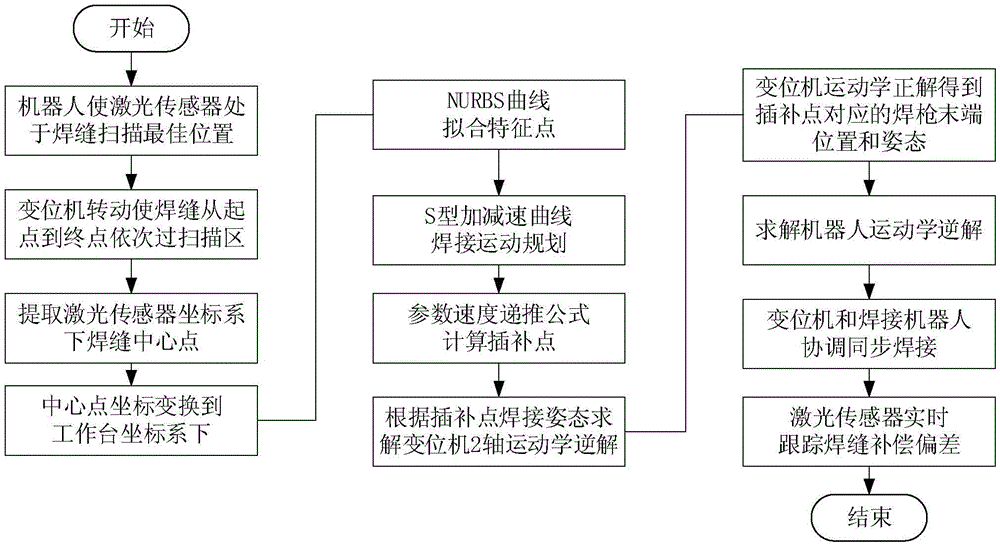

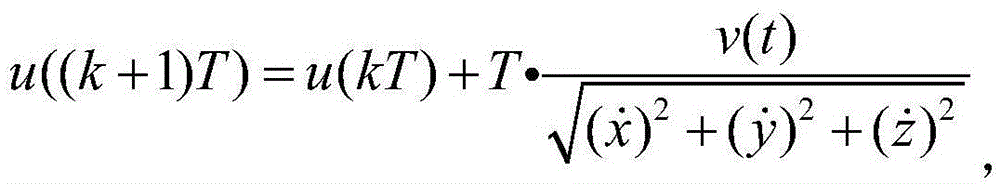

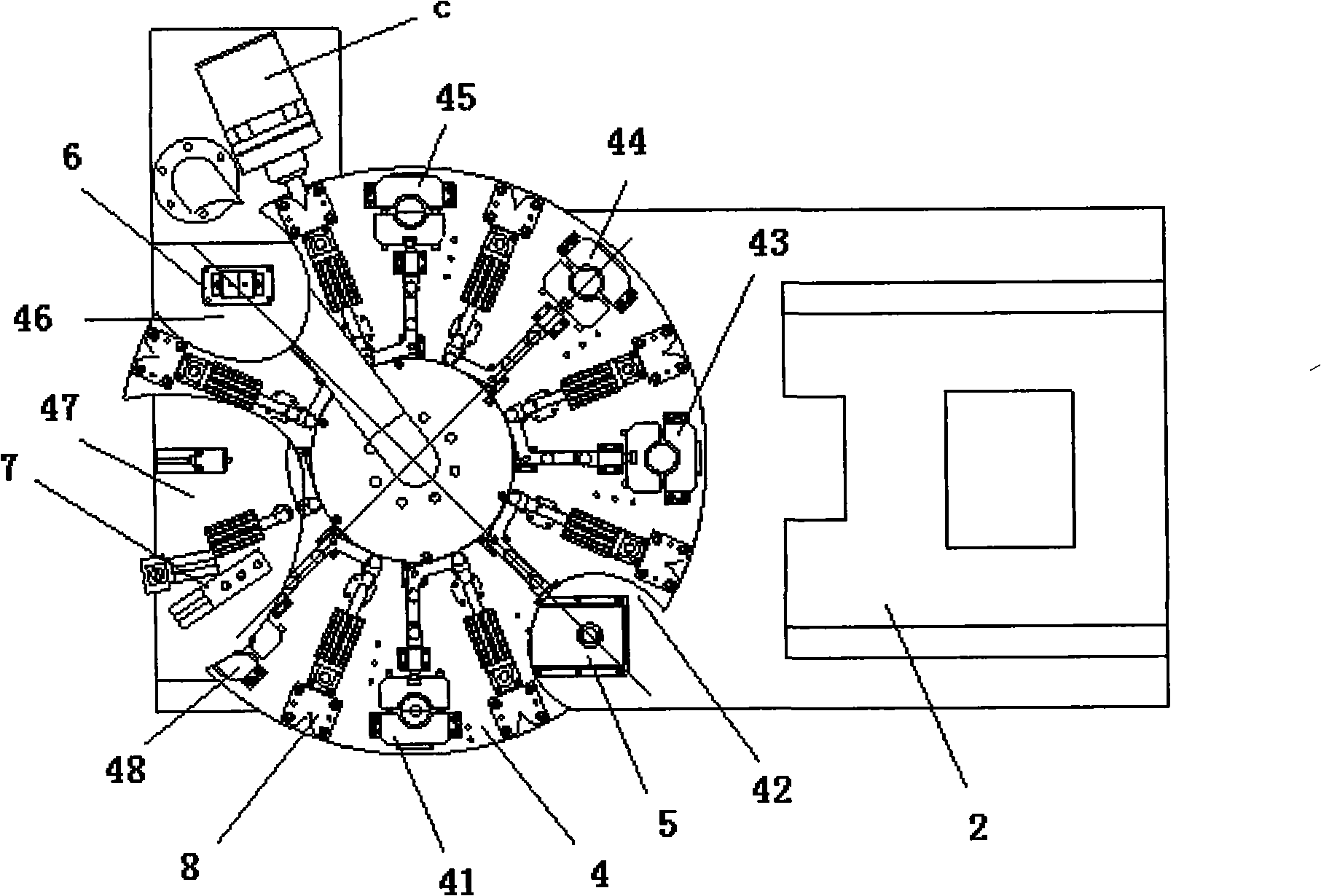

Eight-axis robot space curve welding system and method for recognizing welding line by means of lasers

InactiveCN105562973AEasy maintenanceSimple device structureWelding/cutting auxillary devicesAuxillary welding devicesLaser sensorEngineering

The invention discloses an eight-axis robot space curve welding system for recognizing a welding line by means of lasers. The system comprises a tilting / rotating two-axis positioner used for fixing a workpiece, a laser sensor, a laser sensor fixing element, a welding gun, a welding gun fixing element and a welding robot. The workpiece is fixed to the tilting / rotating two-axis positioner and does tilting and / or rotating motion along with the tilting / rotating two-axis positioner. The laser sensor is mounted on the laser sensor fixing element. The laser sensor fixing element is clamped on the welding gun. The welding gun is mounted on the welding gun fixing element. The welding gun fixing element is mounted on a flange plate at the tail end of the welding robot. Both the laser sensor and the welding gun can move along with the tail end of the welding robot. The invention further discloses an eight-axis robot space curve welding method for recognizing the welding line by means of the lasers. The problems that existing space curve welding line off-line programming is not high in precision, the teaching workload of space curve welding line teaching programming is large, and efficiency is low are solved. Efficiency and precision are high.

Owner:SOUTH CHINA UNIV OF TECH

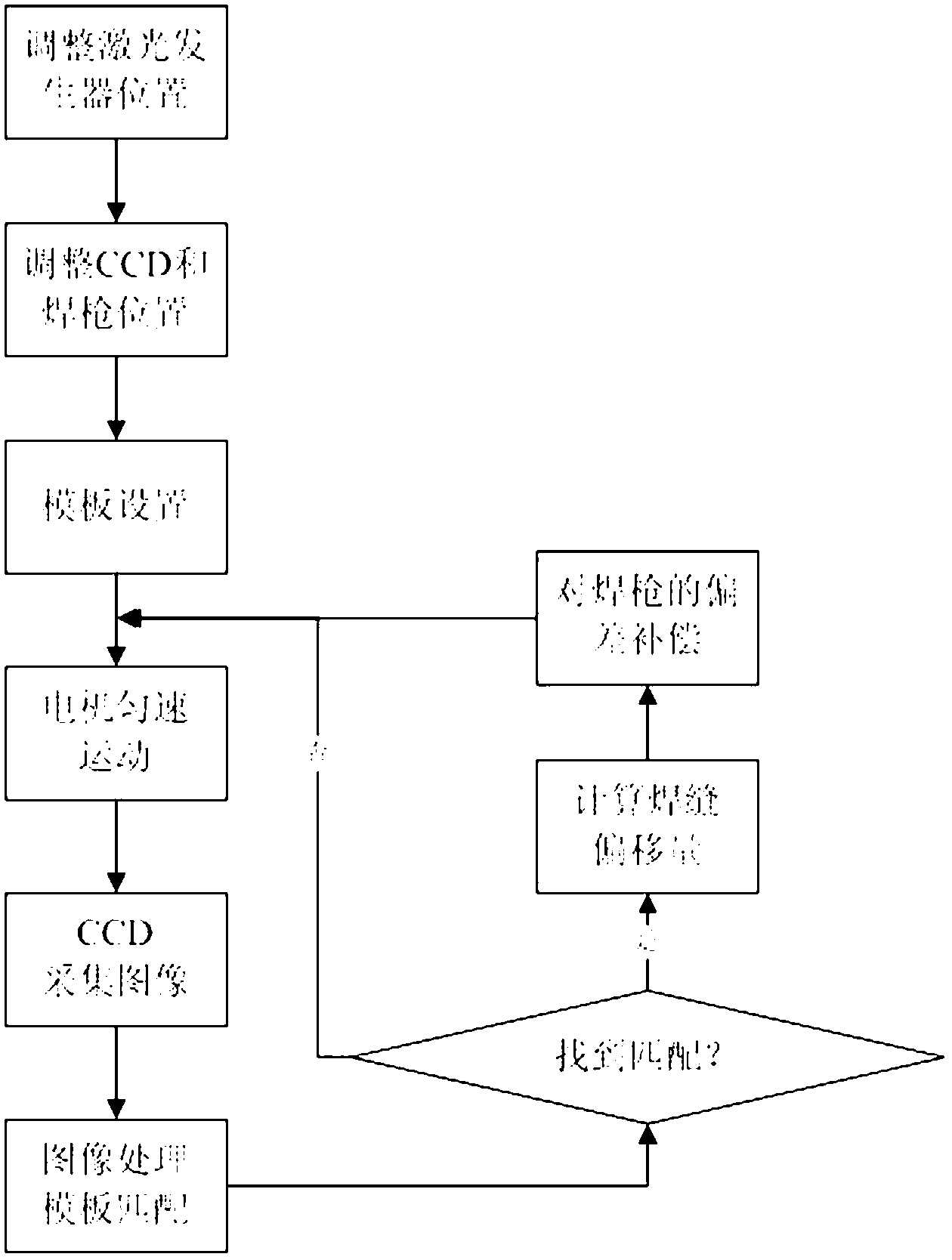

Seam tracking method based on template matching

InactiveCN103008881AQuality assuranceEasy to operateLaser beam welding apparatusTemplate matchingLaser imaging

The invention discloses a seam tracking method based on liner laser imaging, and the seam tracking method comprises the following steps of step1, equipment calibration: adjusting a linear laser source generator, adjusting the position of a welding gun, fixing a charge coupled device (CCD) camera right in front of the welding gun, collecting an image and transmitting the collected image to a computer; step 2, setting a template; step 3, setting an interesting area; step 4, carrying out the template matching and acquiring a position deviation of the center of a weld seam; step 5, if an image which is matched with the template is found, compensating the deviation of the position of the welding gun; step 6, returning to the step 3 if no image which is matched with the template is found; and step 7, stopping a motor if the finding times of the image which is matched with the template is greater than a set threshold value. Due to the adoption of the seam tracking method, the position of a seam can be precisely positioned in the welding position, the seam tracking accuracy and reliability can be improved, the method is applicable to the tracking of the seams in different shapes, and a purpose for automatically tracking the seam in the welding process can be realized.

Owner:THE 45TH RES INST OF CETC

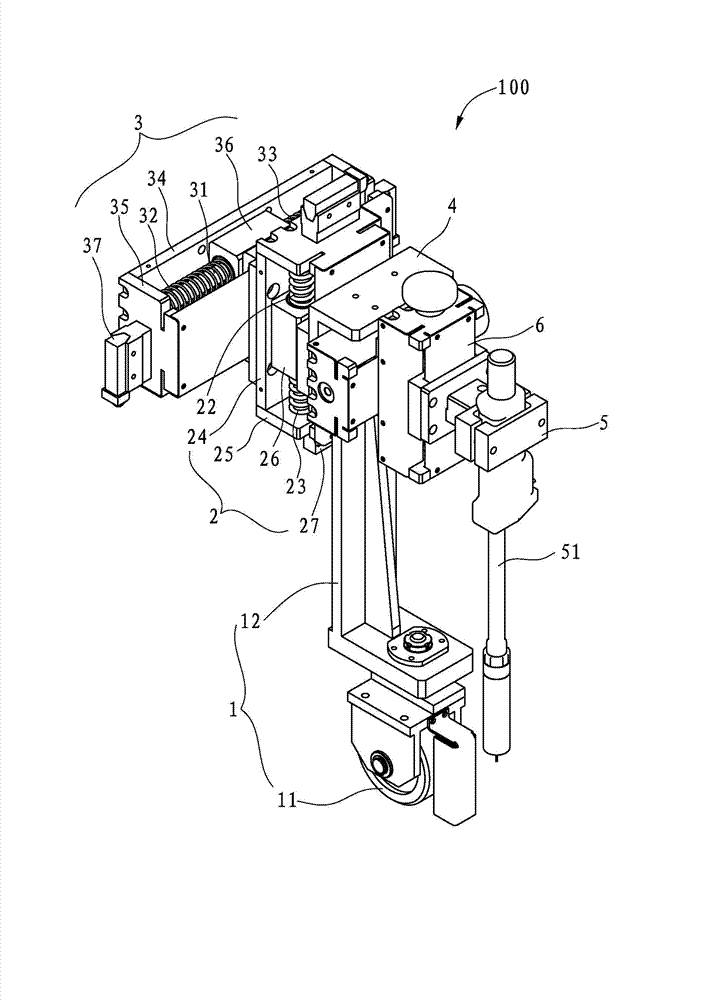

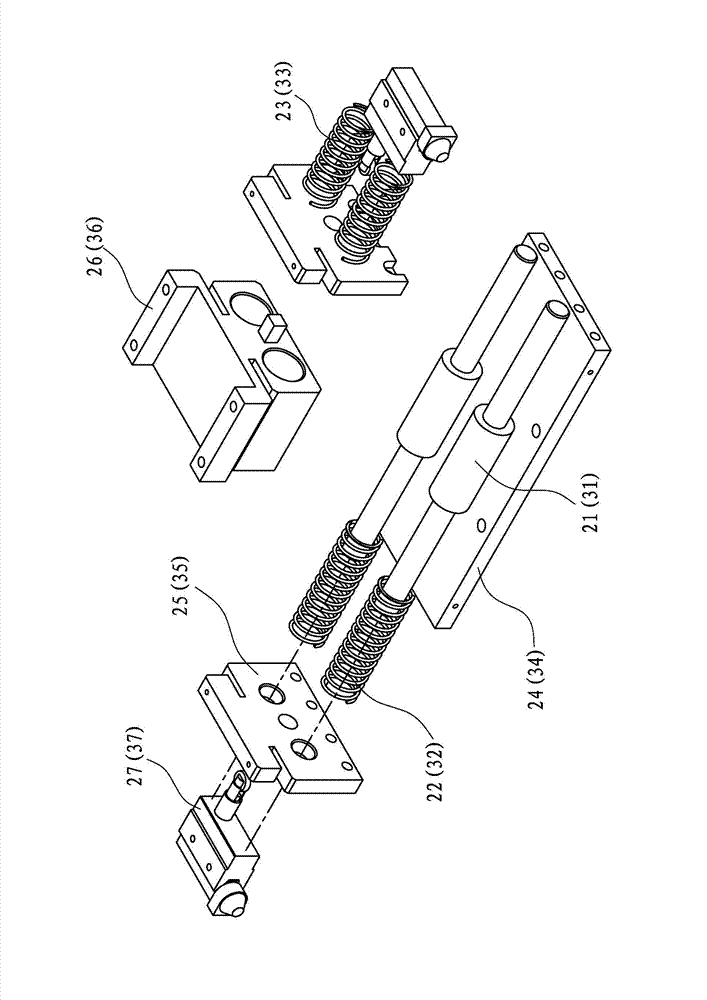

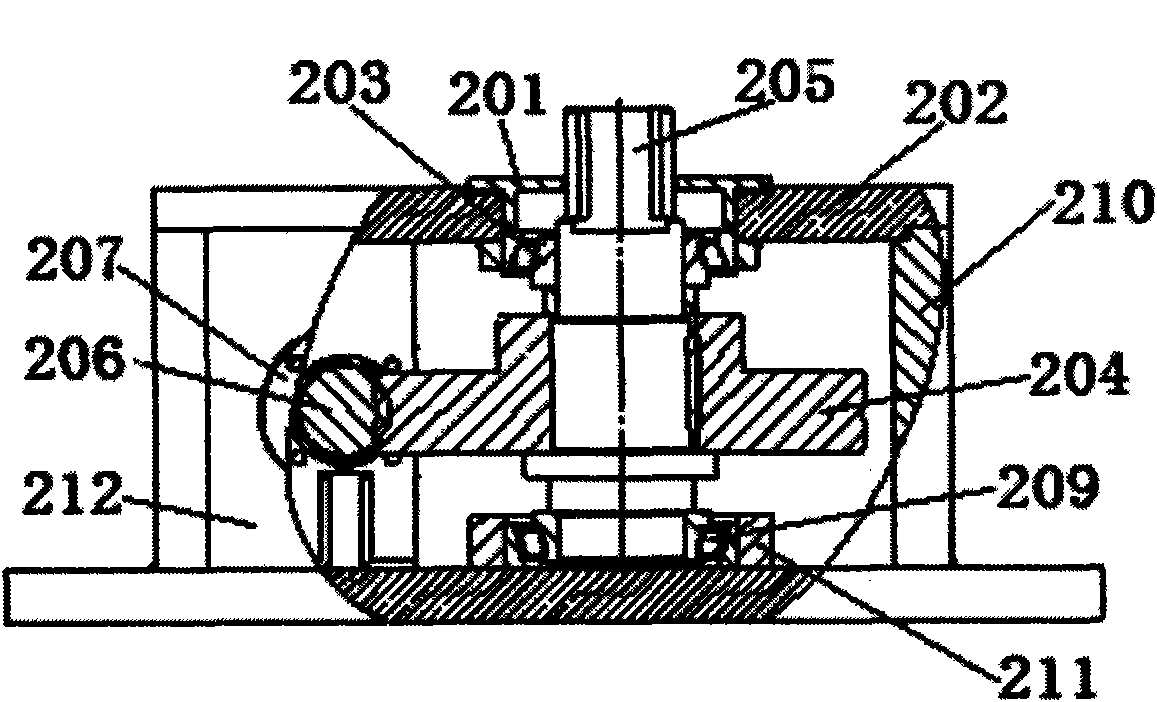

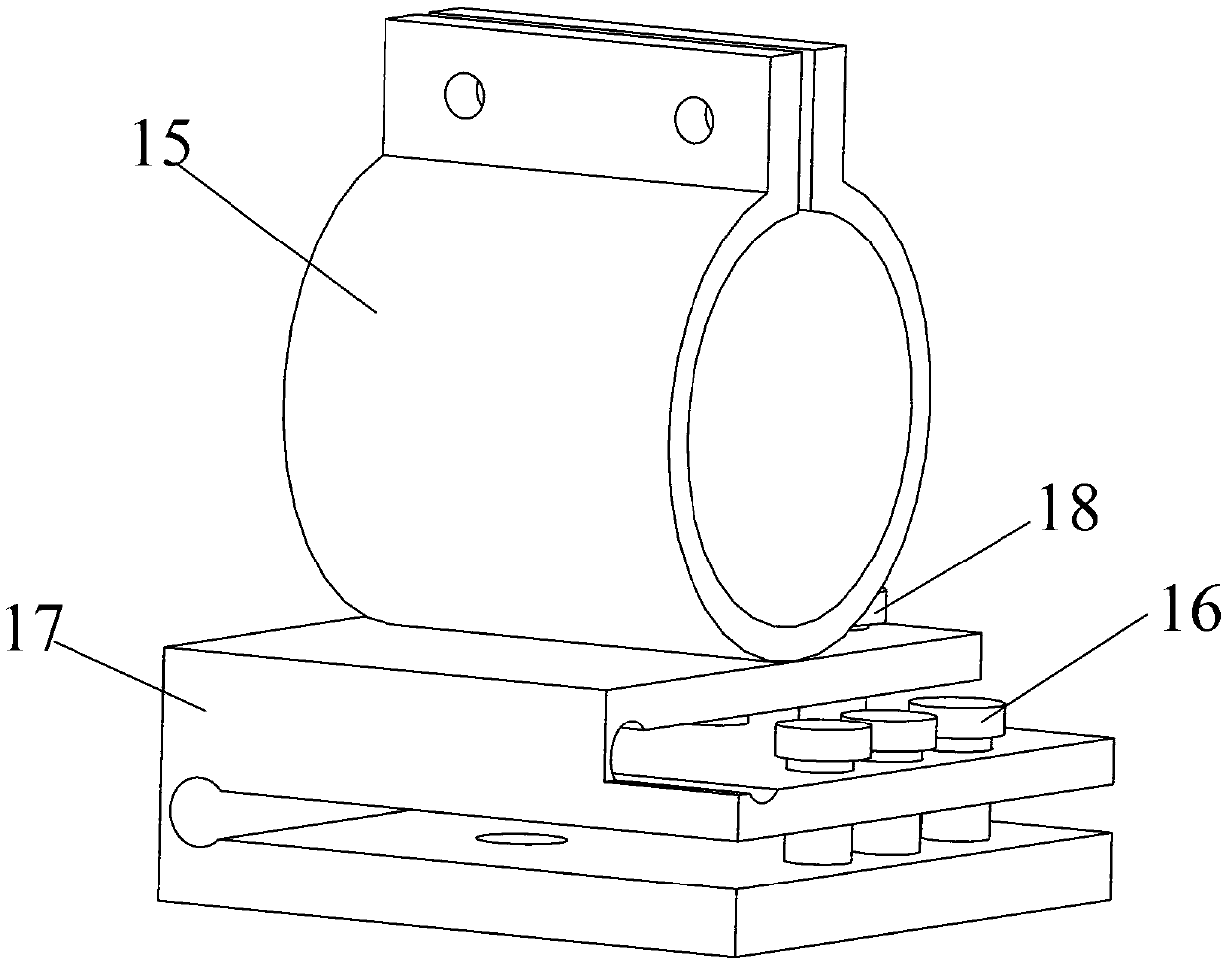

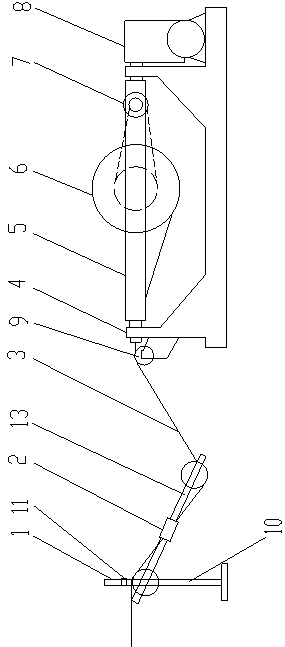

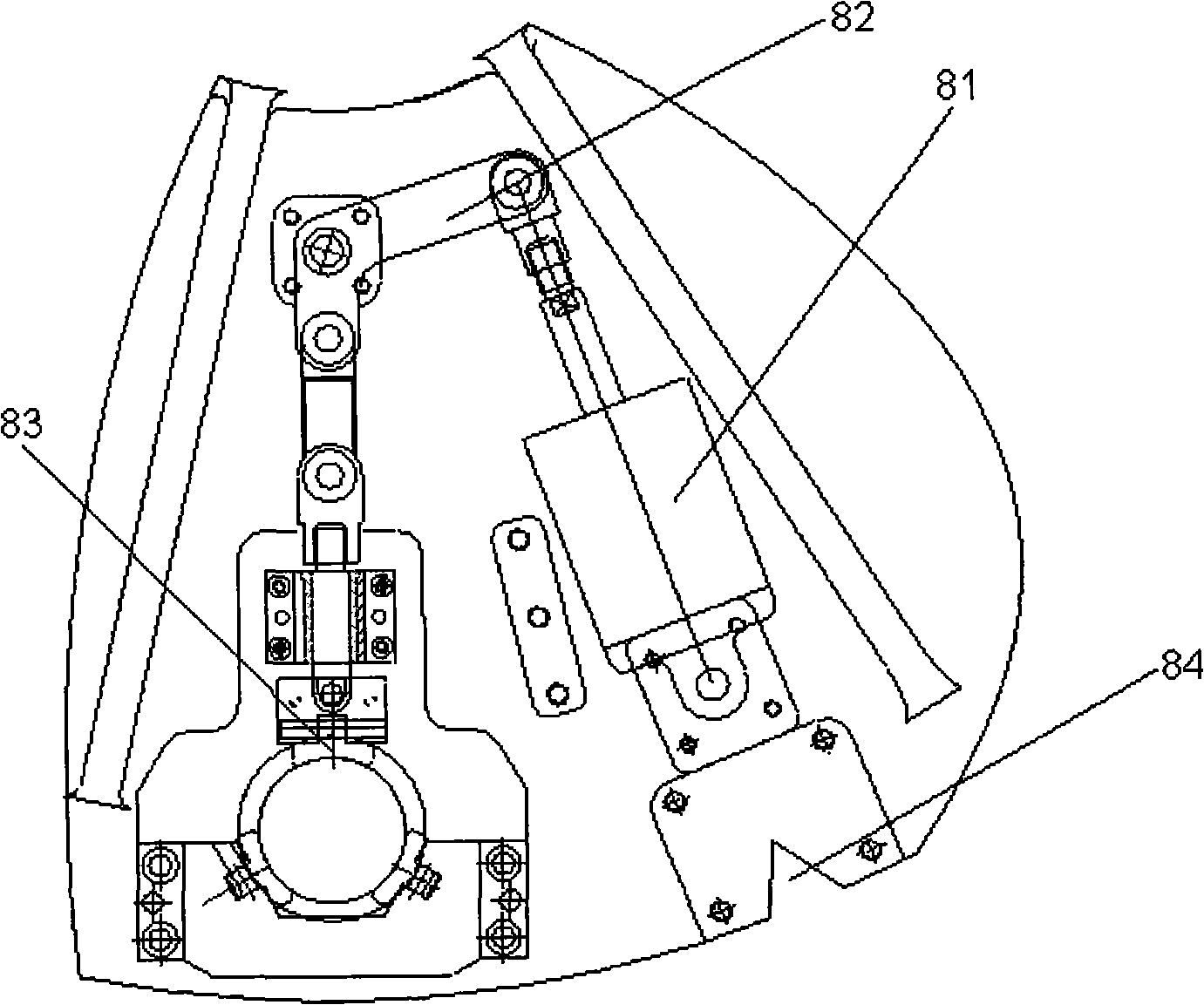

Automatically tracking device of welded joint machinery

ActiveCN102785009AImplement automatic trackingRealize regulationArc welding apparatusEngineeringMechanical engineering

The invention discloses an automatically tracking device of welded joint machinery. The automatically tracking device comprises a guide wheel mechanism which is provided with a guide wheel capable of rotating freely; an upper and lower adjustment mechanism which is provided with a first linear bearing extending along the vertical direction and an upper elastic body and a lower elastic body which are arranged separately at the upper side and the lower side of the first linear beating; a left and right adjustment mechanism which is provided with a second linear bearing extending along the left and right direction and a left elastic body and a right elastic body which are arranged separately at the left side and the right side of the second linear bearing; a fine adjustment mechanism which is fixedly connected with the guide wheel mechanism and drives the guide wheel to keep close contact with both one side and the top part of a weld groove; and a welding gun fixing mechanism which is matched with the guide wheel mechanism, is correspondingly connected with the first linear bearing or the second linear bearing, and is fixedly provided with a welding gun at the end part. The left and right adjustment mechanism is connected with the upper and lower adjustment mechanism, and the guide wheel mechanism is connected with the first linear bearing or the second linear bearing. The automatically tracking device can automatically adapt to shift of the left and right, the upper and lower positions of a welded joint, so as to automatically track the welded joint.

Owner:XIAMEN AEROSPACE SIERT ROBOT SYST CO LTD

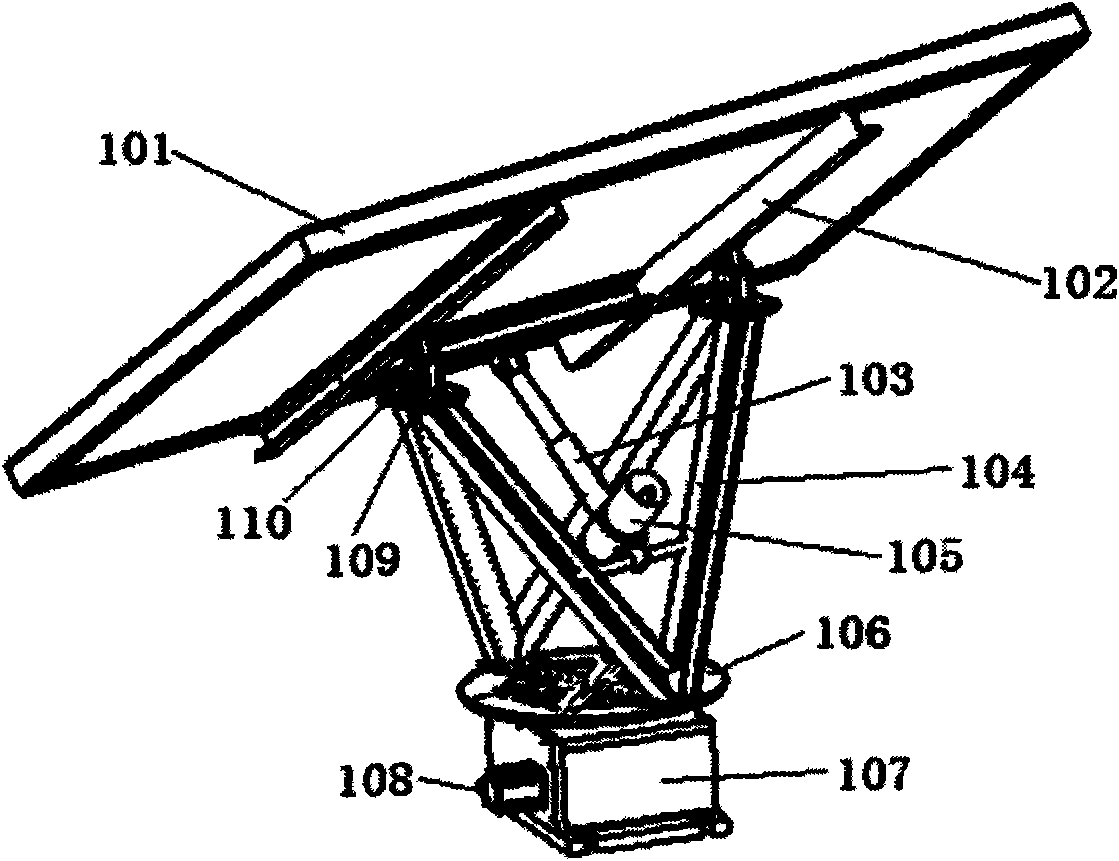

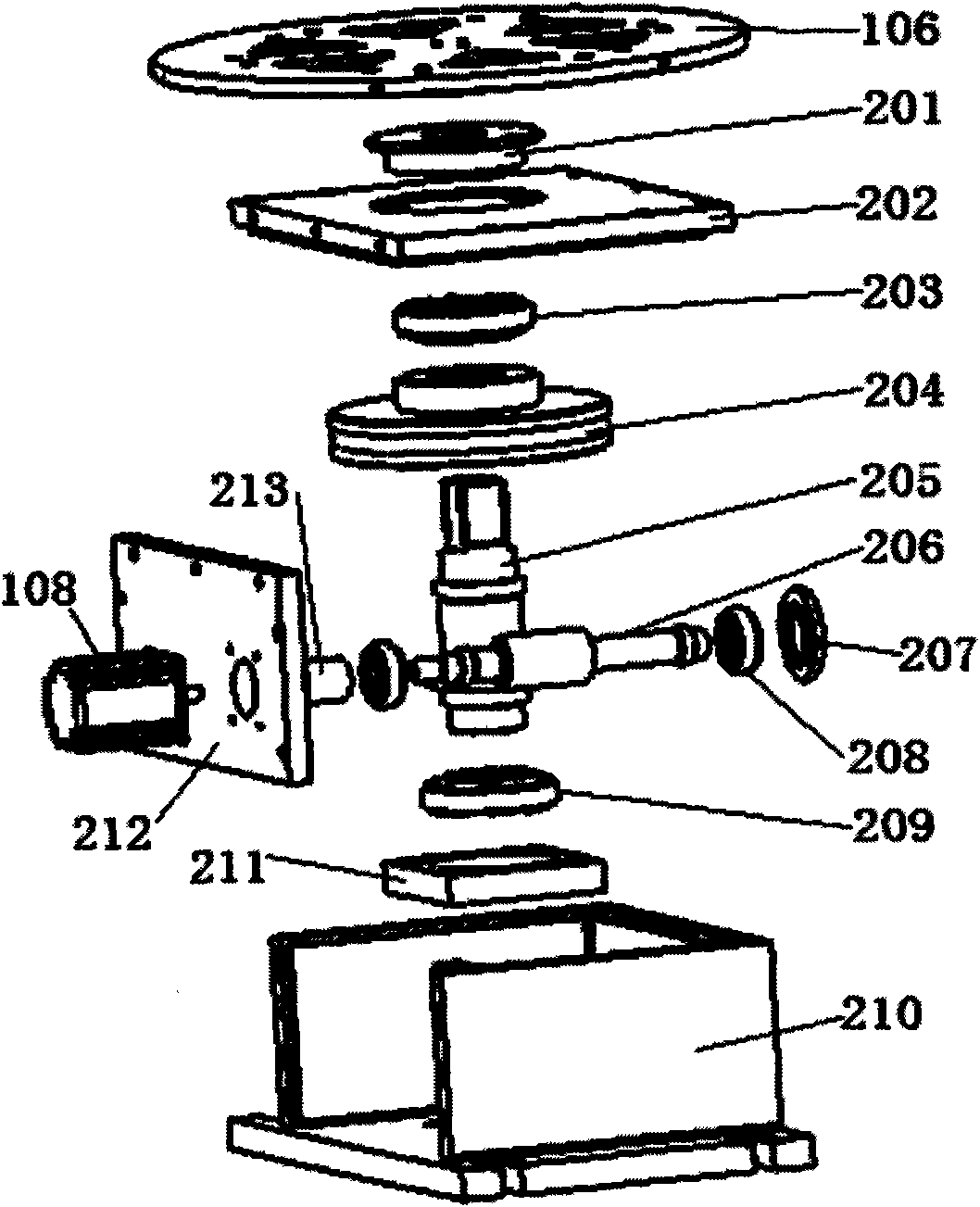

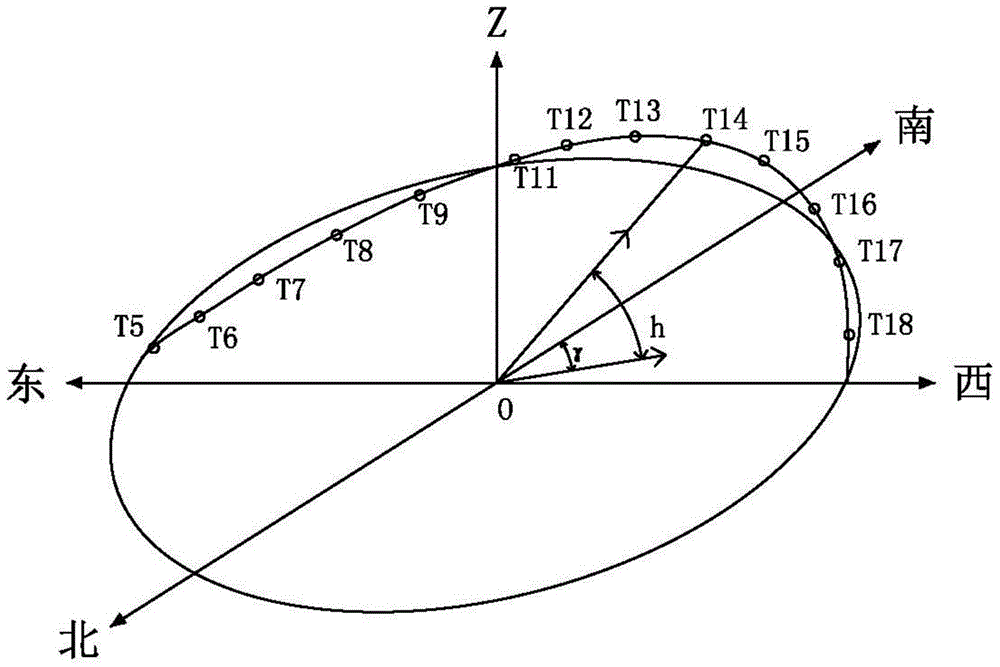

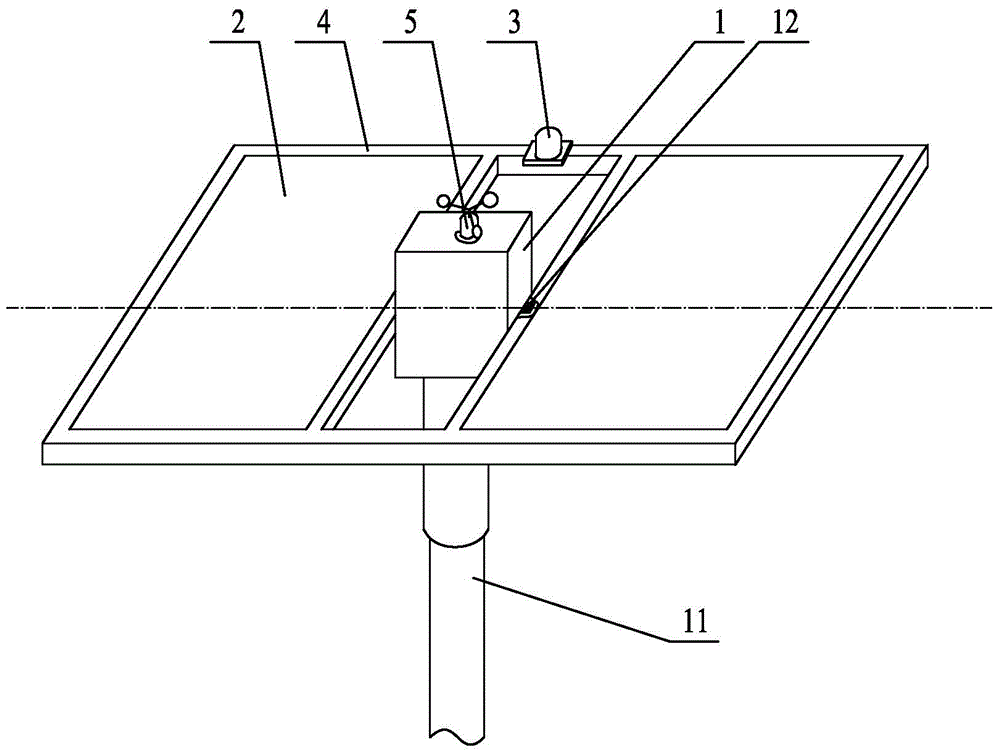

Active sun tracker

InactiveCN101881973ASimple structurePrevent lost locationPhotovoltaic supportsPhotovoltaic energy generationProgrammable logic controllerEngineering

The invention discloses an active sun tracker, which comprises a base, a central controller, a servo driver, a mechanical rotary unit of azimuth angles, a mechanical rotary unit of altitude angles, a solar battery module and an external sensor module, wherein the central controller comprises a PLC (Programmable Logic Controller), the PLC converts the computed change of the azimuth angle and the altitude angle of the sun into output pulses, and the output pulses are respectively sent to a rotary stepping motor driver of azimuth angles and an encoder and a counter of a brushless DC motor of altitude angles; and the servo driver comprises the stepping motor driver, the encoder and the counter, wherein the encoder and the counter are used for controlling the brushless DC motor to close the position loop. The sun tracker of the invention can realize the purpose of tracking sunrays in real time with high precision and low energy consumption under various climatic and optical environments.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

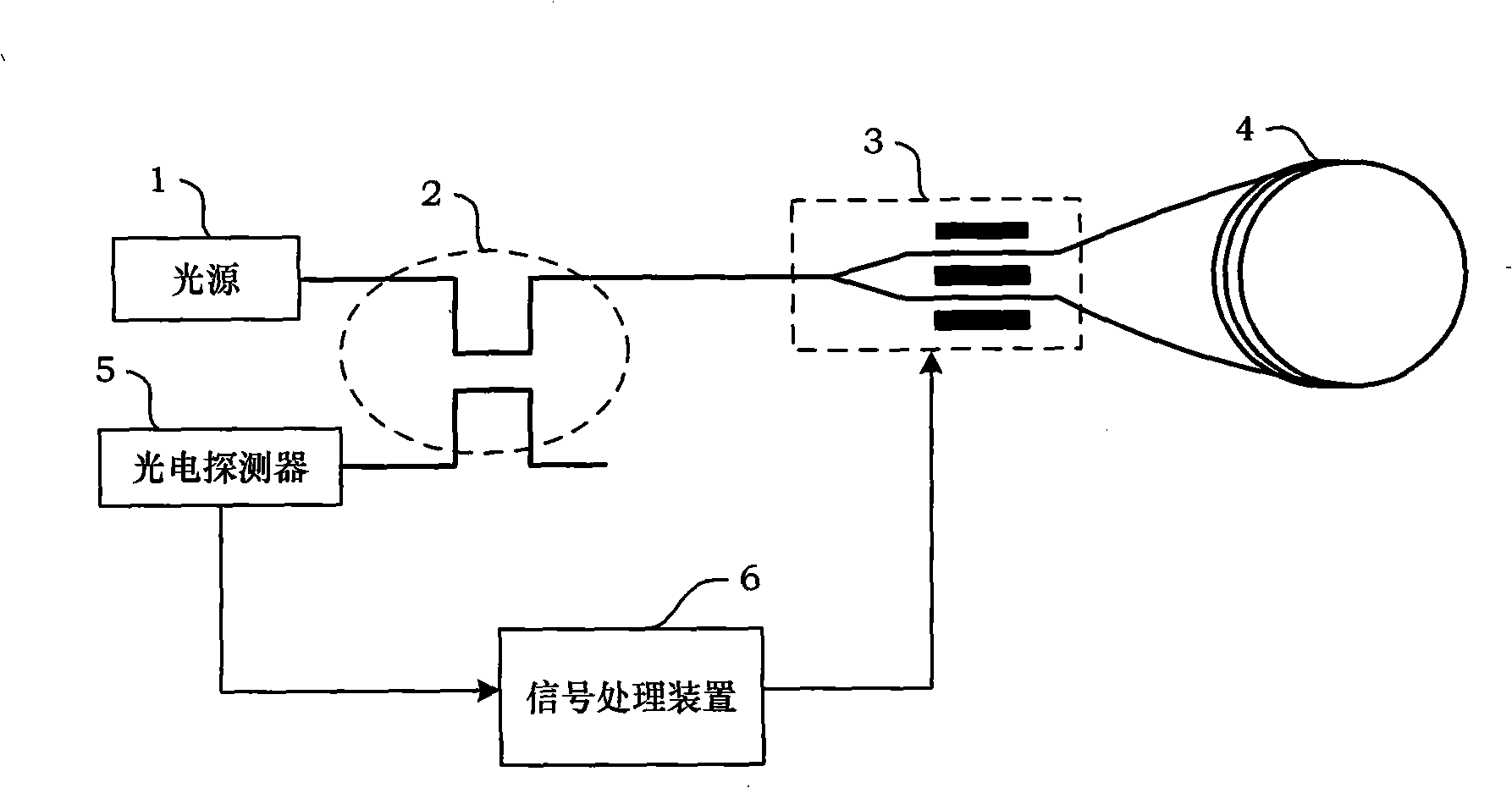

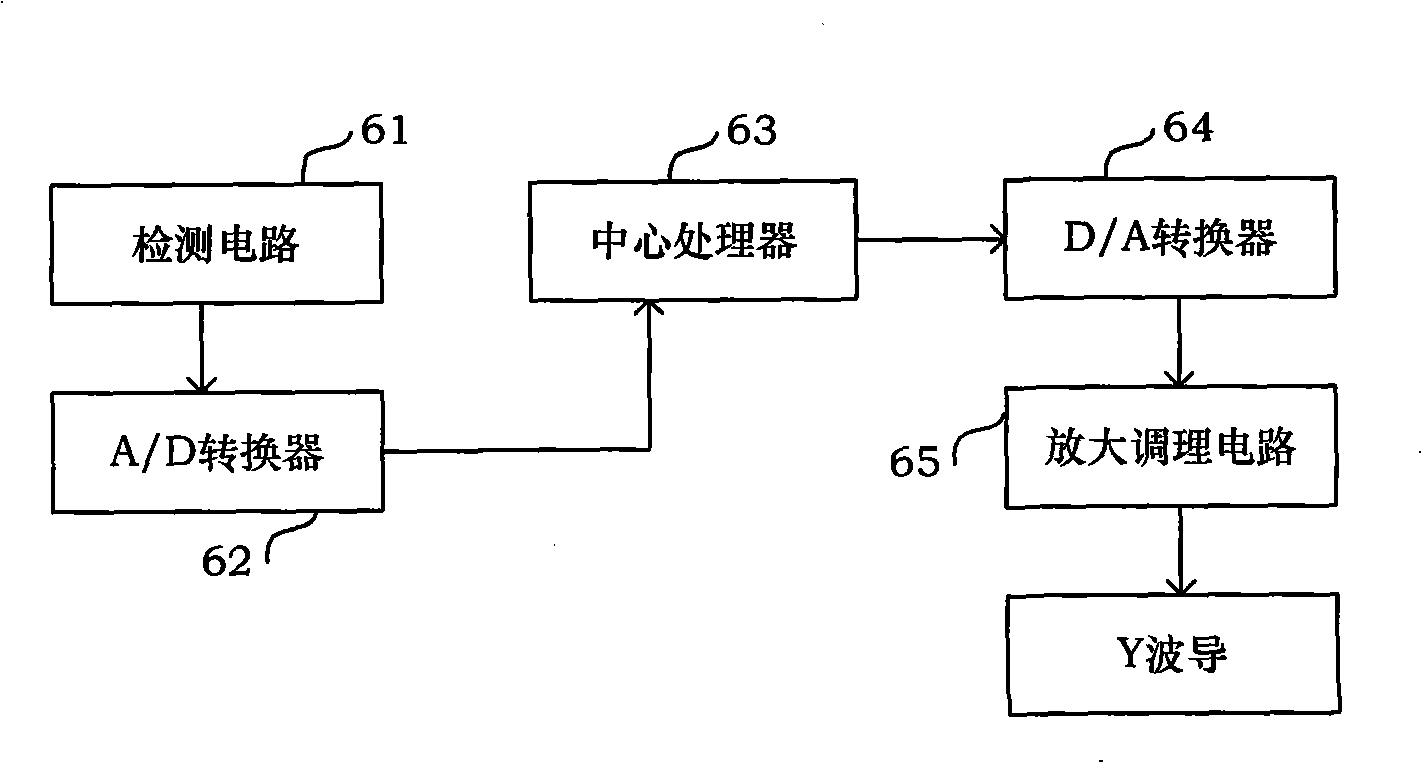

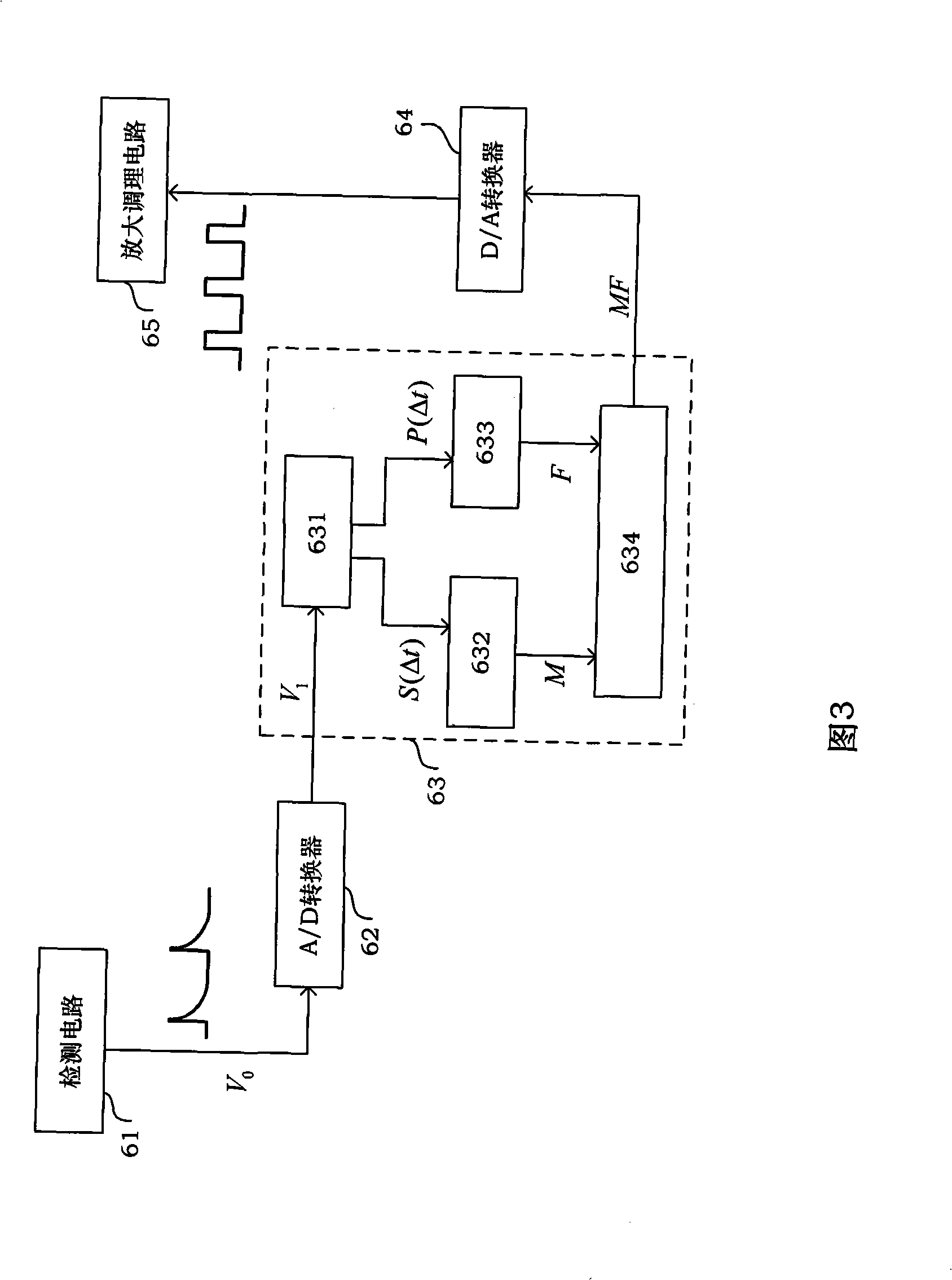

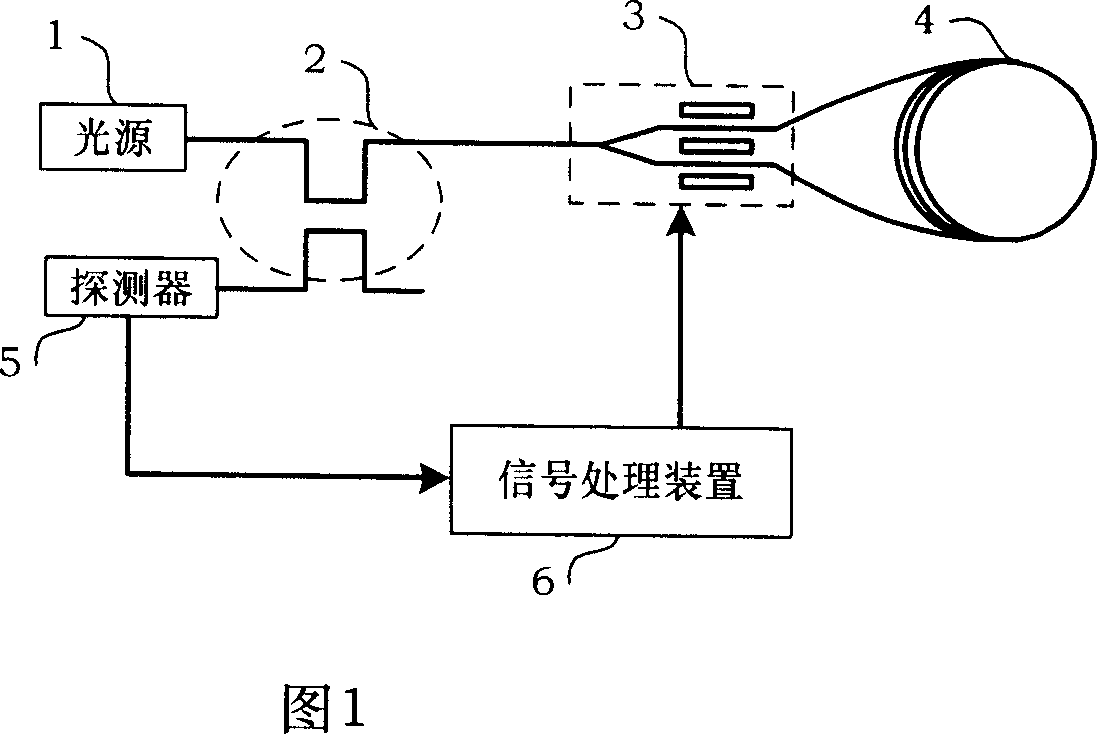

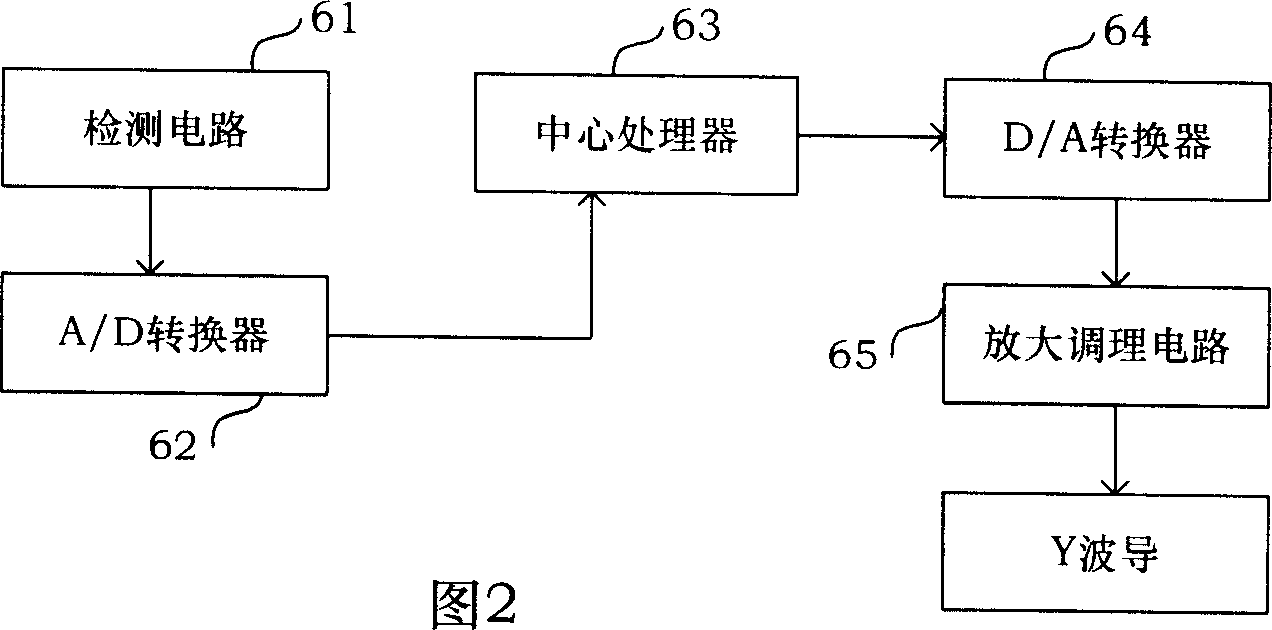

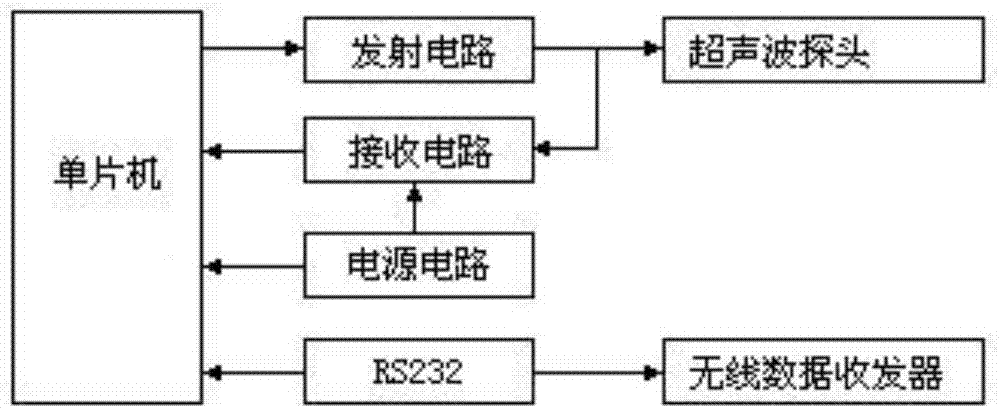

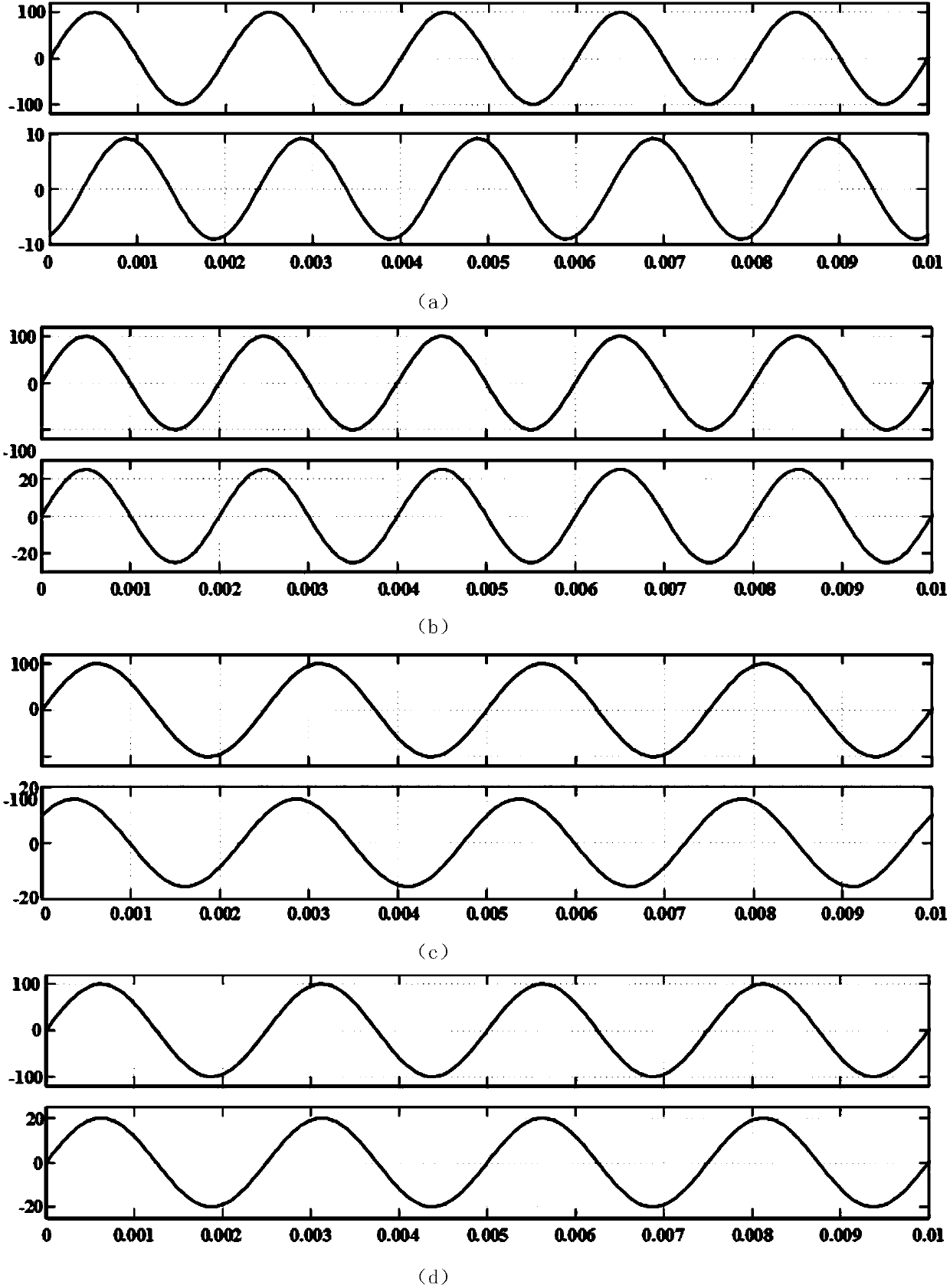

System for measuring interfere type optic fiber gyroscope eigenfrequency and half-wave voltage adopting square wave modulation

InactiveCN101270991AImplement automatic trackingAccurate measurementResonant frequencySagnac effect gyrometersFiberEigen frequency

The invention discloses a system adopting square wave to modulate and measure eigen frequency and half-wave voltage of an interferometric fiber-optic gyroscope, wherein a central processor (63) is composed of a demodulation unit (631), a frequency modulation unit (632), an amplitude modulation unit (633) and a direct digital synthesis unit (634); and the demodulation unit (631) is used to (A) extract a demodulation value P(Delta t<+>) of an effective modulation positive half-period Delta t<+>> from received optical power information V1 during a modulation period Delta T, (B) extract a demodulation value P(Delta t<->) of an effective modulation positive half-period Delta t<-> from received optical power information V1 during a modulation period Delta T, (C) average over the demodulation value P(Delta t<+>) of the positive half-period and the demodulation value P(Delta t<->) of the negative half-period to get demodulation average value P(Delta t), and transmit the demodulation average value P(Delta t) to the amplitude modulation unit (633), (D) extract an optical power average value S (Delta t) from received optical power information V1 during a modulation period Delta T and transmit the optical power average value S (Delta t) to the frequency modulation unit (632). The satisfying condition of the modulation frequency fd is 2fe / 5<Fd<8fe / 5, and the satisfying condition of the initial amplitude A0 is Pi / 8<A0< Pi / 2, and the wide range is enough for application in construction.

Owner:BEIHANG UNIV

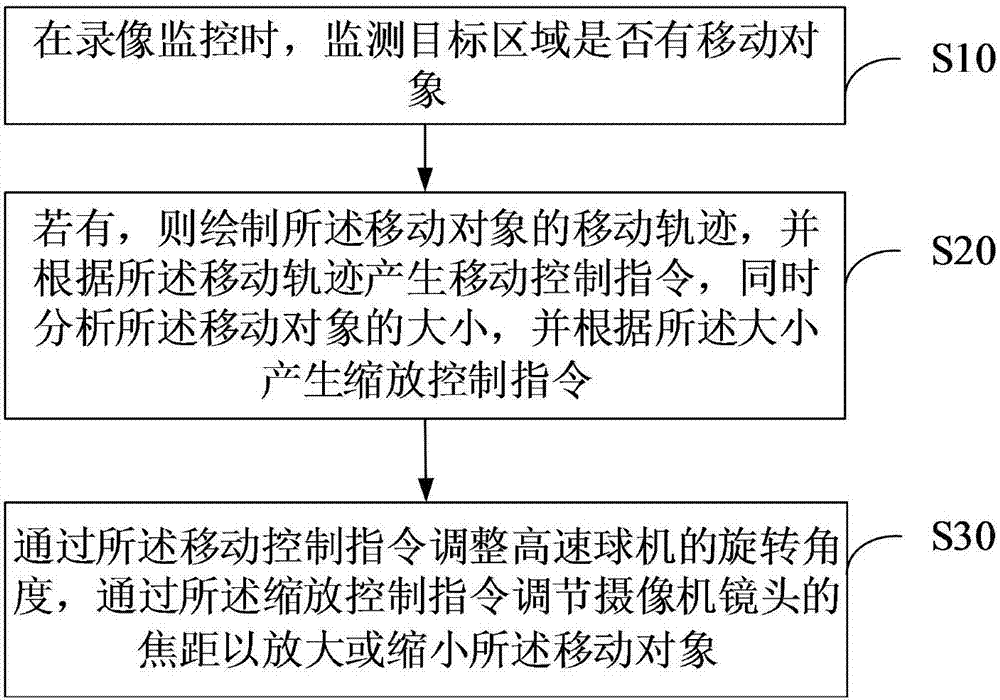

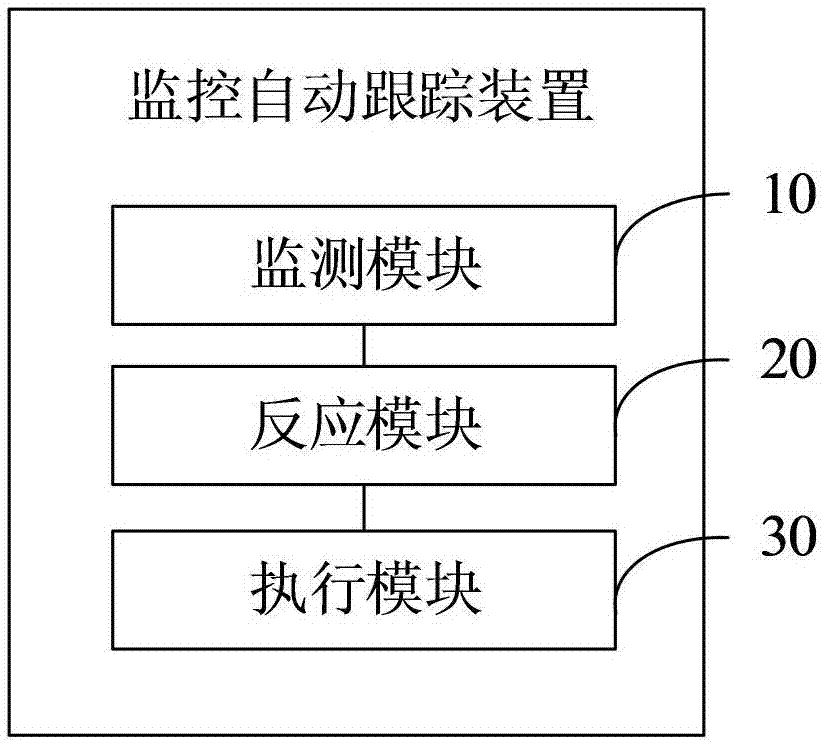

Surveillance automatic tracking method and device

InactiveCN107135377AImplement automatic trackingClear picture informationTelevision system detailsColor television detailsCamera lensMovement control

The invention provides a surveillance automatic tracking method and device. The method comprises the following steps: monitoring whether a moving object is existent in a monitoring target region when performing the video surveillance; if the moving object is existent in the monitoring target region, drawing the movement trajectory of the moving object, producing a movement control instruction according to the movement trajectory, analyzing the size of the moving object, and producing a zoom control instruction according to the size; adjusting a rotation angle of a speed dome through the movement control instruction, and regulating the focal length of a camera lens according to the zoom control instruction so as to zoom in or zoom out the moving object. By use of the automatic tracking method provided by the invention, the automatic tracking on the target object can be realized, and the picture information of the moving object can be acquired more clearly when the shot moving object is focused through the automatic focusing of the equipment.

Owner:SUNELL TECH CORP

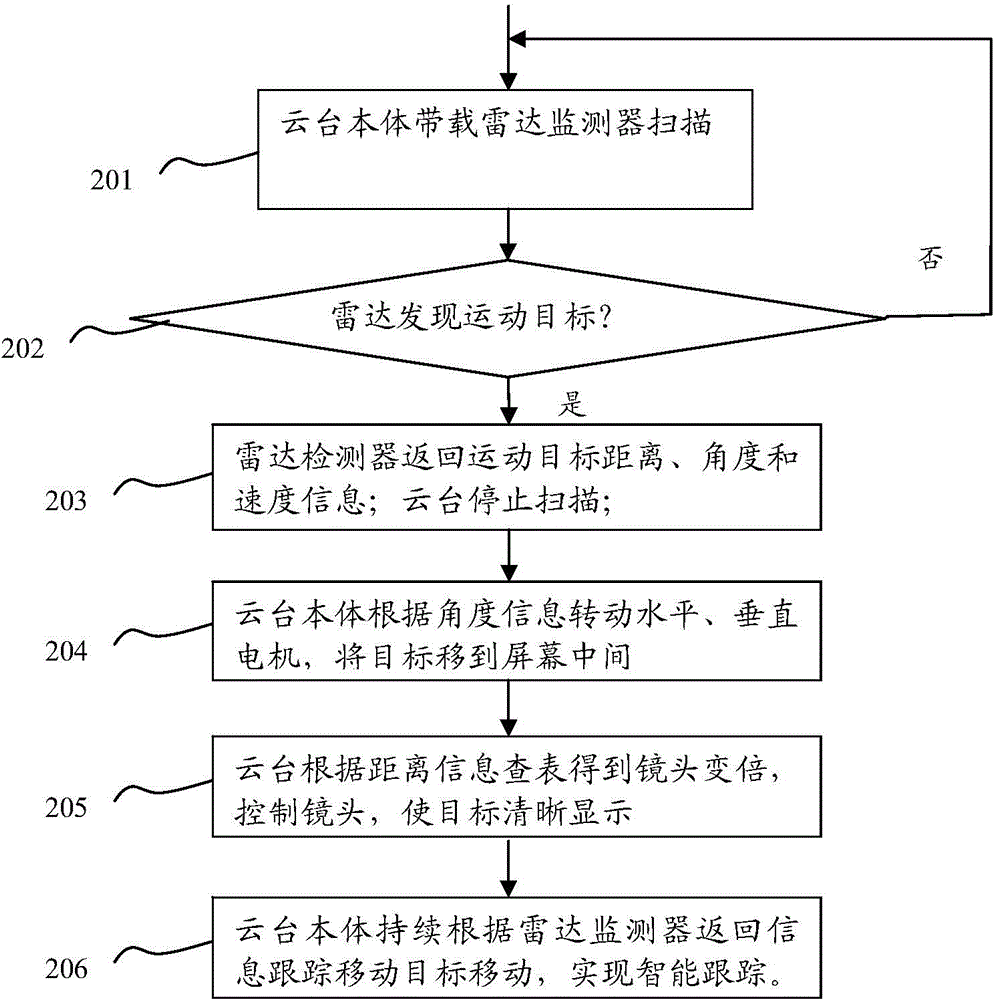

Intelligent tracking cradle head having radar monitoring function and monitoring method

InactiveCN104135644ARealize intelligent monitoringRealize functionClosed circuit television systemsControl using feedbackIntelligent lightingActive monitoring

The invention provides an intelligent tracking cradle head having a radar monitoring function. The intelligent tracking cradle head comprises a cradle head body and a radar monitor, wherein the radar monitor is arranged on the cradle head body; the cradle head body is used for supplying a working power supply to the radar monitor through a power line; and the cradle head body is communicated with the radar monitor through a communication line. A monitoring method is further provided. Compared with the prior art, the intelligent tracking cradle head having the radar monitoring function and the monitoring method have the advantages that I, by using the active monitoring function of the radar monitor, intelligent monitoring and automatic tracking functions of the cradle head can be rapidly realized; II, the radar monitor is carried by using the cradle head, so that all-dimensional coverage of a monitoring region can be realized; III, by using the active monitoring effect of the radar monitor, monitoring dead corners and monitoring dead zones of a visible light camera can be effectively avoided, and meanwhile the application effect of the cradle head under severe weathers or in special environments is ensured; and IV, The intelligent tracking cradle head is wide in application, and can be widely applied to various monitoring fields.

Owner:TIANJIN YAAN TECH CO LTD

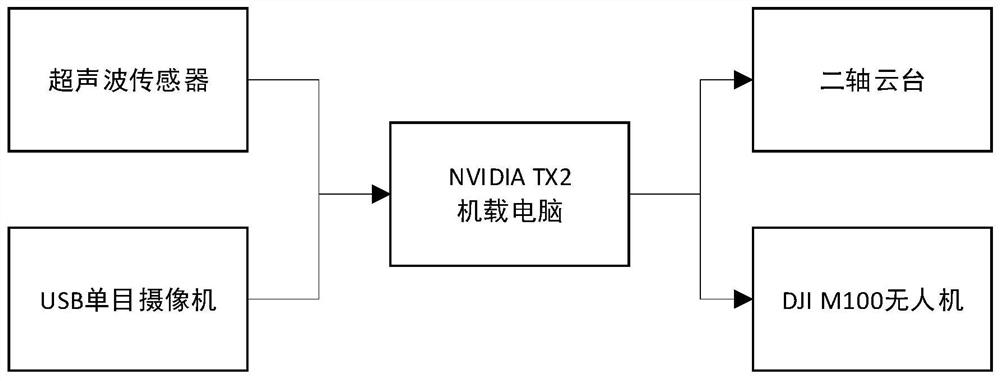

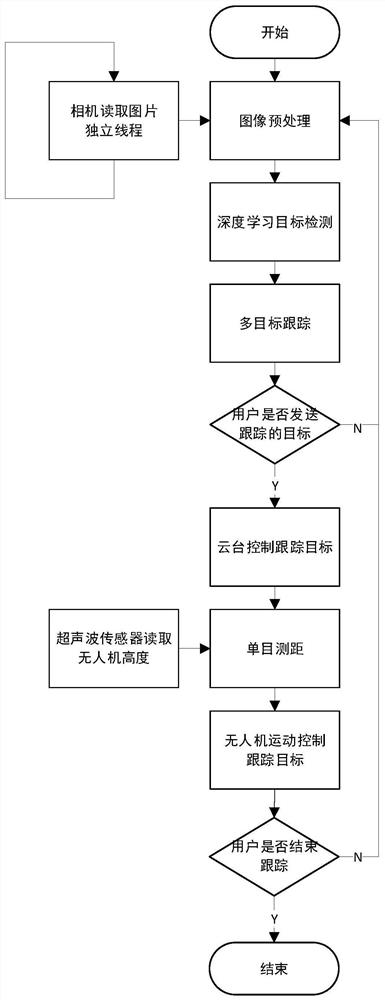

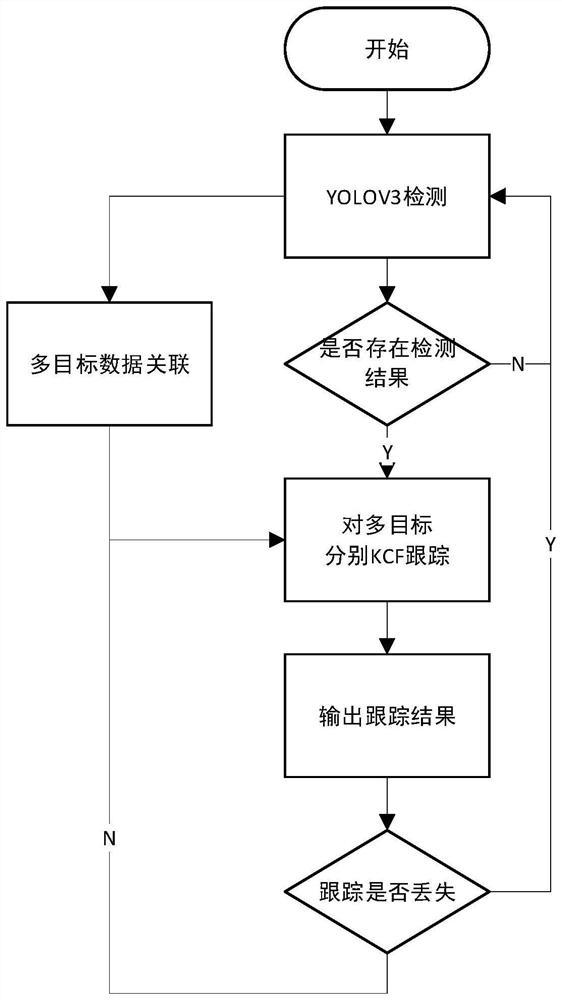

Tracking method of airborne unmanned aerial vehicle multi-target tracking system based on deep learning

PendingCN111932588AImplementation statusAchieving Records for Historical MovementsImage enhancementImage analysisUncrewed vehicleRemote sensing

The invention discloses a tracking method of an airborne unmanned aerial vehicle multi-target tracking system based on deep learning, and belongs to the field of unmanned aerial vehicle target tracking. Real-time image information is obtained through a pan-tilt camera; after basic preprocessing is carried out, multiple targets in the image are detected and tracked through a deep learning algorithm, meanwhile, a data association algorithm is used for carrying out association of adjacent frame motions on the targets, one-to-one matching is completed, and current state estimation and historical motion recording of the multiple targets are achieved; according to the position and speed prediction results of the targets, the holder is adjusted to keep the targets in the center of the image, monocular distance measurement is realized, and tracking flight of the targets is realized in combination with the position and speed of the targets. The method does not depend on a GPS, realizes visual angle maintenance in the tracking process, can rapidly, accurately and stably track multiple targets and perform selective tracking, and can better solve the problems that tracking disappears and thenappears and the like; meanwhile, interaction with a user can be performed through wireless communication, and a tracking state is fed back.

Owner:ZHEJIANG UNIV

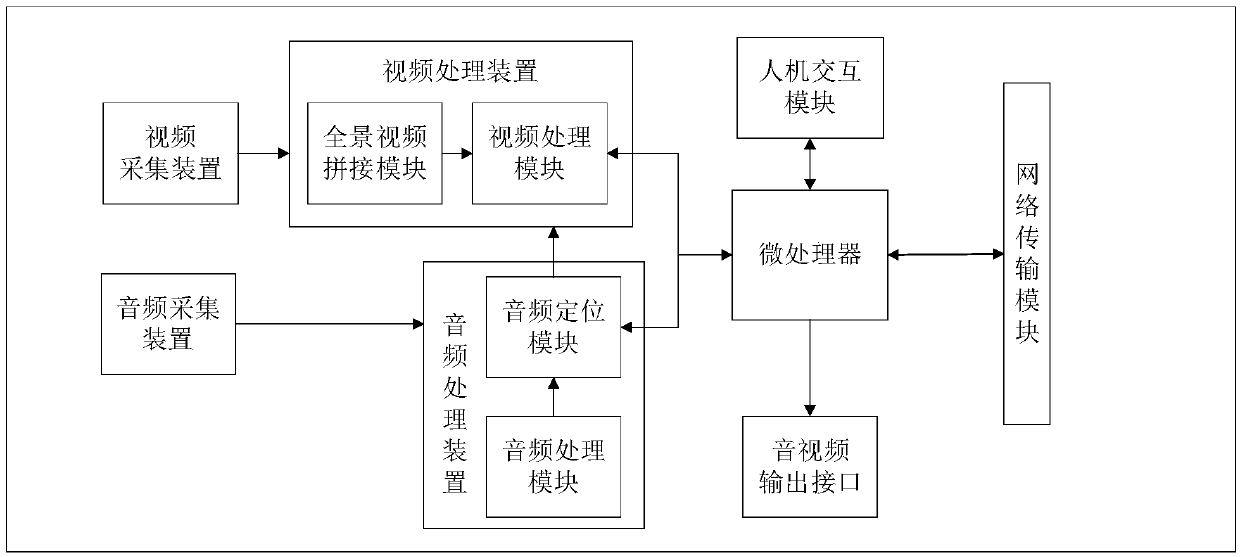

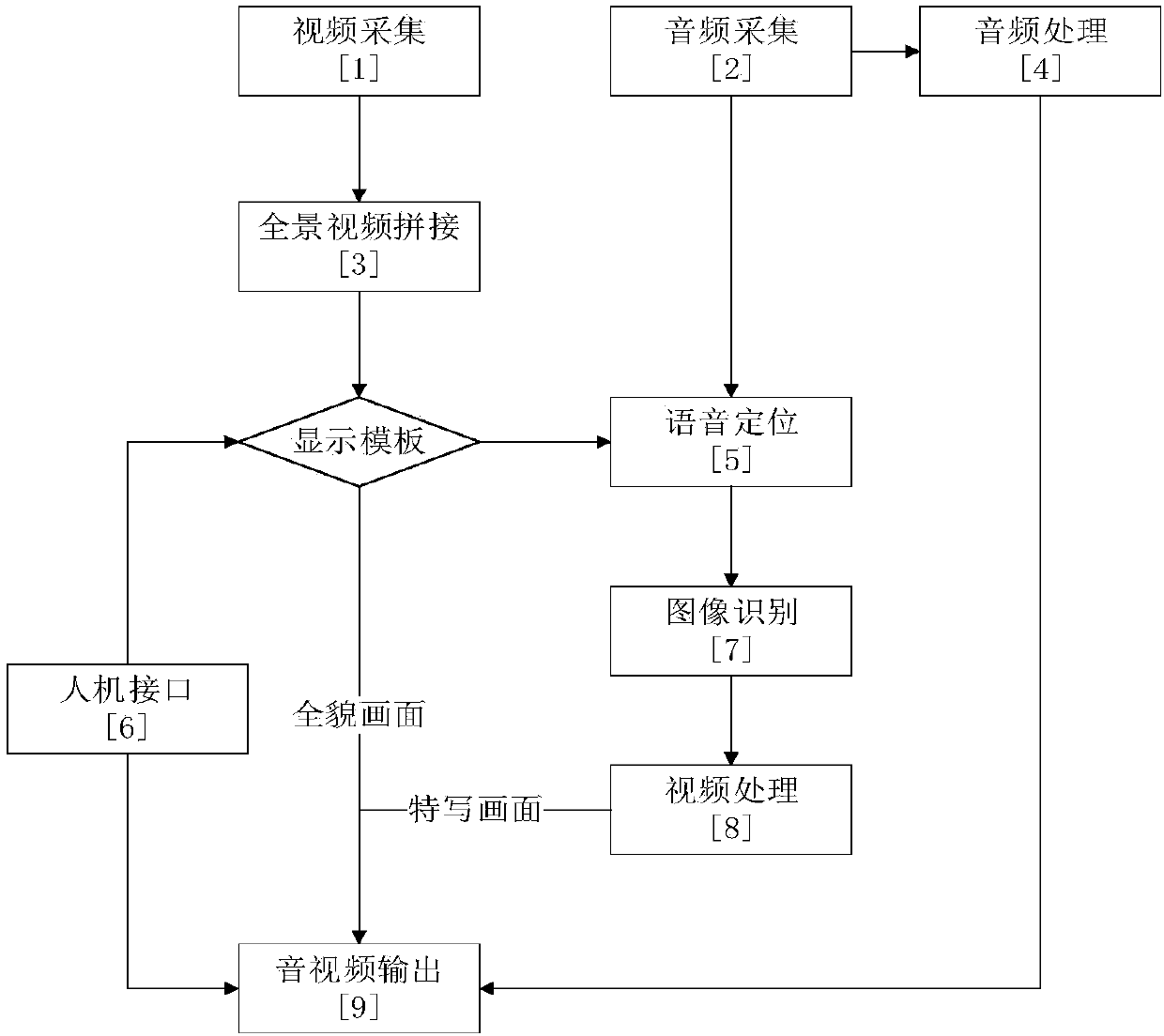

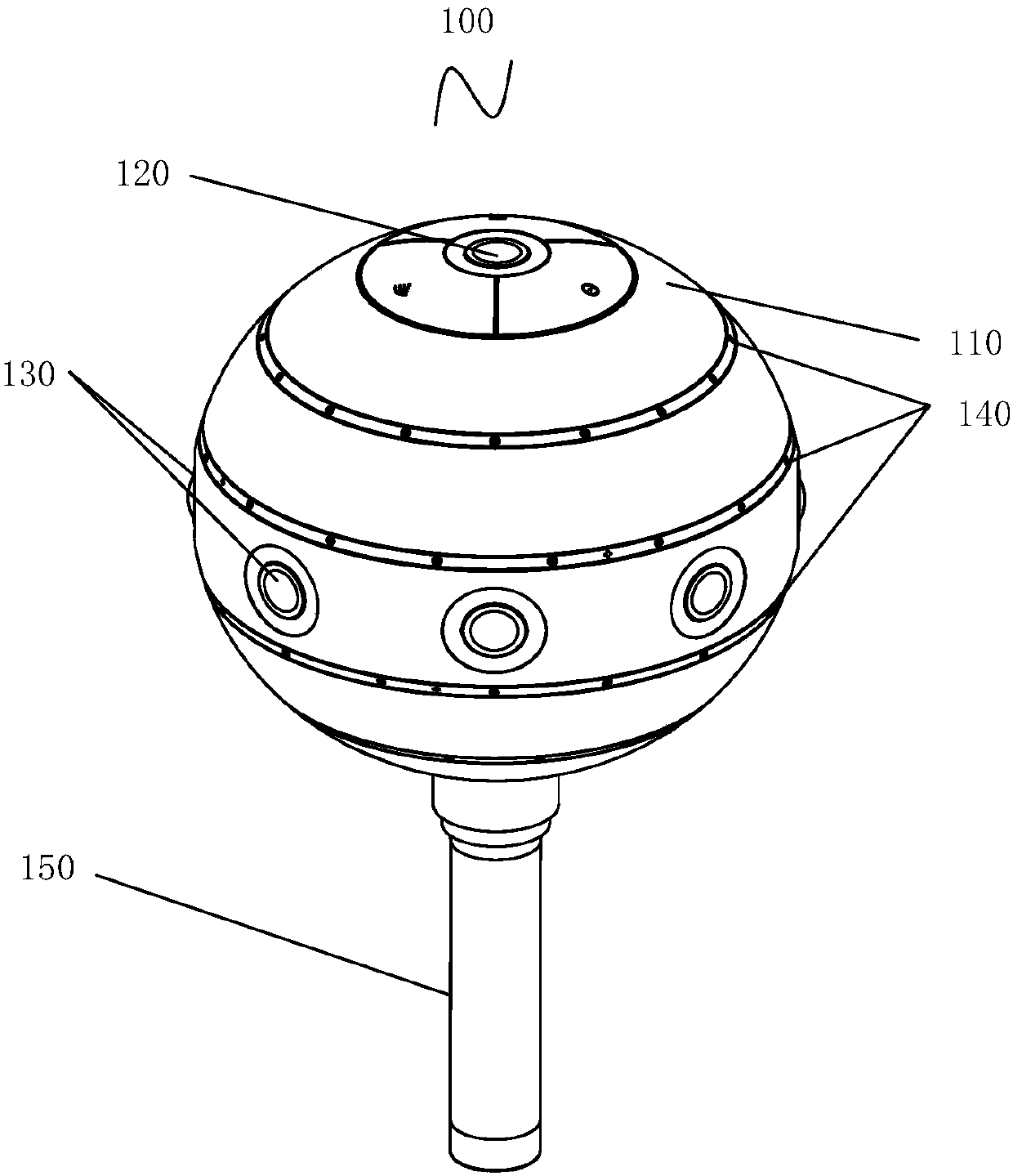

Audio tracking based panoramic video recording device and method

PendingCN107613243AImplement automatic trackingImplement featuresTelevision system detailsTelevision conference systemsVideo processingVideo record

The invention discloses an audio tracking based panoramic video recording device and method. The audio tracking based panoramic video recording device comprises a shell, a video acquisition unit and an audio acquisition unit are arranged on the shell, and a video processing unit, an audio processing unit, a microprocessor, a man-machine interaction module and a network transmission module are arranged in the shell. In the method, close-up tracking of a speaker is realized by adopting panoramic video combined with voice positioning and image recognition. The audio tracking based panoramic videorecording device and method has the advantages that tracking and close-up functions of the speaker in video are realized by adopting the single highly-centralized recording device, a function of seamless switching of close-up and full view of a meeting is achieved, cost can be further lowered, and promotion of recording system is benefited.

Owner:深圳市裂石影音科技有限公司

Laser emitting device and automatic tracking method

ActiveCN103345269ASolve the horizontal emission problemImplement automatic trackingUsing optical meansControl using feedbackLaser transmitterCommunication unit

The invention discloses a laser emitting device and an automatic tracking method to achieve rapid and accurate automatic tracking on a moving laser receiver target. The laser emitting device comprises a laser installation platform and a bottom frame. The laser installation platform comprises a laser emitter used for emitting modulation laser signals, a laser emitter rotating mechanism used for driving the laser emitter to rotate, a laser emitter rotating control unit used for controlling the rotating speed of the laser emitter and automatically tracking a laser receiver, an automatic leveling mechanism used for leveling the laser emitter, and a communication unit used for receiving rotating speed data of the laser emitter and emitting laser emitting angle data. The bottom frame comprises a three-foot frame supporting the whole laser installation platform and a laser installation platform lifting unit used for ascending and descending of the laser installation platform.

Owner:HUNAN AGRICULTURAL UNIV

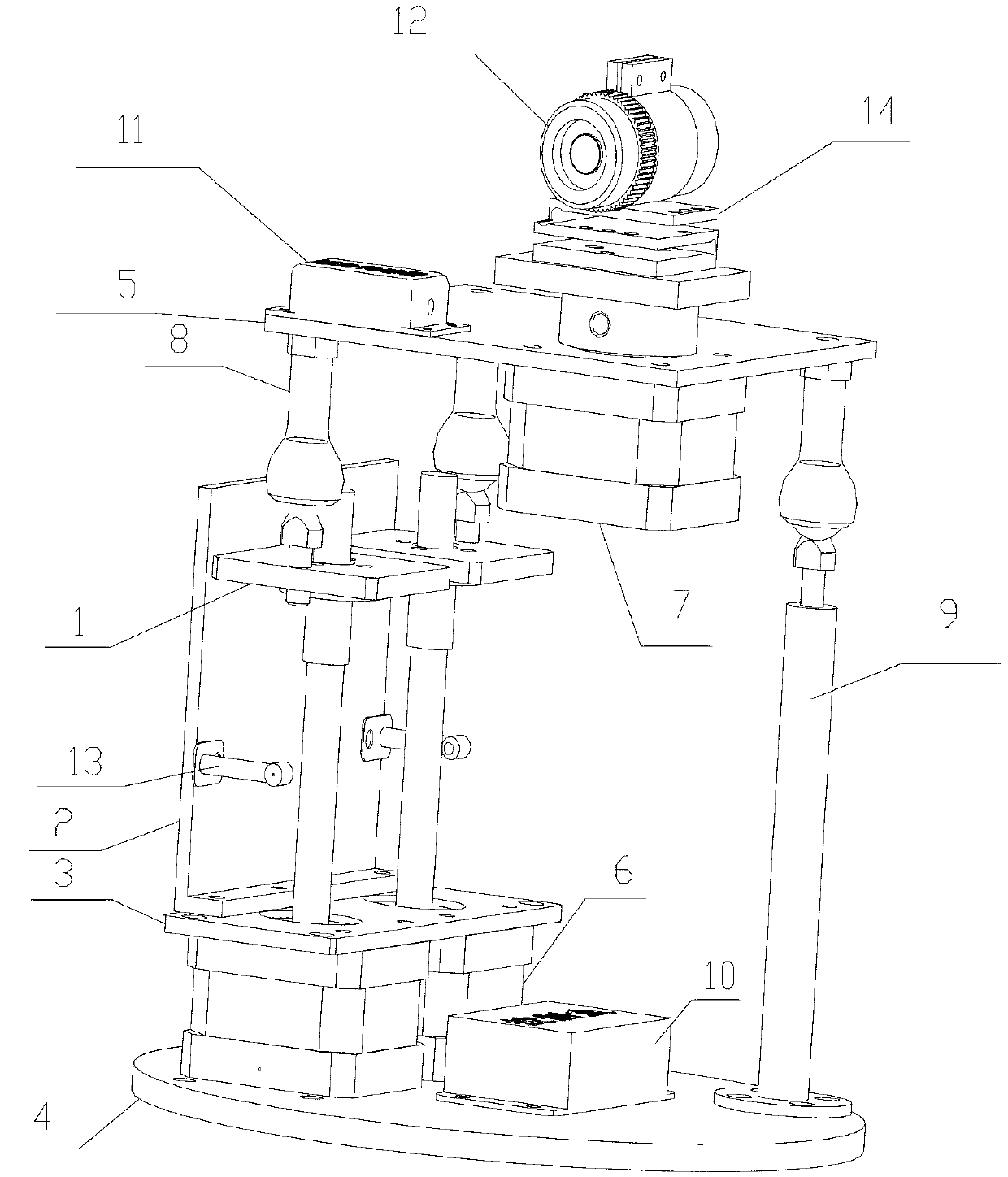

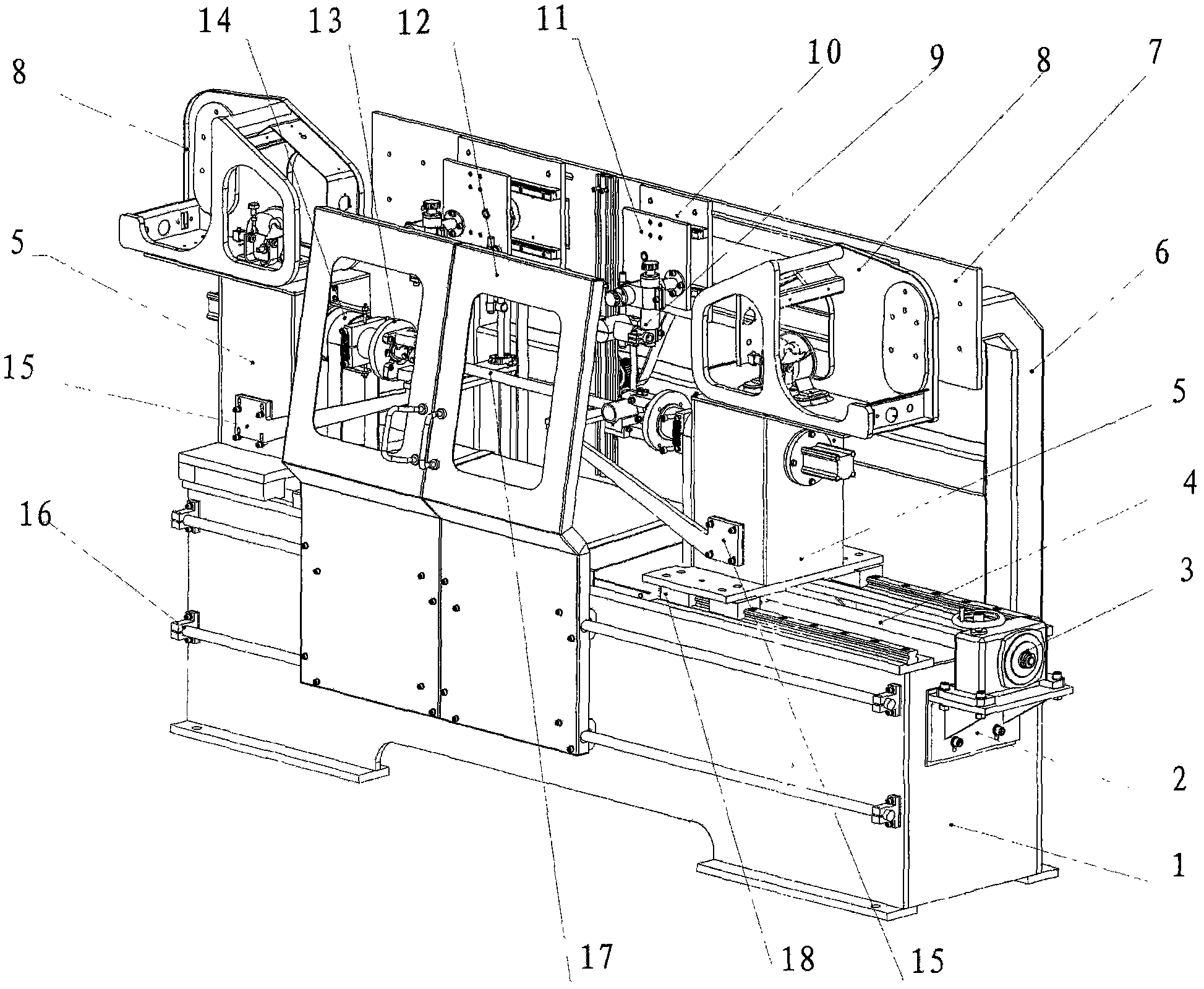

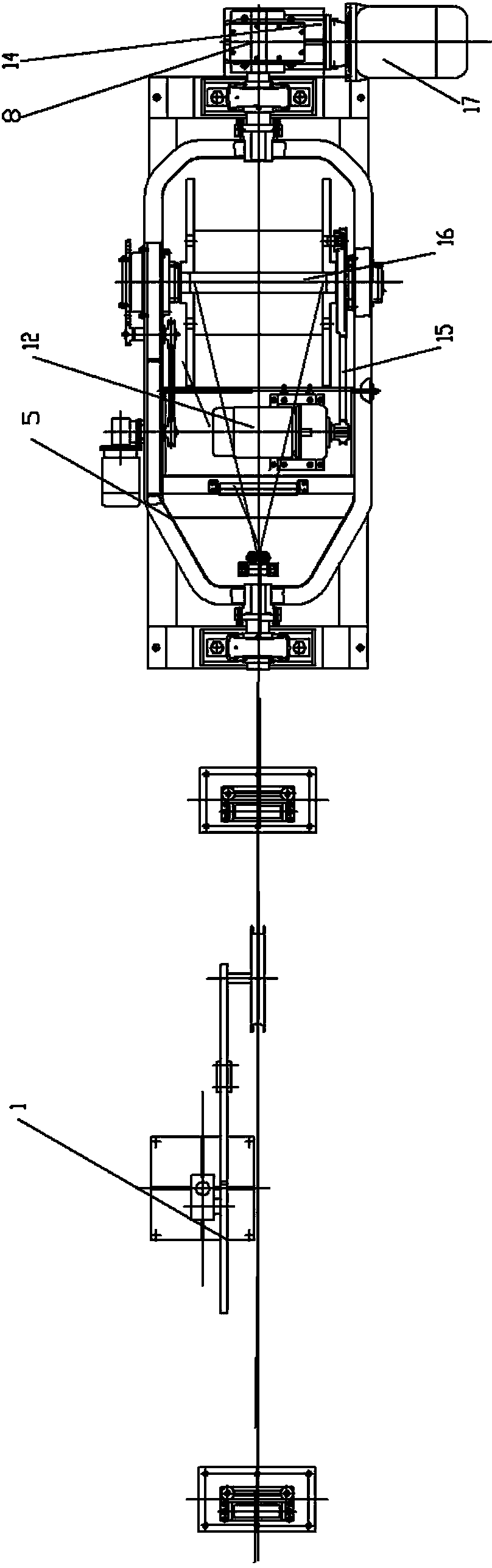

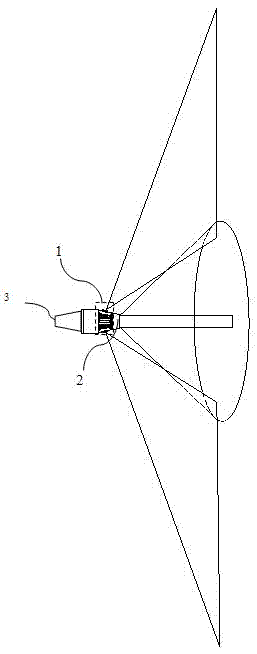

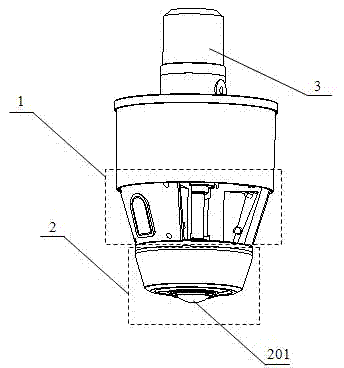

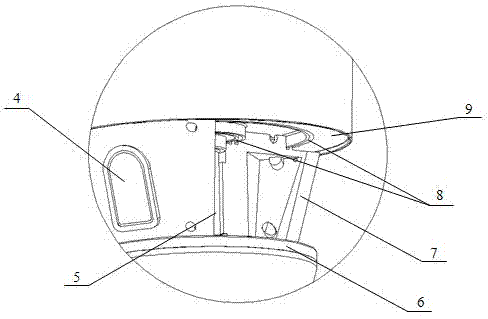

Intersecting line girth welding device

InactiveCN102059434AEliminate pointing processSimple welding processWelding accessoriesEngineeringWeld seam

The invention relates to an intersecting line girth welding device which is a circular tube girth welding device, and in particular relates to an automatic intersecting line girth welding machine between circular tubes, which has very high requirements for the welding line tracking technology, belonging to the technical field of a welding device. The intersecting line girth welding device mainly comprises a base, a tail seat adjusting device, a power driving device, a workpiece clamping device, a workpiece locating device, a cam mechanism, a welding gun adjusting device, an arc light protecting screen and the like. Compared with the prior art, the invention has the prominent substantial characteristics and remarkable progresses that the working procedure of defining a point is omitted, location and automatic welding are directly combined into the same station to be completed, the welding technique is simplified, the efficiency is improved, a spot welding fixture is omitted, and the accuracy of a welding part and the welding line tracking accuracy are guaranteed.

Owner:上海气焊机厂有限公司

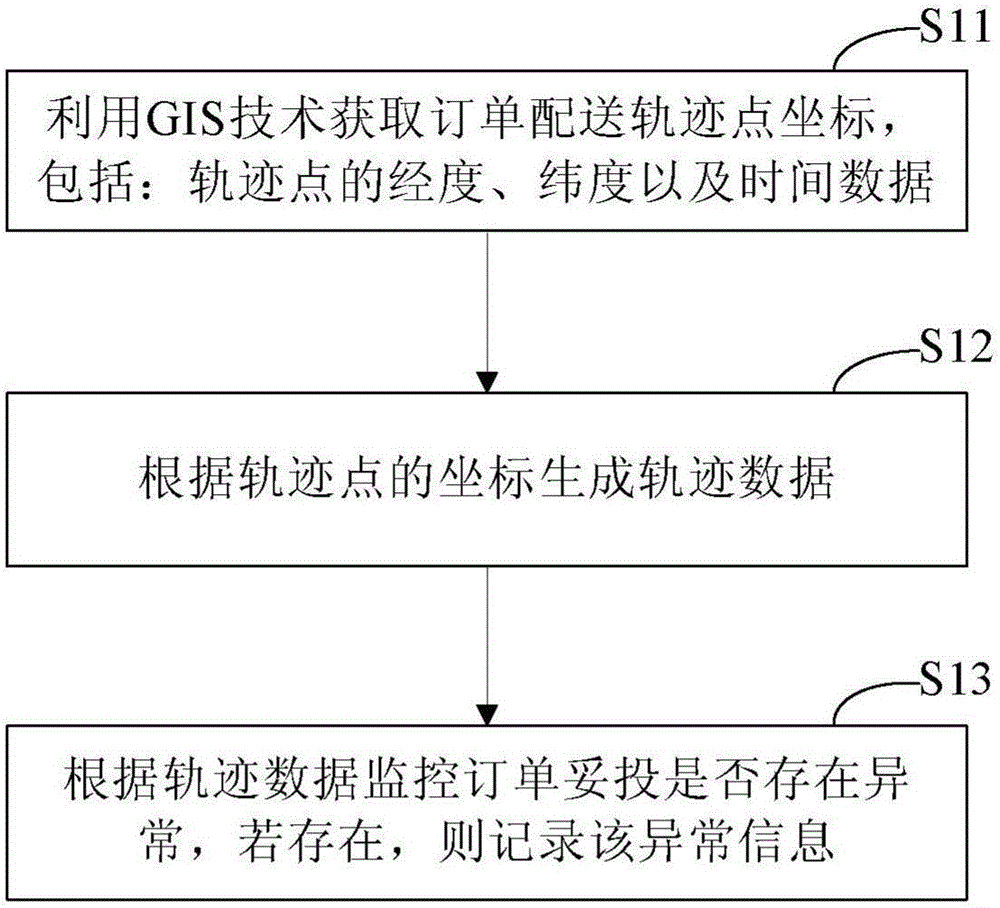

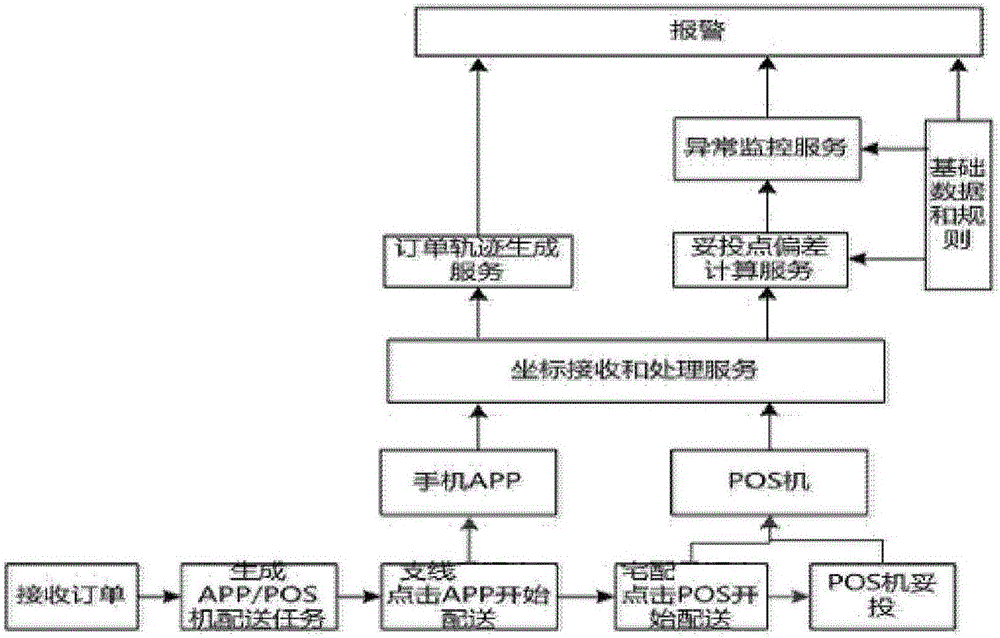

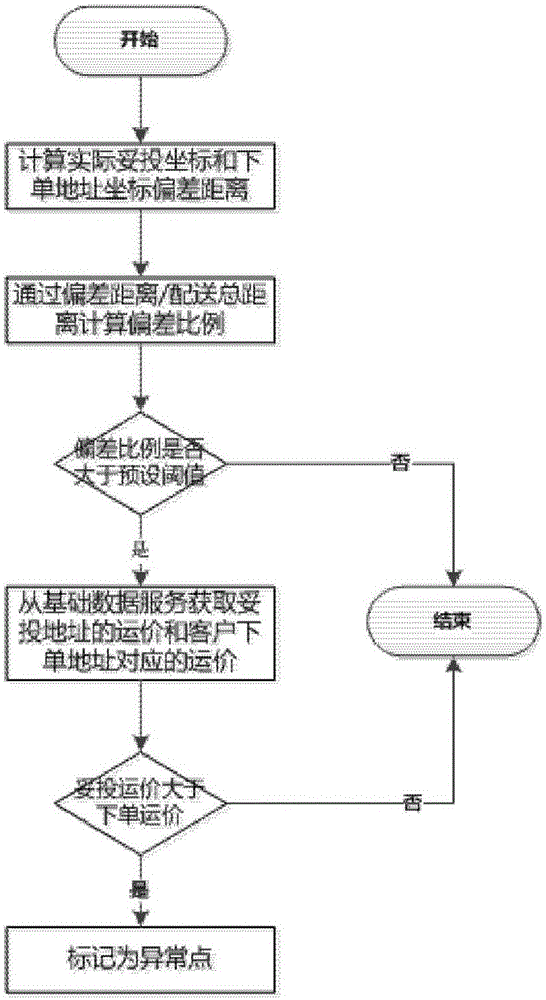

Method, device and system for monitoring order delivery anomaly based on GIS technology

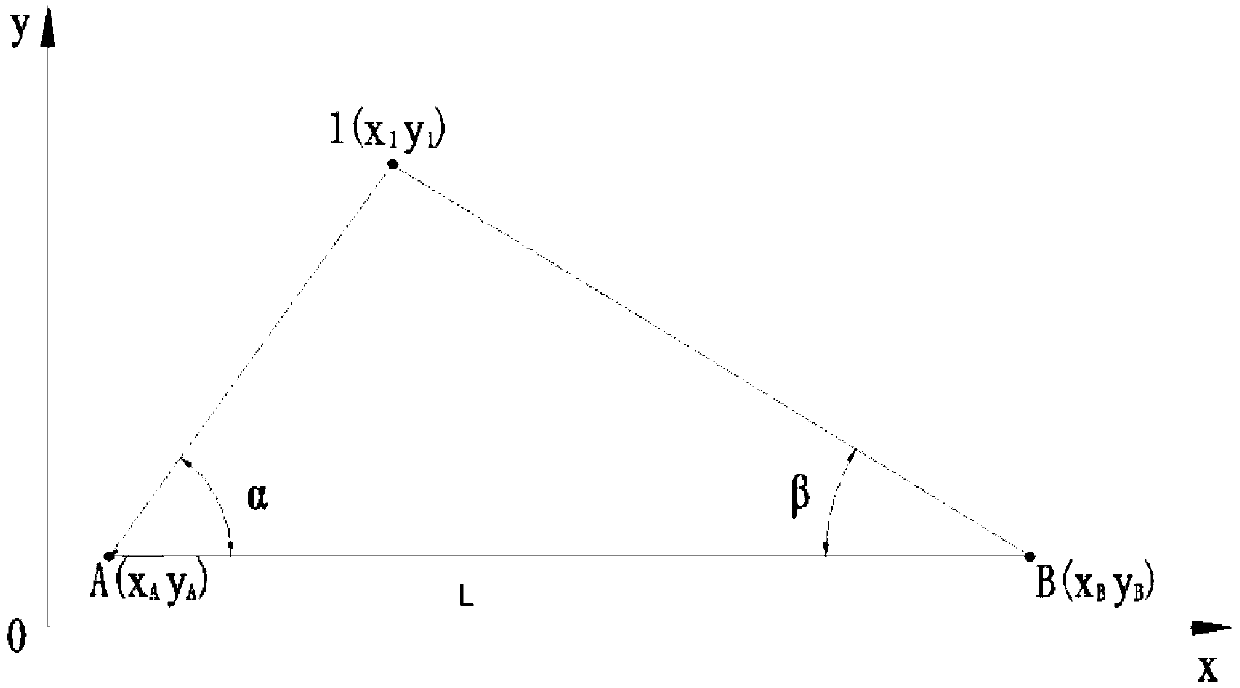

InactiveCN106296065AImplement automatic trackingRealize monitoringGeographical information databasesLogisticsLongitudeOrder form

The invention provides a method, a device and a system for monitoring an order delivery anomaly based on a GIS technology, which can realize whole-process monitoring and tracking on order delivery, and can realize monitoring and alarming on an order delivery anomaly when freight deviation for the order delivery is automatically calculated. The monitoring method comprises steps: the GIS technology is used for acquiring coordinates of an order delivery trace point, wherein the coordinates comprise the latitude and the longitude of the trace point and time data; trace data are generated according to the coordinates of the trace point; according to the trace data, whether an order delivery anomaly happens is monitored, if yes, the anomaly information is recorded, the offset between the coordinates of a delivery point and the coordinates of an order address is calculated, the offset is compared with an offset threshold, if the offset is no larger than the offset threshold, the monitoring is over, if the offset is larger than the offset threshold, whether the freight generated actually is larger than the freight paid for delivery to the order address is judged, if the actually-generated freight is larger than the freight paid for delivery to the order address, the anomaly information is recorded, or otherwise, the monitoring is over.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

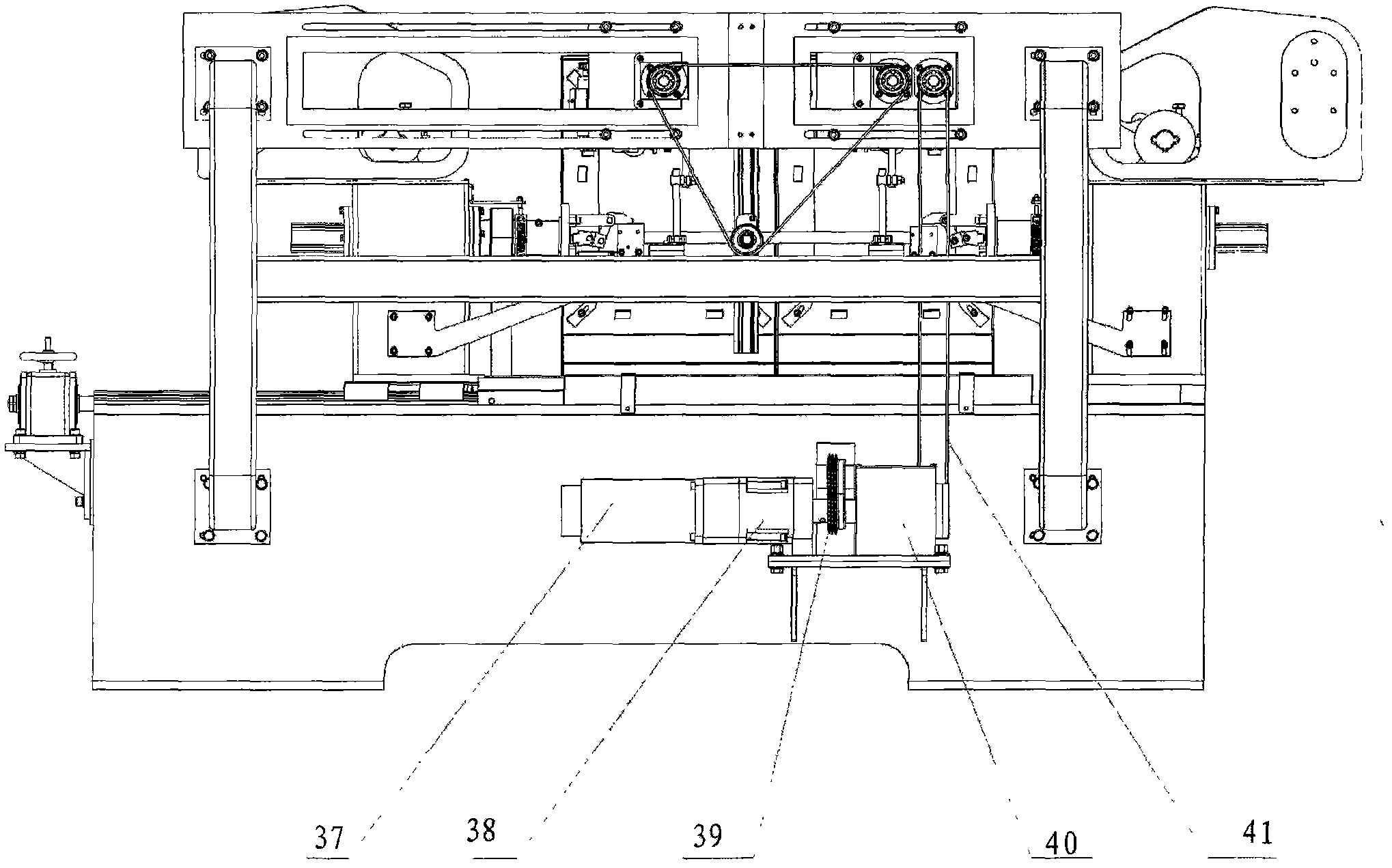

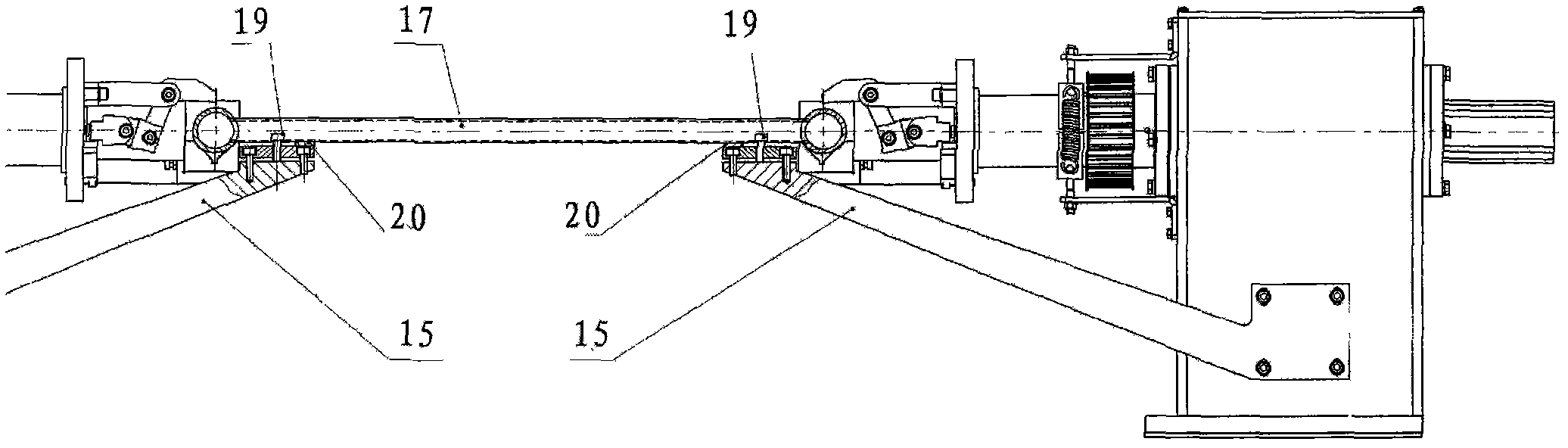

Optical fiber composite cable optical unit cabling pay-off device and cabling method thereof

ActiveCN103935833AMeet the needs of various functionsImprove uniformityFilament handlingEngineeringTransmission performance

The invention discloses an optical fiber composite cable optical unit cabling pay-off device. The optical fiber composite cable optical unit cabling pay-off device comprises a swing arm type tension dancing wheel assembly, a tension adjusting sliding block, a pay-off rack base, a bassinet stand, a pay-off motor, a driving assembly and a bassinet stand rotary driving assembly. The pay-off motor and the driving assembly installed on the bassinet stand drive an optical unit reel to rotate. A pay-off pulley is arranged on the pay-off rack base. After passing through the pay-off pulley, a cable unreeled from the optical unit reel passes through the swing arm type tension dancing wheel assembly. The invention further discloses an optical fiber composite cable optical unit and conductive cable core cabling method. The method comprises the steps of optical unit pay-off preparation, conductor cable core pay-off preparation and the like. The pay-off device has constant tension and the cable can be unreeled automatically, so that tension of an optical unit is kept stable, the optical unit and a conductive cable core are twisted, synchronous back-twist is achieved, and the optical transmission performance and the service life of the optical fiber composite cable are guaranteed.

Owner:江苏通光强能输电线科技有限公司

Prewarning positioning monitoring device of multi-directional monitoring area

InactiveCN102857741AAchieve positioningImplement automatic trackingTelevision system detailsColor television detailsDisplay deviceEngineering

The invention provides a prewarning positioning monitoring device of a multi-directional monitoring area, which can monitor a panorama region with a larger monitoring range under the condition of low illumination level. The prewarning positioning monitoring device comprises a vertical prewarning mechanism, a horizontal prewarning mechanism and a warning part. The monitoring device directly detects trends in a plurality of prewarning video images through acquiring prewarning videos in multiple directions, thereby determining position information of a movement object to be monitored, marking an outline and a movement curve of the movement target in a monitoring area, and carrying out illumination warning and sound warning on the movement target; meanwhile, warning signals are added in the corresponding video images, retransmitted commands control a main control device to generate a warning action, and a plurality of prewarning videos marked with the outlines and the movement curves of the movement target are stored and transmitted to a display device of a video monitoring system. The monitoring device has a function of regulating the multi-direction monitoring area and is remarkably improved in applicability and flexibility.

Owner:TIANJIN YAAN TECH CO LTD

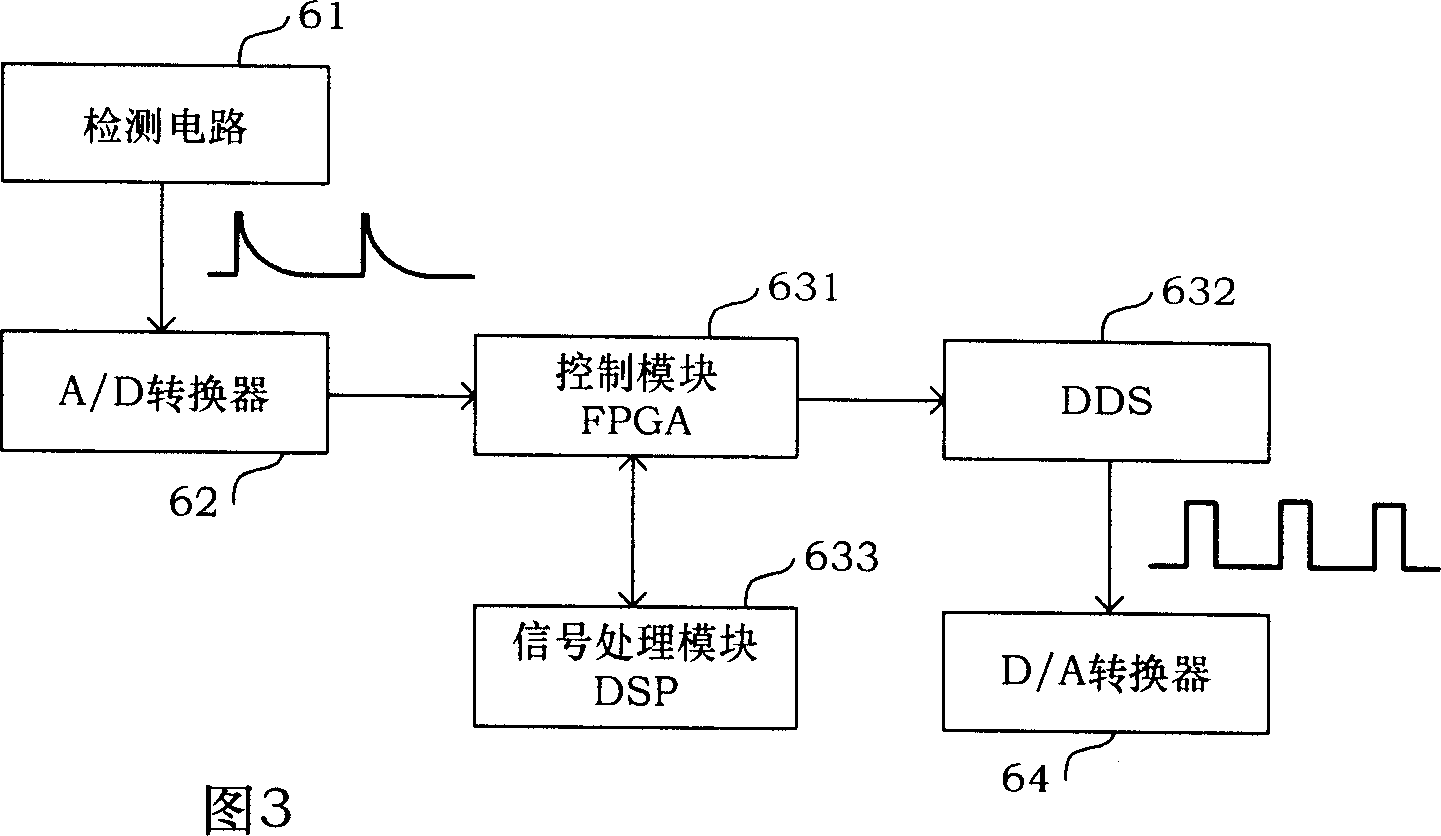

Measurement for eigenfrequency of interferometric type fiber-optic gyroscope by using asymmetrical square wave modulation method

InactiveCN1967146AAccurate measurementImplement automatic trackingResonant frequencySpeed measurement using gyroscopic effectsFiberGyroscope

The invention discloses an asymmetric square wave modulation method to measure interference fiber gyro eigenfrequency. By controlling module FPGA, the method controls DDS to generate different frequency asymmetric square wave to process phase modulation to Y waveguide; and the signal processing module DSP real-time calculates the margin absolute DeltPd of the accumulation in A / D sampling time T, and processes the absolute minimum judgment to the said margin absolute DeltPd, and when the margin absolute DeltPd close to zero, gets the fiber gyro eigenfrequency fe equaling modulation frequency fd. Such measurement method measures the eigenfrequency Fe with high accuracy, and frequency tracking speed adjustment quick, and highly real-time.

Owner:BEIHANG UNIV

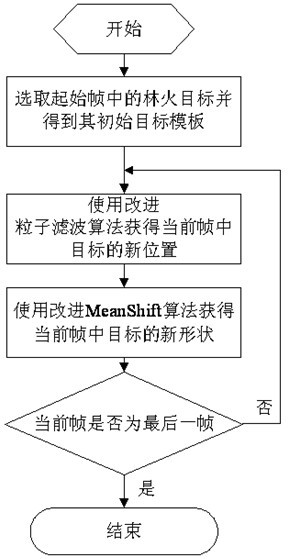

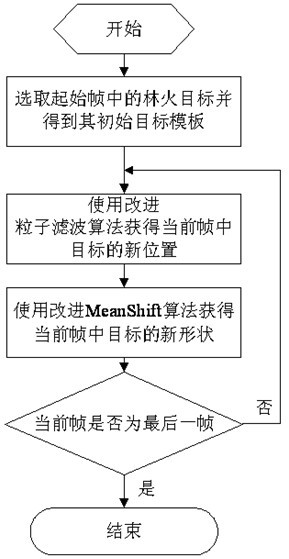

Robust tracking method for moving flame target in forest region monitoring video

ActiveCN102142085AReasonable representationEasy to distinguishImage analysisCharacter and pattern recognitionShape changeWeight adjustment

The invention relates to the fields of forest fire prevention and digital image processing, in particular to a robust tracking method for a moving flame target in a forest region monitoring video. The method comprises the following steps of: representing a tracking target by using a multi-feature fusion model of which the weight is determined together by using coherent elements; handling the problem of discontinuity in a region through target probability based element weight adjustment in the tracking region; acquiring shape change of a forest fire target in a current frame by using a Gaussian mixture model probability based improved Mean Shift window adaptive algorithm; obtaining a new position of the forest fire target in the current frame by using an improved particle filter tracking algorithm based on flame pixel proportion in the region; realizing robust tracking of the forest fire target by using a new tracking algorithm combined with an improved particle filter and an improved Mean Shift; and recognizing combination and division of the flame in the forest region during motion to realize the tracking of a plurality of forest fire targets. Compared with the conventional tracking algorithm aiming at the forest fire target, the method has the advantages of higher tracking accuracy and higher robustness on the premise of guaranteeing real-time property.

Owner:武汉万德智新科技股份有限公司

Single lens image dynamic identification-based camera automatic tracking system and method

The invention discloses a single lens image dynamic identification-based camera automatic tracking system and method, and relates to the technical field of image tracking shooting. The system comprises an image identification module, a target tracking module and a target shooting module, wherein the image identification module is used for identifying a human body motion; the image identification module comprises a tracking camera; the target tracking module is used for tracking a motion of a target; the target tracking module comprises a pan-tilt-zoom control mainboard; the pan-tilt-zoom control mainboard is electrically connected with a camera mainboard of the image identification module through a pan-tilt-zoom control line; the target shooting module comprises a recording and broadcasting host; and the recording and broadcasting host is connected to the camera mainboard. The system and the method have the beneficial effects that analysis is performed according to an obtained image; the coordinate position of the target is located according to an image calculation result; and single lens automatic tracking of the moving target is realized through controlling the pan-tilt-zoom control mainboard.

Owner:深圳正谱教育技术有限公司

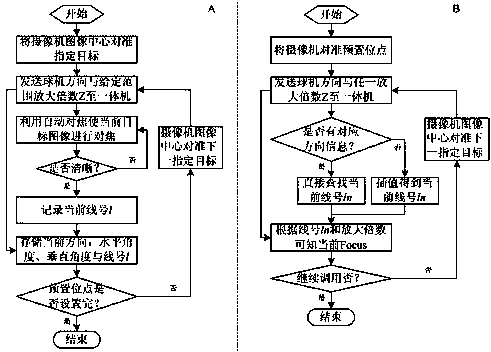

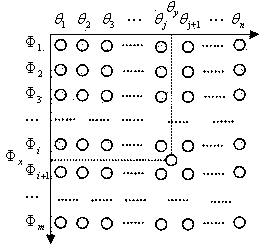

Preset bit method and control system

ActiveCN103841333ALarge amount of informationPresets can be recalledTelevision system detailsColor television detailsControl systemMagnification

The invention discloses a preset bit method and a control system. The preset bit method comprises the steps of preset bit setting and preset bit calling. According to the step of preset bit setting, current wire numbers are determined mainly according to the current direction information and magnification times of a dome camera, and the direction information and the wire numbers are stored. According to the step of preset bit calling, the wire numbers are searched for according to the current direct information of the dome camera, the current focal length is determined according to the magnification times sent to a camera by the dome camera, and therefore preset bit calling can be carried out fast and accurately.

Owner:CHENGDU POWERVIEW SCI & TECH

Primer automatic screwing device

ActiveCN101290205AReduce labor intensityEnsure consistencyAmmunition fuzesEngineeringMechanical engineering

The invention relates to an automatic primer tightening device which is characterized in comprising a pneumatic swing-table mechanism and primer tightening machines, wherein the pneumatic swing-table comprises a turn plate which is provided with at least six working positions according to the same included angles, four of the sixed working positions are provided with a video acquisition system, a primer tightening machine, a primer tightening depth measuring device and a turn plate working position encoder approach switch respectively; the turn plate is provided with the same number of clamping devices as the working positions, each of the clamping device corresponds to one working position; the pneumatic swing-table mechanism completes the rotation of the turn plate depending on the combined action of three cylinders. When a pre-tightening primer bomb clamped on the turn plate reaches the working position of the primer tightening machine, the primer tightening machine can tighten the primer into the bomb to complete the tightening action. The automatic production of the automatic primer tightening device can not only ensure the reliability, correspondence and safety of the primer products, but also can improve the production efficiency so as to reduce large amount of repetitive labor of workers.

Owner:廊坊智通机器人系统有限公司

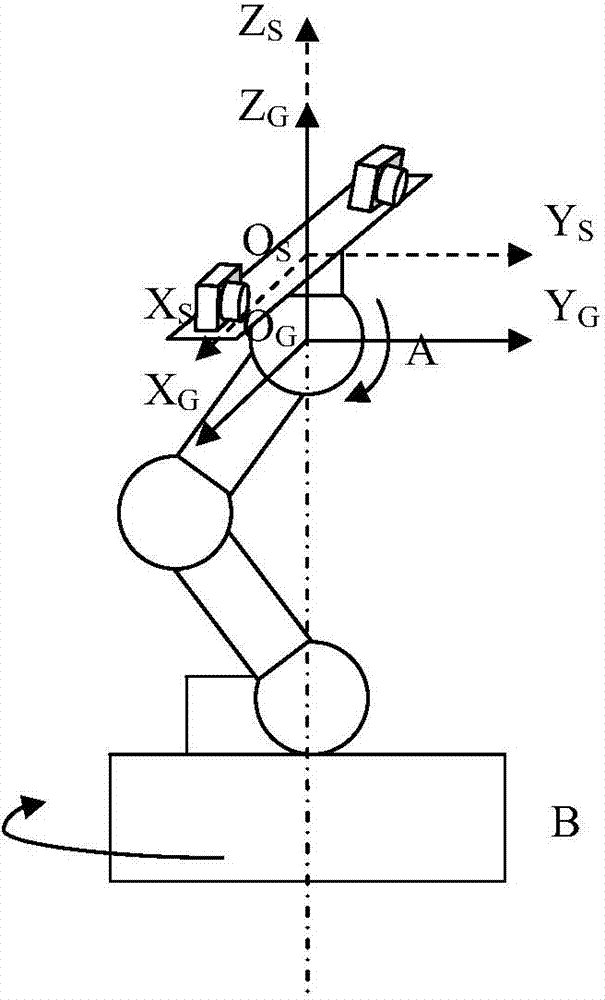

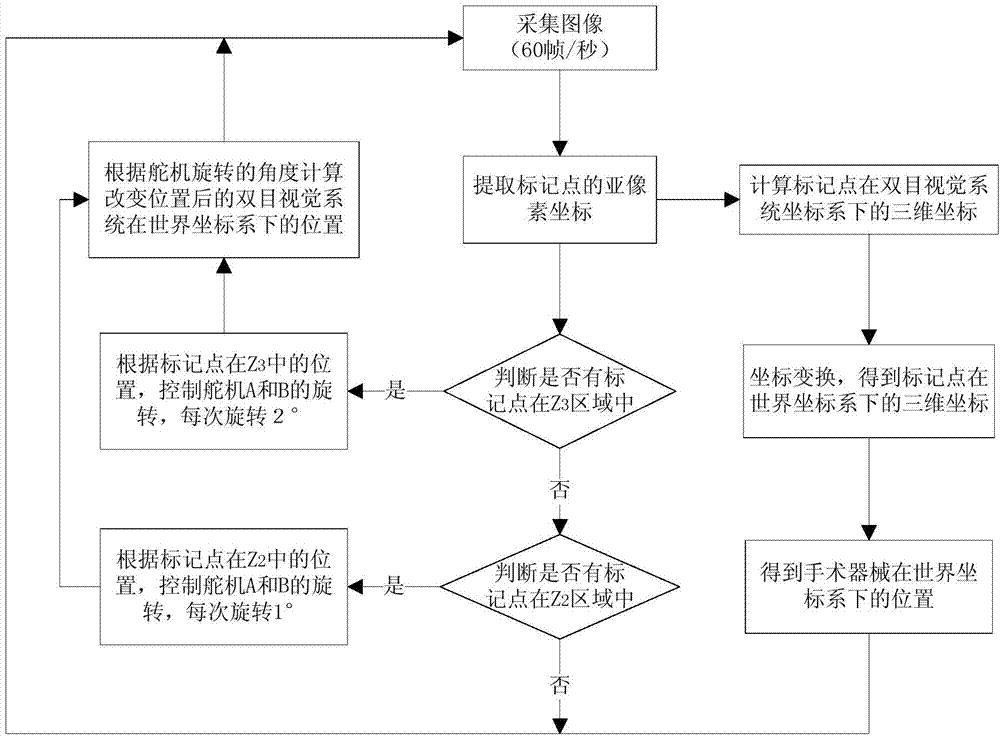

Automatic tracking and positioning method for surgical instrument in large visual field

InactiveCN104739514AAddress effectivenessSolve positioningSurgeryDiagnostic recording/measuringVisual field lossVisual perception

The invention discloses an automatic tracking and positioning method for a surgical instrument in a large visual field. The automatic tracking and positioning method comprises the following steps of 1 using a mechanical arm to control motions of a binocular vision system to obtain the large visual field and automatically tracking the surgical instrument in the large visual field, 2 determining the space position of the binocular vision system according to the position relation of a steering engine of the mechanical arm, and 3 positioning the surgical instrument through space coordinate transformation. The problem that the binocular vision system is small in effective visual field and cannot position the surgical instrument in a wide-range mode is effectively solved, and the automatic tracking and positioning method has the advantages of achieving automatic tracking and positioning of the surgical instrument in the large visual field and the like.

Owner:SOUTH CHINA UNIV OF TECH

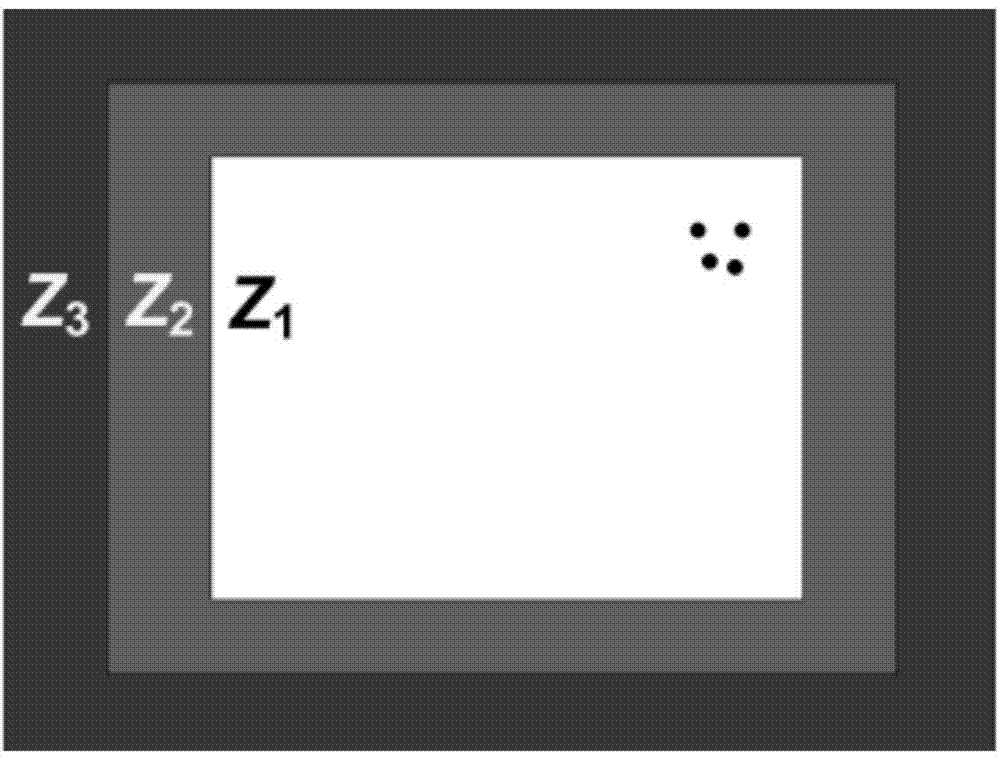

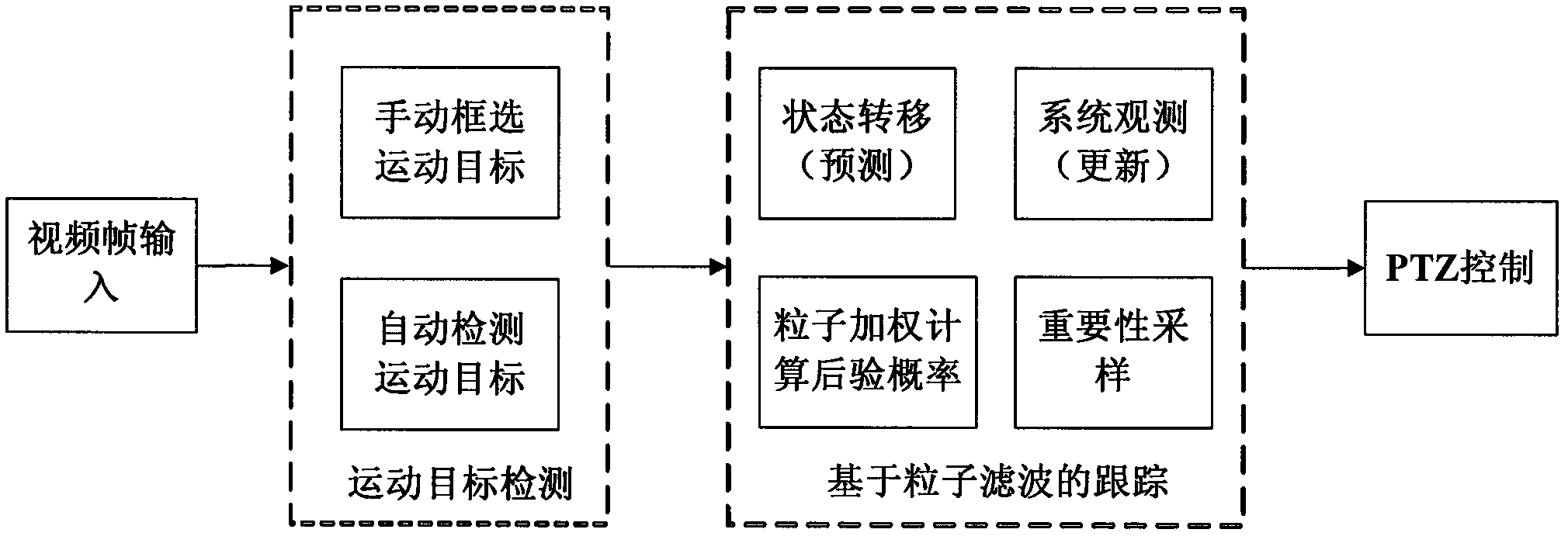

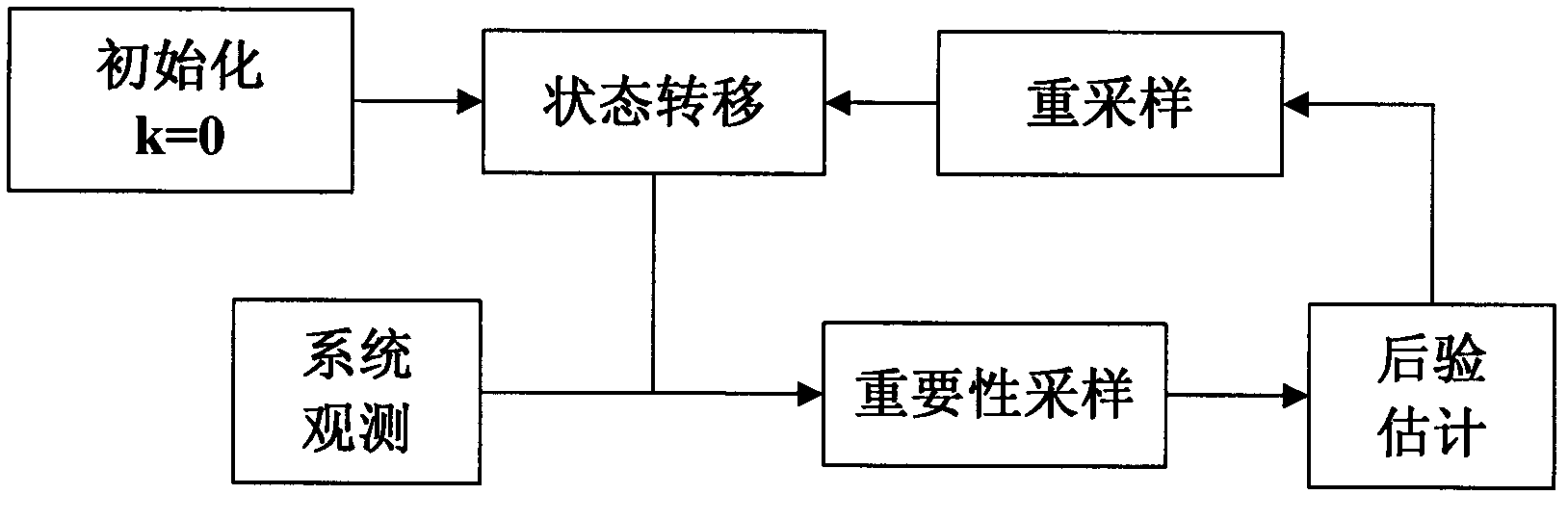

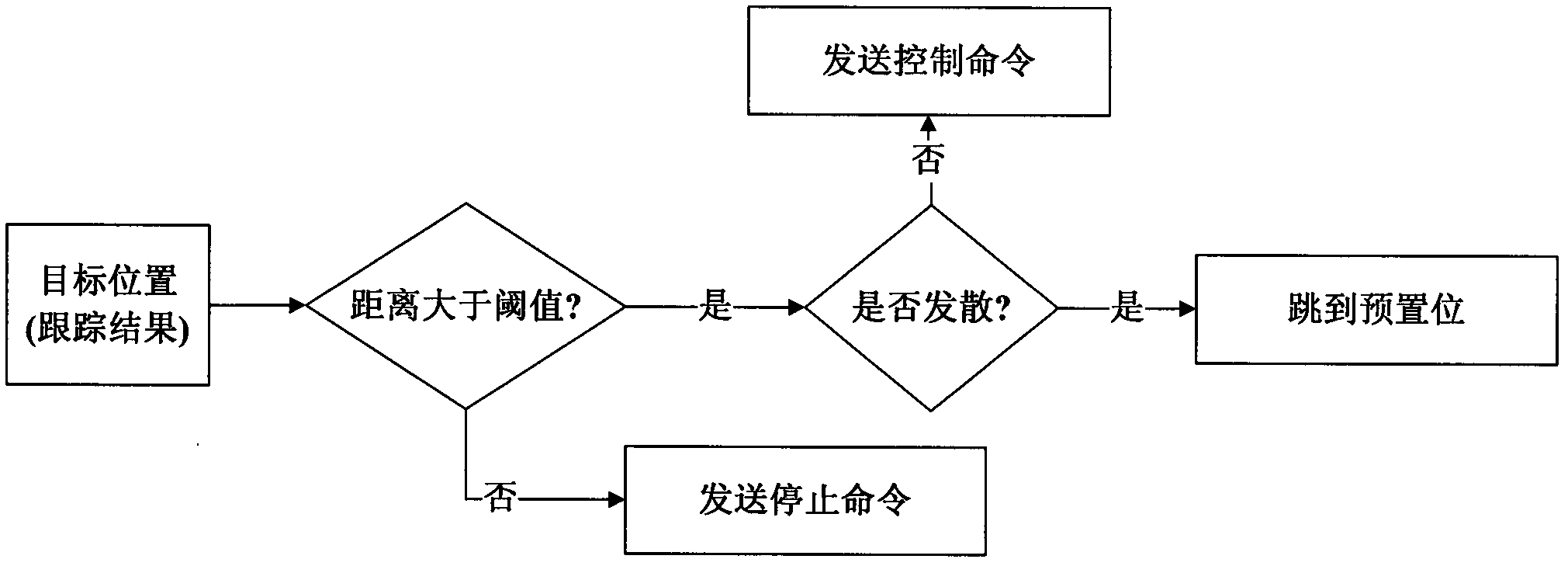

Automatic PTZ (Pan/Tilt/Zoom) target tracking method based on particle filter

InactiveCN103024344AImplement automatic trackingTelevision system detailsColor television detailsVisual field lossCamera lens

The invention discloses an automatic PTZ (Pan / Tilt / Zoom) target tracking method based on particle filter. The automatic PTZ target tracking method comprises the steps of detection of a moving target, target tracking and pan-and-tilt control. The method can allow a camera to lock the moving target automatically and implement automatic tracking of vision guidance, thereby overcoming the defect that a fixed camera has a narrow monitoring visual field. At first, the moving target is selected by a manual frame in a pre-set position or the moving target is automatically detected by a vision consistency algorithm; secondly, a target position is matched and tracked by the classic particle filter; and finally, a control order is sent according to the position and the size of the target, so that the position and the focal distance of the camera can be adjusted. When a tracking process fails, the camera automatically skips back to the pre-set position, and the detection of next turn can be carried out. The automatic PTZ target tracking method provided by the invention is reasonable in design, so that the automatic tracking function of the camera to the target can be realized, and the target is located in the middle of a lens all along. Therefore, the automatic PTZ target tracking method brings convenience to monitoring personnel.

Owner:PCI TECH GRP CO LTD

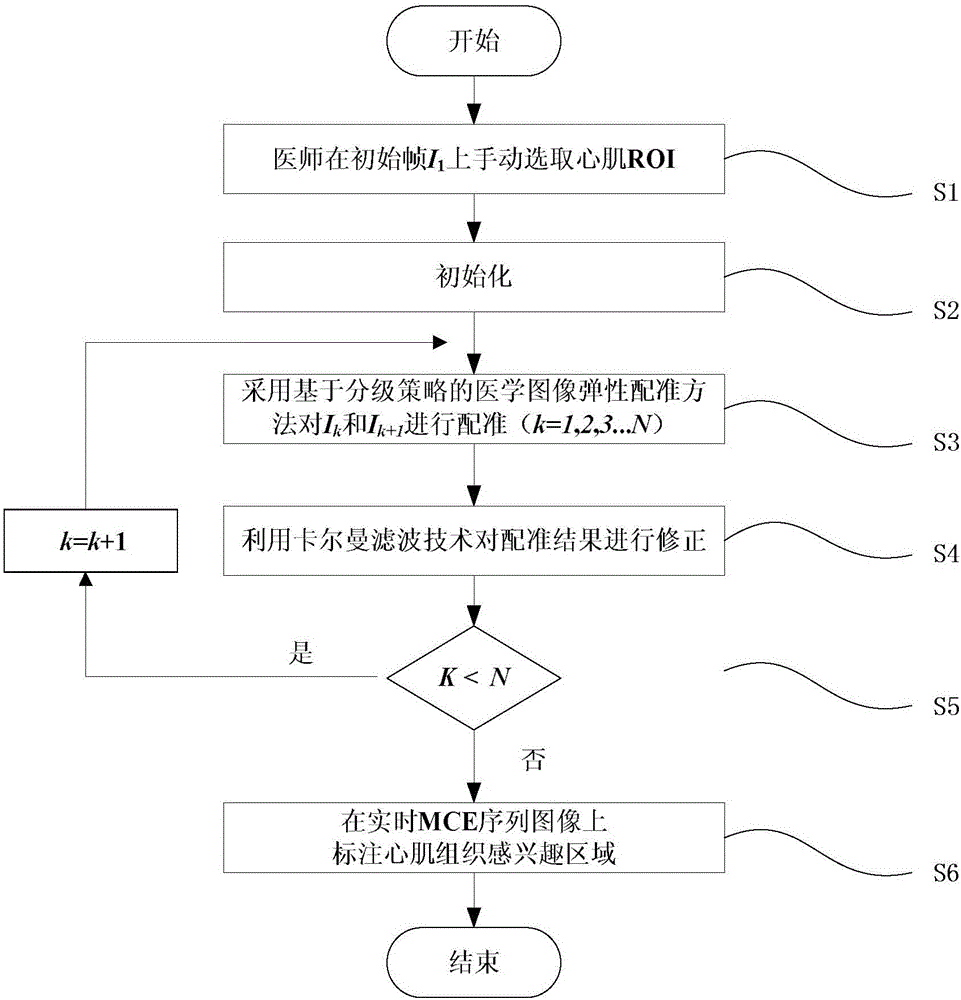

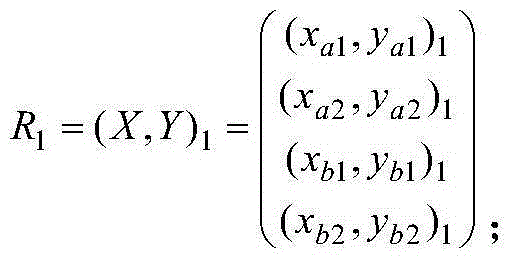

Automatic real-time MCE sequence image myocardial tissue region-of-interest tracking method

ActiveCN105160294AImplement automatic trackingAvoid accumulation between framesOrgan movement/changes detectionCharacter and pattern recognitionSonificationImaging analysis

The invention discloses an automatic real-time MCE sequence image myocardial tissue region-of-interest (ROI) tracking method and belongs to the medical ultra-sound sequence image analysis processing technology field. The method is characterized in that, a medical image elastic registration method based on hierarchical strategies is in combination with the Karman filtering technology to realize automatic real-time MCE sequence image myocardial tissue ROI tracking. The method comprises steps, the myocardial ROI is selected; initiation is carried out; the medical image elastic registration method based on the hierarchical strategies is employed for registration of sequence images; correction on the registration result is carried out by utilizing the Karman filtering technology; and the myocardial ROI is marked on the sequence image. Through the method, automatic real-time MCE sequence image myocardial tissue ROI tracking can be reliably realized, the tracking method has relatively high precision and accuracy, and inter-frame accumulation of a tracking error can be effectively avoided. The method is further applicable to automatic tracking on other medical ultra-sound sequence image ROI.

Owner:SHANDONG UNIV

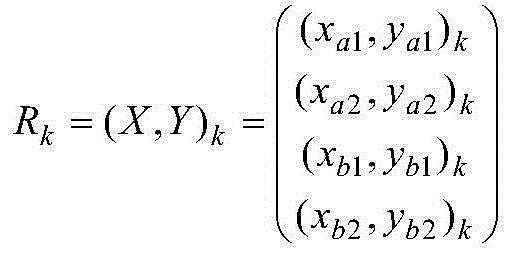

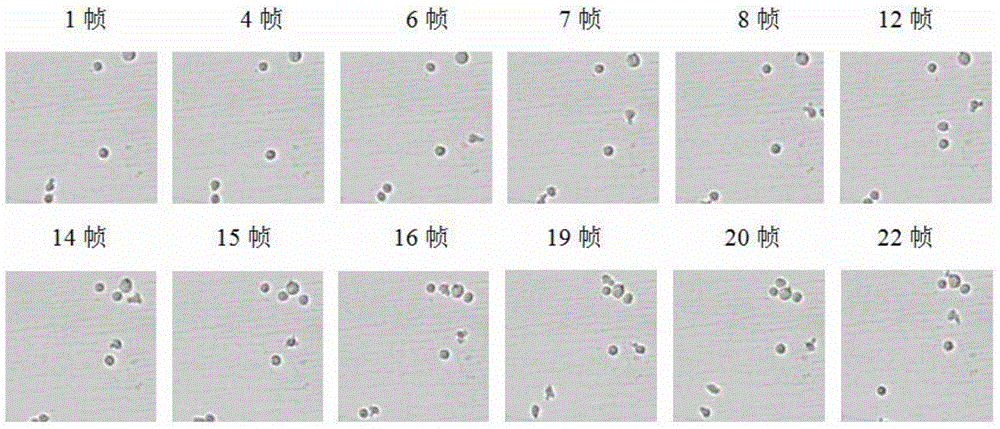

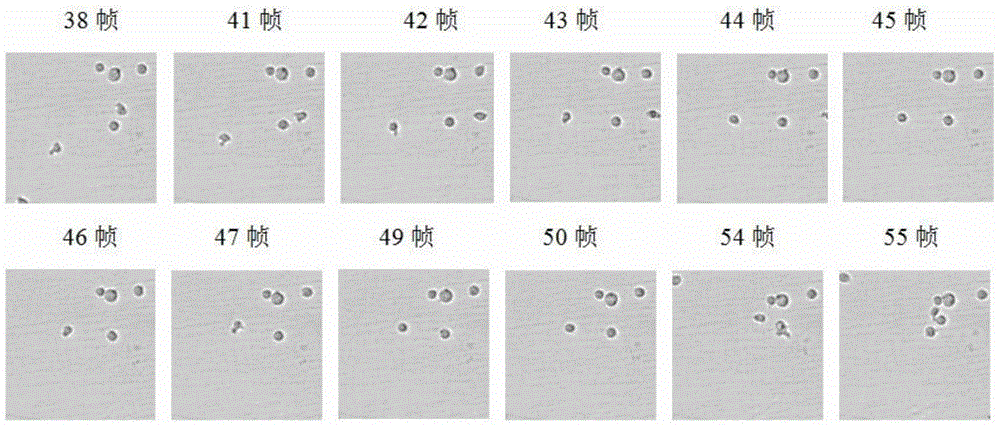

Variable density cell tracking method based on multi-mode ant colony system

ActiveCN105279768AImplement automatic trackingImprove tracking stabilityImage analysisInitial distributionDensity change

The present invention provides a variable density cell tracking method based on a multi-mode ant colony system. The method comprises the steps of acquiring a plurality of frames of continuous original grey-scale maps of a variable density cell, selecting one frame of the original grey-scale map as a current frame, calculating an average likelihood score of pixels in the current frame of the original grey-scale map, and placing ants in regions where the cells might appear according to a calculation result, thus to obtain generator ant colony initial distribution. The method provided by the present invention has the beneficial effects that automatic tracking of cell density changing situations (especially a cell concentrating situation) caused by movements, collision and fission can be realized, all cyto-dynamics characteristic parameters such as a track and speed are given, and automatic tracking of variable density cells caused by entering or leaving a view can be realized.

Owner:JIANGSU SAIKANG MEDICAL EQUIP

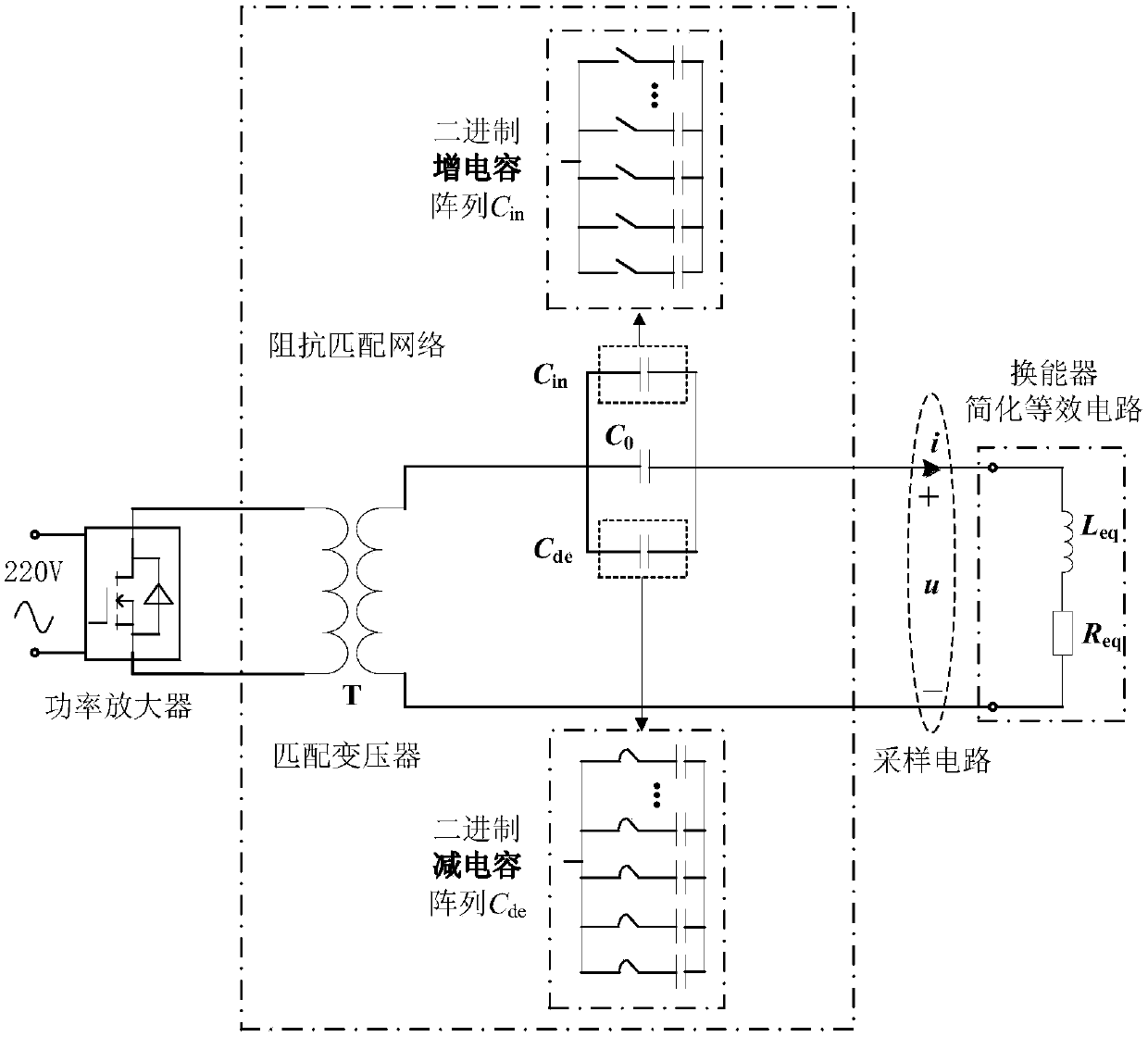

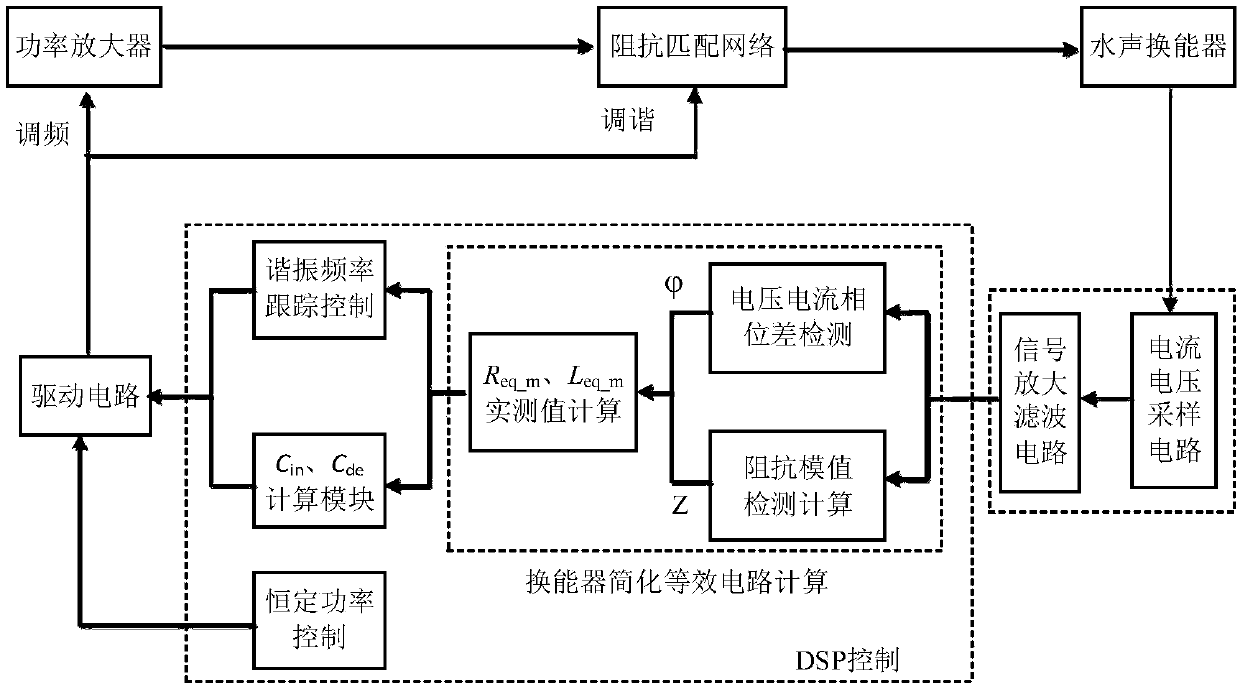

Impedance matching system suitable for marine communication electroacoustic transducer, and matching method thereof

ActiveCN108882108AImplement automatic trackingImprove energy conversion efficiencyFrequency/directions obtaining arrangementsPeak valueImpedance matching

The invention discloses an impedance matching system suitable for a marine communication electroacoustic transducer, and a matching method thereof. The impedance matching system comprises a precedingstage power amplifier, an impedance matching network, a magnetostrictive transducer equivalent circuit and an impedance matching cooperative control system, the impedance matching network and the preceding stage power amplifier perform cooperative control, and static matching and dynamic matching are combined to achieve good matching of the transducer. Compared with the traditional static matching, the impedance matching network proposed by the invention for the marine communication electroacoustic transducer can measure an equivalent resistance value and an inductance value of the transducerin real time under the condition that the working environment of the transducer changes and the load changes to achieve dynamic matching, and track the resonance frequency by detecting the peak valueof the equivalent resistance of the transducer, improve the electroacoustic conversion efficiency of the system, and reduce the heat generation of the transducer; and compared with the traditional dynamic matching, the impedance matching system greatly reduces the capacity of a binary capacitor array and improves the precision, thereby improving the matching effect.

Owner:HUNAN UNIV

Double-shaft solar automatic tracking power generation device and sensing probe thereof

InactiveCN104375514AImprove applicabilitySimple production processControl using feedbackEngineeringPosition of the Sun

The invention discloses a double-shaft solar automatic tracking power generation device and a sensing probe thereof. The sensing probe comprises a probe base, four photosensitive components and a cross-shaped partition board, and is characterized in that the cross-shaped partition board is arranged on the probe base and divides the probe base into four independent areas in light isolation, and the four photosensitive components are installed in the four independent areas of the probe base respectively. The sensing probe further comprises a light shielding piece and a dimming shell used for filtering away diffusion light, the light shielding piece is arranged on the top of the cross-shaped partition board, the four photosensitive components are located in an orthographic projection area, of the light shielding piece, on the probe base, namely when sunlight vertically irradiates the probe base, the four photosensitive components are located in the shade, formed on the probe base, of the light shielding piece, the dimming shell covers the cross-shaped partition board and the light shielding piece, a gap is reserved between the dimming shell and the light shielding piece, and the side end face of the cross-shaped partition board is tightly attached to the inner wall of the dimming shell. By means of the double-shaft solar automatic tracking power generation device and the sensing probe, automatic tracking of the position of the sun can be achieved.

Owner:于银龙 +1

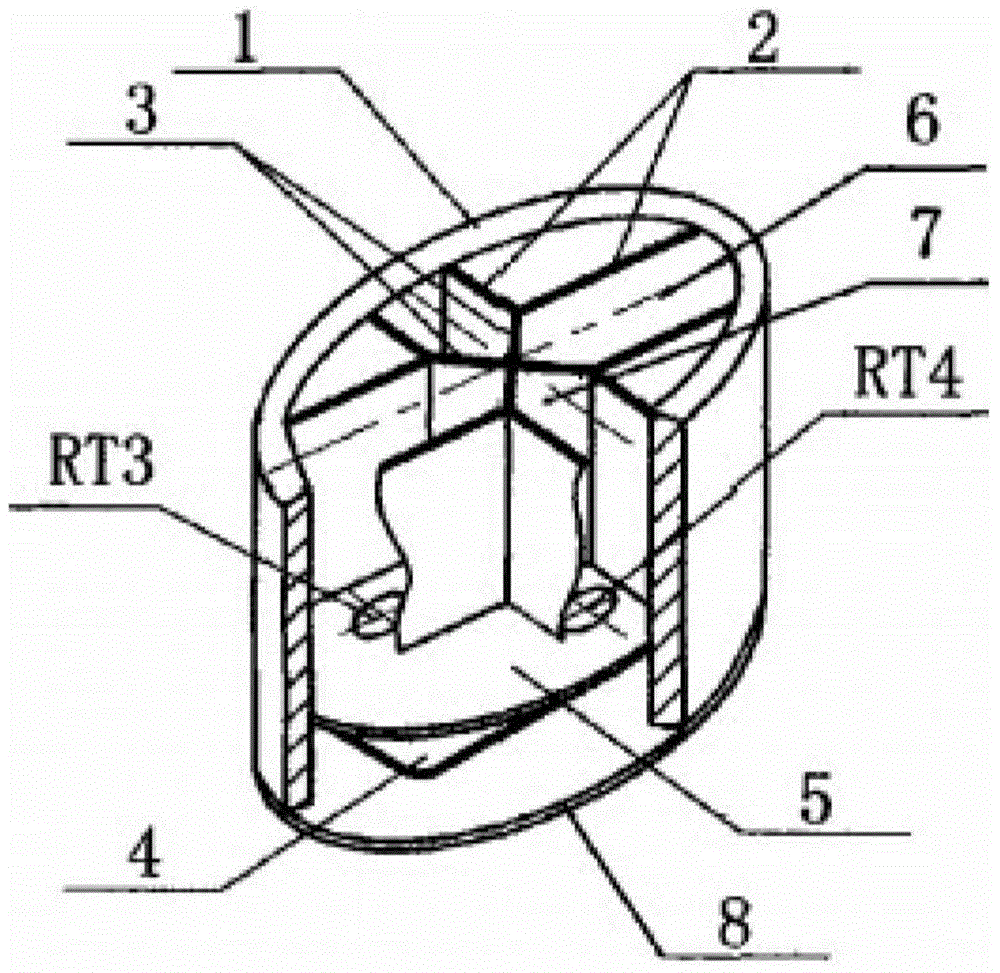

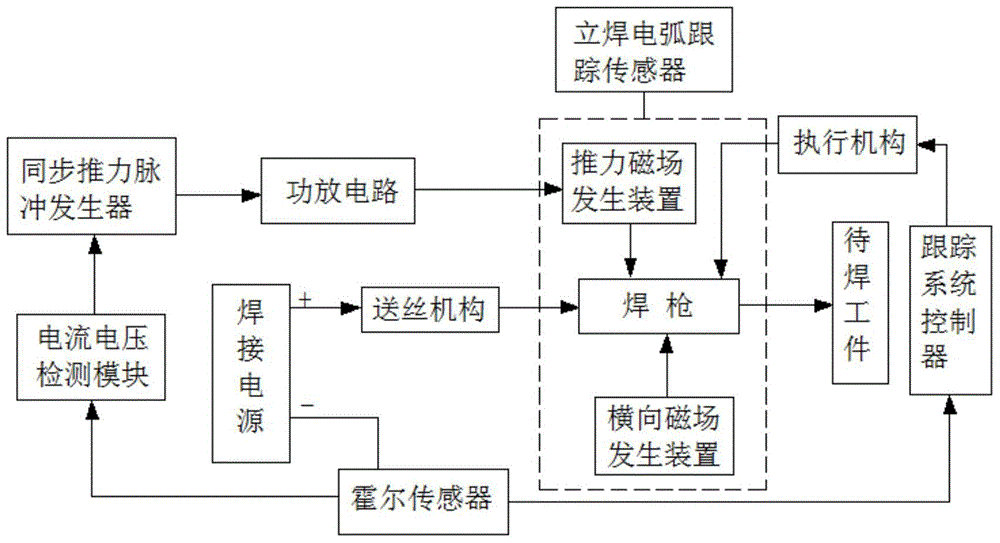

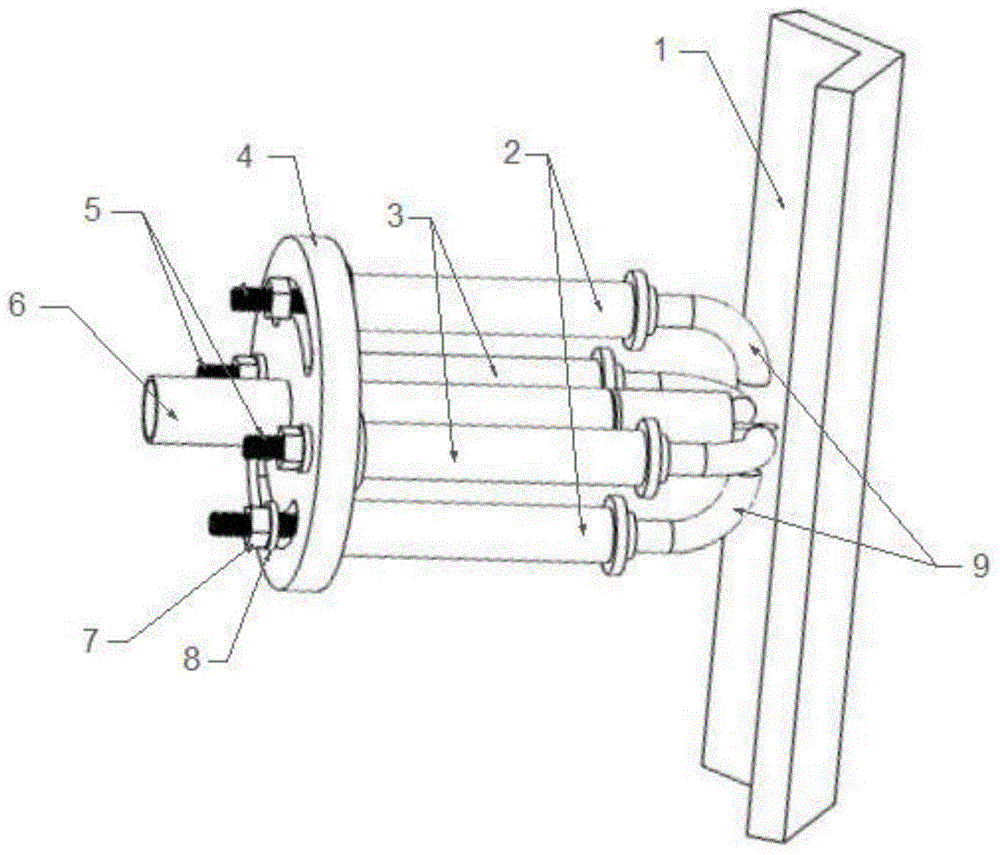

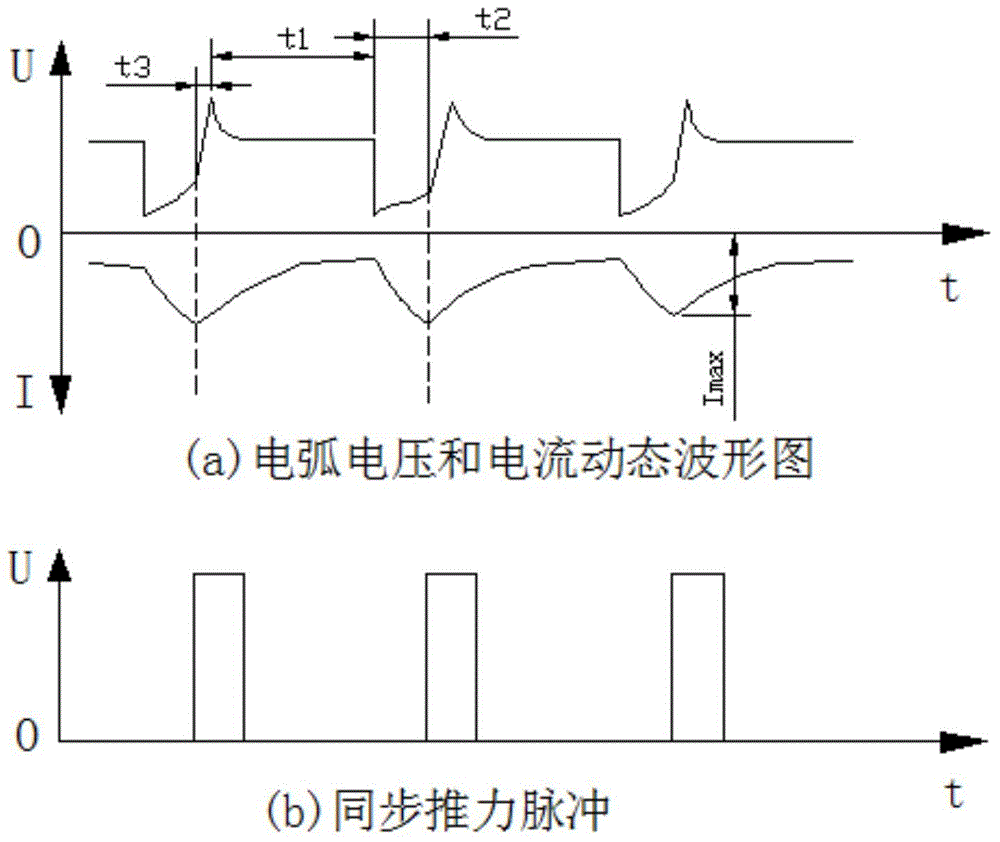

Method and device for controlling vertical welding process of applying synchronizing pulse compound magnetic field

ActiveCN105149733AQuality assuranceImplement automatic trackingArc welding apparatusWelding power supplyTransverse magnetic field

The invention relates to a method and a device for controlling a vertical welding process of applying a synchronizing pulse compound magnetic field. The method and device are used for mainly solving the technical problems of low degree of automation of the present vertical welding, difficulty in seam tracking, and the like. The device comprises a vertical welding arc tracking sensor, a welding source, a wire feeder, a Hall sensor, a tracking system controller, an executing mechanism, a current voltage detecting module, a synchronous thrust pulse generator and a power amplifier circuit, wherein the vertical welding arc tracking sensor comprises a welding gun, a horizontal magnetic field generating device and a thrust magnetic field generating device; the horizontal magnetic field generating device is used for generating an alternating magnetic field and causing an electric arc to laterally oscillate and scan the welding joint, thereby acquiring welding joint information and performing welding joint tracking; a thrust magnetic field generated by the thrust magnetic field generating device is used for causing the electric arc and molten drop to be affected by a suitable upward thrust, so that the gravity suffered by the molten drop and a melting pool during the vertical welding process is counteracted, the welding joint tracking of the vertical welding is realized and the welding efficiency of the vertical welding is increased under the condition of ensuring the welding joint quality of the vertical welding.

Owner:XIANGTAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com