Intersecting line girth welding device

A technology of circular seam welding and intersecting line, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve problems such as high cost and complexity, and achieve safety and durability, accuracy, and equipment versatility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to these embodiments, and any improvement or replacement in the basic spirit of the present invention still belongs to the scope of protection claimed in the claims of the present invention.

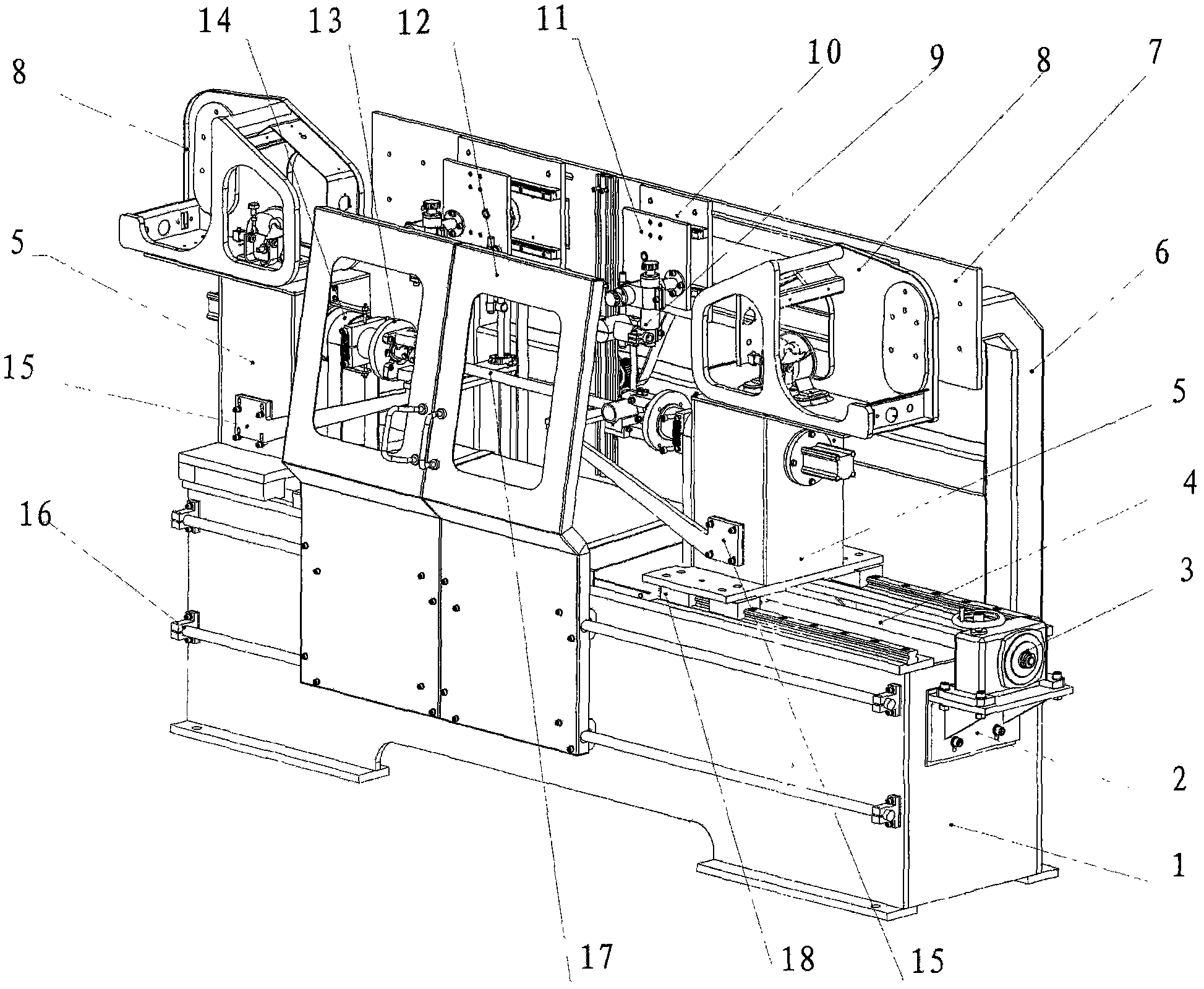

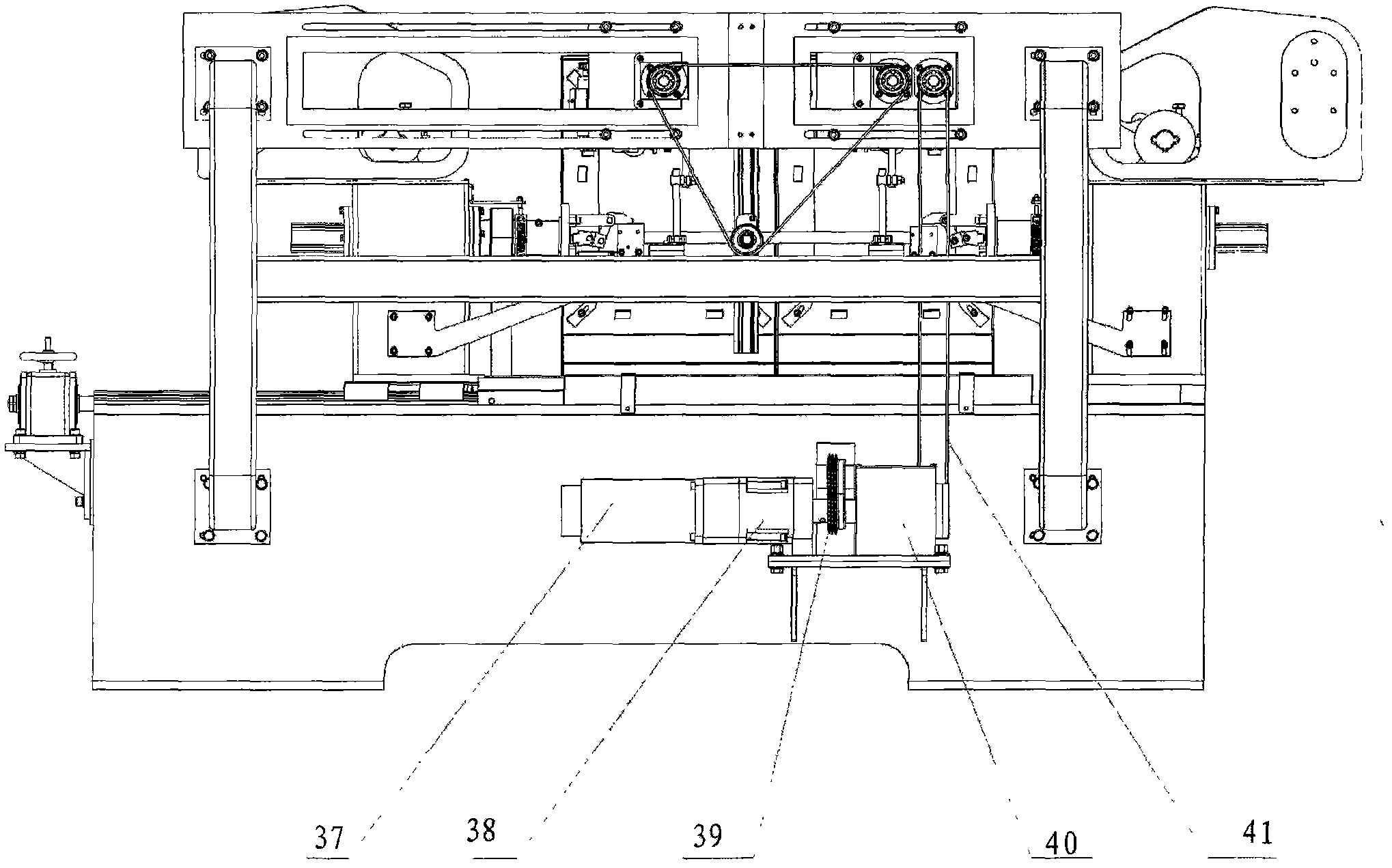

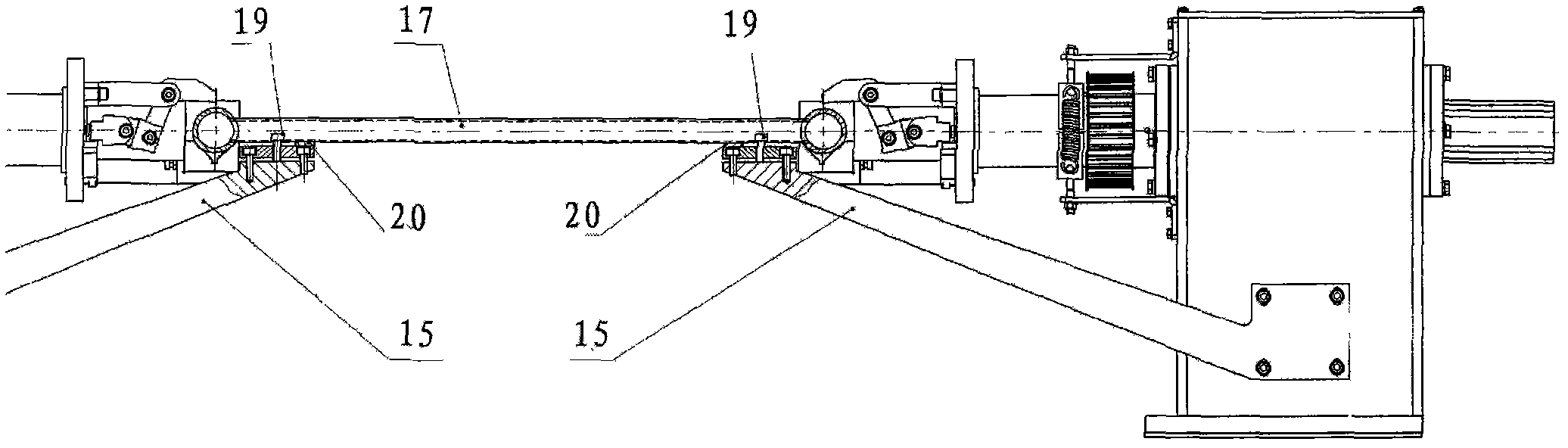

[0029] In this embodiment, please refer to Figure 1 and Figure 2, the structural components of an intersecting line circular seam welding device in the present invention mainly include: a base (1), a worm reducer mounting seat (2), Worm gear reducer (3), ball screw (4), tailstock (5), beam support (6), beam (7), wire feeder (8), welding torch adjustment device (9), linear slide rail ( 10), cam mechanism (11), arc protection screen (12), workpiece clamping, positioning device (13), timing belt (14), adjustment frame (15), protection screen slide rail (16), workpiece (17) , tailstock slide rail (18), stepper motor (37), speed r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com