Primer automatic screwing device

An automatic tightening device and clamping device technology, which is applied in the direction of weapon accessories, fuzes, offensive equipment, etc., can solve problems such as difficulty in ensuring product consistency, affecting production efficiency, and electrostatically triggered explosions, so as to liberate a lot of repetitive labor and improve production. Efficiency, the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

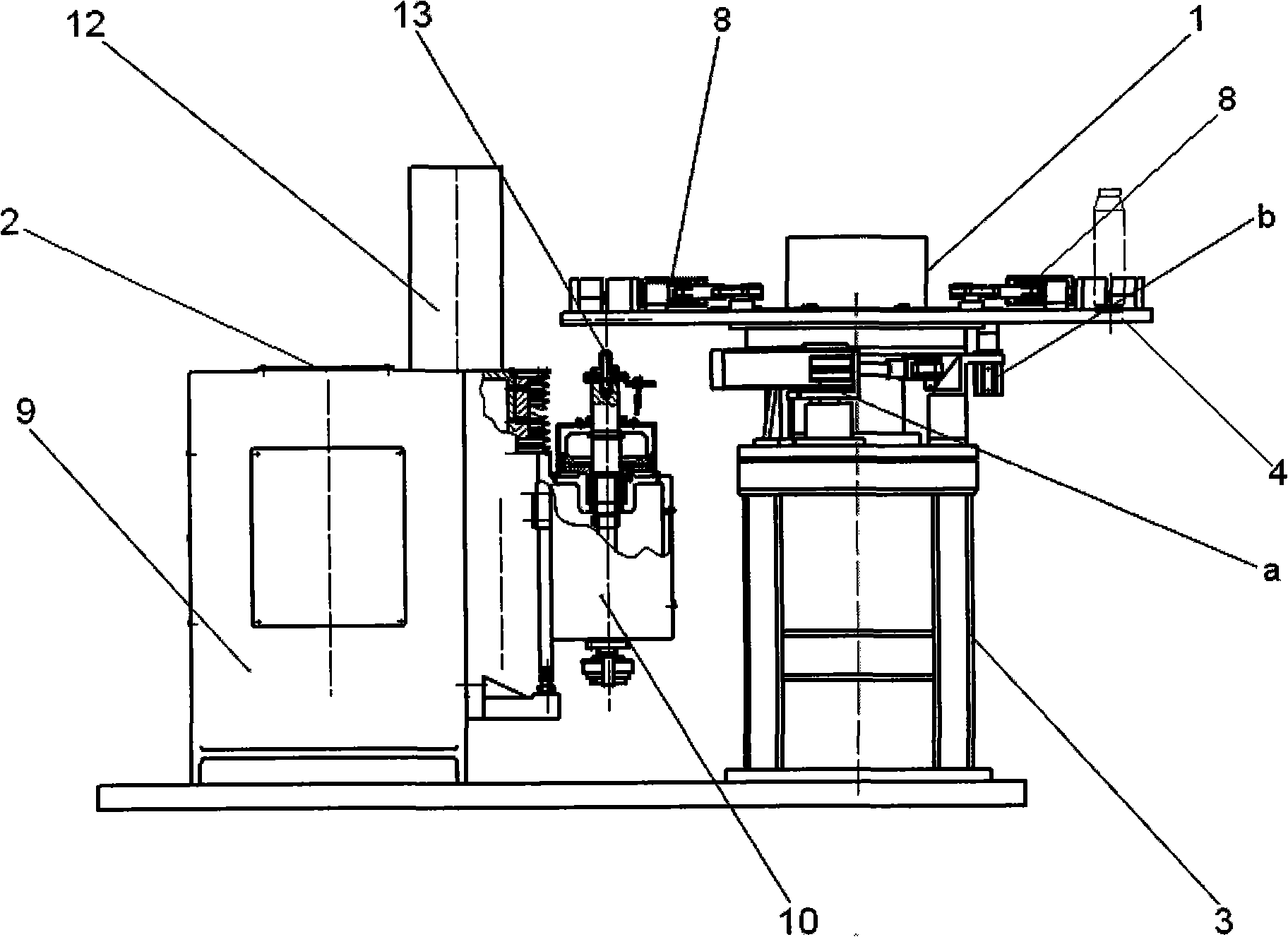

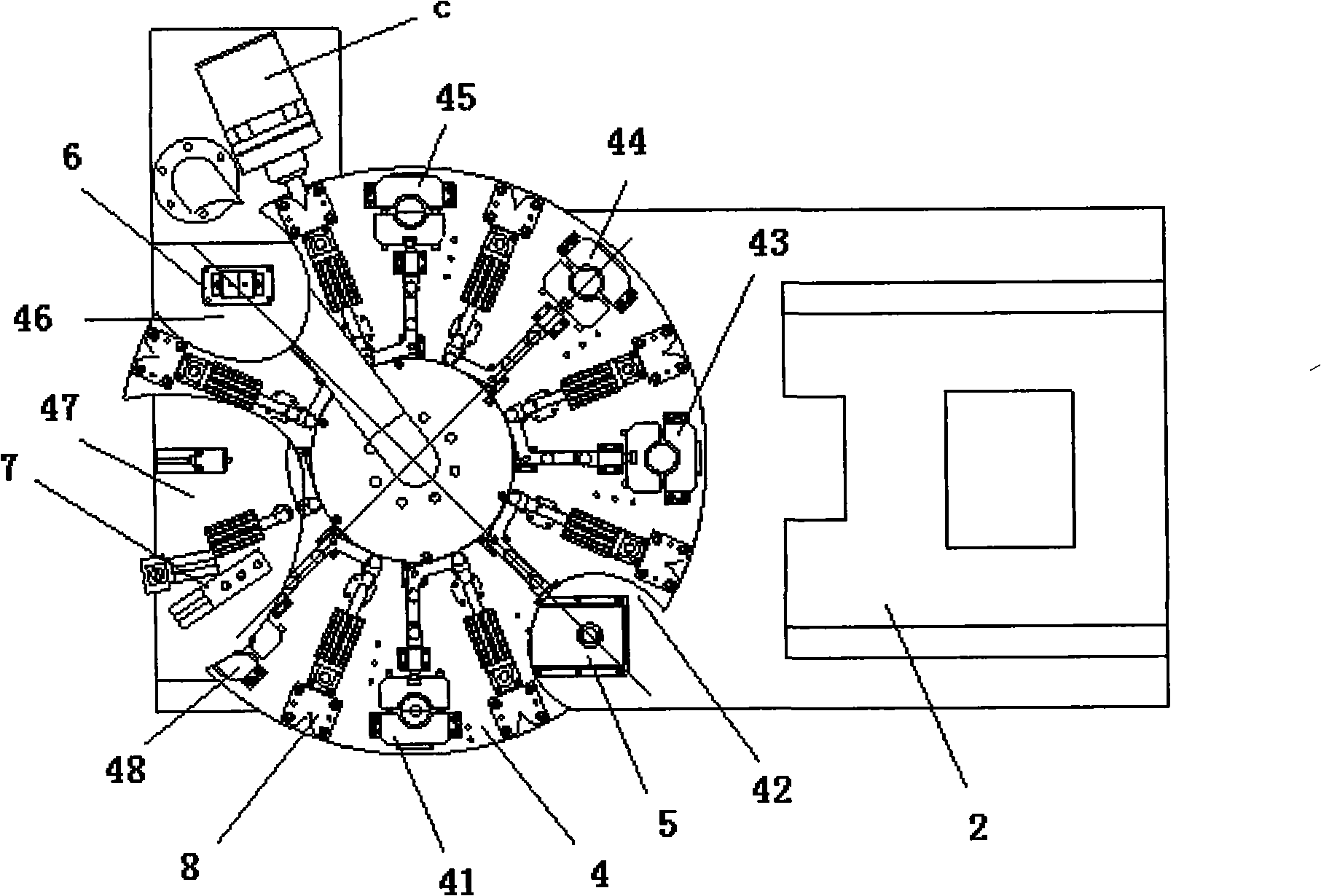

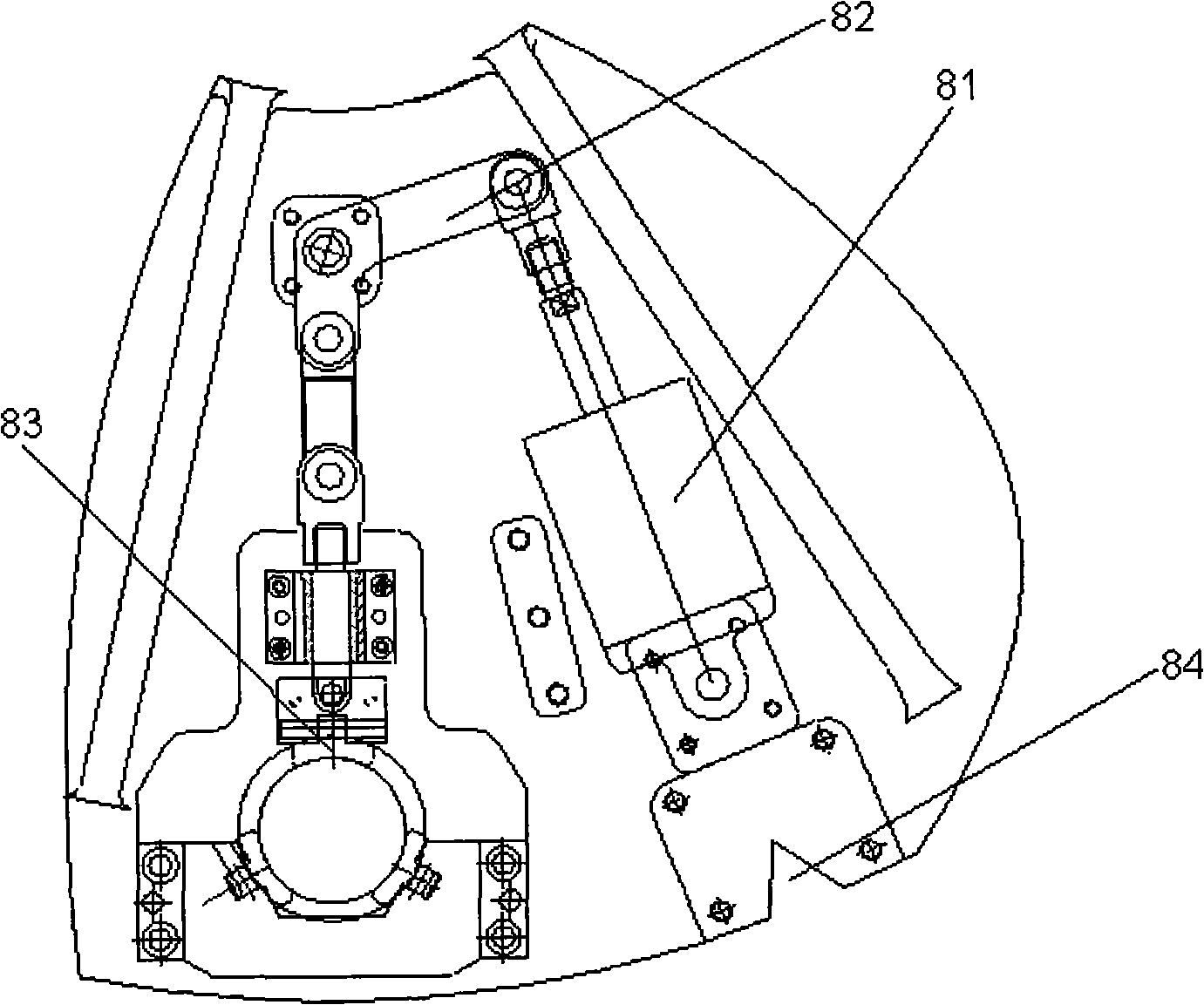

[0015] Such as figure 1 , figure 2 As shown, the present invention includes a pneumatic turntable mechanism 1 and a special machine 2 for twisting the primer. The pneumatic turntable mechanism 1 includes a bracket 3, on which a turntable 4 is rotated, and the turntable 4 is divided into 8 stations according to the same included angle. The corresponding relationship between the stations and the functional stations is: 1# station 41 is manually Material station, 2# station 42 is the image acquisition station, 3# station 43 is the tightening machine station, 4# station 44 and 5# station 45 are idle stations, 6# station 46 is the depth inspection Stations, 7# station 47 is an automatic blanking station, and 8# station 48 is a manual blanking station. An image acquisition system 5 is arranged below the station 42 of the turntable 4, and the images coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com