Automatically tracking device of welded joint machinery

An automatic tracking device and mechanical technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as undercutting and missing welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

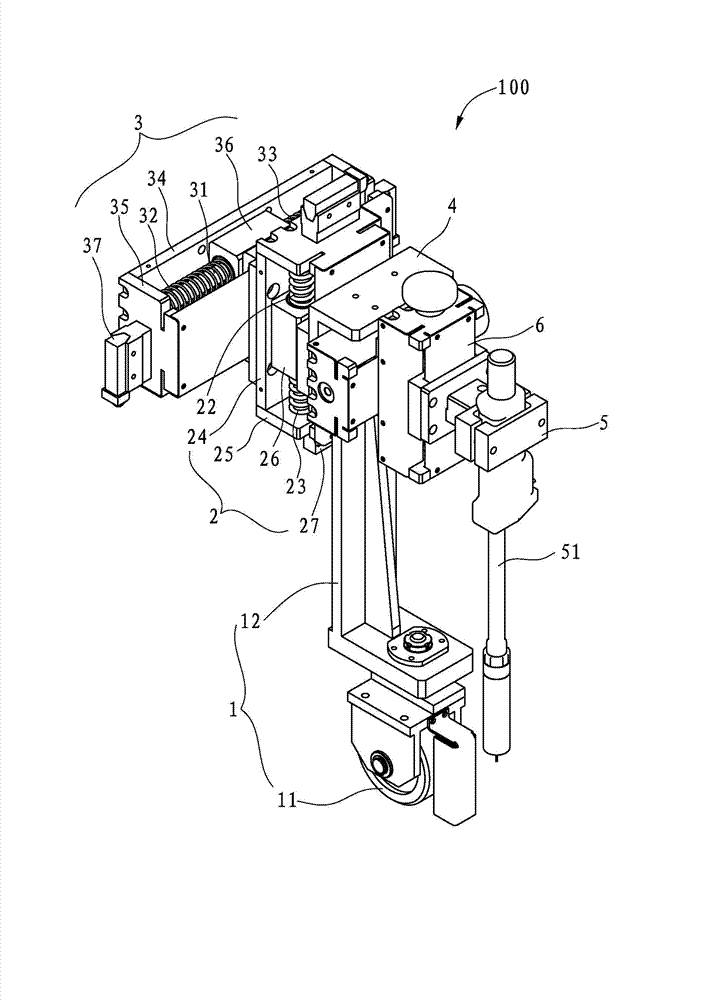

[0032] like figure 1 As shown, it is an automatic seam tracking device 100 according to the present invention, which includes a guide wheel mechanism 1 , an up-down adjustment mechanism 2 , a left-right adjustment mechanism 3 , an adjustment fine-tuning mechanism 4 and a welding torch fixing mechanism 5 .

[0033] The guide wheel mechanism 1 has a freely rotatable guide wheel 11;

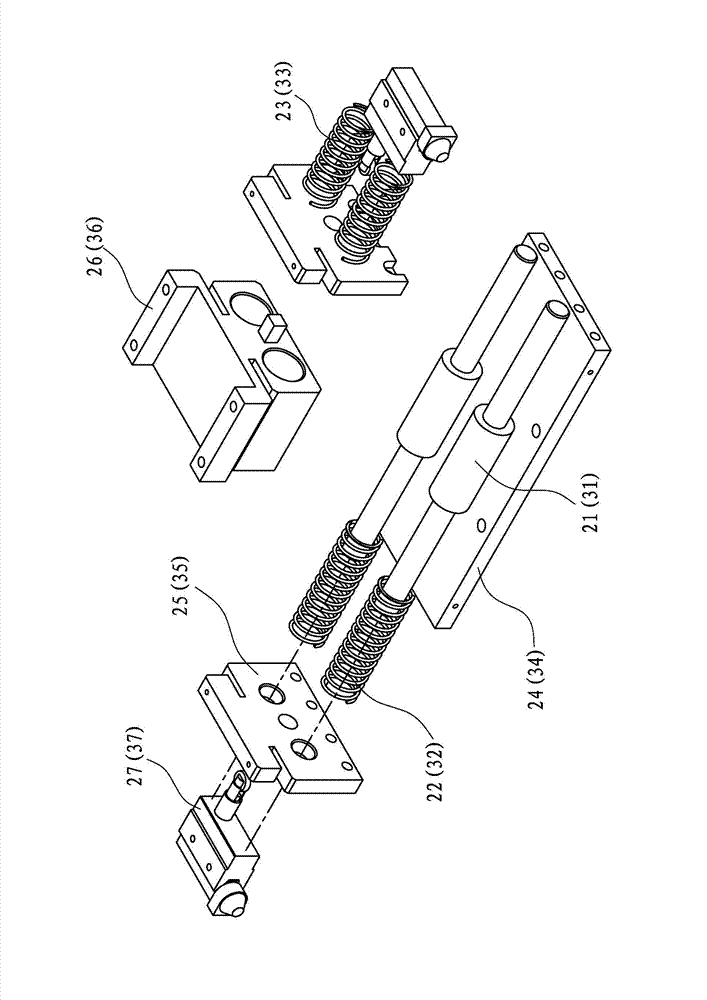

[0034] The up and down adjustment mechanism 2 has a first linear bearing 21, an upper elastic body 22 and a lower elastic body 23, the first linear bearing 21 extends in the vertical direction, and the upper elastic body 22 and the lower elastic body 23 are respectively arranged on the first linear bearing The upper and lower sides of 21; for its specific structure, please refer to figure 2 As shown, the up and down adjustment mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com