Method and device for controlling vertical welding process of applying synchronizing pulse compound magnetic field

A composite magnetic field and synchronous pulse technology, which is applied in the direction of manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems of high labor intensity, easy overheating of weld tissue, large energy of gas-electric welding welding line, etc., to ensure quality, weld Seam forming excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

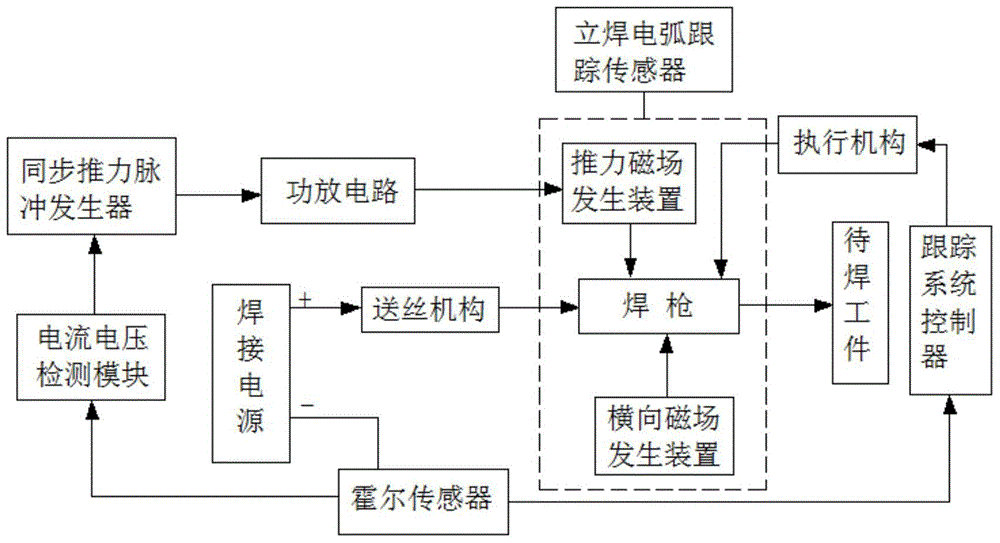

[0015] Example 1, see figure 1 , the present invention is a vertical welding process control method and device for applying a synchronous pulse composite magnetic field, including a vertical welding arc tracking sensor, a welding power supply, a wire feeding mechanism, a Hall sensor, a tracking system controller, an actuator, and a current and voltage detection module , Synchronous thrust pulse generator and power amplifier circuit. The vertical welding arc tracking sensor is composed of a welding torch, a transverse magnetic field generator and a thrust magnetic field generator. The sensor will simultaneously generate a composite magnetic field of the transverse magnetic field and the thrust magnetic field. During vertical welding, the transverse magnetic field generating device generates a transverse alternating magnetic field, and the arc oscillates transversely and regularly under the action of Lorentz force, thereby scanning the weld seam. The Hall sensor detects the weld...

Embodiment 2

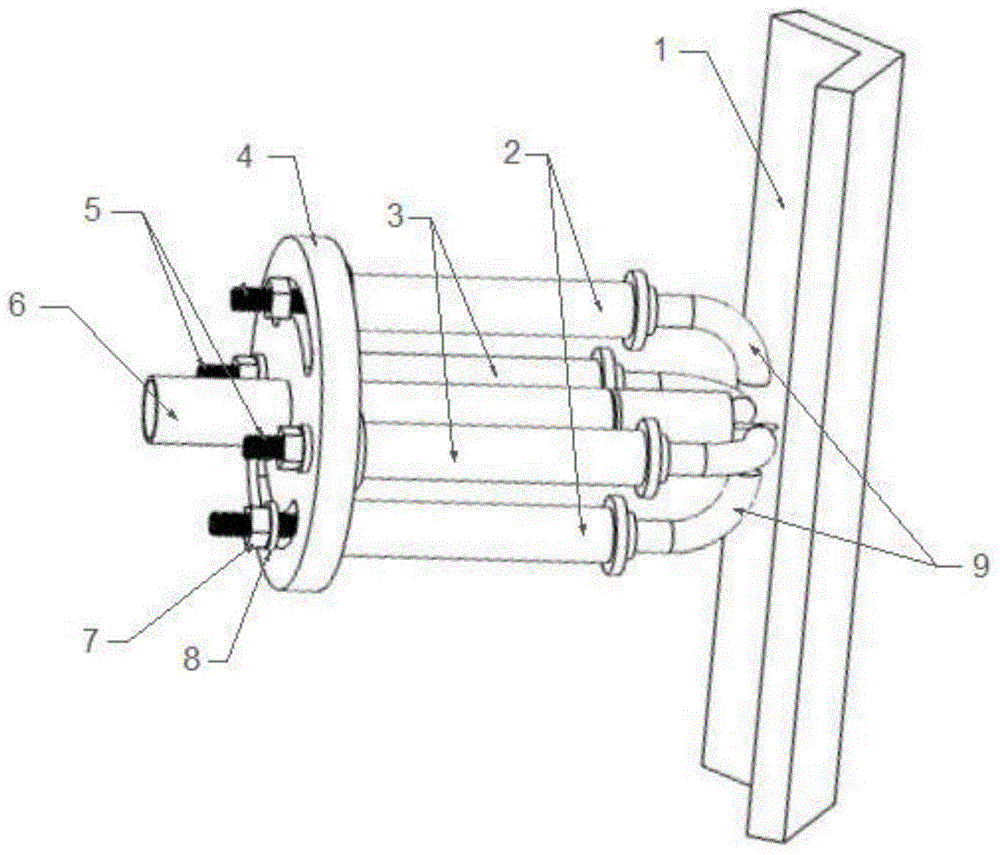

[0016] Embodiment 2, the structure of described vertical welding arc tracking sensor is as figure 2 As shown, the transverse magnetic field generating device of the sensor is composed of a transverse excitation coil (2) and a transverse excitation core (9). The two transverse excitation cores (9) are symmetrically distributed on the upper and lower sides of the welding torch (6), and (6) On the same plane, use gaskets (8) and nuts (7) to fix in the arc-shaped groove of the mounting plate (4), and adjust according to the angle of the vertical welding seam to ensure that the arc scanning direction is perpendicular to the welding seam The thrust magnetic field generating device is made up of a thrust excitation coil (3) and a thrust excitation core (5), and two thrust excitation cores (5) are symmetrically distributed on the left and right sides of the welding torch (6), and the thrust excitation core (5) uses Gasket (8) and nut (7) are fixed on the mounting plate (4).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com