Patents

Literature

424 results about "Density change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

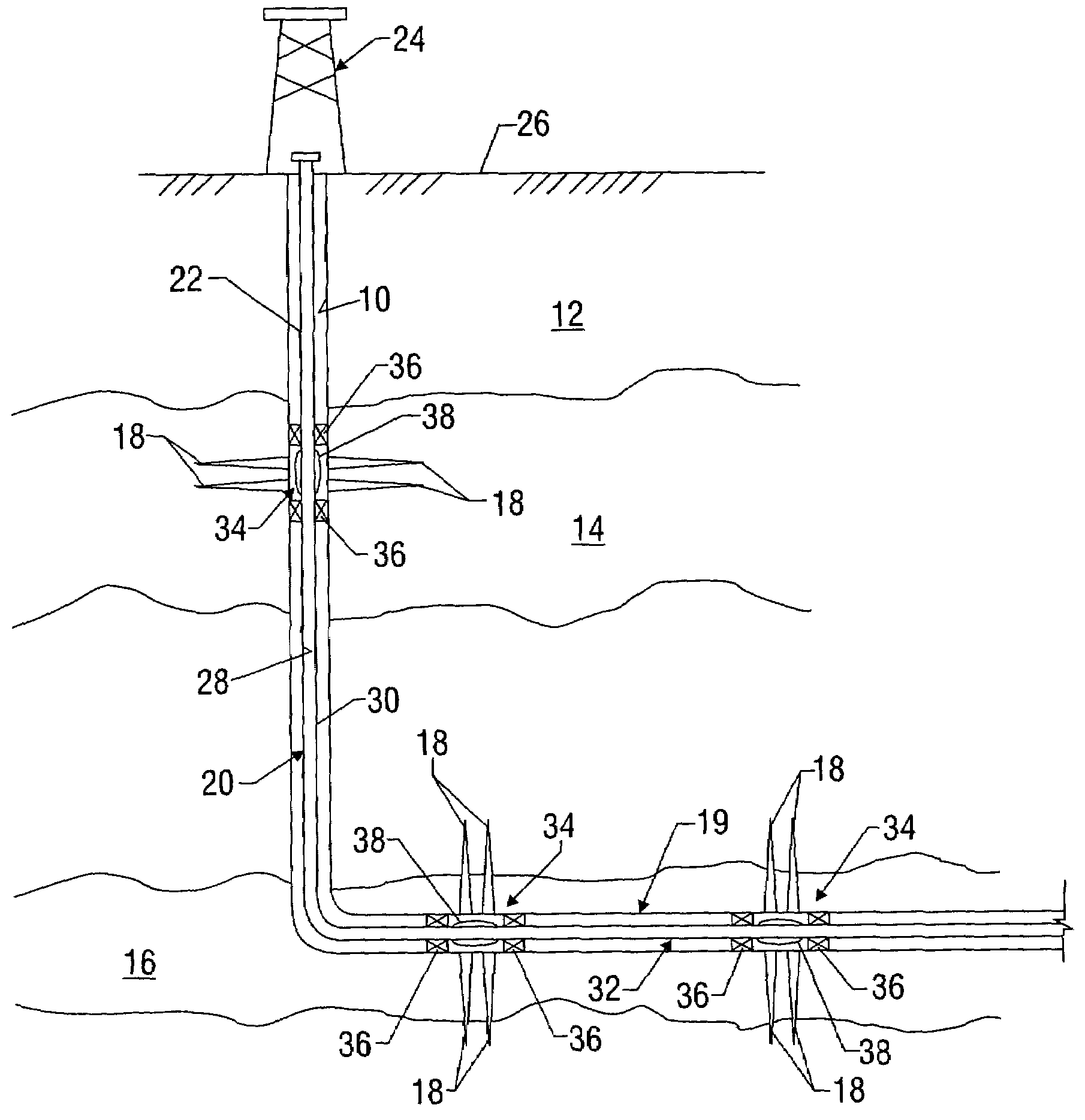

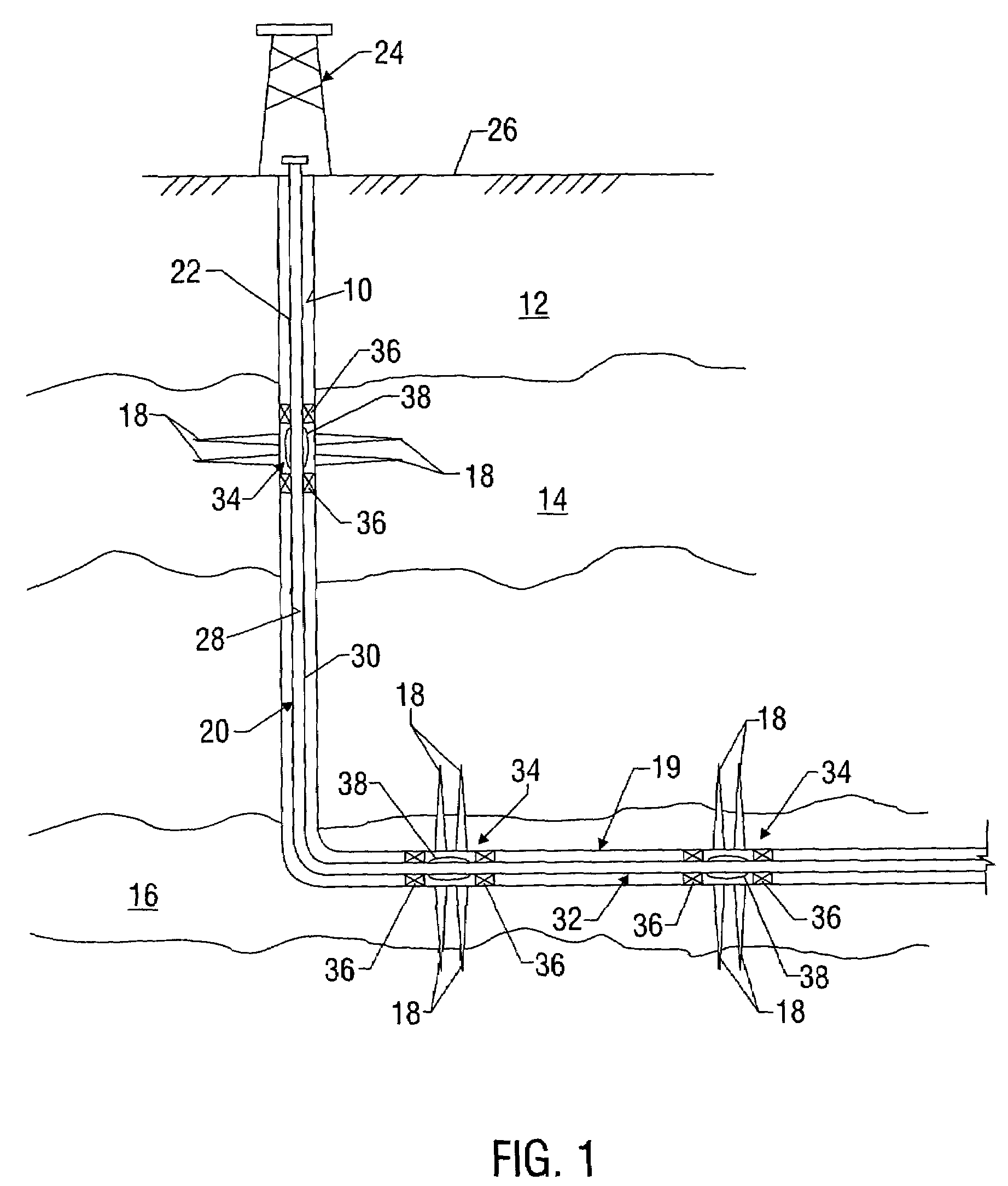

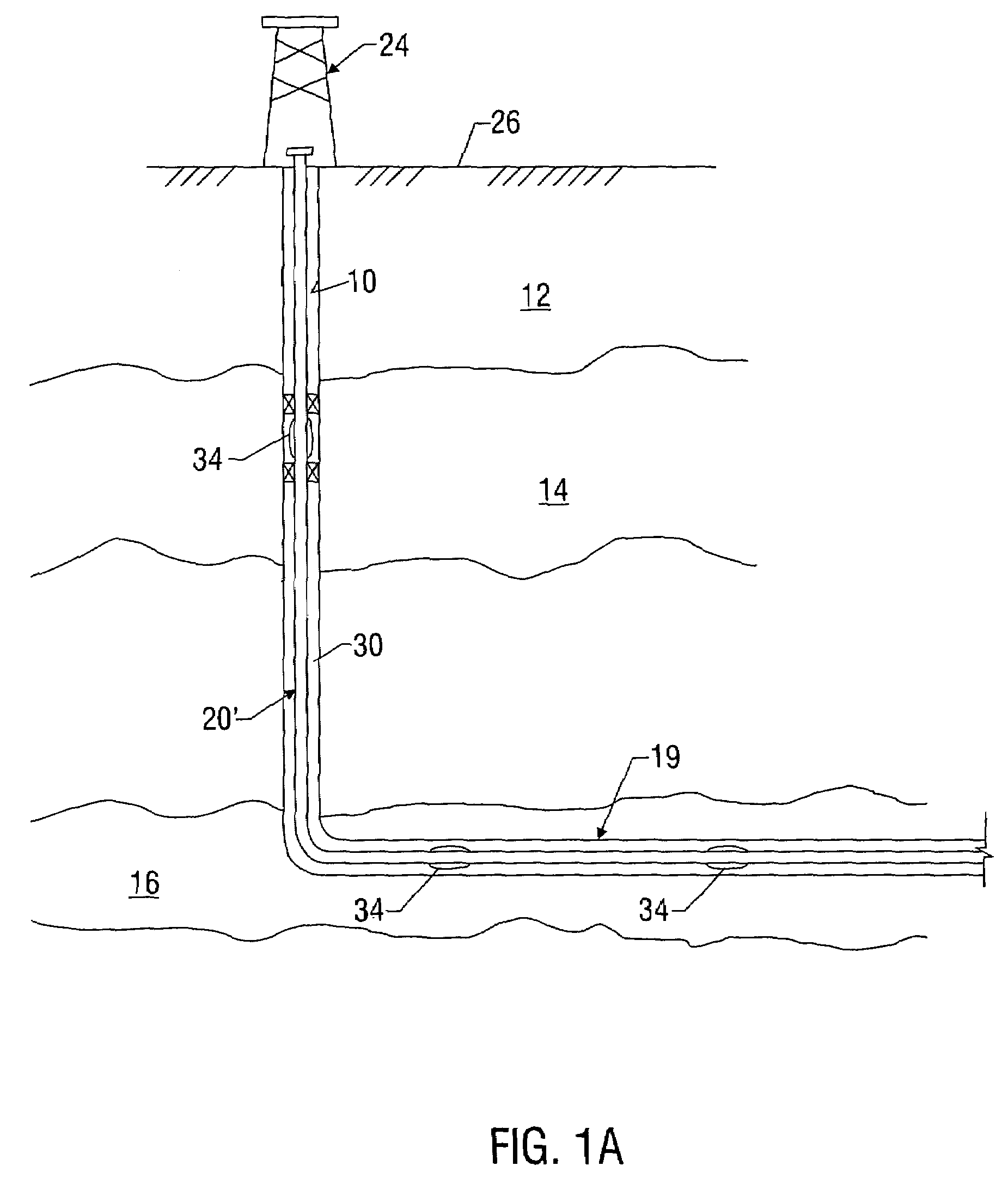

Inflow control device with passive shut-off feature

InactiveUS7290606B2Reduce gas flowConsistent service lifeSurveyConstructionsControl flowControl signal

Devices and methods for control flow of formation fluids respect to one or more selected parameter relating to the wellbore fluid. In one embodiment, a flow control device for controlling fluid flow into the production tubular uses a flow restriction member that is actuated by a character change of the formation fluid, such as liquid to gas or oil to water. The flow restriction member can be sensitive to a change in density of the formation fluid. The flow restriction member is passive, self-regulating and does not need any power source or control signal to control fluid flow. In one embodiment, the flow control device automatically rotates into a predetermined orientation upon being positioned in the wellbore. A seal disposed on the flow control devices expands into sealing engagement with an enclosure after the flow control device assumed the desired predetermined position.

Owner:BAKER HUGHES INC

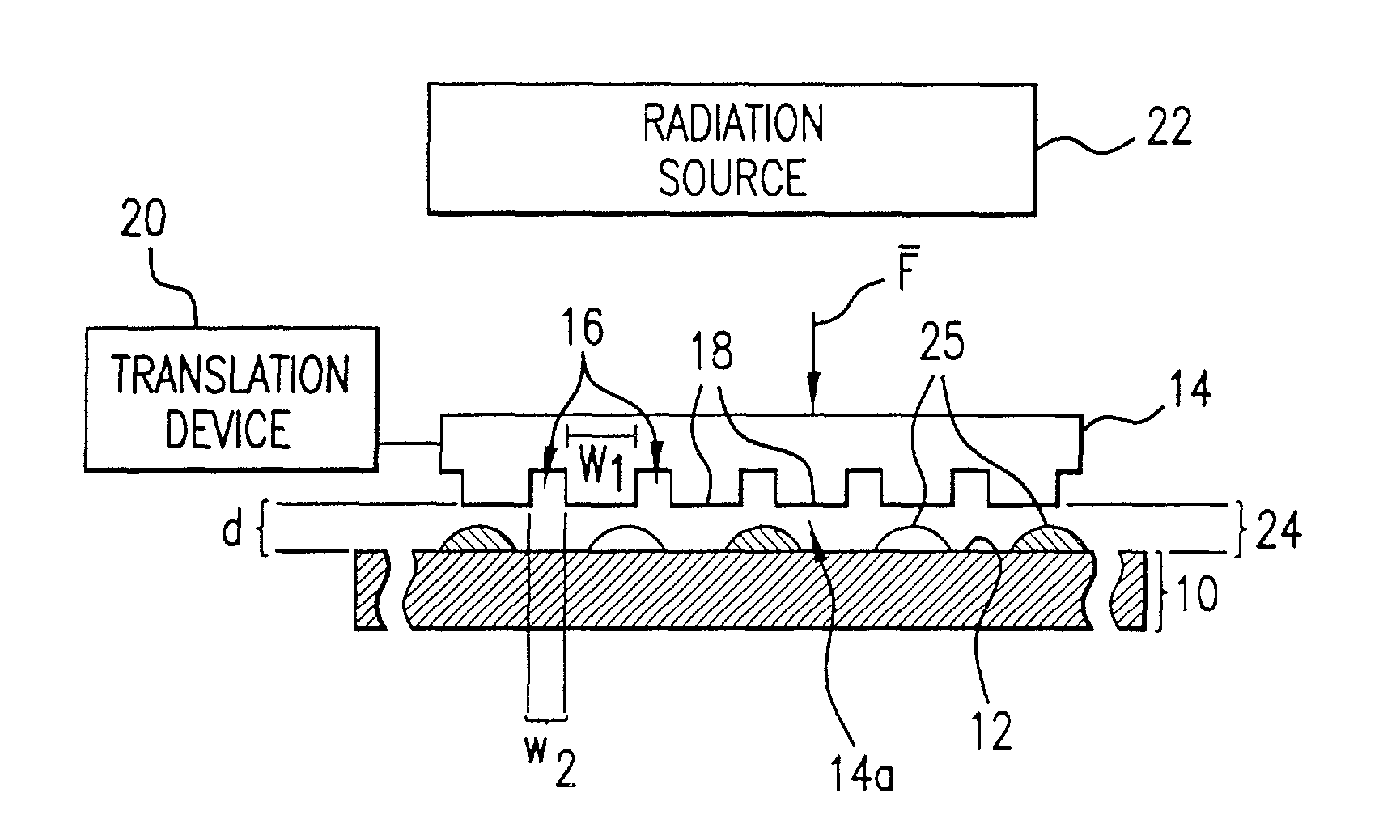

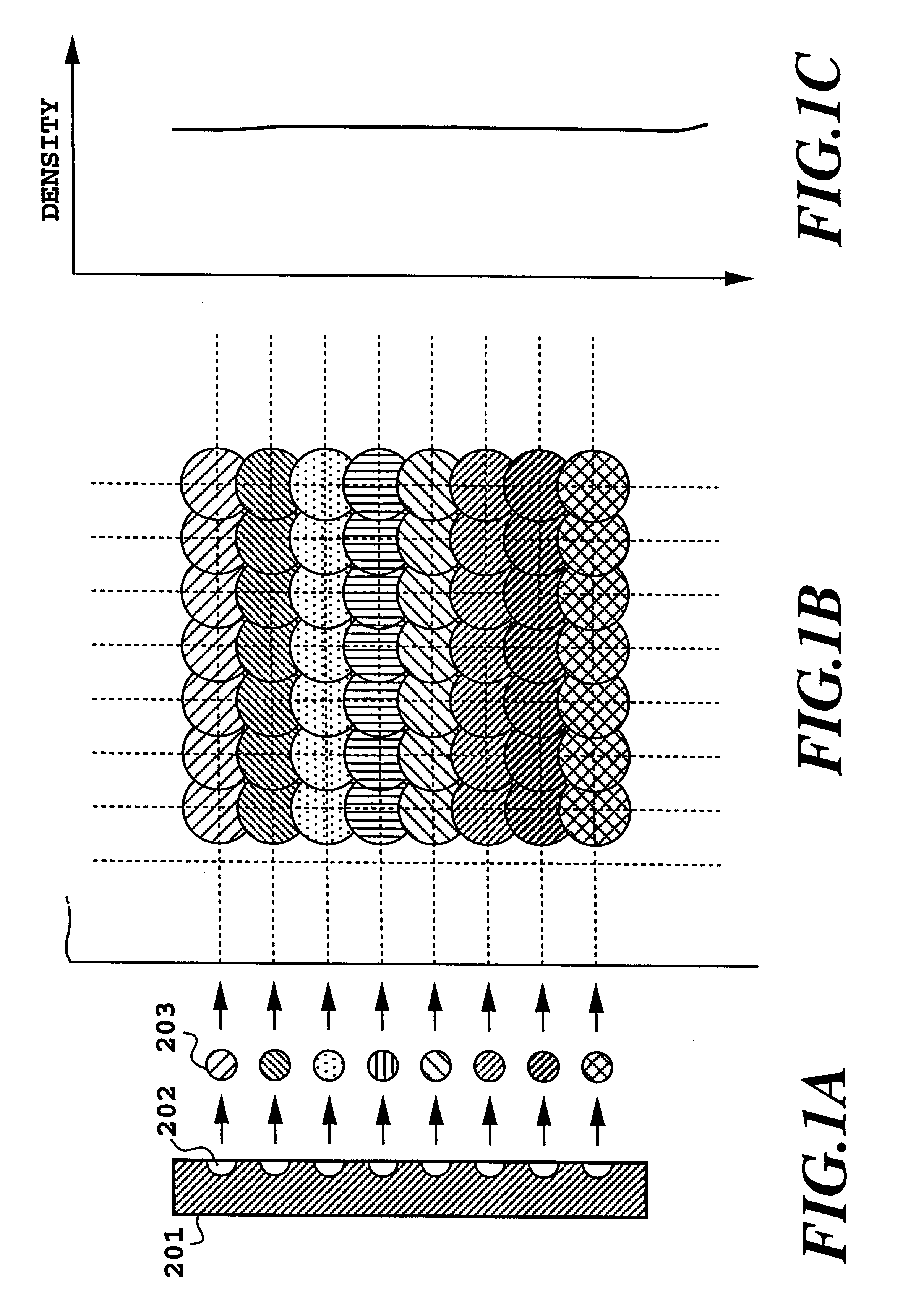

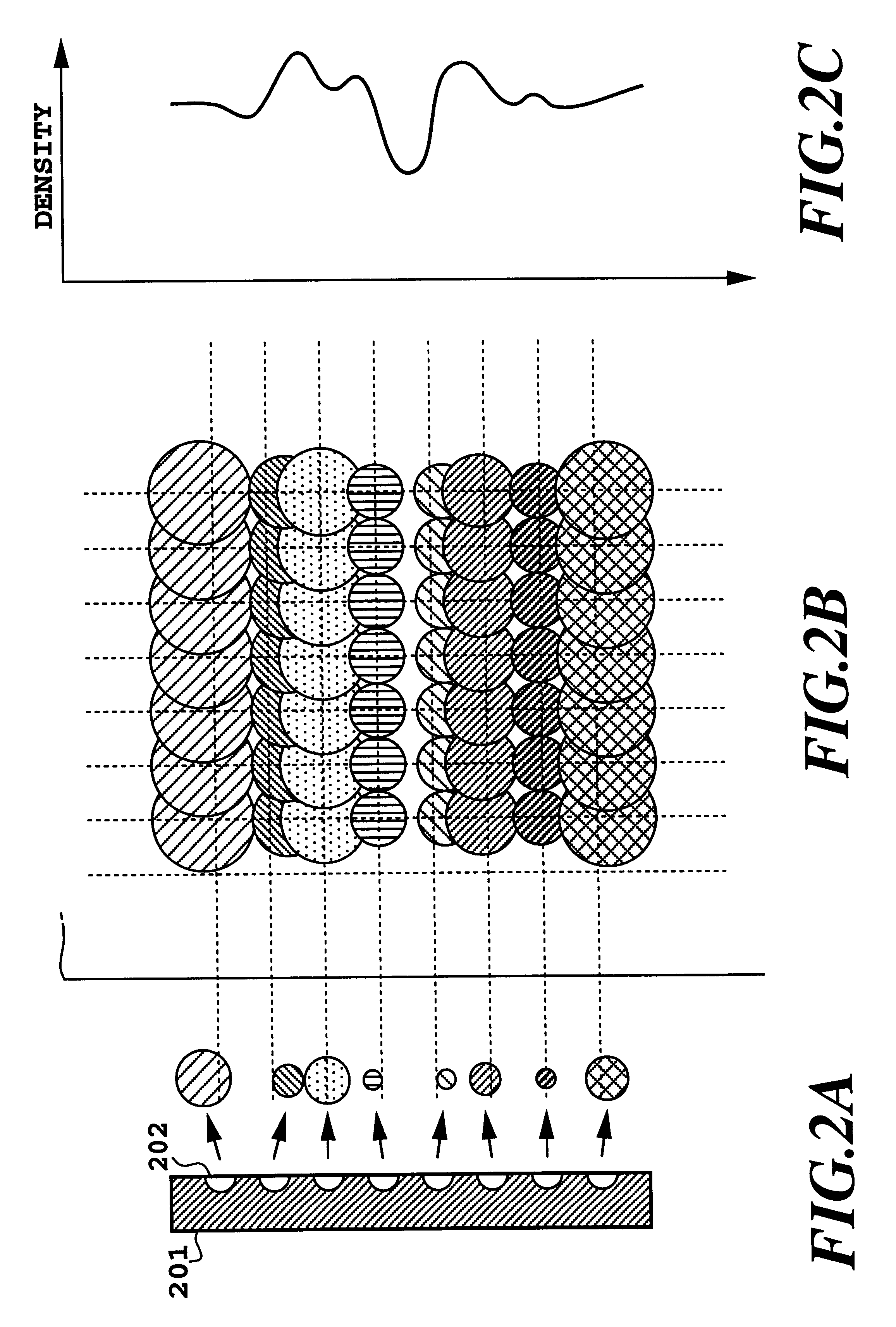

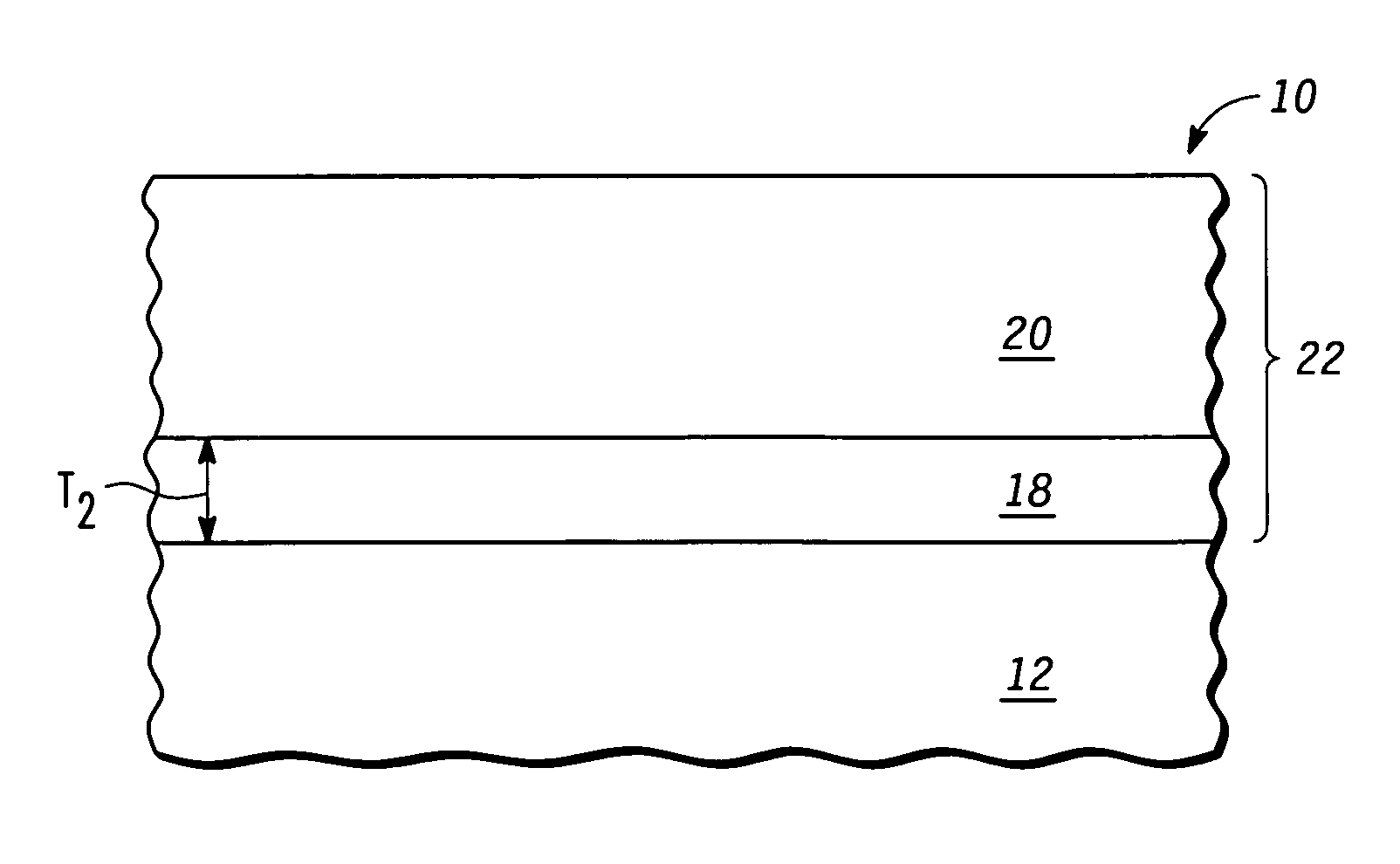

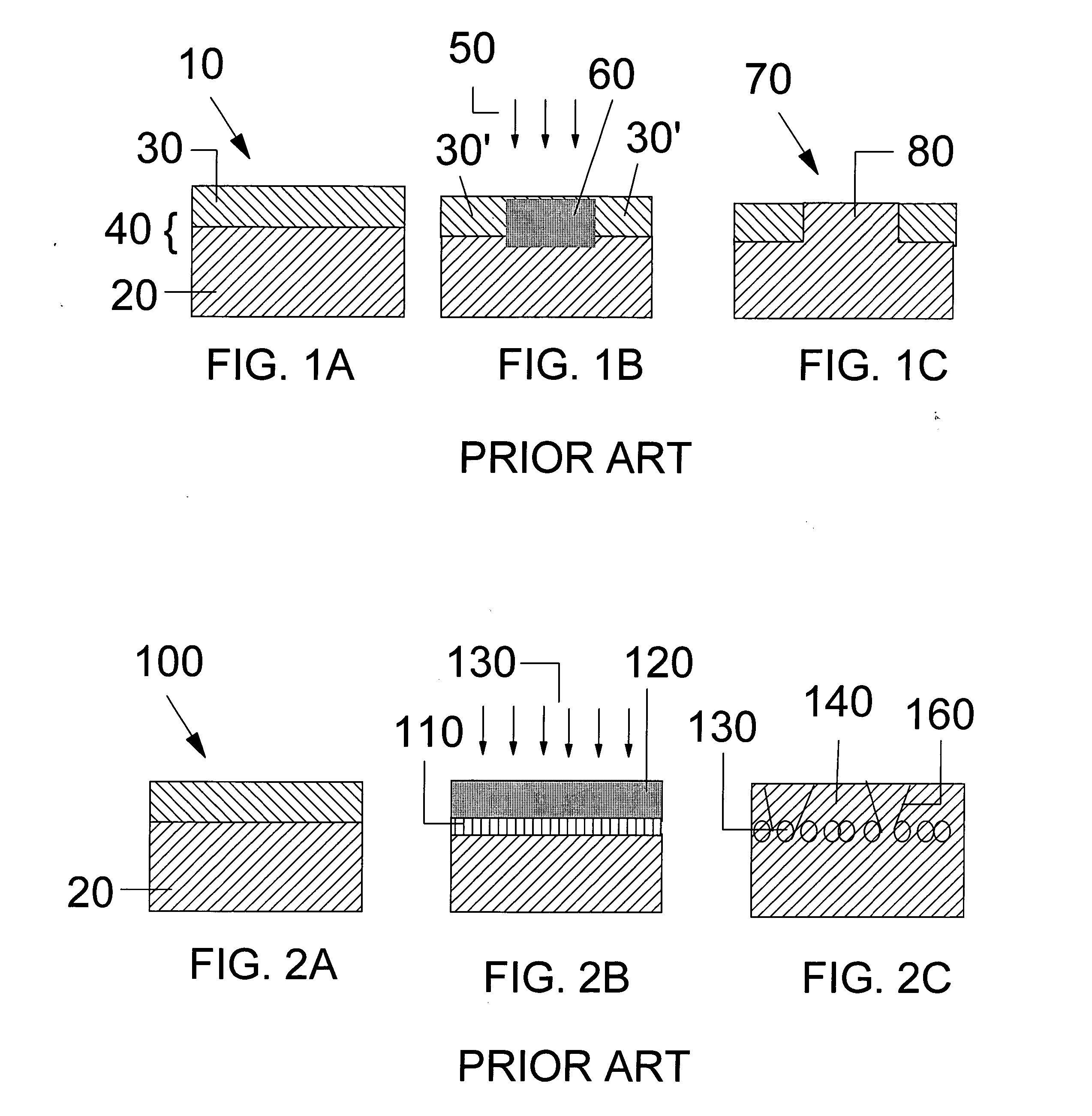

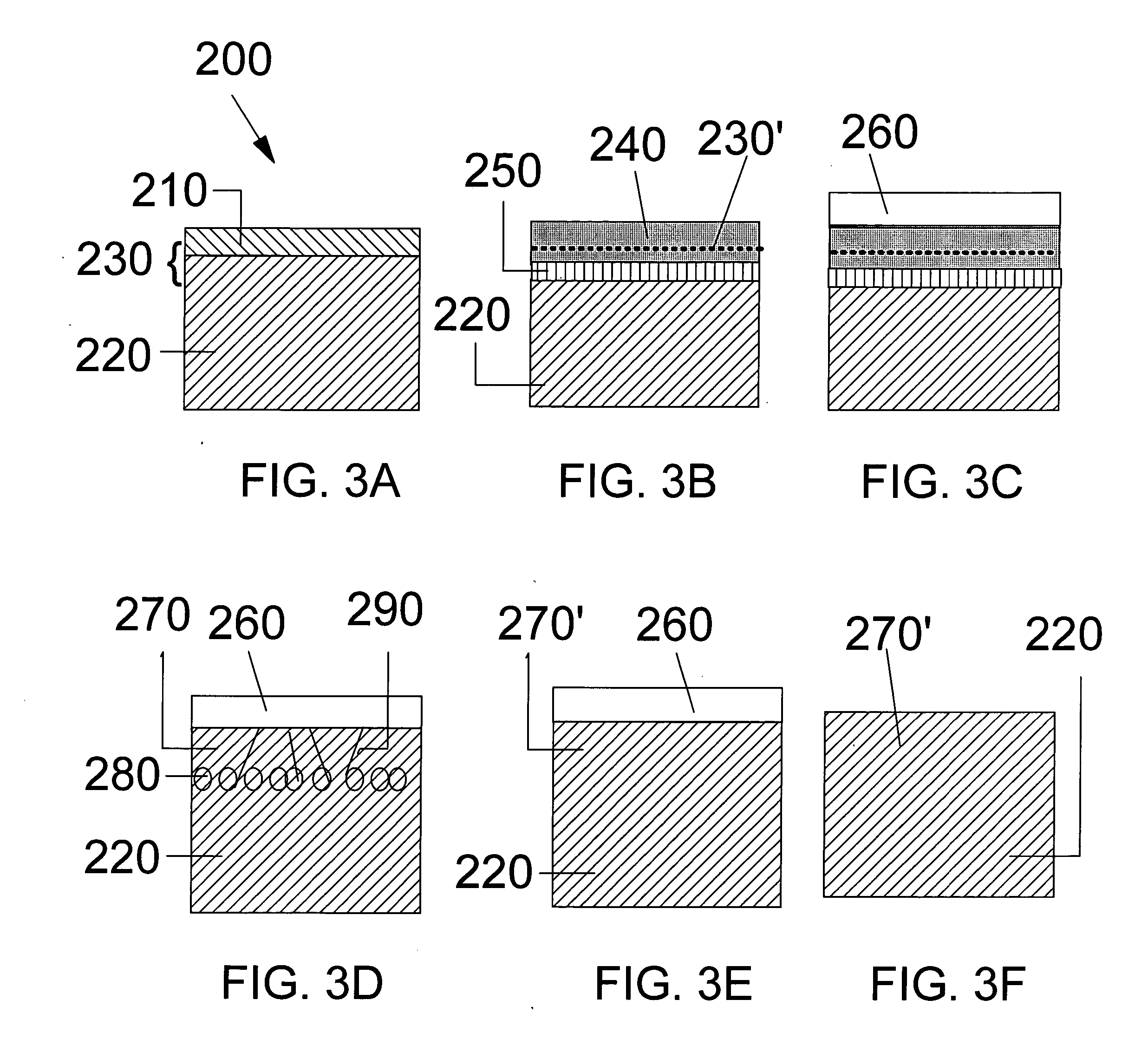

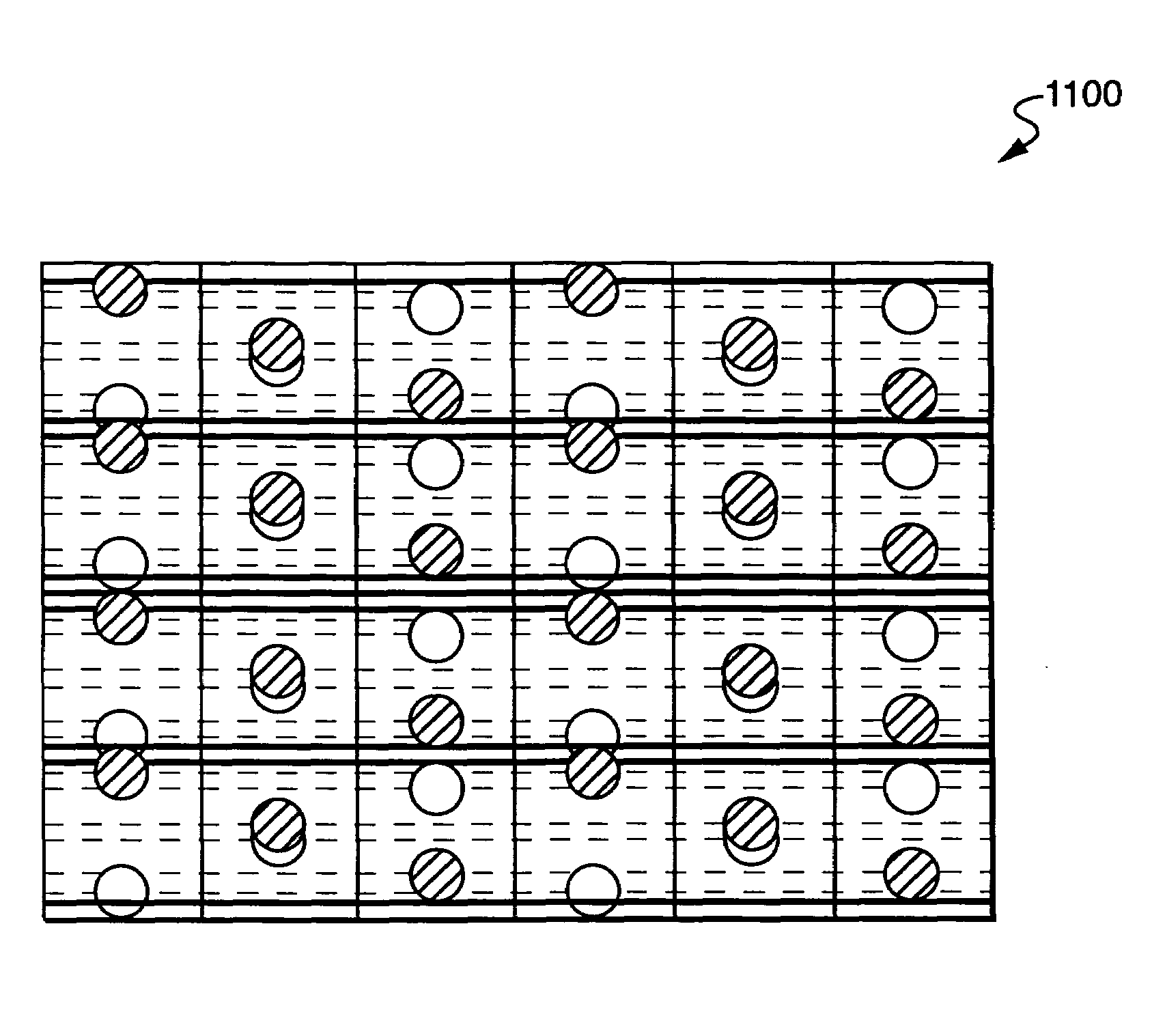

Method to arrange features on a substrate to replicate features having minimal dimensional variability

ActiveUS8349241B2Minimizing dimensional variabilityMinimizing thickness variationDecorative surface effectsNanoinformaticsFill factorVolumetric Mass Density

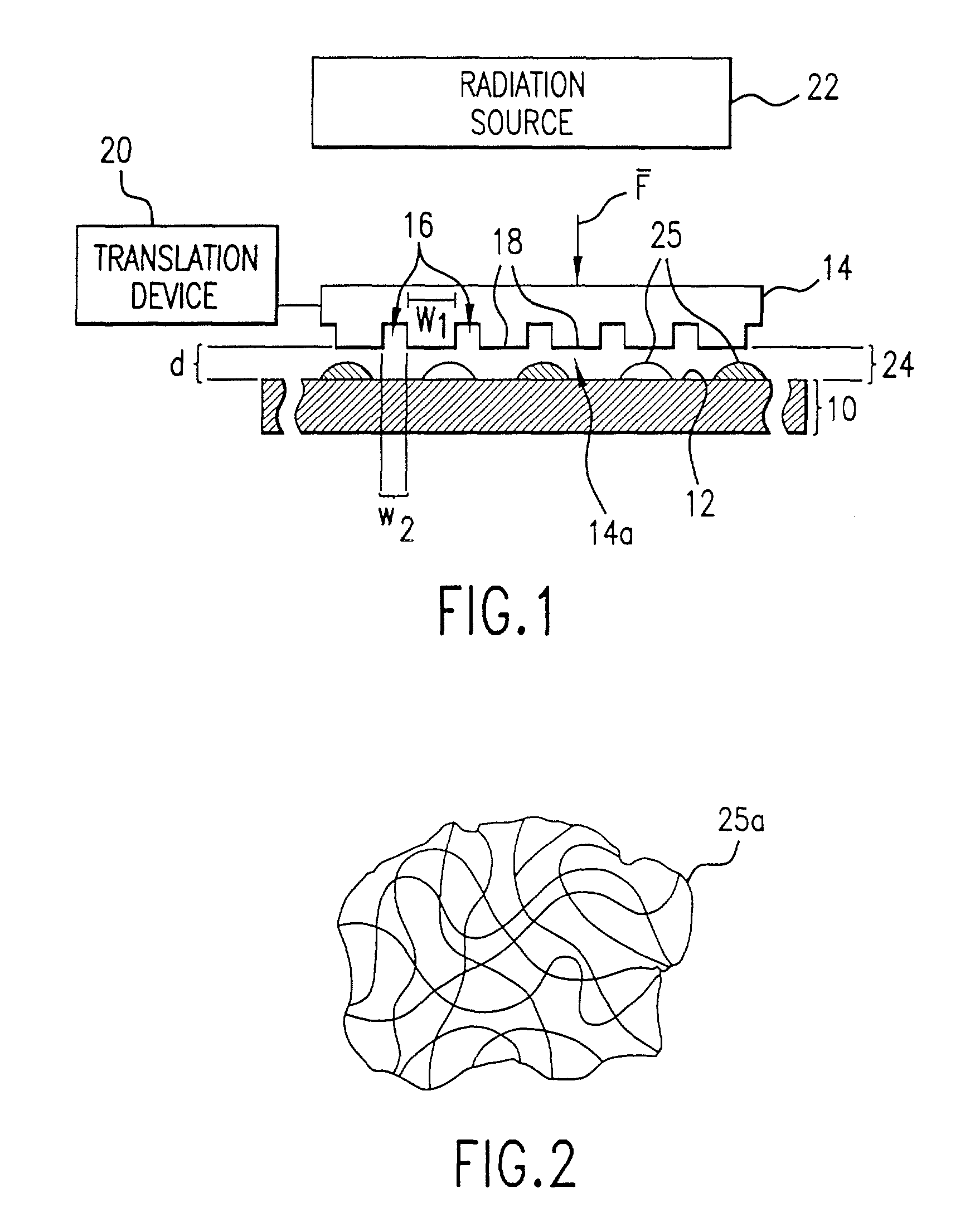

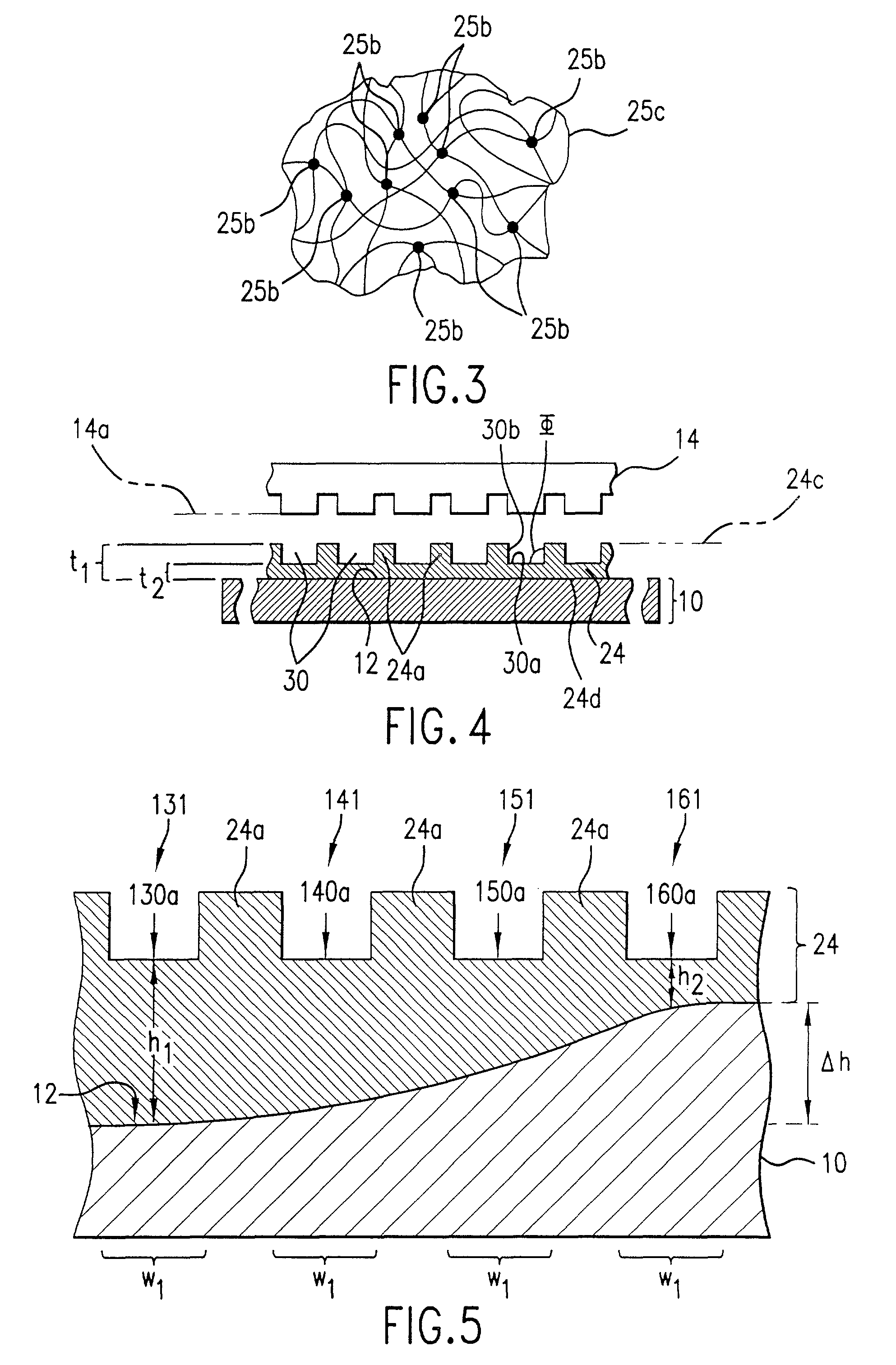

The present invention is directed to a method of and a mold for arranging features on a substrate to replicate the features with minimal dimensional variability. The method includes arranging features on a layer to minimize thickness variations in the layer that are attributable to density variations of the plurality of features on the layer. The features are transferred into an underlying substrate. It is believed that by forming the features so as to define a uniform fill factor in the layer, the thickness variations may be reduced, if not abrogated. To that end, one method in accordance with the present invention includes forming a flowable material on the substrate. Thereafter, a plurality of features is formed in a region of the flowable material. The plurality of features are arranged to provide a substantially uniform fill factor in the region.

Owner:MOLECULAR IMPRINTS

Ink jet printing apparatus and ink jet printing method for forming an image on a print medium

InactiveUS6874864B1Preventing Image Quality DeteriorationIncrease speedVisual representation by matrix printersOther printing apparatusImaging qualityVolumetric Mass Density

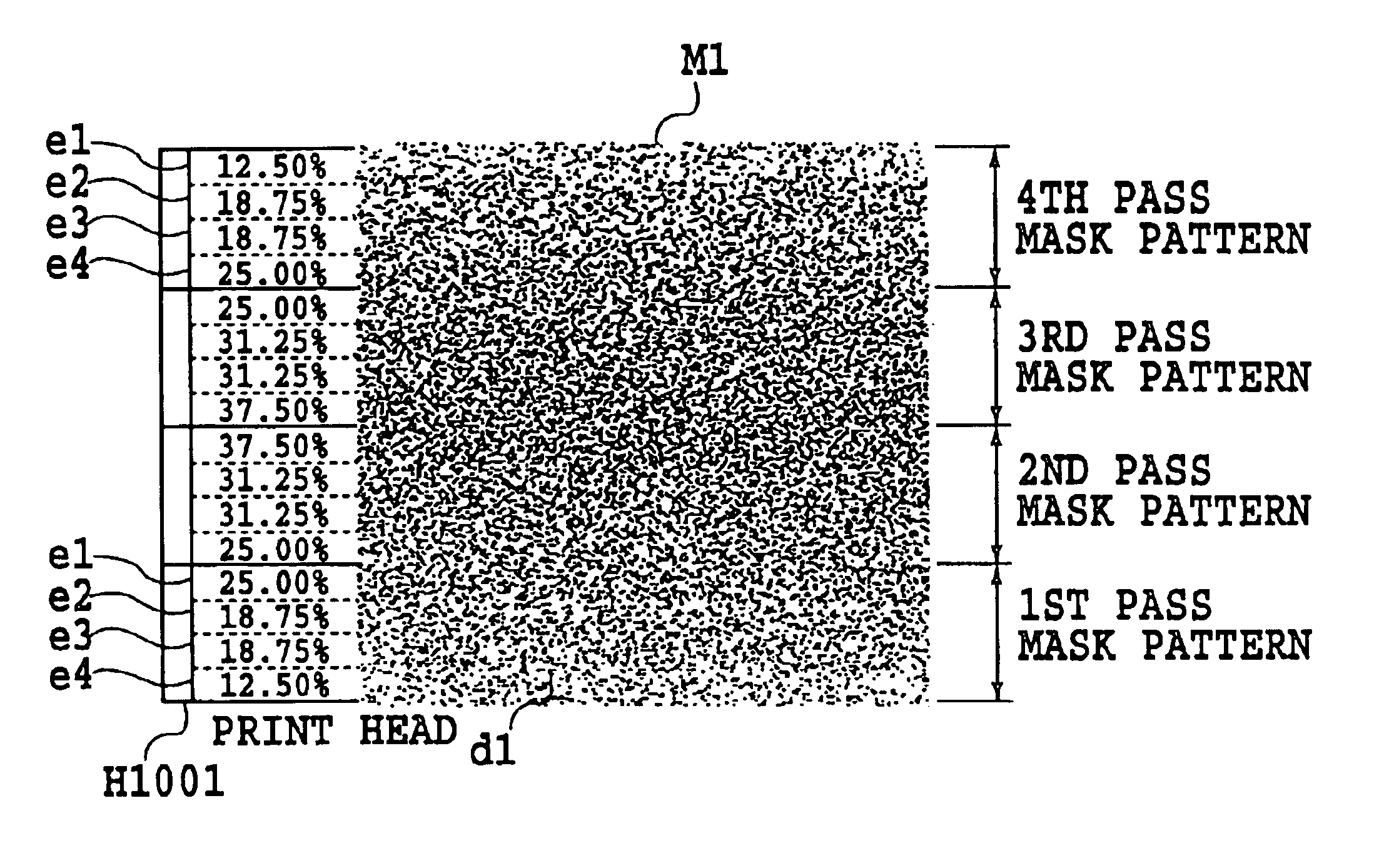

An apparatus and method are provided to enable high speed printing of an image with high resolution while suppressing degradation of image quality due to white stripes and density variations. In an ink jet printing apparatus using a multi-pass printing system, the same scan print area is divided at a predetermined pitch and the printing duties of the divided areas determined by the thinning out mask pattern are set to different values. In regard to the same scan print area formed by a plurality of the main scans, the divided areas corresponding to the ends of the print head have their printing duties set smaller than those of the divided areas on the inner side of the ends of the print head.

Owner:CANON KK

Adjustment method of dot printing positions and a printing apparatus

InactiveUS6532026B2Improve image qualityEasy to seeSpacing mechanismsOther printing apparatusPrinting registrationDensity change

In complementarily printing by bi-directional scannings of a head or by a plurality of print heads, first patterns and second patterns including reference dots for example, dots formed by a forward scan of the bi-directional scannings or by one of the plurality of print heads and dots each having the different direction of shifting of relative printing positions to the reference dots are printed in corresponding to the plurality of shifting amounts. These first and second patterns have the similar characteristics of a change in density. The difference is only that their characteristics in density change are inverted according to the direction of shifting. The intersection point of these two characteristics in density change is obtained as a position for adjustment where dot-formed positions match. This makes it easy to perform printing registration in a printing apparatus in the case of printing by a forward and reverse scan of a printing head or in the case of printing by means of a plurality of printing heads. In this case, operations by a user etc. are also unnecessary and are easily performed.

Owner:CANON KK

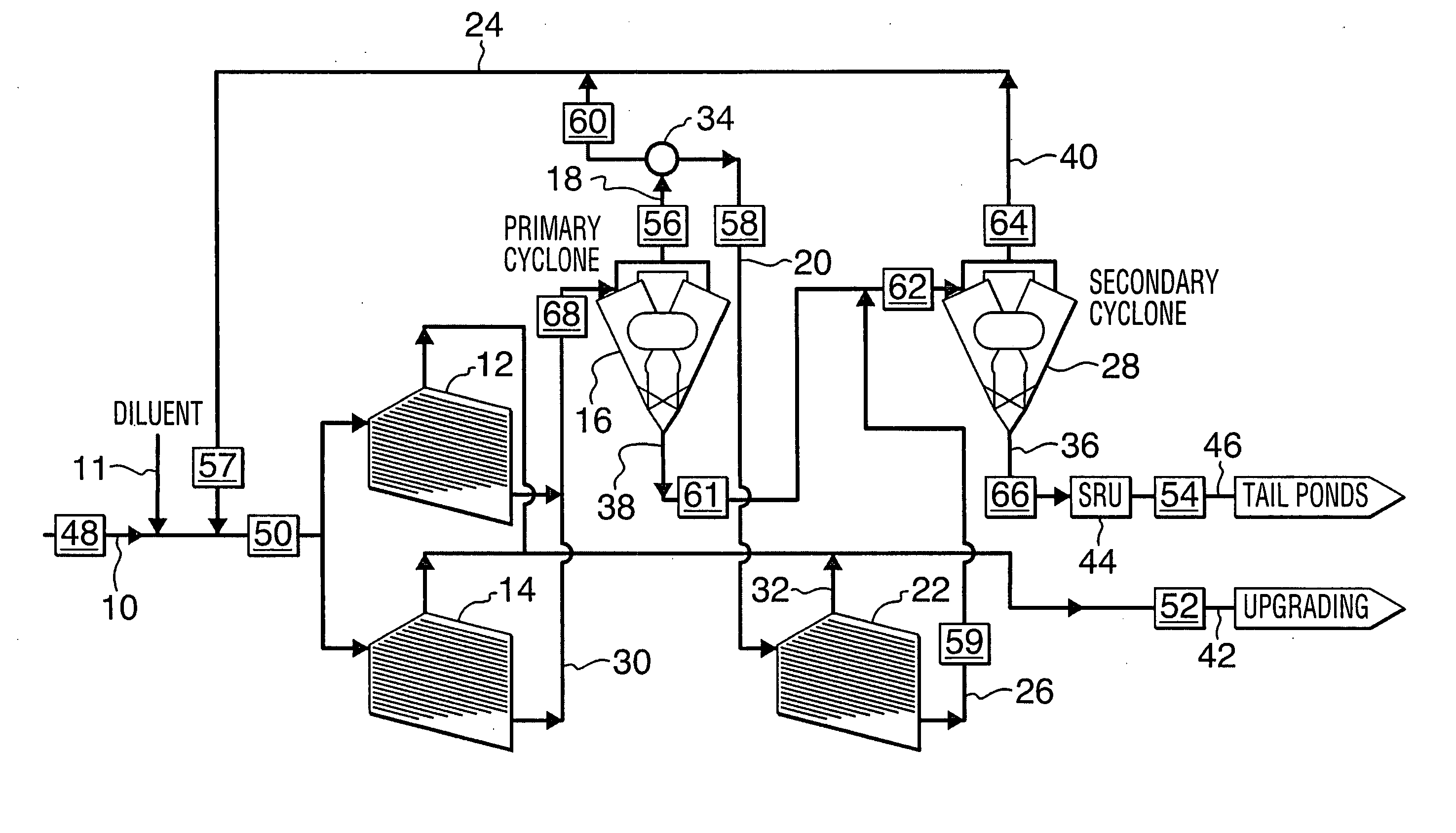

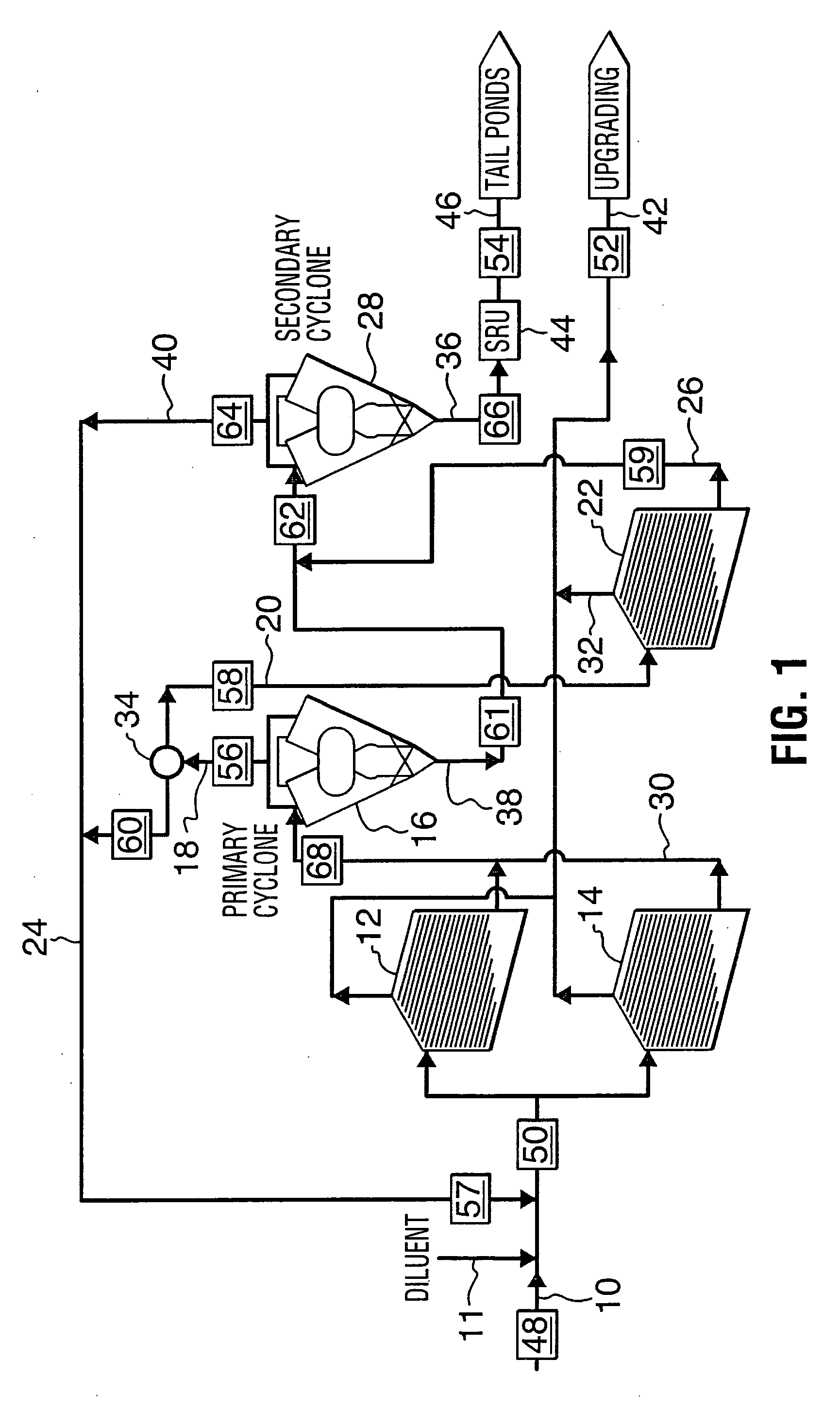

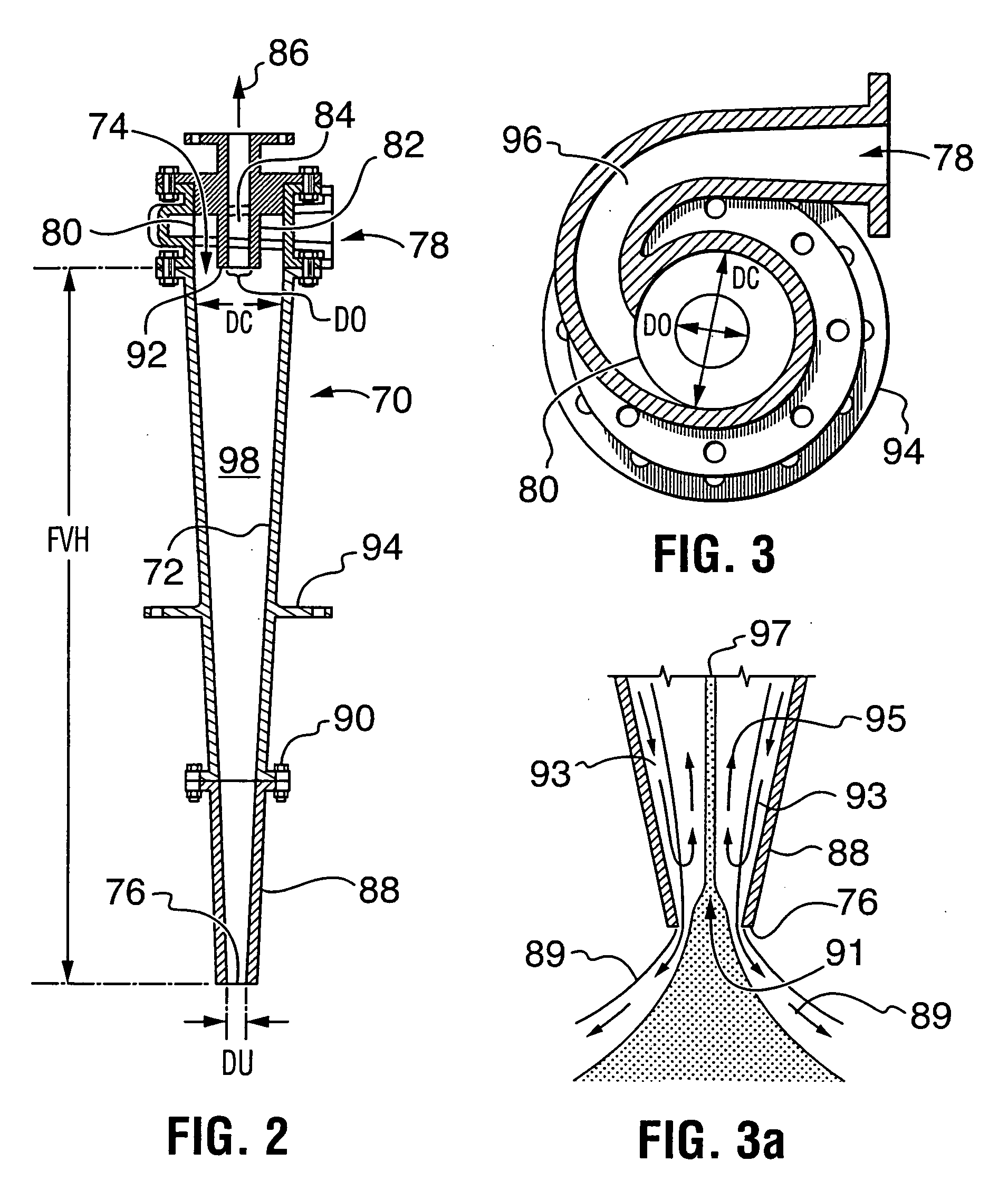

Bituminous froth hydrocarbon cyclone

InactiveUS20060138055A1Poor separationEasy to separateReversed direction vortexCentrifugal force sediment separationCycloneHydrocotyle bowlesioides

An apparatus to perform a process to remove water and minerals from a bitumen froth output of a oil sands hot water extraction process comprises: (i) a cyclone body having an elongated conical inner surface defining a cyclone cavity extending from an upper inlet region with a diameter DC to a lower apex outlet with a diameter DU; (ii) an inlet means forming an inlet channel extending into the upper inlet region of the cyclone cavity; and (iii) a vortex finder forming an overflow outlet of a diameter (DO) extending into the upper inlet region of the cyclone cavity toward the lower apex outlet and having a lower end extending an excursion distance below the inlet channel; wherein a fluid composition entering the inlet channel into the cyclone cavity is urged by force of gravity and velocity pressure downward toward the lower apex and variations in density of the constituent components of the fluid composition cause the lighter component materials to be directed toward the overflow outlet of the vortex finder.

Owner:GARNER WILLIAM NICHOLAS +2

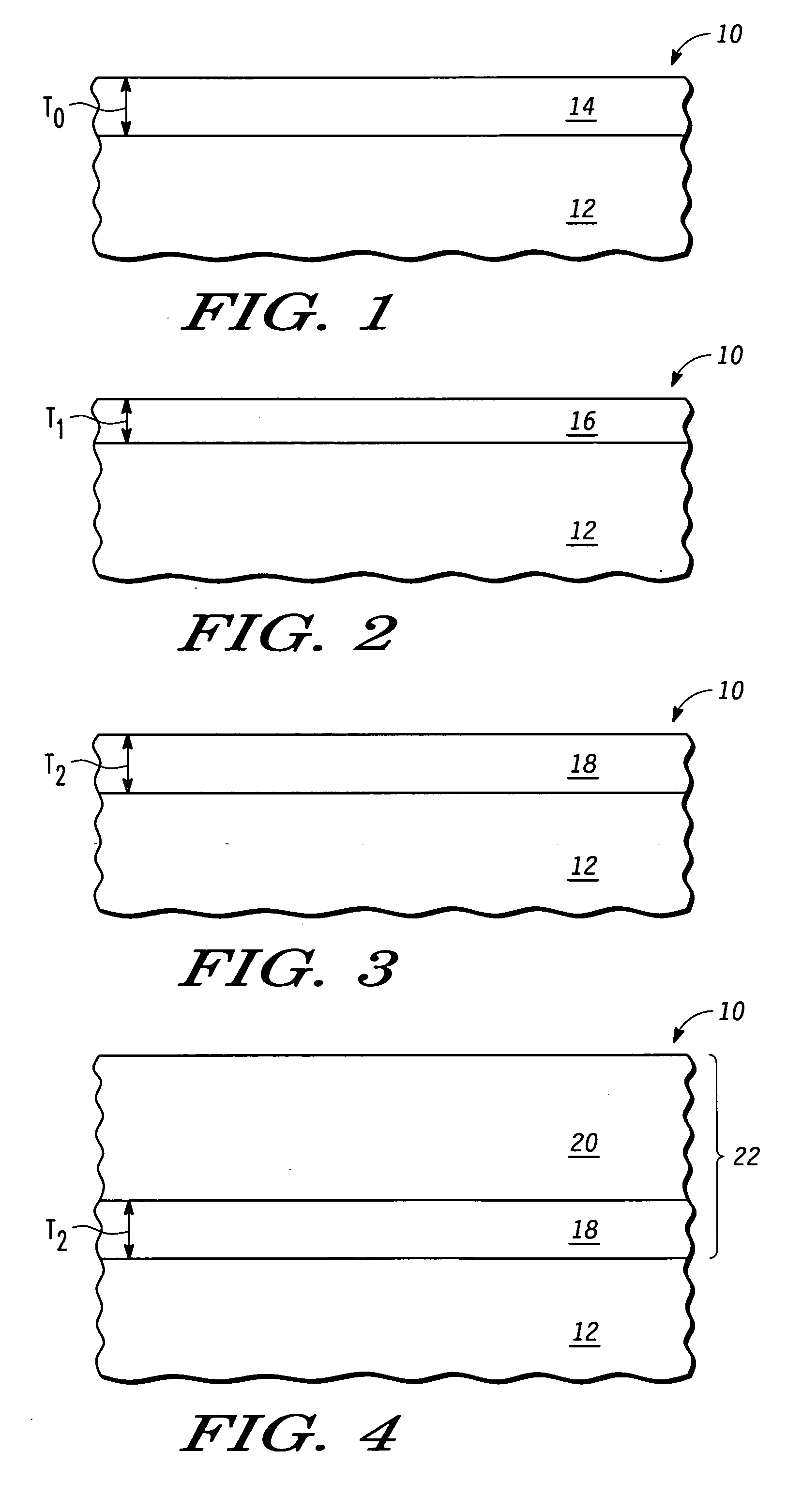

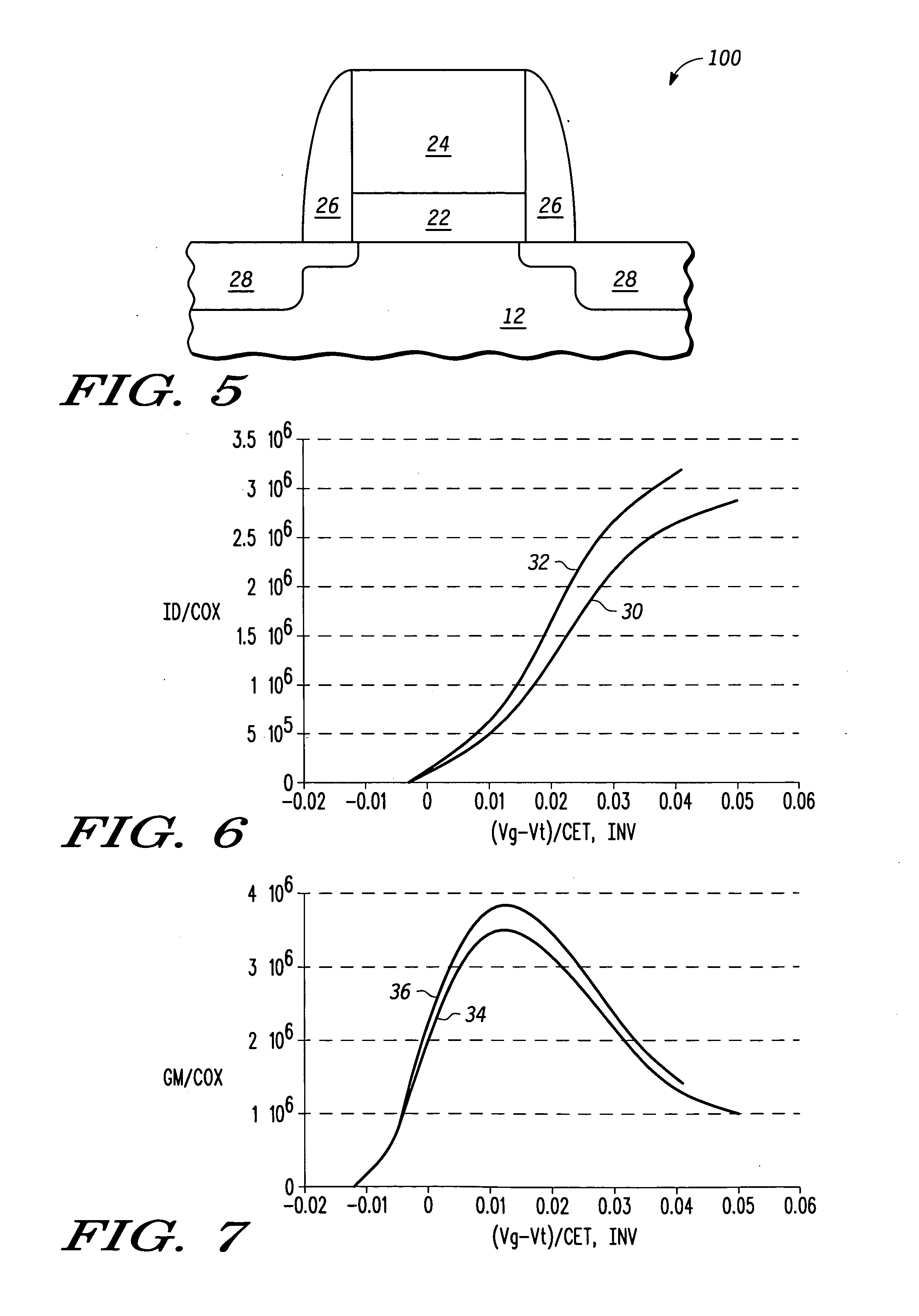

High quality thin dielectric layer and method of making same

ActiveUS20050245019A1Semiconductor/solid-state device manufacturingSemiconductor devicesOptoelectronicsDielectric layer

A high quality thin dielectric layer is achieved by annealing a substrate and base oxide layer at a first temperature in a first ambient and subsequently annealing the substrate and base oxide layer at a second temperature in a second ambient, the base oxide layer overlying a top surface of the substrate. Prior to the first anneal, the base oxide layer has an initial thickness and density. The first anneal causes a first density and thickness change in the base oxide layer from the initial thickness and density to a first thickness and density, with no incorporation of a component of the ambient within the base oxide layer. The first thickness is less than the initial thickness and the first density is greater than the initial density. The second anneal causes a second density and thickness change in the base oxide layer from the first thickness and density to a second thickness and density. The second thickness is larger than the first thickness and the second density is on the order of the greater than or equal to the first density.

Owner:NXP USA INC

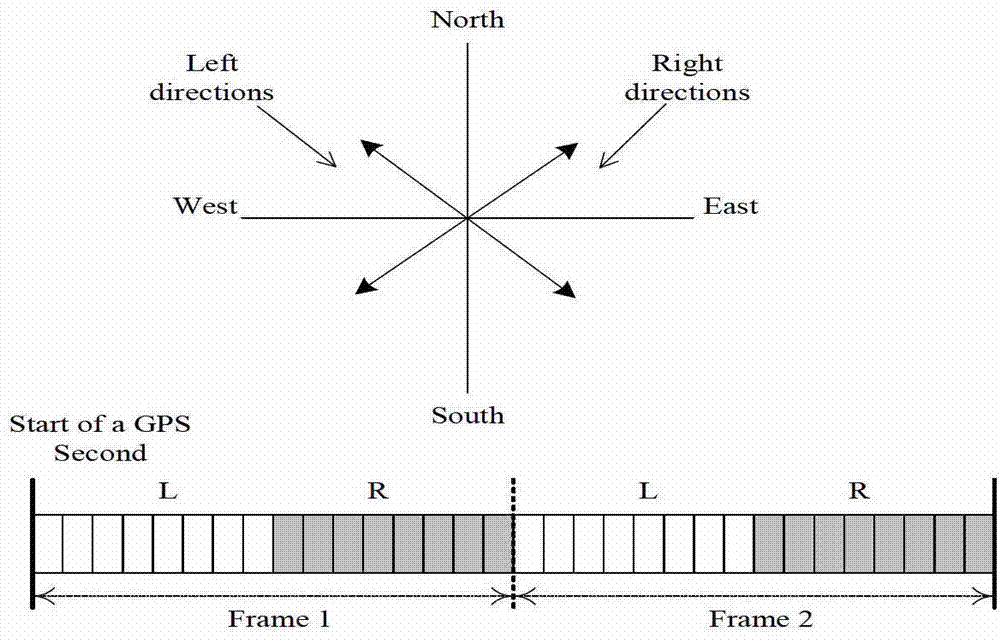

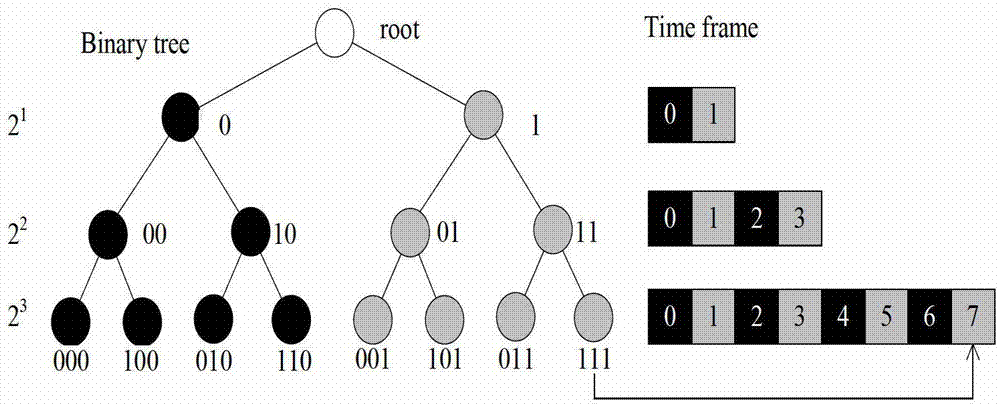

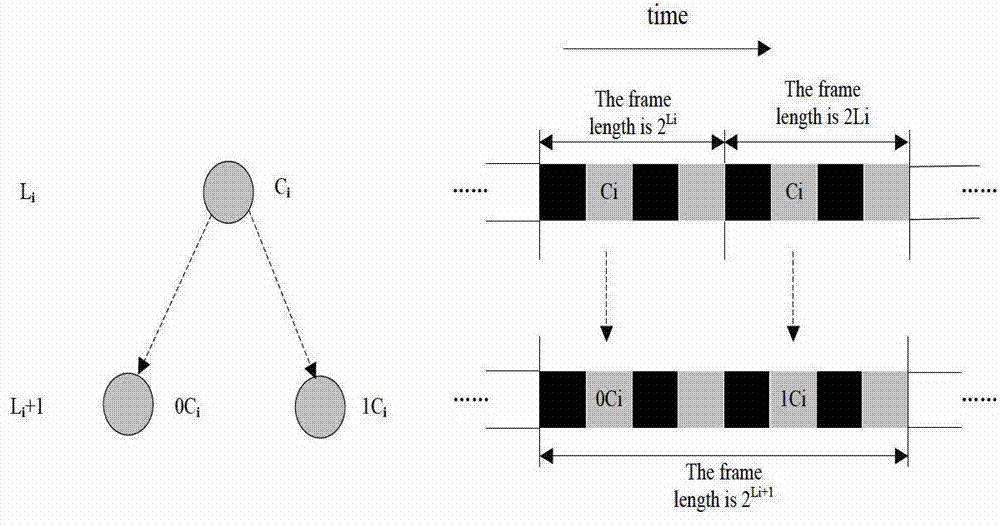

Vehicle-mounted ad hoc network self-adaptive time slot distributing method based on a time division multiple address (TDMA)

InactiveCN103096327AReduce access conflictsReduce the chance of merge conflictsRadio transmission for post communicationNetwork planningTime division multiple accessCode division multiple access

The invention relates to a vehicle-mounted ad hoc network self-adaptive time slot distributing method based on a time division multiple address (TDMA), the vehicle-mounted ad hoc network self-adaptive time slot distributing method divides a time frame into a left time slot set and a right time slot set, nodes are divided into a left node set and a right node set based on the moving direction of the nodes, and the nodes in the left / right node sets choose competition time slots in the left / right time slot set based on the current geographical location information and according to certain rules. The vehicle-mounted ad hoc network self-adaptive time slot distributing method based on the TDMA reduces the ratio of a connect-in confliction and an amalgamation confliction occurred by the nodes to a large degree; and based on density changes of the nodes sensed by the nodes, the lengths of frames are dynamically adjusted, so that the demand that the nodes swiftly connect-in channels is satisfied; low time delay of the vehicle-mounted ad hoc network self-adaptive time slot distributing method based on the TDMA is authenticated by both theoretical analysis and simulating experiments. Compared with the prior art, the vehicle-mounted ad hoc network self-adaptive time slot distributing method based on the TDMA has the advantages of having less quantities of confliction nodes, higher utilizing ratio of the channels and good expansibility.

Owner:HENAN UNIVERSITY OF TECHNOLOGY +1

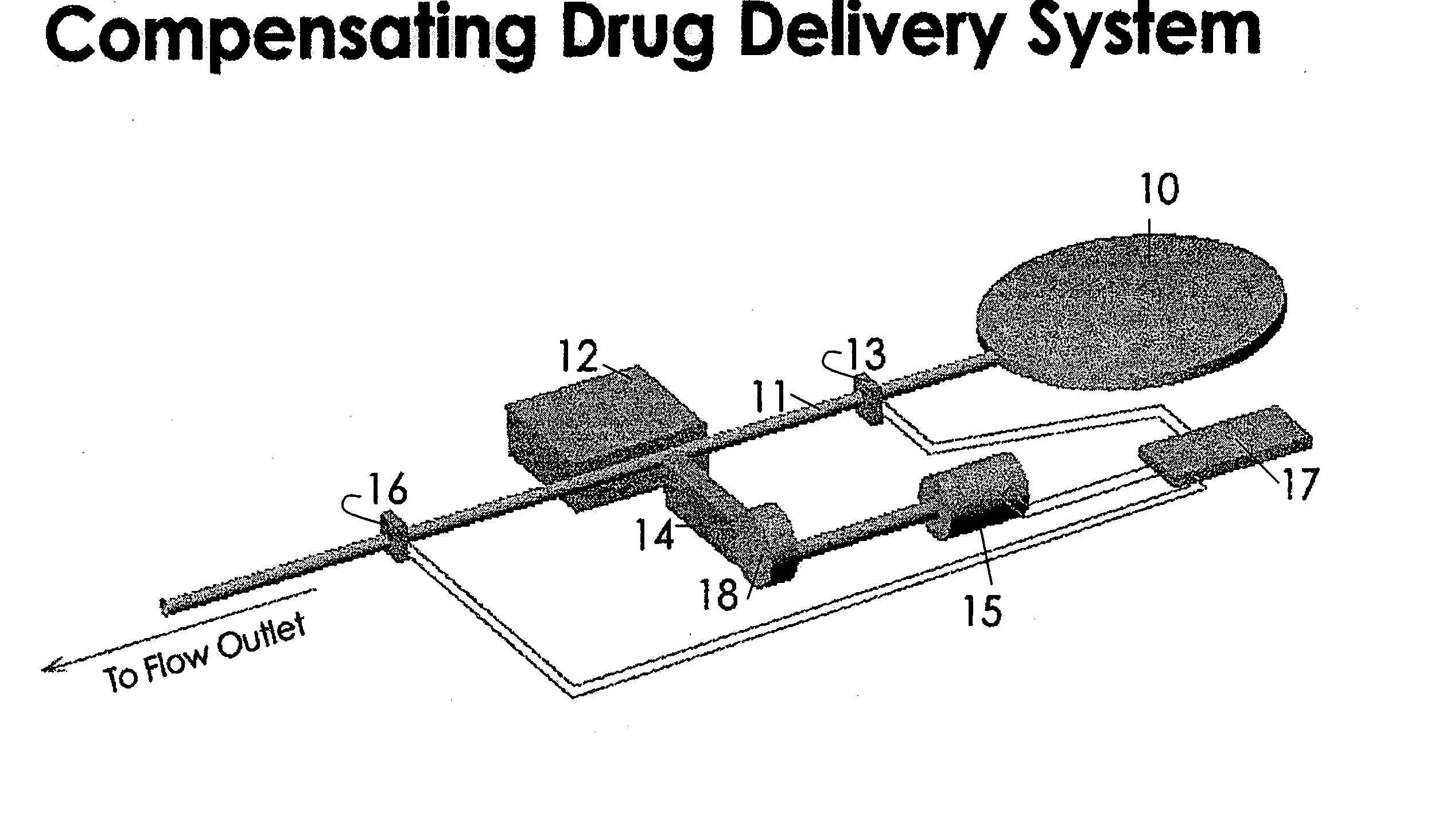

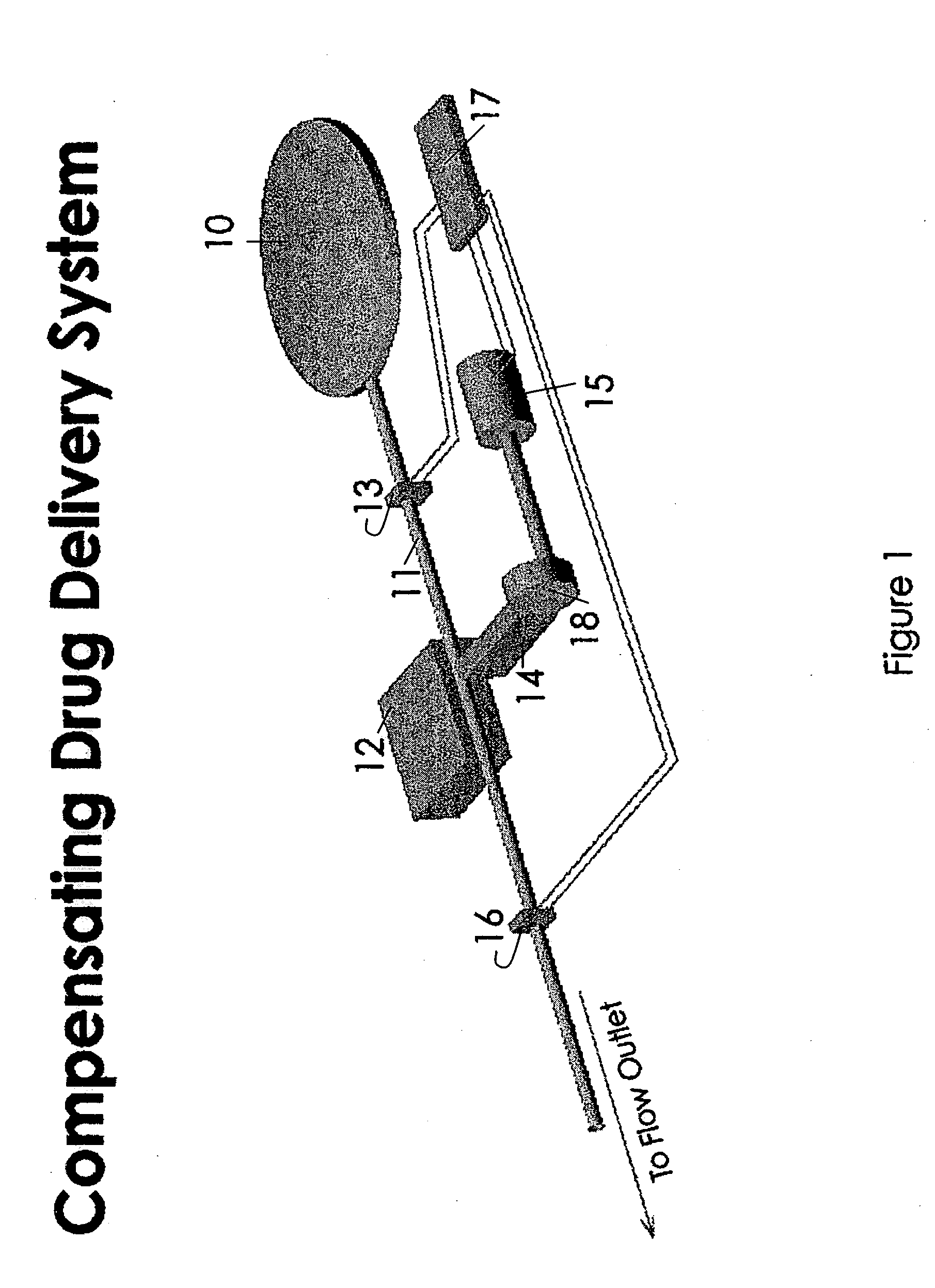

Liquid metering system

InactiveUS20050005710A1Volume variation compensation/correction apparatusIndirect mass flowmetersThermal energyEngineering

Systems and methods for measuring the flow of a fluid along a passageway are disclosed. A heat source applies thermal energy to a portion of the fluid thereby elevating its temperature and decreasing its density. An optical sensing means measures a change in a property of illumination directed through the passageway caused by the change in the density of the heated portion of fluid. The time required for the heated portion of the liquid to move from the point of application of thermal energy to the point of optical sensing is measured. This measured time, and the distance of separation of the source of heat and the optical sensor permits calculation of the fluid velocity in the passageway.

Owner:THERAFUSE

Dispensing stitching method and embroidery method for embroidery

ActiveCN101824714ANo "spot" phenomenonImprove visual effectsEmbroidering machines apparatusHair streamsEngineering

The invention relates to a needle dispensing method and an embroidery method for embroidery. In the embroidery, the stitch length between two needle eyes is twice more than the diameter of the stitching thread and less than or equal to ten times of the diameter of the stitching thread, so that the stitches of the embroidery thread is of a spotted shape or a short-line shape on the front face of the embroidery fabric; and the stitches of the spotted shape or the short-line shape form embroidery patterns in at least one of four organizational forms, i.e. separation, overlapping, connection and crossing, and the embroidery patterns are arranged in a density-changing way on the plane of the embroidery substrate. The invention overcomes traditional prejudices and creates a novel embroidery stitching method, which shows light and shadow changes with discrete spots in the embroidery picture, and is particularly suitable for sketch representation, in particular to the texture of toner particles in toner sketches, the texture of mist obscuration in ink paintings, drag marks in calligraphy and fine parts in various embroidery pictures such as the eyes and hair of human beings and animals, branches, rods and the like. When in use, the invention can bring more transparency and three-dimensional feeling into the embroidery work, so that the embroidery work is more delicate with nimbus.

Owner:邹英姿

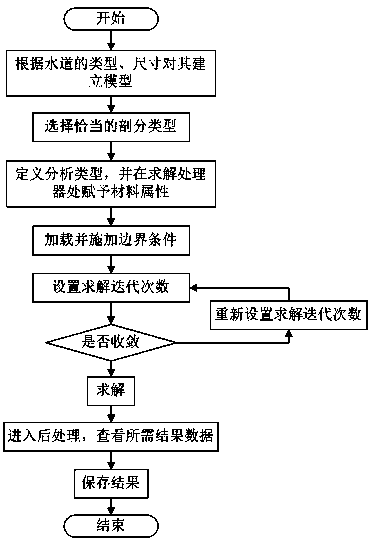

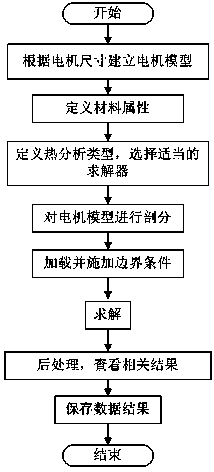

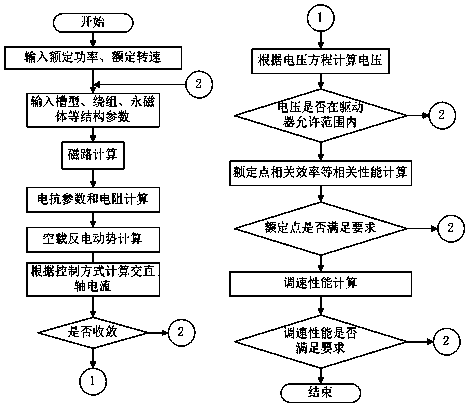

Optimization design method for high-efficiency synchronous motor of new energy automobile

InactiveCN104319969AElectronic commutation motor controlVector control systemsSynchronous motorNew energy

The invention relates to an optimization design method for a high-efficiency synchronous motor of a new energy automobile. The method includes the steps that an iron loss computation model is established for the permanent magnet synchronous motor, and magnetic density changes are researched, so that magnetic hysteresis losses and no-load iron losses corresponding to different sub-harmonic magnetic fields are obtained; theoretical analysis and finite element solving are performed on load stray losses of the permanent magnet synchronous motor of the automobile in the aspects of a stator, a rotor and a permanent magnet, and permanent magnet eddy-current losses are restrained; a water cooling system of the motor is analyzed, influences on the high-efficiency range and weak magnetic performance by parameter matching are analyzed, the rotor structure form, polar trough matching and no-load counter electromotive force of the motor sample are designed, and the motor sample is tested. Through analyzing the magnetic field features, the magnetic hysteresis losses and eddy-current losses, the degree and distribution of rotor losses and the permanent magnetic eddy-current losses are accurately computed under matching between different rotor structures and polar troughs, and therefore effective measures for restraining the rotor losses and permanent magnetic eddy-current losses are found.

Owner:芜湖杰诺瑞汽车电器系统有限公司

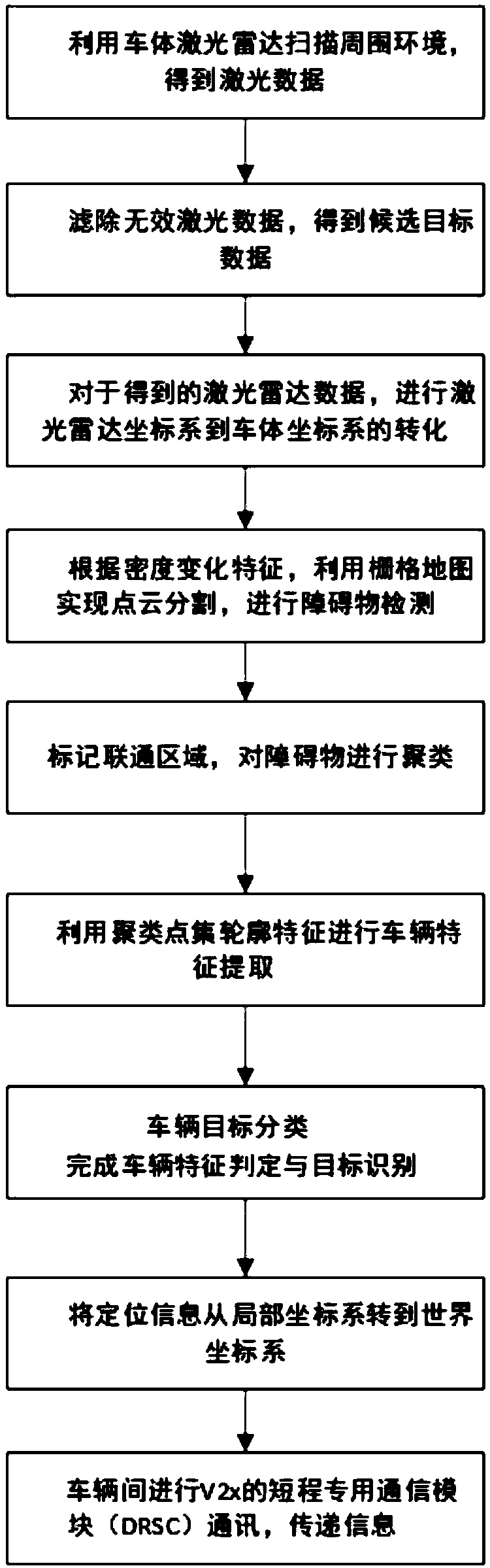

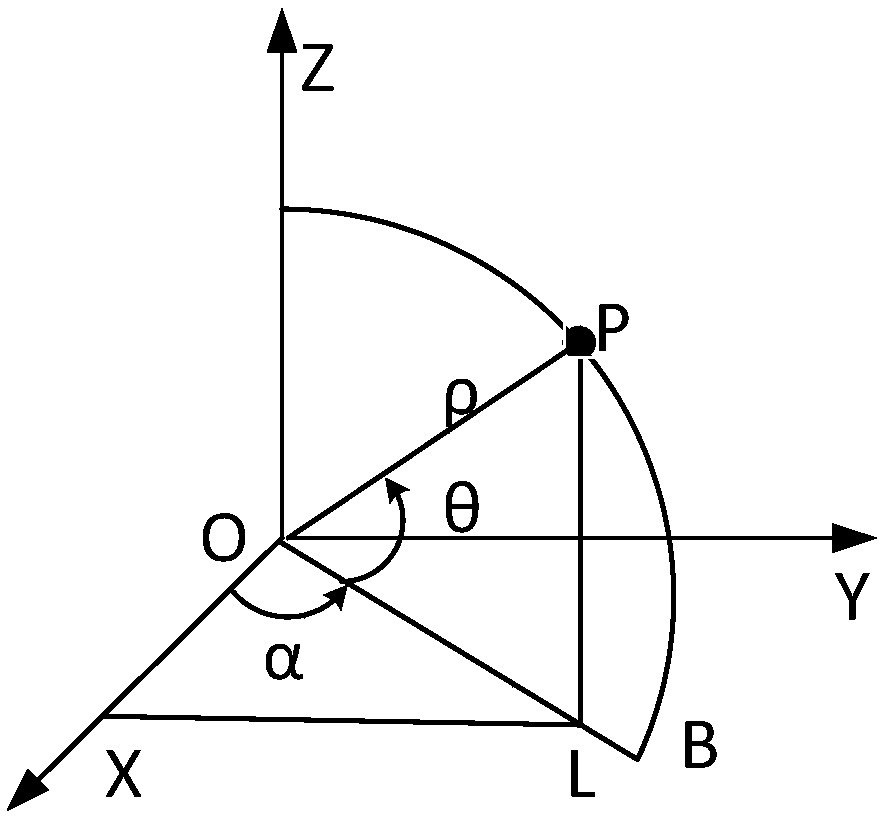

Network-connected vehicle positioning method based on 3D laser radar and V2X

InactiveCN108983248AAvoid crowdingAvoid cloggingElectromagnetic wave reradiationRadarComputer module

The invention discloses a network-connected vehicle positioning method based on a 3D laser radar and V2X. The method comprises the following steps of using a laser radar installed on a network-connected vehicle to scan an environment around a network-connected vehicle so as to obtain radar data; preprocessing the radar data, acquiring preprocessed laser point cloud data, converting the point clouddata to a network-connected vehicle coordinate system, and then, according to the density change characteristic of a radar point in the point cloud data, using a raster map to carry out point cloud segmentation so as to realize the separation of a pavement and barriers; carrying out the clustering of the barriers, acquiring a radar point set corresponding to each barrier, and then obtaining the contour of the barrier, then carrying out linear fitting to obtain the shape of the barrier, and combining the size of the barrier to realize barrier identification; and finally, realizing the exchangeof barrier information among other network-connected vehicles through a V2X module. In the invention, a problem that an existing vehicle positioning method has low accuracy and poor reliability is solved, and simultaneously problems that a requirement to the speed of a mobile communication network is high and cost is high are alleviated.

Owner:CHANGAN UNIV

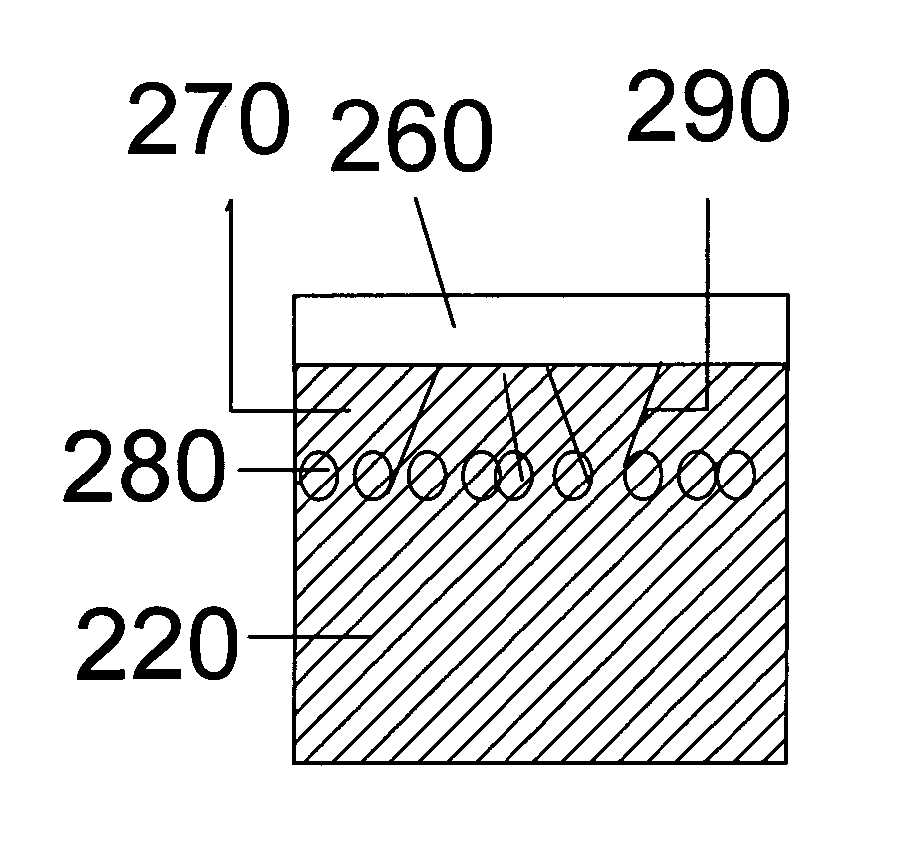

Method for fabricating low-defect-density changed orientation Si

InactiveUS20060154429A1Solve the small densitySemiconductor/solid-state device manufacturingSemiconductor materialsCrystal orientation

The present invention provides a method for forming low-defect density changed-orientation Si by amorphization / templated recrystallization (ATR) processes in which regions of Si having a first crystal orientation are amorphized by ion implantation and then recrystallized into the orientation of a template layer having a different orientation. More generally, the invention relates to the high temperature annealing conditions needed to eliminate the defects remaining in Si-containing single crystal semiconductor materials formed by ion-implant-induced amorphization and templated recrystallization from a layer whose orientation may be the same or different from the amorphous layer's original orientation. The key component of the inventive method is a thermal treatment for minutes to hours in the the temperature range 1250-1330° C. to remove the defects remaining after the initial recrystallization anneal. The invention also provides a low-defect density changed-orientation Si formed by ATR for use in hybrid orientation substrates.

Owner:GLOBALFOUNDRIES INC

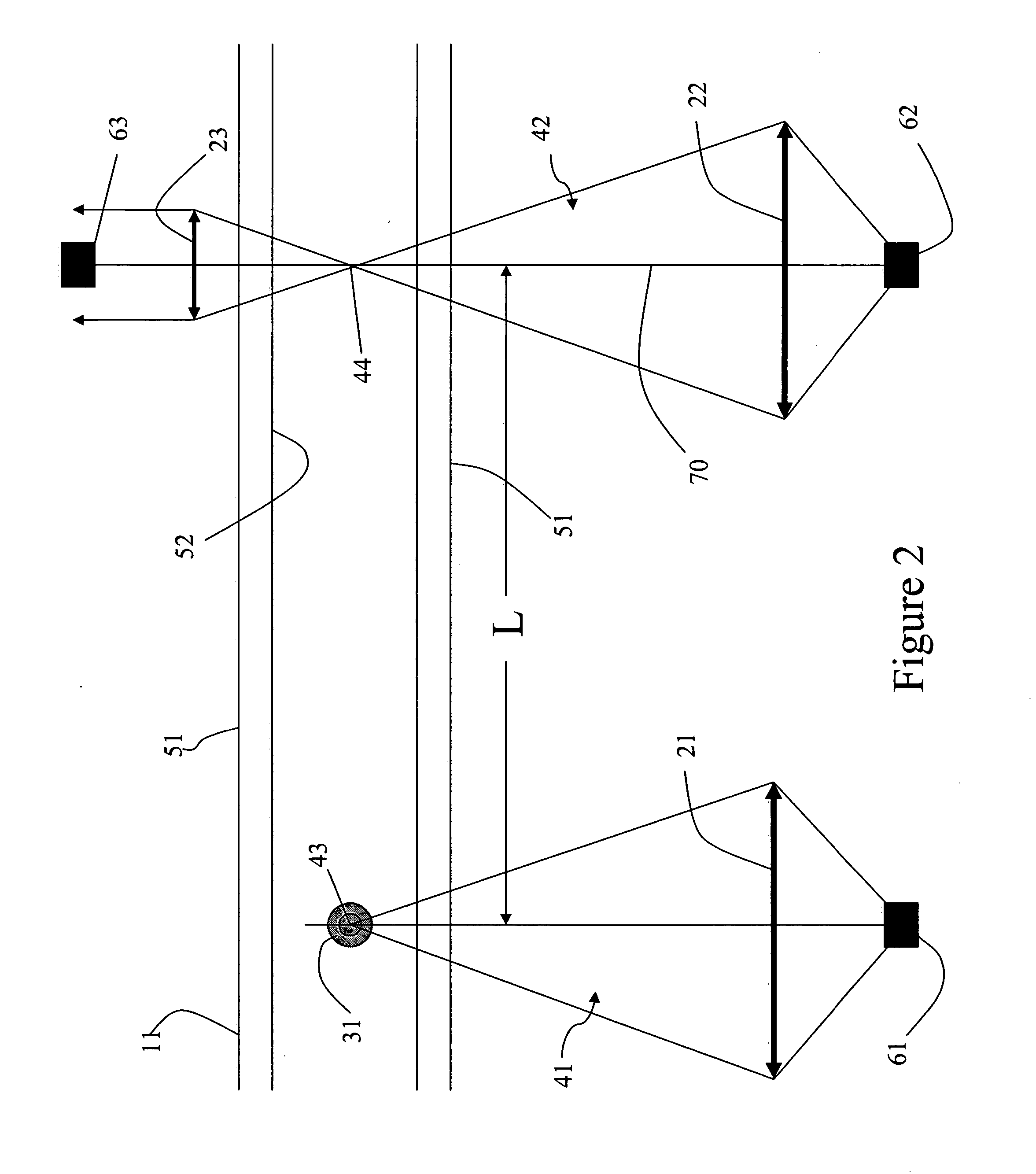

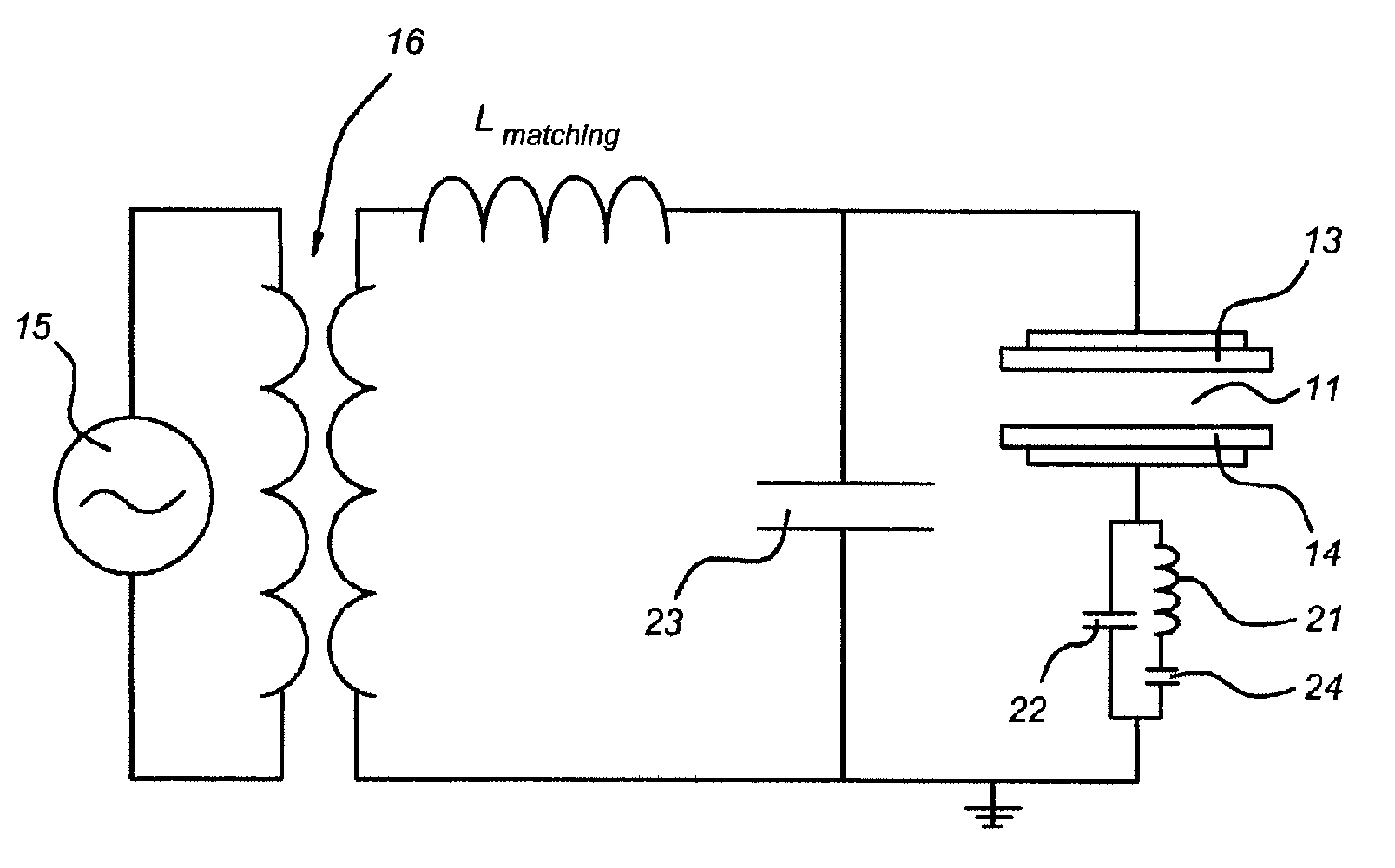

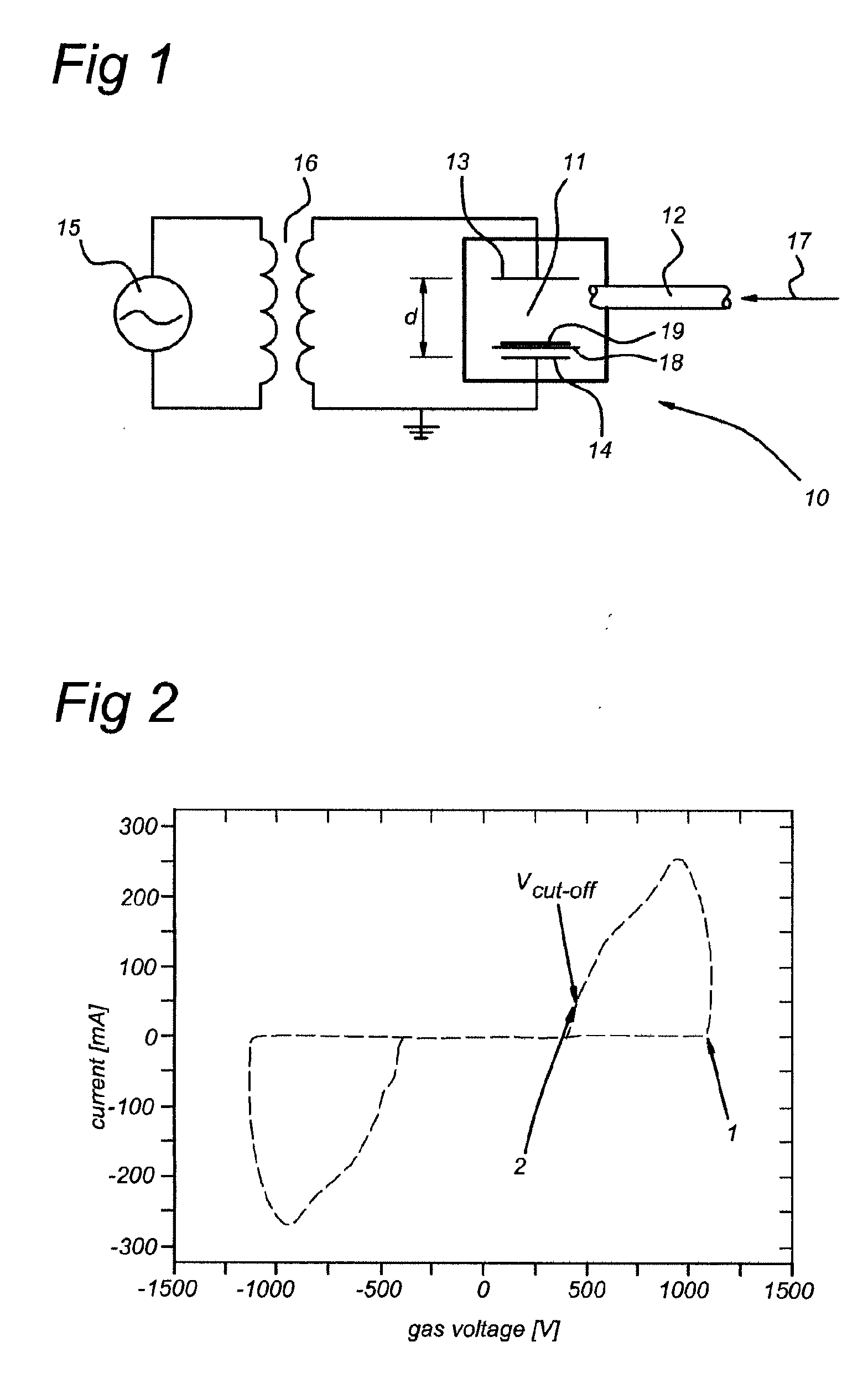

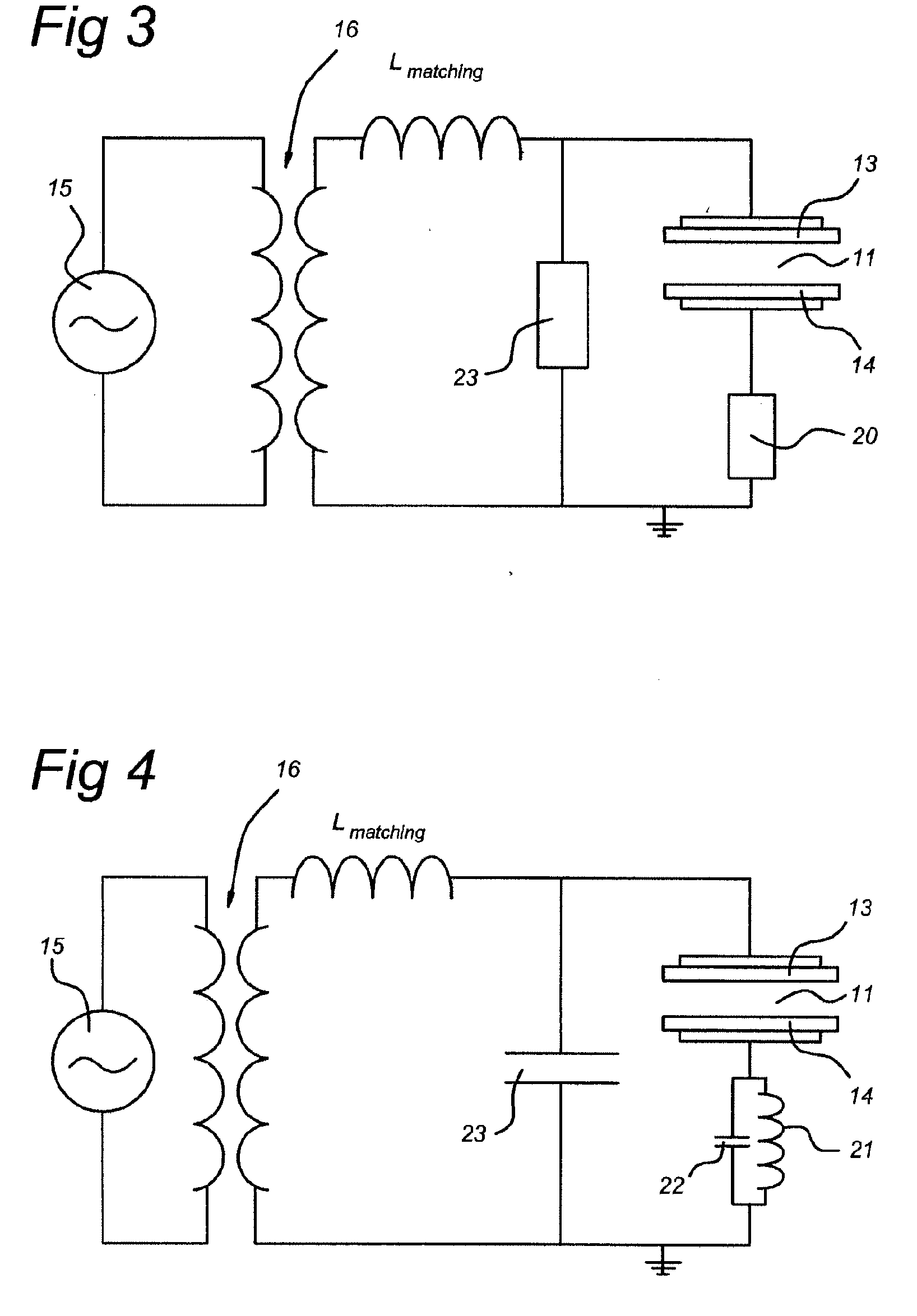

Method and Arrangement for Generating and Controlling a Discharge Plasma

InactiveUS20080317974A1Improve controllabilityLower ratioElectric discharge tubesElectric arc lampsVolumetric Mass DensityLocal current

Method and arrangement for controlling a discharge plasma in a discharge space (11) having at least two spaced electrodes (13, 14). A gas or gas mixture is introduced in the discharge space (11), and a power supply (15) for energizing the electrodes (13, 14) is provided for applying an AC plasma energizing voltage to the electrodes (13, 14). At least one current pulse is generated and causes a plasma current and a displacement current. Means for controlling the plasma are provided and arranged to apply a displacement current rate of change for controlling local current density variations associated with a plasma variety having a low ratio of dynamic to static resistance, such as filamentary discharges. By damping such fast variations using a pulse forming circuit (20), a uniform glow discharge plasma is obtained.

Owner:FUJIFILM MFG EURO

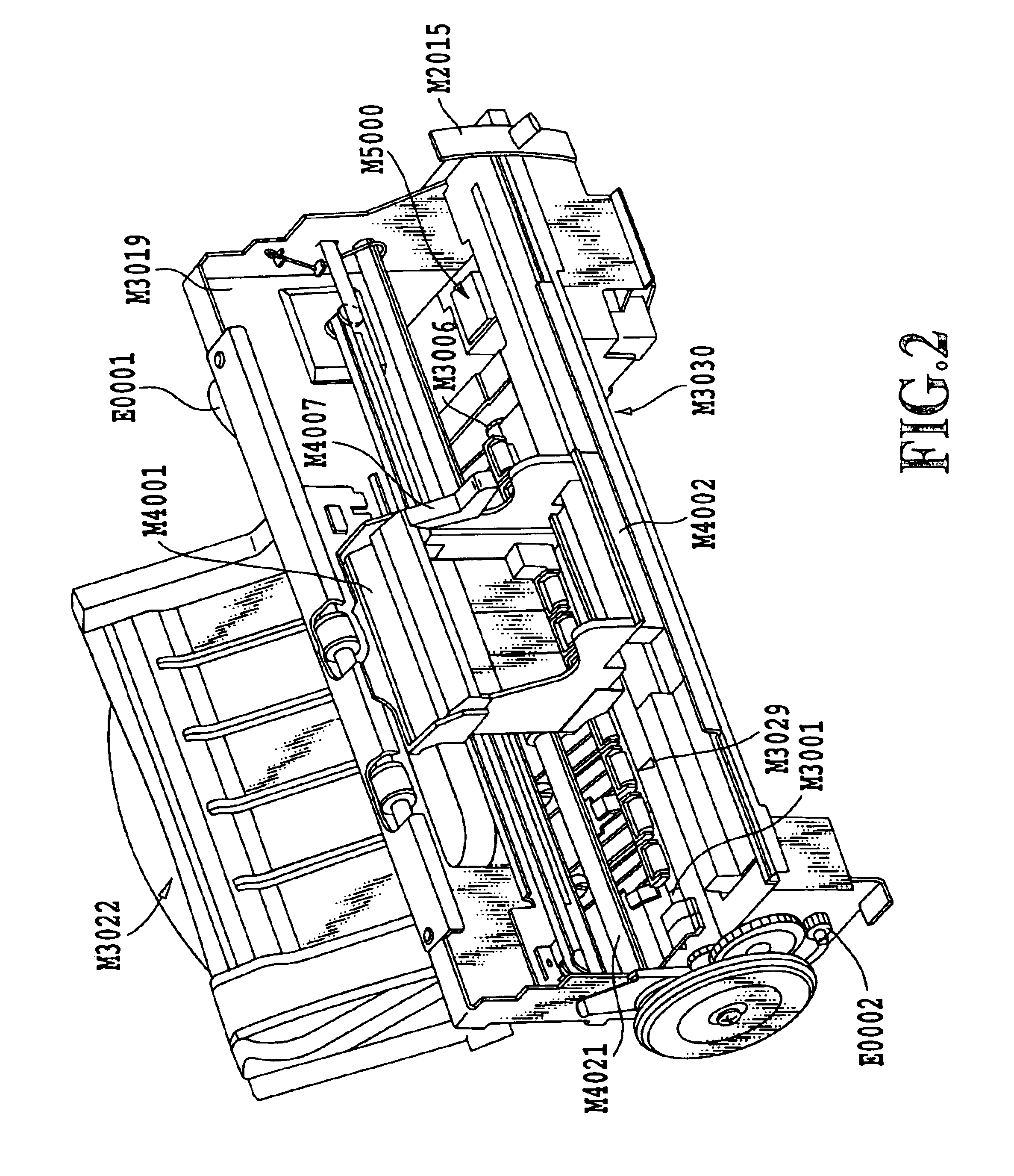

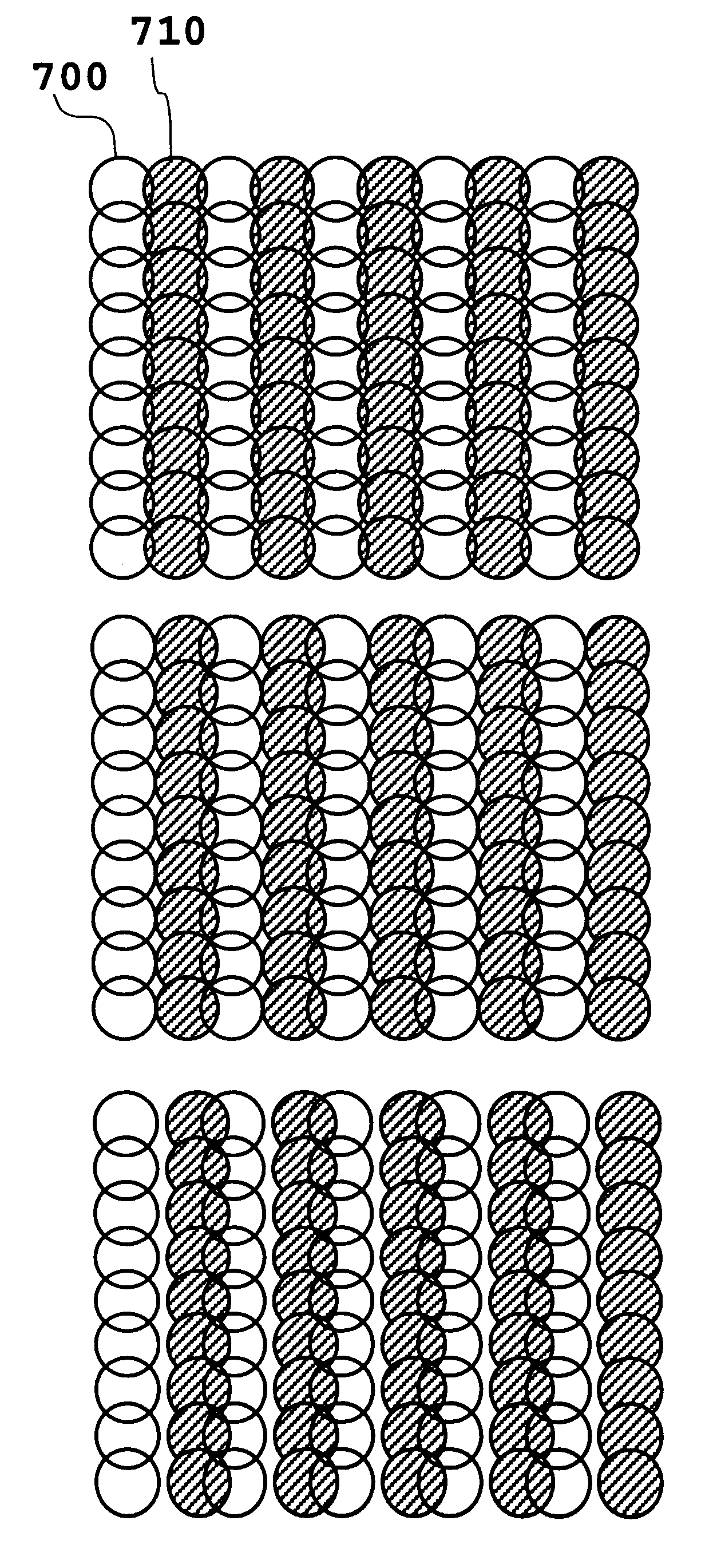

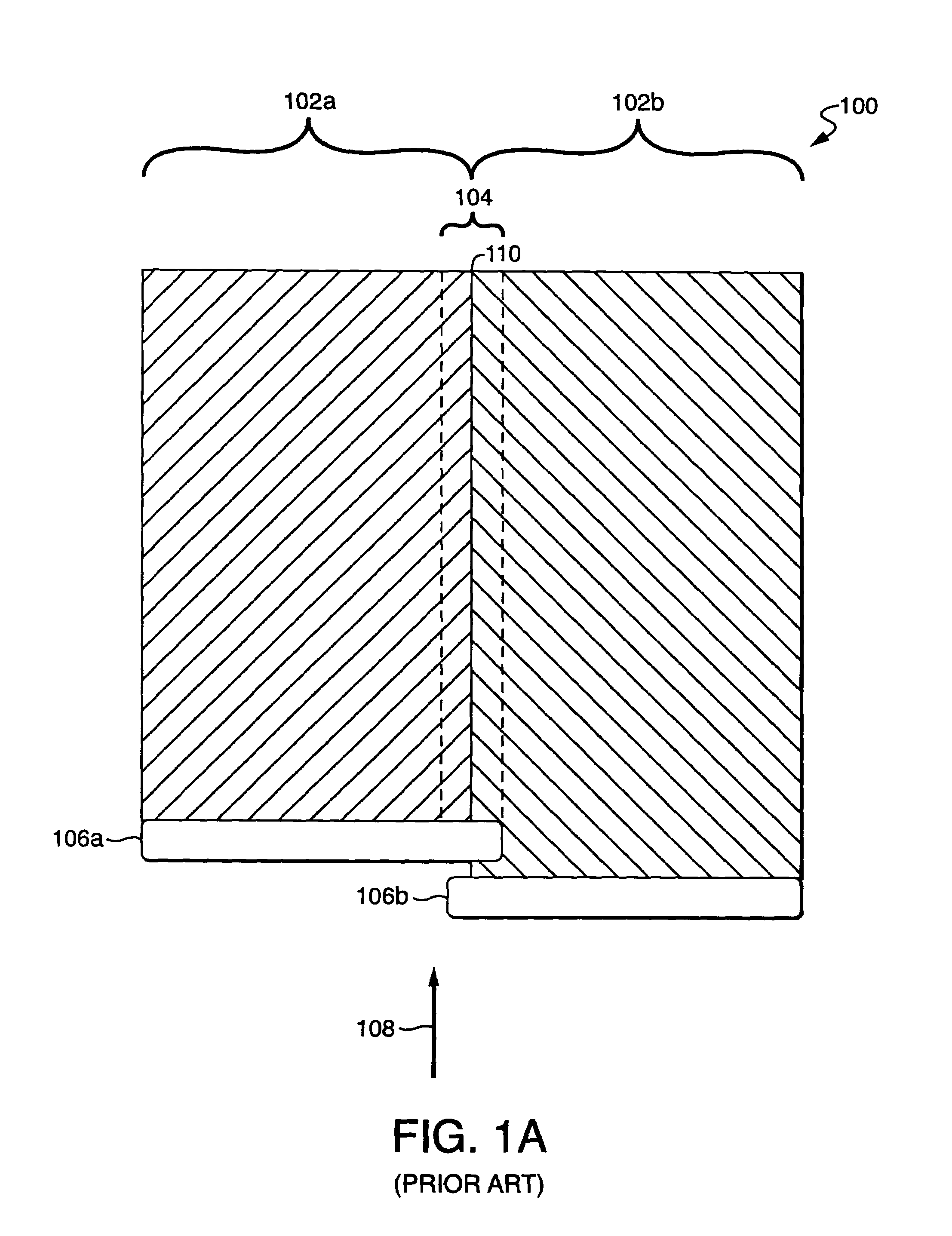

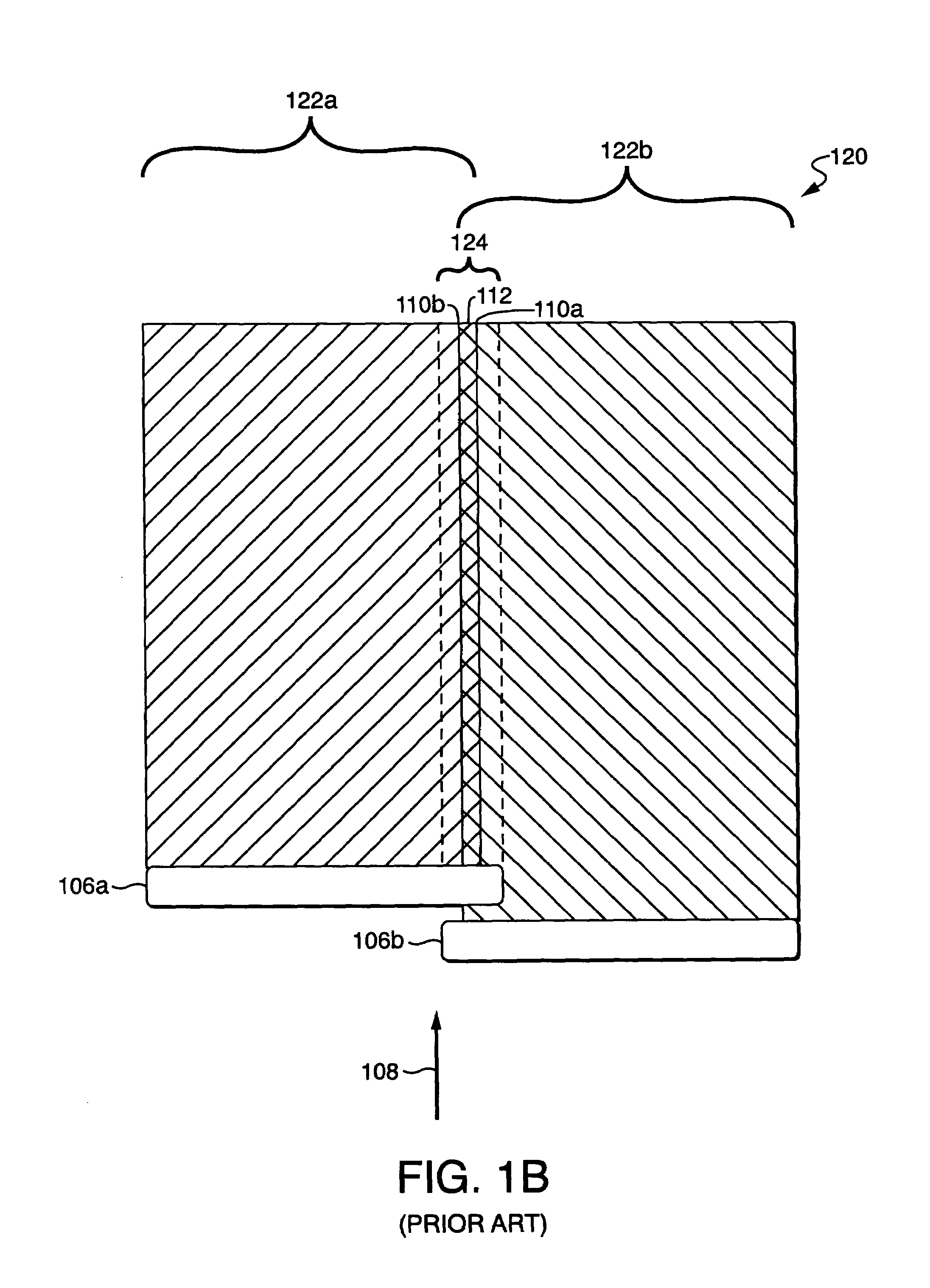

Image stitching for a multi-head printer

InactiveUS7388686B2Minimize variation in densityDensity variationRecording apparatusImage enhancementEngineeringVolumetric Mass Density

Techniques are disclosed for stitching images printed by a multi-head printer in a manner that is relatively insensitive to misregistration of the image segments. When a pair of overlapping print heads print a pair of adjacent image segments which meet in a stitching region, printing at each location in the stitching region is accomplished by both print heads with a weighting that depends on the location being printed within the stitching region. In one embodiment, for example, the output of each print head is weighted by a linear function of horizontal pixel position. Techniques are also disclosed for selecting screening patterns for use when stitching is performed with variable-dot printers. Such screening patterns are selected to minimize variations in density that may arise as the result of cross-web and / or down-web misregistration.

Owner:ZINK IMAGING

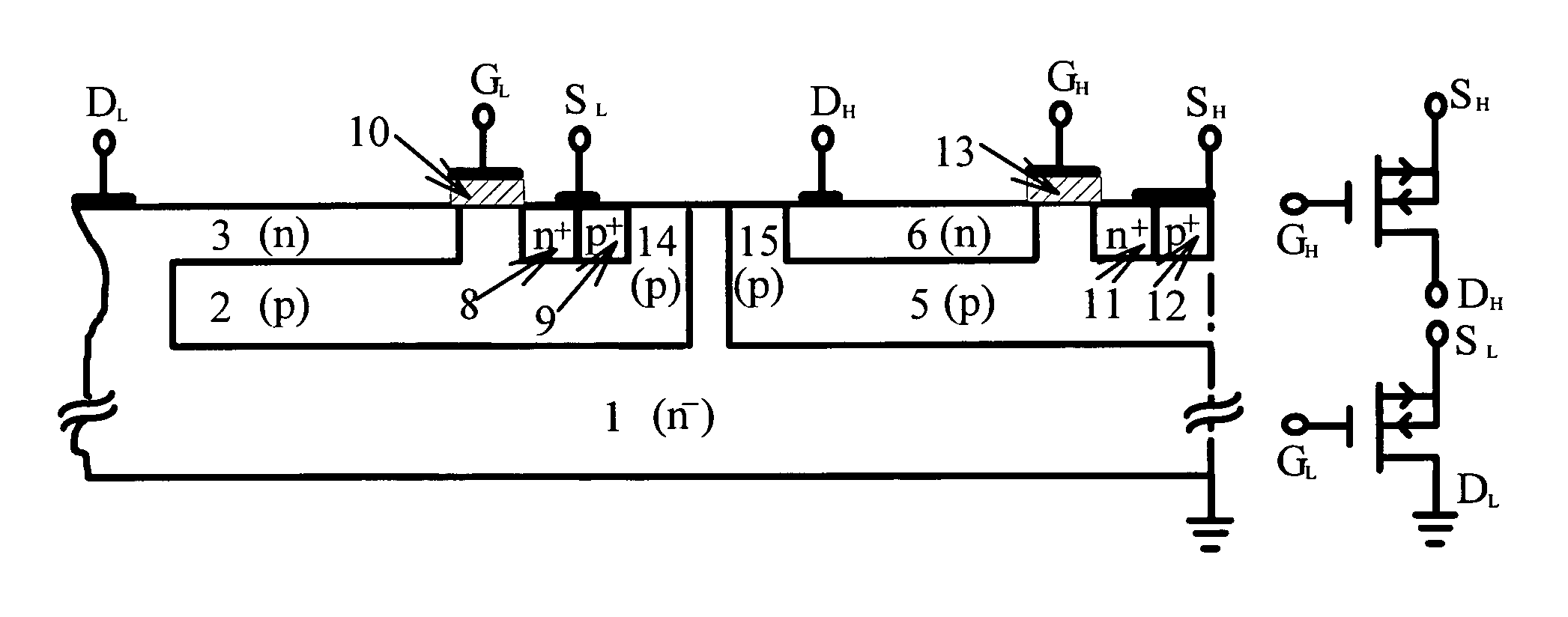

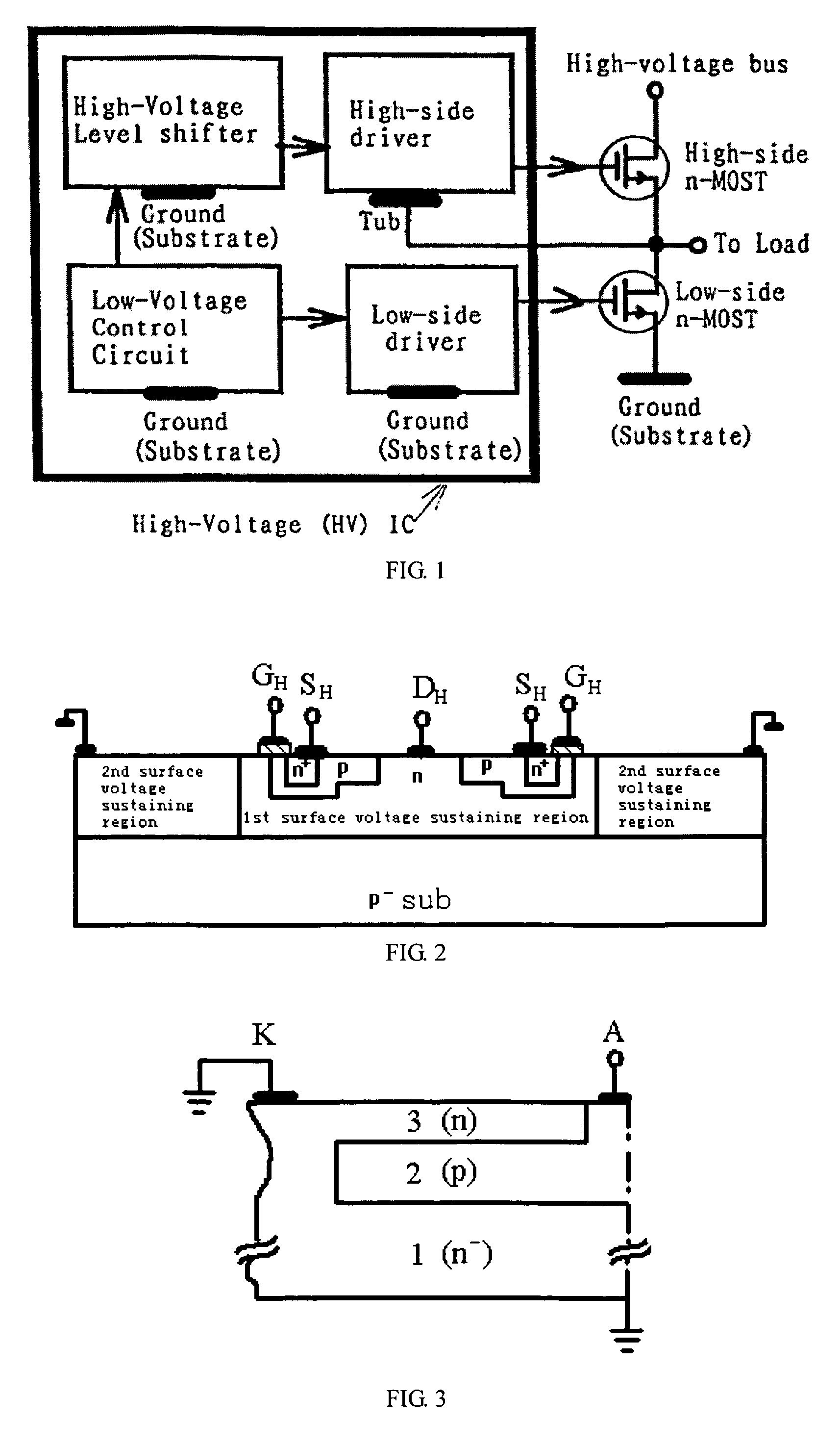

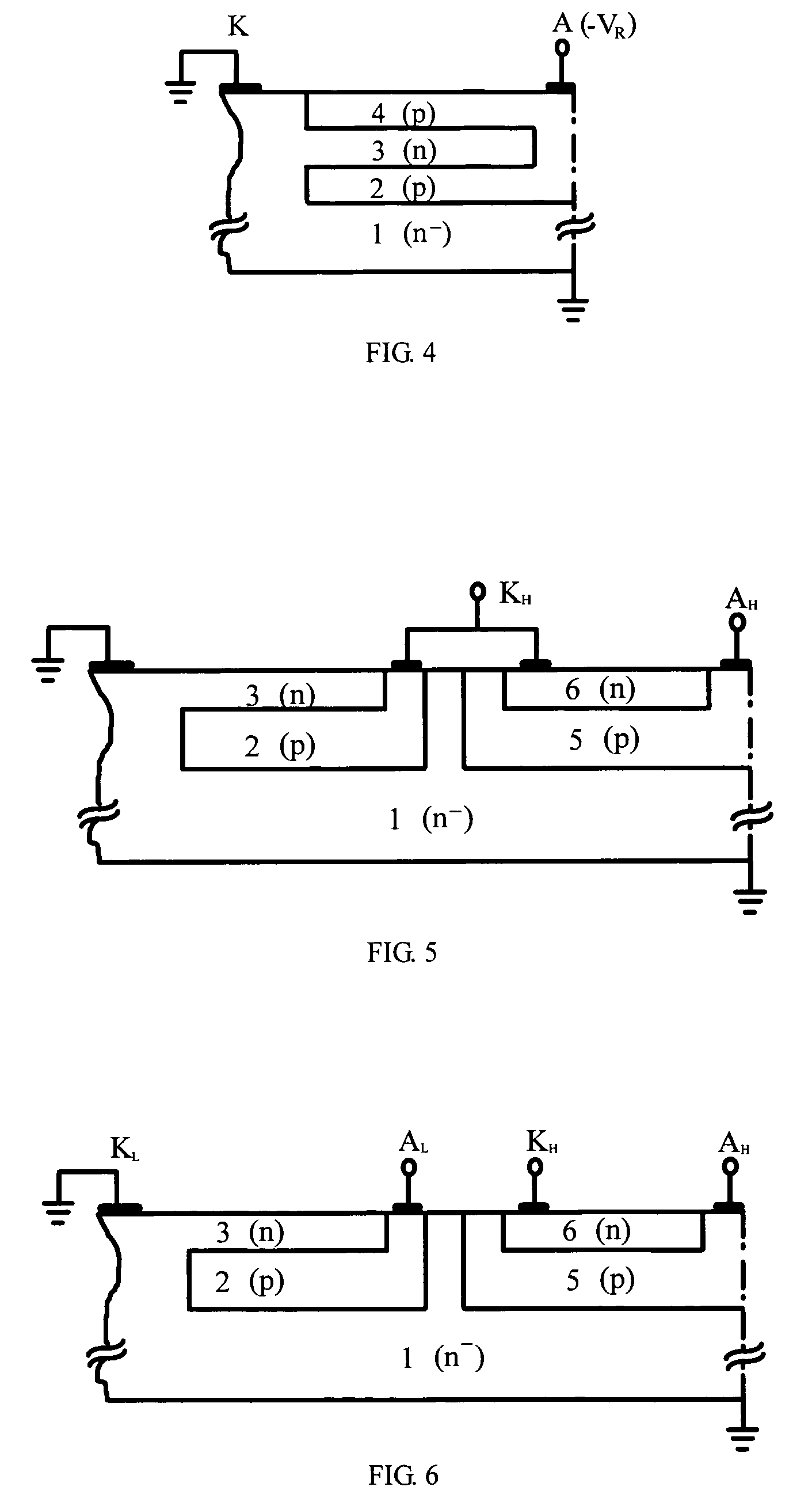

Lateral low-side and high-side high-voltage devices

ActiveUS6998681B2Smaller specific on-resistanceTransistorSolid-state devicesHigh pressureDensity change

Lateral high-side and low-side high-voltage devices with low specific on-resistances are made in a first and in a second surface voltage-sustaining region, respectively. In the on-state of high-side MOST (the right portion of the figure), the voltage across its source and its drain is very low and only layer 5 (p-type) is depleted to a large extent, layer 6 and layer 7 remain neutral and can serve as drift region(s) of electrons and / or holes. The drift region can be used for a single n-MOST or p-MOST, or even a parallel connection of n-MOST and p-MOST as shown in the figure. In the off-state of the high-side MOST, the voltage across its source and its drain is very large, but the voltage across its drain and the substrate 1 can be very low, and all of the layers in the first surface voltage-sustaining region are depleted, the depleted layer 5 produces an optimum variation lateral density of charge.The low-side MOST (the left portion of the figure) is similar to the high-side MOST.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

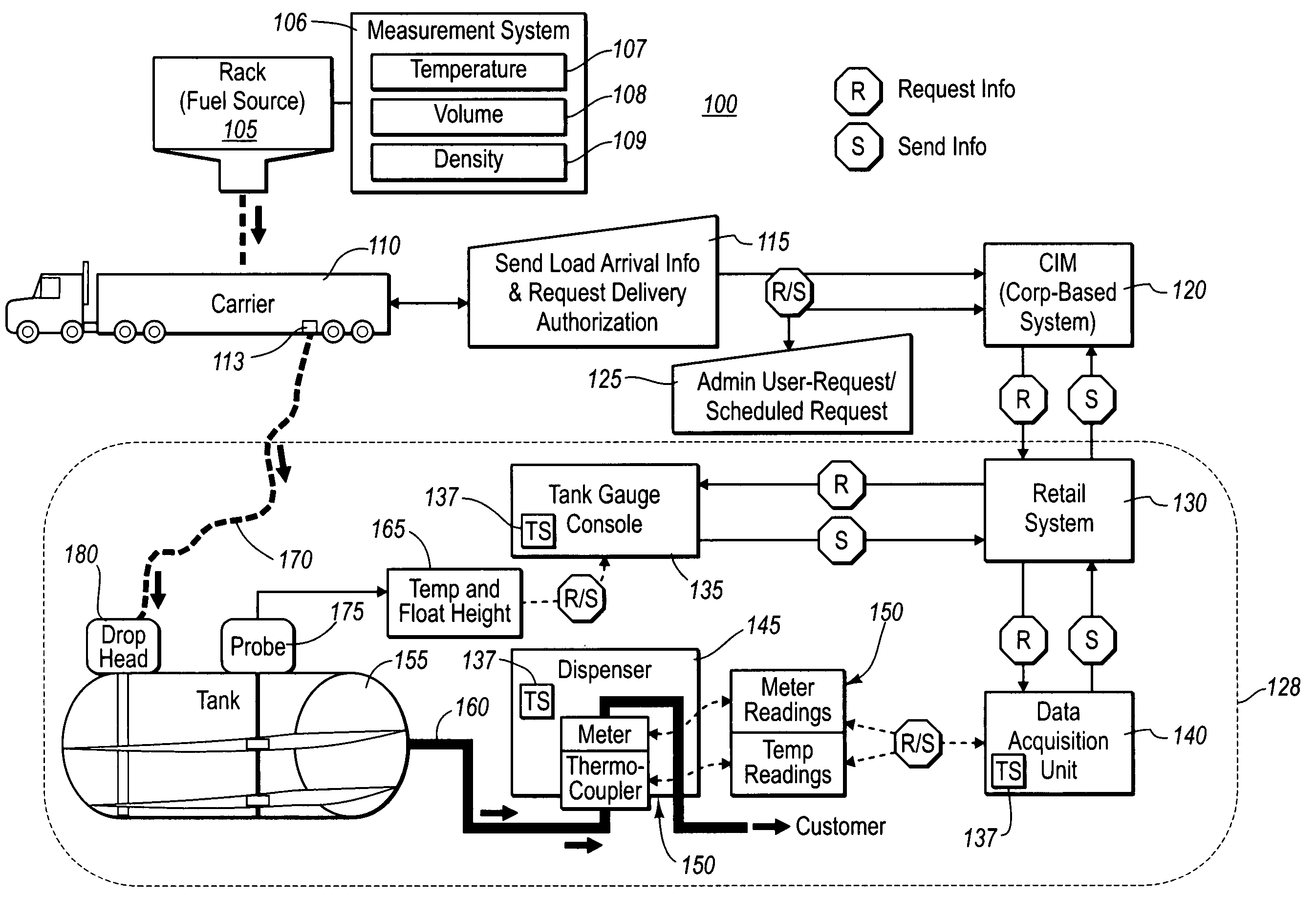

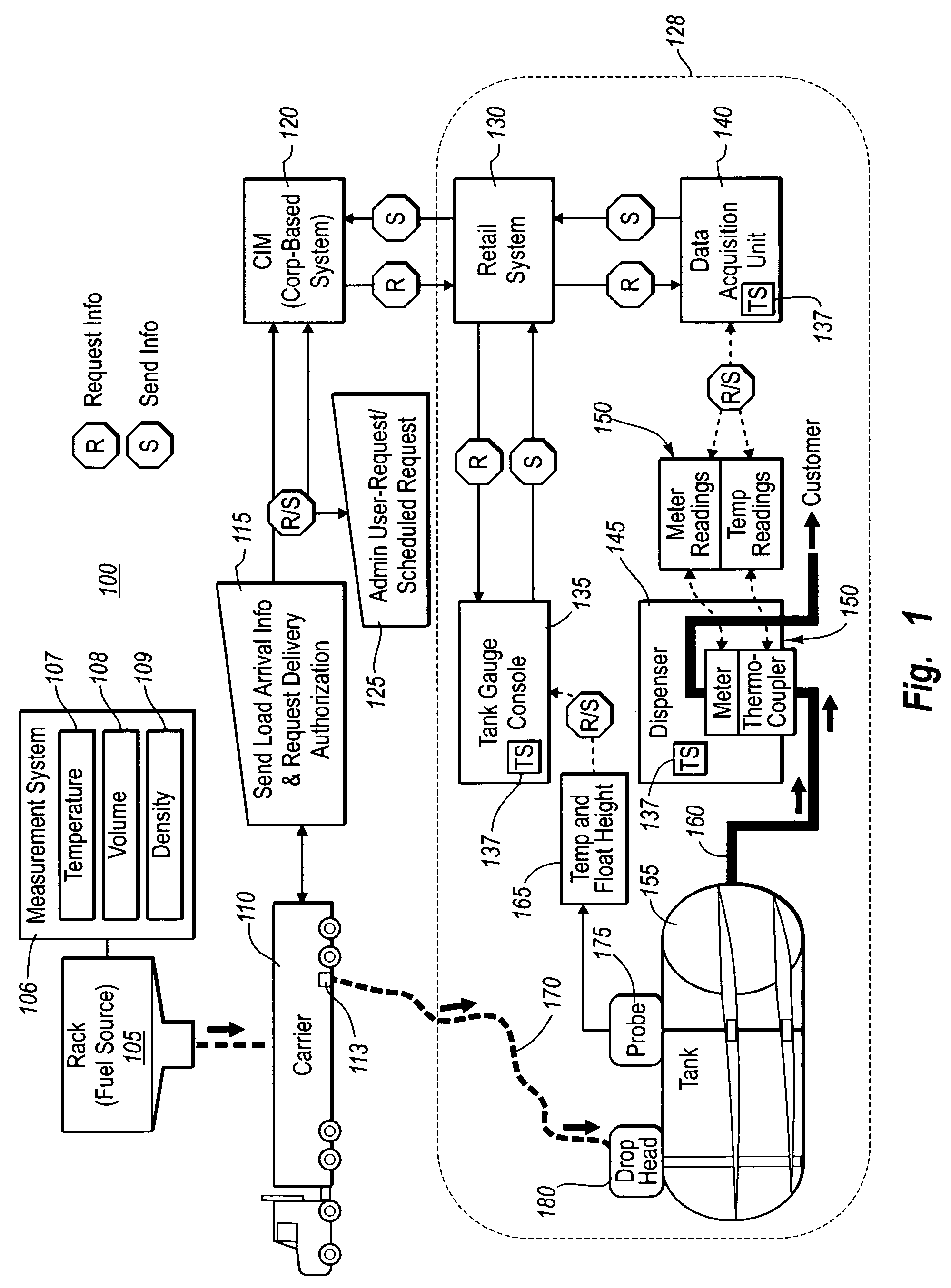

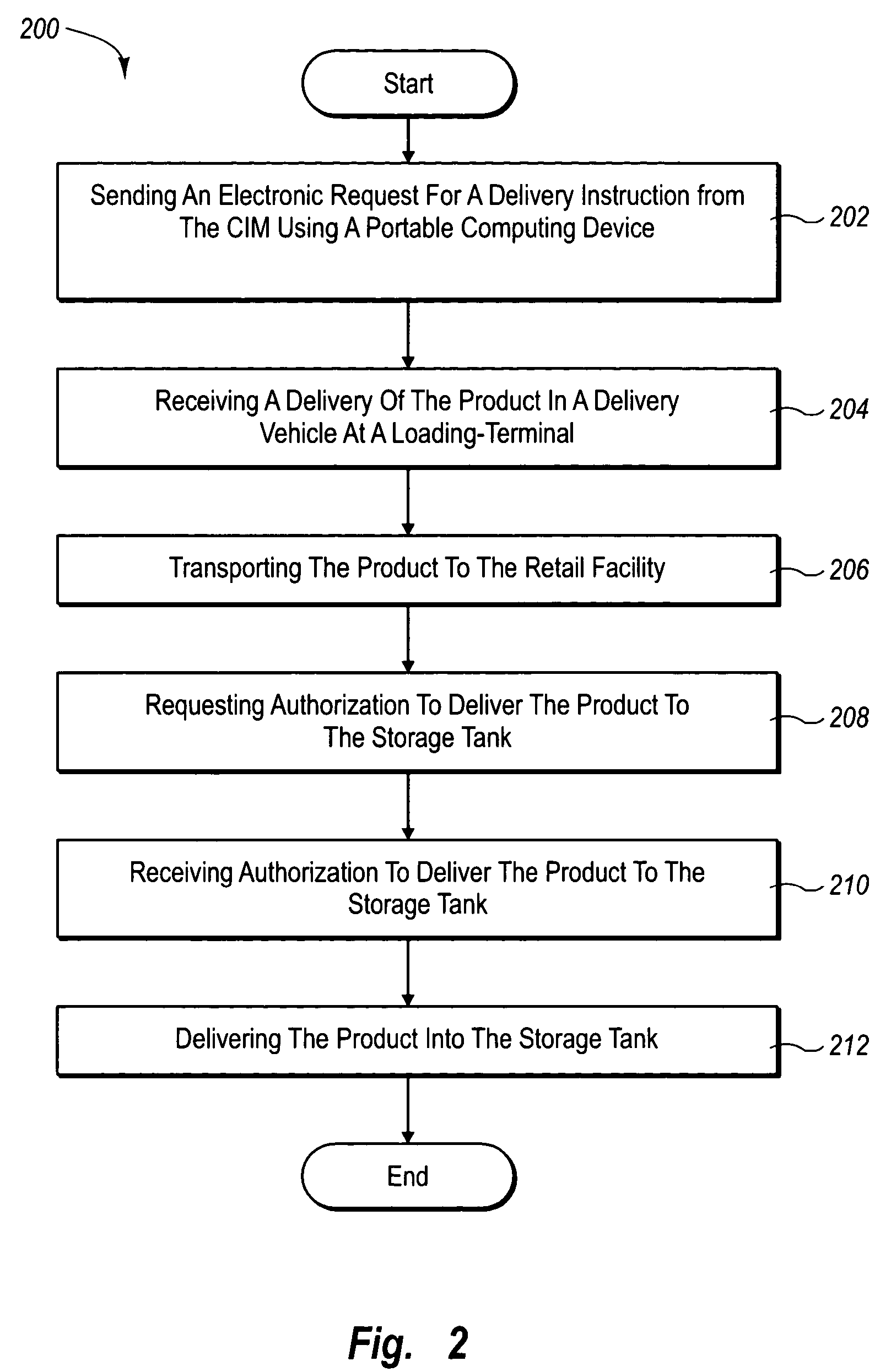

Balancing net inventory using a dynamic expansion coefficient of liquid product relative to temperature changes

InactiveUS7536264B2Block deliveryFlow interruptionTesting/calibration apparatusLevel controlLiquid productAPI gravity

Disclosed are methods, systems, and computer program products for balancing net inventory using a dynamic expansion coefficient of liquid product relative to the temperature changes with density. The method can include receiving an API gravity report that includes a measurement of a specific gravity and a temperature of the product reported at a rack. Utilizing the API gravity report, the method can include maintaining correct densities of the liquid product by utilizing a plurality of expansion coefficients to dynamically convert a gross volume measurement to a net volume measurement for transactions of liquid product in a tank and at a dispenser in order to maintain a net perpetual book balance.

Owner:PILOT TRAVEL CENTS LLC

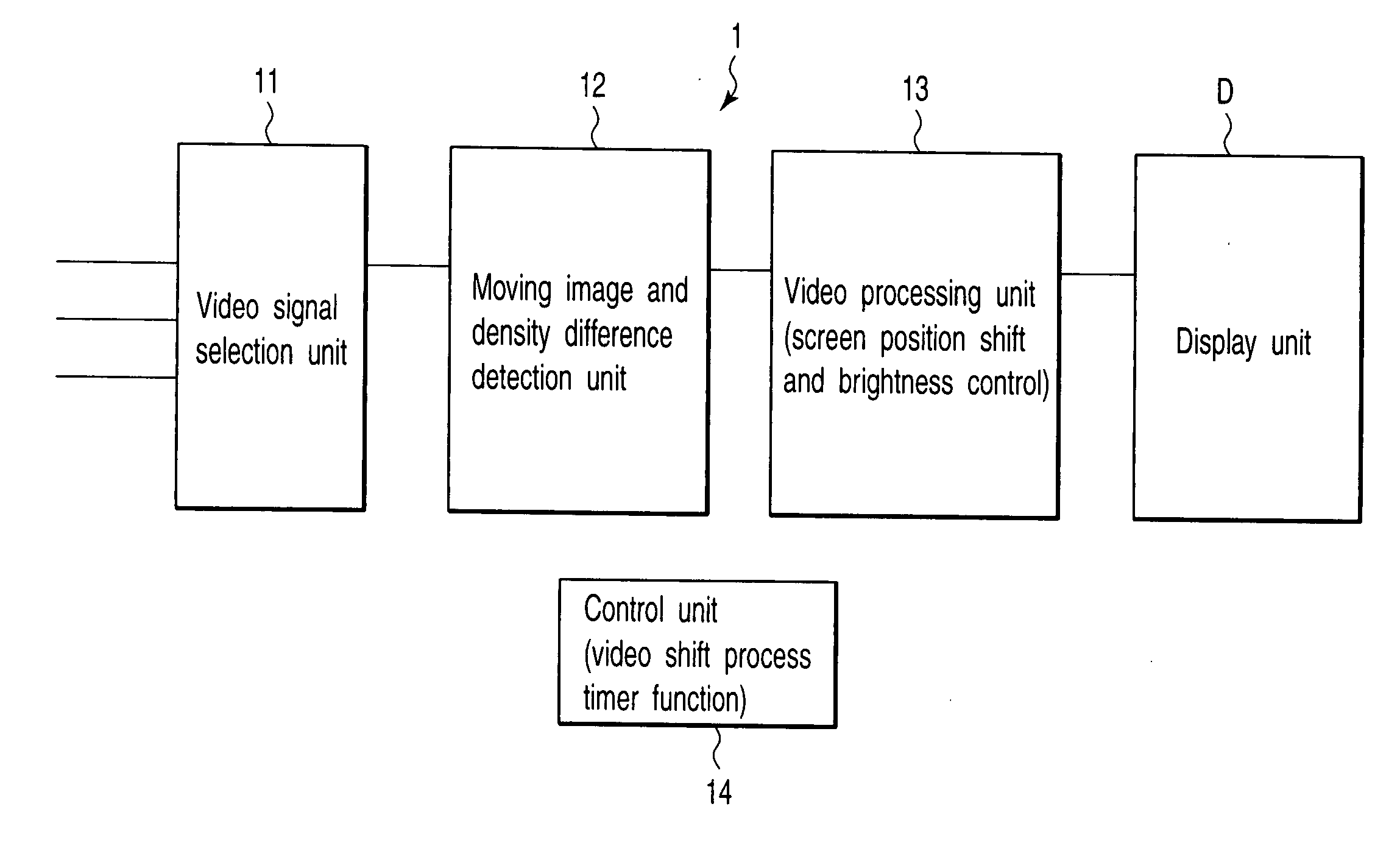

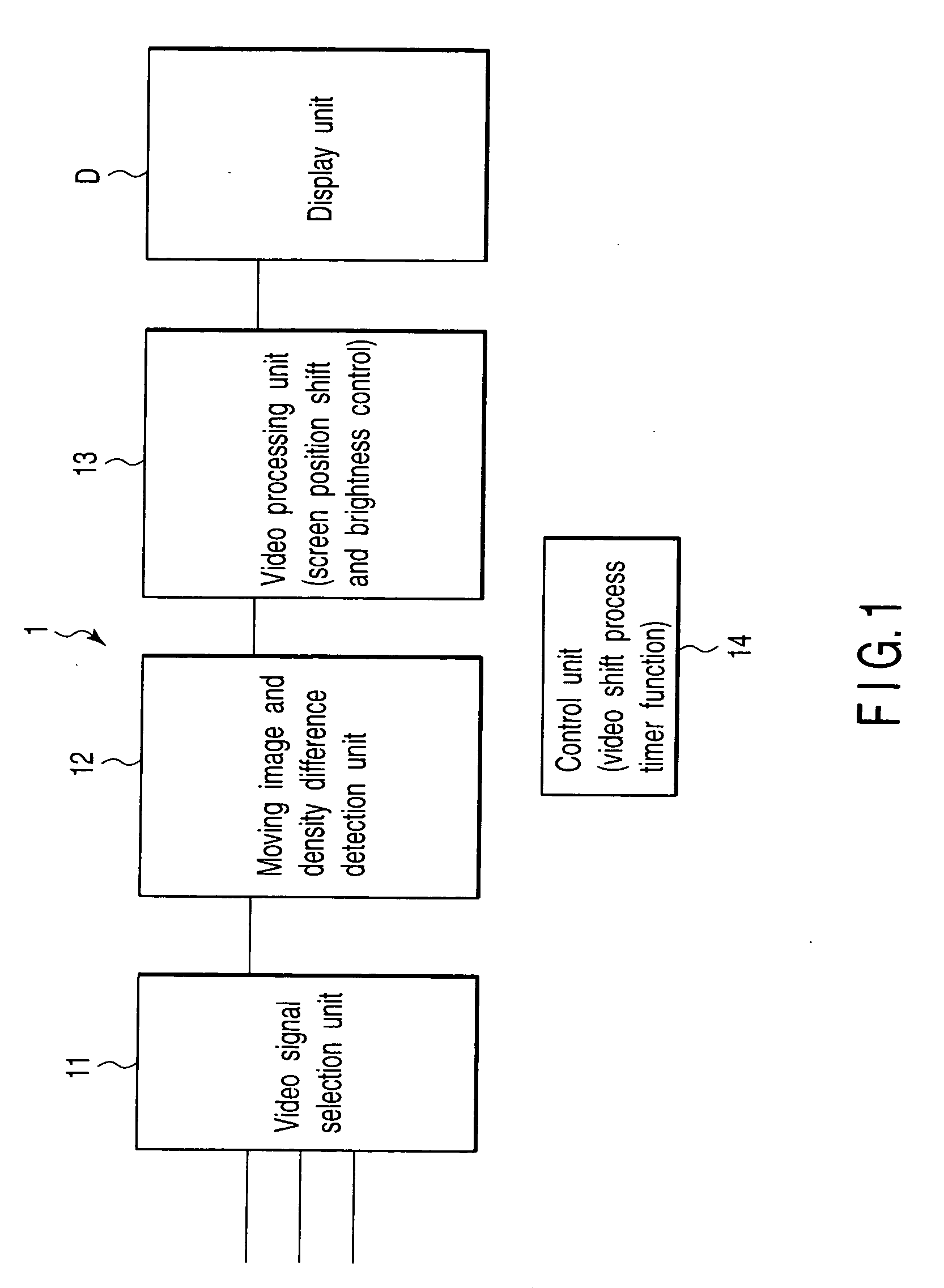

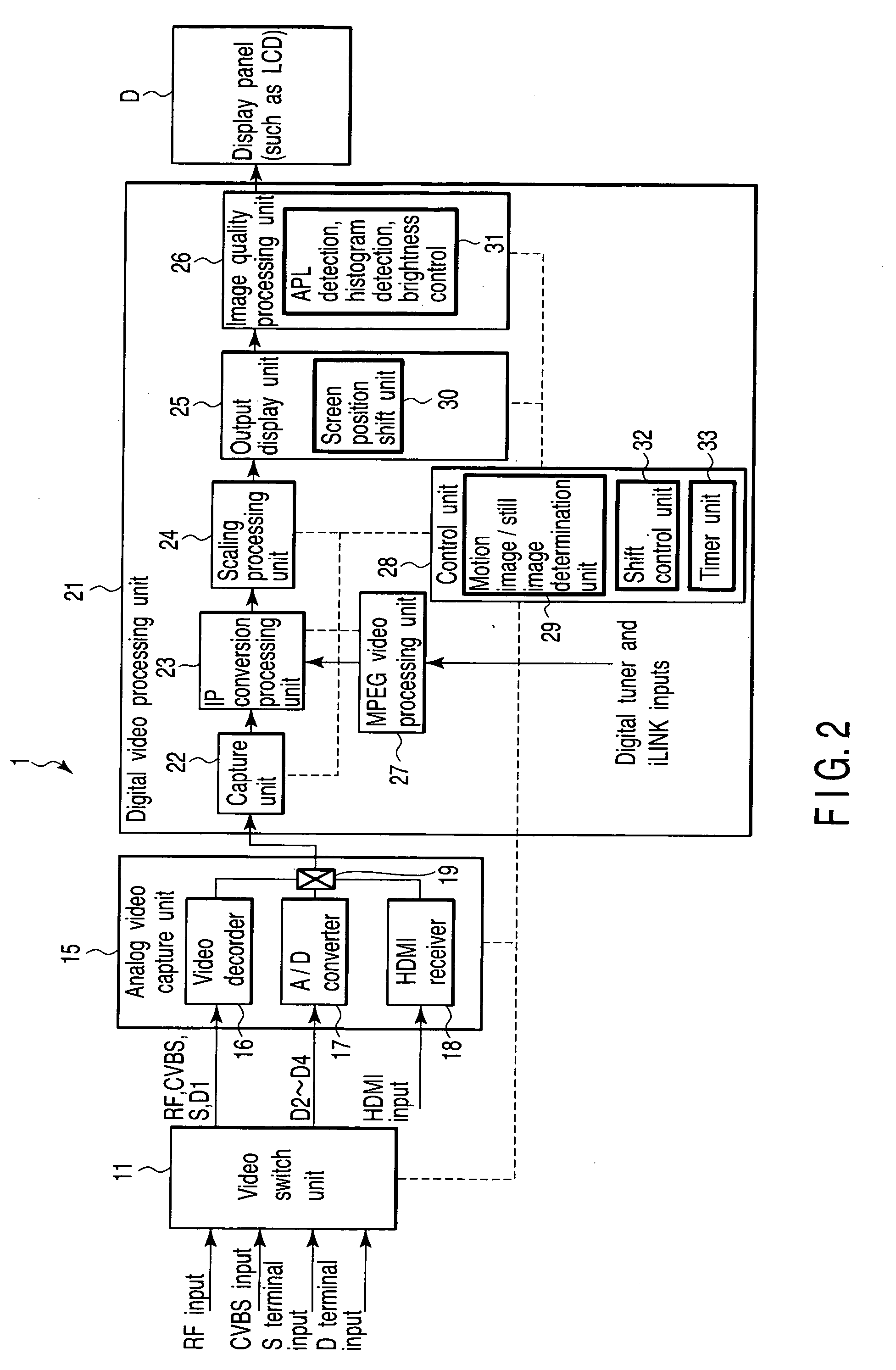

Video display apparatus and video display method

InactiveUS20070146485A1Television system detailsTelevision system scanning detailsComputer graphics (images)Signal on

According to one embodiment, a video display apparatus includes a detection unit which detects a video density change based on a given video signal, a processing unit which processes the video signal to change a position of a video based on the video signal on a screen at timing of the video density change when the video density change detected by the detection unit is not lower than a predetermined amount, and a display unit which displays the video on the screen according to the video signal processed by the processing unit.

Owner:KK TOSHIBA

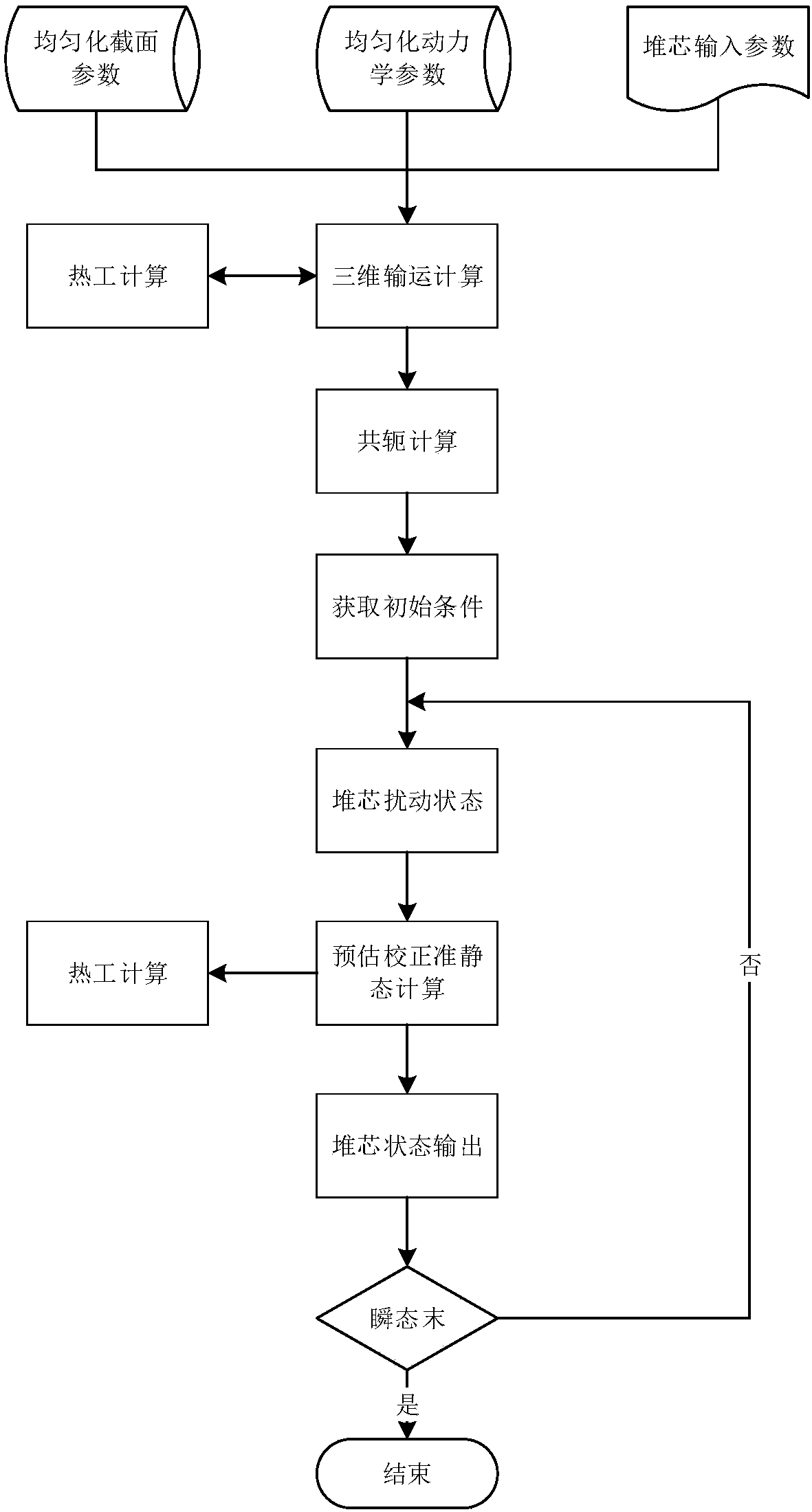

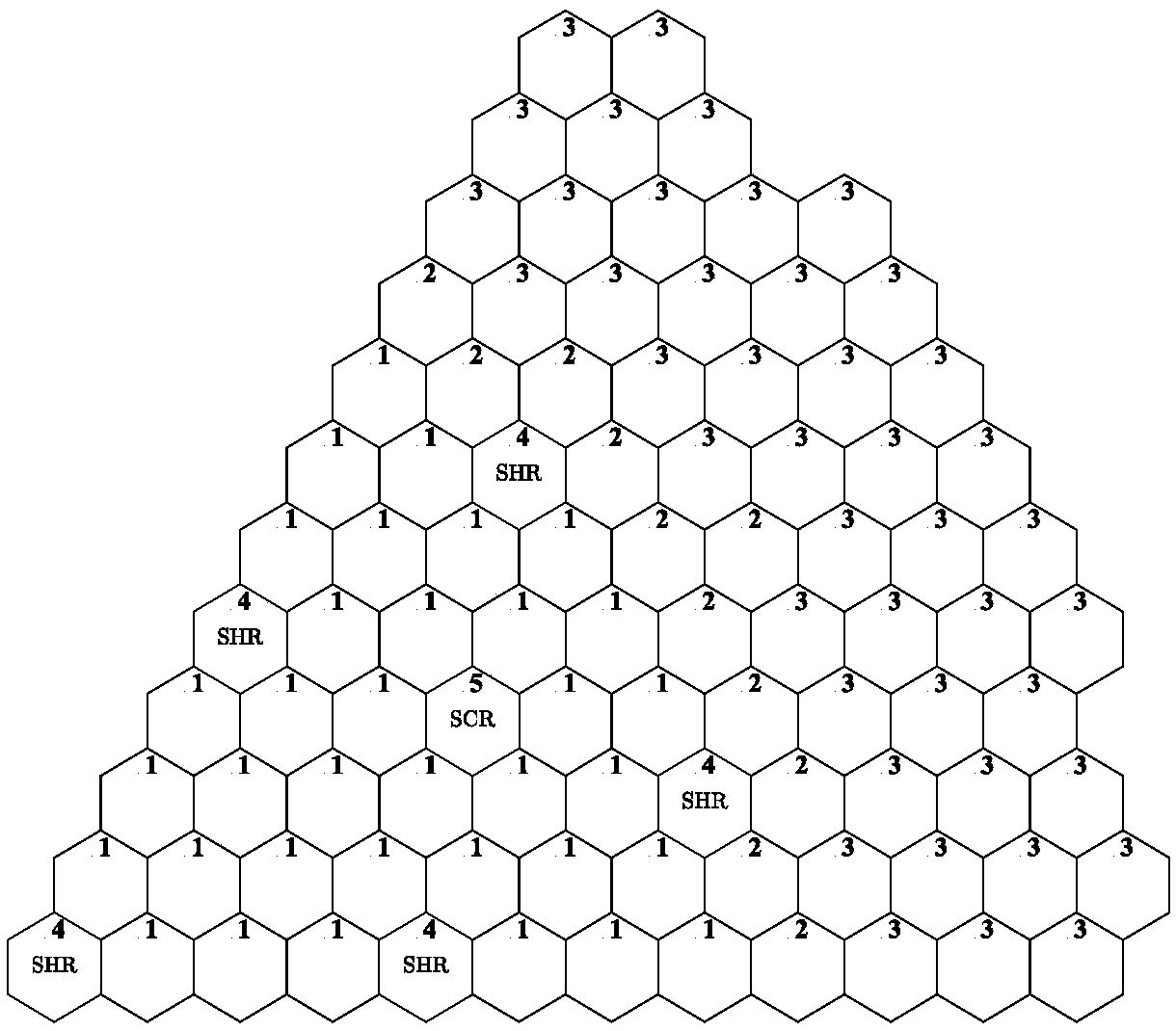

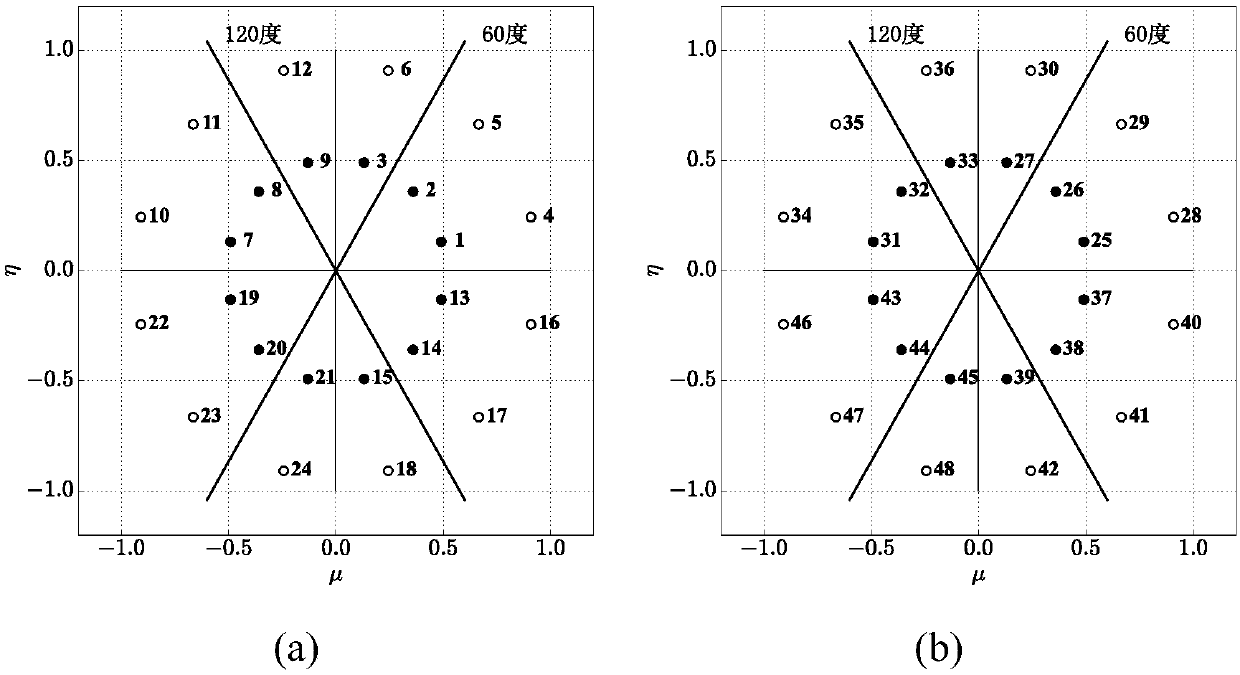

Method for obtaining three-dimensional neutron flux density distribution in reactor core transient process of fast neutron reactor

ActiveCN107066745AIsotropic simplificationTime derivative simplificationNuclear energy generationNuclear monitoringDensity distributionCoupling

The invention discloses a method for obtaining three-dimensional neutron flux density distribution in a reactor core transient process of a fast neutron reactor. A polygonal prism grid is adopted for the anisotropic neutron flux density of the reactor core of the fast neutron reactor to carry out fully-three-dimensional transportation space dispersion, a semi-spherical surface of a sixty-degree region is taken as a unit to carry out alternate scanning, and iterative format degradation in an angle parallel process is weakened; and the characteristics of the weak local effect and the global space coupling of the neutron flux density of the reactor core of the fast neutron reactor are considered, an estimated correction quasi-static strategy is adopted for neutron flux density change in a transient process to carry out time dispersion, ingredients of different change rates along with time in the neutron flux density can be decomposed, separated solution is carried out on different time scales, meanwhile, nonlinear iteration among above ingredients is avoided, and calculation efficiency is improved. The method for obtaining the three-dimensional neutron flux density distribution in the reactor core transient process of the fast neutron reactor has the advantages of being high in calculation accuracy and reasonable in calculated amount.

Owner:XI AN JIAOTONG UNIV

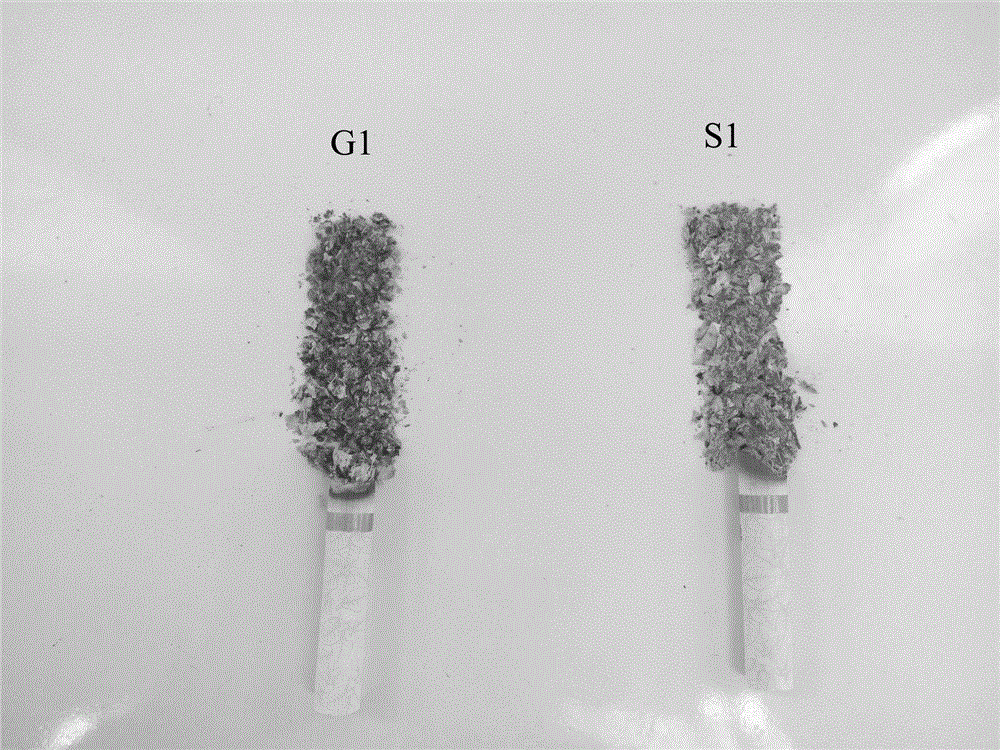

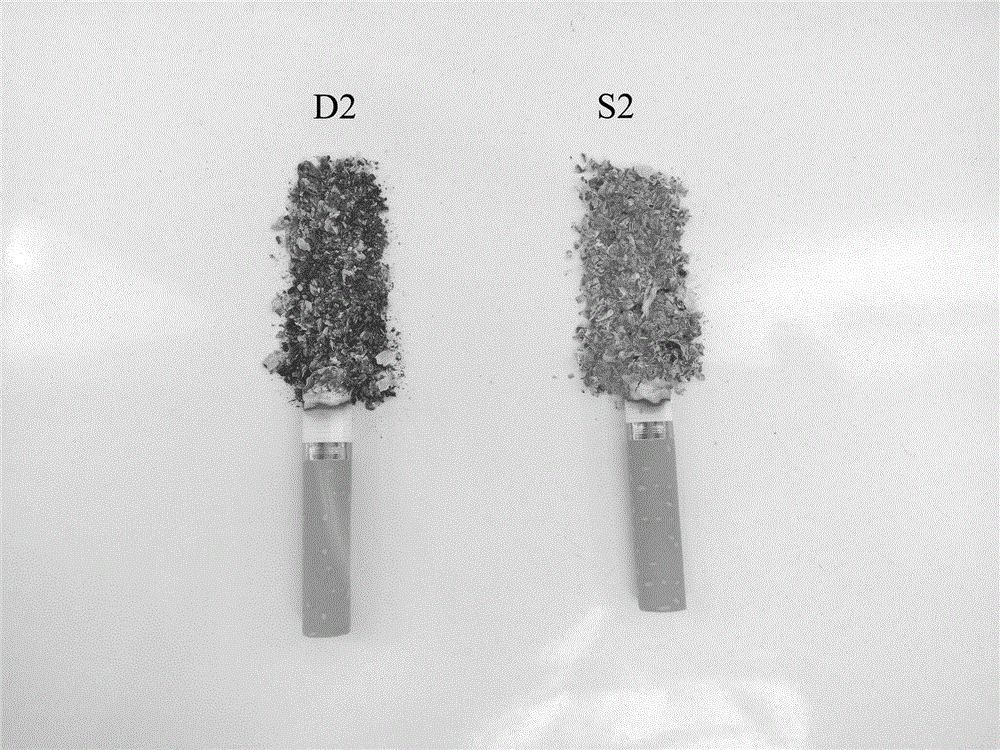

Method for improving cigarette soot whiteness

ActiveCN105725255AIncrease moisture contentUniform sizeTobacco preparationTobacco treatmentRolling paperPotassium

The invention provides a method for improving cigarette soot whiteness. Tobacco raw materials include mature tobacco with the potassium-chlorine ratio large than 4, and papermaking process reconstituted tobacco at least accounting for 5% of the tobacco raw materials. Finished product tobacco is obtained by conducting vacuum moisture regaining, loose moisture regaining, screening and casing, shredding, the leaf and tobacco temperature increase procedure before drying, the leaf and tobacco drying procedure, leaf and tobacco winnowing and perfuming. A collimator of the appropriate specification is selected to conduct cigarette rolling on finished product cut tobacco, and it is ensured that the density change rate of finished product tobacco distribution at the ends and in the middles of the cigarettes is smaller than 11.5%. By controlling the cigarette production process, finished product cut tobacco can have the appropriate moisture content, an appropriate filling value and appropriate elasticity, and the problem that the tobacco combustibility is poor is solved; by selecting cigarette rolling paper matched with cut tobacco and controlling relatively-low-weight cigarettes, combustion of smoked cut tobacco of cigarettes is more complete, the cigarette soot whiteness is obviously improved, and the tar release amount and the CO release amount are decreased.

Owner:CHINA TOBACCO HENAN IND

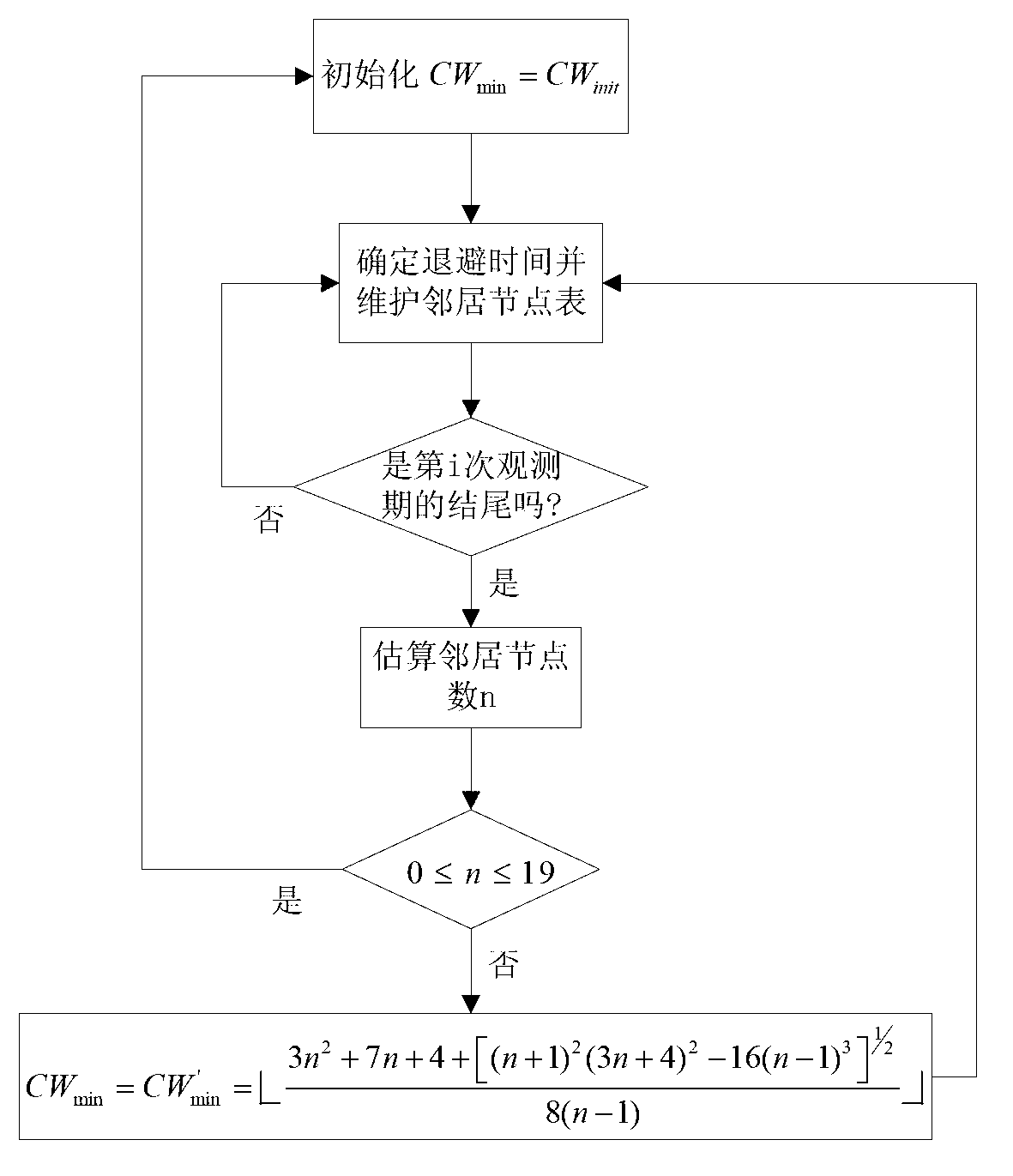

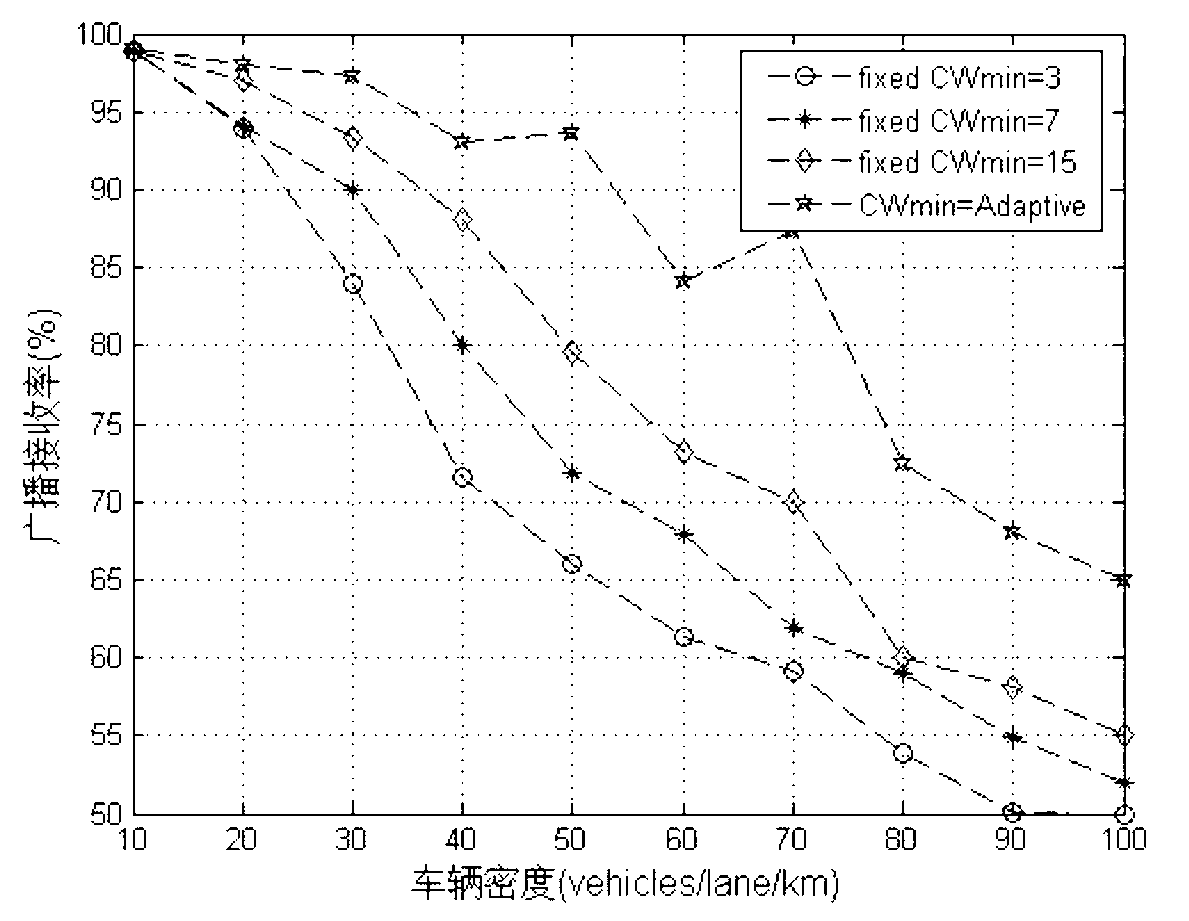

Minimum competition window adjusting method based on neighbor node number estimation in vehicle-mounted network

ActiveCN103259741AImprove scalabilityImprove broadcast reception rateNetwork topologiesData switching networksIn vehicleNode count

The invention discloses a minimum competition window adjusting method based on a neighbor node number estimation in a vehicle-mounted network, wherein the minimum competition window adjusting method based on the neighbor node number estimation in the vehicle-mounted network aims to solve the problem of radio expandability of a vehicle-mounted Ad hoc network MAC layer with a faster vehicle density change. Under the premise of an aim of minimizing the radio frame collision probability, the minimum competition window adjusting method based on the neighbor node number estimation in the vehicle-mounted network derivates a relationship between a minimum competition window and the number of competition anodes, a minimum competition window value is dynamically adjusted according to a real-time estimation of the number of vehicle neighbor nodes, the change of the minimum competition window value is made to reflect competition conditions in the network, therefore, waste of channel resources is reduced, and radio performance is improved. The minimum competition window adjusting method based on the neighbor node number estimation in the vehicle-mounted network has the aim of minimizing the collision probability, deviates the relationship between a CWmin and the number of active competition nodes, the minimum competition window is adjusted in a self-adjusting mode according to the real-time estimation of the number of the vehicle neighbor nodes, and the vehicle density change is reflected through adjustment of the minimum competition window, and therefore radio expandability of an IEEE802.11p MAC layer is improved.

Owner:NANJING UNIV OF POSTS & TELECOMM

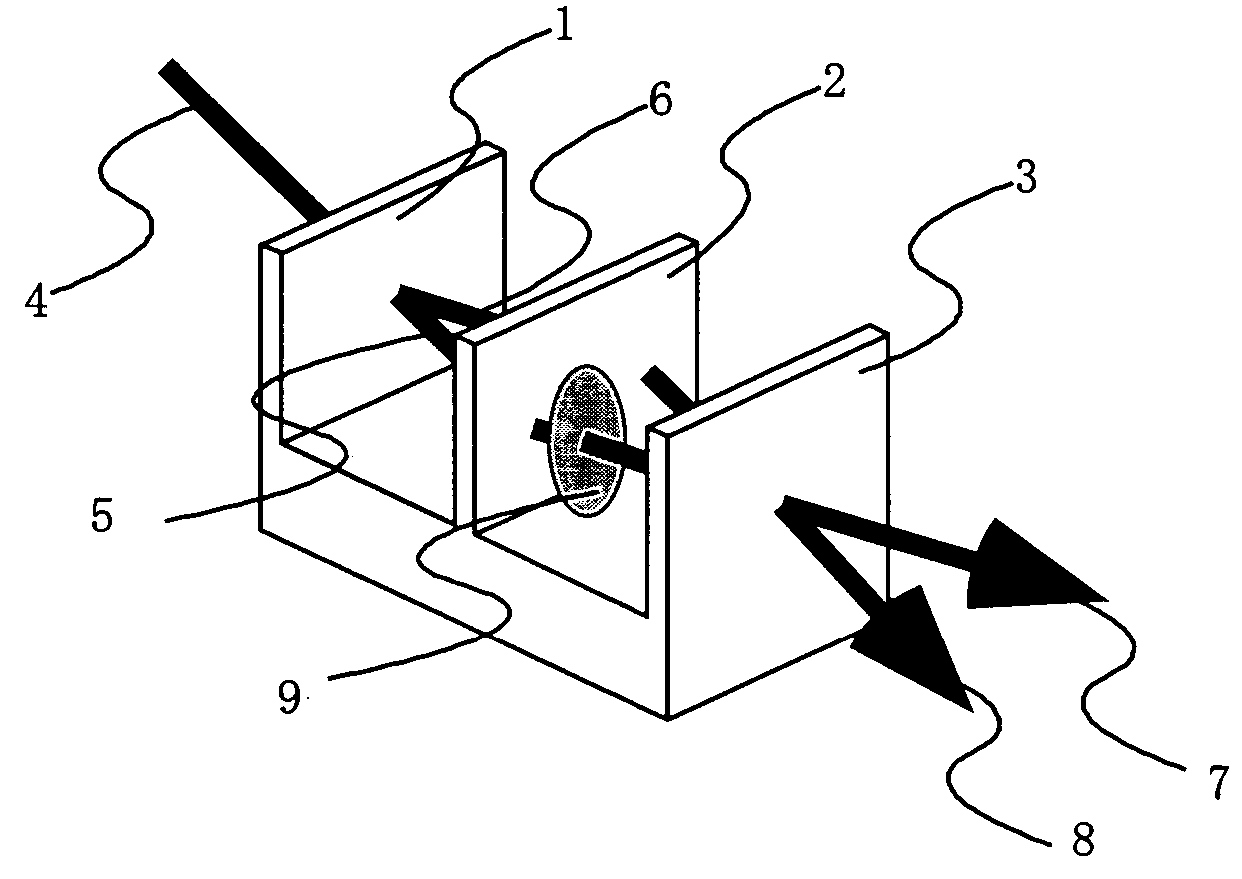

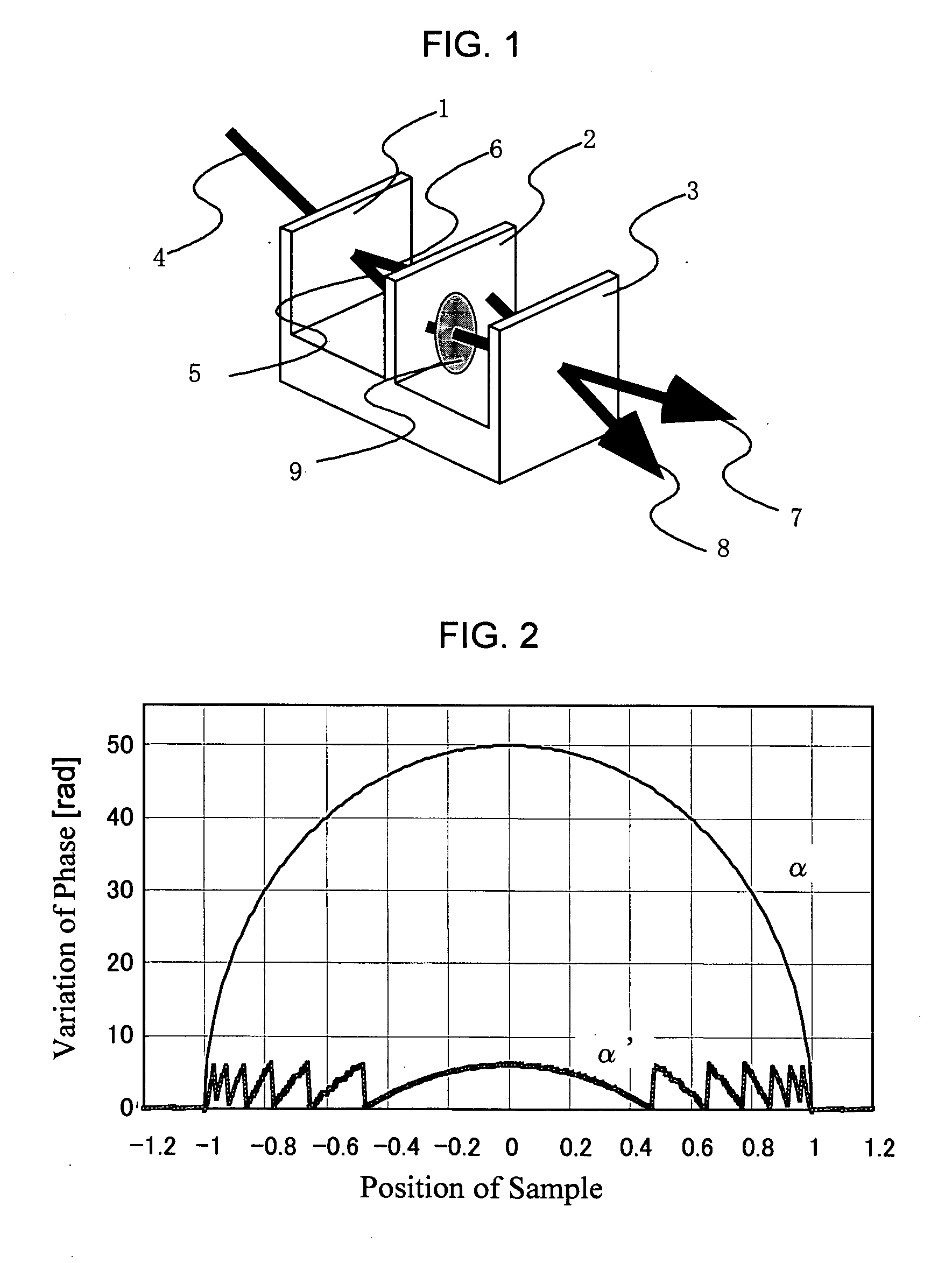

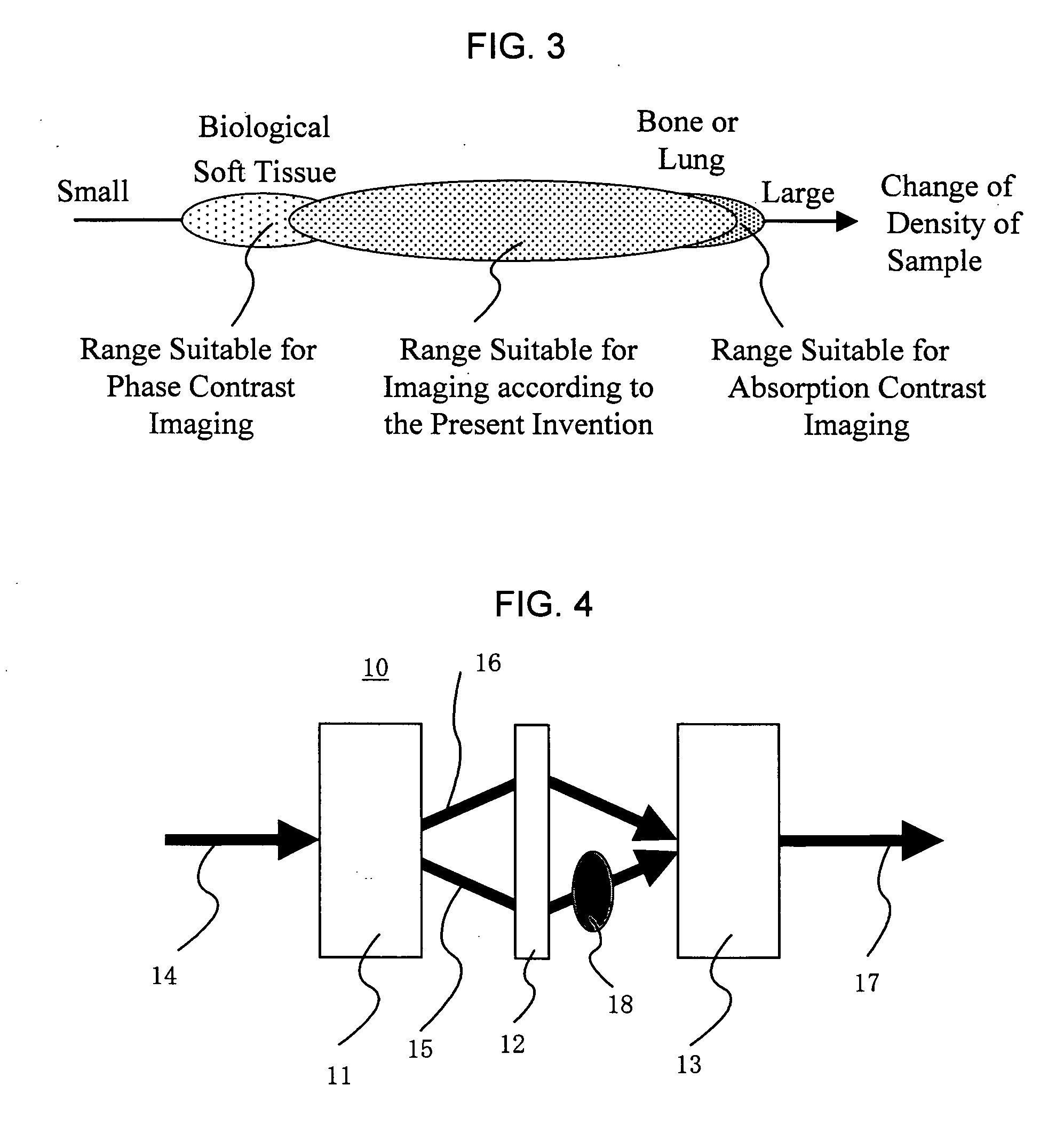

X-ray imaging apparatus and x-ray imaging method

ActiveUS20050117699A1Imaging devicesHandling using diffraction/refraction/reflectionX-rayVolumetric Mass Density

Even a sample including a organ of large density change such as the bone or the lung and a organ of small density change such as biological soft tissue, which has been difficult to measure by using conventional absorption and phase contrast X-ray imaging apparatuses, can be observed by the present invention in a state of high sensitivity. A transmission image and a cross sectional image of a change in an amplitude, a change in a phase, and a composite value of the change in the amplitude and the phase of an interference beam caused by the sample as contrast, are obtained.

Owner:HITACHI LTD

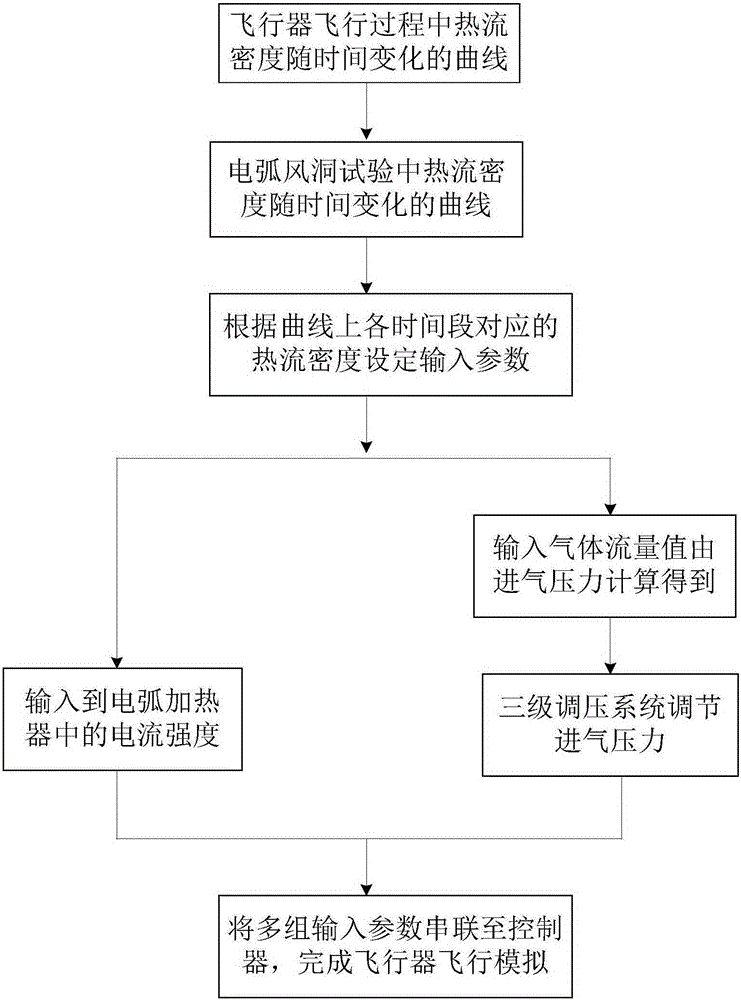

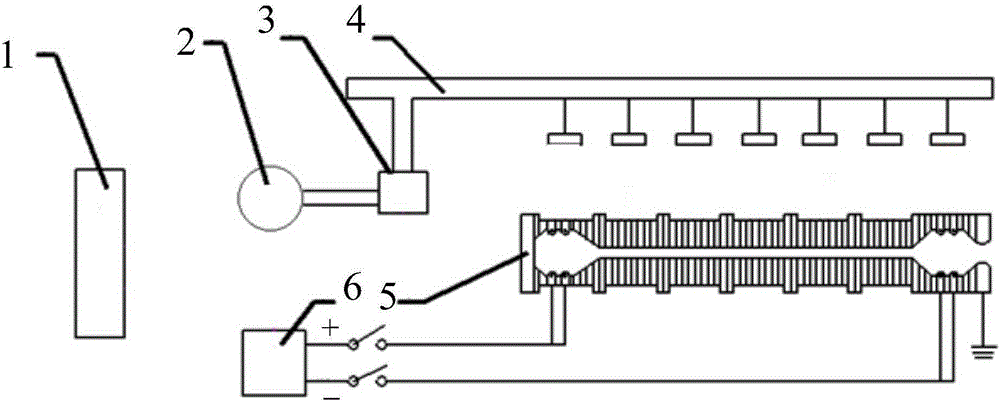

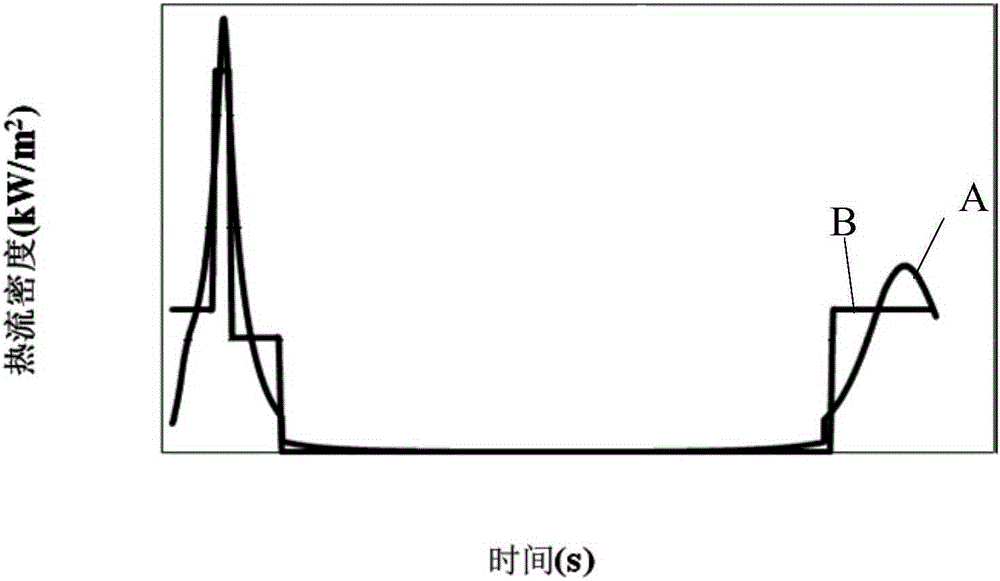

Test method for simulating thermal environment in aircraft flight process

ActiveCN105173128ASimulate the realRegulating pressureCosmonautic condition simulationsTemporal changeHeat flow

The invention discloses a test method for simulating a thermal environment in an aircraft flight process. The simulation of the thermal environment is realized through an arc tunnel test, and comprises the following steps: (1) a curve of heat flow density, changed along with the time, of an aircraft trajectory is fitted to a curve of heat flow density changed along with time in the arc tunnel test; (2) multiple time periods on the curve of heat flow density changed along with time in the arc tunnel test are read; each time period is corresponding to a heat flow density; and input parameters of laminated type arc heaters are set according to the time periods and the heat flow densities corresponding to the time periods; and (3) the input parameters corresponding to the multiple time periods are set in a controller in sequence to control the completion of the simulation test of the thermal environment in the aircraft flight process. The test method, provided by the invention, uses a computer for controlling, operates the thermal environment changed in the aircraft flight process in primary test process, and can simulate the thermal environment of an aircraft in the flight process more really.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

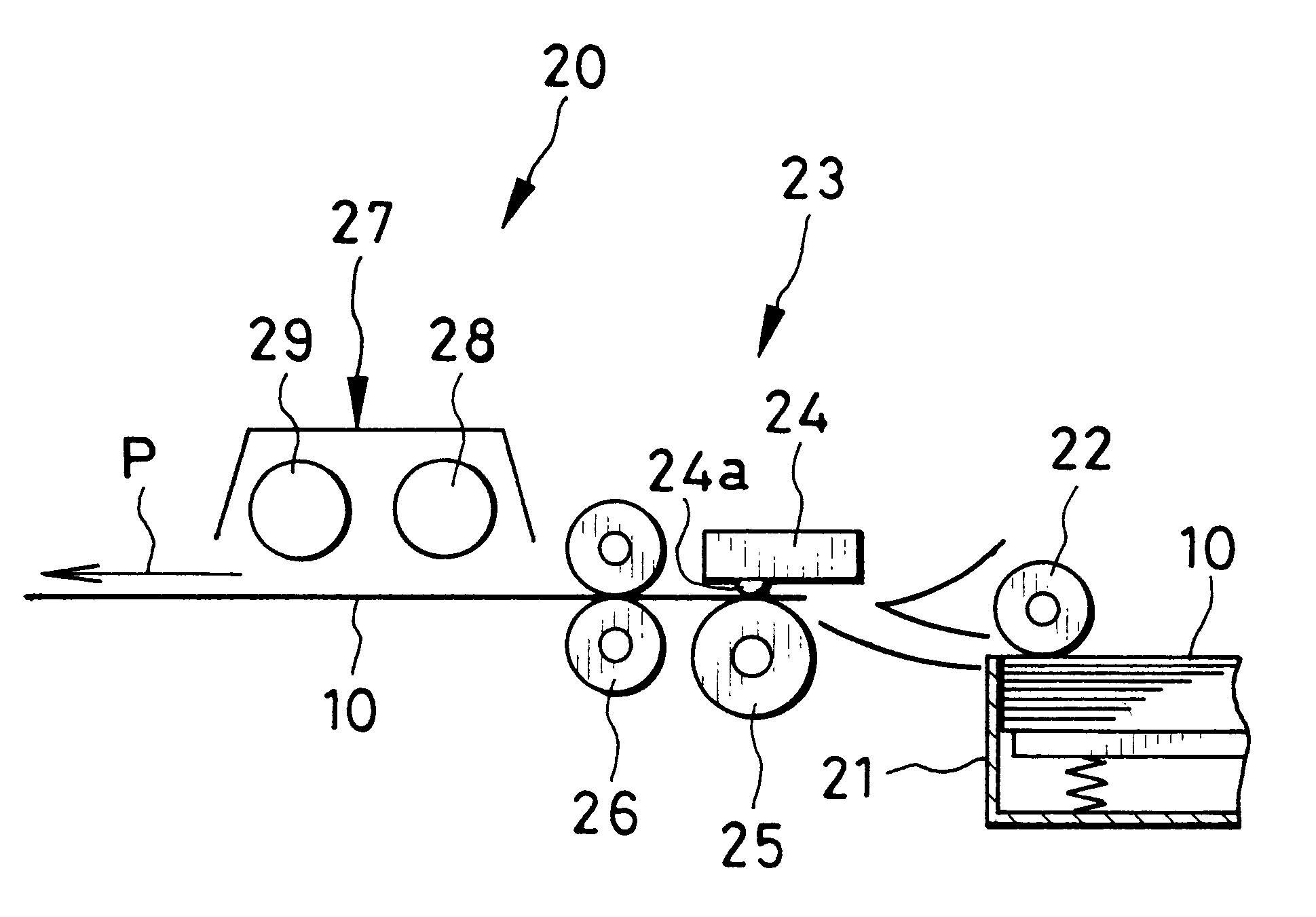

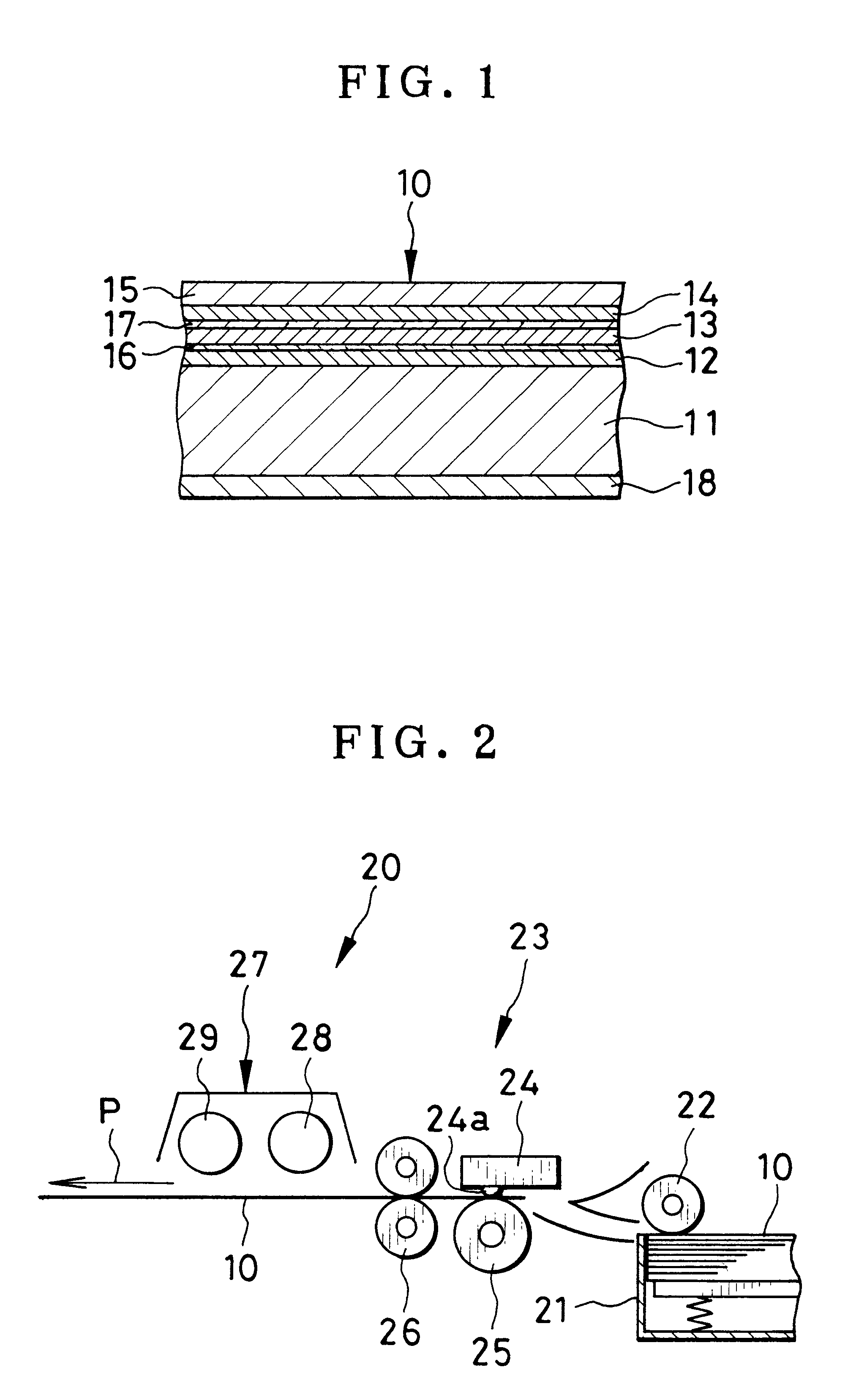

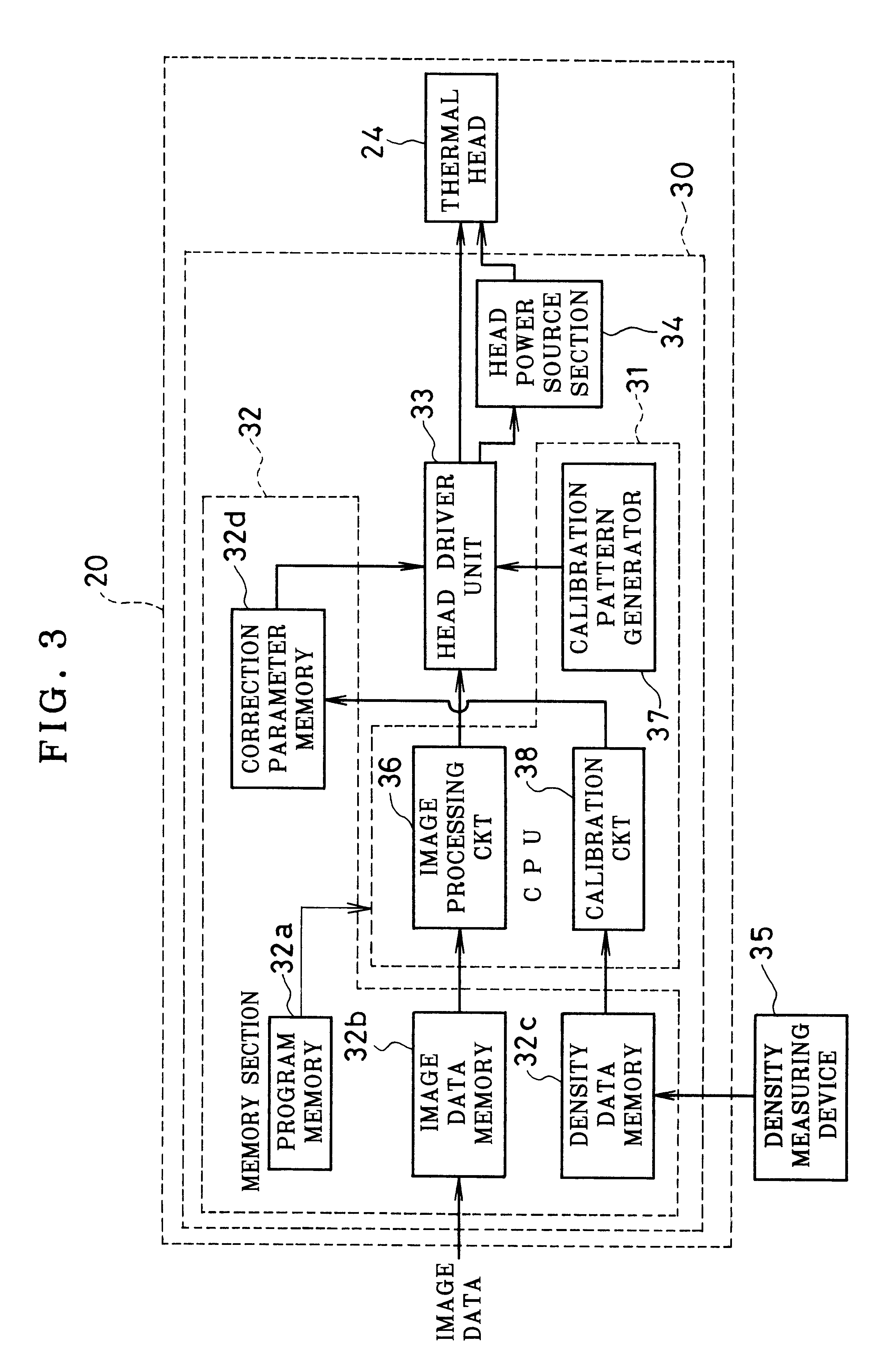

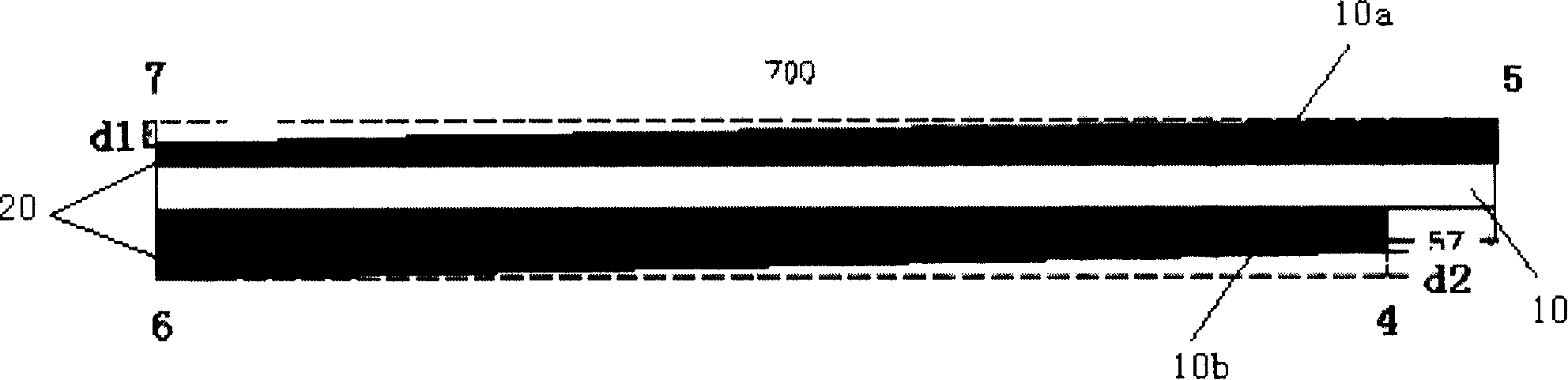

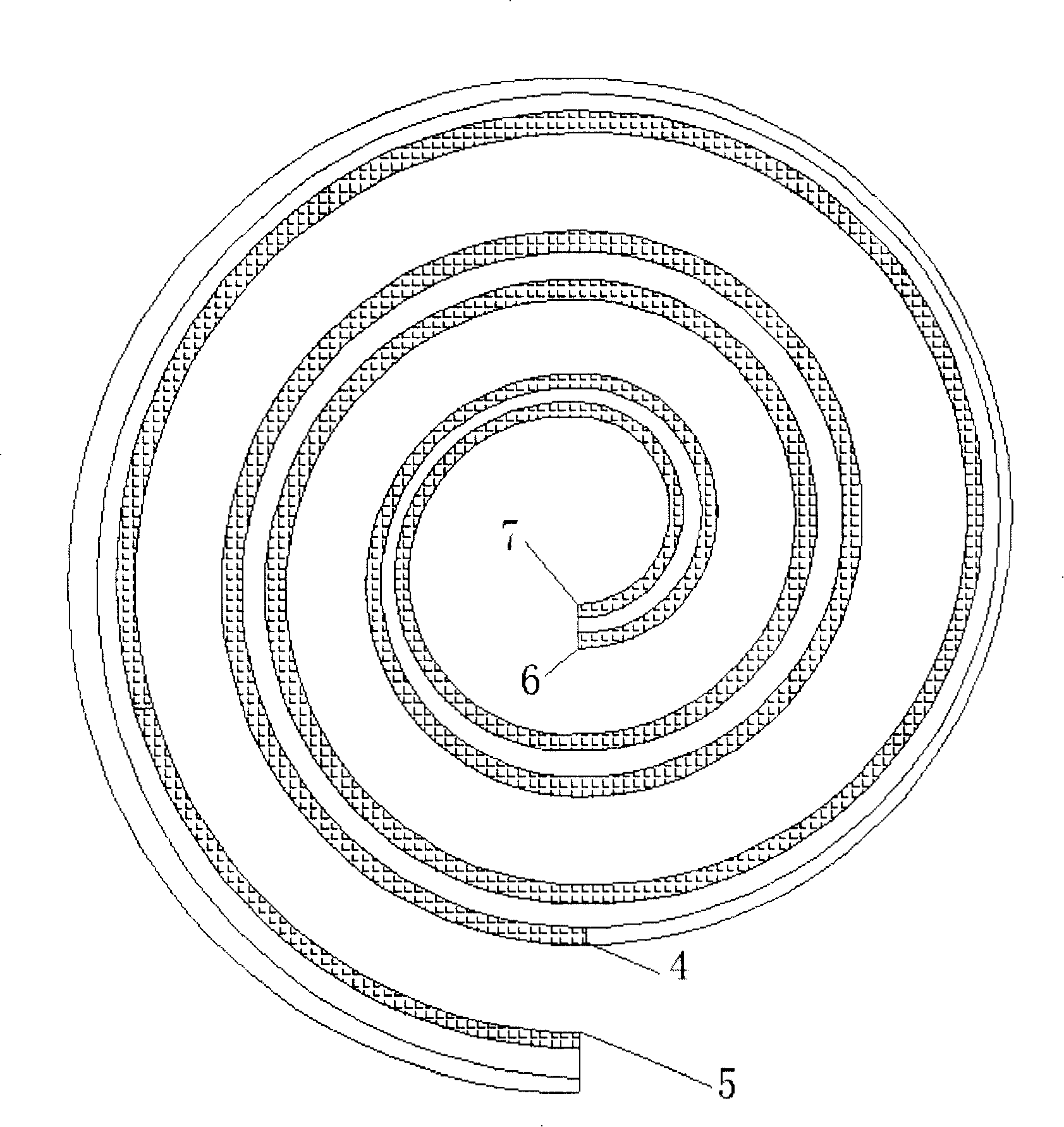

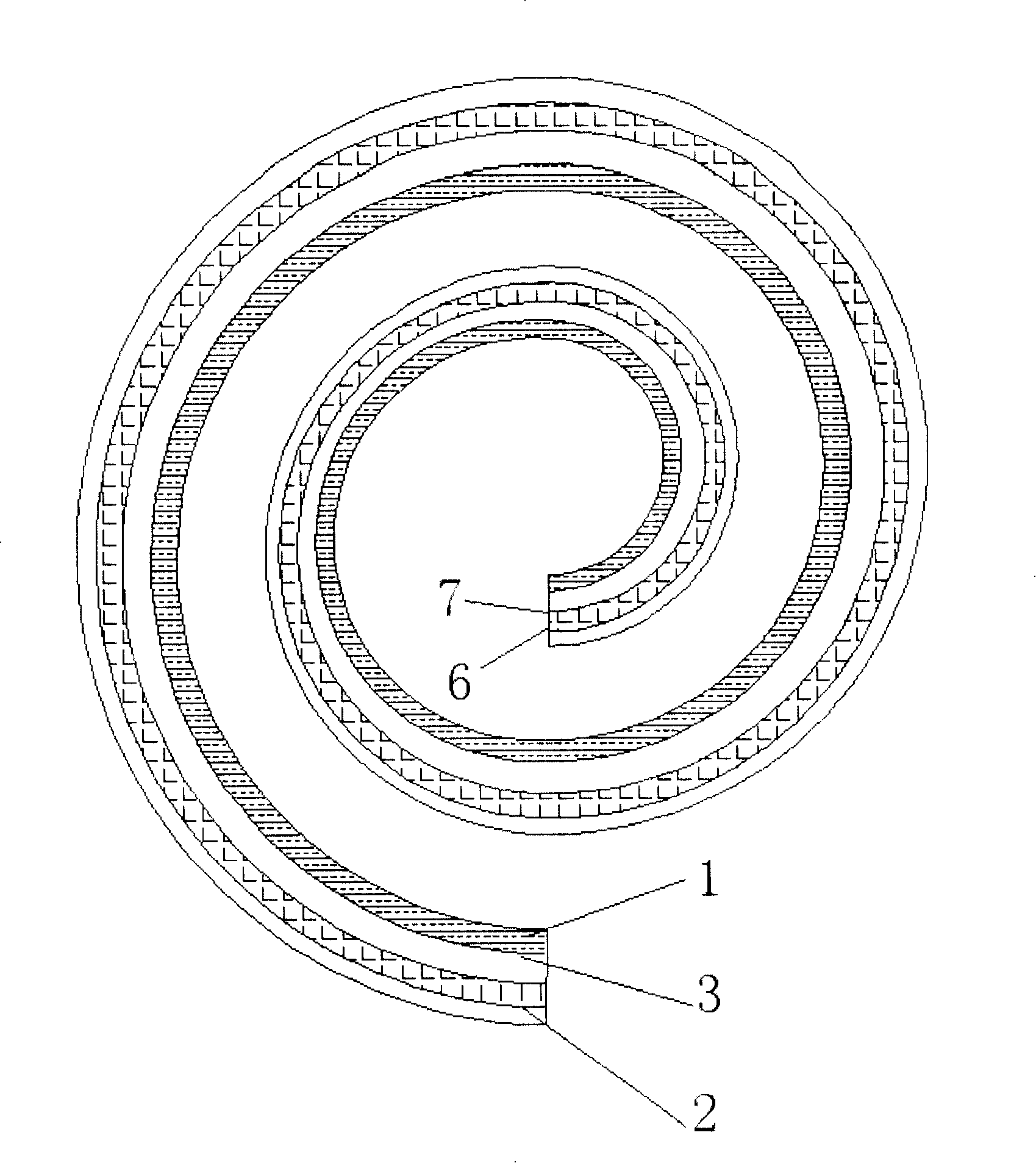

Printer calibration method and apparatus therefor

To calibrate a printer that prints a full-color image on a recording paper in a color frame sequential fashion, a gray pattern is printed by the printer onto a recording paper, to three color densities of the gray pattern. A recording energy correction amount for magenta is determined based on a difference between the measured magenta density and a set magenta density. Then density variations in yellow and cyan from their set values are estimated that would be resulted from the recording energy correction for magenta. Then recording energy correction amounts for yellow and cyan that reduce the estimated density variations are calculated. Thereafter, density variations in magenta and cyan that would be resulted from the recording energy correction for yellow are estimated, and recording energy correction amounts for magenta and cyan that reduce the estimated density variations are calculated. Also, density variations in magenta and yellow that would be resulted from the recording energy correction for cyan are estimated, and recording energy correction amounts for magenta and yellow that reduce the estimated density variations are calculated. The same procedures are repeated till estimated three color densities approximate the respective set values.

Owner:FUJIFILM HLDG CORP +1

Battery pole plate, method and device for producing the battery pole plate, and pole plate core and secondary battery

ActiveCN101212039AUniform thicknessPrecise thickness variationElectrode manufacturing processesFinal product manufactureSlurryEngineering

Owner:BYD CO LTD

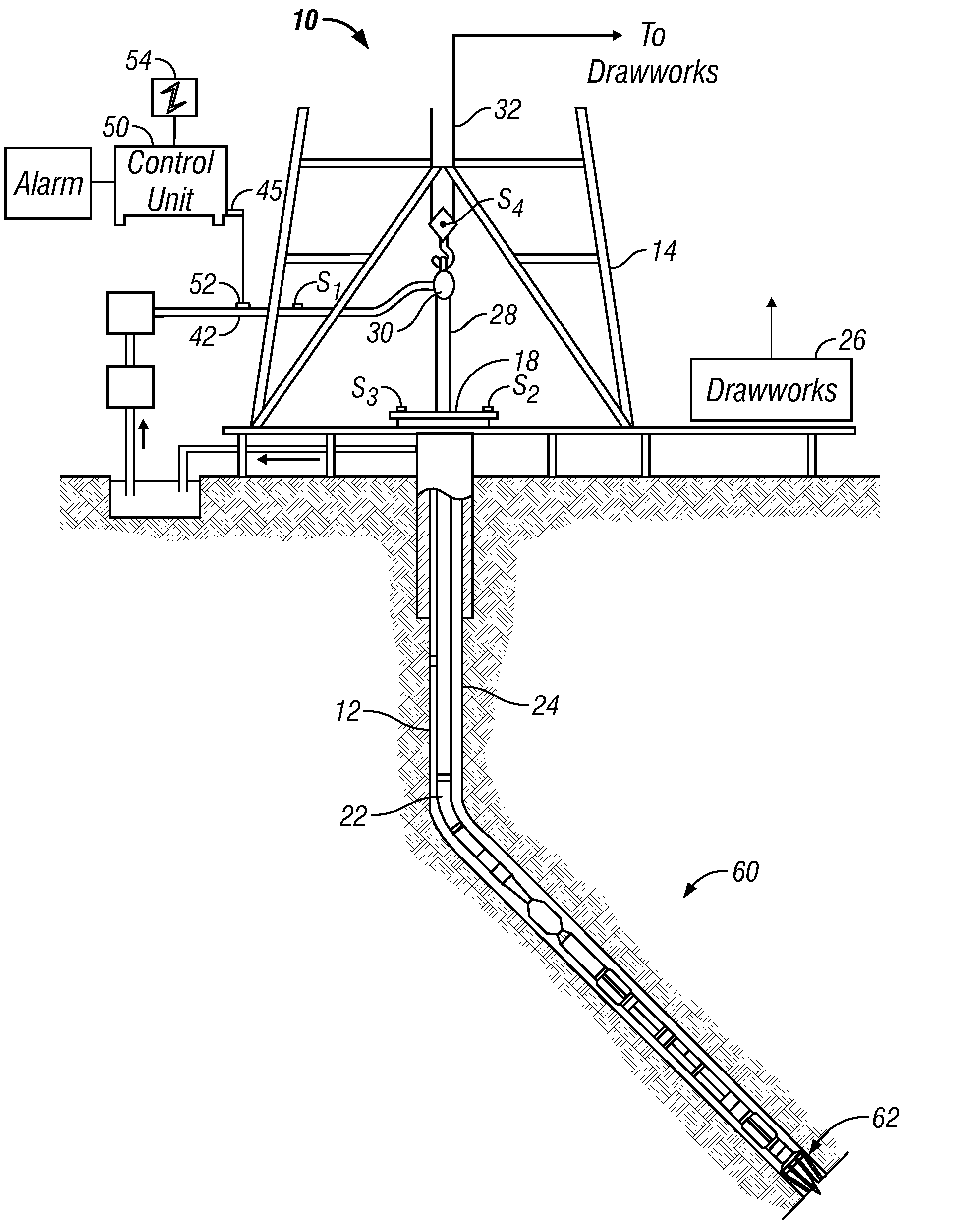

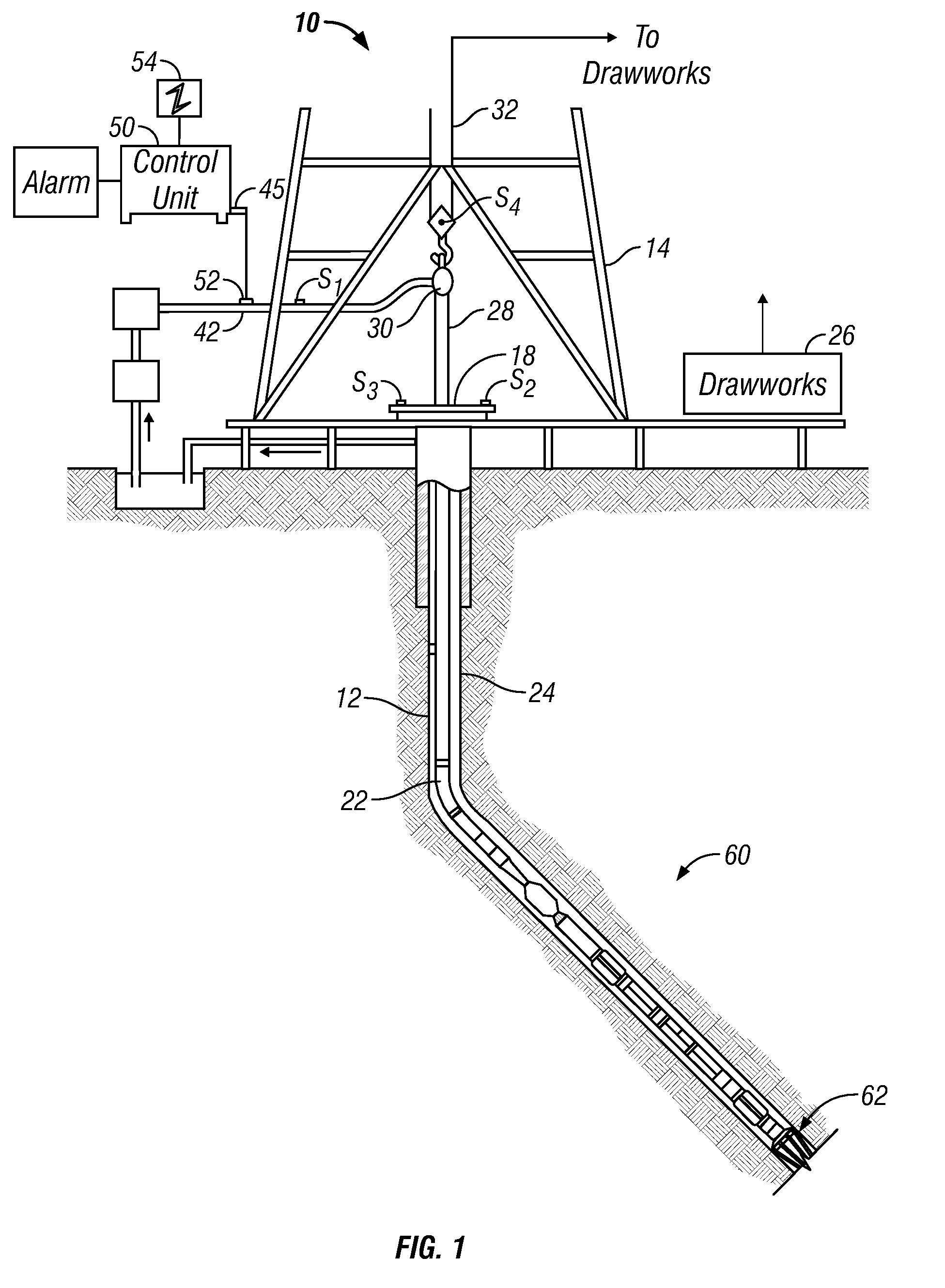

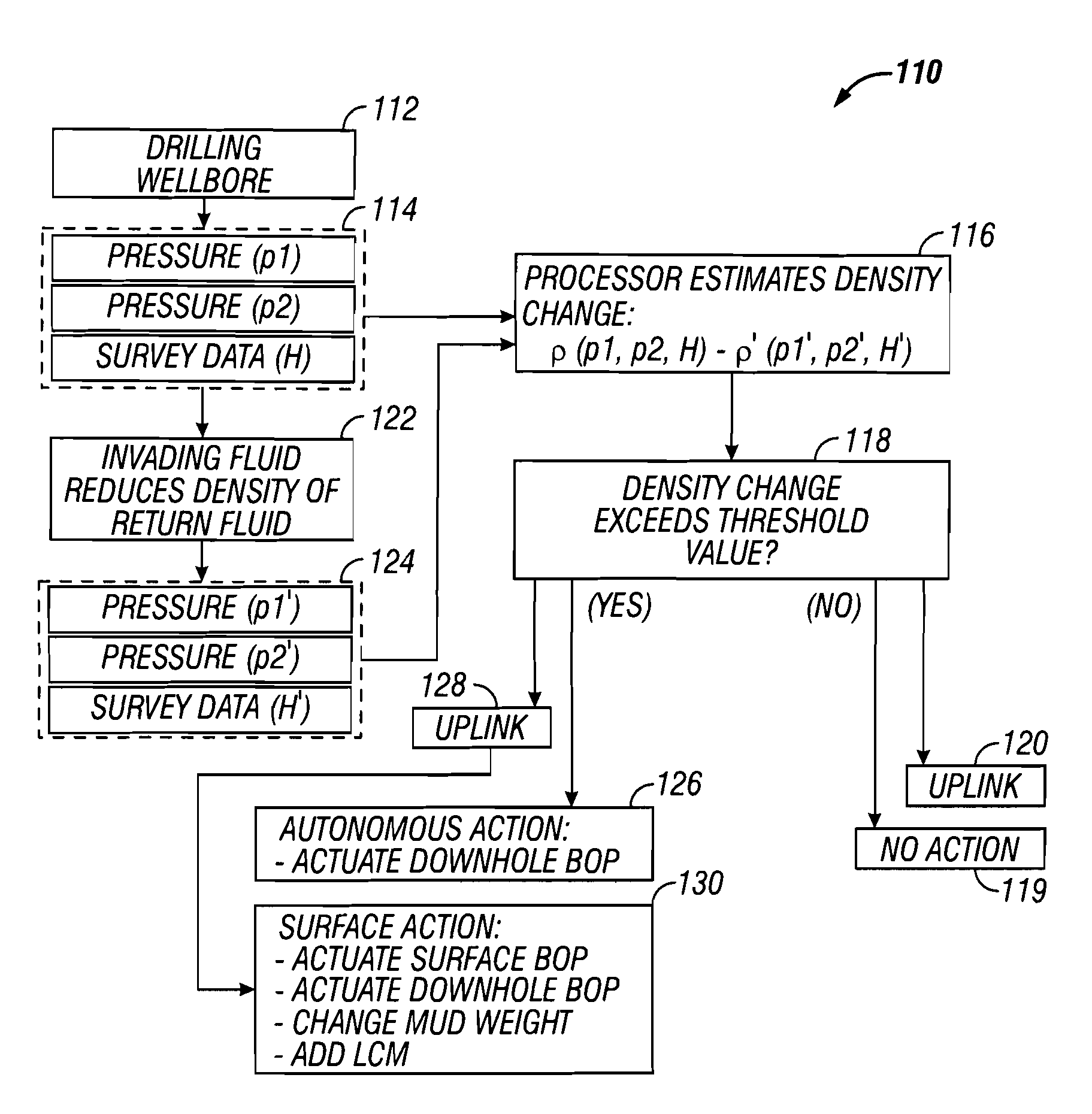

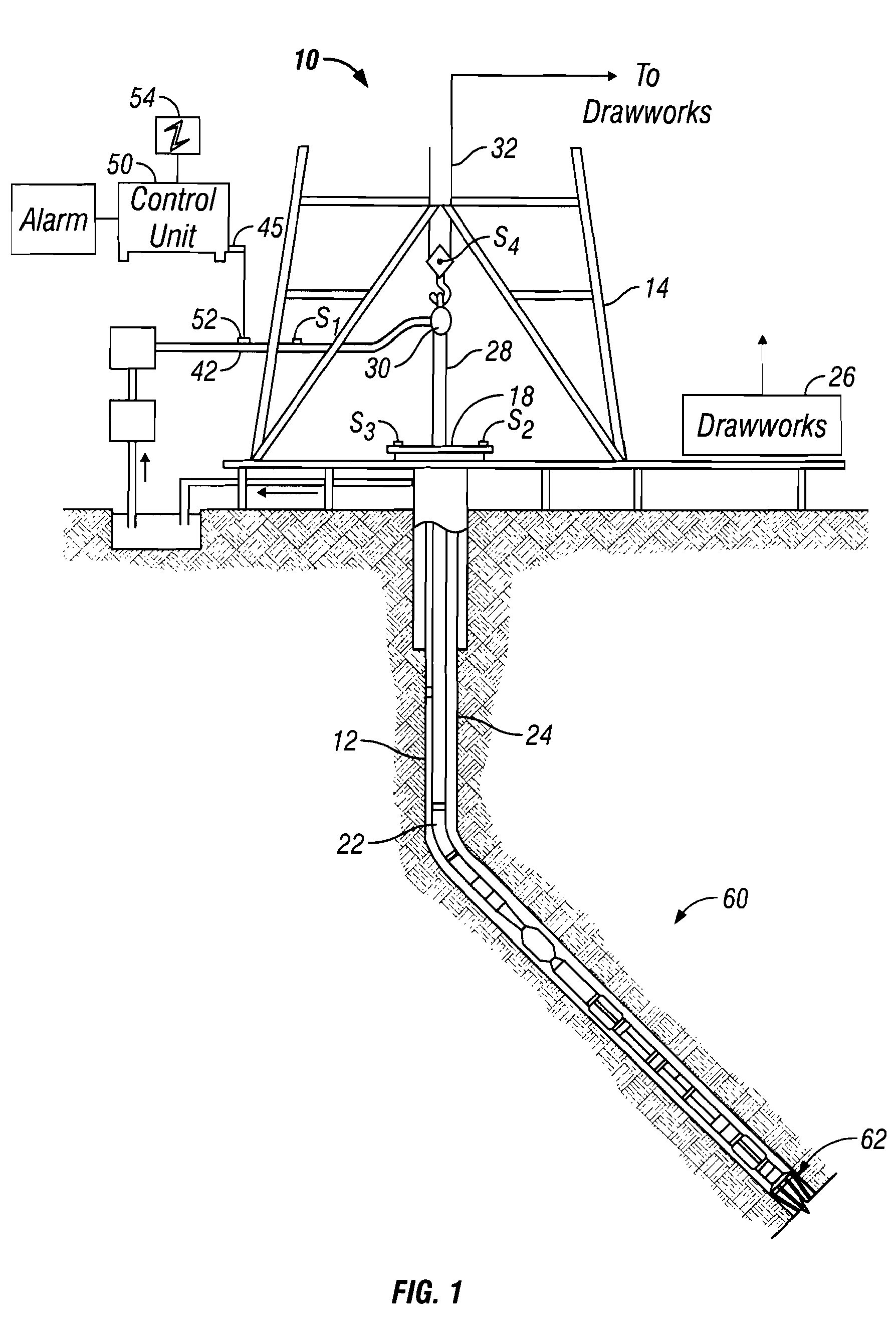

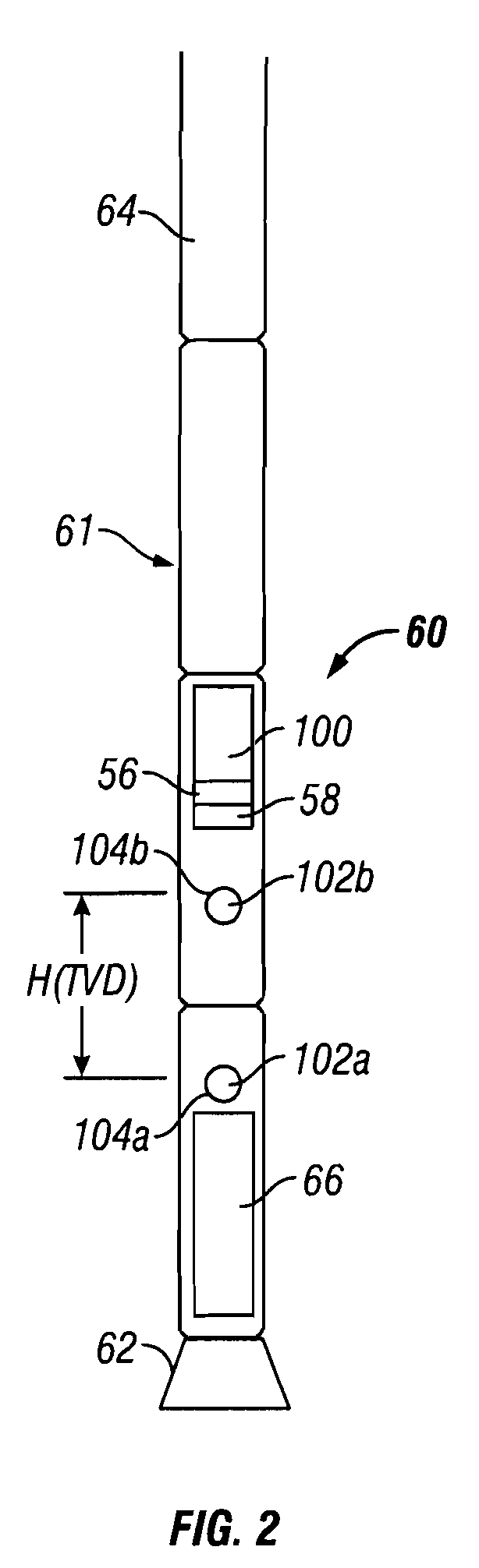

Downhole Local Mud Weight Measurement Near Bit

ActiveUS20090205822A1Reduce offsetElectric/magnetic detection for well-loggingSurveyVolumetric Mass DensityPressure difference

A method for detecting a change in a wellbore fluid includes estimating at least two pressure differences in the wellbore fluid and estimating a change in a density of the fluid using the at least two pressure differences. The density change may be estimated by the equation, Δρ=(ΔPbefore<sub2>—< / sub2>influx−ΔPafter<sub2>—< / sub2>influx) / (g×ΔTVD), wherein ΔP is a fluid pressure difference between two points along the wellbore, ρ is a mean value of density of the fluid between the two points, g is gravity and ΔTVD is a vertical distance between the two points. The method may include estimating a density change using an estimated inclination of the wellbore. An apparatus for estimating density changes includes at least two axially spaced apart pressure sensors. The sensor positions may be switched to estimate a correction term to reduce a relative offset between the two pressure sensors.

Owner:BAKER HUGHES INC

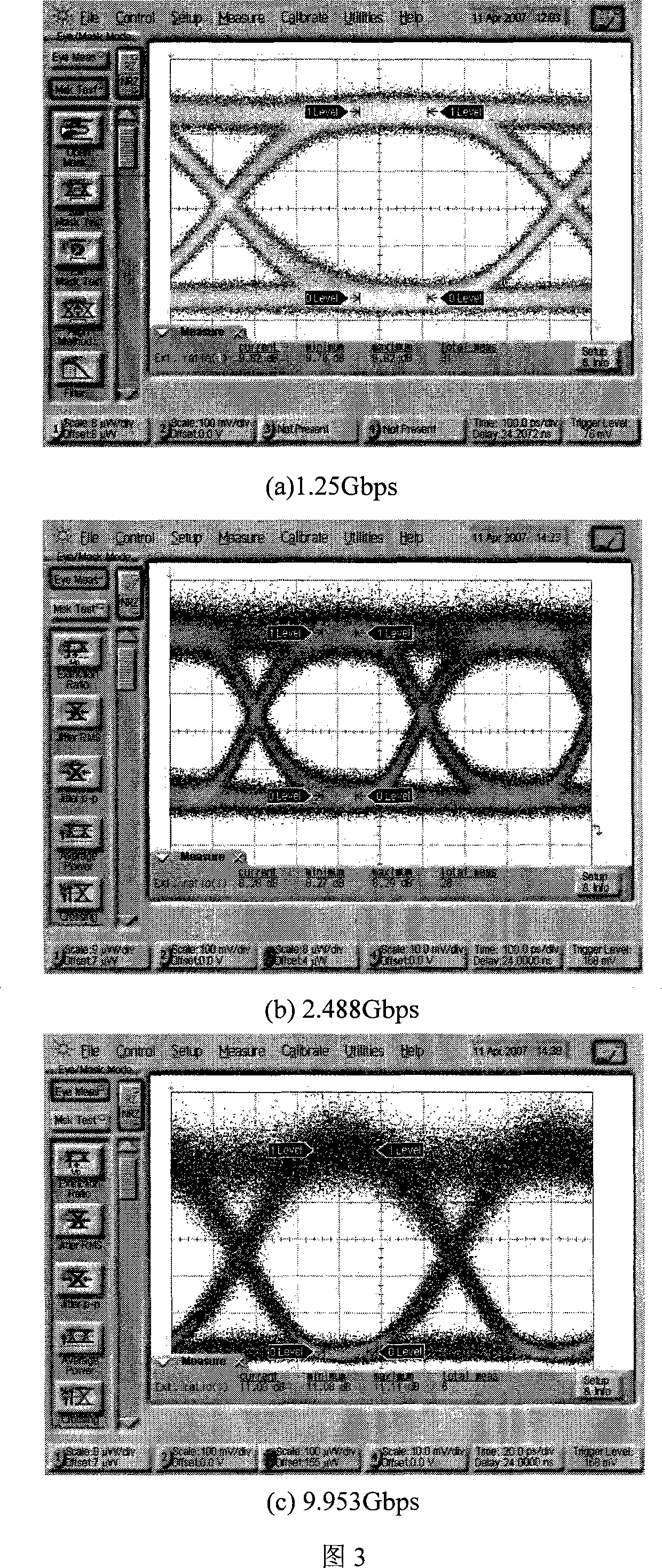

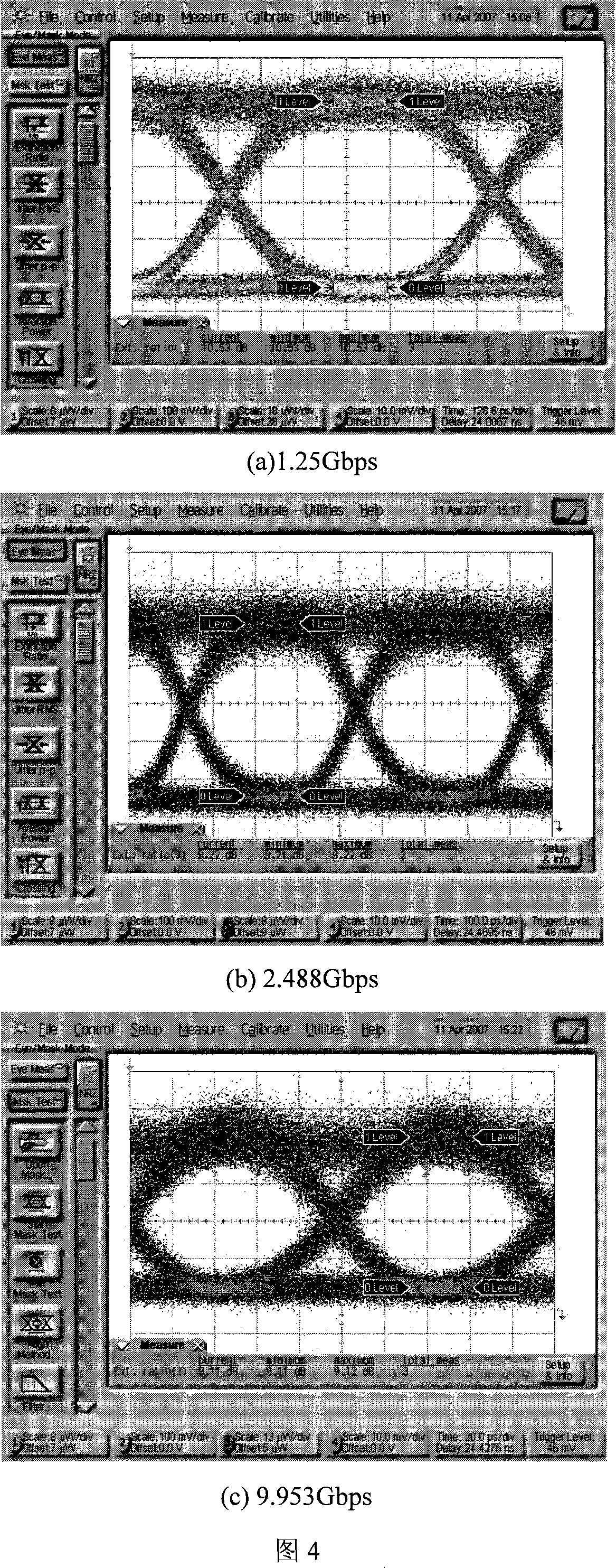

Low noise tunable single frequency fiber laser for full-optical communication and its test system

InactiveCN101083382AEfficient heat dissipationStable output powerCladded optical fibreActive medium materialPolarizerFiber gratings

The invention publishes a low noise harmonious mono-frequent optical fiber laser which is used in the entire optical communication and its test system, aimed at solving the density change of the free current carrier in the source area of the semiconductor laser launch process, caused the twitter effect to cause the line-breadth phenomenon, could not satisfy the question that the high speed large capacity development request of the high speed wavelength division multiplying system and the optical communication. The laser contains the pump source, the optical coupler, the light isolator, the invariable light attentuator, the wavelength division multiplexer, the erbium ytterbium double mix optical fiber, the light circulator, the optical fiber polarizer, the er-doped optical fiber and the harmonious fiber grating. The test system is composed of the optical fiber laser, the light modulator, the actuation module, the error code analyzer, the light oscilloscope or the error code analyzer, the receive module and the light attentuator. The laser has mono-frequent, low noise, low twitter; the output is stable; suitable to use in the high speed long distance optical communication and take as the photo source in the optical fiber sensing; the test system may carry on the test analysis to laser's high speed electric light modulating characteristic.

Owner:JILIN UNIV

Downhole local mud weight measurement near bit

ActiveUS7950472B2Reduce offsetSurveySpecific gravity by measuring pressure differencesVolumetric Mass DensityPressure difference

A method for detecting a change in a wellbore fluid includes estimating at least two pressure differences in the wellbore fluid and estimating a change in a density of the fluid using the at least two pressure differences. The density change may be estimated by the equation, Δρ=(ΔPbefore<sub2>—< / sub2>influx−ΔPafter<sub2>—< / sub2>influx) / (g×ΔTVD), wherein ΔP is a fluid pressure difference between two points along the wellbore, ρ is a mean value of density of the fluid between the two points, g is gravity and ΔTVD is a vertical distance between the two points. The method may include estimating a density change using an estimated inclination of the wellbore. An apparatus for estimating density changes includes at least two axially spaced apart pressure sensors. The sensor positions may be switched to estimate a correction term to reduce a relative offset between the two pressure sensors.

Owner:BAKER HUGHES HLDG LLC

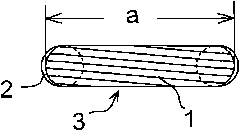

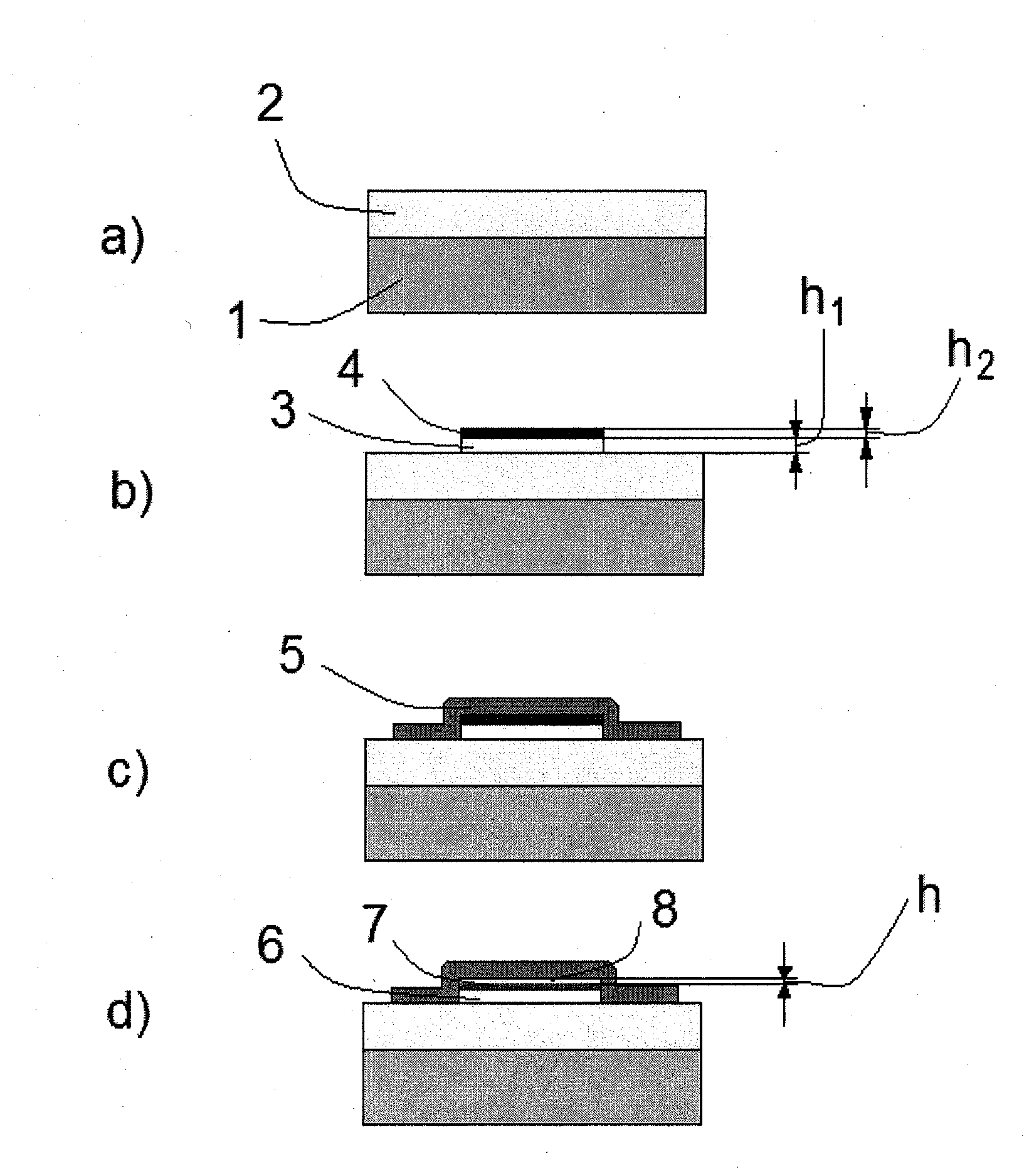

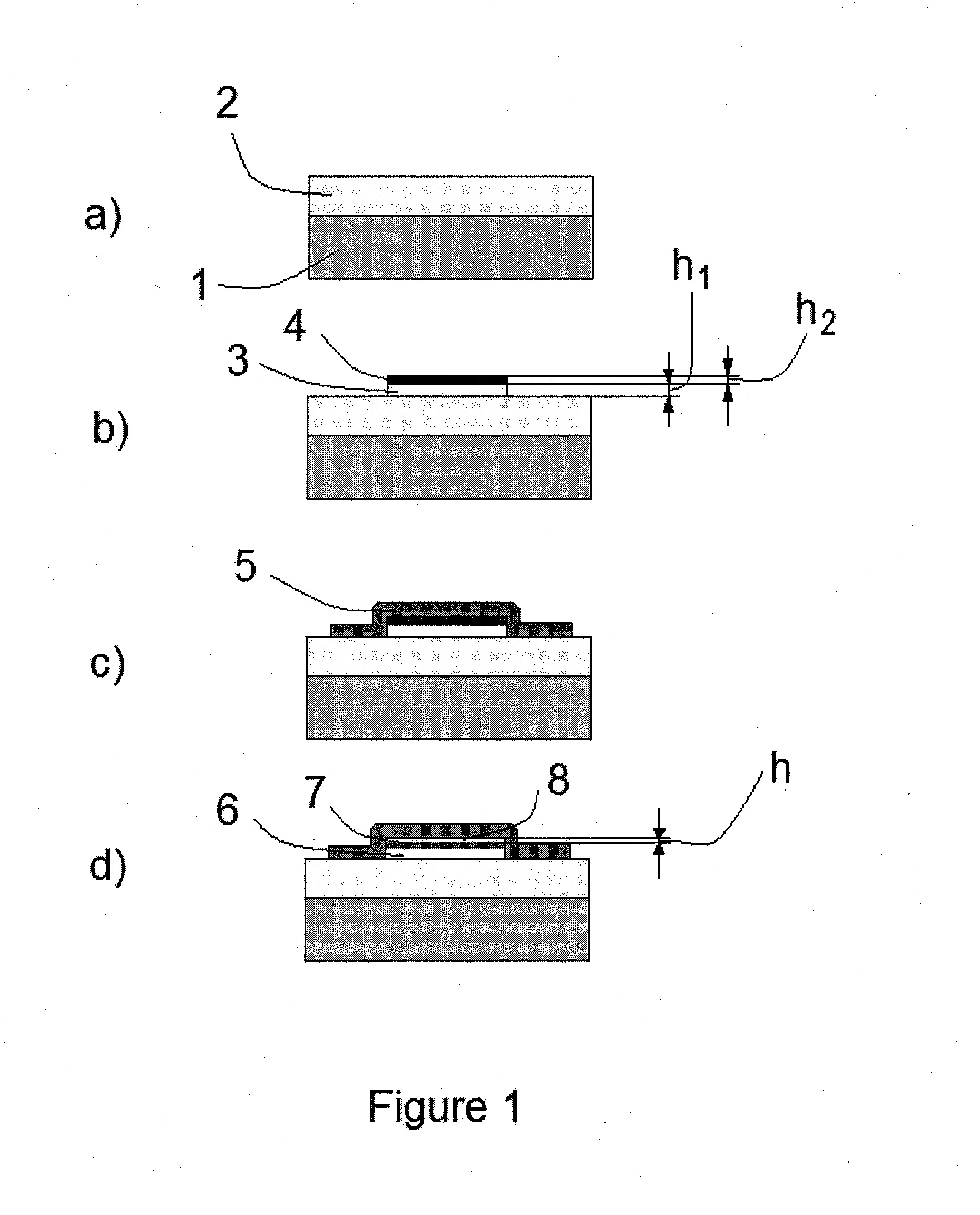

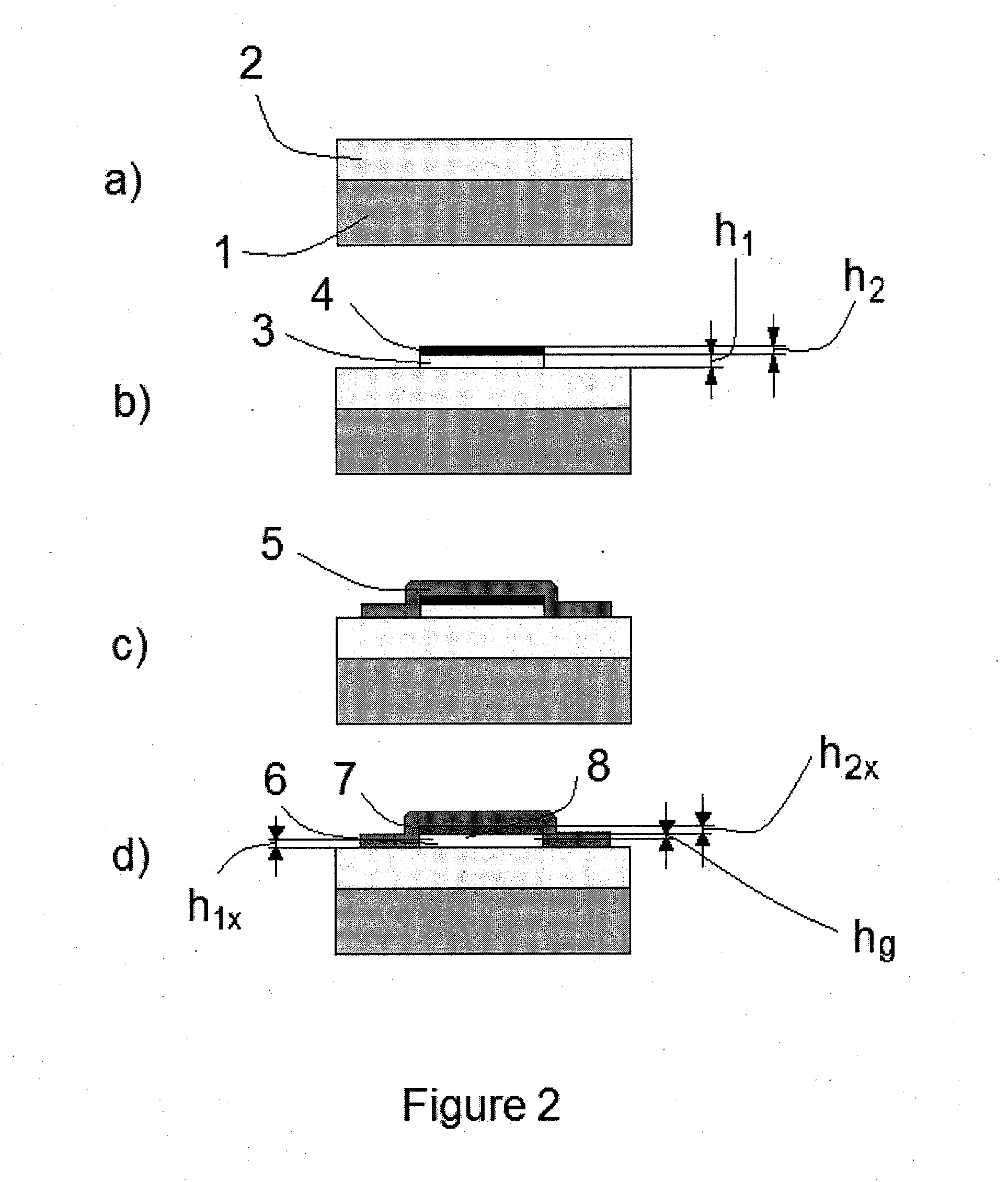

Electromechanical systems, waveguides and methods of production

InactiveUS20110133597A1Wave amplification devicesElectrostatic/electro-adhesion relaysMethods of productionWaveguide

A method of producing an electromechanical device includes forming a layer of density-changing material on a substructure, and forming a support layer on at least a portion of the layer of density-changing material. The density-changing material has a first density during the forming the layer and a second density subsequent to the forming the support layer, the second density being greater than the first density such that the layer of density-changing material shrinks in at least one dimension to provide a gap between the layer of density changing material and at least one of the support layer and the substructure. A combined electronic and electromechanical device has a substrate, an electronic circuit formed on the substrate, and an electromechanical system formed on the substrate to provide a combined electronic and electromechanical device on a common substrate. The electromechanical system comprises a structure that is free to move within a gap defined by the electromechanical system.

Owner:SCANNANOTEK

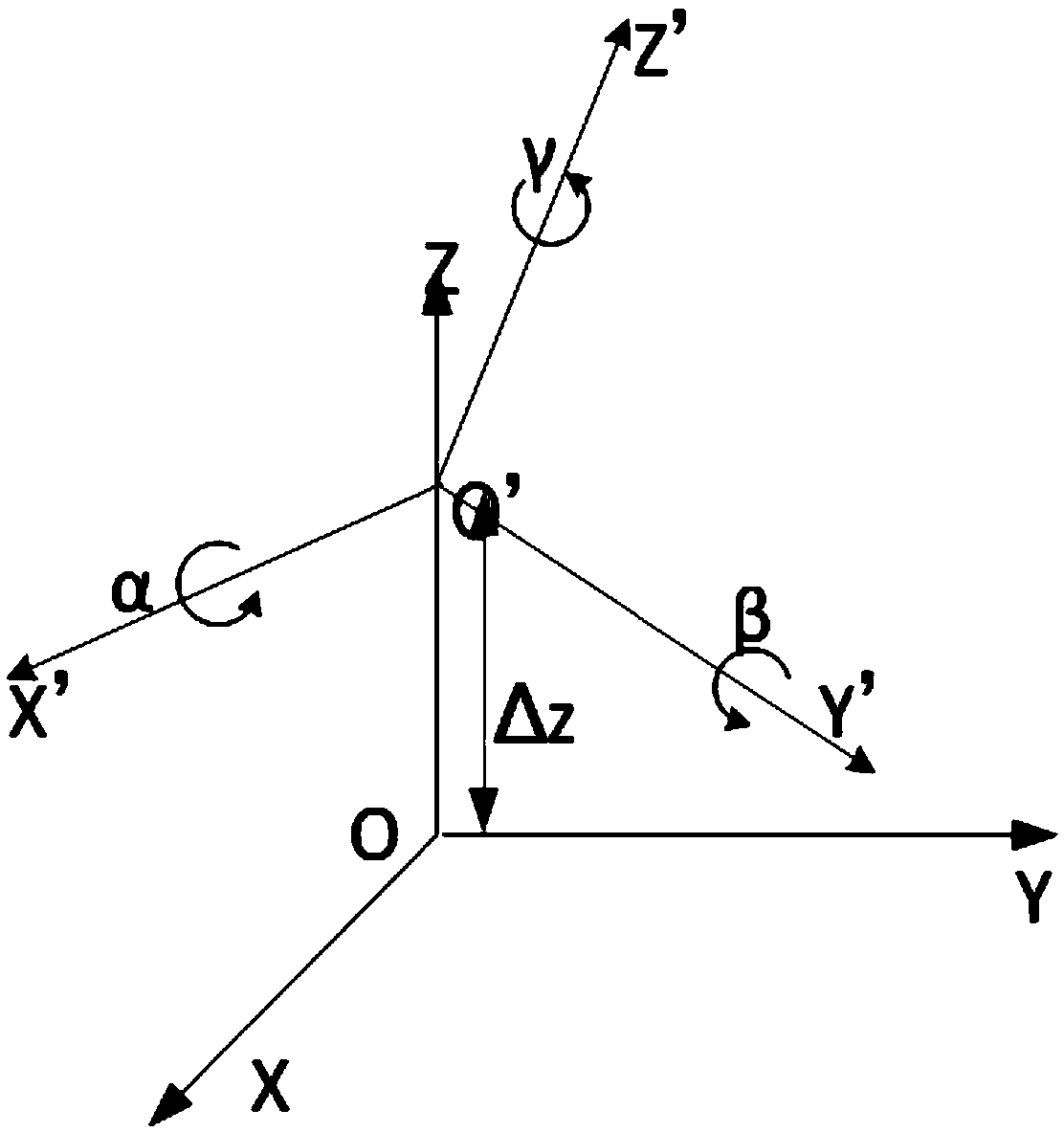

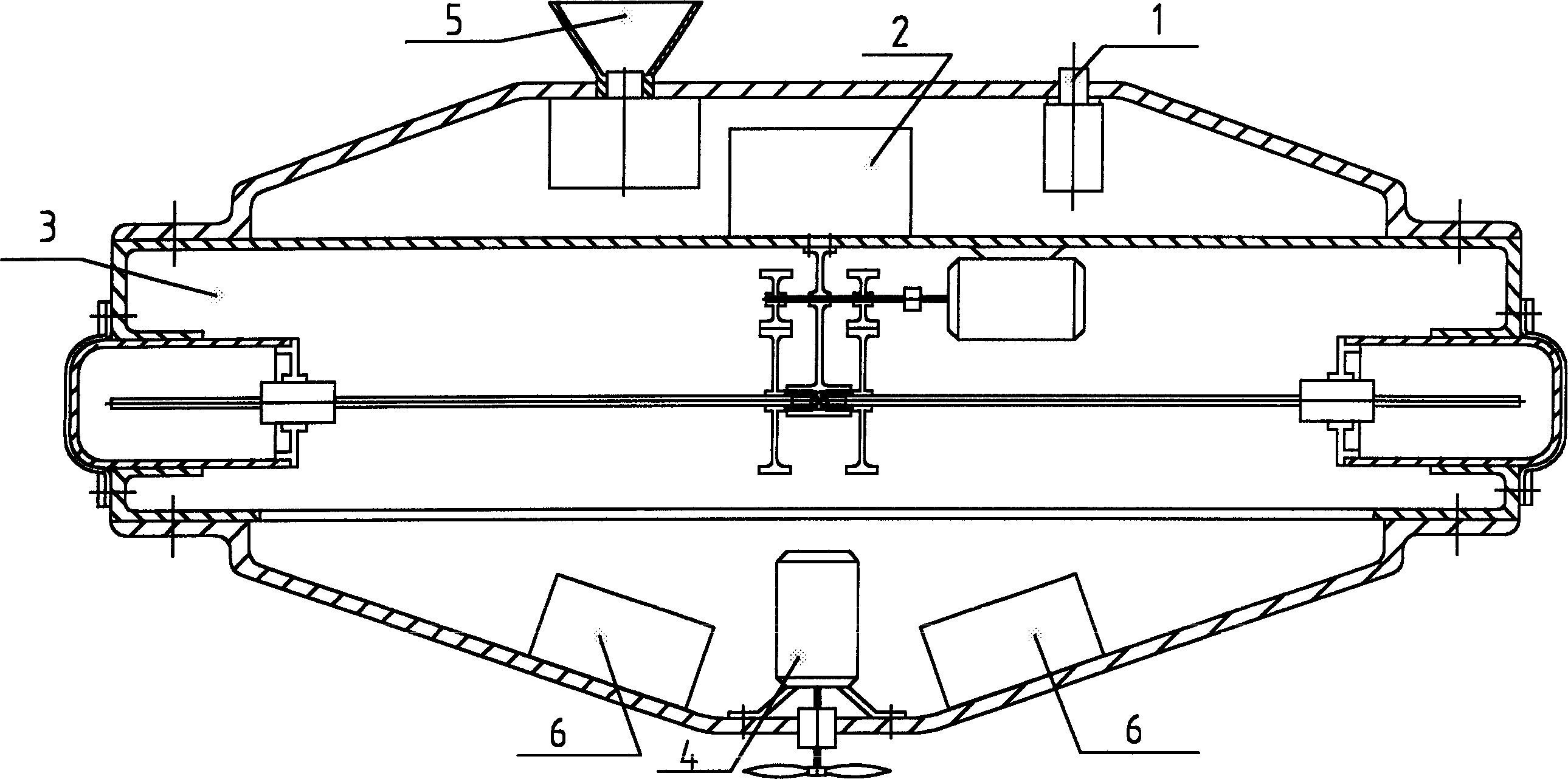

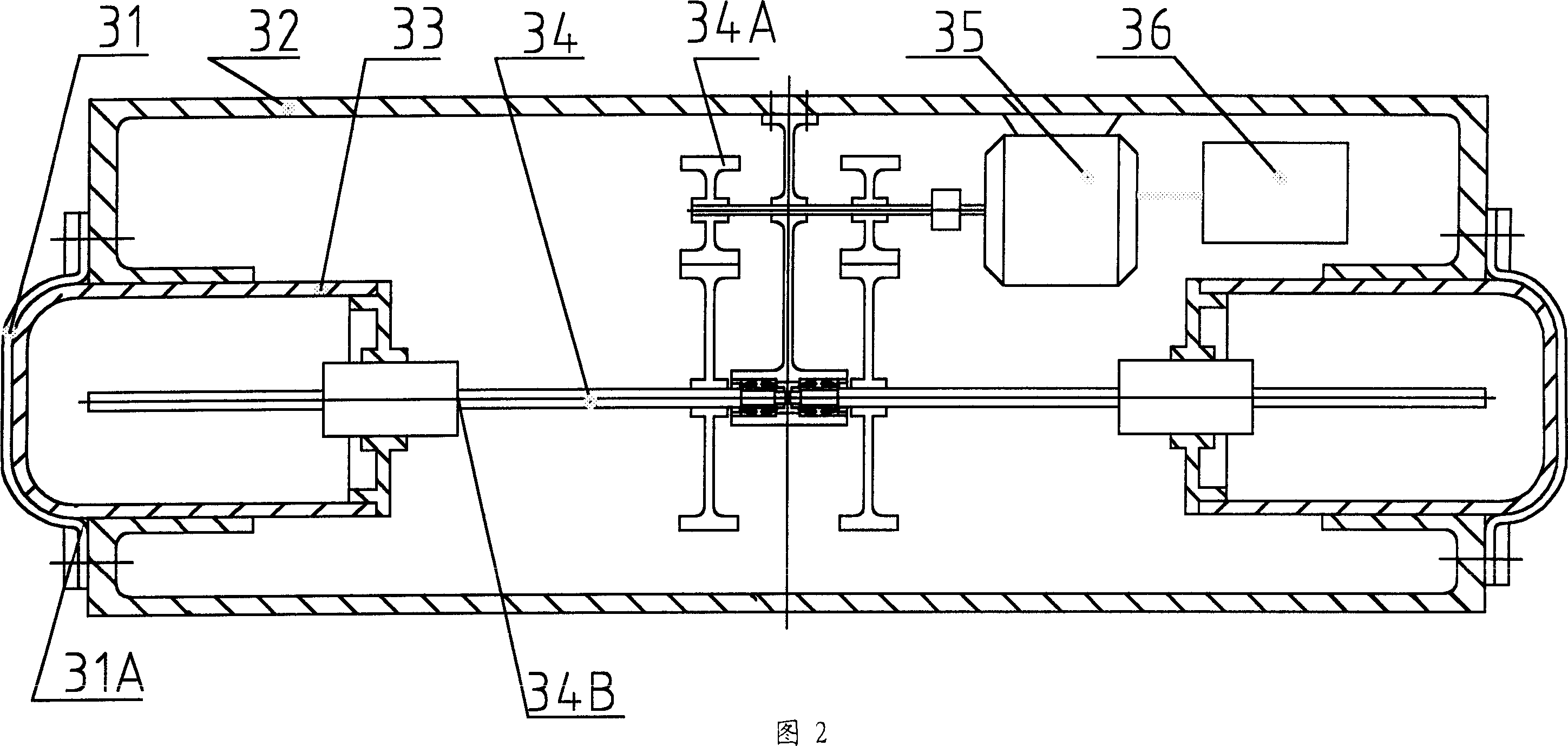

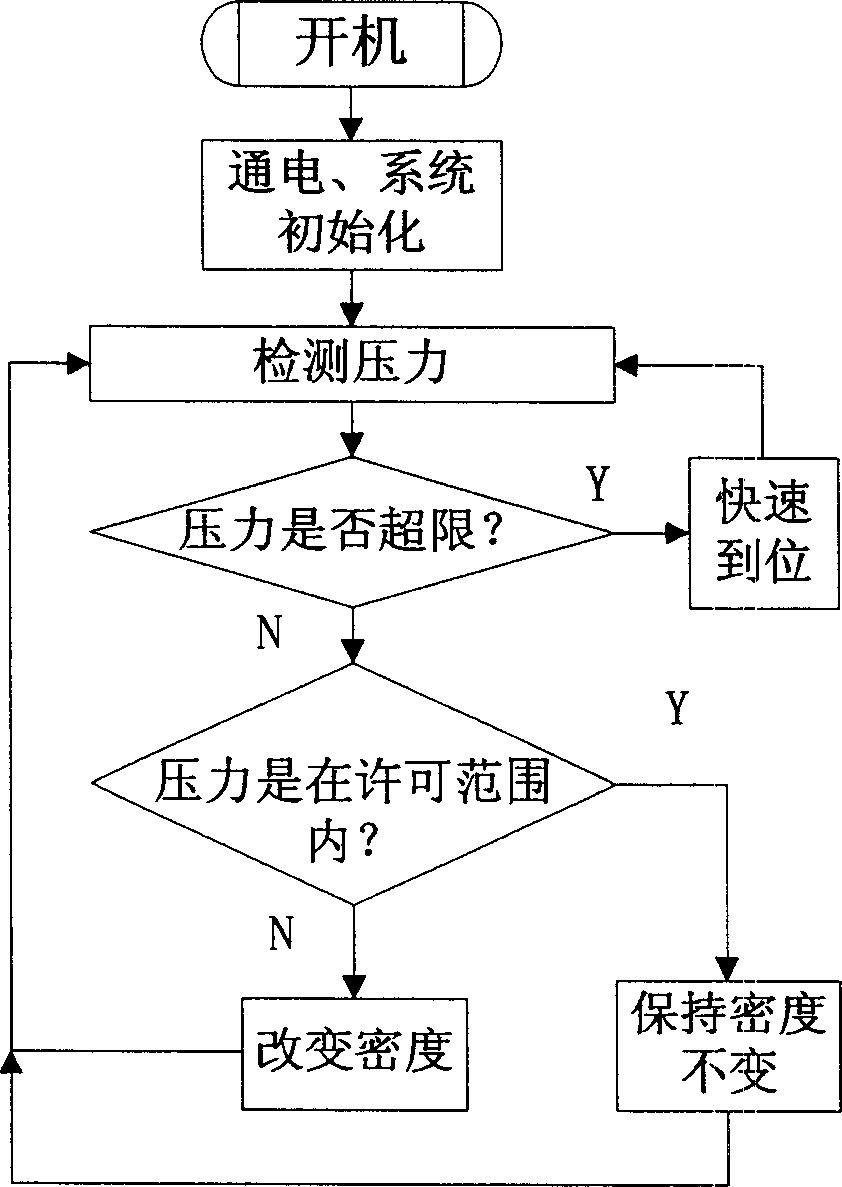

Location coordinate system for ocean work rising and sinking compensation and its location method

InactiveCN1515460AQuick responseShort transition timeVessel salvagingUnderwater equipmentOcean bottomTransducer

The present invention relates to a location coordinate system capable of retaining position stable marine work lifting-sinking compensation in underwater predefined depth and its location method. The system includes pressure sensor and transducer, controller, density change device, quickly in-position and reset device, power supply device and outer shell. The location coordinate system can utilize the control of density change device and quickly in-position and reset device to make it can autonomously drive and rise in the sea-water, and can dynamically be retained in predefined depth, location method is fast in response speed, short in transition time and quick and accurate in location.

Owner:GUANGDONG UNIV OF TECH

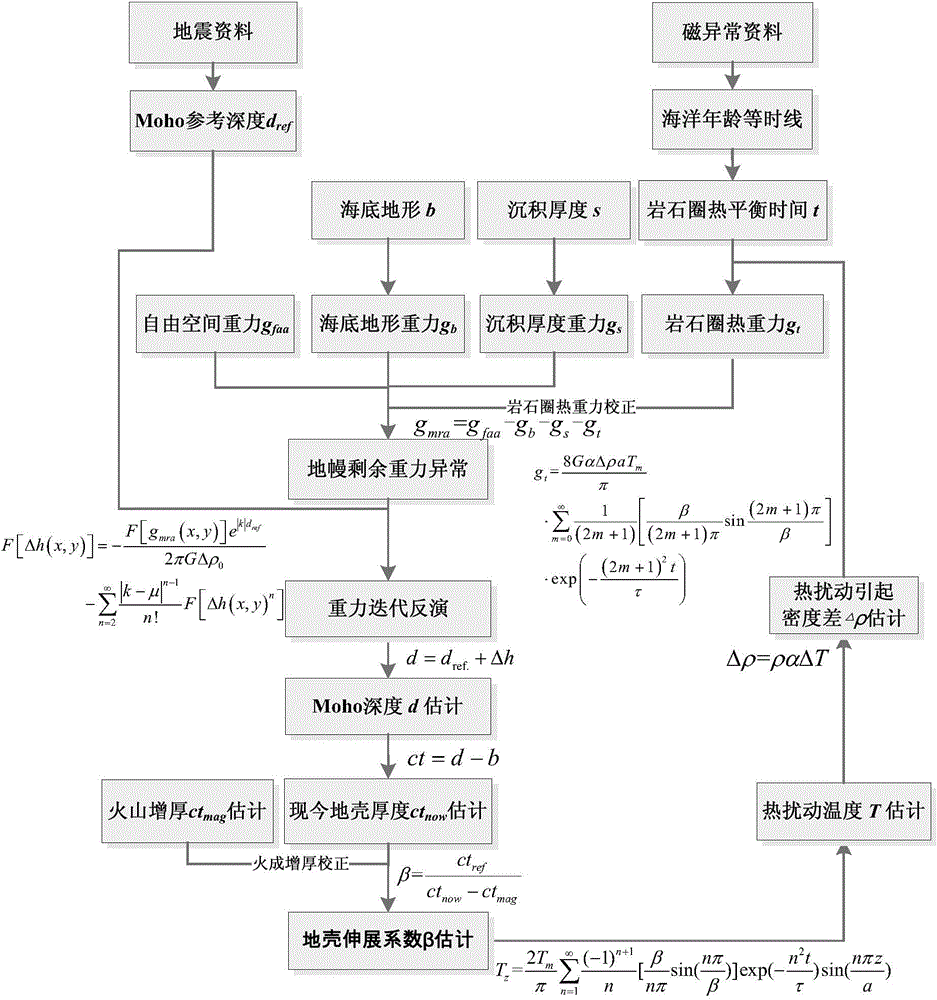

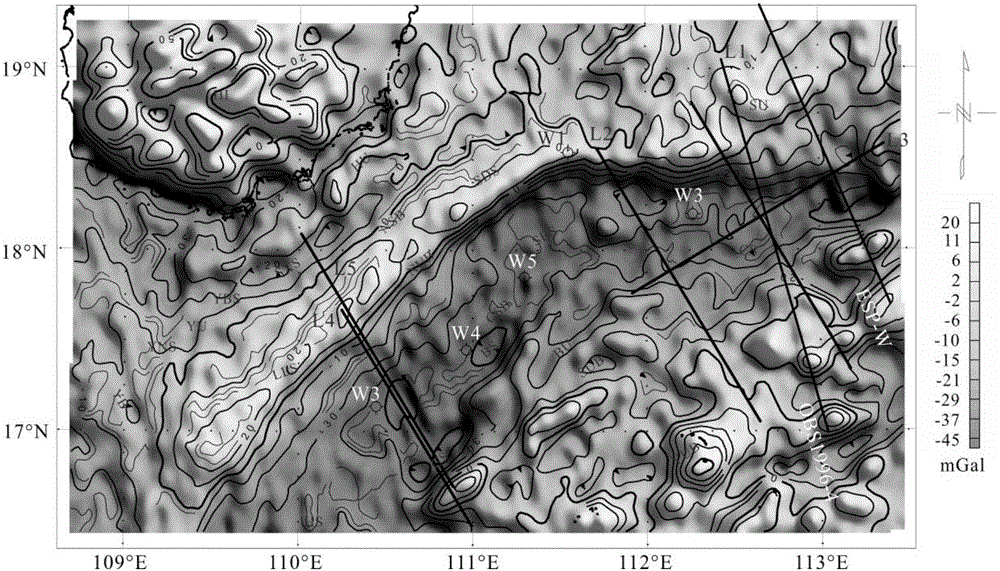

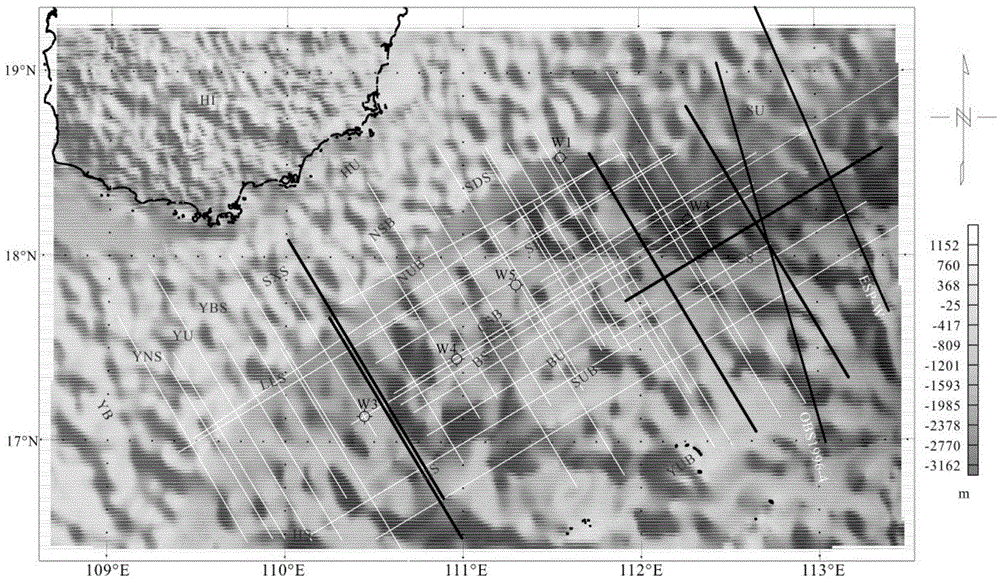

Depth-varying-to-density earth crust extension coefficient thermal calibration gravity anomaly retrieval method

InactiveCN104459795AReduce distortion effectsReduce calculationSeismic signal processingTopographyMagnetic anomaly

The invention discloses a depth-varying-to-density earth crust expansion coefficient thermal calibration gravity anomaly retrieval method. In the calculation process of a gravity retrieval earth crust expansion coefficient, a lithosphere thermal gravity anomaly calibration and depth constraint strategy is introduced, according to an iterative computation method of multiple parameter constraints such as a submarine topography, a sedimentary thickness, magnetic anomaly, an ocean age isochron and earthquake reflection and refraction, a distortion effect, caused by earth crust density changes resulted from lithosphere thermal disturbance, on gravity interpretation is corrected, and a basis is provided for knowing earth crust expansion and cracking processes.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com