Battery pole plate, method and device for producing the battery pole plate, and pole plate core and secondary battery

A battery electrode and electrode sheet technology, which is applied in secondary battery manufacturing, electrode manufacturing, active material electrodes, etc., can solve the problems of low safety, small battery capacity decay rate, and large battery capacity decay rate, and achieve accurate thickness changes , good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

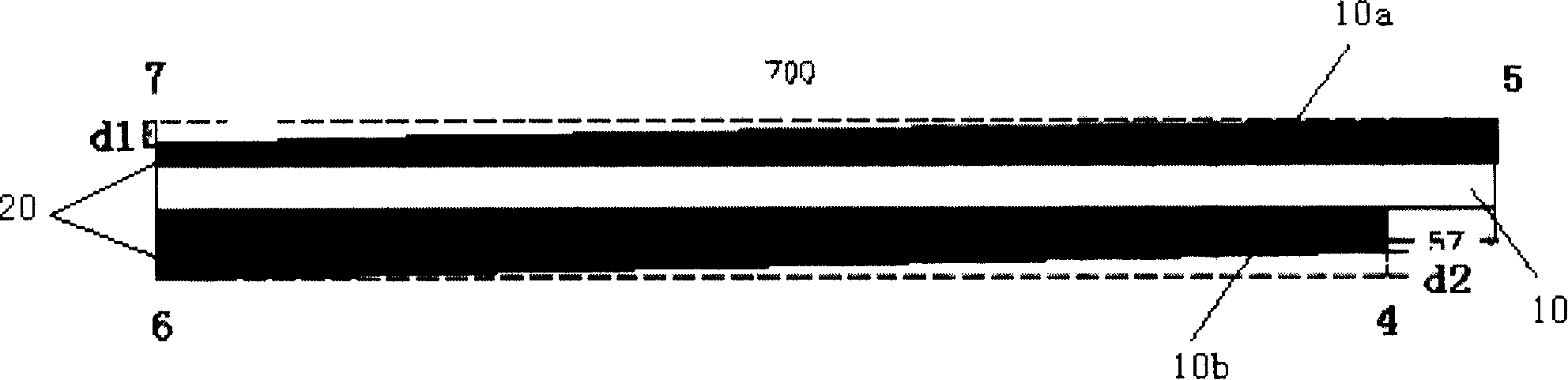

[0033] According to the preparation method of the battery electrode sheet provided by the present invention, the method comprises coating the slurry containing the electrode active material on both sides of the current collector 10, drying and pressing the sheet, wherein the slurry containing the electrode active material is coated on the The amount of both sides of the current collector 10 makes the surface density of the electrode material on the two surfaces of the electrode sheet change along the length direction of the electrode sheet, and the direction of change of the surface density of the electrode material on the two surfaces is opposite.

[0034] When preparing the battery pole piece, to achieve the surface density of the electrode material on the pole piece to change along the length direction of the electrode pole piece, it is easy to realize the thickness of the electrode material used to control the coating. Therefore, the preparation method is preferably: The sl...

Embodiment 1

[0072] This embodiment illustrates the negative electrode sheet, battery cell and lithium-ion battery provided by the present invention, as well as the pulping equipment used.

[0073] (1) Preparation of positive pole piece

[0074] The positive electrode material coating slurry is prepared by the following method: 15 parts by weight of polyvinylidene fluoride (Atofina Company, 761#PVDF) is dissolved in 225 parts by weight of N-methyl-2-pyrrolidone (NMP) solvent. Obtain binder solution, disperse 15 parts by weight of carbon black (the commodity of TIMICAL company, super-p under the trade name) in the above-mentioned binder solution, then add 500 parts by weight of positive electrode active material lithium manganese oxide in the gained solution, fully Mix evenly to prepare the positive electrode material coating slurry.

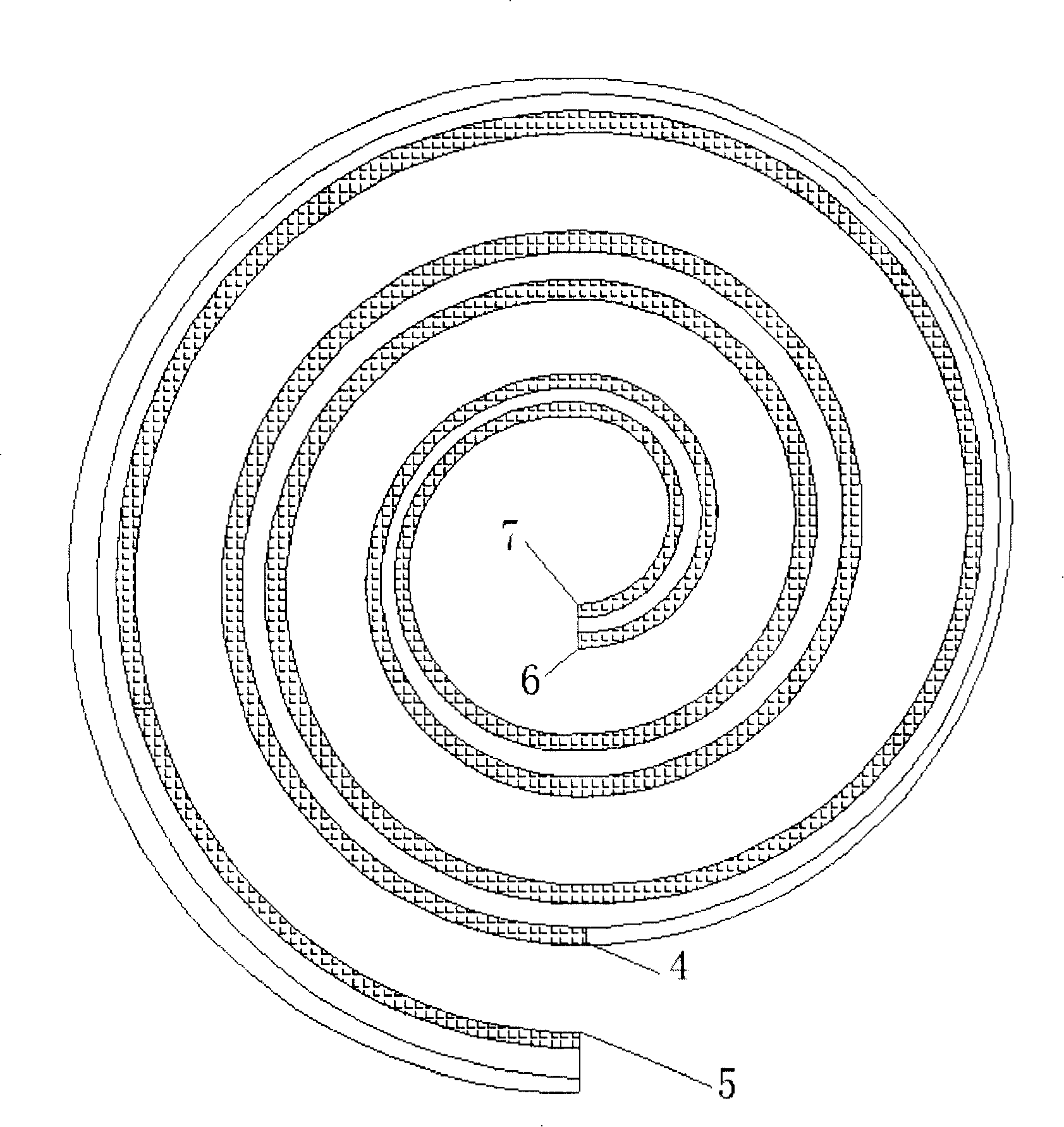

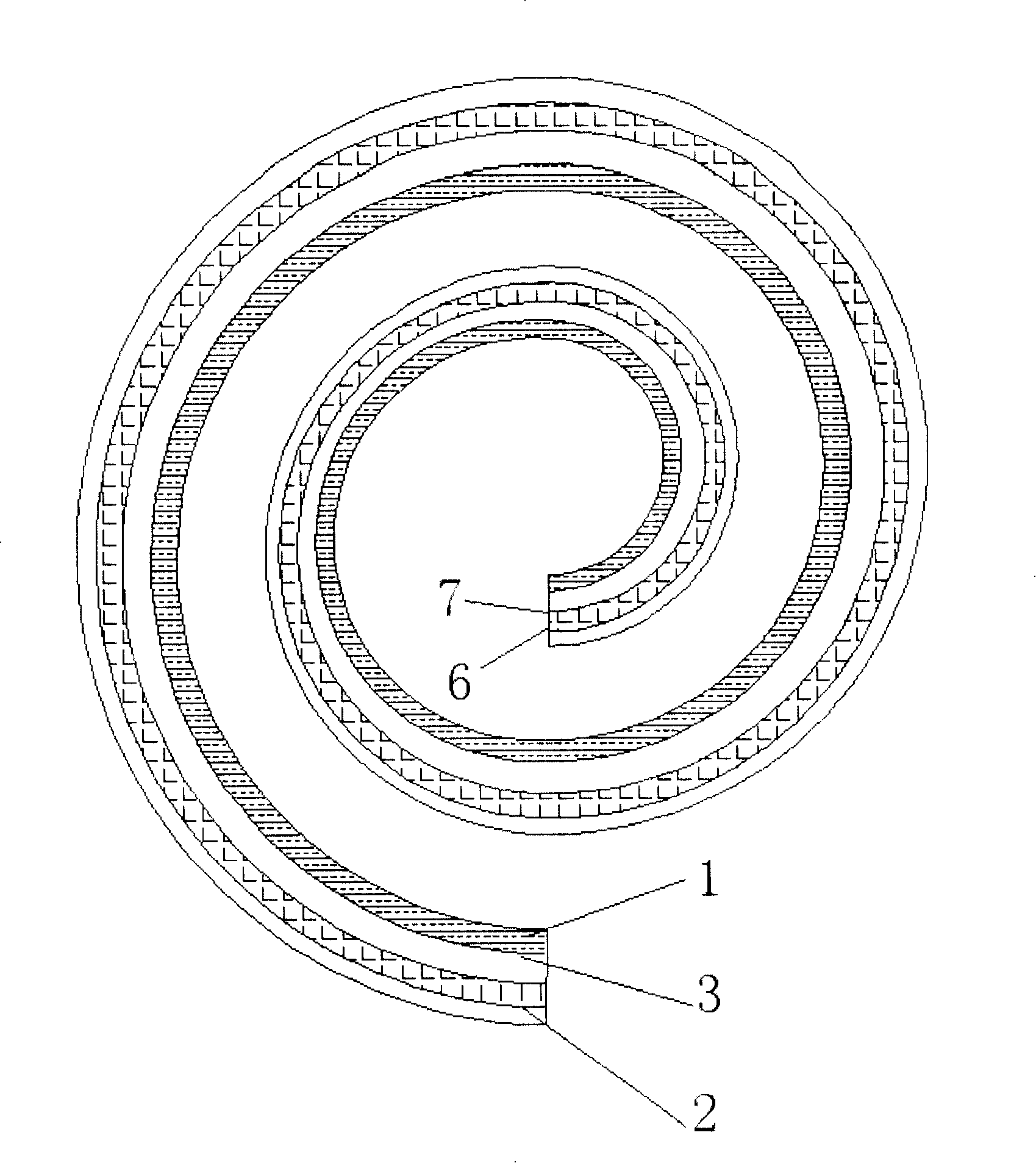

[0075] Coat the positive electrode material coating slurry on the aluminum foil with ordinary slurry drawing equipment, the thickness of the positive electr...

Embodiment 2

[0086] This embodiment illustrates the positive electrode sheet, battery cell and lithium ion battery provided by the present invention and the used pulping equipment.

[0087] (1) Preparation of positive pole piece

[0088] The positive electrode material coating slurry is prepared by the following method: 15 parts by weight of polyvinylidene fluoride (Atofina Company, 761#PVDF) is dissolved in 225 parts by weight of N-methyl-2-pyrrolidone (NMP) solvent. Obtain binder solution, disperse 15 parts by weight of carbon black (the commodity of TIMICAL company, super-p by trade name) in the above-mentioned binder solution, then add 500 parts by weight of lithium manganese oxide in the gained solution, fully mix and prepare Obtain positive electrode material coating slurry.

[0089] The above-mentioned positive electrode slurry is coated on both sides of the aluminum foil serving as a current collector with the slurry drawing equipment provided by the present invention, wherein the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com