Method for improving cigarette soot whiteness

A technology for ash whiteness and cigarettes, which is applied in the fields of tobacco, tobacco preparation, tobacco processing, etc., can solve the problems of reduced tar release and CO release, poor flammability of cut tobacco, etc., and achieves reduced tar release, rich aroma, and improved purity. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

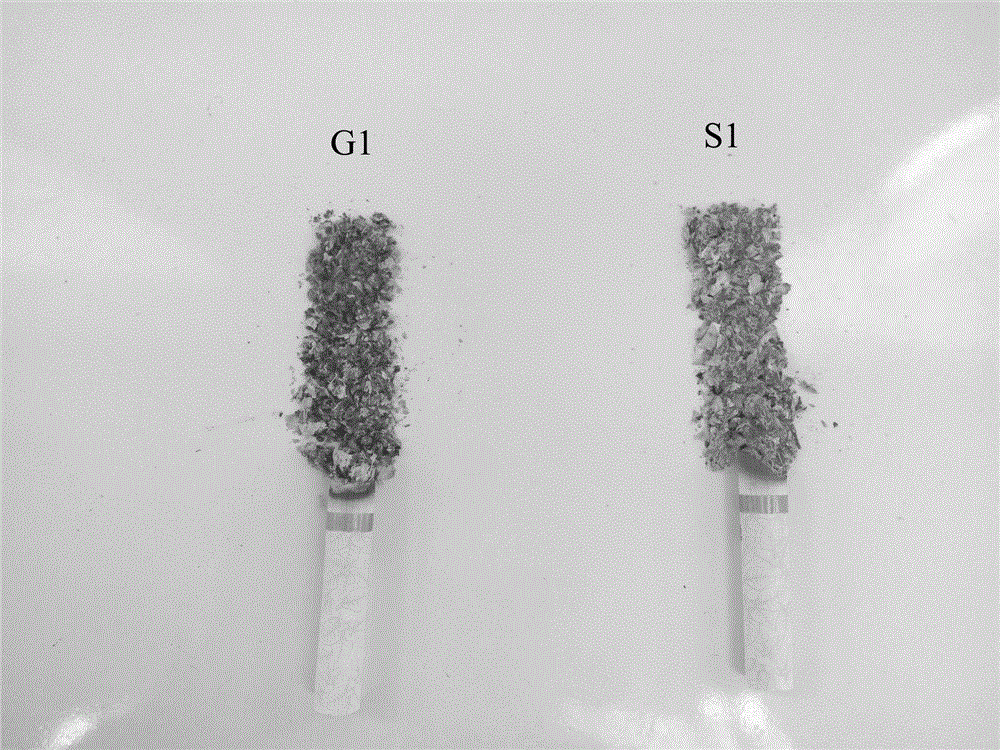

Embodiment 1

[0038] Utilize the method for improving cigarette ashes of the present invention to roll conventional high-grade cigarettes, comprising the following steps:

[0039] (1) Raw material preparation: tobacco leaf raw materials include paper-making reconstituted tobacco leaves and mature tobacco leaves with a potassium-to-chlorine ratio greater than 4, and the amount of paper-making reconstituted tobacco leaves is 10%;

[0040] (2) Silk production:

[0041] ①Vacuum moisture regain and loose moisture regain: the tobacco leaf raw material obtained in step (1) is subjected to vacuum moisture regain and loose moisture regain in sequence, and the moisture content is increased to 18.0%, so as to facilitate the treatment of subsequent processes;

[0042] 2. Sieving and charging: firstly, the tobacco leaves with a length of less than 6mm are screened out and their moisture content and temperature are appropriately increased to facilitate further processing in the subsequent process, and th...

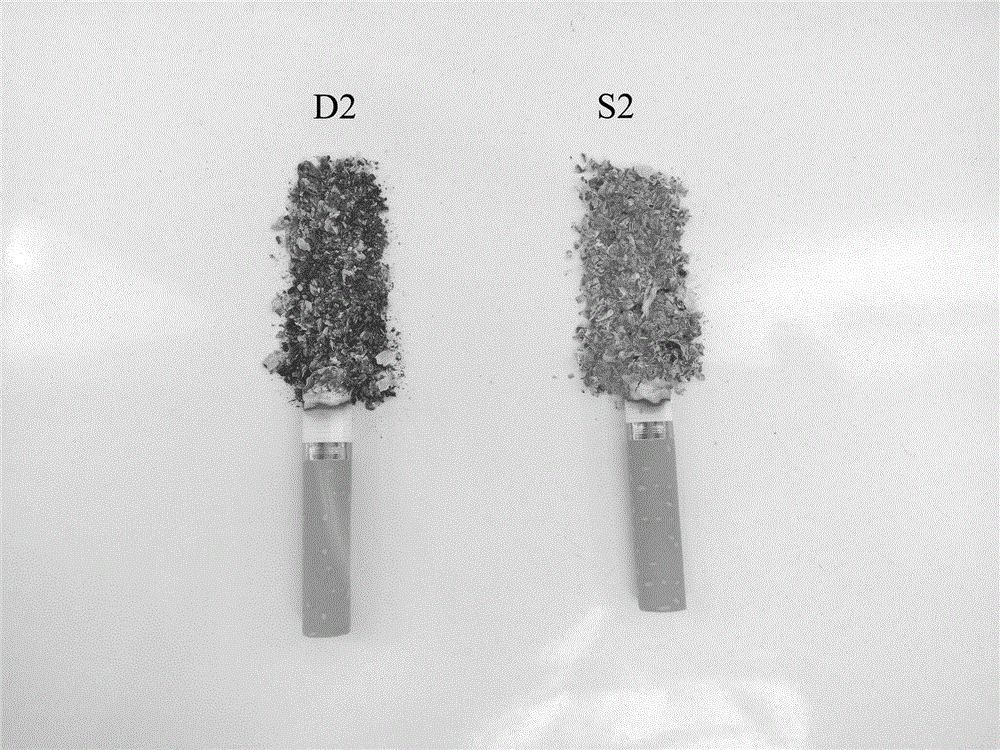

Embodiment 2

[0056] Utilize the method for improving the grayness of cigarettes described in the present invention to roll conventional low-grade cigarettes, comprising the following steps:

[0057] (1) Raw material preparation: tobacco leaf raw materials include paper-making reconstituted tobacco leaves and mature tobacco leaves with a potassium-to-chlorine ratio greater than 4, and the amount of paper-making reconstituted tobacco leaves is 6%;

[0058] (2) Silk production:

[0059] ①Vacuum moisture regain and loose moisture regain: the tobacco leaf raw material obtained in step (1) is subjected to vacuum moisture regain and loose moisture regain, and the moisture content is increased to 20%, so as to facilitate the treatment of subsequent processes;

[0060] ② shredding process: shredding the tobacco leaf raw material through step ① to obtain shreds, the knife door pressure is set to 0.20Mpa, and the width of the shreds is 1.1mm;

[0061] ③Sieving and feeding: firstly, sieve the leaf si...

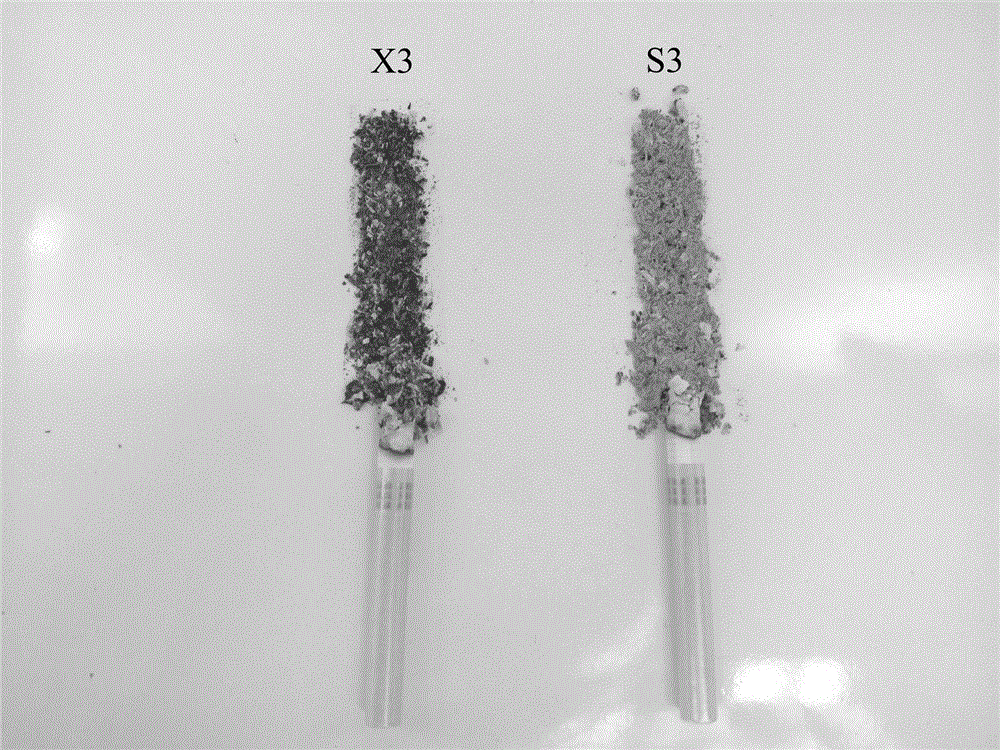

Embodiment 3

[0074] Utilize the method for improving the grayness of cigarettes according to the present invention to roll fine-branched high-grade cigarettes, comprising the following steps:

[0075] (1) Raw material preparation: tobacco leaf raw materials include paper-making reconstituted tobacco leaves and mature tobacco leaves with a potassium-to-chlorine ratio greater than 4, and the amount of paper-making reconstituted tobacco leaves is 5%;

[0076] (2) Silk production:

[0077] ①Vacuum moisture regain and loose moisture regain: the tobacco leaf raw material obtained in step (1) is subjected to vacuum moisture regain and loose moisture regain, and the moisture content is increased to 18.5%, so as to facilitate the treatment of subsequent processes;

[0078] 2. Sieving and charging: firstly, the tobacco leaves with a length of less than 6mm are screened out and their moisture content and temperature are appropriately increased to facilitate further processing in the subsequent proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com