Gantry type four dimensional automatic measurement used for detecting display screen color performance

A display light and automatic measurement technology, which is applied in testing optical properties, color measuring devices, measuring electricity, etc., can solve problems such as poor motion stability, large turning radius of the rotating arm, and large driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

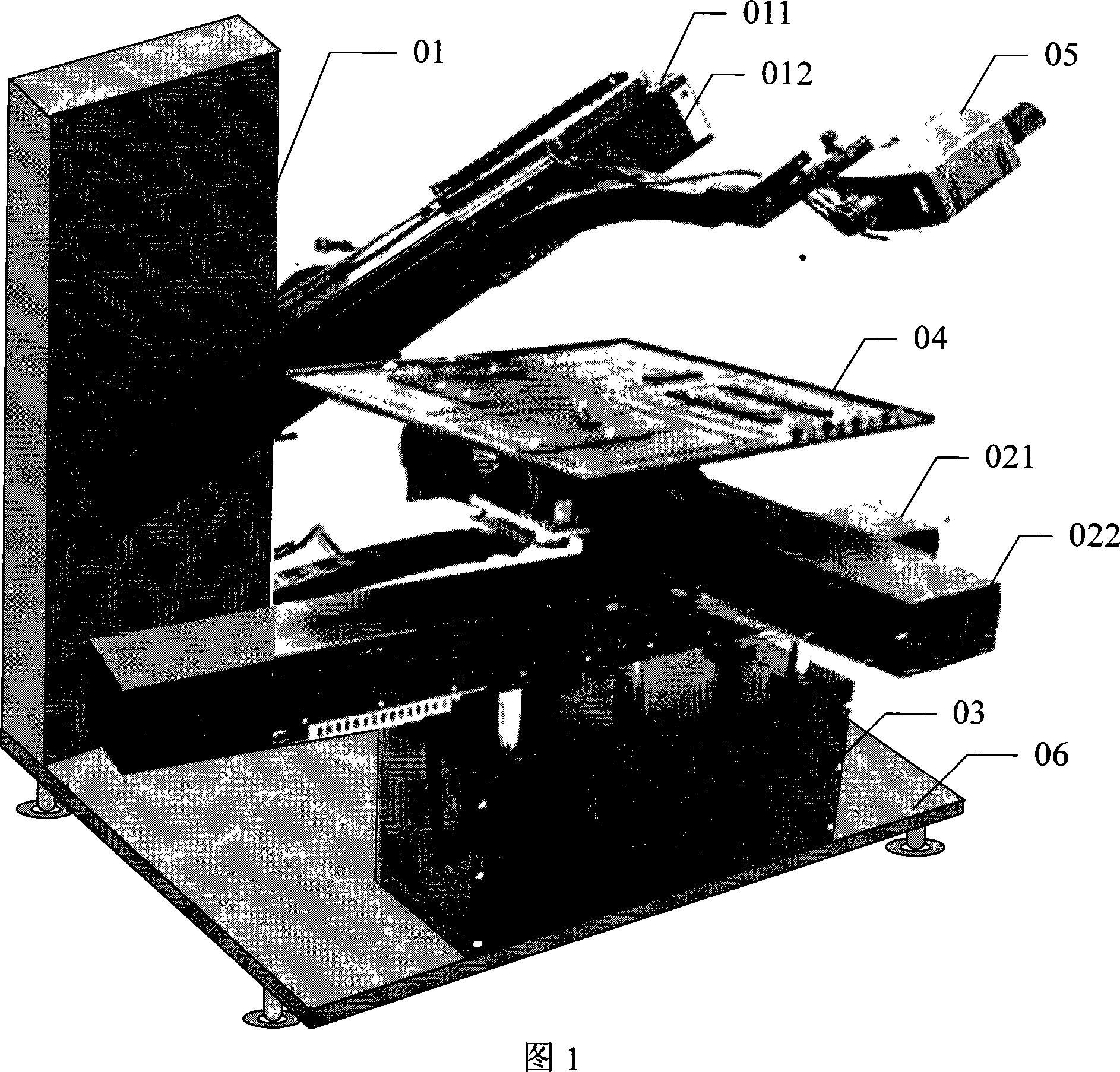

Image

Examples

Embodiment Construction

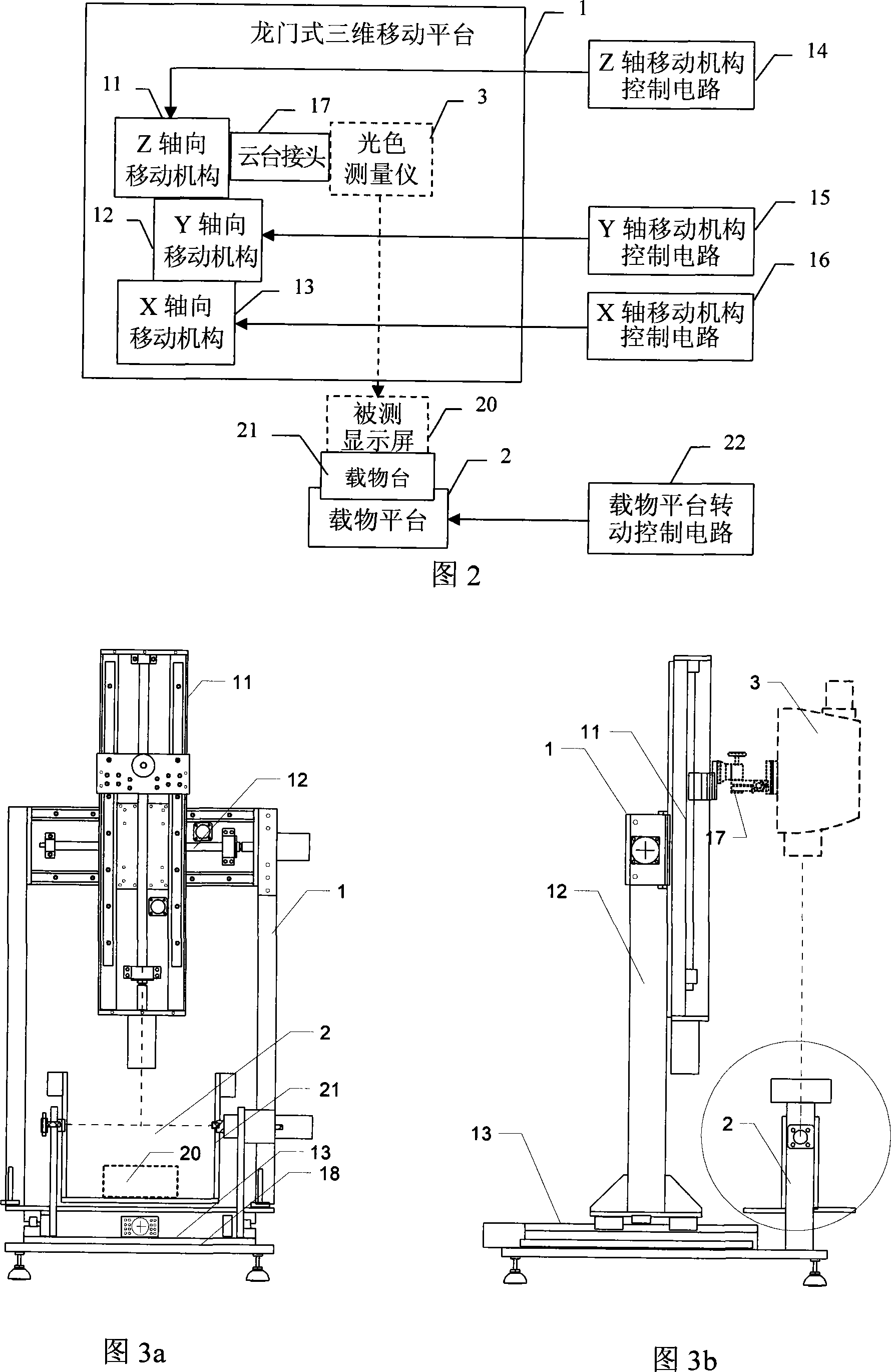

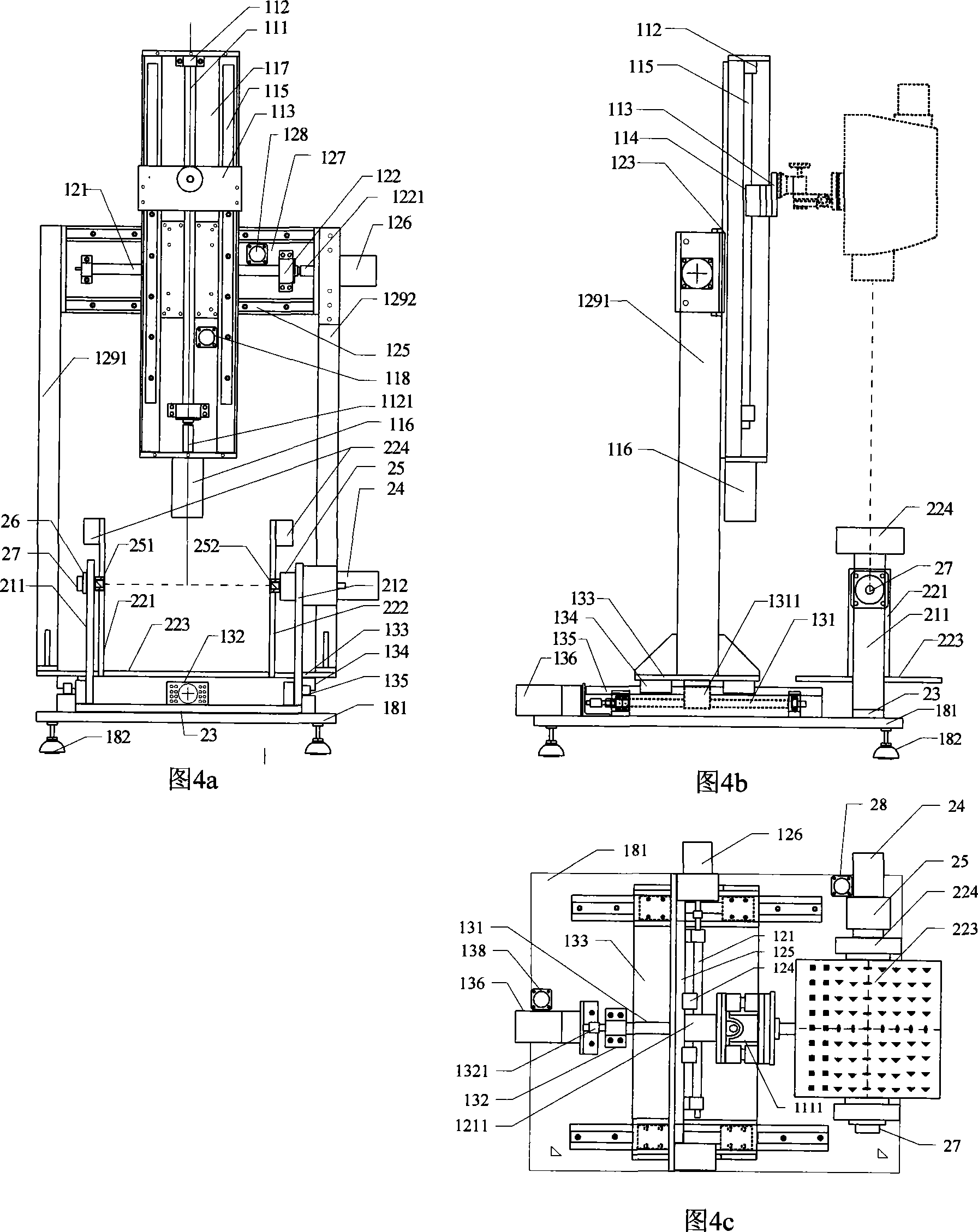

[0087] The technical solution of the gantry-type three-dimensional mobile platform will be further described below with reference to the embodiments of the present invention and the accompanying drawings.

[0088] The principle block diagram of the gantry type four-dimensional automatic measuring platform used for detecting the light and color performance of the display screen of the present invention is shown in Figure 2. The direction movement mechanism 13 is composed of the Z-axis movement control circuit 14, the Y-axis movement control circuit 15, the X-axis movement control circuit 16 and the mounting joint 17. The Z-axis movement mechanism 11 is connected to the Z-axis movement control circuit 14, and the Y-axis movement mechanism 12 is connected to the Y-axis movement control circuit 15 , and the X-axis movement mechanism 13 is connected to the X-axis movement control circuit 16 . The one-dimensional loading platform 2 is composed of a loading platform 21 and a loading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com