Eight-axis robot space curve welding system and method for recognizing welding line by means of lasers

A space curve and laser recognition technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low efficiency and low accuracy of automatic weld seam recognition methods, achieve high automation and improve efficiency , The effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

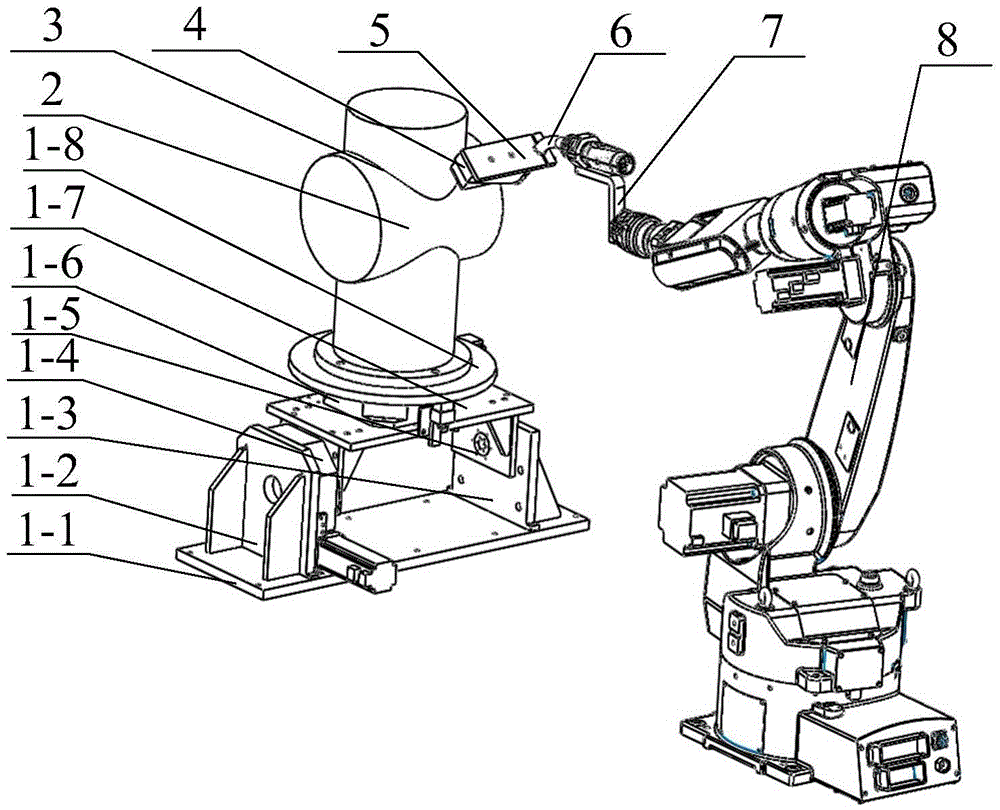

[0044] Such as figure 1 As shown, an 8-axis robot space curve welding system for laser recognition welds, including a tilt / rotation two-axis positioner for fixing workpieces, a laser sensor 4, a laser sensor fixing element 5, a welding torch 6, a welding torch fixing element 7, Welding robot 8, the workpiece is fixed on the tilt / rotation two-axis positioner, following the tilt / rotation two-axis positioner for tilting and / or rotation movement, the laser sensor 4 is installed on the laser sensor fixing element 5, and the laser sensor is fixed The component 5 is clamped on the welding torch 6, the welding torch 6 is installed on the welding torch fixing element 7, the welding torch fixing element 7 is installed on the end flange of the welding robot 8, the laser sensor 4 and the welding torch 6 can follow the movement of the welding robot 8 end.

[0045] The welding robot brings the laser sensor to the position where it is easy to scan the weld seam of the workpiece space curve, ...

Embodiment 2

[0051] An 8-axis robot space curve welding system for laser recognition welding seams, including a tilt / rotation two-axis positioner for fixing workpieces, a laser sensor 4, a laser sensor fixing element 5, a welding torch 6, a welding torch fixing element 7, and a welding robot 8 , the workpiece is fixed on the tilt / rotation two-axis positioner, following the tilt / rotation two-axis positioner for tilting and / or rotation movement, the laser sensor 4 is installed on the laser sensor fixing element 5, and the laser sensor fixing element 5 is installed Clamped on the welding torch 6, the welding torch 6 is installed on the welding torch fixing element 7, the welding torch fixing element 7 is installed on the end flange of the welding robot 8, and the laser sensor 4 and the welding torch 6 can follow the movement of the welding robot 8 end.

[0052] The welding robot brings the laser sensor to the position where it is easy to scan the weld seam of the workpiece space curve, and the...

Embodiment 3

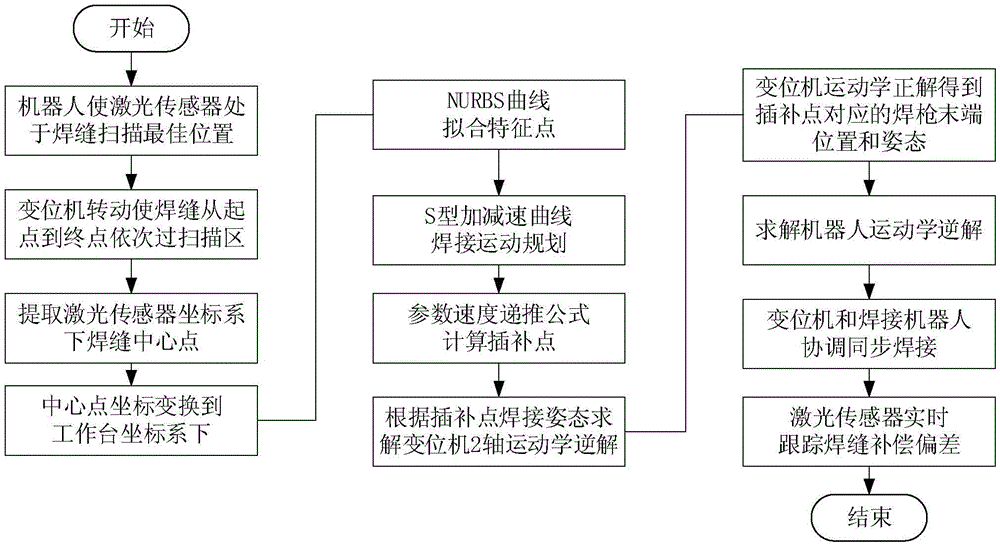

[0059] Such as figure 2 As shown, the laser recognition seam 8-axis robot space curve welding method based on the laser recognition seam 8-axis robot space curve welding system includes the following steps:

[0060] S1. Adjust the position and posture of the welding robot 8 so that the laser sensor 4 fixed on the welding torch 6 is in the best position for scanning the weld 3, that is, the weld 3 is in the effective working range of the laser sensor 4, and the continuous scanning welding is ensured. During the process of sewing 3, the workpiece 2 will not interfere with the laser sensor 4;

[0061] S2. The tilt / rotation two-axis positioner rotates continuously, so that the welding seam 3 passes through the scanning area of the laser sensor 4 sequentially from the starting point to the end point;

[0062] S3. Extract the feature points of the weld 3 from the scanning result of the laser sensor 4, and calculate the coordinates of the center point of the weld 3 under the coor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com