Optical fiber composite cable optical unit cabling pay-off device and cabling method thereof

An optical fiber composite cable and pay-off device technology, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and processing of thin materials to achieve the effects of guaranteeing expected service life, improving uniformity, and stabilizing optical fiber transmission performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with embodiments and drawings. The embodiments are only used to explain the present invention and do not constitute a limitation on the protection scope of the present invention.

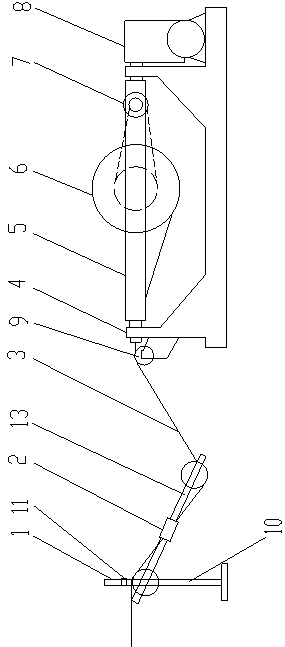

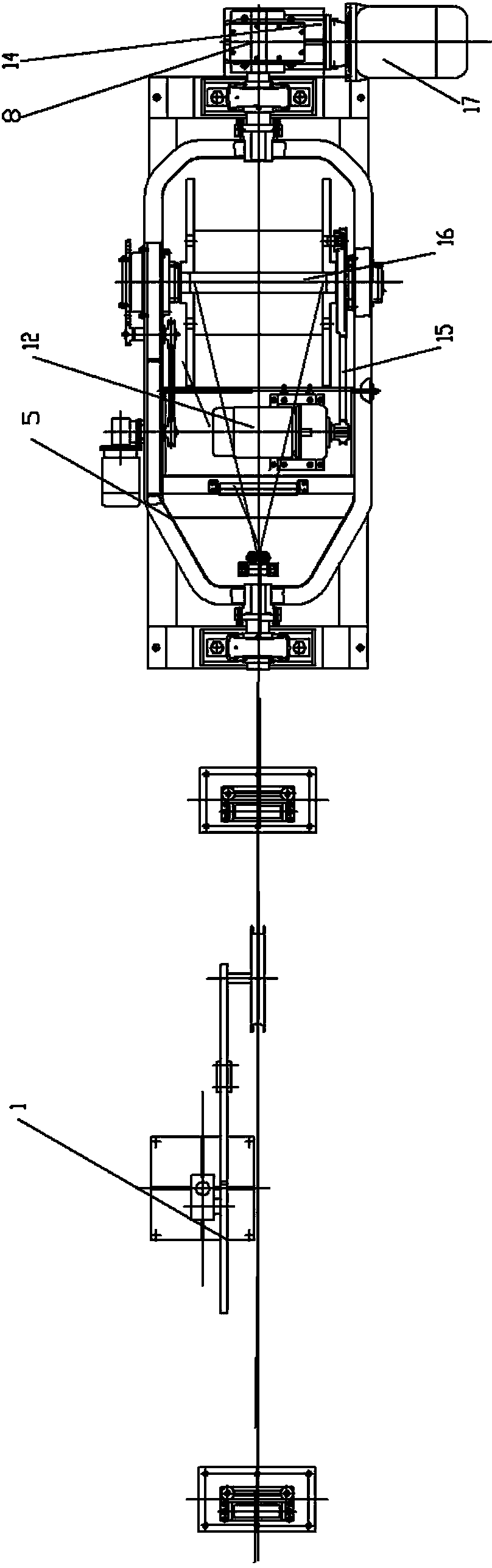

[0031] Such as figure 1 with 2 As shown, an optical fiber composite cable optical unit of the present invention is a cable pay-off device. The pay-off device includes a swing arm type tension dance wheel assembly 1, a tension adjustment slider 2, a pay-off stand base 4, a cradle stand 5, and The wire motor and drive assembly 7 and the cradle frame rotation drive assembly 8. The two shaft ends of the cradle frame 5 are movably fixed on the pay-off frame base 4, and the shaft end of the cradle frame 5 is rotated by the cradle frame fixed on the pay-off frame base 4 The drive assembly 8 drives and rotates. The pay-off motor and drive assembly 7 installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com