A kind of multifunctional gear and knob transmission assembly using the same

A transmission component and multi-functional technology, applied in the direction of gear transmission, toothed components, transmission, etc., can solve the problems of high rework cost, single function, low efficiency, etc., and achieve the goal of reducing production cost and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The multifunctional gear of the present invention and the knob transmission assembly using it will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

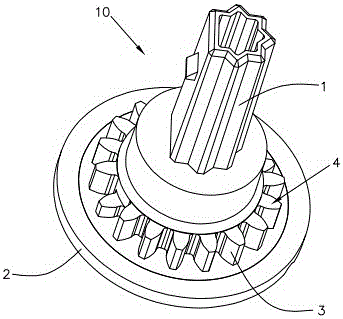

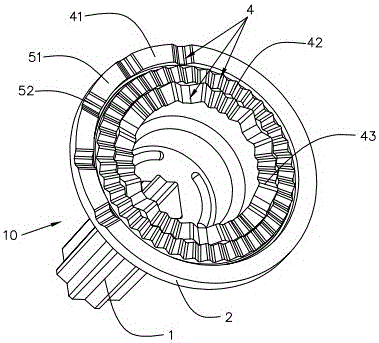

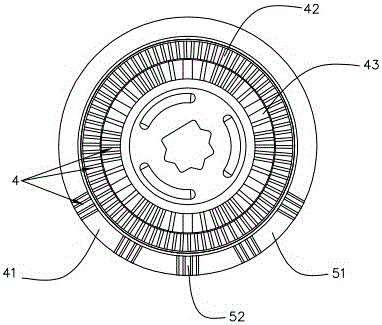

[0021] exist Figure 1 to Figure 4 Shown in is a schematic diagram of the multifunctional gear 10 in an embodiment of the present invention. The multifunctional gear 10 mainly includes a wheel 2 , a gear 4 fixed on the wheel and a gear shaft 1 extending from the bottom of the wheel 2 . When the gear shaft 1 rotates, it will drive the wheel disc 2 and the gear 4 to rotate.

[0022] The gear 4 includes at least two face gears fixed on the upper surface of the wheel disc 2, and three face gears 41, 42, 43 are used in this embodiment. The face gears 41, 42, 43 and the gear shaft 1 are coaxially arranged, so the rotation angle of the gear shaft 1 is consistent with the rotation angle of the face gears 41, 42, 43, and the face gears 41, 42 can be accurately controlled by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com