Seam tracking method based on template matching

A template matching and template technology, applied in the field of image processing, can solve the problems of large weld seam tracking deviation, poor algorithm adaptability, and weld shape gradient, etc., to achieve the effects of avoiding welding deviation, fast calculation speed, and image symmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The substantive features and advantages of the present invention will be further described below in conjunction with examples, but the present invention is not limited to the listed embodiments.

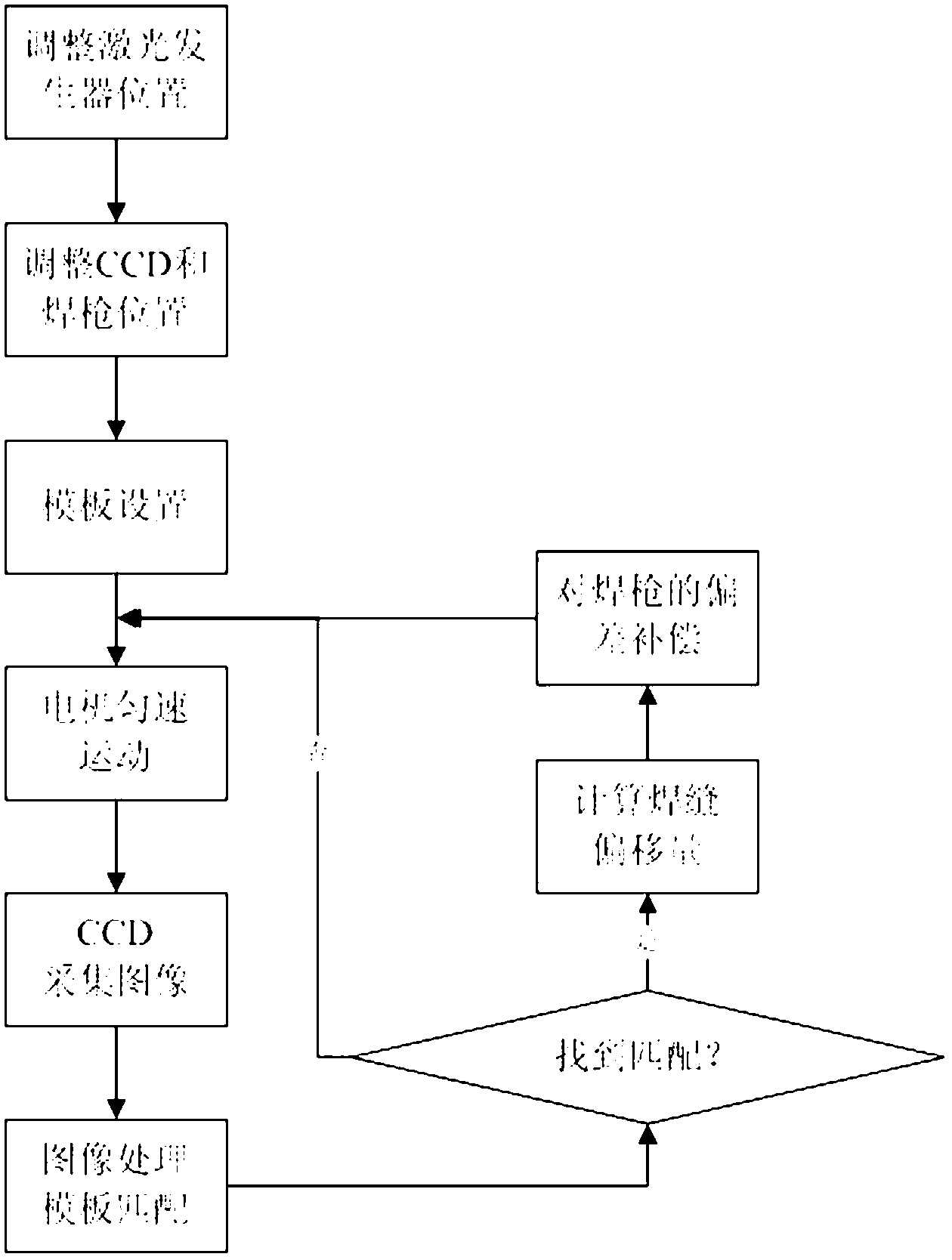

[0027] see figure 1 Shown: This figure shows the flowchart of the template matching-based welding seam tracking method provided by the embodiment of the present invention. For ease of description, only parts related to the embodiments of the present invention are shown.

[0028] A seam tracking method based on template matching, the steps are as follows:

[0029] Step 1: Equipment calibration, adjust the linear laser source generator, fix the linear laser source generator at a certain angle, so that there is a certain angle with the CCD camera, the laser source generator emits a laser beam, and forms a narrow laser beam through the cylindrical mirror. The laser plane is irradiated at a certain angle to the weld seam on the surface of the workpiece to be welded, showing a str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com