Equipment for coating paper on square wood parts

A square wood and sticker technology, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve the problem of inability to square wood precision stickers, and achieve seamless joints with no step difference, good quality, and reduced labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

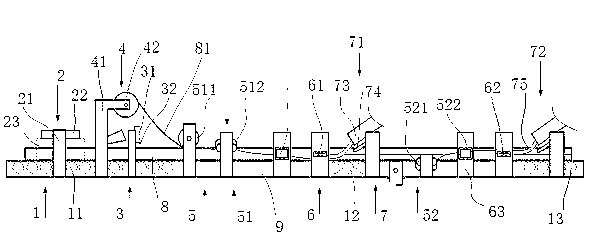

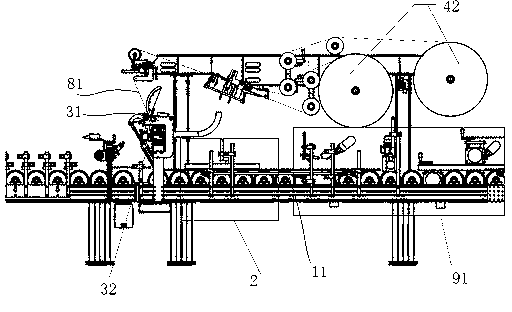

[0033] Embodiment 1: as figure 1 , 2 As shown, a square wood sticker equipment includes a frame 9 and a controller, and the frame is sequentially provided with a transmission unit 1, a heating unit 2, a gluing unit 3, a paper releasing unit 4, and a paper pressing unit 5. , paper cutting unit 6 and waste paper recovery unit 7; wherein

[0034] (1), the conveying unit 1 includes the input conveying roller 11, the middle conveying roller 12 and the output conveying roller 13 of the whole machine;

[0035] (2), the heating unit 2 includes an infrared heater 22 fixed on the corresponding space position above the input conveying roller through the heating frame 21, and a set of infrared heaters 22 are respectively provided at the front and rear, so as to elongate the heating distance to facilitate the square wood 8 The heat absorption time prolongs, and the front, rear, left, and right sides and inside and outside of the square wood can be more evenly heated, and the tempera...

Embodiment 2

[0043] Embodiment 2: two front and rear height adjustment devices 63 are connected with the frame through a height adjustment base connected to the side of the frame 9, the upper surface of the base is a plane datum plane arranged horizontally, and the installation datum of the two height adjustment devices The surface is fixed on the plane reference plane, and the bottom of the base is provided with an adjustment mechanism, through which the heights of the two height adjustment devices can be uniformly adjusted, so that the height of the two height adjustment devices are the same as above and below, and their heights are always on the same horizontal line Make sure that the two sides of the sticker are tightly bonded without leaving any traces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com