Ground source heat exchange well backfilling device capable of tamping well bottom and well wall

A technology of ground source heat exchange and well wall, applied in geothermal energy power generation, heat collectors using groundwater as working fluid, buildings, etc., can solve the problems of slurry vacancy, heat exchange efficiency reduction, accumulation at the bottom of wells, etc. , to achieve the effect of reducing the probability of air bubbles and reducing the degree of slurry leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

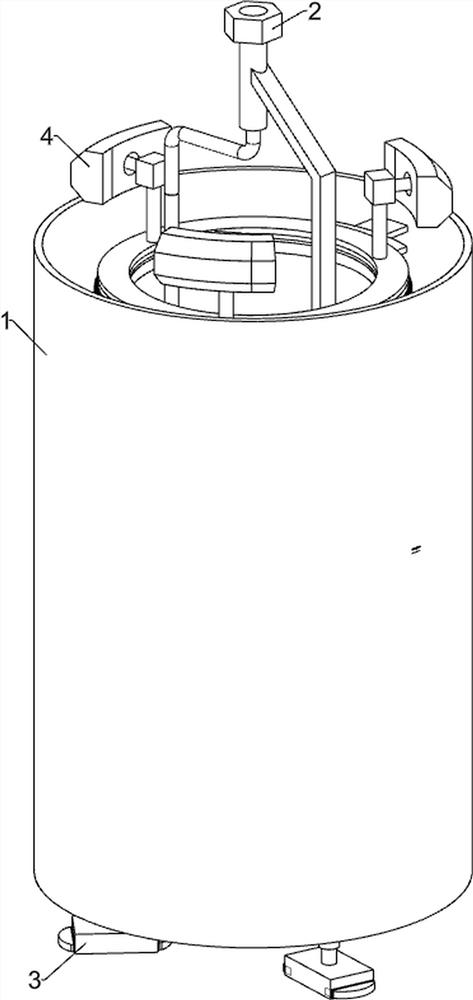

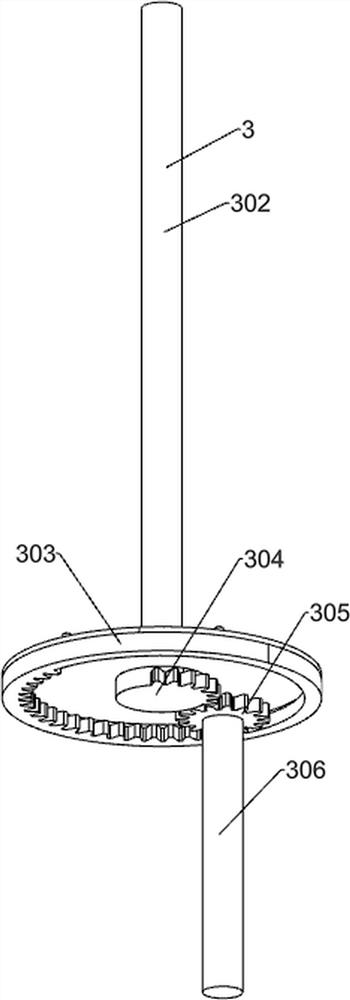

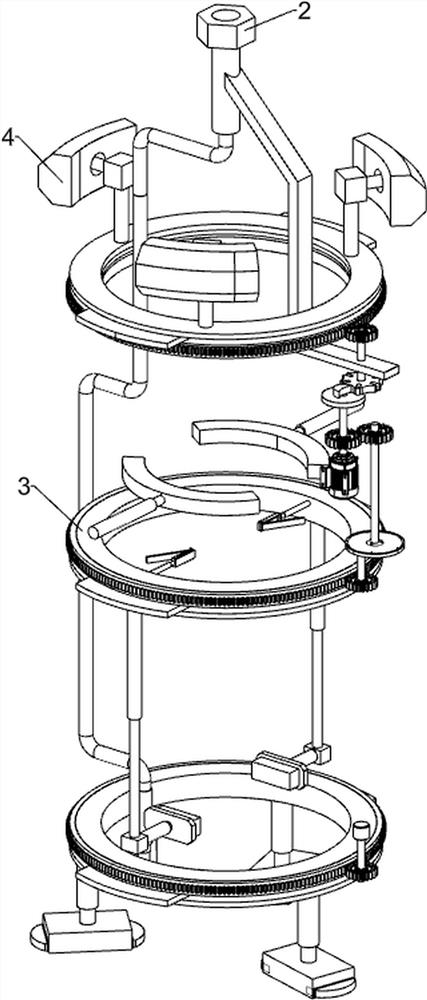

[0031] A ground source heat exchange well backfill device capable of tamping well bottom and well wall, such as Figure 1-10 As shown, it includes a first support frame 1, a transportation component 2, a bottom hole treatment component 3 and a well wall treatment component 4; the first support frame 1 is connected to the transportation component 2; the first support frame 1 is connected to the bottom hole treatment component 3 The first support frame 1 is connected with the well wall processing assembly 4; the transportation assembly 2 is connected with the well wall processing assembly 4; the bottom hole processing assembly 3 is connected with the well wall processing assembly 4.

[0032] Working principle: When preparing for work, connect the external hose to the transportation component 2, insert the tail of the U-shaped tube into the device, make the U-shaped tube penetrate the device, and then put the device vertically into the heat exchange well to make the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com