Meal box based on degradable composite material

A composite material and lunch box technology, which is applied in the field of lunch boxes based on degradable composite materials, can solve the problems of reducing consumer experience, soup leakage, and affecting the taste and appearance of food.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

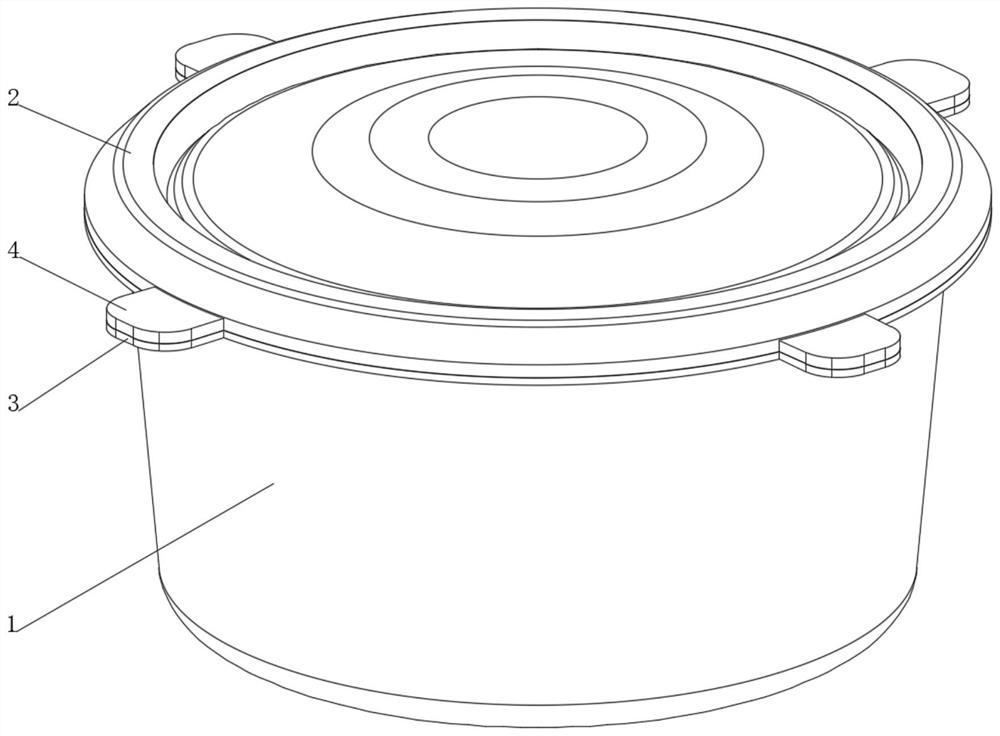

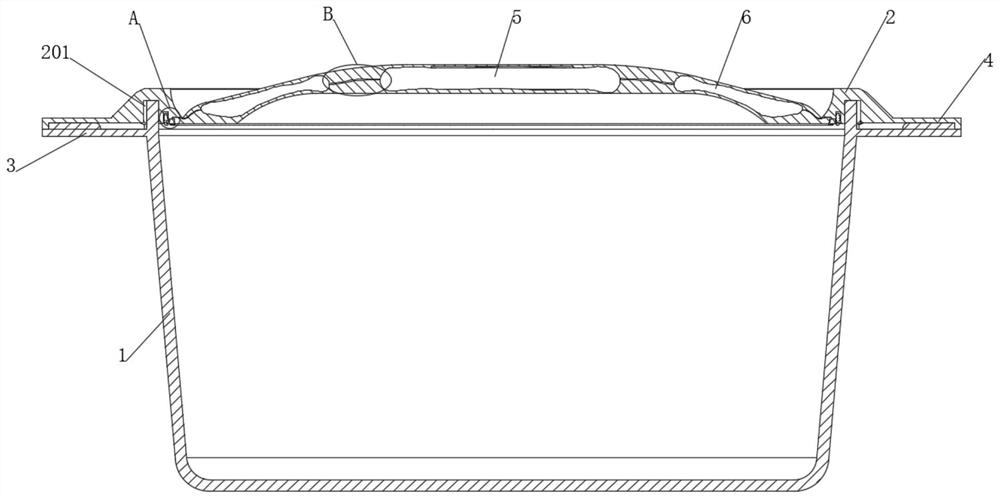

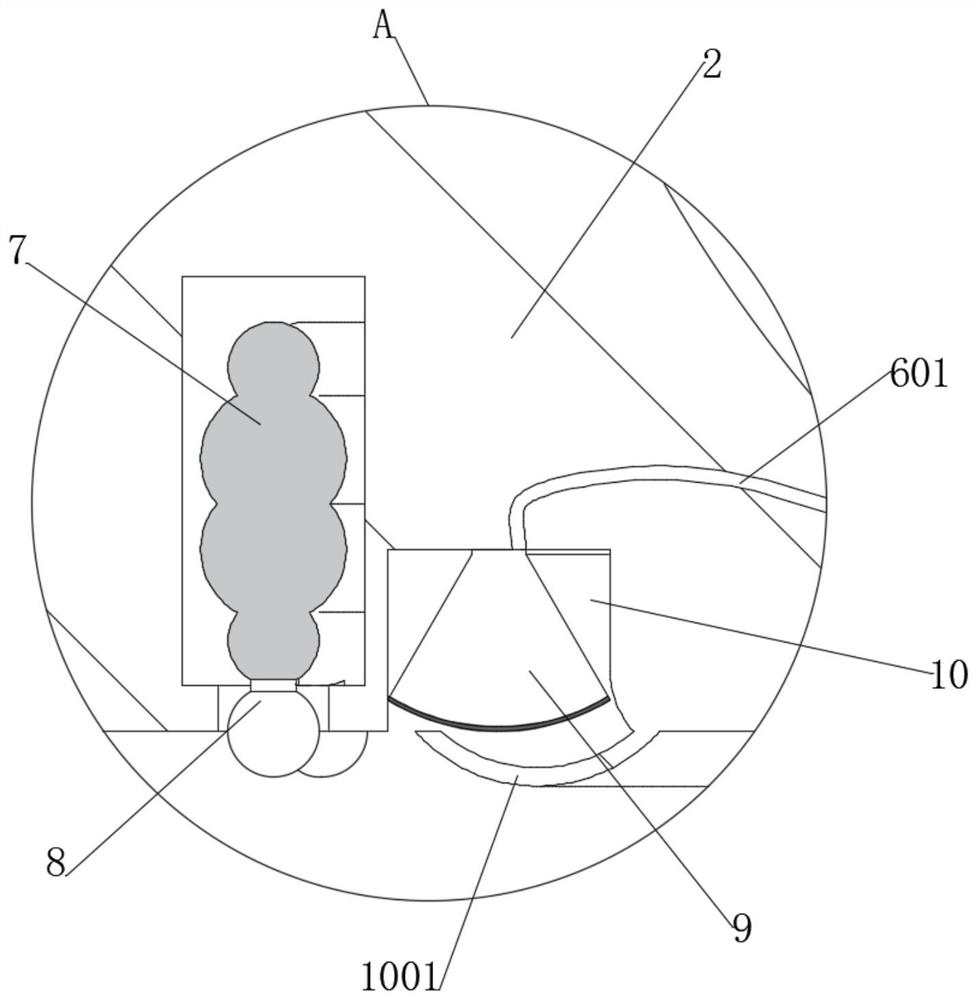

[0046] see Figure 1-10 , a lunch box based on degradable composite materials, including a degradable box body 1 and an oil-absorbing concave lid 2 buckled on the upper end of the degradable box body 1, the outer side of the degradable box body 1 is close to the oil-absorbing concave lid 2 One end is fixedly connected with a buckle platform 101, the upper end of the buckle platform 101 is fixedly connected with a box body sealing port 102, and the lower end of the oil-absorbing concave box cover 2 is provided with a box cover sealing ring groove 201 matching the box body sealing port 102, The degradable box body 1 and the oil-absorbing concave box cover 2 are equipped with cat ear auxiliary components on the outside, and the oil-absorbing concave box cover 2 is provided with an oil-absorbing chamber on the side close to the degradable box body 1, and the oil-absorbing chamber is located on the sealing ring of the box cover Inside the groove 201, an annular oil-absorbing bar 7 ...

Embodiment 2

[0053] see Figure 1-10 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 2 and embodiment 1 is: please refer to figure 2 , image 3 , Figure 8 and Figure 9 , the lower end of the oil-absorbing inner concave box cover 2 is provided with an anti-pollution wrapping groove 10, and the anti-pollution wrapping groove 10 is located inside the oil-absorbing cavity, and the anti-pollution wrapping groove 10 avoids being fixedly connected with a wrap-type air drum membrane 9, and the anti-pollution wrapping groove 10 The side away from the oil suction cavity is fixedly connected with a guide shaping arc plate 1001, and the guide shaping arc plate 1001 is matched with the wrapped air drum membrane 9 to act on the oil absorbing tentacles 8. The gap between the guide sh...

Embodiment 3

[0059] see Figure 1-10 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 3 and embodiment 1 is: please refer to figure 1 , Figure 5 and Figure 6 , The upper end of the buckle platform 101 is provided with a circle of oil storage tank, and the oil storage tank is located outside the sealing port 102 of the box body. When the oil storage tank leaks soup at the joint between the degradable box body 1 and the oil-absorbing concave box cover 2, it can effectively collect the soup water, reduce the spread of soup water on the degradable box body 1, and effectively spill on the surface The soup in the soup pollutes other takeaway boxes.

[0060] see figure 1 , Figure 5 and Figure 6 , the oil storage tank is fixedly connected with an oil stop band, and the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com