Test interface structure

A technology of test interface and side opening, which is applied in the direction of pipes/pipe joints/fittings, connections with fluid cut-off devices, passing components, etc., which can solve the problems of cumbersome structure of the test interface and poor sealing performance, and achieve simple structure and improved performance. The effect of long service life and low assembly difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

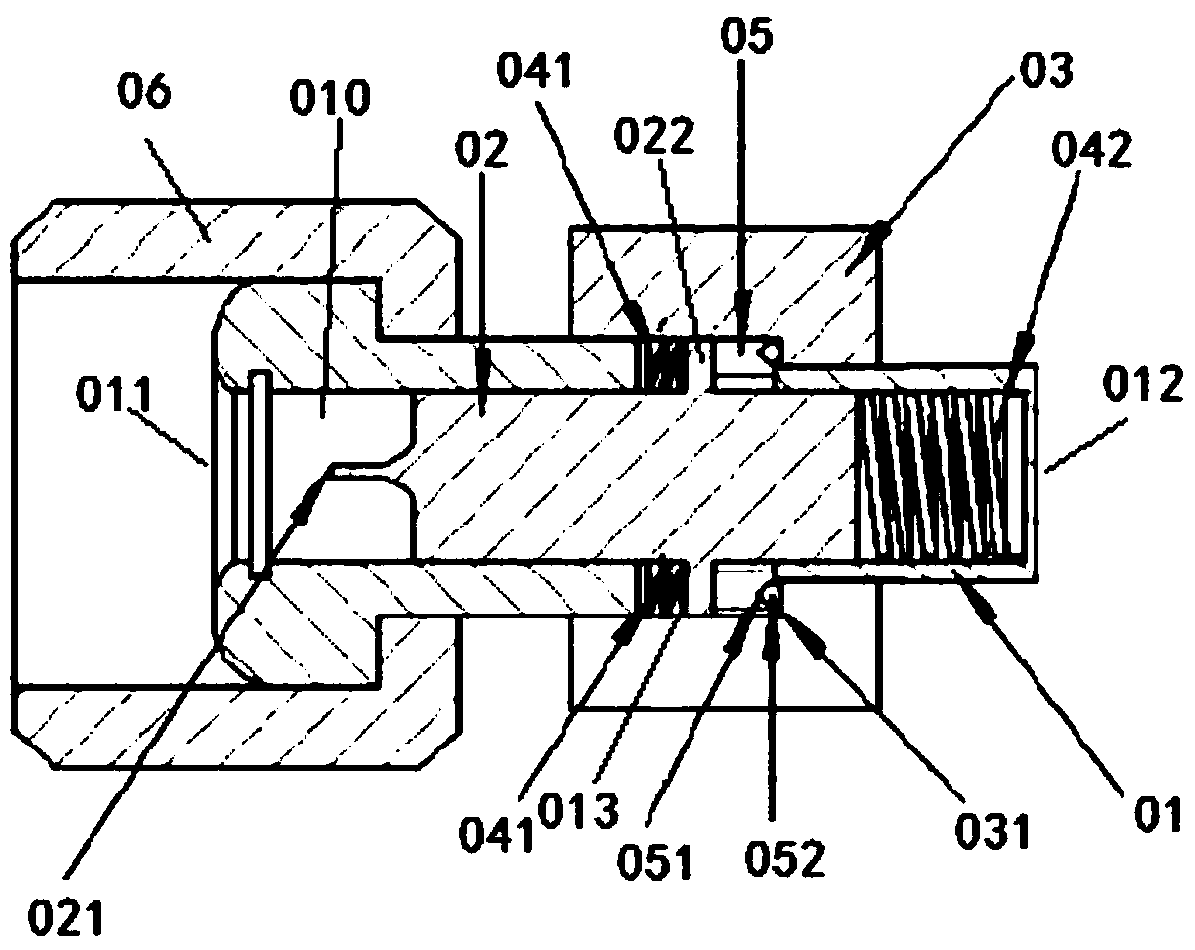

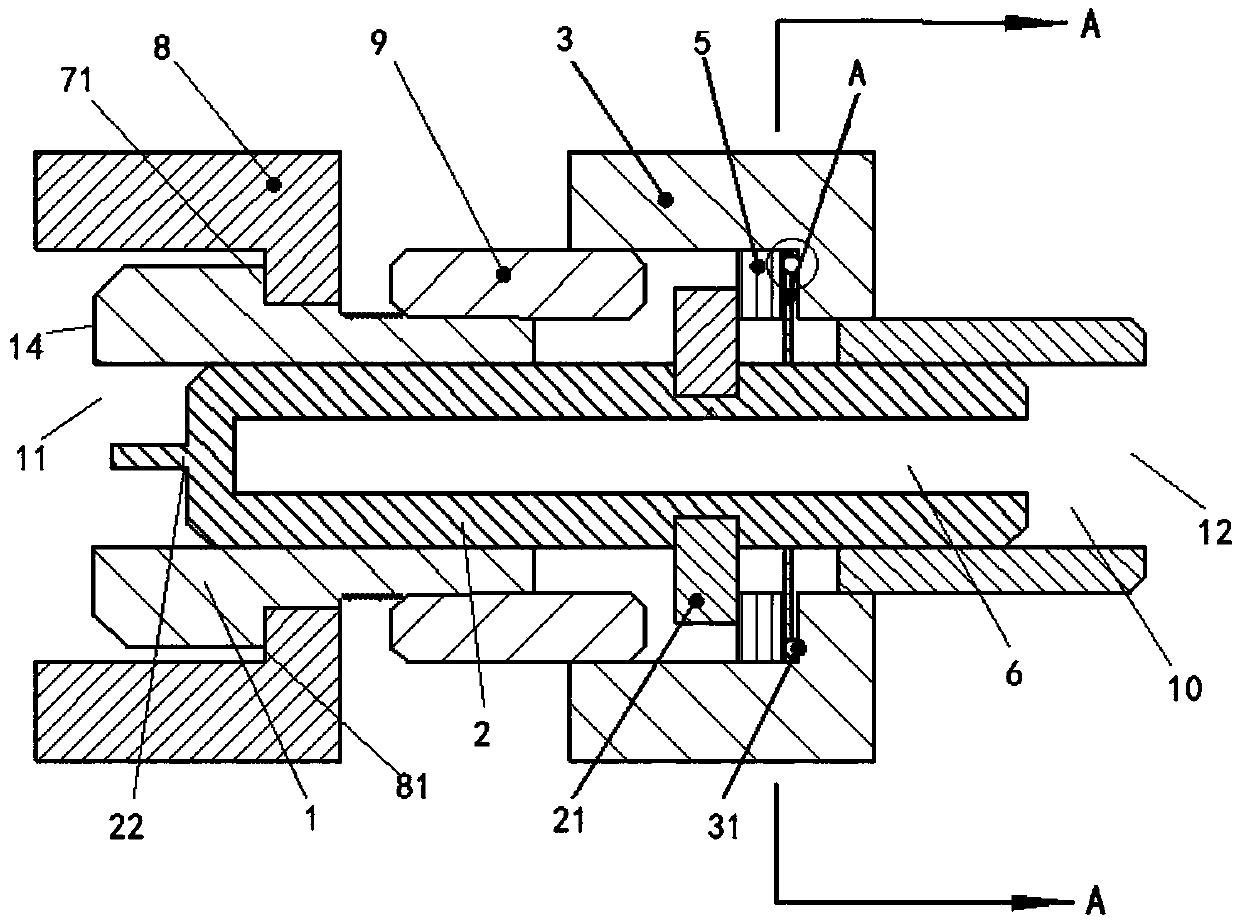

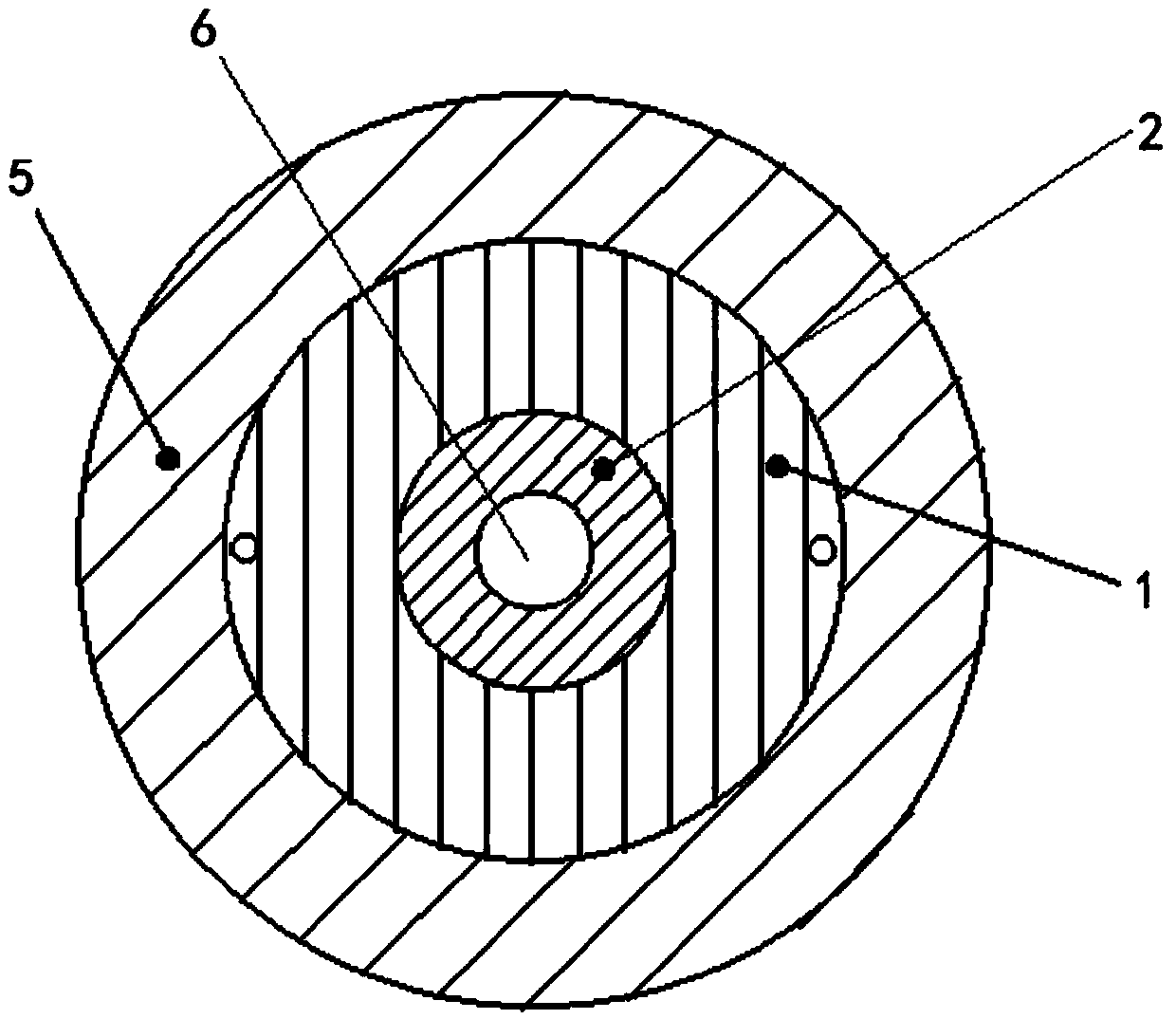

[0044] This embodiment provides a test interface structure, such as Figure 2-3 As shown, it includes: a valve body 1 with an inner cavity 10, the inner cavity 10 has a first opening 11 for communicating with a check valve, and a second opening 12 for communicating with a test device; a valve core 2, It is movably installed inside the inner chamber 10, has a thimble 22, and has a first plug inserted into the inside of the check valve to open the check valve, so that the second opening 12 communicates with the check valve. One position, and withdrawn from the inside of the check valve to close the check valve, so that the second opening 12 is cut off from the check valve and communicated with the second position; the strip through hole 13 is at least one, It is set on the outer wall of the valve body 1 and communicates with the inner cavity 10; at least one pushing part 21 is arranged on the valve core 2 and extends out of the valve core 2 through the long through hole 13. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com