Pipe joint monitored by utilizing computer

A technology of computer monitoring and pipe joints, which is applied in the field of pipe joints, can solve problems such as the trouble of replacing pipes, affecting residents' water use, and waste of water sources, and achieves the goal of improving the degree of fixing, improving the degree of sealing and fixing effect, and improving the degree of sealing and fixing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

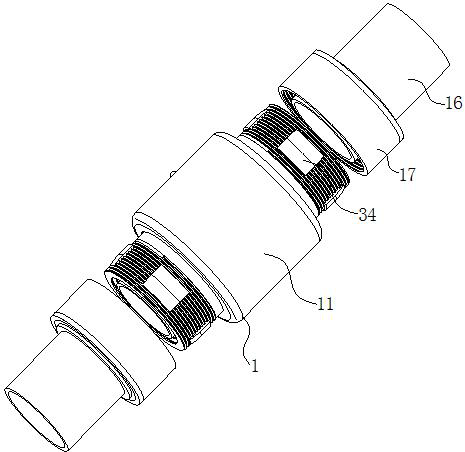

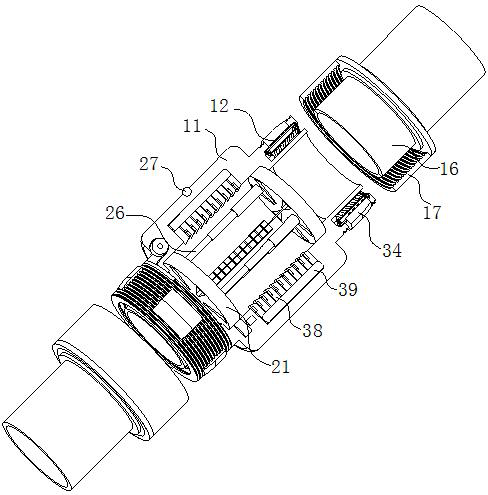

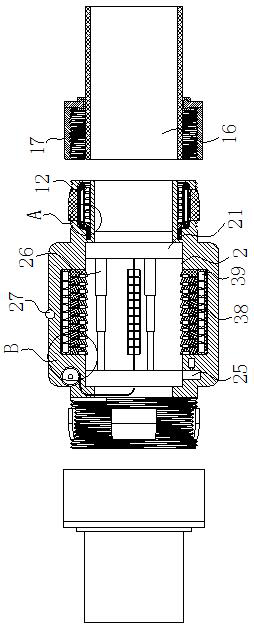

[0031] Example 1, such as Figure 1-Figure 6 As shown, a computer-monitored pipe joint according to the present invention includes a connector 1 and a pipe body 16; the connector 1 includes a fixed tube 11, and the middle part of the fixed tube 11 is designed as a protrusion; the fixed tube 11. The left and right sides of the protrusion are provided with a first annular groove 12 in the inner wall of the fixed pipe 11, and the first annular groove 12 is designed around the fixed pipe 11; the outer sides of the two first annular grooves 12 are on the outer surface of the fixed pipe 11. There are threads; both sides of the fixed pipe 11 are provided with pipe bodies 16; the outer surfaces of the two pipe bodies 16 are rotatably connected with threaded rings 17 through slip rings, and the threaded rings 17 are all connected to the surfaces of both sides of the fixed pipe 11. The threads are engaged with each other; the bottoms of the two first annular grooves 12 are provided with...

Embodiment 2

[0033] Embodiment 2, different from Embodiment 1, is that the inner walls of the two first annular grooves 12 are fixedly connected with evenly arranged annular rods 3 by short rods, and the number of annular rods 3 is two; each of the first annular The outer surfaces of the two annular rods 3 in the groove 12 are rotatably connected with an annular layer 31, and the annular layer 31 is made of rubber material; the outer surface of each annular layer 31 is fixed with a uniformly arranged first arc-shaped shaft 32;

[0034] During work, since the second annular groove 2 is rotationally connected with the annular layer 31, when the pipe body 16 is inserted into the first annular groove 12, the annular layer 31 will be pushed to rotate on the annular rod 3, and the annular layer 31 will rotate During the process, it will be attached to the outer surface of the tube body 16 and squeeze the tube body 16. In this process, the sealing degree and fixing effect between the tube body 16 ...

Embodiment 3

[0035] Embodiment 3 is different from Embodiment 2 in that the outer sides of the two first annular grooves 12 are provided with evenly arranged second slide grooves 33 in the inner wall of the fixed pipe 11, and the second slide grooves 33 pass through the fixed pipe 11; the second slider 34 is slidably connected to the inner wall of each second chute 33, and the side of the second slider 34 close to the tube body 16 is arc-shaped and lower than the fixed tube 11. The inner surface of each of the second sliders 34 is fixed with uniformly arranged second arc-shaped shafts 35, and the second arc-shaped shafts 35 and the first arc-shaped shafts 32 are alternately arranged;

[0036]During operation, since the side of the second slider 34 close to the pipe body 16 is designed in an arc shape, when the threaded ring 17 engages with the thread on the fixed pipe 11, it will squeeze the second slide groove 33 under the second slider 34 Slide, and extrude the annular layer 31, in this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com