Patents

Literature

44results about How to "No dross" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrial fuel gas for metal cutting and welding

This invention discloses an industrial fuel gas used for metal cutting and welding. Additive and dimethyl enther are added to cylinder to make-up the fuel, dimethyl enther is 40~99.9% and other rest additive. The additive is consisted by one or any several kind of following fuels as arbitrary proportion, petroleum liquefied gas, propane, butane, propylene, pentane, clean oil, methanol, ethanol. This invention has good burning property, security, environmental protection capability and extra high burning flame temperature. Comparing to acetylene, it is not easy to bomb, and its storage, transportation, using and management is more convenient and safe. There is no pollution to environment and operator. Its preheating and cutting velocity is fast, welding and welding line quality is good, oxygen consumption is low, so it improves work efficiency and reduces cost.

Owner:郑长同 +3

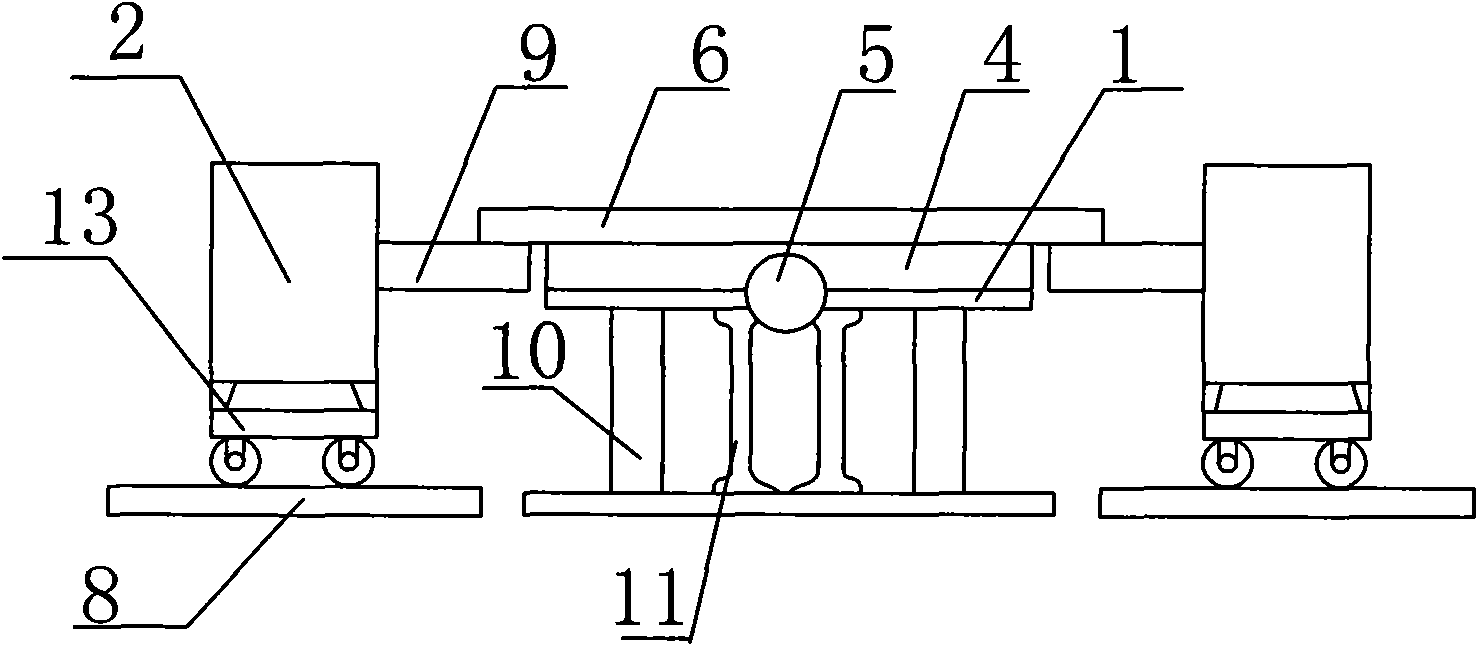

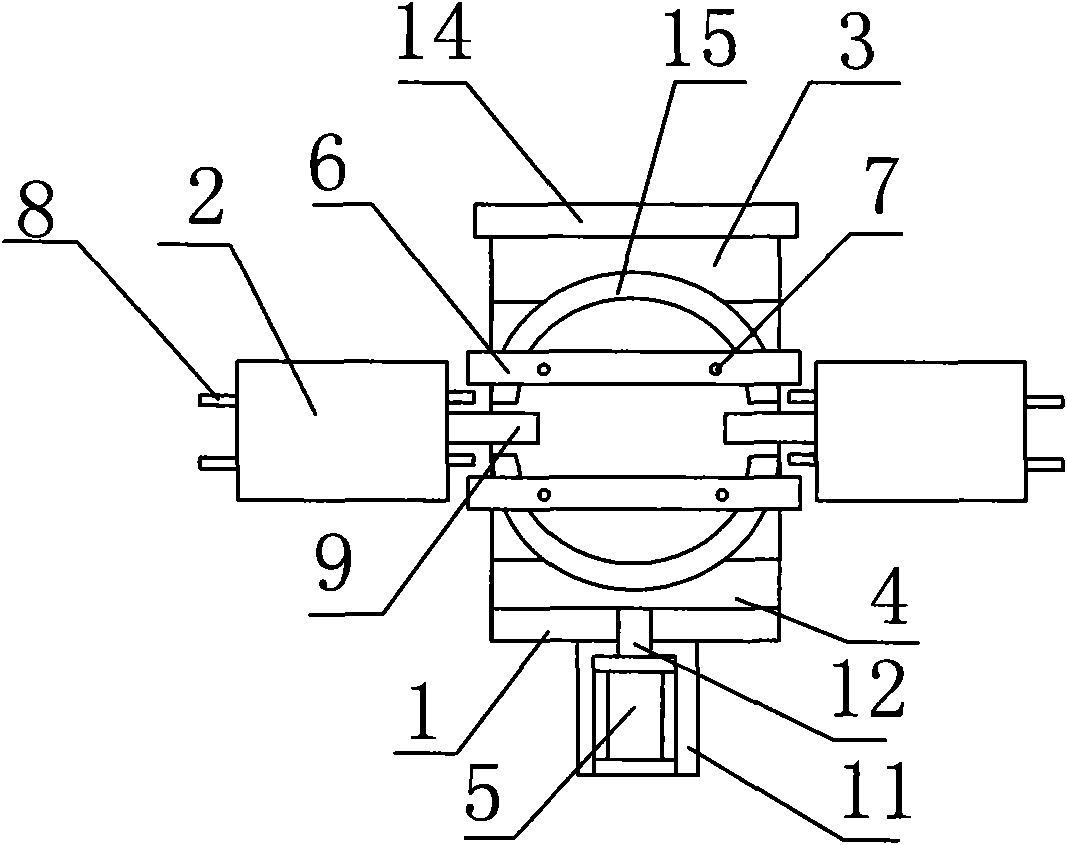

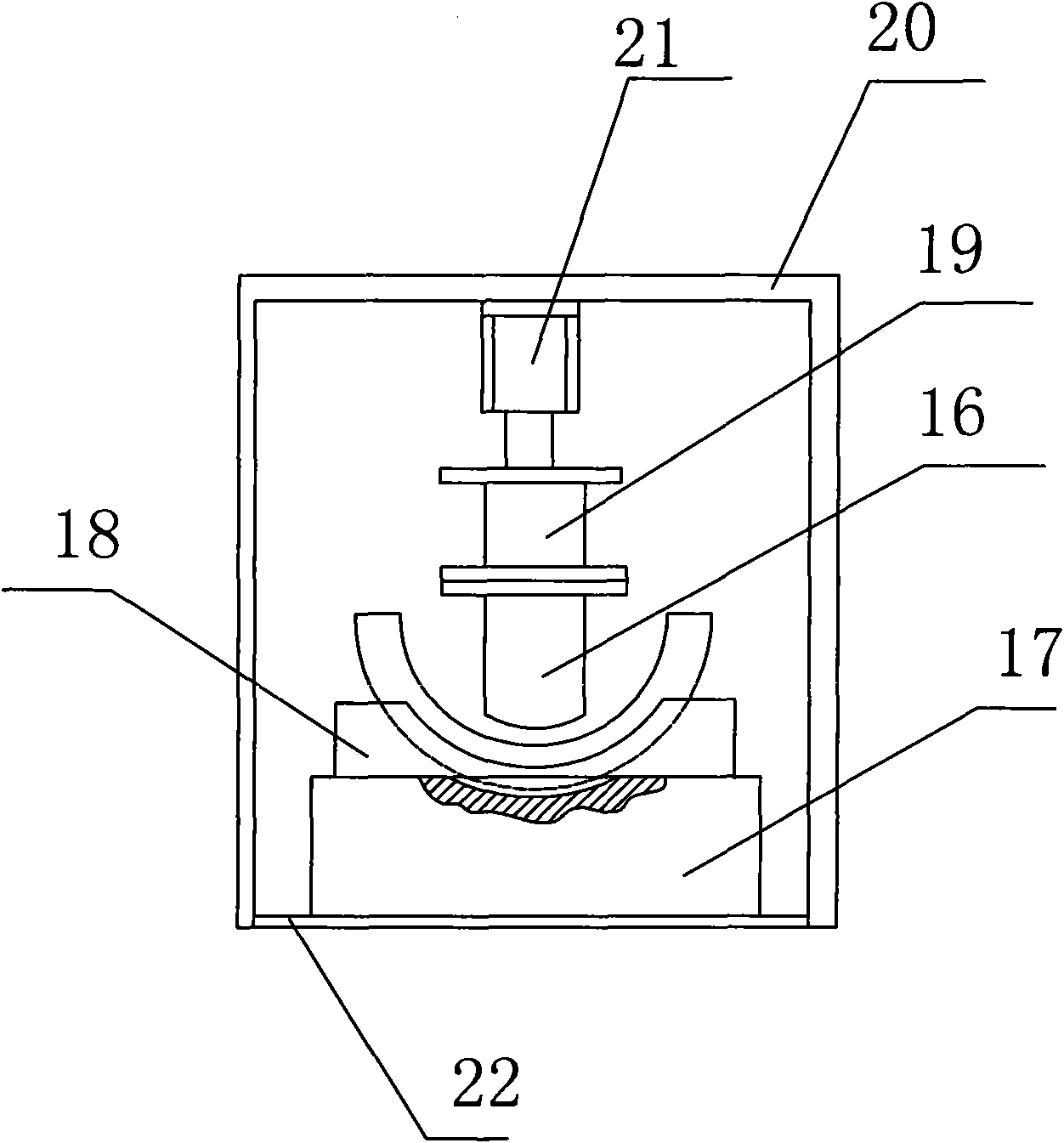

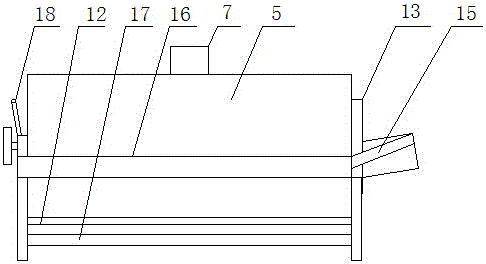

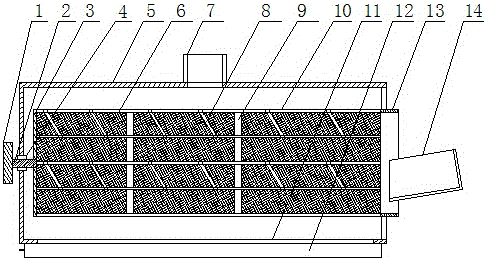

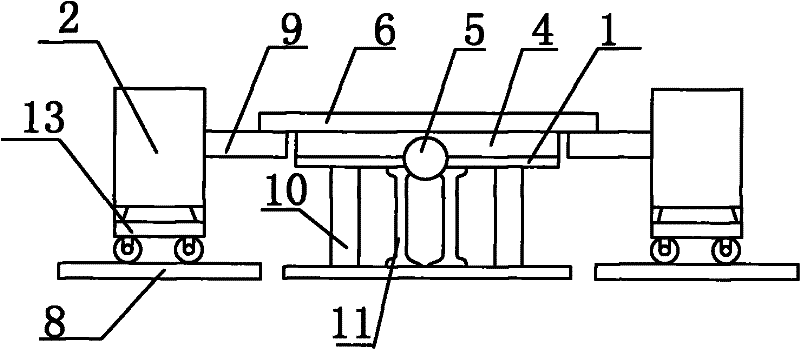

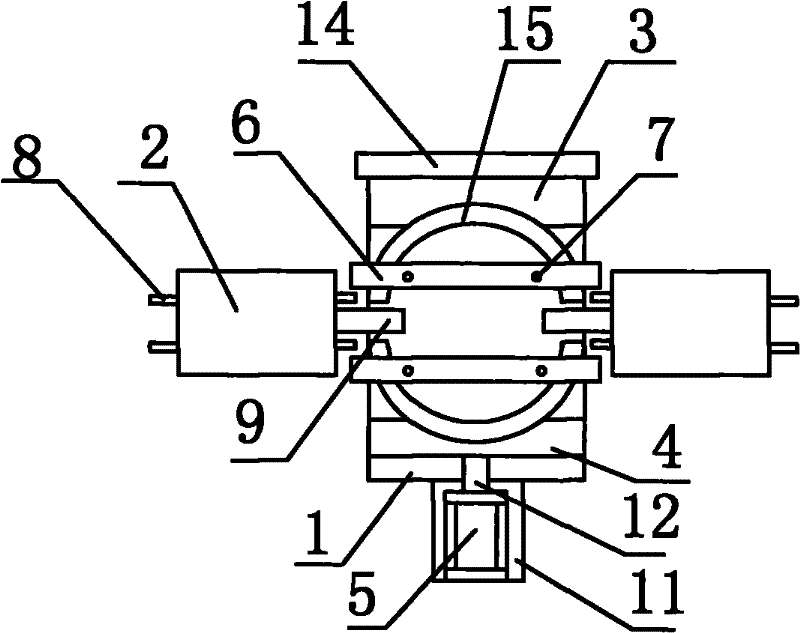

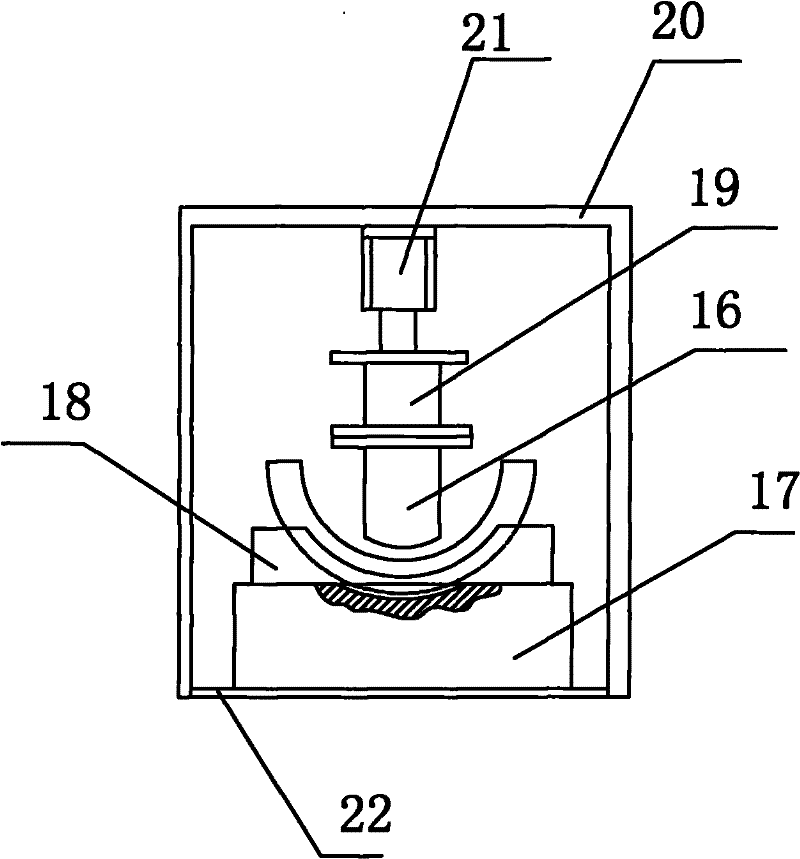

Manufacturing process and equipment for upset forging of flanges

InactiveCN101961765AQuality improvementGuaranteed traceless weldingEngine componentsHeating/cooling devicesUpset forgingManufacturing engineering

The invention relates to manufacturing process and equipment for the upset forging of flanges, relating to manufacturing process and equipment for flanges. The manufacturing process comprises the following steps of: making materials into flange metal semicircles, evenly heating and butting the flange metal semicircles by adopting upset forging equipment, wherein the pressure on an extrusion surface is 40 to 70MP and the heating temperature is 500 to 1300 DEG C; and quickly connecting the two semicircles after the extrusion through the upset forging equipment to obtain a product. The invention has the advantages of capability of producing various annular steel flanges and aluminum flanges with different specifications only by using the upset forging equipment and simple matched moulding beds so that the investment in equipment and the energy consumption only account for a fraction or one of dozens of that of traditional equipment, cost is saved by more than 30% and production efficiency is increased by several times.

Owner:岳炳坤

Zinc chemical surface treatment technology

InactiveCN103320790ANo drossIncreasing the thicknessSolid state diffusion coatingSuperimposed coating processSlagLayer thickness

The invention provides a zinc chemical surface treatment technology, which is characterized in that: the zinc chemical surface treatment technology comprises the following steps of: carrying out deoiling, rust-removing, washing and drying treatment for surfaces of a steel screw workpiece; preparing a zinc penetrating agent; carrying out zinc penetrating treatment on the steel screw workpiece; cooling the steel screw workpiece; carrying out flushing and polishing treatment, passivating treatment and air-drying treatment on the steel workpiece; and electroplating the steel screw workpiece at 20-30 DEG C under a condition of 2.0A / dm2 of current density, wherein the steel screw workpiece needed to be electroplated is used as a cathode, a zinc plate is used as an anode, an area ratio of the anode to the cathode is 2:1, and an electroplating solution is an alkaline and cyanide-free galvanizing solution. The zinc chemical surface treatment technology combines the zinc penetrating technology and a galvanizing technology to carry out surface treatment on a steel screw, and combines advantages of the two technologies, and the treated steel screw has advantages of brightening surface, no zinc slag, no zinc flow, accurate dimension, good zinc layer thickness and good antirust effect.

Owner:洪求耀

Novel industrial cutting gas with dimethyl ether as main component

The invention discloses novel industrial cutting gas with dimethyl ether as a main component. The novel industrial cutting gas comprises (but not limited to) the following components in percentage by mass: 60-99.99% of the dimethyl ether, 0.01-40% of additives and the like, wherein the additive is prepared from tert-butylferrocene, diethyl ether, aromatic hydrocarbon, solvent oil No.6, tert-butyl alcohol and potassium permanganate according to a certain proportion. Auxiliary gas can also be added into the cutting gas and is one or some of acetylene, propane, propylene, butane and butylene. The novel industrial cutting gas disclosed by the invention presents strong advantages in the aspects of economy, safety, environment friendliness and cutting performance.

Owner:ENN XINNENG BEIJING TECH

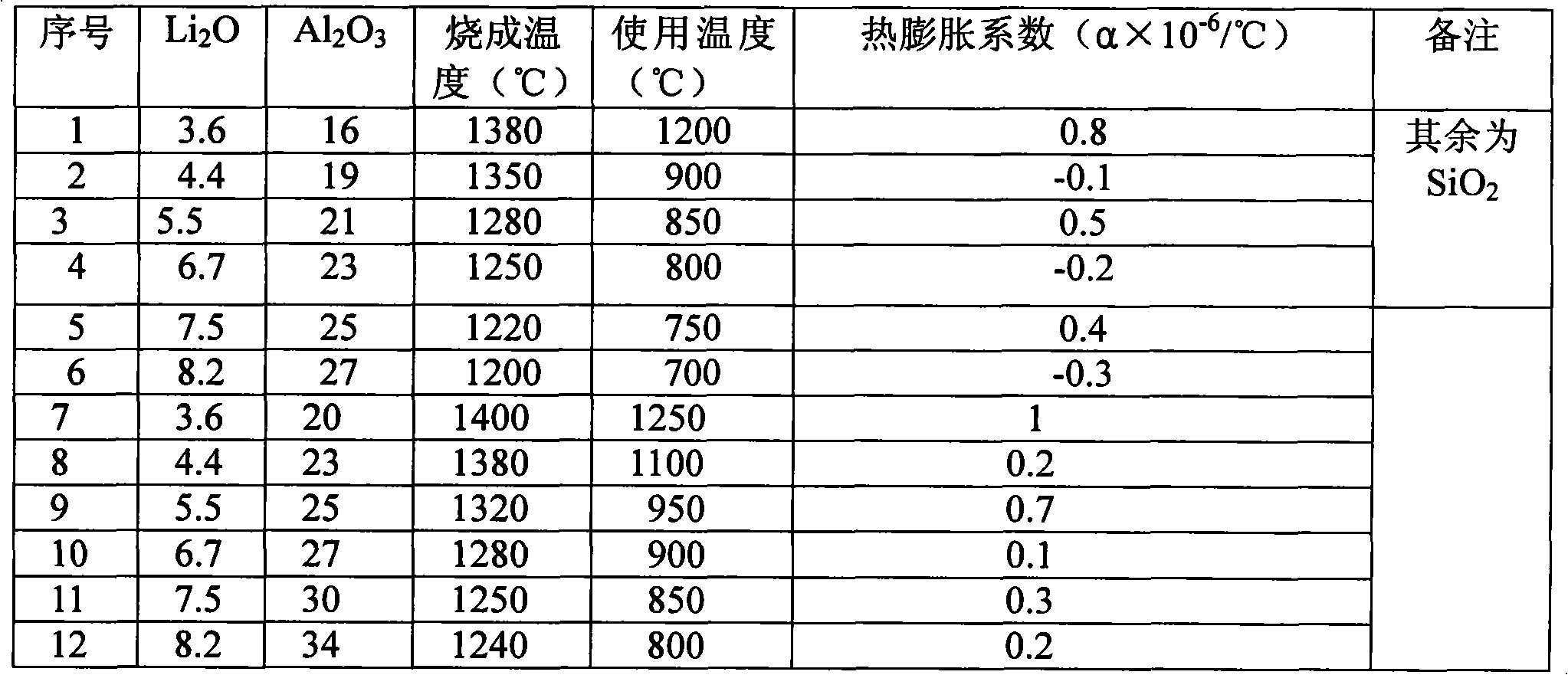

Production method of lithium non-expansion heat-resistant ceramic

The invention relates to a production method of lithium non-expansion heat-resistant ceramic, comprising the following steps: pre-compounding a raw material by adopting industrial lithium salts of lithium carbonate, lithium hydroxide, lithium phosphate, and the like, silaceous and aluminiferous ceramic and fireproof materials at the temperature of 650-1,150 DEG C, and compounding the raw materialaccording to a corresponding formula and proportioning by a corresponding prescription to prepare a compound with the following components by weight percent: 3.0-8.5 percent of Li2O, 13-30 percent ofAl2O3 and the balance of SiO2; grinding; molding; drying; and sintering at the temperature of 1,240-1,410 DEG C. The method uses the industrial lithium salts to compound high-purity lithium mineralizers, thereby preparing the high temperature ceramic with a thermal expansion coefficient near zero.

Owner:苏平宇

Red copper crucible welding method

ActiveCN104708180AReduce generationNot easy to produceArc welding apparatusWelding/cutting media/materialsCrucibleSlag

The invention discloses a red copper crucible welding method, and belongs to the technical field of red copper crucible welding. Welding joints are high in quality, air flow is protected to be stable, surrounding air can be effectively isolated, a weld pool is stable during welding, flashing is little, air holes are not generated easily, argon arc welding heat is concentrated, temperature is high, welding speed is high, and arcs are stable. When a red copper crucible is welded in an argon arc welding mode, no slag or splashing is generated, the weld pool and the electric arcs are good in resolvability, and operation is convenient.

Owner:南京宝泰特种材料股份有限公司

Method for laser cutting of 0.5 mm stainless steel

InactiveCN112222639AImprove cleanlinessQuality improvementWelding/soldering/cutting articlesLaser beam welding apparatusLaser cuttingSS - Stainless steel

The invention relates to a method for laser cutting of a 0.5 mm stainless steel. The method comprises the following steps: (1) removing greasy dirt and dust on the surface of stainless steel, and keeping the surface of the stainless steel smooth; and (2) cutting a 0.5 mm stainless steel panel by a ProCutter laser cutting gun, wherein the technological parameters are as follows: the cutting speed is 14-16 m / min; the laser power is 1-2kW; the gas pressure is 1-2 MPa; the defocusing amount is -1-0 mm; the working distance is 0.6 to 1.0 mm; the diameter of a cutting nozzle is 0.8 to 1.2 mm; and the cutting gas is nitrogen. The method is stable in process, has repeatability, is safe, stable and reliable, and a kerf is smooth, level, free of adhering slag and good in quality.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

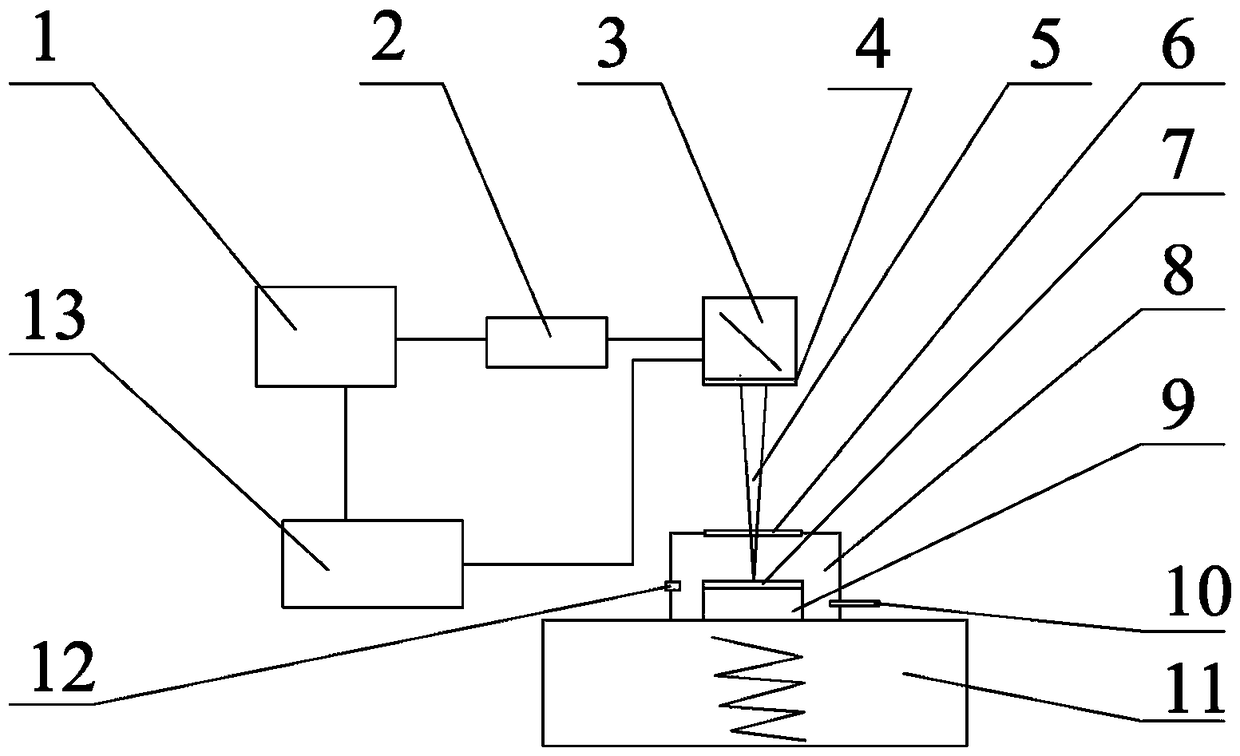

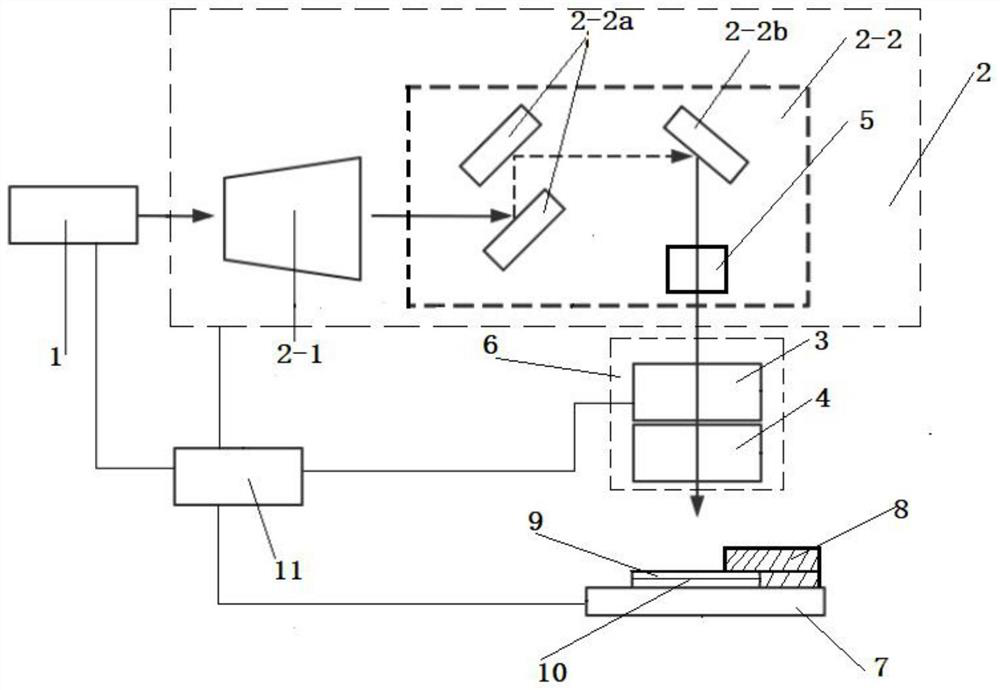

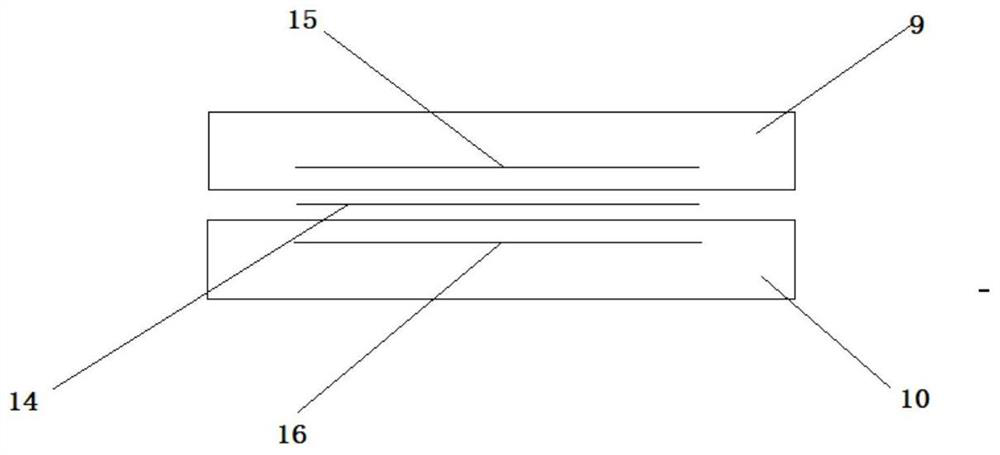

Laser cutting method and system used for amorphous thin belts

The invention discloses a laser cutting method and system used for amorphous thin belts. The cutting system comprises a pulse laser, a beam expansion collimating mirror, a scanning galvanometer, a focus lens, an industrial personal computer, an inflation chamber and a worktable, wherein the industrial personal computer is used for controlling the pulse laser and the scanning galvanometer; a clampused for fixing the amorphous thin belts is arranged on the worktable; a light-transmitting lens is arranged on a top surface of the inflation chamber; an inflation opening and an oxygen content measuring interface are arranged on a side surface of the inflation chamber; a pulse laser beam generated by the pulse laser is expanded by the beam expansion collimating mirror, then enters the scanning galvanometer, and is focused by the focus lens through deflection of the scanning galvanometer; and the laser beam enters the surface of the amorphous thin belt through the light-transmitting lens on the inflation chamber after being focused. By adopting the laser cutting method and system, the 0.01-0.05 mm-thick amorphous thin belt can be subjected to complicated-shape high-speed cutting; besides,cutting joints are smooth; and oxidation and slag adhering are avoided.

Owner:GUANGDONG PROVINCIAL INST OF WELDING TECH GUANGDONG PROVINCIAL ACADEMY OF UKRAINE

Method for laser cutting of 0.5 mm titanium alloy

InactiveCN112222640AExtended maintenance cycleCut nozzle long lifeWelding/soldering/cutting articlesLaser beam welding apparatusLaser cuttingTitanium alloy

The invention relates to a method for laser cutting of a 0.5 mm titanium alloy. The method comprises the steps: (1) removing greasy dirt and dust on the surface of the titanium alloy; and (2) cuttinga titanium alloy panel with the thickness of 0.5 mm by using a ProCutter laser cutting gun, wherein the technological parameters are as follows: the cutting speed is 14-16 m / min; the laser power is 1-2kW; the gas pressure is 1-1.5 MPa; the defocusing amount is -1-0 mm; the working distance is 0.8 to 1.2 mm; the diameter of a cutting nozzle is 0.8 to 1.2 mm; and cutting gas is argon. According to the method, the process stability can be guaranteed, and the method is repeatable, safe, stable and reliable, and a kerf is smooth, level, free of adhering slag and good in quality.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Corrosion-resisting die casting aluminum alloy easy to anodize

The invention discloses a corrosion-resisting die casting aluminum alloy easy to anodize. The corrosion-resisting die casting aluminum alloy comprises, by mass, 100 parts of Al, 7.5-9.0 parts of Si, 1.0-1.4 parts of Cu, 0.3-0.5 part of Mg, 0.5-0.8 part of Mn, 0.5-0.7 part of Zn, 0.5-3.0 parts of Sn, 0.3-0.6 part of Fe, 0.3-1.0 part of V, 0.05-0.20 part of Ti, 0-0.15 part of Pb and 0-0.5 part of Ni, wherein Al is the main body, and an additive is composed of the other components. The corrosion-resisting die casting aluminum alloy is prepared through the steps from A to P. The corrosion-resisting die casting aluminum alloy easy to anodize is good in corrosion resistance performance, easy to anodize and good in overall performance.

Owner:QINGYUAN SHUNBO ALUMINUM ALLOY

Die-casting aluminum alloy

A die-casting aluminum alloy comprises the following components in percentages by weight: 9.5-11.0% of Si, 0.05-0.08% of Cu, 3.3-3.5% of Mg, 0.3-0.5% of Mn, 0.1-0.2% of Zn, 2.8-3.0% of Fe, 0-0.03% of Pb, 0.03-0.18% of Ti, 0-0.03% of Ni, 0-0.05% of Cr, 0-0.03% of Sn and the balance of Al. Al is the main body, and the rest components are addition materials. The die-casting aluminum alloy is prepared by a method comprising step A, step B, step C, step D, step E, step F, step G, step H, step I, step J, step K, step L, step M, step N, step O and step P. The die-casting aluminum alloy has the characteristics of good anodic oxidation property and corrosion resistance.

Owner:QINGYUAN SHUNBO ALUMINUM ALLOY

Sesame turning, airing, cooling and residue removing device and application method thereof

InactiveCN104939175AImprove the airflow effectImprove cooling effectFood preparationSpecific gravityFlavor

The invention discloses a sesame turning, airing, cooling and residue removing device and an application method thereof. The sesame turning, airing, cooling and residue removing device is composed of an inner cavity and an outer cavity. Openings are formed in the inner cavity and the outer cavity. The inner cavity is composed of a silk screen. The inner cavity is arranged in the outer cavity, and a gap is formed between the inner cavity and the outer cavity. The inner cavity is driven by a transmission device to rotate. A smoke outlet is formed in the top of the outer cavity, and a residue stone falling opening is formed in the bottom of the outer cavity. The sesame turning, airing, cooling and residue removing device is simple in structure and integrates multiple functions, feeding is conducted in the forward rotation process, and when sesame is cooled, light impurity particles such as smashed residues which are made brown by stir-heating and smoke contained inside can be removed; gravel particles with the large specific gravity can be removed; discharging is conducted in the reverse rotation process, the device can relieve manual turning and airing labor intensity and further improve sesame oil quality, and produced sesame oil is clear, transparent and free of sediments and residues; flavor is natural and pure, and taste is mellow, normal and palatable.

Owner:WULI FENGXIANGYUAN SESAME FOOD

Method for laser cutting of 1mm titanium alloy

InactiveCN112589287AImprove cleanlinessQuality improvementLaser beam welding apparatusLaser cuttingTitanium alloy

The invention relates to a method for laser cutting of 1mm titanium alloy. The method comprises the following steps: (1) removing oil stains and dust on the surface of the titanium alloy; and (2) adopting a ProCutter laser cutting gun to cut the titanium alloy plate with the thickness of 1mm, wherein the technological parameters are as follows: the cutting speed is 15-20m / min; the laser power is 3-4kW; the gas pressure is 0.8 to 2.0MPa; the defocusing amount is -1 to 0mm; the working distance is 0.6 to 1.0mm; the diameter of a cutting nozzle is 1.0-1.5mm; and cutting gas is argon. When the method is used for cutting the titanium alloy, no slag adheres to the back face of a kerf, the kerf quality is good, the process is stable, and repeatability is achieved.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Method for cutting 4 mm titanium alloy by laser

InactiveCN112756817AExtended maintenance cycleCut nozzle long lifeWelding/soldering/cutting articlesLaser beam welding apparatusLaser cuttingTitanium alloy

The invention relates to a method for cutting a 4 mm titanium alloy by laser. The method comprises the following steps of removing oil stains and dust on the surface of the titanium alloy, and keeping the surface of the titanium alloy smooth; and adopting a ProCutter laser cutting gun for cutting a 4 mm titanium alloy, wherein the process parameters are that the cutting speed is 2-4 m / min, the laser power is 3-4 kW, the gas pressure is 1.5-2.5 MPa, the defocusing amount is -4 mm to -1 mm, the working distance is 0.6-1.0 mm, the diameter of a cutting nozzle is 2.0-3.0 mm, and the cutting gas is argon. When the method is used for cutting the titanium alloy, a cutting process window which is free of adhering slag on the back face of a kerf and good in kerf quality and the optimal cutting process parameters are obtained by changing all the process parameters, the process stability is guaranteed, and repeatability is achieved.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Method for cutting 5 mm titanium alloy by laser

InactiveCN112756816AExtend your lifeExtended maintenance cycleWelding/soldering/cutting articlesLaser beam welding apparatusSlagLaser cutting

The invention relates to a method for cutting a 5 mm titanium alloy by laser. The method comprises the following steps of removing oil stains and dust on the surface of the titanium alloy, and keeping the surface of the titanium alloy smooth; and cutting a 5 mm titanium alloy plate by using a ProCutter laser cutting gun, wherein the process parameters are that the cutting speed is 2-4 m / min, the laser power is 3-4 kW, the gas pressure is 1.5-2.5 MPa, the defocusing amount is -4-0 mm, the working distance is 0.6-1.0 mm, the diameter of a cutting nozzle is 2.5-3.5 mm, and the cutting gas is argon. When the method is used for cutting the titanium alloy, a cutting process window which is free of adhering slag on the back face of a kerf and good in kerf quality and the optimal cutting process parameters are obtained by changing all the process parameters, the process stability is guaranteed, and repeatability is achieved.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Method for laser cutting of 1.5 mm stainless steel

InactiveCN112756815AExtended maintenance cycleCut nozzle long lifeWelding/soldering/cutting articlesLaser beam welding apparatusSlagLaser cutting

The invention relates to a method for laser cutting of 1.5 mm stainless steel. The method comprises the following steps of removing oil stains and dust on the surface of the stainless steel to keep the surface of the stainless steel smooth; and cutting a 1.5 mm stainless steel plate by adopting a ProCutter laser cutting gun, wherein the process parameters are that the cutting speed is 3-8 m / min, the laser power is 3-4 kW, the gas pressure is 1.2-1.8 MPa, the defocusing amount is -2-0 mm, the working distance is 0.6-1.0 mm, the diameter of a cutting nozzle is 1.8-2.2 mm, and the cutting gas is nitrogen. When the method is used for cutting the stainless steel, a cutting process window with no adhering slag on the back surface of a kerf and good kerf quality and the optimal cutting process parameters are obtained by changing all the process parameters, the process stability is ensured, and repeatability is achieved.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

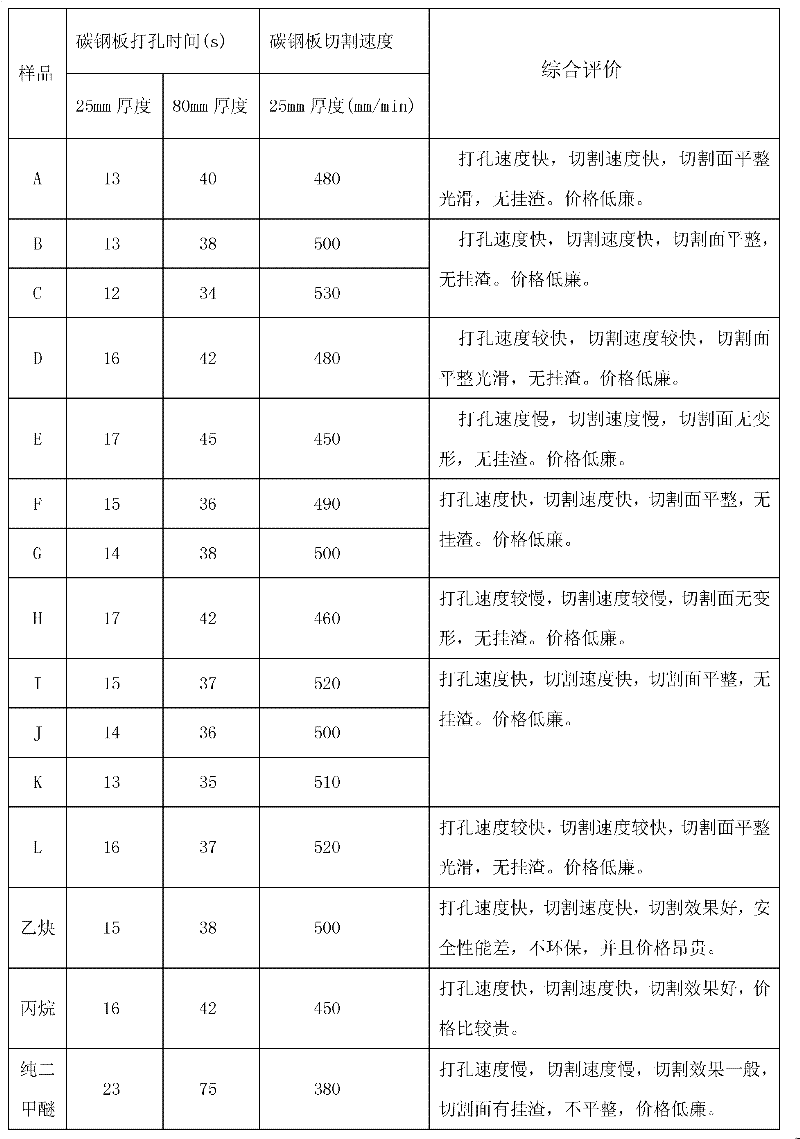

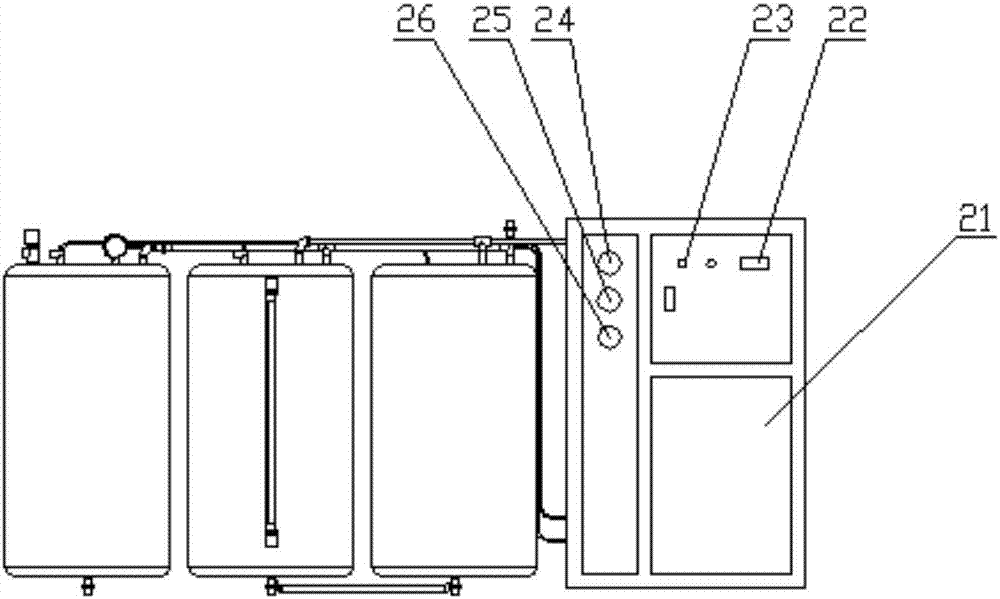

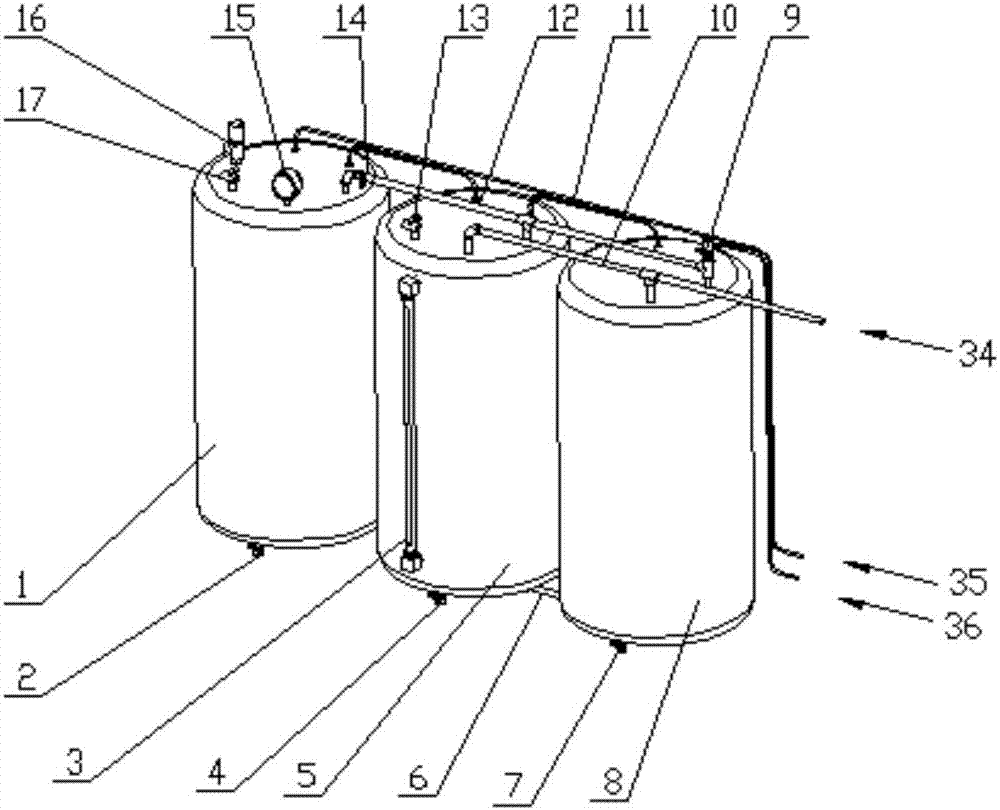

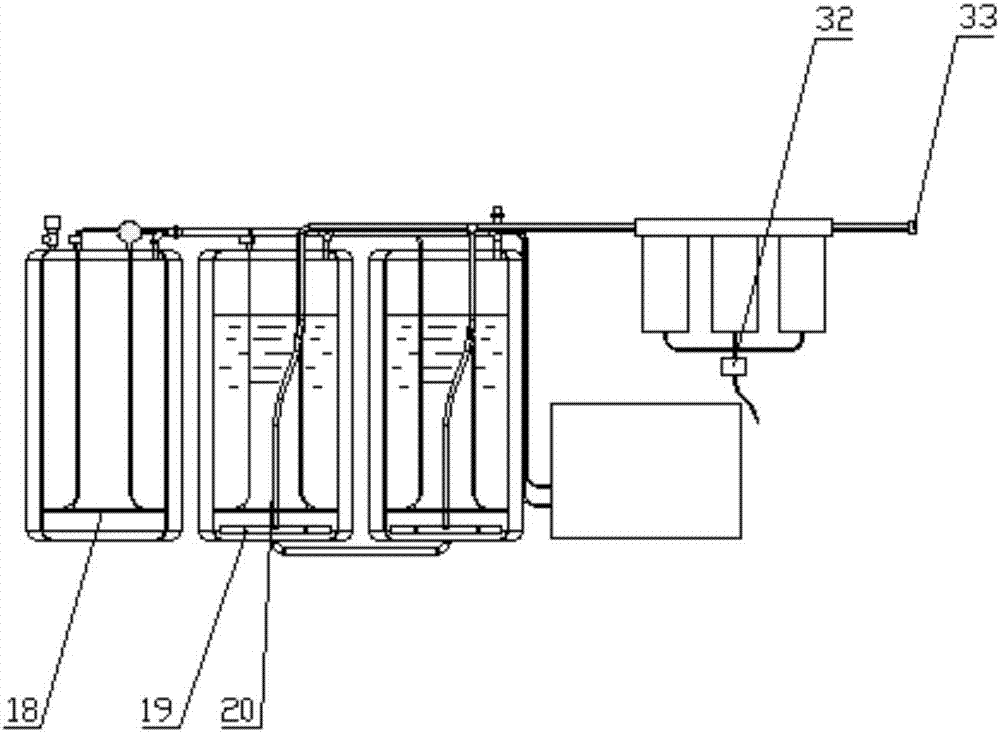

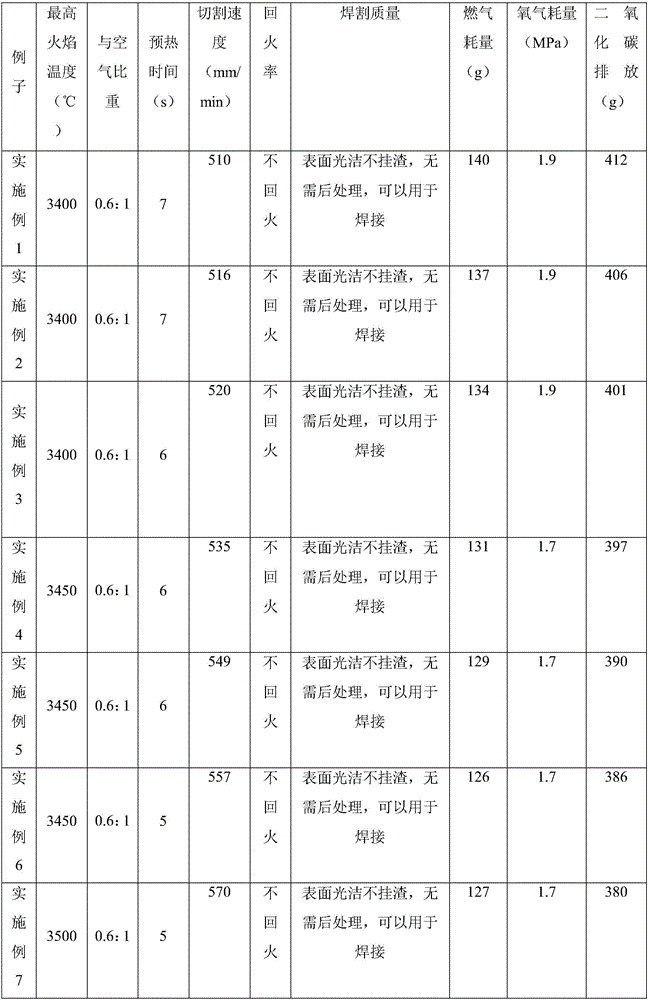

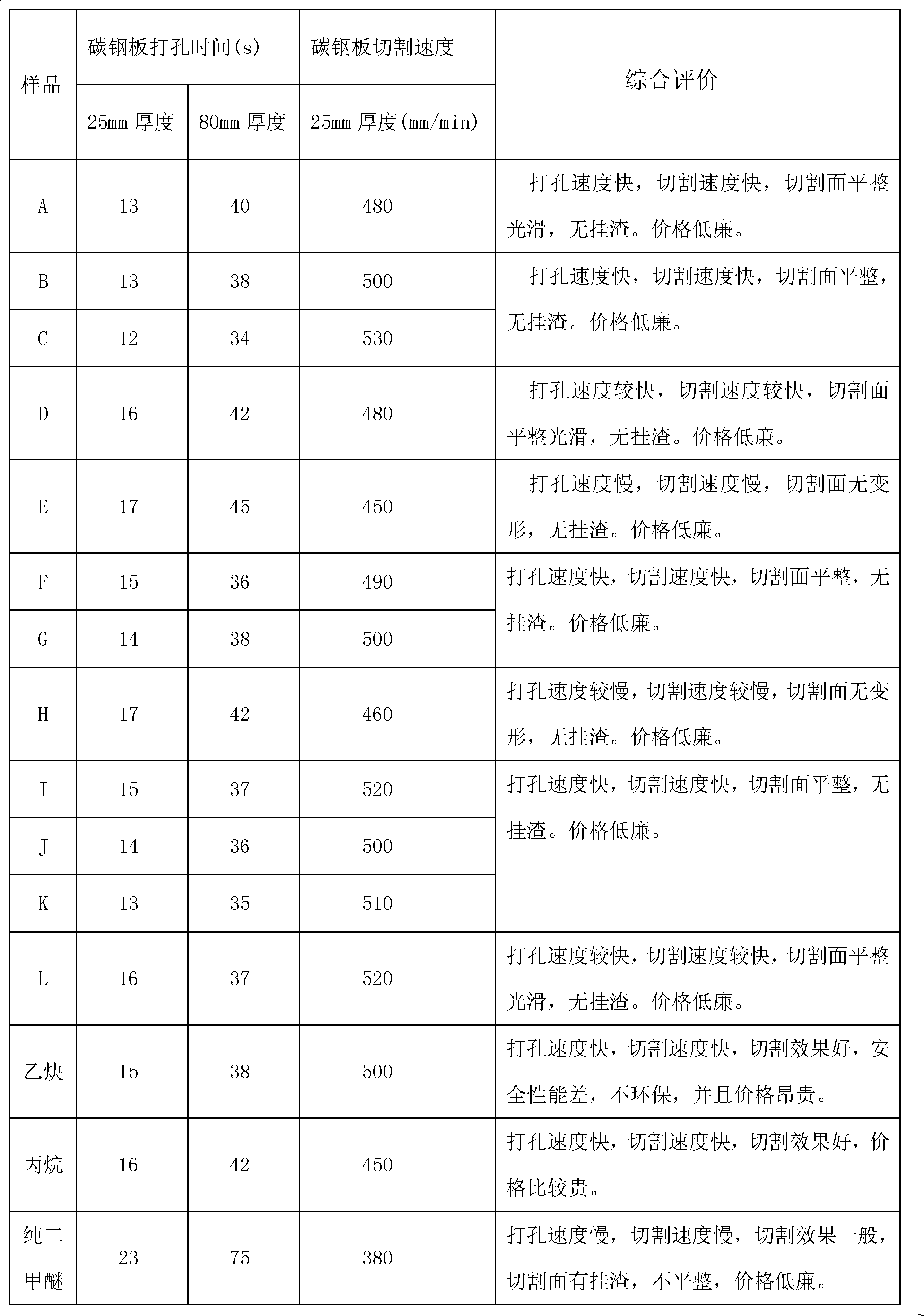

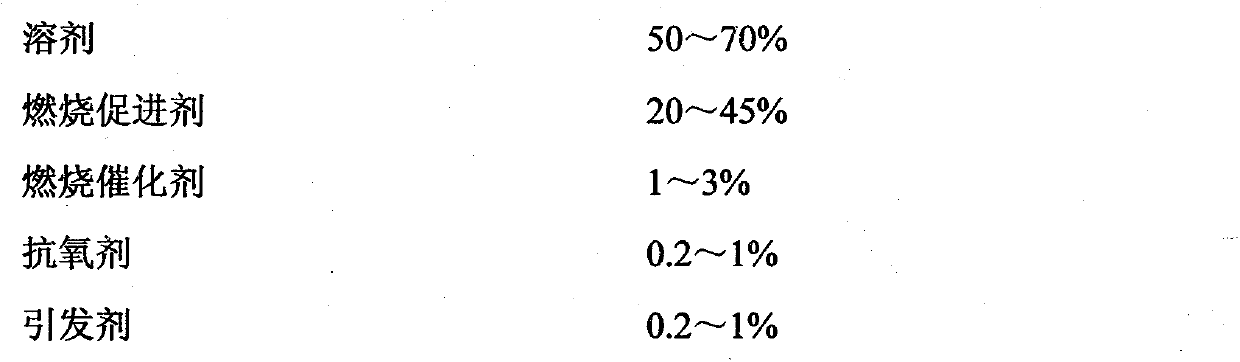

Production technique of acetylene-free industrial cutting gas

ActiveCN106867606ARaise the combustion temperatureHigh calorific valueGaseous fuelsCombustible gasProcess engineering

The invention provides a production technique of acetylene-free industrial cutting gas. The technique comprises the following steps: (1) pretreatment of compressed air: compressed air is dried, and enters a storage tank via a compressed air inlet, wherein a liquid fuel is stored in the storage tank; (2) primary gasification of liquid fuel: the compressed air entering the storage tank is treated by a gasifier to generate abundant bubbles so as to promote the primary gasification of the liquid fuel, and meanwhile, the liquid fuel is heated to generate primary combustible gas; and (3) secondary gasification of liquid fuel: the primary combustible gas enters a gas collection tank via a gas outlet connecting pipe, and is heated to implement secondary gasification, thereby preparing the industrial cutting gas. The liquid fuel comprises a light hydrocarbon fuel, a combustion improver, a dispersing agent, a solubilizer, a catalyst and a solvent.

Owner:巨烃新能源技术有限公司

Anti-corrosion die-casting aluminum alloy

The invention relates to an anti-corrosion die-casting aluminum alloy. The anti-corrosion die-casting aluminum alloy comprises, by mass, 100 parts of Al, 15.5-20.5 parts of Si, 0.08-0.20 part of Cu, 0.3-0.5 part of Mg, 0.3-0.5 part of Mn, 0-0.1 part of Zn, 0.3-1.0 part of In, 1.8-3.0 parts of Fe, 0.3-1.0 part of V and 1.03-3.15 parts of Ti; and the Al serves as a main part, and the rest of components forms an additive. The aluminum alloy is prepared through the step A to step P. The anti-corrosion die-casting aluminum alloy is excellent in anti-corrosion performance, and the overall performance is better.

Owner:QINGYUAN SHUNBO ALUMINUM ALLOY

Manufacturing process and equipment for upset forging of flanges

InactiveCN101961765BReduce bending momentReduce the height of the hook shellEngine componentsHeating/cooling devicesEnergy consumptionHeating temperature

The invention relates to manufacturing process and equipment for the upset forging of flanges, relating to manufacturing process and equipment for flanges. The manufacturing process comprises the following steps of: making materials into flange metal semicircles, evenly heating and butting the flange metal semicircles by adopting upset forging equipment, wherein the pressure on an extrusion surface is 40 to 70MP and the heating temperature is 500 to 1300 DEG C; and quickly connecting the two semicircles after the extrusion through the upset forging equipment to obtain a product. The inventionhas the advantages of capability of producing various annular steel flanges and aluminum flanges with different specifications only by using the upset forging equipment and simple matched moulding beds so that the investment in equipment and the energy consumption only account for a fraction or one of dozens of that of traditional equipment, cost is saved by more than 30% and production efficiency is increased by several times.

Owner:岳炳坤

Zinc chemical surface treatment process

InactiveCN103320790BNo drossIncreasing the thicknessSolid state diffusion coatingSuperimposed coating processCyanideSlag

The invention provides a zinc chemical surface treatment technology, which is characterized in that: the zinc chemical surface treatment technology comprises the following steps of: carrying out deoiling, rust-removing, washing and drying treatment for surfaces of a steel screw workpiece; preparing a zinc penetrating agent; carrying out zinc penetrating treatment on the steel screw workpiece; cooling the steel screw workpiece; carrying out flushing and polishing treatment, passivating treatment and air-drying treatment on the steel workpiece; and electroplating the steel screw workpiece at 20-30 DEG C under a condition of 2.0A / dm2 of current density, wherein the steel screw workpiece needed to be electroplated is used as a cathode, a zinc plate is used as an anode, an area ratio of the anode to the cathode is 2:1, and an electroplating solution is an alkaline and cyanide-free galvanizing solution. The zinc chemical surface treatment technology combines the zinc penetrating technology and a galvanizing technology to carry out surface treatment on a steel screw, and combines advantages of the two technologies, and the treated steel screw has advantages of brightening surface, no zinc slag, no zinc flow, accurate dimension, good zinc layer thickness and good antirust effect.

Owner:洪求耀

Gas synergist and application method thereof

InactiveCN106701226AImprove performanceIncrease combustion temperature and calorific valueGaseous fuelsChemistryEther

The invention relates to the technical field of industrial combustion gas synergists and particularly relates to a pentane combustion synergist for metal cutting and welding and an application method thereof. The gas synergist comprises the following ingredients in parts by weight: 30-50 parts of methanol, 10-20 parts of acetone, 10-20 parts of ethylbenzene, 15-25 parts of xylene, 1-3 parts of biferrocene ether, 20-30 parts of turpentine, 3-5 parts of solubilizer and 2-5 parts of dispersant. The gas synergist is capable of obviously improving the combustion temperature, combustion heat, combustion velocity and combustion efficiency of pentane, improving the total available energy of the pentane, improving the flame temperature, improving combustion product ingredients, and achieving the technical effects of reducing energy consumption, reducing pollution, reducing the production cost of using institutions, improving the production efficiency and the like.

Owner:巨烃新能源技术有限公司

Industrial fuel gas for metal cutting and welding

This invention discloses an industrial fuel gas used for metal cutting and welding. Additive and dimethyl enther are added to cylinder to make-up the fuel, dimethyl enther is 40~99.9% and other rest additive. The additive is consisted by one or any several kind of following fuels as arbitrary proportion, petroleum liquefied gas, propane, butane, propylene, pentane, clean oil, methanol, ethanol. This invention has good burning property, security, environmental protection capability and extra high burning flame temperature. Comparing to acetylene, it is not easy to bomb, and its storage, transportation, using and management is more convenient and safe. There is no pollution to environment and operator. Its preheating and cutting velocity is fast, welding and welding line quality is good, oxygen consumption is low, so it improves work efficiency and reduces cost.

Owner:郑长同 +3

Method for laser cutting of 2 mm titanium alloy

InactiveCN113210891AExtended maintenance cycleCut nozzle long lifeWelding/soldering/cutting articlesLaser beam welding apparatusLaser cuttingTitanium alloy

The invention relates to a method for laser cutting of 2 mm titanium alloy. The method comprises the following steps that oil stains and dust on the surface of the titanium alloy are removed, and the surface of the titanium alloy is kept smooth; a titanium alloy plate with the thickness of 2 mm is cut through a ProCutter laser cutting gun, and the technological parameters are as follows, the cutting speed is 12-16 m / min; the laser power is 3-4 kW; the gas pressure is 1.2-2.0 MPa; the defocusing amount is -2-0 mm; the working distance is 0.8-1.2 mm; the diameter of a cutting nozzle is 1.8-2.2 mm; and the cutting gas is argon. When the method is used for cutting the titanium alloy, a cutting process window which is free of adhering slag on the back face of a cutting seam and good in cutting seam quality and the optimal cutting process parameters are obtained by changing all the process parameters, the process stability is guaranteed, and repeatability is achieved.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

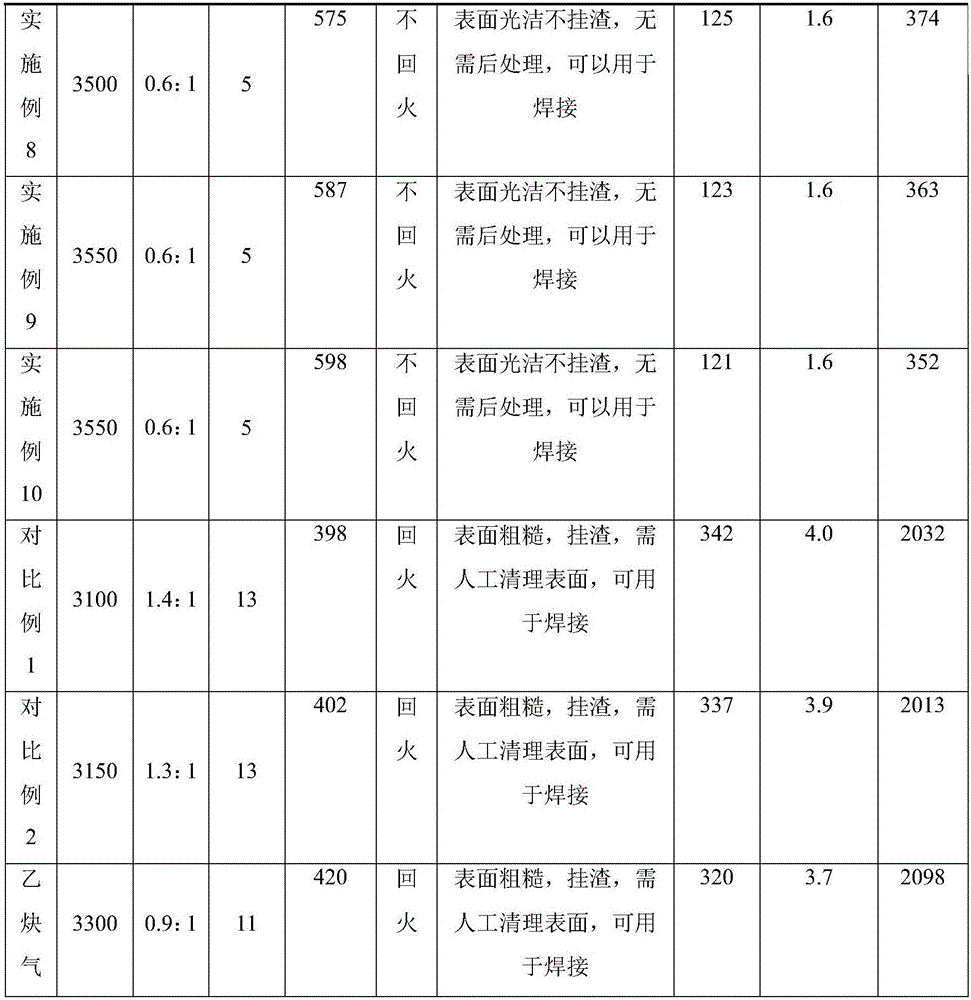

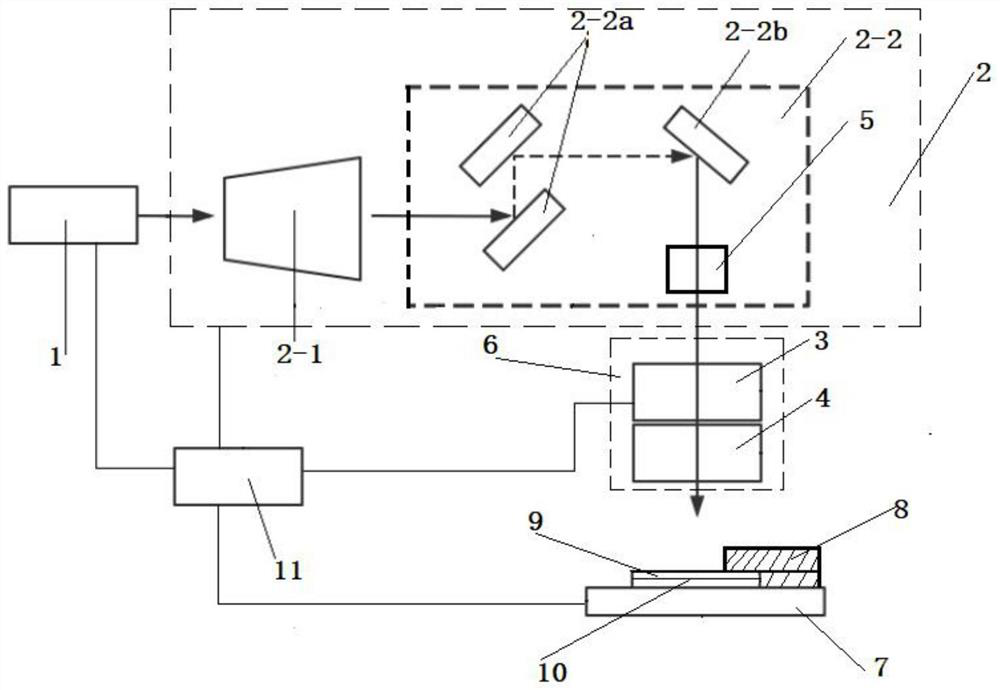

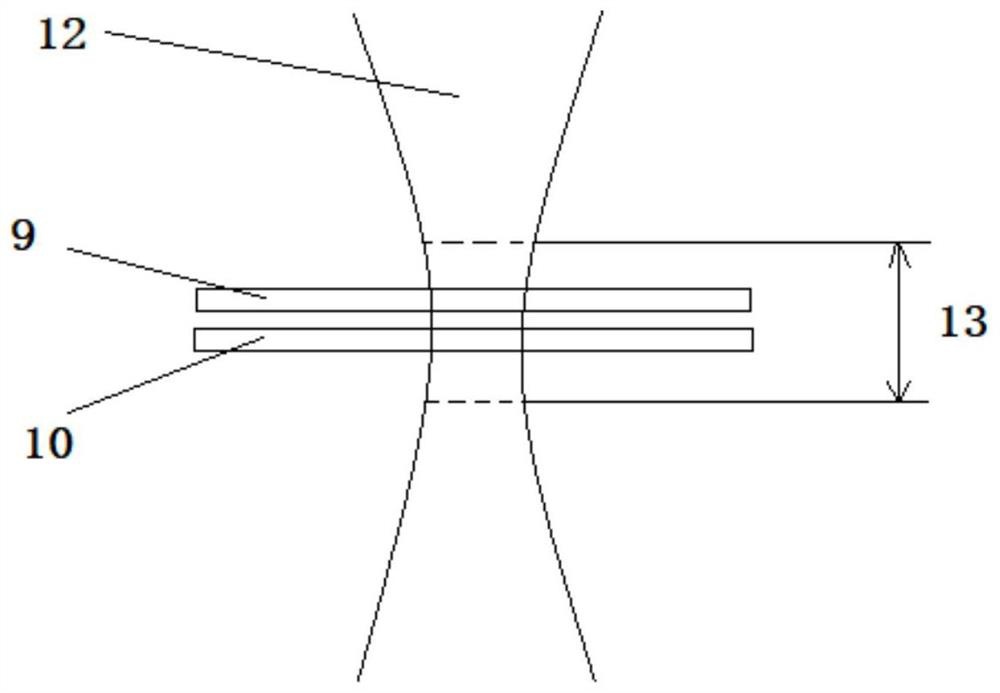

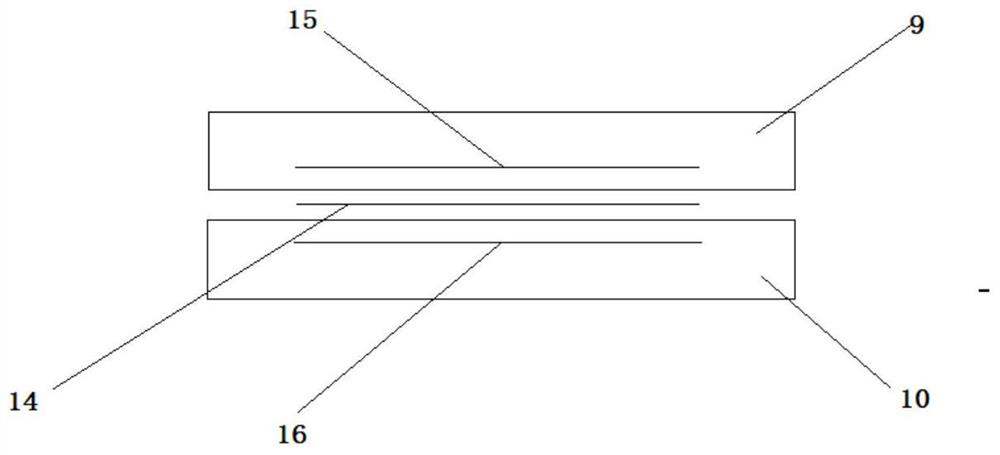

Infrared ultrafast laser welding method and system between glass

PendingCN114273781AMeet a wide variety of needsIntensity unchangedLaser beam welding apparatusLaser lightUltimate tensile strength

The invention provides an infrared ultrafast laser welding method and system between glass. The infrared ultrafast laser welding method comprises the following steps: 1) ultrasonically cleaning and drying a substrate to be welded; (2) two substrates to be welded are stacked together and placed on a workpiece bearing table to be welded; (3) under the control of a software and hardware controller, focusing parameters of a dynamic focusing module are controlled, and a laser light path is adjusted, so that the laser focal depth of the welding position is larger than the distance between welding substrates; and (4) laser welding of 1-N welding faces is achieved, and the distance resolution between the welding faces is controlled to be 1-10 micrometers. According to the welding method, the laser focal depth is larger than the distance between the glass workpieces, photon monopulse energy is high, consistency is good, the requirement for the distance between the two surfaces to be welded is low, and the welding area is high in strength, uniform in quality and high in sealing performance.

Owner:北京赢圣科技有限公司

A copper crucible welding method

ActiveCN104708180BReduce generationNot easy to produceArc welding apparatusWelding/cutting media/materialsMelting tankSlag

The invention discloses a red copper crucible welding method, and belongs to the technical field of red copper crucible welding. Welding joints are high in quality, air flow is protected to be stable, surrounding air can be effectively isolated, a weld pool is stable during welding, flashing is little, air holes are not generated easily, argon arc welding heat is concentrated, temperature is high, welding speed is high, and arcs are stable. When a red copper crucible is welded in an argon arc welding mode, no slag or splashing is generated, the weld pool and the electric arcs are good in resolvability, and operation is convenient.

Owner:南京宝泰特种材料股份有限公司

Novel industrial cutting gas with dimethyl ether as main component

Owner:ENN XINNENG BEIJING TECH

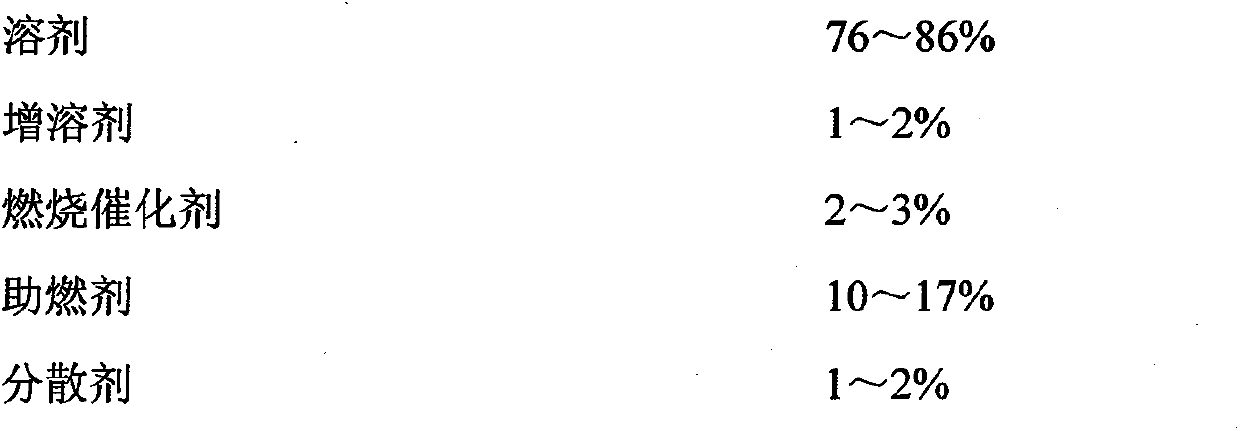

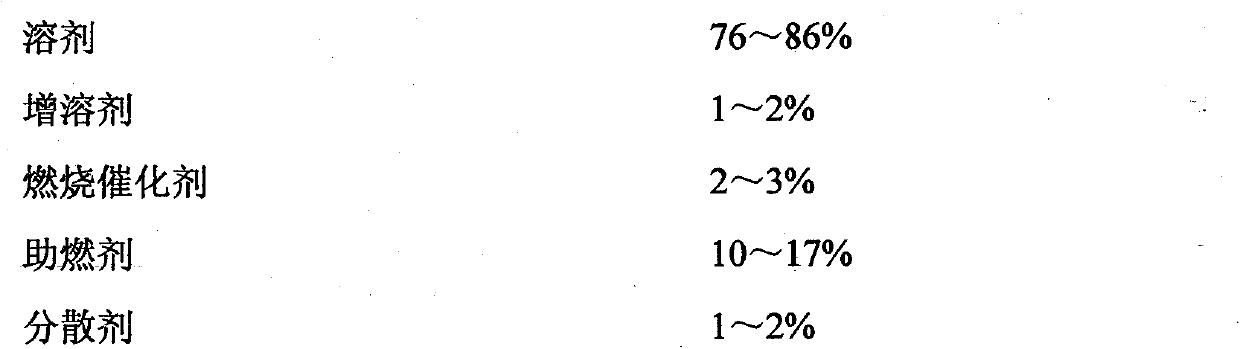

Combustion synergist for industrial fuel gas

InactiveCN102492504BImprove performanceRaise the combustion temperatureGaseous fuelsProcess engineeringSolvent

The invention relates to a combustion synergist for natural gas and liquefied petroleum gas used for cutting and welding of metals. The combustion synergist comprises a solvent, a solubilizing agent, a combustion catalyst, a combustion improver and a dispersant. The combustion synergist provided in the invention can substantially improve combustion temperature, heat and speed of industrial fuel gas, enables a high flame temperature, a short preheating time, a fast cutting speed, a smooth cutting surface of metals and no adherent dross to be obtained during cutting of metals, can be fully mixed with industrial fuel gas, promotes complete combustion of industrial fuel gas, does not produce black smoke, residues or pollutants and has the advantages of safety, convenience, environmental friendliness, convenient popularization and application, etc. The combustion synergist can be widely used for a variety of industrial fuel gas and is especially applicable to natural gas and liquefied petroleum gas.

Owner:CHONGQING UNIV +1

Green ultrafast laser welding method and system between glass

PendingCN114211114AMeet a wide variety of needsIntensity unchangedWelding/soldering/cutting articlesLaser beam welding apparatusLaser lightUltimate tensile strength

The invention provides a green-light ultrafast laser welding method and system between glass. The green-light ultrafast laser welding method comprises the following steps: 1) ultrasonically cleaning and drying a substrate to be welded; (2) two substrates to be welded are stacked together and placed on a workpiece bearing table to be welded; (3) under the control of a software and hardware controller, focusing parameters of a dynamic focusing module are controlled, and a laser light path is adjusted, so that the laser focal depth of the welding position is larger than the distance between welding substrates; and (4) laser welding of 1-N welding faces is achieved, and the distance resolution between the welding faces is controlled to be 1-10 micrometers. According to the welding method, the laser focal depth is larger than the distance between the glass workpieces, photon monopulse energy is high, consistency is good, the requirement for the distance between the two surfaces to be welded is low, and the welding area is high in strength, uniform in quality and high in sealing performance.

Owner:北京赢圣科技有限公司

Method for cutting 3mm stainless steel by laser

InactiveCN112756813AExtended maintenance cycleCut nozzle long lifeWelding/soldering/cutting articlesLaser beam welding apparatusSlagLaser cutting

The invention relates to a method for cutting 3mm stainless steel by laser. The method comprises the following steps: removing greasy dirt and dust on the surface of the stainless steel, and keeping the surface of the stainless steel smooth; cutting stainless steel plate of 3 mm by adopting a ProCutter laser cutting gun, wherein the technological parameters are as follows: the cutting speed is 2-5 m / min, the laser power is 2.5 to 4 kW, the gas pressure is 1.2 to 1.8 MPa, the defocusing amount is -2 to 0 mm, the working distance is 0.6 to 1.0 mm, the diameter of a cutting nozzle is 2-3mm, and the cutting gas is nitrogen. When the method is used for cutting the stainless steel, the cutting process window which is free of adhering slag on the back face of a cutting seam and good in cutting seam quality and the optimal cutting process parameters are obtained by changing all the process parameters, the process stability is guaranteed, and repeatability is achieved.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Method for cutting 6mm titanium alloy by laser

InactiveCN112756812AExtended maintenance cycleCut nozzle long lifeWelding/soldering/cutting articlesLaser beam welding apparatusSlagLaser cutting

The invention relates to a method for cutting 6mm titanium alloy by laser. The method comprises the following steps of removing oil stains and dust on the surface of the titanium alloy, and keeping the surface of the titanium alloy smooth; and cutting a 6mm titanium alloy plate by a ProCutter laser cutting gun, wherein the technological parameters are as follows: the cutting speed is 0.5 to 1.5 m / min, the laser power is 3 to 4 kW, the gas pressure is 1.5 to 2.5 MPa, the defocusing amount is -5 to -1 mm, the working distance is 0.6 to 1.0 mm, the diameter of a cutting nozzle is 2.5 to 3.5 mm, and the cutting gas is argon. When the method is used for cutting the titanium alloy, the cutting process window which is free of adhering slag on the back face of a cutting seam and good in cutting seam quality and the optimal cutting process parameters are obtained by changing all the process parameters, the process stability is guaranteed, and repeatability is achieved.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com