Gas synergist and application method thereof

A synergist, gas technology, applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of induced hydrogen cracks, low total combustion calorific value, slow combustion speed, etc. Conducive to environmental protection and the effect of promoting full combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

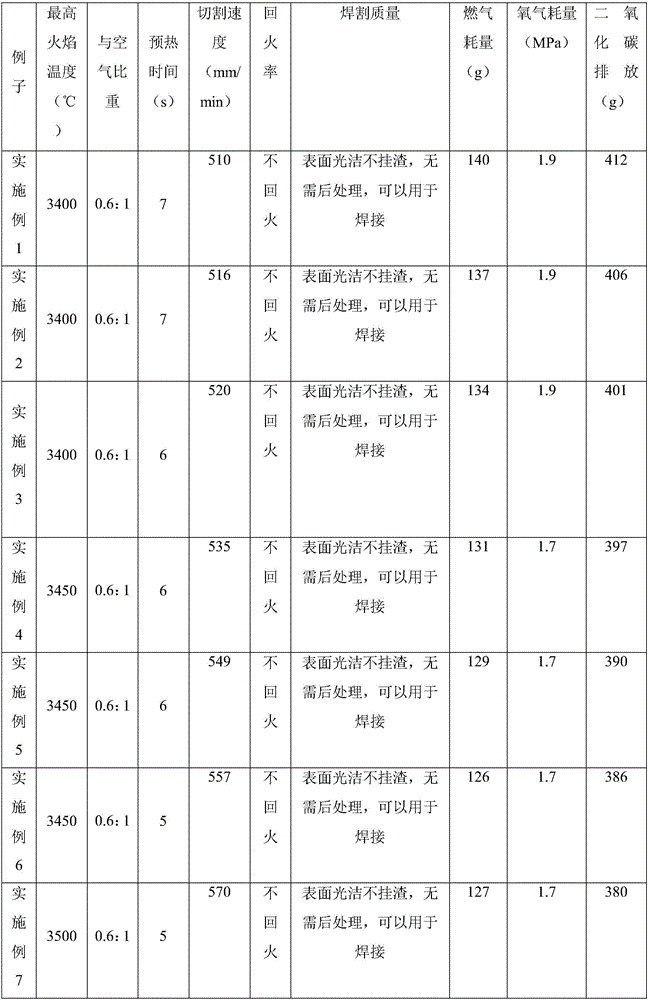

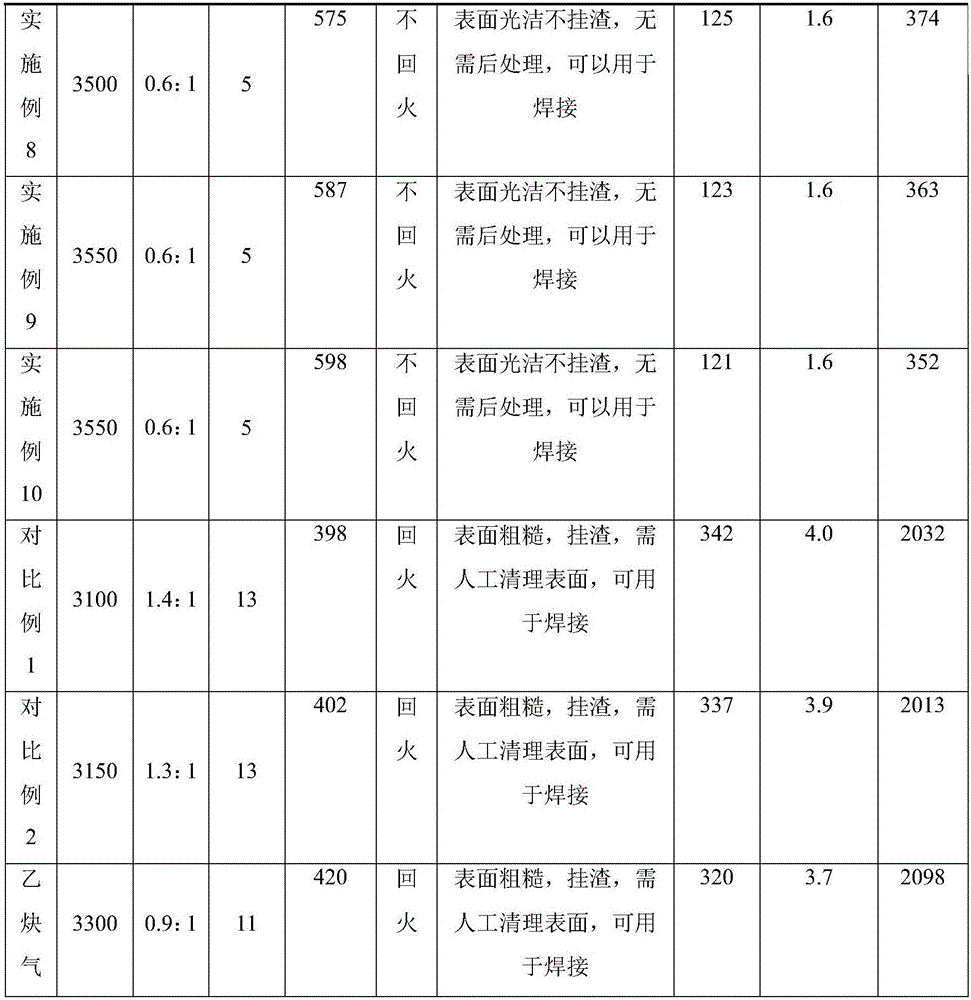

Examples

Embodiment approach

[0029] As a preferred embodiment of the present invention, the gas synergist includes the following components by weight: 30-40 parts by weight of methanol, 15-20 parts by weight of acetone, 15-20 parts by weight of ethylbenzene, 20 parts by weight 25 parts by weight of xylene, 1-3 parts by weight of bisferrocene ether, 25-30 parts by weight of turpentine, 3-5 parts by weight of solubilizer and 3-5 parts by weight of dispersant.

[0030] As a preferred embodiment of the present invention, the gas synergist includes the following components by weight: 35 parts by weight of methanol, 15 parts by weight of acetone, 20 parts by weight of ethylbenzene, 20 parts by weight of xylene, 3 parts by weight of bis-ferrocenyl ether, 30 parts by weight of turpentine, 3 parts by weight of solubilizer and 3 parts by weight of dispersant.

[0031] The term "methanol" in the present invention: has another name called wood alcohol, molecular weight 32.04, boiling point 64.7°C, volatile, colorless...

Embodiment approach 1

[0046] Embodiment 1, a gas synergist, the gas synergist includes the following components by weight:

[0047] 30-50 parts by weight of methanol, 10-20 parts by weight of acetone, 10-20 parts by weight of ethylbenzene, 15-25 parts by weight of xylene, 1-3 parts by weight of bis-ferrocene ether, 20-30 parts by weight The turpentine of 3-5 parts by weight, the solubilizer of 3-5 parts by weight and the dispersant of 2-5 parts by weight.

Embodiment approach 2

[0048] Embodiment 2 is the same as Embodiment 1, except that the gas synergist includes the following components by weight: 30-40 parts by weight of methanol, 15-20 parts by weight of acetone, 15-20 parts by weight of Ethylbenzene, 20-25 parts by weight of xylene, 1-3 parts by weight of bis-ferrocene ether, 25-30 parts by weight of turpentine, 3-5 parts by weight of solubilizer and 3-5 parts by weight of dispersant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com