Manufacturing process and equipment for upset forging of flanges

A manufacturing process and upsetting technology, which is applied in the field of upsetting flange manufacturing process and equipment, can solve the problems of easy generation of trachoma and pores, slag inclusion, waste of materials and energy, and limitation of application range, so as to shorten the production time and cost Save money and ensure the effect of traceless welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

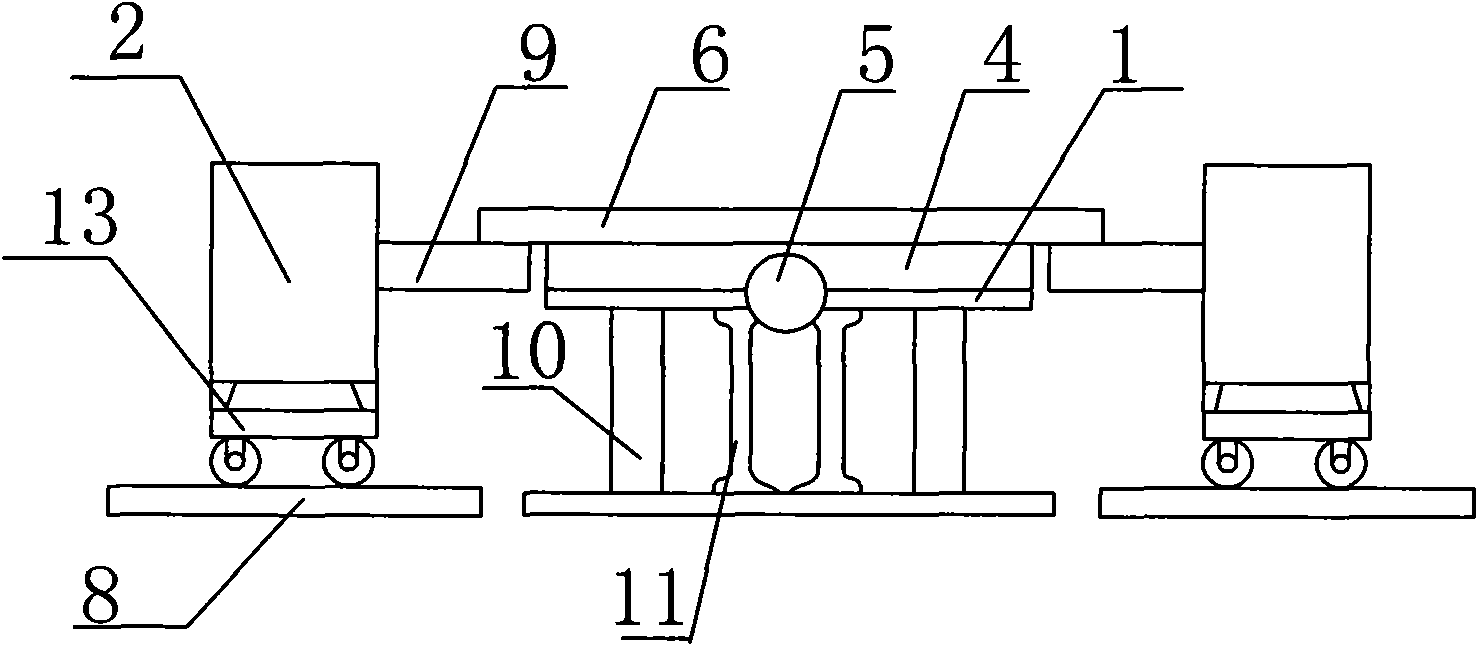

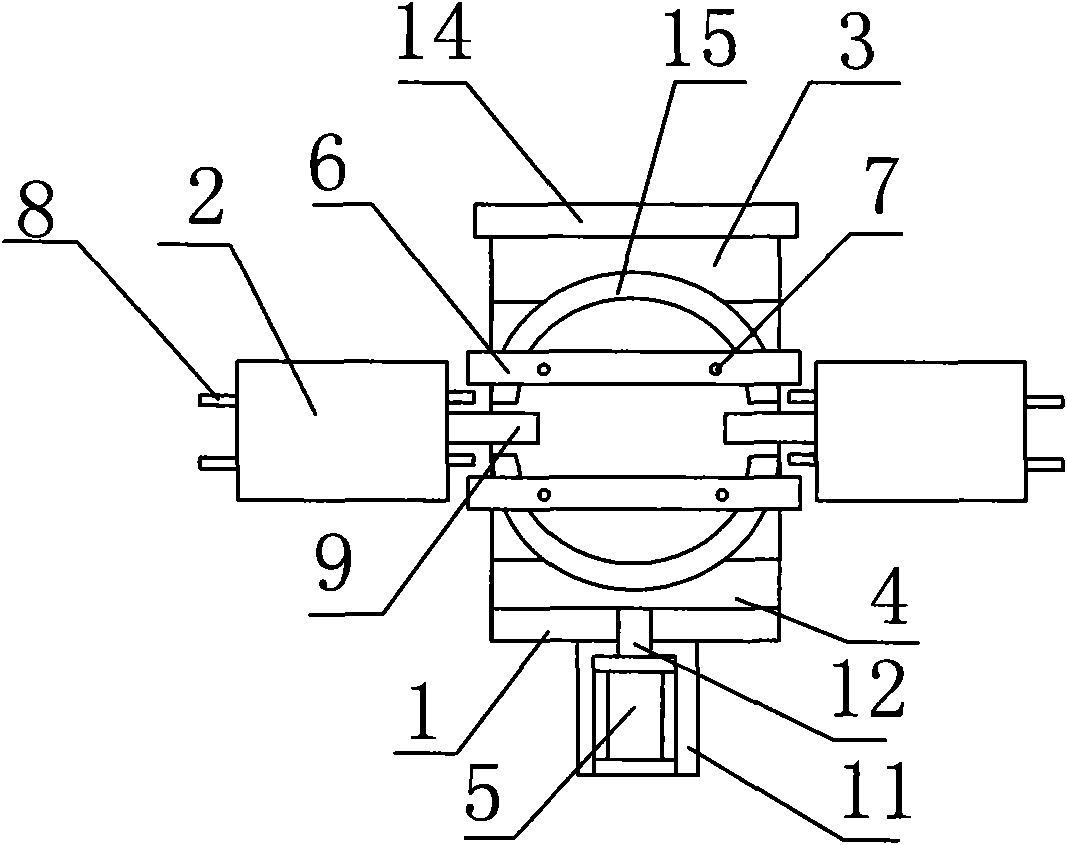

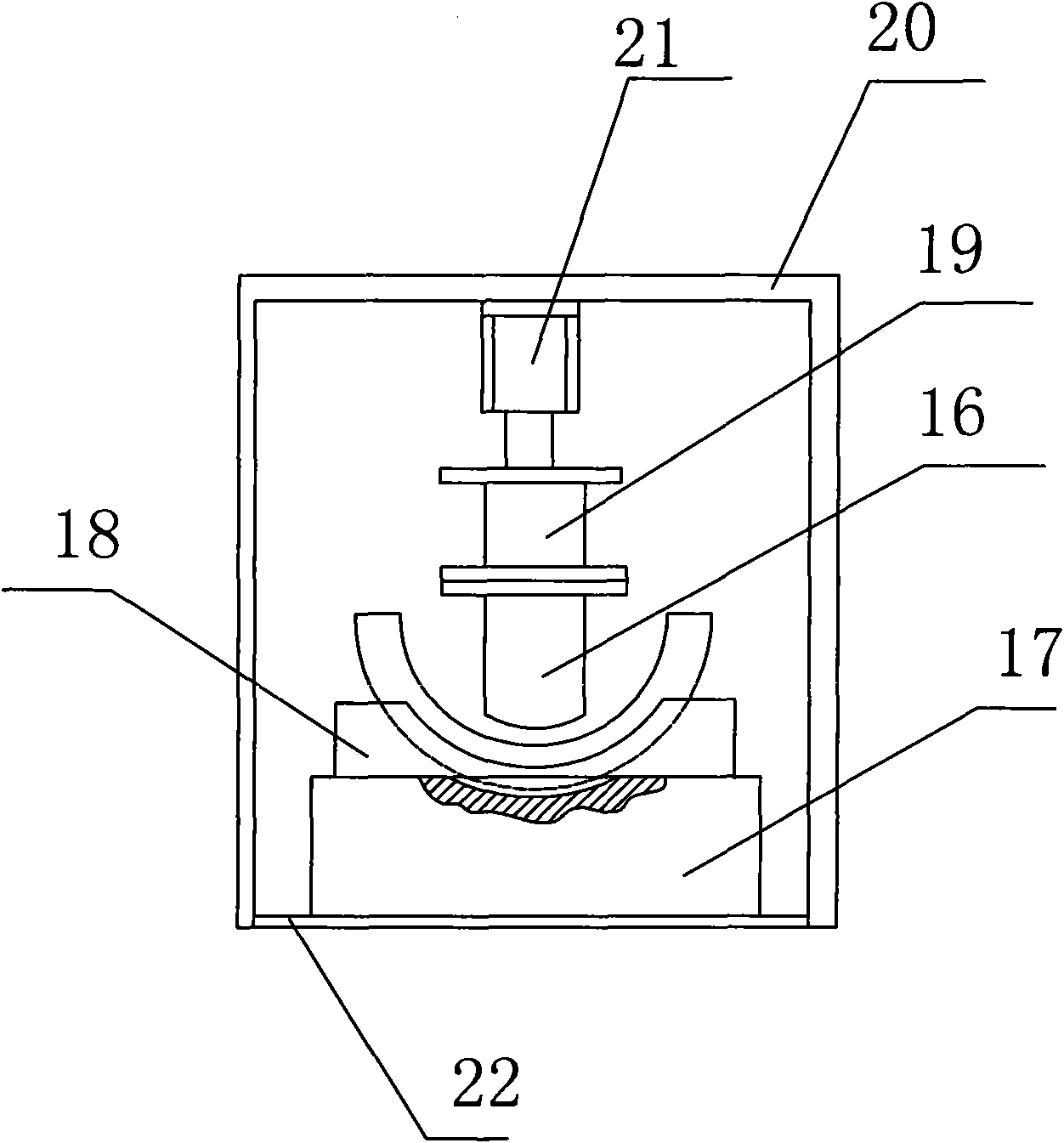

[0046] Upsetting flange manufacturing process, the pre-made steel flange strips are pressed into semicircles by a compression molding machine, and then the four end faces of the two semicircles are uniformly heated by an IGBT induction heating device, and the two semicircles are extruded by the upsetting equipment to make the two A half-circle quick connection, the process steps are as follows:

[0047] Step 1. Select steel materials according to production requirements in the production preparation stage, gas-cut the steel materials that meet the production requirements into corresponding widths and lengths, and make steel flange strips (the strips have processing allowances);

[0048] Step 2. Place the steel flange strips in the die core of the molding machine, and adjust the position of the steel flange through the anti-twist wall on the die core, and then use segmental extrusion, first pressing the steel method The two ends of the blue strip, and then press the middle of t...

Embodiment 2

[0052] The upsetting flange manufacturing process uses a compression molding machine to press the pre-made aluminum flange strip into a semicircle, and then uses an IGBT induction heating device to evenly heat the four end faces of the two semicircles. After being extruded by the upsetting equipment, the two A half-circle quick connection, the process steps are as follows:

[0053] Step 1. Select aluminum materials according to production requirements in the production preparation stage, and cut the aluminum materials that meet the production requirements into corresponding width and length by gas cutting to make aluminum flange strips;

[0054] Step 2. Place the aluminum flange strip in the die core of the molding machine, and use segmental extrusion to press the two ends of the aluminum flange strip first, and then press the middle of the aluminum flange strip to make aluminum Flange semicircle;

[0055] Step 3. Based on the standard parts, correct and cut the semicircle of...

Embodiment 3

[0058] The upsetting flange manufacturing process uses a compression molding machine to press the pre-made copper flange strip into a semicircle, and then uses an IGBT induction heating device to evenly heat the four end faces of the two semicircles. A half-circle quick connection, the process steps are as follows:

[0059] Step 1. In the production preparation stage, copper materials are selected according to production requirements, and the copper materials that meet the production requirements are cut into corresponding widths and lengths by gas cutting to make copper flange strips;

[0060] Step 2. Place the copper flange strip in the die core of the molding machine, and use segmental extrusion to first press the two ends of the copper flange strip, and then press the middle of the copper flange strip to make a copper flange. Flange semicircle;

[0061] Step 3. Based on the standard parts, correct and cut the semicircle of the pressed copper flange, and then clean and der...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com