Patents

Literature

55results about How to "Less oxygen consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

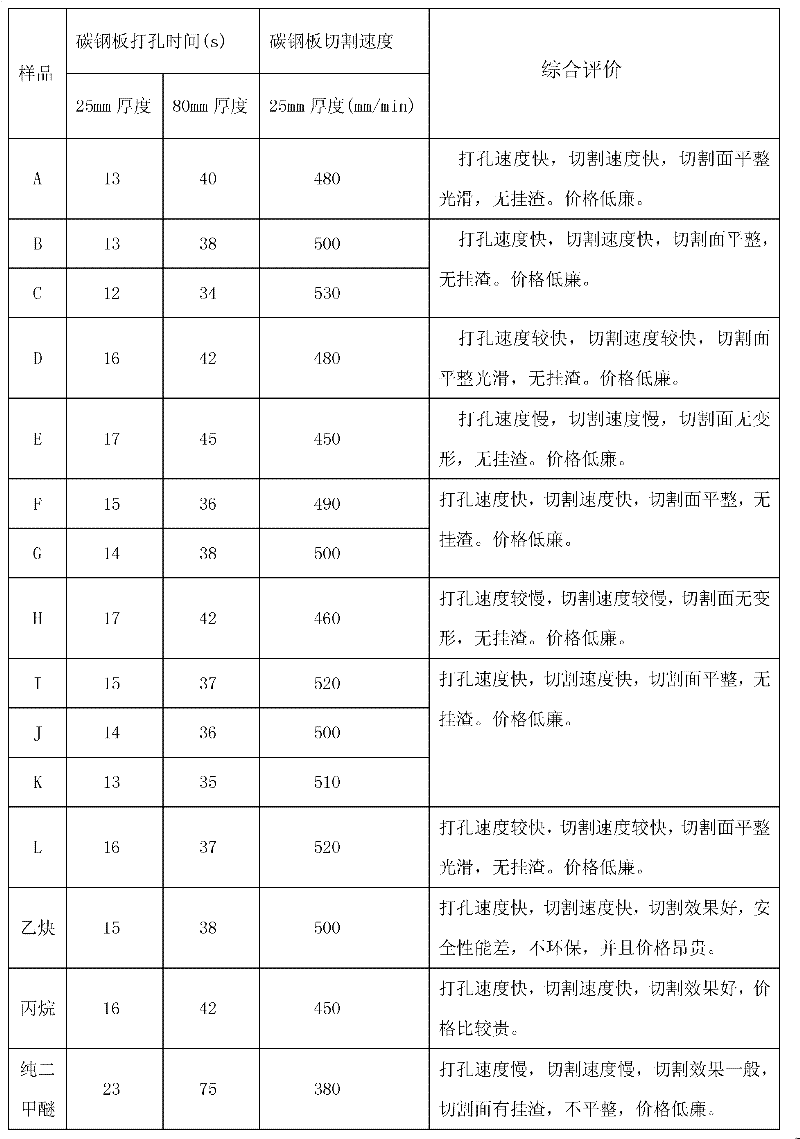

Industrial fuel gas for metal cutting and welding

This invention discloses an industrial fuel gas used for metal cutting and welding. Additive and dimethyl enther are added to cylinder to make-up the fuel, dimethyl enther is 40~99.9% and other rest additive. The additive is consisted by one or any several kind of following fuels as arbitrary proportion, petroleum liquefied gas, propane, butane, propylene, pentane, clean oil, methanol, ethanol. This invention has good burning property, security, environmental protection capability and extra high burning flame temperature. Comparing to acetylene, it is not easy to bomb, and its storage, transportation, using and management is more convenient and safe. There is no pollution to environment and operator. Its preheating and cutting velocity is fast, welding and welding line quality is good, oxygen consumption is low, so it improves work efficiency and reduces cost.

Owner:郑长同 +3

Chinese traditional medicine for treating insufficiency of kidney-yang and preparaton method

InactiveCN1562337AReduce apoptosisImprove disease resistanceAnthropod material medical ingredientsDigestive systemLycium barbarum fruitTherapeutic effect

Owner:DONGLING MEDICINES INST SHENYANG CITY

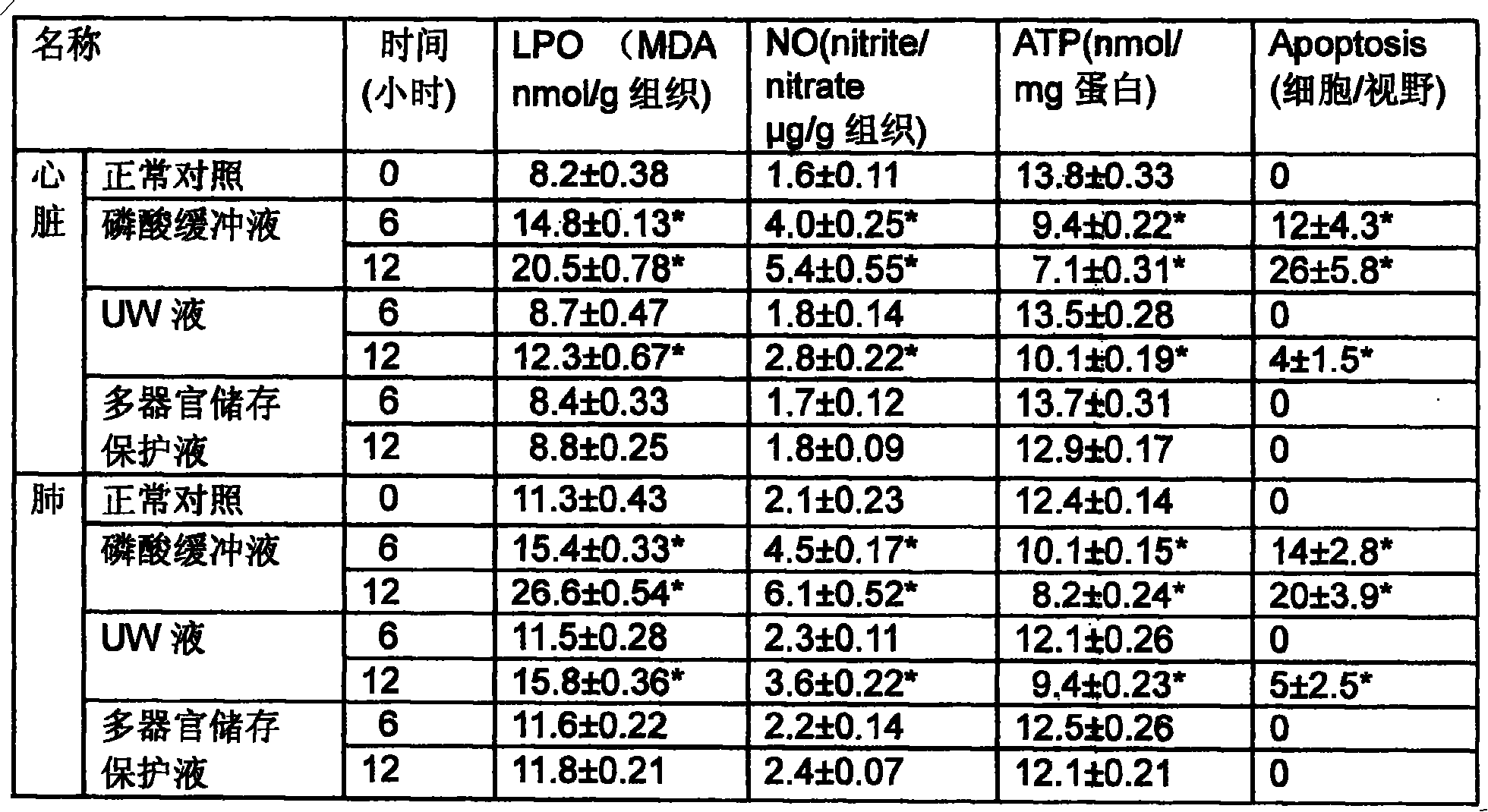

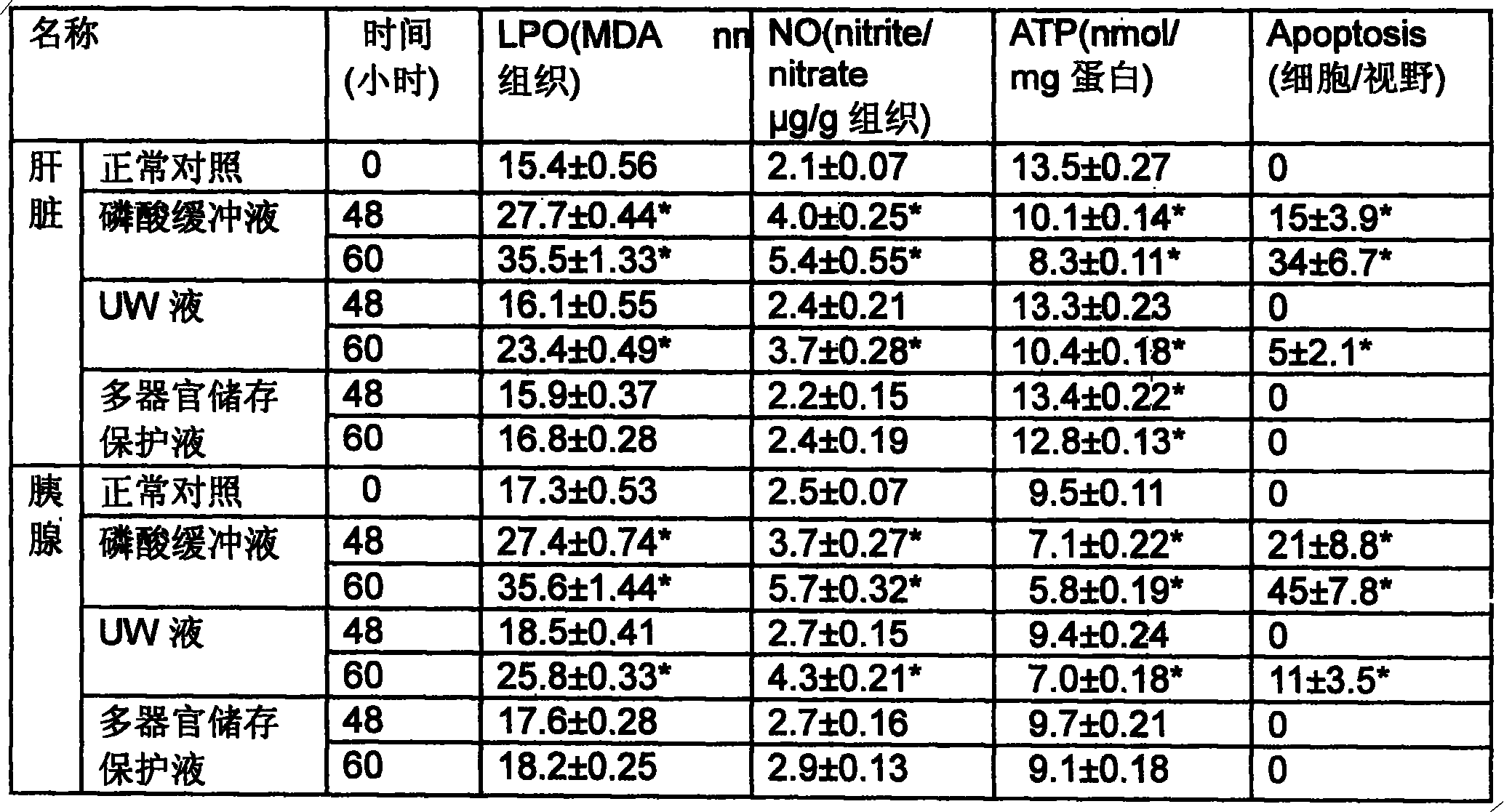

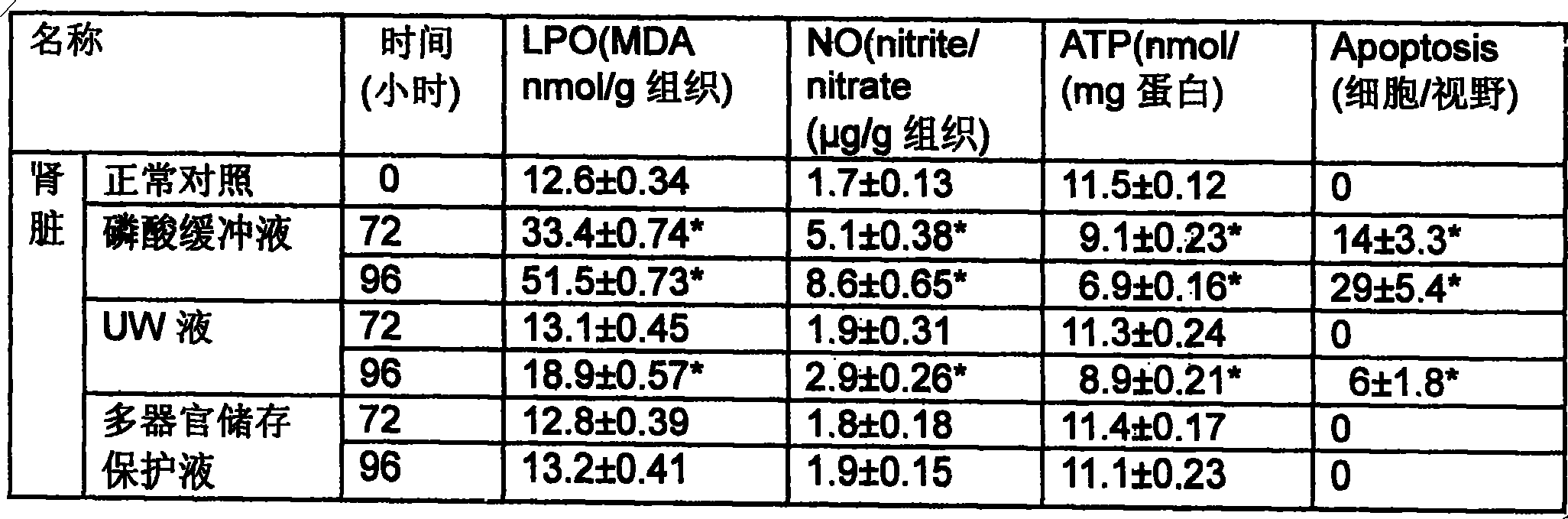

Novel multiple organs storage protection liquid

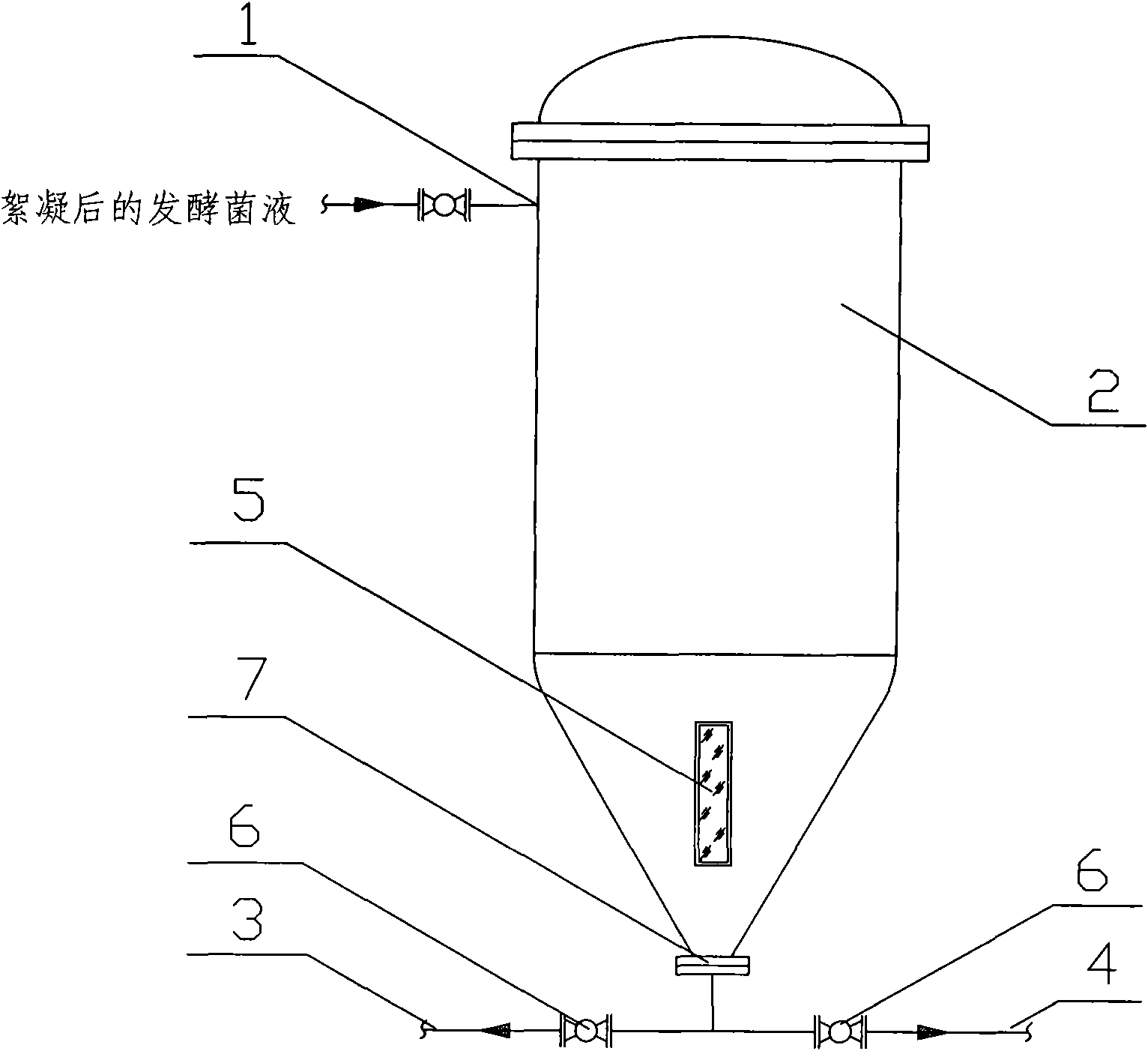

InactiveCN101199273APerfusion slowed downIncrease infusion timeDead animal preservationPancreatic structureConcentrations glucose

The invention is a novel multi-organ storage protective solute, which belongs to the organ transplantation section in the biomedicine technique field. The organ transplantation has the critical step of organ storage which decides the success or failure of transplantation. The phenomena of ischemia and reperfusion during organ storage lead to mass generation of free radicals which cause the oxidative damage to the stored organ. The invention creatively applies an anti-oxidation system composed of melatonin, vitamin C and water miscible vitamin E for reducing the oxidative damage caused by free radical generation during organ storage; mannitol is used to maintain the solution osmotic pressure and reduce the solution viscosity; and light concentration glucose is used for meeting the lowest metabolism requirements of the organ. The experiment shows that the multi-organ storage effects of the invention are superior over the organ storage solution (UW liquid) widely applied worldwide and nationwide currently. The invention is used for storing the off-body kidney, liver, pancreas, heart and lung before transplantation, thereby extending the effective storage time, increasing the transplantation success rate and offering chances of organ transplantation for more patients.

Owner:谭敦宪

Biological water purification agent powder and preparation thereof

InactiveCN101538089AReduce contentImprove water qualityBacteriaMicroorganism based processesMicroorganismSludge

The invention discloses a biological water purification agent powder and a preparation thereof, belonging to the technical field of microorganism environment protection. The biological water purification agent powder comprises 35-55 wt% of composite bacillus, 10-20 wt% of nitrobacteria and 25-55 wt% of auxiliary material. In the preparation of the biological water purification agent powder, a primary solid content separator is used for removing 60-70% of water, a secondary solid content separator is used for obtaining a formed solid content with the solid content being 30-45%, and finally mixing preparation is carried out to obtain the finished product. The biological water purification agent powder can be used in purification treatment of contaminated water to improve the water quality, and the substrate sludge is decomposed to provide an excellent water quality environment for aquaculture animals.

Owner:上海兴胜生物科技有限公司

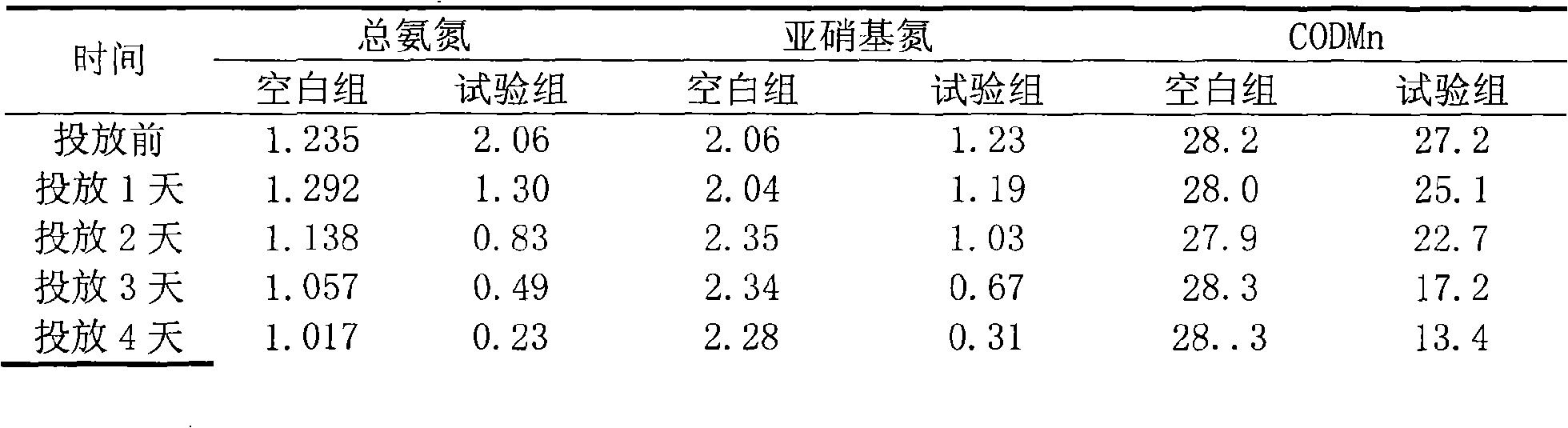

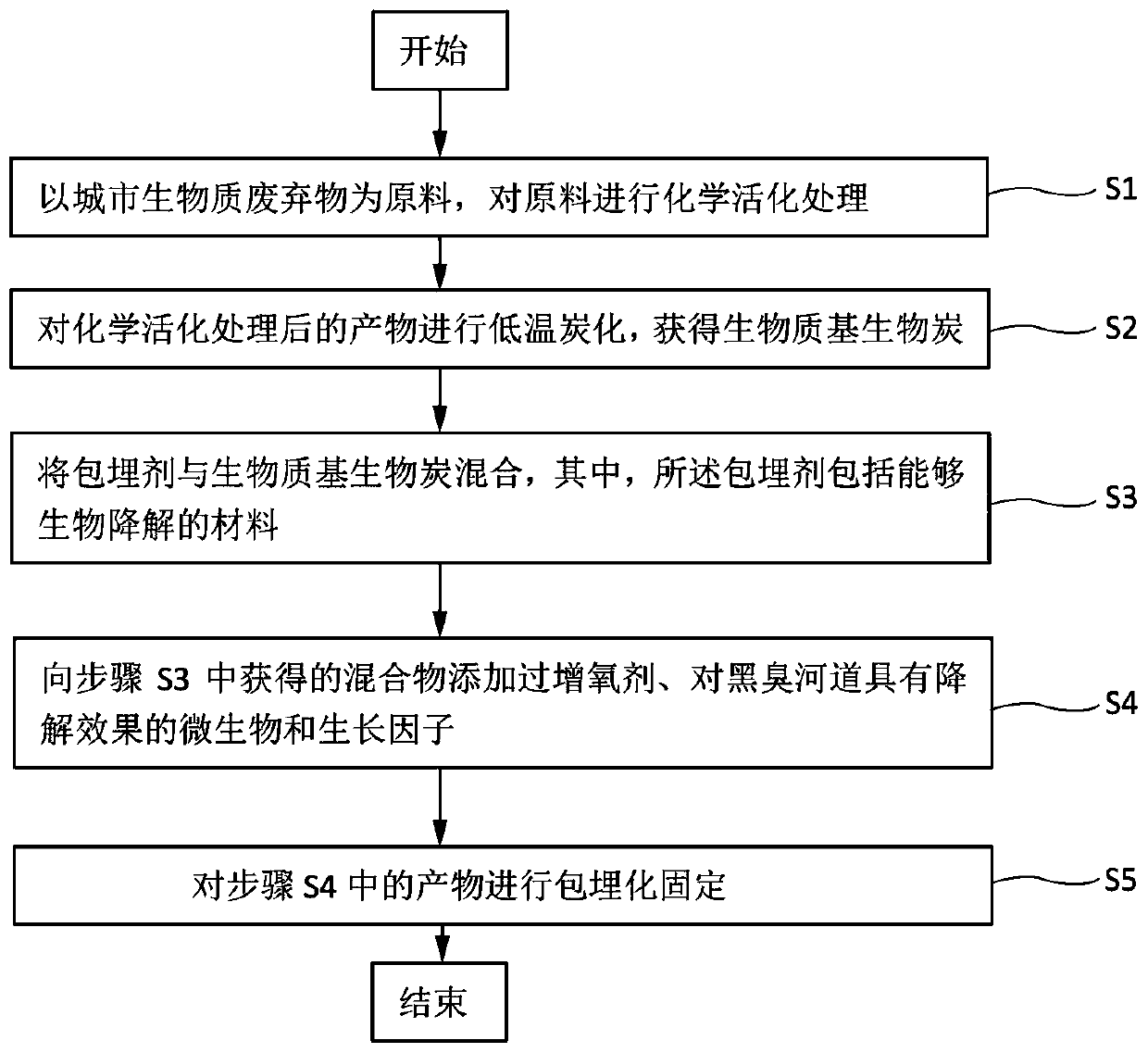

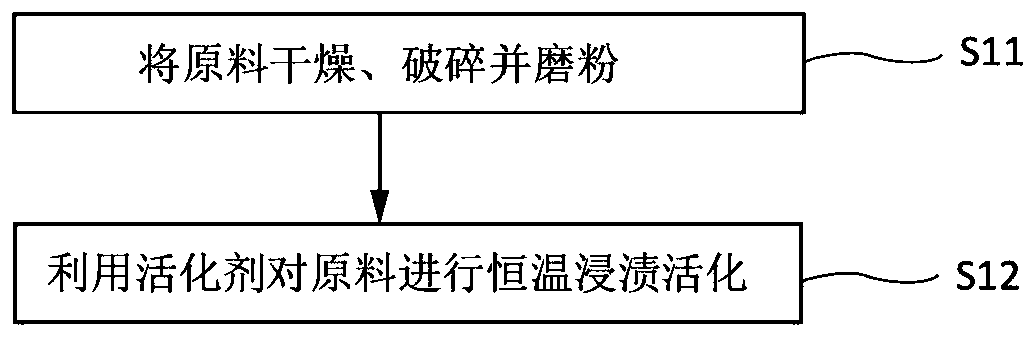

Immobilized microorganism structural body and preparation method thereof

InactiveCN109734199ALess oxygen consumptionAchieve reductionTreatment using aerobic processesSustainable biological treatmentBiomassChemistry

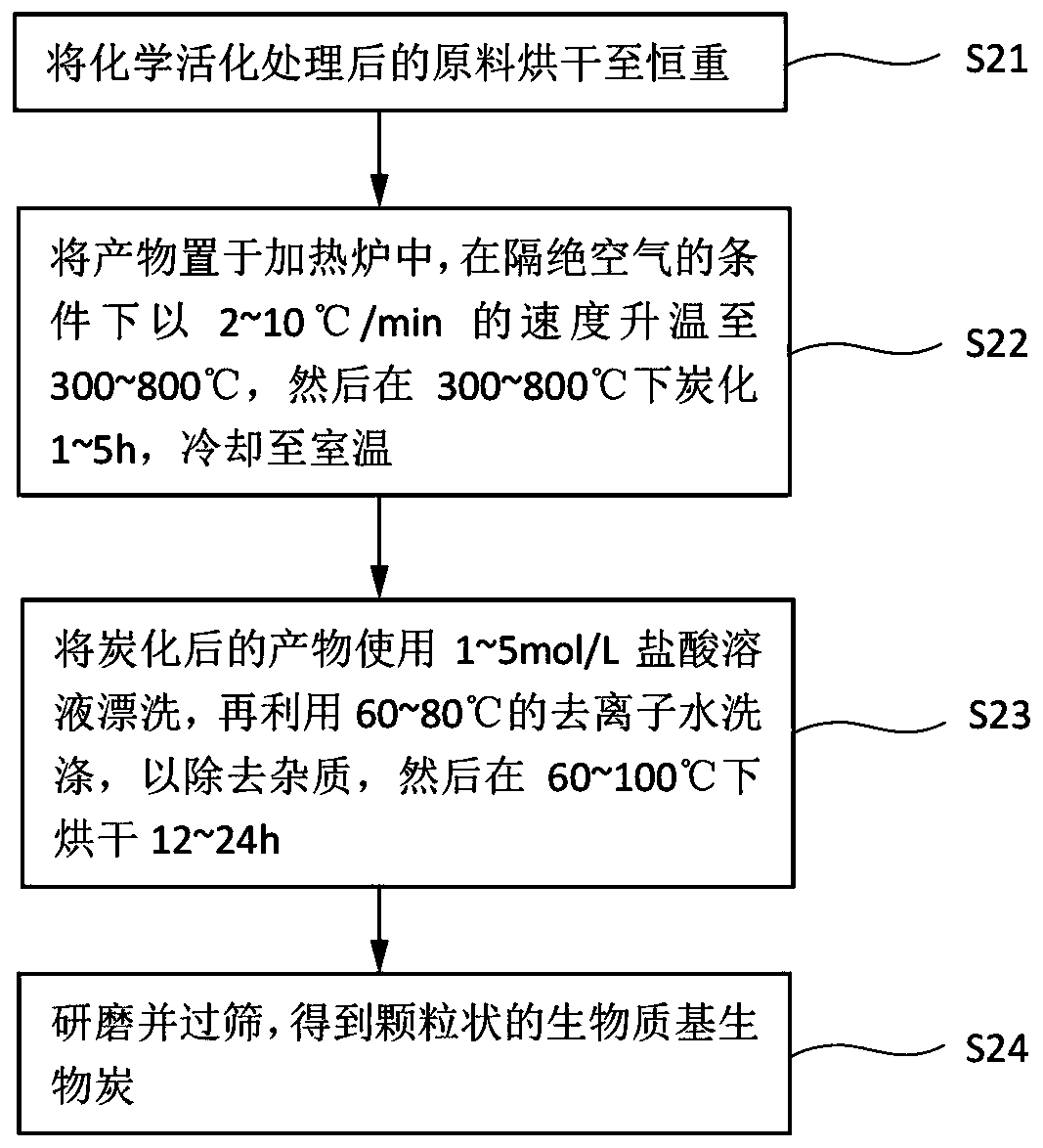

The invention provides an immobilized microorganism structural body and a preparation method thereof. The method comprises the following steps: S1, taking municipal biomass waste as a raw material, and chemically activating the raw material; S2, carbonizing the chemically activated product at a low temperature to obtain biomass-based biochar; S3, mixing an embedding agent with the biomass-based biochar, wherein the embedding agent comprises a biodegradable material; S4, adding an oxygenation agent, microorganisms with a degradation effect for black and smelly river channels and growth factor to the mixture obtained in step S3; and S5, embedding and immobilizing the product in step S4.

Owner:SHENZHEN HONGKONG INSTITUTION OF IND EDUCATION & RES ENVIRONMENTAL ENG TECH CO LTD

Disease preventing and curing medicinal mouth-muffle and medicinal composite

InactiveCN101524190AEasy to wearShort course of treatmentAntibacterial agentsHeavy metal active ingredientsCinnabarMyrrh

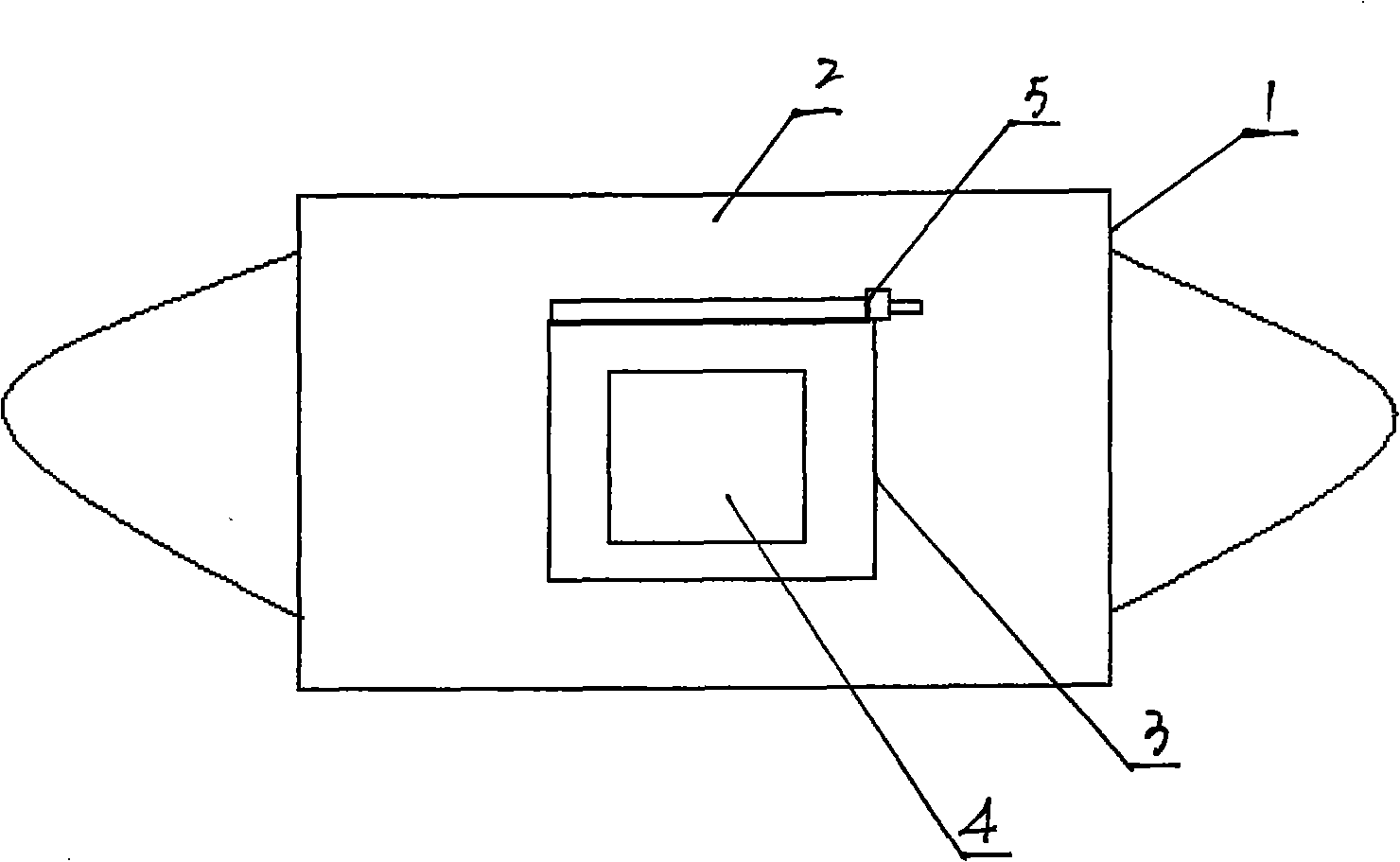

The invention relates to a disease preventing and curing medicinal mouth-muffle and a medicinal composite. The disease preventing and curing medicinal mouth-muffle (1) comprises a mouth-muffle body (2), one surface of the mouth-muffle body (2) is provided with an insert pocket (3), and a powder bag (4) which packages the medicinal composite is placed in the insert pocket (3). The medicinal composite comprises the following Chinese herbs by weight: 2.2 percent of chrysanthemum and muskiness, 4.2 percent of cinnamon, good ginger, long pepper, radix aconite, frankincense, myrrh and clove, 5.0 percent of vermilion, 6.4 percent of asarum, eaglewood, croton, resina draconis, early plum flowers and rhizoma ligustici wallichii and 7.6 percent of tooth soap, arsenic sulphide and brain sand. The disease preventing and curing medicinal mouth-muffle internally carries the medicinal composite which plays a role during the mouth-muffle wearing process, thereby having disease prevention and cure and being simple and direct and also effective in treatment.

Owner:孙永春

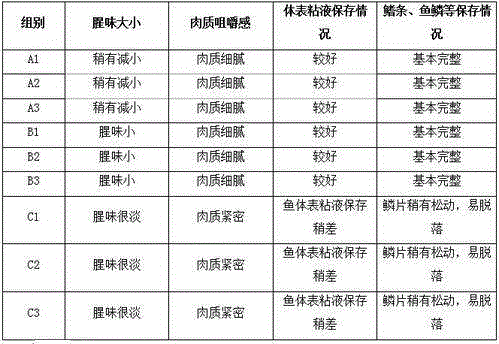

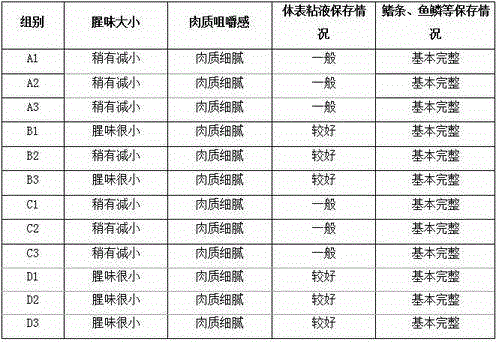

Application of fishing electrified water for removing fishy smell of living freshwater fish

ActiveCN104782547ASolve the difficulty of removalEfficient removalClimate change adaptationPisciculture and aquariaEnvironmental engineeringFishing

The invention relates to application of fishing electrified water for removing fishy smell of living freshwater fish, and belongs to the field of aquaculture. The fishing electrified water is applied to remove the fishy smell of the living freshwater fish, the fishy smell can be effectively removed, and good appearance and quality of commercial fish are guaranteed. According to the application and method of the fishing electrified water for removing the fishy smell of the living freshwater fish, the operation is sample, the controllability is strong, the effect achievement is fast, the market vacancy and the technology gap of products capable of removing the fishy smell are filled up, and the fishing electrified water for removing the fishy smell of the living freshwater fish has wide application prospect. The method can effectively solve the problem that the fishy smell of the living freshwater fish is difficult to remove, the operation is simple and convenient, the controllability is strong, and the environmental protection, the high efficiency and pollution-free performance are achieved.

Owner:TONGWEI

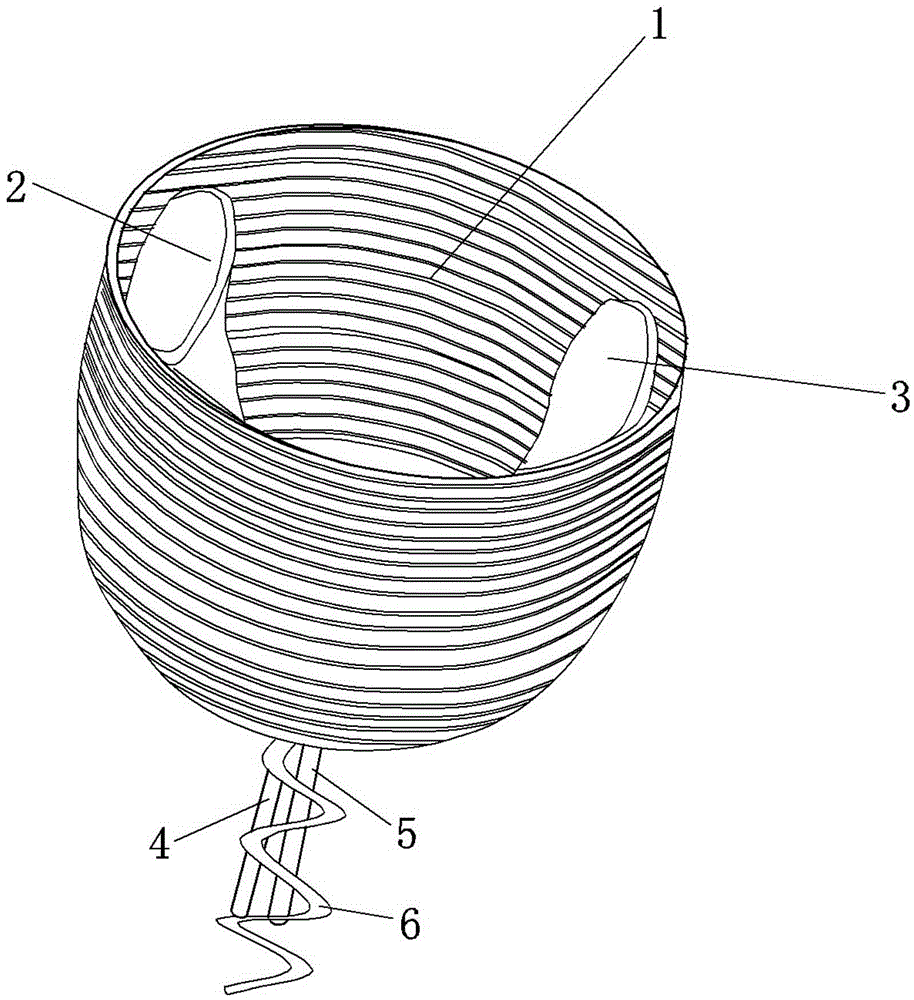

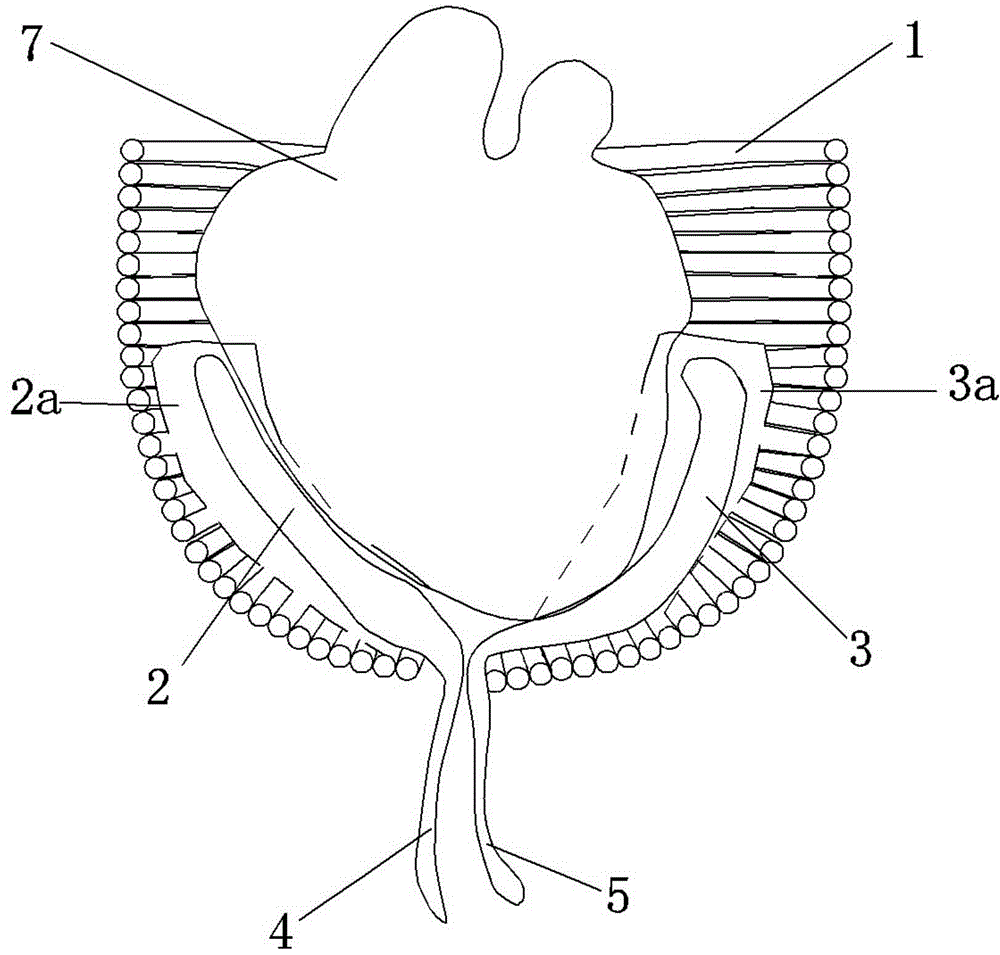

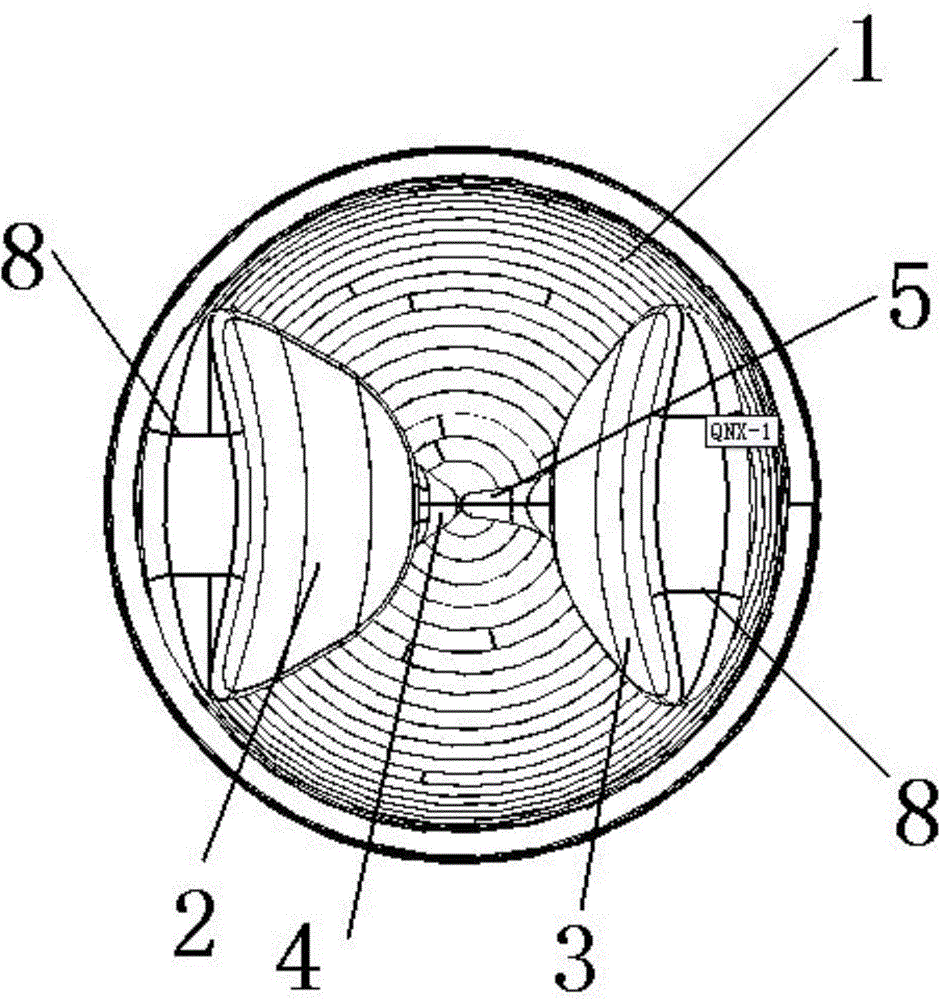

Heart auxiliary device

InactiveCN104146855AAvoid bleedingPrevent thrombosisElectrotherapyArtificial respirationHeart apexHeart right

The invention discloses a heart auxiliary device which comprises an outer shell. The outer shell is formed by bonding and fixing a non-elastic flexible rope on the outer surface of a heart model in a spiral mode, a sealed left air bag is arranged along the outer surface of a left heart chamber of the heart model and located in the outer shell, a sealed right air bag is arranged along the outer surface of a right heart chamber of the heart model and located in the outer shell, buckling rings are arranged on the upper portions of the inner walls, close to the side wall of the left air bag and the side wall of the right air bag, of the outer shell respectively, the upper end of the left air bag and the upper end of the right air bag are fixed on the buckling rings, a lower opening of the left air bag is communicated with a left air inlet pipe, a lower opening of the right air bag is communicated with a right air inlet pipe, the left air inlet pipe and the right air inlet pipe penetrate out of the heart apex at the bottom of the outer shell and extend outwards, and the extending parts of the left air inlet pipe and the right air inlet pipe are communicated with an air source control device. The heart auxiliary device is not in direct contact with blood, anticoagulation is not needed in the application process, a series of blood vessel complications like bleeding, thrombosis, hemolysis and immunoreactions are avoided, the infection rate is reduced, and the heart auxiliary device can be suitable for single-heart-chamber assistance and double-heart-chamber assistance, and is flexible in using method.

Owner:刘超

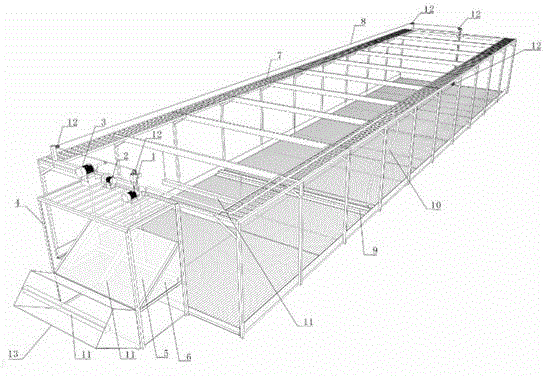

Automatic clean-up culture cage in pond

ActiveCN104396835AImprove water qualityReduce frictionClimate change adaptationPisciculture and aquariaWater qualitySewage

The invention belongs to the technical field of aquaculture devices, particularly relates to an automatic clean-up culture cage in a pond, and aims to mainly solve the technical problems of poor water quality of inlet water and incomplete improvement of the water quality existing in an existing automatic clean-up culture device of a pond cage. According to the adopted technical scheme, the automatic clean-up culture cage in the pond comprises a sewage suction pump, a fan, a driving device, an aeration bracket, a baffle plate, an aeration disk, a traction rope, a sewage sucker, a drainage pipe, six fixed pulleys, a culture cage, a water inlet and a microbial treatment device. The culture cage has the advantages of good water quality of the inlet water and complete improvement of the water quality of the automatic clean-up culture device of the pond cage.

Owner:董美英

Novel industrial cutting gas with dimethyl ether as main component

The invention discloses novel industrial cutting gas with dimethyl ether as a main component. The novel industrial cutting gas comprises (but not limited to) the following components in percentage by mass: 60-99.99% of the dimethyl ether, 0.01-40% of additives and the like, wherein the additive is prepared from tert-butylferrocene, diethyl ether, aromatic hydrocarbon, solvent oil No.6, tert-butyl alcohol and potassium permanganate according to a certain proportion. Auxiliary gas can also be added into the cutting gas and is one or some of acetylene, propane, propylene, butane and butylene. The novel industrial cutting gas disclosed by the invention presents strong advantages in the aspects of economy, safety, environment friendliness and cutting performance.

Owner:ENN XINNENG BEIJING TECH

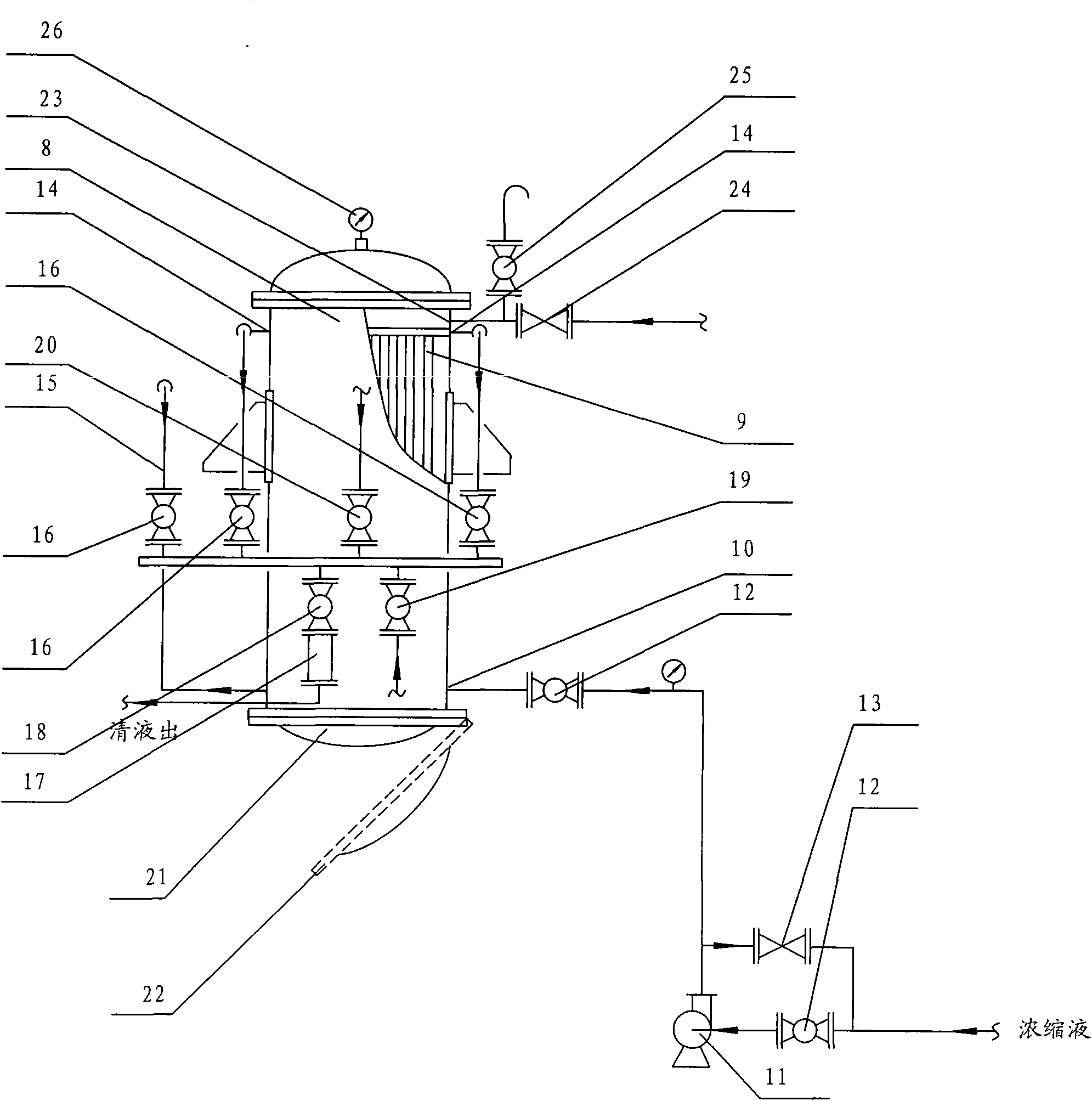

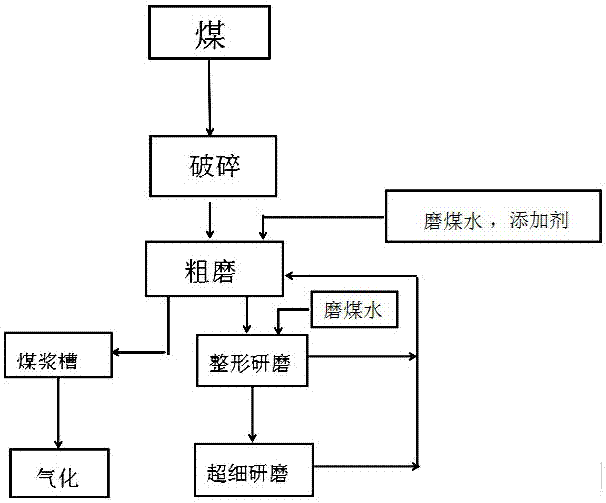

Coal slurry concentration increasing and industrial wastewater treating process and device

ActiveCN107312580AImprove liquidityReduce apparent viscosityLiquid carbonaceous fuelsGrain treatmentsIndustrial effluentEnergy consumption

The invention discloses a coal slurry concentration increasing and industrial wastewater treating process and device. The process comprises the following steps: (1) crushing coal, and then adding water and a dispersant for coarse grinding till the particle size is 50 microns or below, thus obtaining slurry 1; (2) performing shaping grinding on 25 to 35 weight percent of slurry 1 till the particle size is 20 to 30 microns, thus obtaining slurry 2, and pumping the residual slurry 1 serving as a water coal slurry product into a water coal slurry storage tank for gasification; (3) performing ultrafine grinding on 15 to 25 weight percent of the slurry 2 till the particle size is 5 to 10 microns, thus obtaining slurry 3, and conveying the residual slurry 2 and the newly obtained slurry 3 into the coarse grinding stage for coarse grinding, wherein after the coarse grinding in the step (1) and the steps (2) and (3) are repeatedly performed for multiple times, the aim of effectively increasing the concentration of the slurry 1 is fulfilled. In the concentration increasing process, used water can be replaced with industrial wastewater. According to the coal slurry concentration increasing and industrial wastewater treating process disclosed by the invention, the concentration of the coal slurry can be increased by at least 3 percent; the gasification energy consumption can be substantially reduced; the coal slurry concentration increasing and industrial wastewater treating process has the characteristics of safety, reliability, convenience in improvement and obvious economical benefits.

Owner:HUBEI YIHUA CHEMICAL INDUSTRY CO LTD

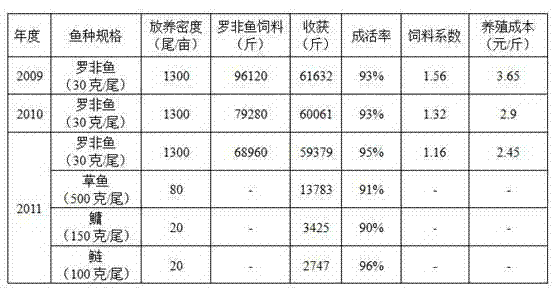

Aquaculture feed feeding technique

InactiveCN102754612ALess oxygen consumptionIncrease stocking densityClimate change adaptationPisciculture and aquariaEconomic benefitsWater quality

The invention relates to an aquaculture feed feeding technique which is characterized in that when fish fingerlings are bred, bean cakes, peanut cakes, wheat bran, bran, silkworm chrysalis, fish meals and the like are fed, and the feeding rate is about 3%. After the fish fingerlings are bred for 15-30 days and grow to certain specifications, full rate artificial particle feeds are fed, and the feeding rate is 1-1.5%. Feeds are fed through automatic feeding machines. One to two automatic feeding machines are arranged on each pond, feeds are fed once every day, feeding time is from 9 o'clock to 14 o'clock, the speed of spraying particle feeds of the feeding machines is controlled, feeds are fed discontinuously, and the range of feeding feeds is enlarged as possible. The aquaculture feed feeding technique improves utilization rate of feeds, reduces feed cost, improves growth speed of pond fishes, guarantees water quality of ponds and improves pond yield and economic benefits.

Owner:PEARL RIVER FISHERY RES INST CHINESE ACAD OF FISHERY SCI

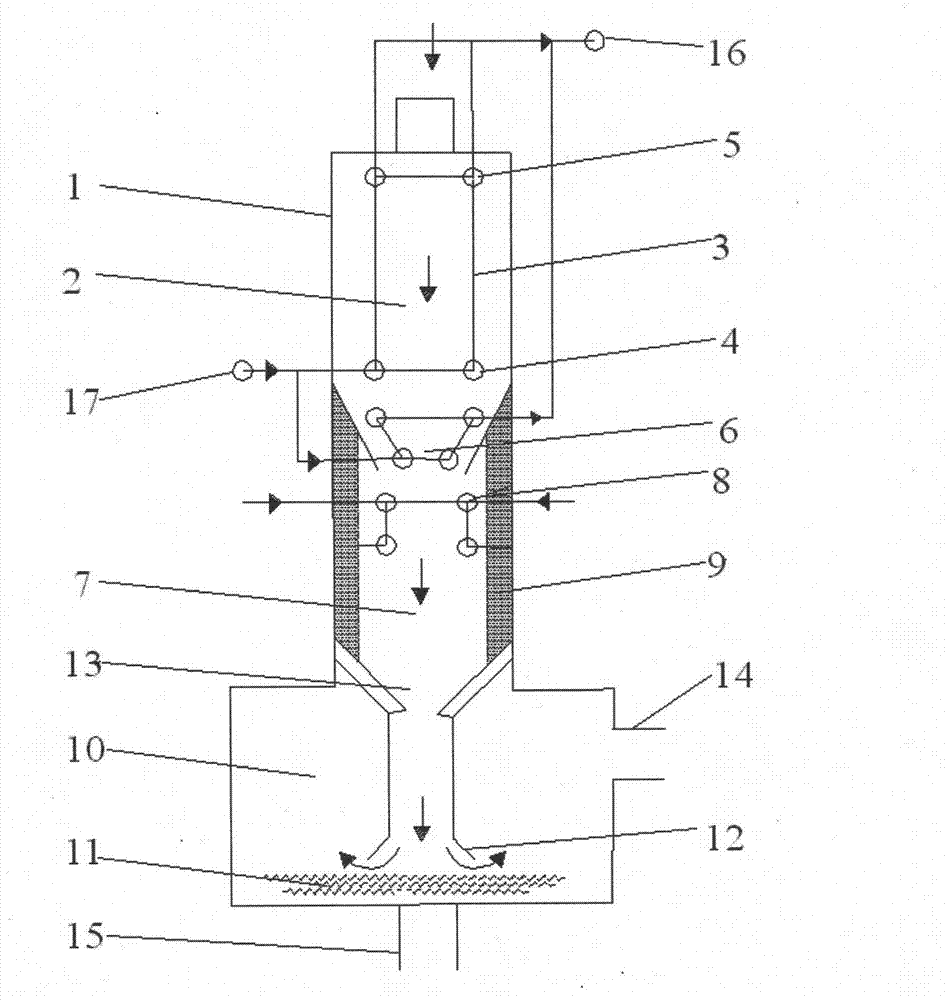

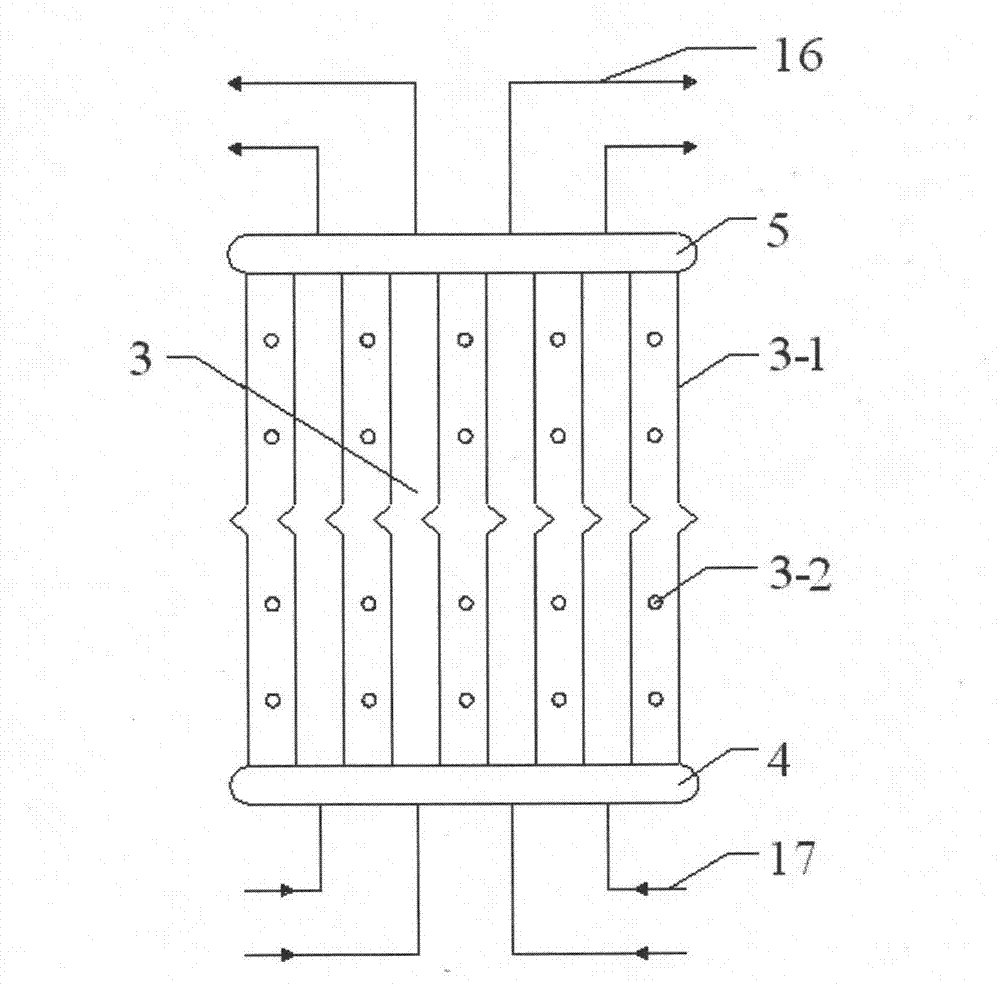

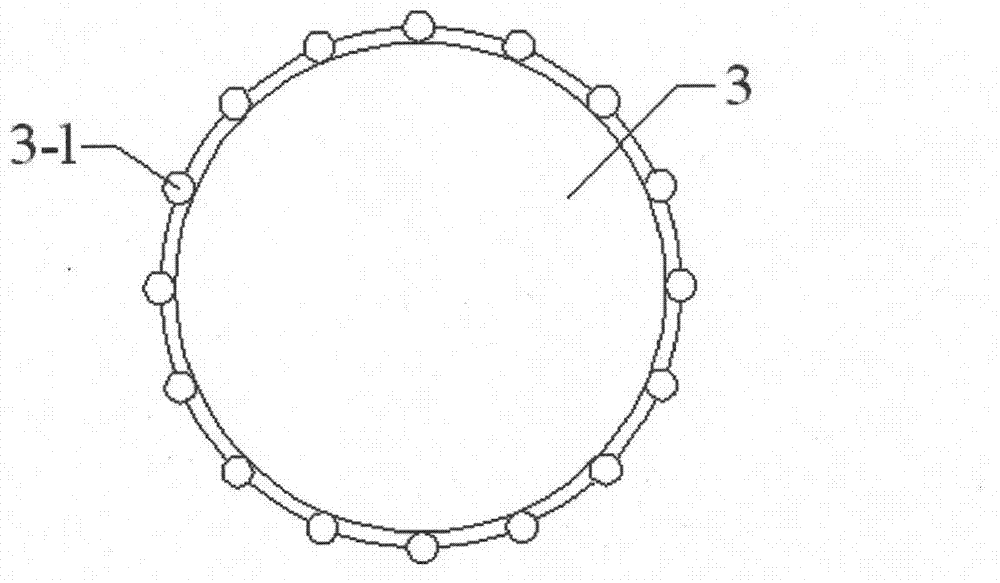

Combustible carbon material gasifying device employing three-section composite dry and wet method

The invention provides a combustible carbon material gasifying device employing a three-section composite dry and wet method. The device is characterized by comprising a reaction section, a quench section and a separating section connected from top to bottom in sequence. The reaction section comprises a casing and a vertical type protection wall arranged in the casing; an upper end and a lower end of the vertical type protection wall are respectively connected to an upper header and a lower header; and an upper slag outlet is arranged below the lower header. An inner wall of the quench section is provided with a refractory material; a chilling device capable of spraying cold air or water is arranged inside the quench section; a solid slag opening is arranged at the lower end of the quench section and connected with a baffle plate in the separation section. The separation section bottom is provided with a water bath; a solid slag outlet is arranged below the separation section; and the upper side part of the separation section is provided with a material outlet. According to the invention, the device is simultaneously applicable to a dry dedusting and wet dedusting by the chilling device capable of spraying cold air or water can be sprayed into the cold gas or water chiller; the cylindrical protection wall with fins realizes small fluid resistance and low oxygen consumption, has compact structure, and is easy for installation. The device has characteristics of low cost, high efficiency, safety and reliability.

Owner:CHANGZHENG ENG

Method for bioleaching and solvent extraction with selective recovery of copper and zinc from polymetal concentrates of sulfides

ActiveUS20160115564A1High content of arsenicIncrease iron contentPhotography auxillary processesProcess efficiency improvementElectrolysisDissolution

A bioleaching and solvent extraction process with selective recovery of copper and zinc from polymetallic sulphide concentrates is described, comprising a bioleaching and ferric ion reducing process and a copper and zinc solvent extraction process.The bioleaching and ferric ion reducing process comprises a concentrates pulp conditioning step; a bioleaching step, wherein once the pulp is conditioned it is subjected to a bioleaching process using a plurality of bioreactors of the stirred-tank type with an air injection and diffusion system, which allows handling of a pulp density higher than 15%; a step of solid separation from a solution rich in metallic ions from the bioleaching step; and, a ferric ion reduction step, wherein the pulp from the previous step is subjected to a transformation step of ferric ions into ferrous ions.The solvent extraction step comprises a copper solvent extraction and electrolysis step; an arsenic control step, wherein arsenic is controlled in the solution once copper has been extracted from it; and, a zinc solvent extraction and electrolysis step, which uses a phosphinic acid-based zinc extraction dissolution.

Owner:SERVICIOS CONDUMEX DE C V

Preparation method for composite-type lactobacillus microecological preparation

The invention discloses a preparation method for a composite-type lactobacillus microecological preparation, and belongs to the field of lactobacillus fementation. The preparation method comprises the following steps of: separating lactobacillus strains by taking bred animals, culture water body and bottom sediment as bacterial sources; then purifying the separated lactobacillus strains to selectively breed 2-5 lactobacillus strains with large calcium-dissolving rings, fast growth speed and strong activity; then carrying out enlarging culture on the lactobacillus strains which are purified and selectively bred, and preparing composite seed solution; and finally, inoculating and fermenting the composite seed solution to obtain the composite-type lactobacillus microecological preparation. Compared with the prior art, the preparation method disclosed by the invention has the beneficial effects of simple culture equipment and operation, and stable storage time compared with a single strain fermentation water agent.

Owner:TONGWEI

Traditional Chinese medicine historic preparation for treating diabetes and compication abnormality on blood lipid

InactiveCN101164606APrevents platelets from stickingReduce contentMetabolism disorderPill deliveryRemove bloodCoptis

The present invention relates to a Chinese medicine prescription preparation with the functions of clearing away heat, moistening illness caused by pathogenic dryness, nourishing yin, promoting production of body fluid, tonifying spleen and kidney, promoting blood circulation and removing blood stasis for effectively curing diabetes and its complication fat metabolic disturbance with obvious therapeutic effect. Said Chinese medicine prescription preparation is made up by using 5 Chinese medicinal materials of lycium root bark, coptis root, epimedium, pueraria root and turmeric through a certain preparation process.

Owner:TIANJIN DANXI TCM INST

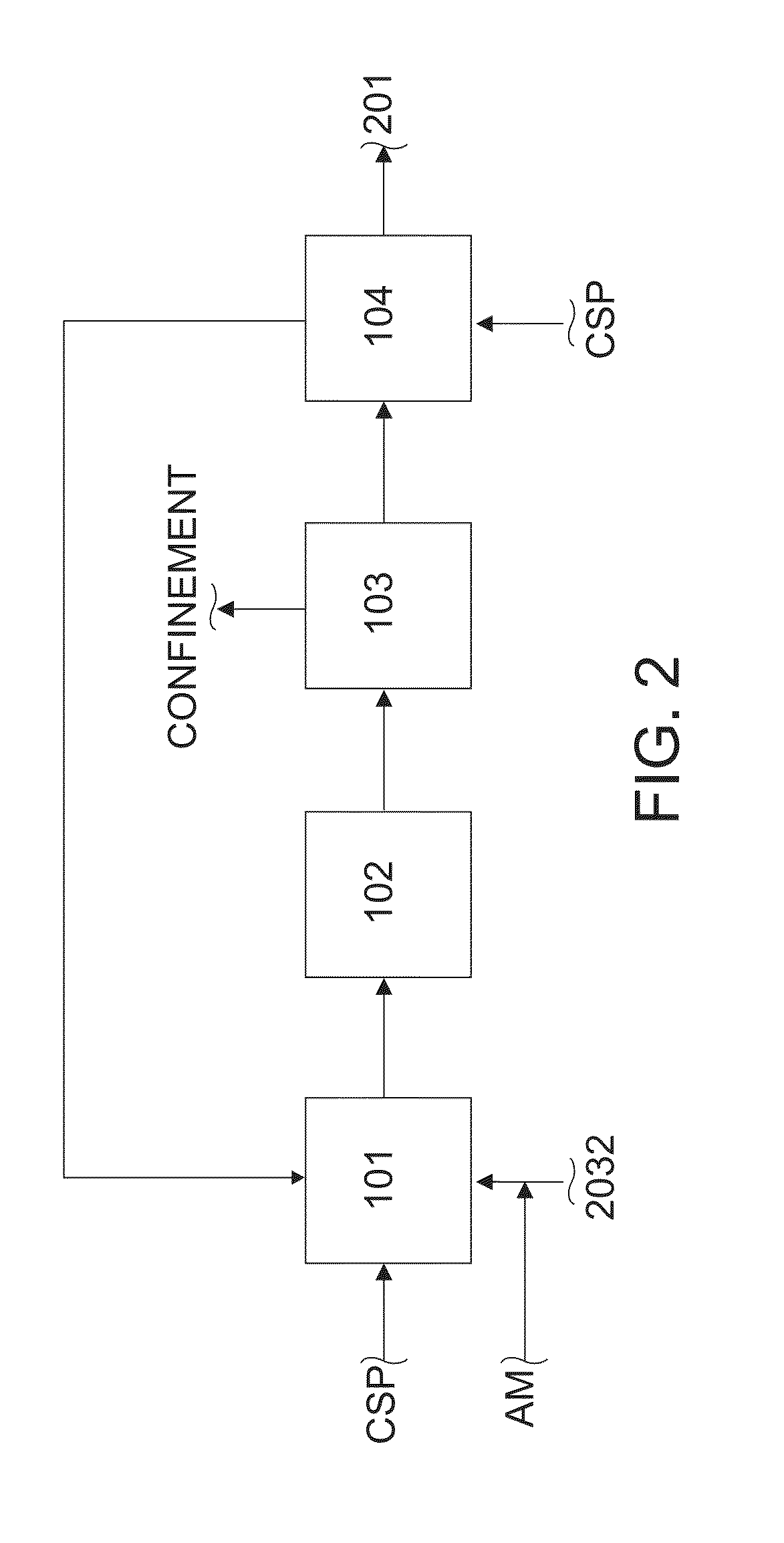

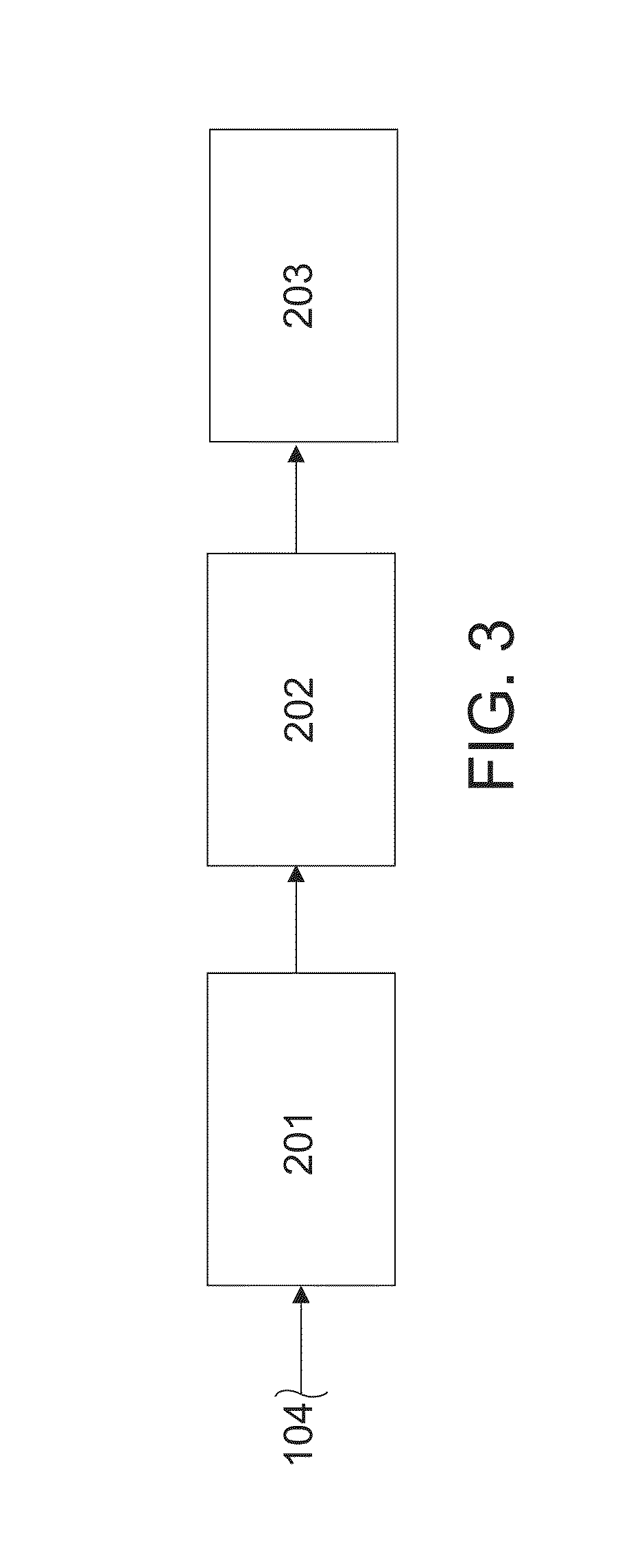

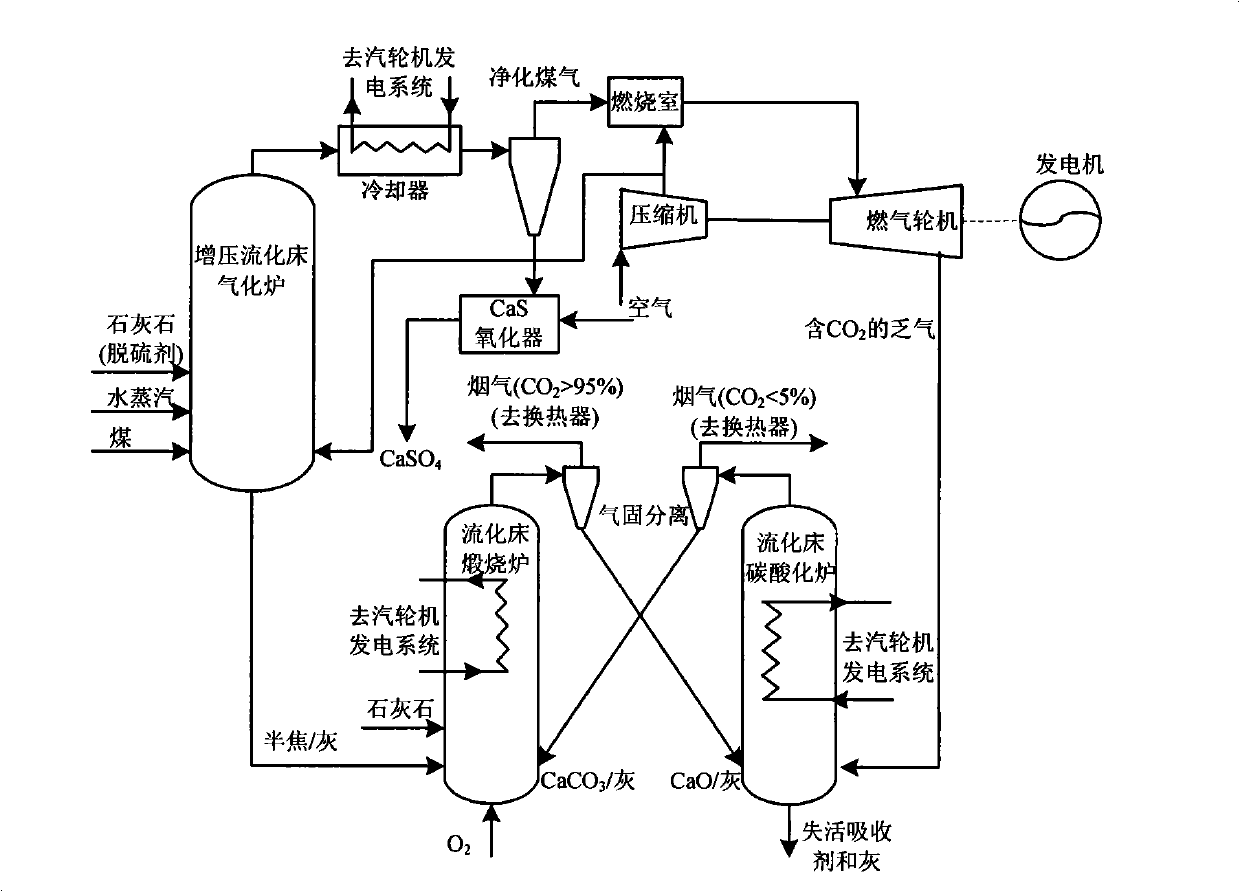

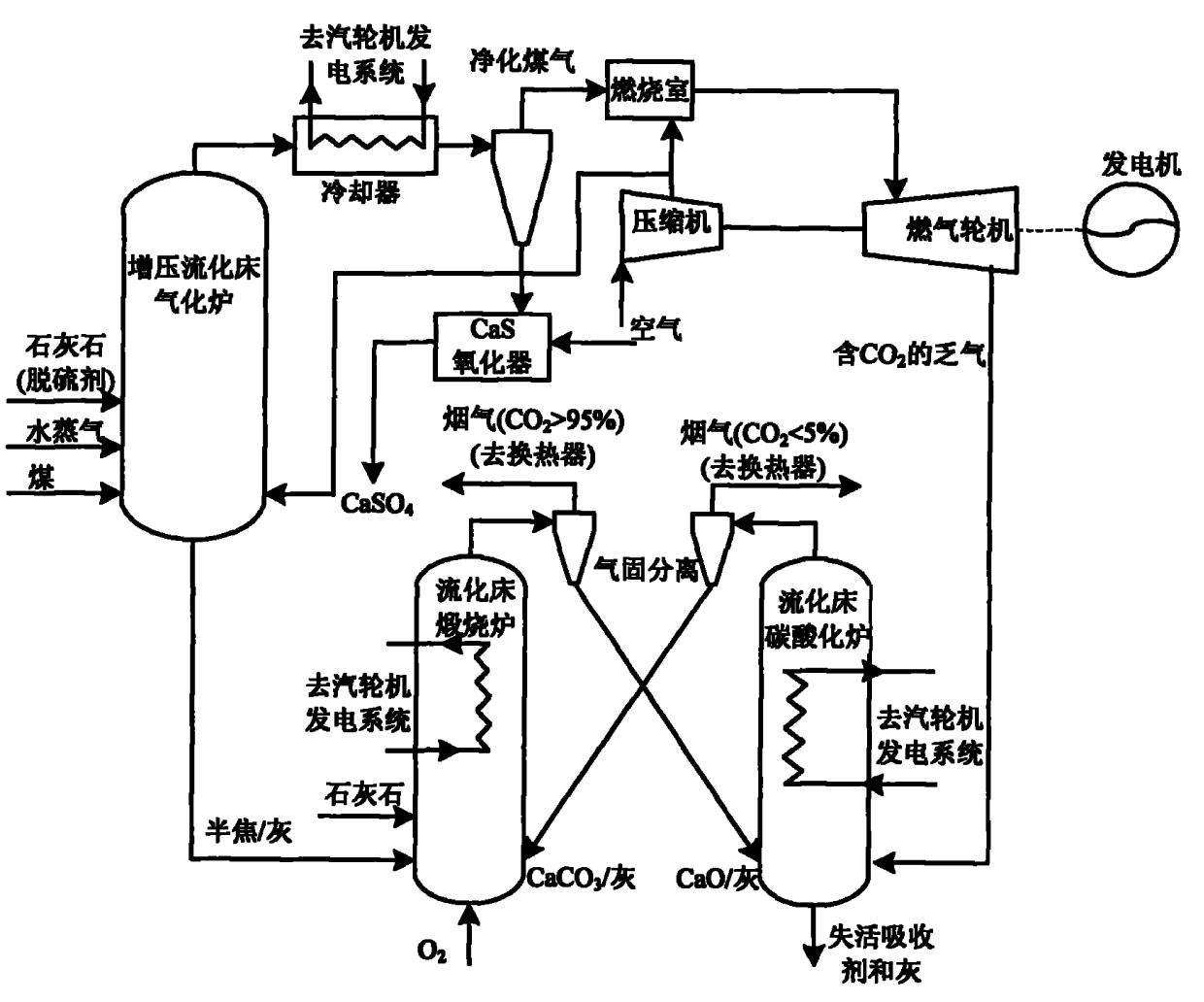

Method for catching carbon dioxide by pressurized fluidized bed combustion combined recycled generating system

InactiveCN101539037BReasonable realization of graded conversionRaise the inlet temperatureGas turbine plantsSteam engine plantsElectricityMulti pollutant

Owner:SOUTHEAST UNIV

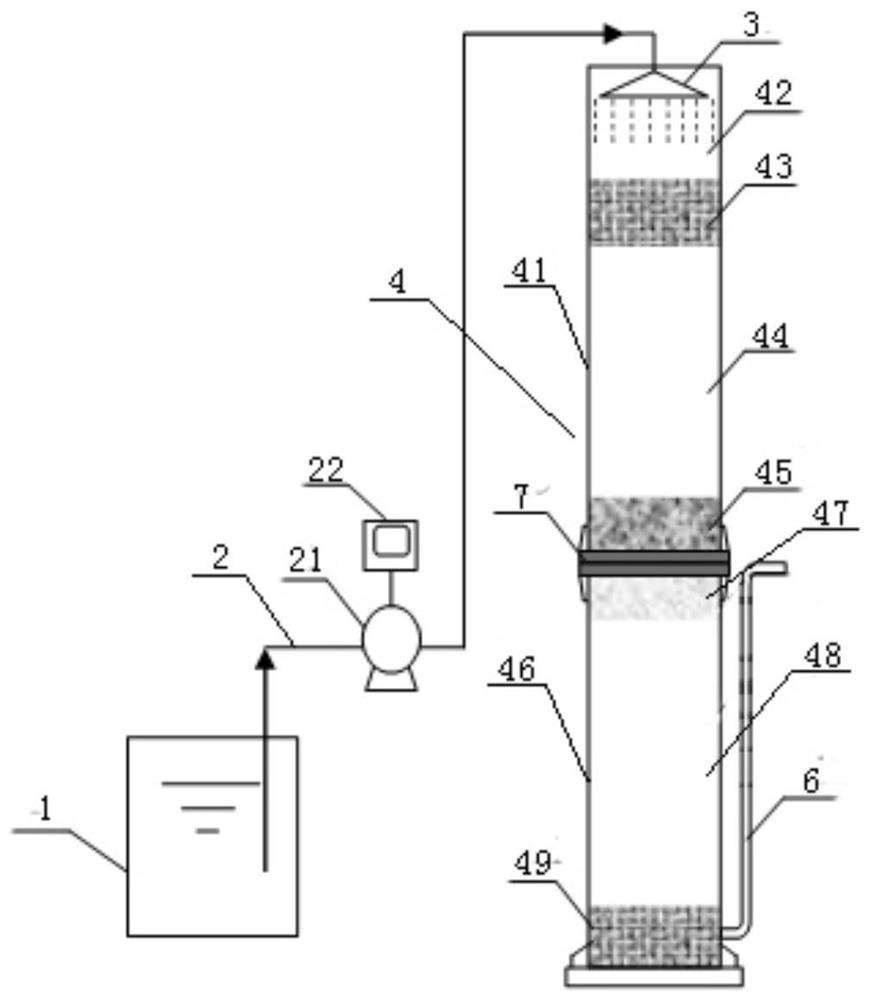

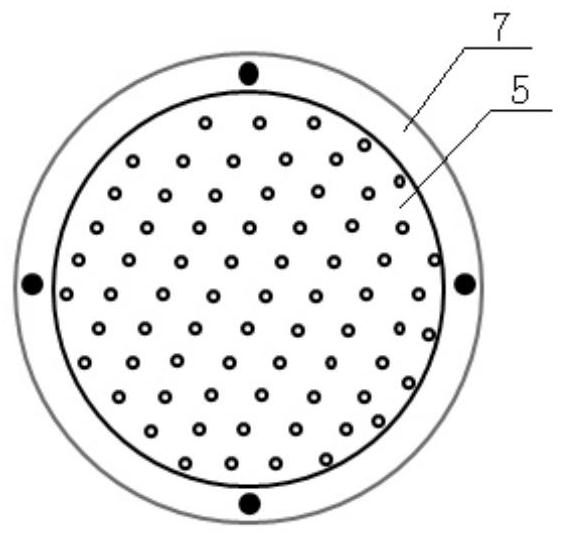

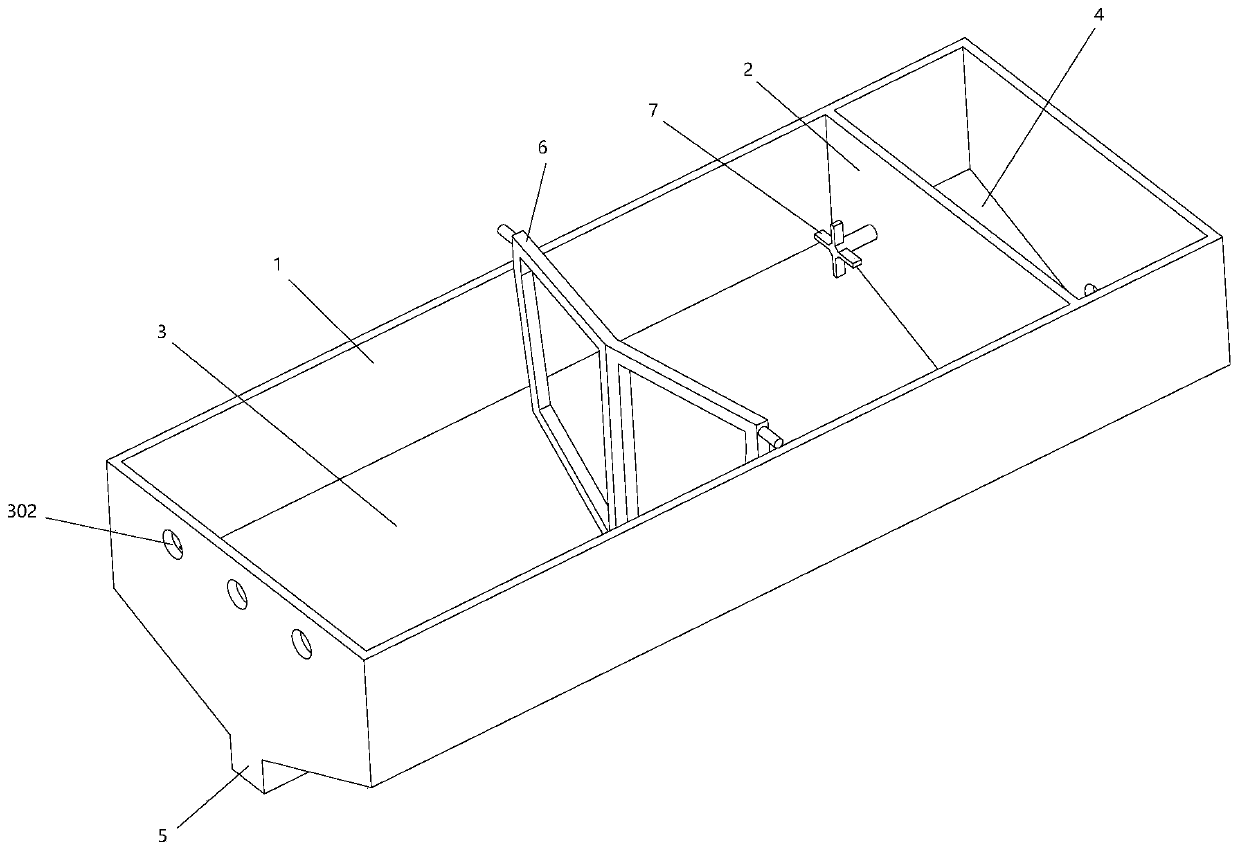

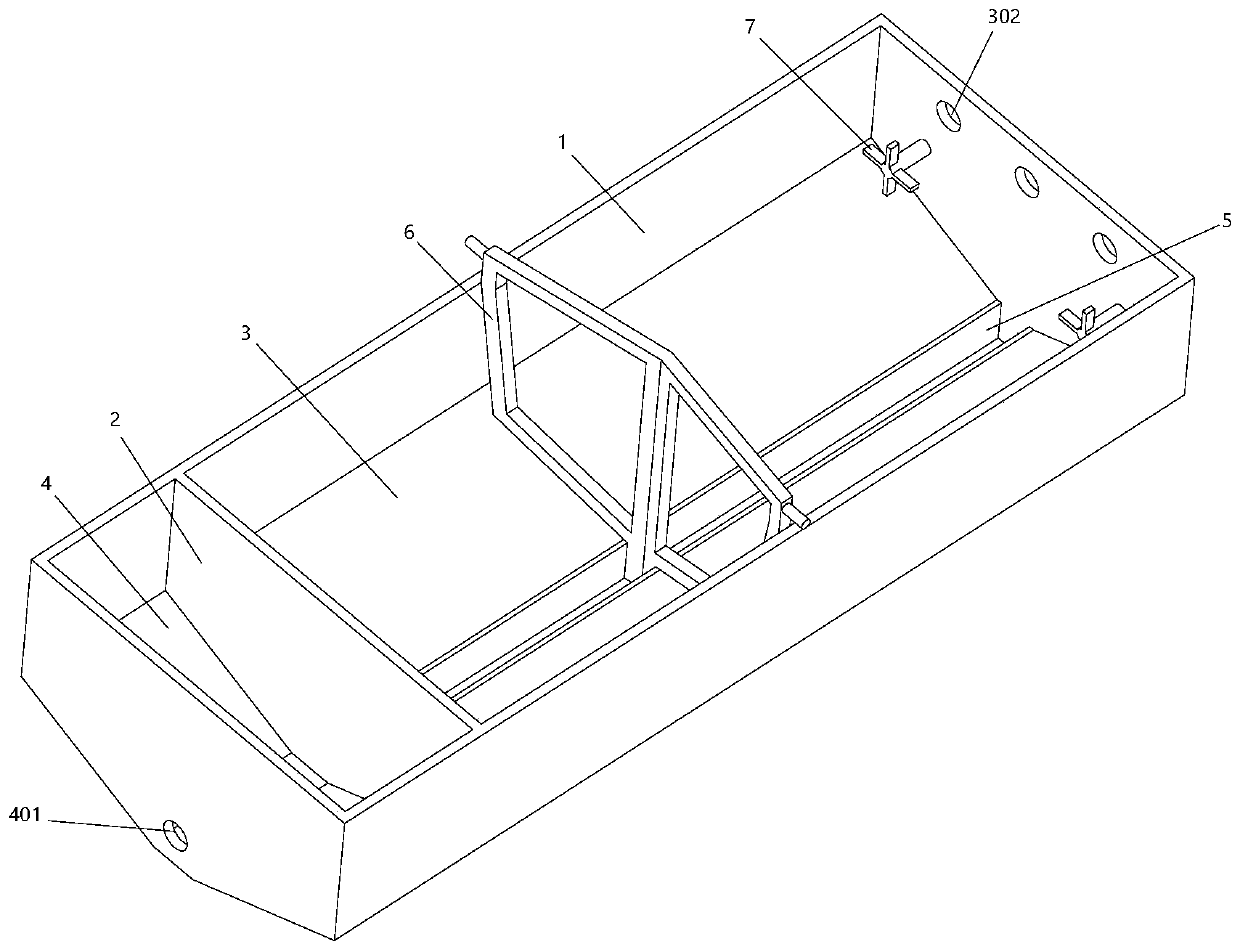

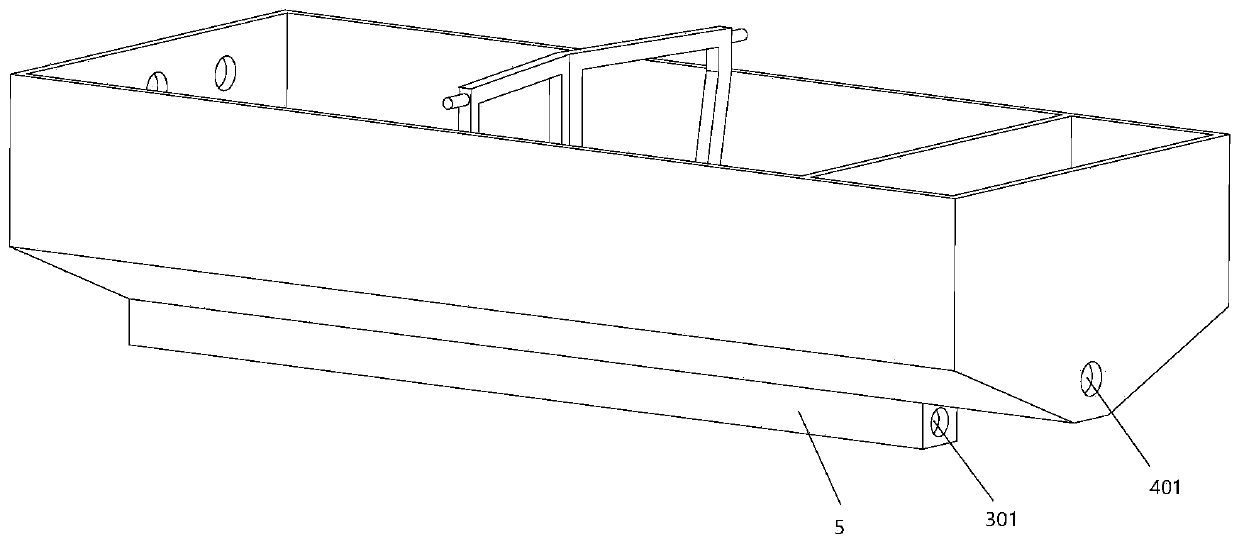

Improved artificial rapid infiltration integrated device based on agricultural waste carbon slow release enhanced biological nitrogen removal and synchronous phosphorus removal and application thereof

PendingCN112429840ASolve the problem of limited denitrificationReduce in quantityWater treatment compoundsWater contaminantsPeristaltic pumpNitrogen removal

The invention discloses an improved artificial rapid infiltration integrated device based on agricultural waste carbon slow release enhanced biological nitrogen removal and synchronous phosphorus removal and application thereof. The device comprises a water inlet tank, a water inlet pipe, a water distributor, an artificial rapid infiltration tank and a water outlet pipe, wherein the water inlet tank is communicated with the water distributor through the water inlet pipe, a peristaltic pump is arranged on the water inlet pipe, the water distributor is arranged at the top of the artificial rapidinfiltration tank, the artificial rapid infiltration tank comprises an upper tank body and a lower tank body which are communicated with each other up and down, and the top of the upper tank body isprovided with an opening, the upper tank body is internally provided with a protective layer, a water distribution layer, a first filter material layer and a capillary blocking layer from top to bottom in order, wherein the lower tank body is in flange connection with the upper tank body, a slow-release carbon source layer, a second filter material layer and a supporting layer are sequentially arranged in the lower tank body from top to bottom, one end of the water outlet pipe is communicated with the bottom of the supporting layer, and the other end of the water outlet pipe is flush with thebottom of the capillary blocking layer. The device is simple in structure and good in nitrogen and phosphorus removal effect on sewage.

Owner:TONGJI UNIV

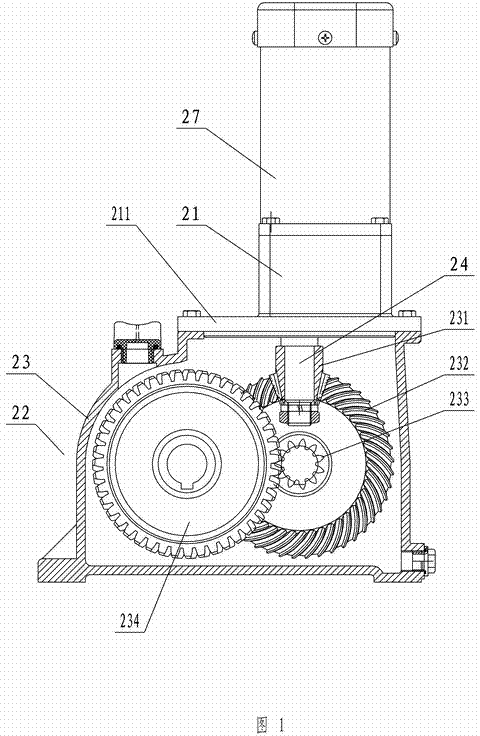

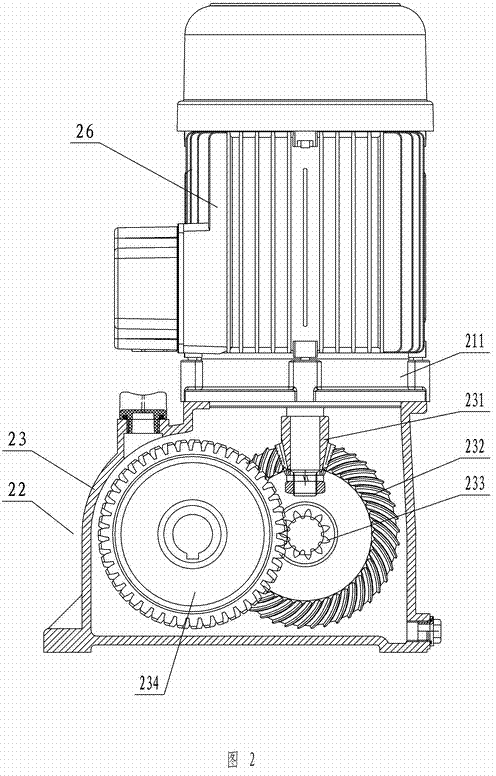

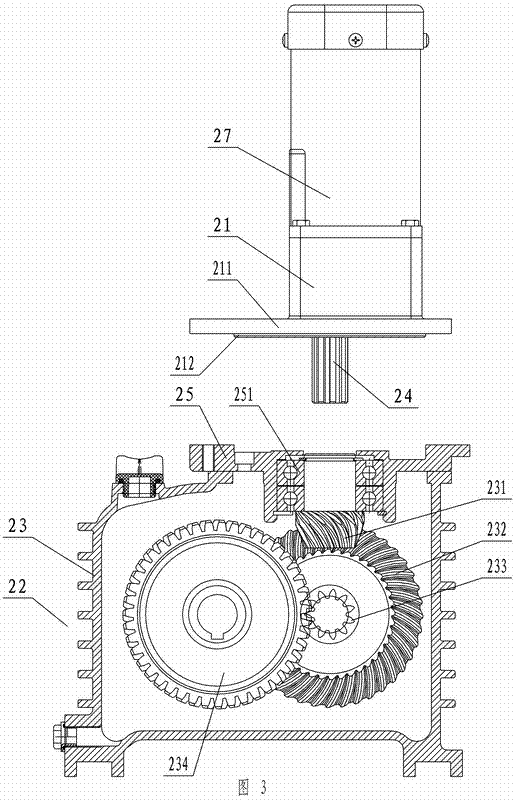

Horizontal water tilling machine

InactiveCN103081849AOutstanding FeaturesHighlight significant progressPisciculture and aquariaImpellerGear wheel

The invention belongs to aquaculture machinery, and relates to a horizontal water tilling machine which mainly comprises a motor, reduction gearboxes, an impeller and a floating body. The reduction gearboxes include a primary reduction gearbox and a secondary reduction gearbox, the primary reduction gearbox is integrated with the motor, an output shaft of the primary reduction gearbox drives a bevel pinion, the bevel pinion drives a bevel gear wheel, the bevel gear wheel and a cylindrical pinion are coaxial, the cylindrical pinion drives a cylindrical gear wheel, the output shaft penetrates through a seal, then extends out of one side or two sides of a gearbox body and drives the impeller to rotate, and the integral horizontal water tilling machine floats on a water surface owing to the floating body. The primary reduction gearbox is connected with the secondary reduction gearbox by a flange, and the positioning dimension of a joint surface of the flange is identical to that of a joint surface of a flange of a motor of an aerator. The horizontal water tilling machine has the advantages that the horizontal water tilling machine is applied to aquaculture, when fish and shrimp are young, oxygen consumption is low, the water tilling machine can be started to enable water to flow, the quality of the water of a pond is improved, and the water tilling machine is low in power consumption; and when the fish and shrimp grow to a certain degree, the oxygen consumption is increased, the pond can be aerated as needed by means of disassembling the primary reduction gearbox and using the horizontal water tilling machine with the motor of the aerator, and other structural change is omitted.

Owner:ZHEJIANG FORDY MACHINERY

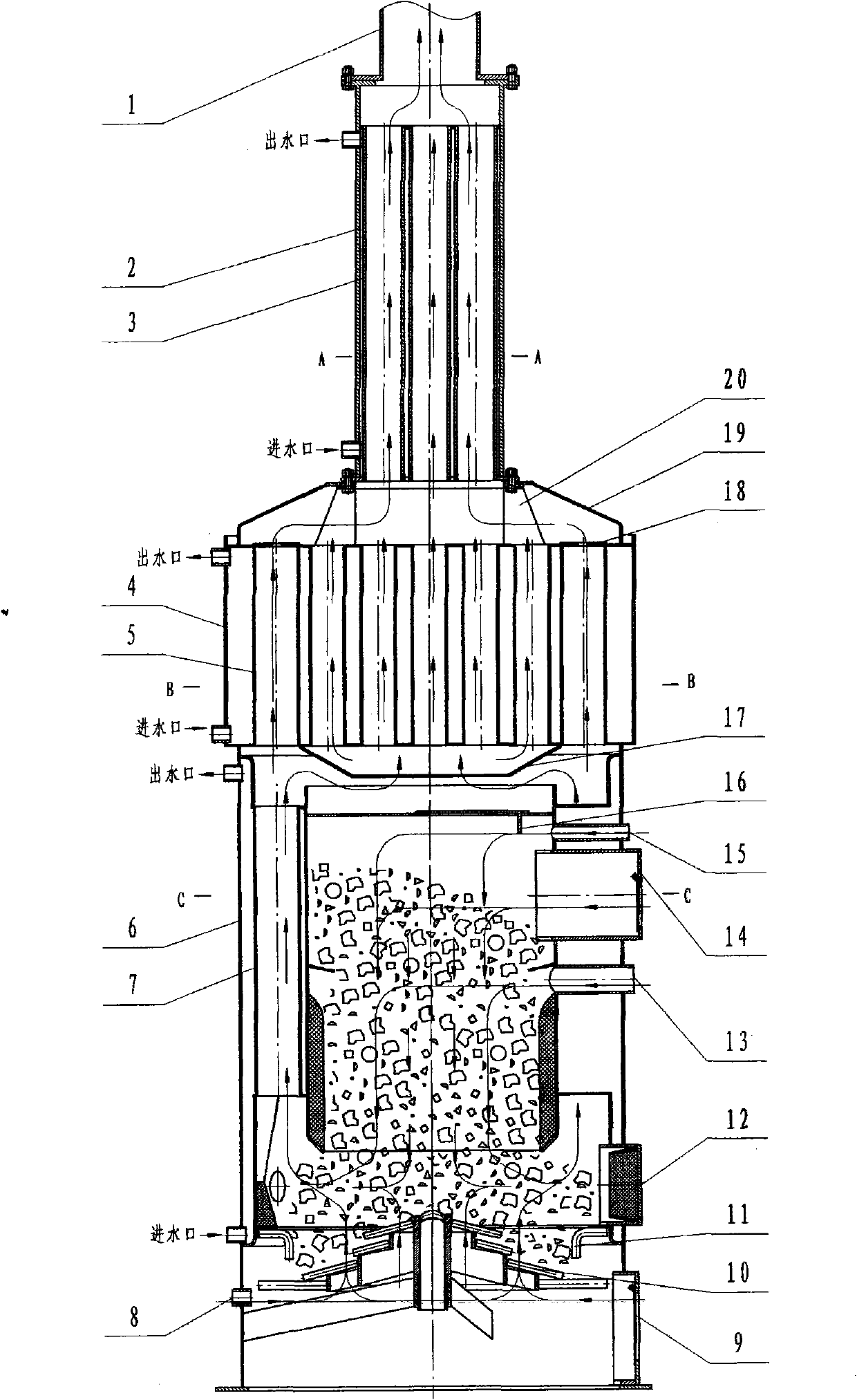

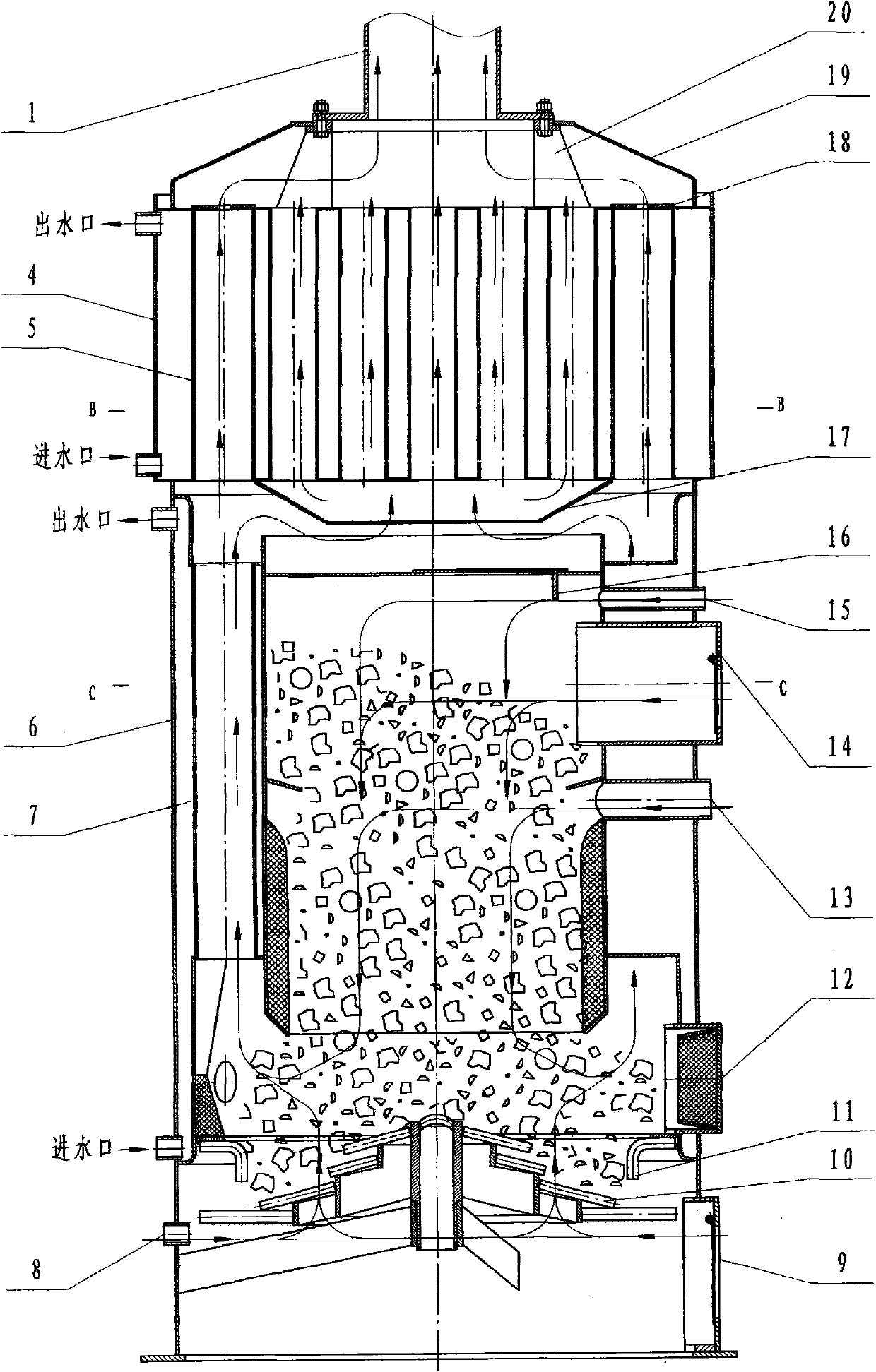

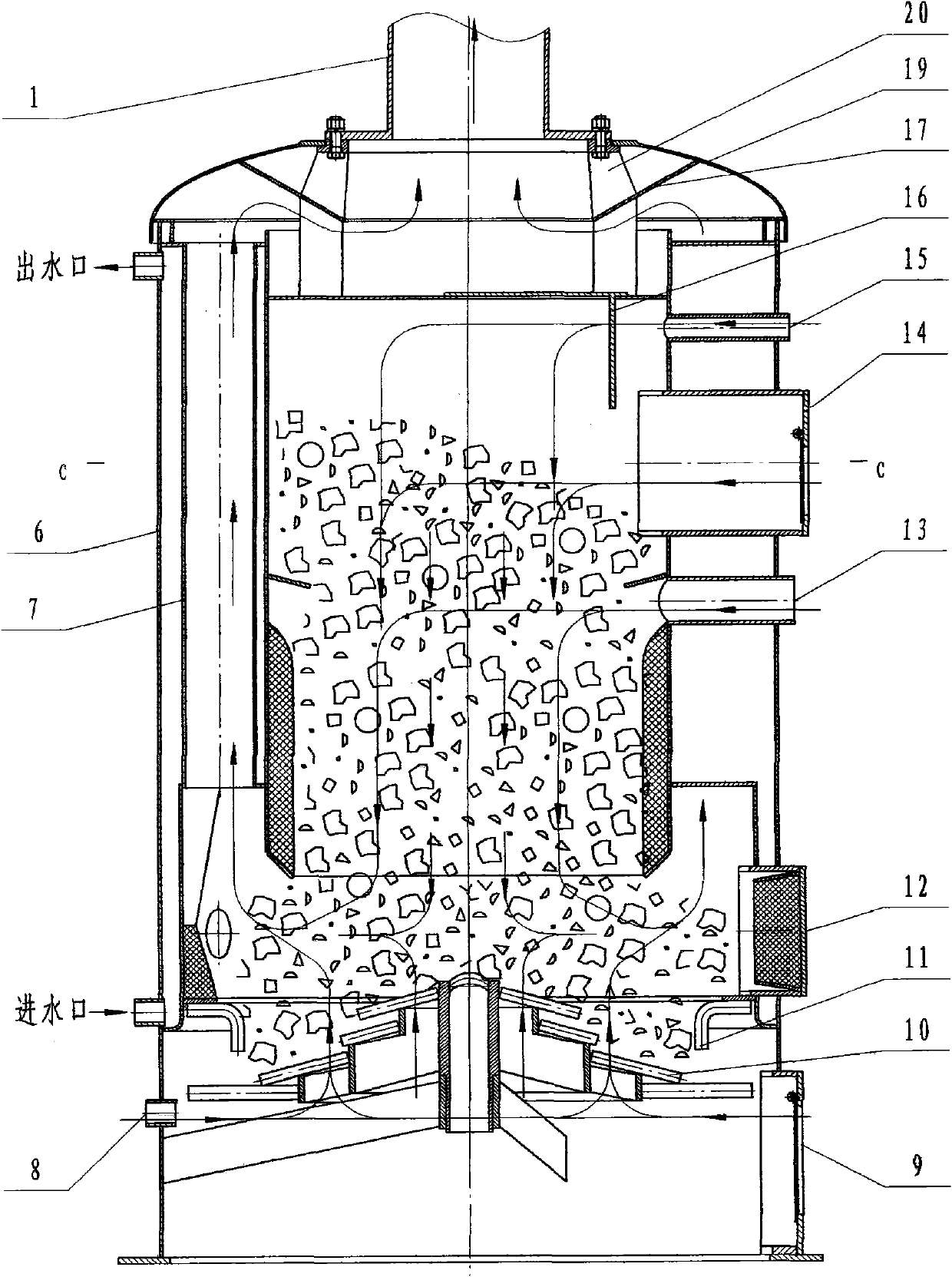

Energy-saving emission-reducing vertical fire-tube boiler capable of using water as oxidant

InactiveCN102563854AAchieve smokeless combustionIncrease burn rateWater heatersOxygen deprivationChemical reaction

The invention relates to an energy-saving emission-reducing vertical fire-tube boiler capable of using water as oxidant. A plurality of water jackets (water containers) are serially connected, a vertical fire tube heating mode is adopted, the water can be used as the oxidant, combustion efficiency is high, the quantity of consumed oxygen is low, accordingly, a heat exchange effect is improved, heat efficiency is enhanced, and energy is saved. A combustion principle of the energy-saving emission-reducing vertical fire-tube boiler includes that hydrogen and carbon are used as energy carriers, and energy can be exchanged between hydrogen and carbon. The carbon or hydrocarbon and water realize 'oxygen deprivation' reaction in a high-temperature environment, namely high-temperature steam is used as the oxidant to realize thermal chemical reaction with the carbon or the hydrocarbon, and hydrogen-rich gas is generated. Energy is absorbed during hydrolysis while energy is released during oxidation of the carbon, and energy is exchanged between the carbon and the hydrogen. The high-temperature environment is required when the energy is exchanged between the carbon and the hydrogen, and the energy is only consumed to maintain the high-temperature environment required by the thermal chemical reaction. Accordingly, by the aid of the energy-saving emission-reducing vertical fire-tube boiler, smokeless combustion of coal can be realized, and biomass fuel containing a large amount of water, domestic garbage and industrial and agricultural combustible waste are suitable to be used as energy sources.

Owner:王振孝

Water quality improver for aquaculture, and preparation method thereof

InactiveCN107364918AImprove obesityReduce the content of harmful substancesWaste water treatment from animal husbandryWater/sewage treatment by substance additionDisinfectantAquatic animal

The invention discloses a water quality improver for aquaculture. The water quality improver comprises, by weight, 5-17 parts of iron-modified montmorillonite, 20-50 parts of peanut meal, 5-15 parts of corn flour, 6-18 parts of wheat bran, 2-5 parts of EM bacteria, 5-13 parts of yeast extract, 10-20 parts of Chinese herb medicines, 3-11 parts of nitrifying bacteria, 1.5-3.5 parts of tea seed cakes, 2-8 parts of acetylcholinesterase, 0.5-0.9 part of selenium, 3-11 parts of chitosan and 2-8 parts of an antifoaming agent. The invention provides the water quality improver for aquaculture, and a preparation method thereof. The preparation method is simple, and the water quality improver improves water quality purification, increases the fertility of water, reduces the content of harmful substances in the water, such as insecticides and disinfectants, and reduces the incidence of aquatic animals.

Owner:HFEI PUBANG AGRI TECH CO LTD

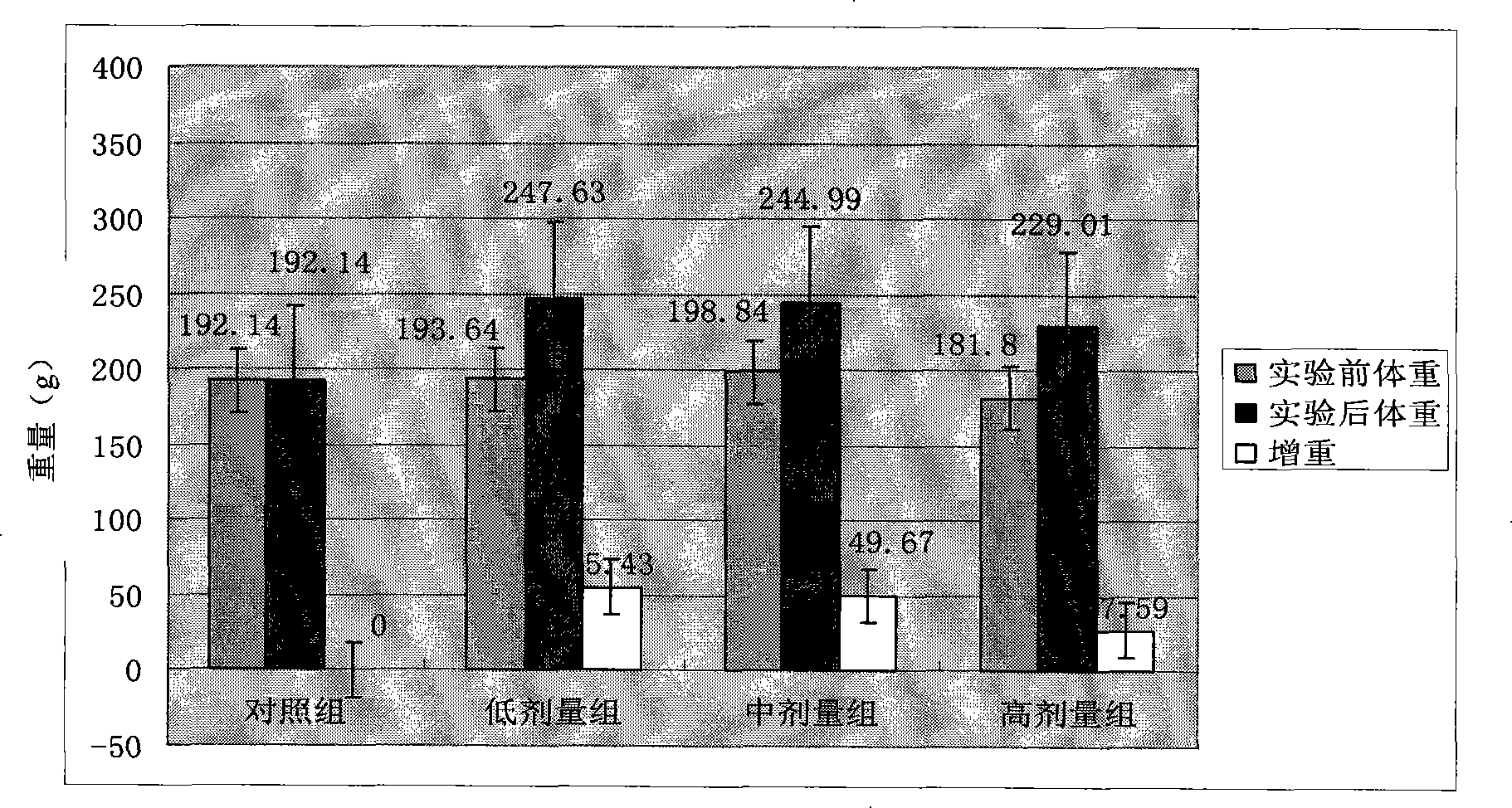

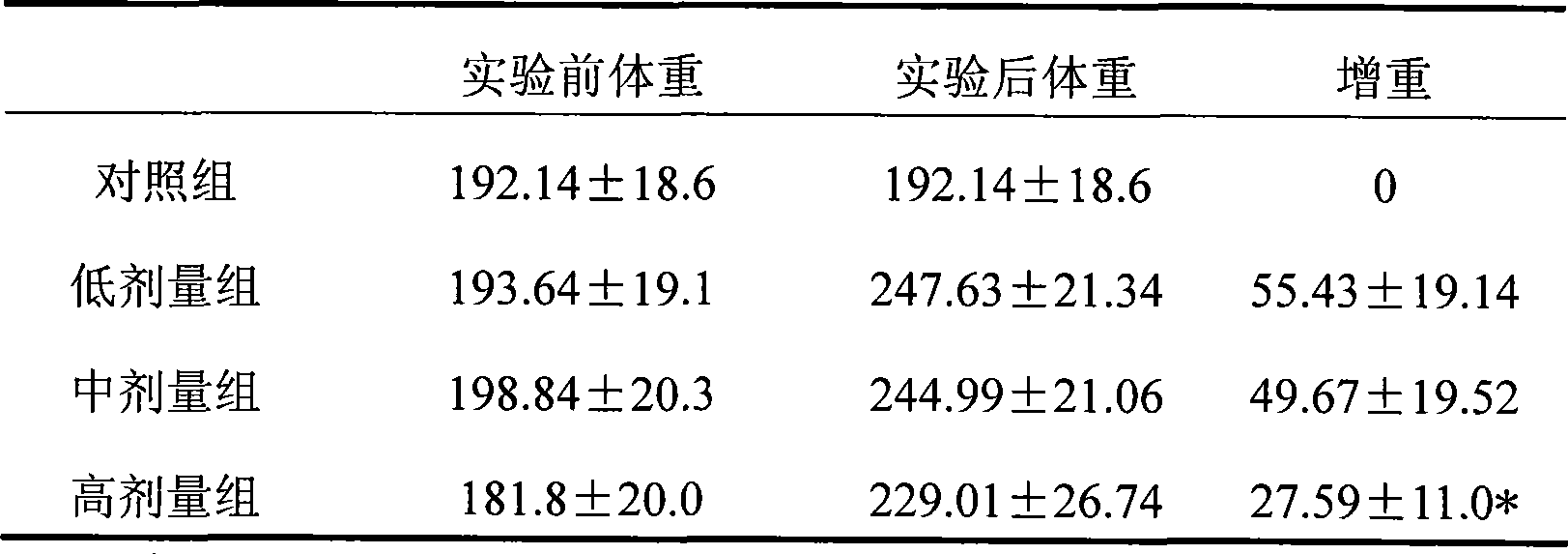

Chinese medicinal composition with bilateral functions for treating angina pectoris and/or arrhythmia

InactiveCN1733029AExtend the action durationLess oxygen consumptionSolution deliveryPill deliveryFreeze-dryingAngina

The invention relates to a traditional Chinese medicinal composition for treating angina pectoris and / or arrhythmia, wherein the preparation comprises notoginseng, Breviscapine and rush pith, and can be prepared into various dosage forms including tablet, capsule, granule, injection, and freeze-dried powder injection.

Owner:GENERAL HOSPITAL OF PLA

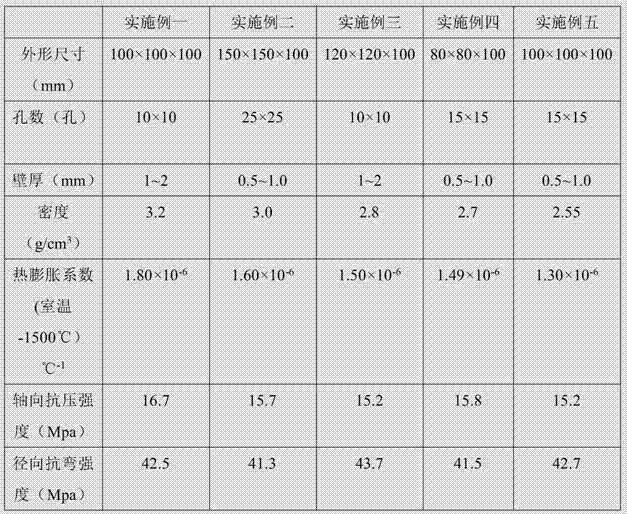

Oil-free honeycomb ceramic regenerator and preparation method thereof

The invention provides an oil-free honeycomb ceramic regenerator, which is prepared from the following components in parts by weight: 15-25 parts of an extrusion assistant mixed solution, 0.5-1.0 part of hydroxy propyl cellulose, 90-110 parts of mullite powder, 20-30 parts of tourmaline powder and 5-10 parts of Suzhou clay; the extrusion assistant mixed solution is prepared from the following components in parts by weight: 90-110 parts of water, 1-5 parts of polyoxyethylene, 1-5 parts of polyacrylamide and 5-15 parts of alumina sol. No black smoke is generated in the production process, the oil-free honeycomb ceramic regenerator has the characteristics of being healthy, environment-friendly, high in mechanical strength, abrasion-resistant, low in cost and short in production period, and can be widely applicable to regenerative kiln equipment. The invention further provides a preparation method of the oil-free honeycomb ceramic regenerator.

Owner:JIANGXI SHINCO ENVIRONMENTAL PROTECTION CO LTD

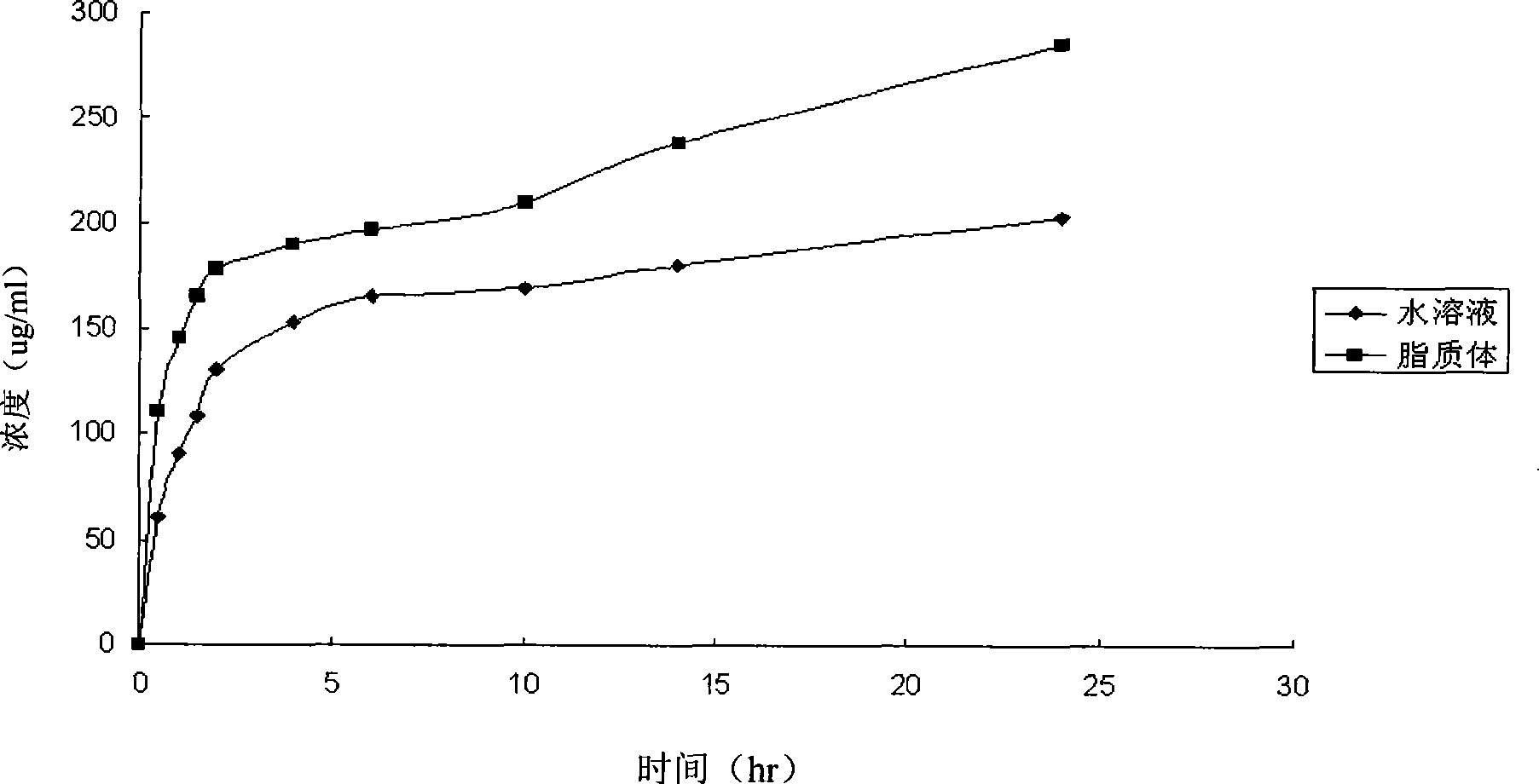

Dioscorea opposita saponin liposome, method for preparing its preparations and uses thereof

ActiveCN101244040AImprove dilation of coronary arteriesProlong the action timeOrganic active ingredientsLiposomal deliveryCholesterolClinical trial

The invention relates to a yam saponin liposome, a preparation method of the yam saponin liposome and the application of yam saponin liposome in preparing the medicine for prevention and treatment of cardiovascular diseases. The composition (parts by weight) of the yam saponin liposome is as follows: phospholipid 1 to 1000, cholesterol 0.5 to 100, yam saponin 1 to 200 and emulsifier 20 to 500. The yam saponin liposome has the advantages of high optical and thermal stability, ability to prolong the active time of the medicine, simple and economical process and convenient transportation and storage compared with the prior art since the yam saponin liposome can be made into coated tablet, syrup, oral liquid, drops and capsules, and obvious therapeutic effect proven by the clinical trial for the cardiovascular diseases such as coronary heart disease and hyperlipidemia.

Owner:江苏黄河药业股份有限公司

Preparation method of stable lactobacillus microecological preparation

The invention provides a preparation method of a stable lactobacillus microecological preparation and belongs to the field of lactobacillus fermentation. The preparation method includes: using breeding animal, breeding water body and bottom mud as bacteria sources to separate out lactobacillus strains; purifying the lactobacillus strains to breed 2-5 lactobacillus strains with large calcium dissolving circle, high growing speed and high vitality; performing enlarging culture on the lactobacillus strains which are bred to prepare composite seed liquid; inoculating the composite seed liquid forfermentation to obtain a composite lactobacillus microecological preparation. Compared with the prior art, the preparation method has the advantages that the lactobacillus microecological preparationis quite simple in both culture equipment and operation and quite stable in storage time when compared with that of single-strain fermentation water agents.

Owner:郑州神草生物技术有限公司

Medicine composition used for treating myocardial ischemia and preparation method thereof

InactiveCN105709228ASimple preparation processNo side effectsHydroxy compound active ingredientsPill deliveryEcdysteroneSide effect

The invention discloses a medicine composition used for treating myocardial ischemia and a preparation method thereof. The medicine composition used for treating myocardial ischemia is prepared from, by weight, 1.2-3.5 parts of bishydroxycoumarin, 1.0-3.0 parts of beta-ecdysterone, 0.8-4.2 parts of betulin, 1.2-3.6 parts of myristic acid, 0.2-0.8 part of bergapten, 0.1-0.5 part of anti-thrombotic medicine, 0.1-0.2 part of naltrexone, 0.3-1.0 part of menthol, 1.2-2.0 parts of kaempferol-3-rhamnoglucoside, 0.5-2.0 parts of phycocyanobilin, 0.2-0.5 part of erythropoietin, 0.1-1.0 part of alginic acid, 0.1-0.6 part of panaxoside, 0.1-0.2 part of catechinic acid, 0.3-1.2 parts of timnodonic acid and 3.0-10 parts of Arab galactose. The medicine composition used for treating myocardial ischemia is safe, effective, easy to prepare and free of toxic or side effect, can lower myocardial oxygen consumption, relieve myocardial metabolic disorder and correct hemodynamics disorder, has the remarkable effect on treating myocardial ischemia, and has the practical application value clinically for treating or preventing myocardial ischemia.

Owner:张长青

Sea-buckthorn six-flavor unguent and preparation method thereof

InactiveCN109674052AReasonable formulaGreat tasteNatural extract food ingredientsFood ingredient functionsFlavorPolygonum odoratum

The invention discloses a sea-buckthorn six-flavor unguent and a preparation method thereof. The invention aims to solve the problem of compatibility of six medicinal and edible materials. The sea-buckthorn six-flavor unguent provided by the invention is composed of sea-buckthorn, hawthorn, folium mori, lotus leaves, burdock roots and polygonatum odoratum. The preparation method of the sea-buckthorn six-flavor unguent comprises the following steps: dosing; soaking; decocting; secondarily decocting; mixing filtrates; concentrating; acquiring extract; packaging. The formula and preparation technology of the sea-buckthorn six-flavor unguent provided by the invention are combined with a modern technology on the basis of following the traditional Chinese medicine theory, so that the curative effect of product is guaranteed and the taste and convenience in taking are suitable for more people. The scheme also solves the problem of deep processing of agricultural products and product conversion.

Owner:杭州科维医药科技有限公司

Aquatic excrement precipitation separation equipment

PendingCN111138061AIncrease dissolved oxygenAchieve separationSludge treatmentSpecific water treatment objectivesWater resourcesSewage

The invention discloses aquatic excrement precipitation separation equipment. The equipment comprises a tank body, wherein the tank body is provided with a separation retaining wall for dividing the tank body into a sewage tank and a clear water tank; a filtering assembly is arranged in the separation retaining wall; the bottom of the sewage tank is inclined from two sides to the middle, and a sewage gathering groove is formed in the lowest inclined position; the clear water tank is provided with a clear water outlet capable of being opened and closed; an excrement outlet capable of being opened and closed is formed in the excrement gathering groove; and the clear water outlet is higher than the excrement outlet. According to the aquatic excrement precipitation separation equipment, a separation retaining wall with the filtering assembly is arranged to divide the tank body into the sewage tank and the clear water tank, and separation of solid dirt and sewage is achieved; the dirt gathering groove and the push-pull component are arranged to push precipitated solid dirt out of the sewage tank; and water in the clear water tank is recycled after being sterilized and disinfected, so that the utilization rate of water resources is increased.

Owner:SHANGHAI NENGZHENG FISHING TECH DEV CO LTD

Industrial fuel gas for metal cutting and welding

This invention discloses an industrial fuel gas used for metal cutting and welding. Additive and dimethyl enther are added to cylinder to make-up the fuel, dimethyl enther is 40~99.9% and other rest additive. The additive is consisted by one or any several kind of following fuels as arbitrary proportion, petroleum liquefied gas, propane, butane, propylene, pentane, clean oil, methanol, ethanol. This invention has good burning property, security, environmental protection capability and extra high burning flame temperature. Comparing to acetylene, it is not easy to bomb, and its storage, transportation, using and management is more convenient and safe. There is no pollution to environment and operator. Its preheating and cutting velocity is fast, welding and welding line quality is good, oxygen consumption is low, so it improves work efficiency and reduces cost.

Owner:郑长同 +3

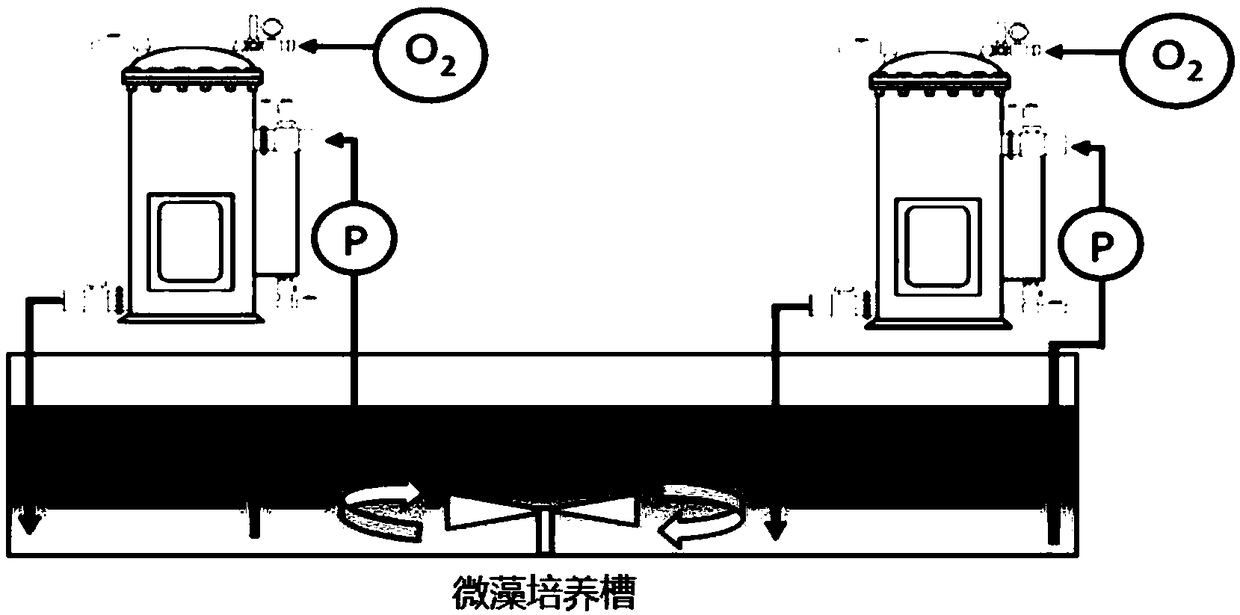

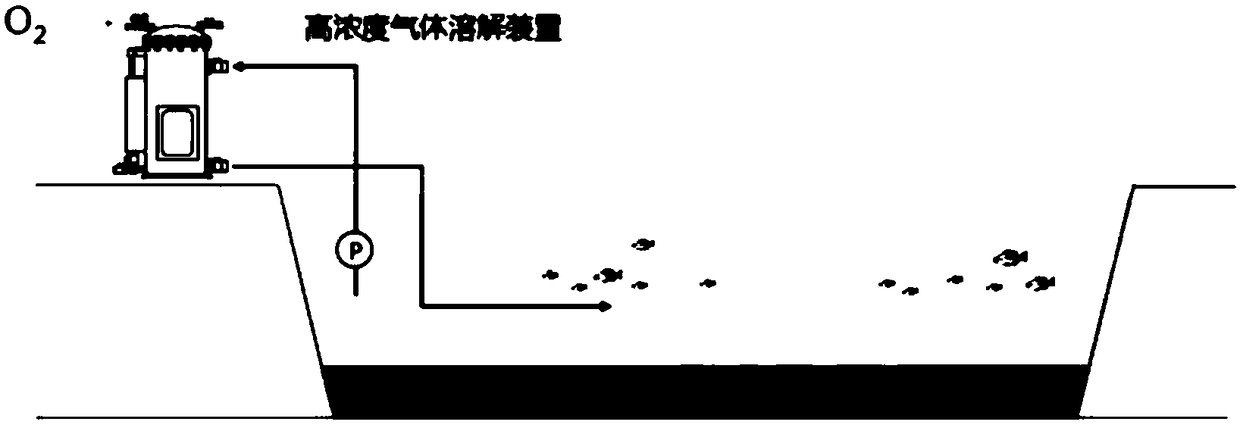

Method for adding dissolved oxygen into water for recycling microalgae

The invention discloses a method for adding dissolved oxygen into water for recycling microalgae. The method comprises the following steps that (1) a water suction pump is adopted for pumping low-oxygen water in a microalgae breeding tank into a high-concentration gas dissolving device, and oxygen is introduced into the high-concentration gas dissolving device simultaneously; (2) the high-concentration gas dissolving device is controlled to dissolve the oxygen in the low-oxygen water so as to obtain high-oxygen water with a larger amount of dissolved oxygen, and then the high-oxygen water is put back into the microalgae breeding tank through drainage holes of the high-concentration gas dissolving device. The method for adding the dissolved oxygen into the water for recycling the microalgaehas the advantages that the O2 dissolving efficiency in the water for recycling the microalgae can be improved, bacteria are difficultly mixed into the microalgae breeding tank, the good growth of microalgae is ensured, the use amount of chemical fertilizers is reduced, the death rate of the microalgae is reduced, the quality and purity of the microalgae are improved, and the breeding cost of themicroalgae is reduced; the consumption amount of oxygen is small, no bubbles are generated when the oxygen is dissolved in the water, it is avoided that the growth of the microalgae is affected due to the fact that algae are damaged, and the problem is solved that the oxygen cannot be supplied to the bottom of the tank during microalgae breeding.

Owner:北海生巴达生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com