Combustible carbon material gasifying device employing three-section composite dry and wet method

A gasification device and dry-wet process technology, which is applied in the field of three-stage composite dry-wet process combustible carbon material gasification device, can solve the problems of no dry-process dust removal and gasification technology, complex structure of the gasification device, and many operation failures. , to achieve the effect of compact structure, low cost and small fluid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

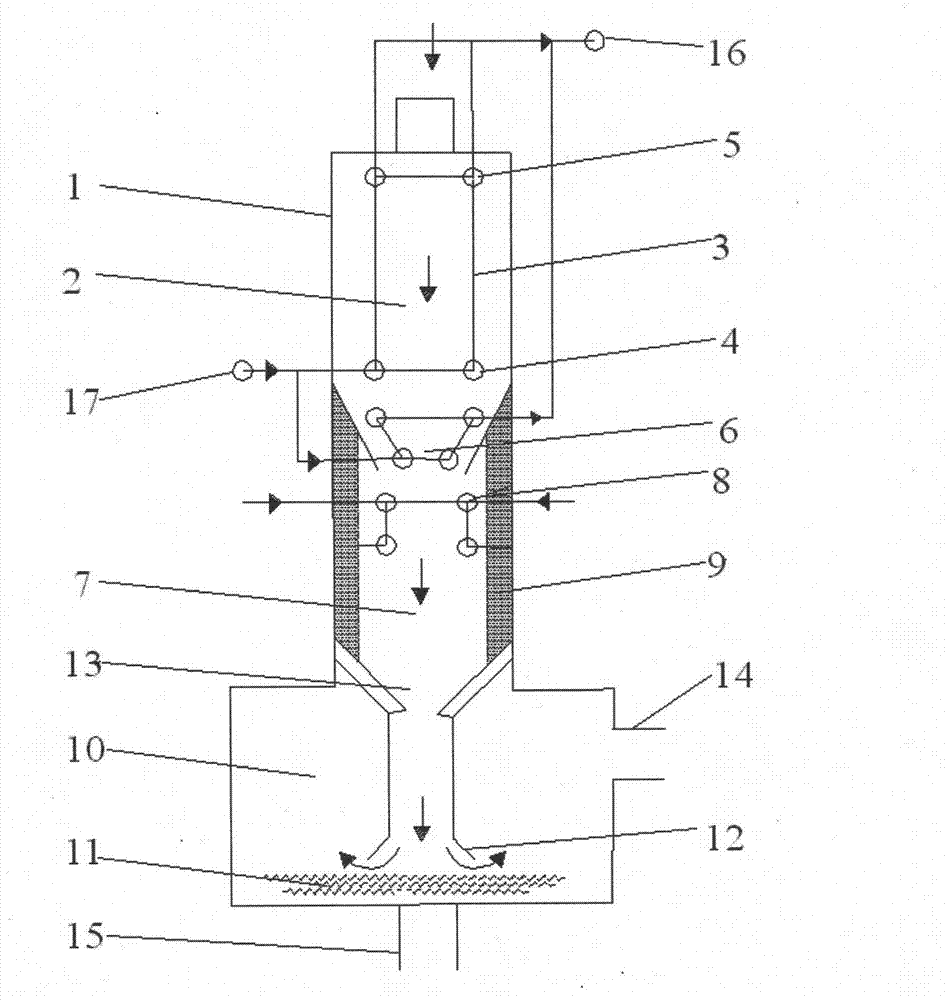

[0020] figure 1 It is a schematic diagram of a three-stage composite dry-wet method combustible carbon substance gasification device provided by the present invention. The three-stage composite dry-wet method combustible carbon substance gasification device consists of a reaction section 2, a quenching section 7 and The separation section 10 is connected sequentially from top to bottom.

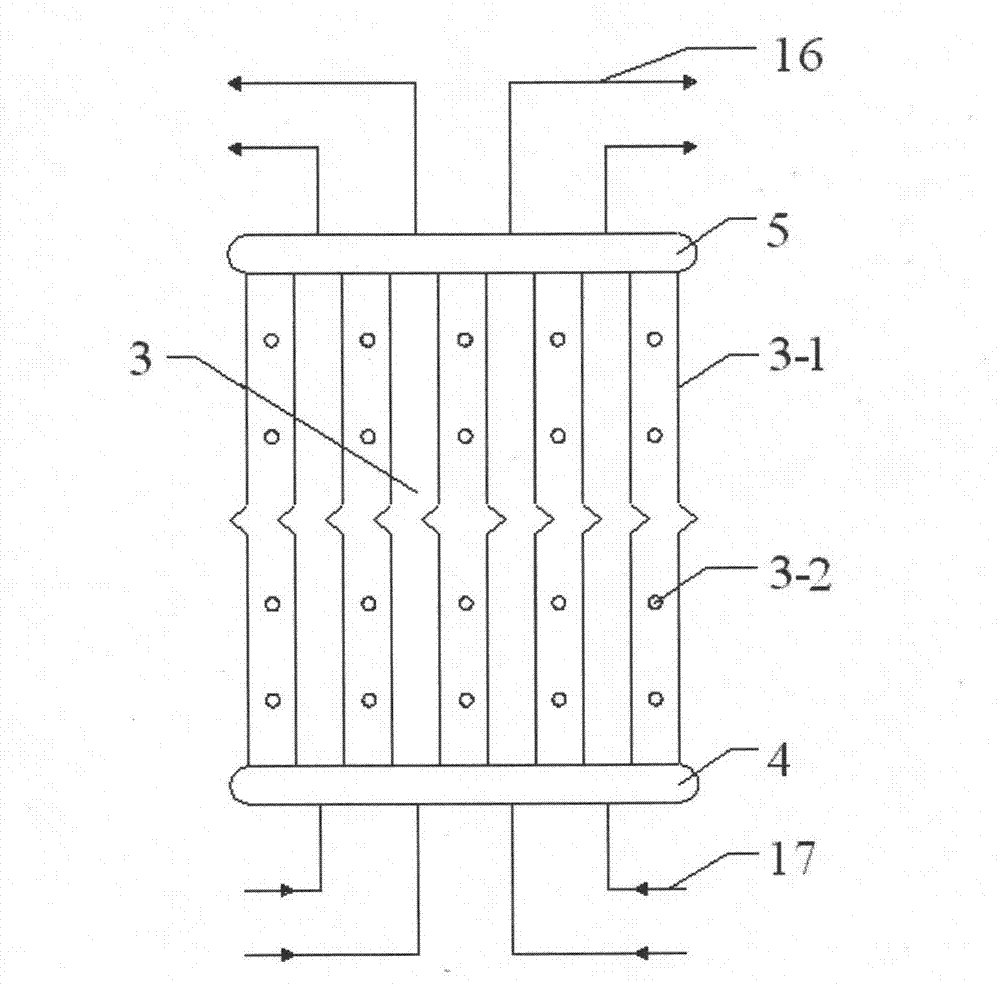

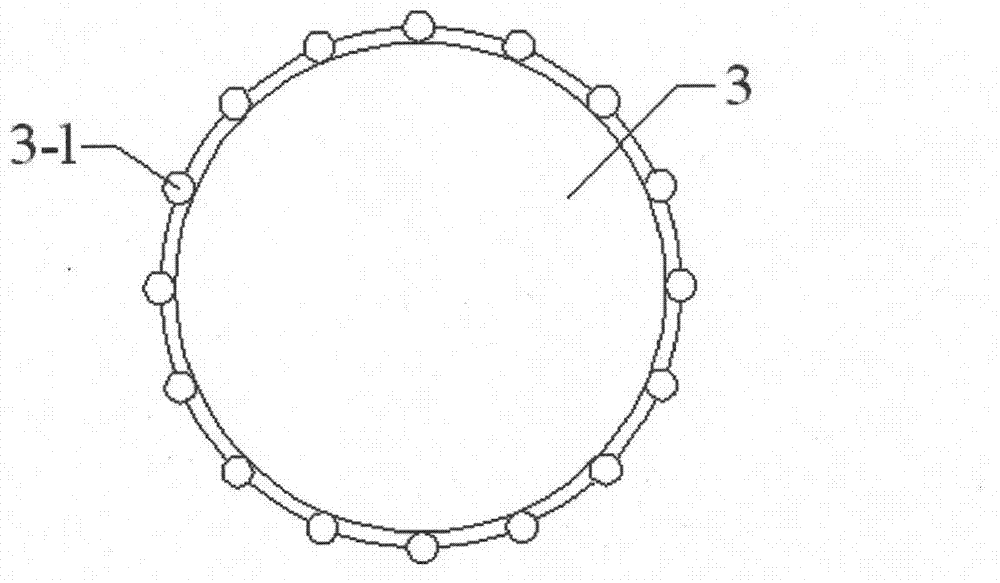

[0021] The reaction section 2 includes a shell 1 and a vertical tube type protective wall 3 installed inside the shell 1. The vertical tube type protective wall 3 is a protective wall formed along the inner wall of the shell 1 and surrounded by finned tubes 3-1 in a cylindrical shape, and is easy to assemble. Right, welded, easy to install, short fluid path, small resistance; a temperature measuring device 3-2 is installed between the finned tub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com