Novel industrial cutting gas with dimethyl ether as main component

A dimethyl ether and industrial technology, applied in the field of new industrial cutting gas, can solve the problems of low calorific value of dimethyl ether, slow drilling and cutting speed, etc., and achieve the effect of increasing flame temperature, strong cutting performance and concentrated heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

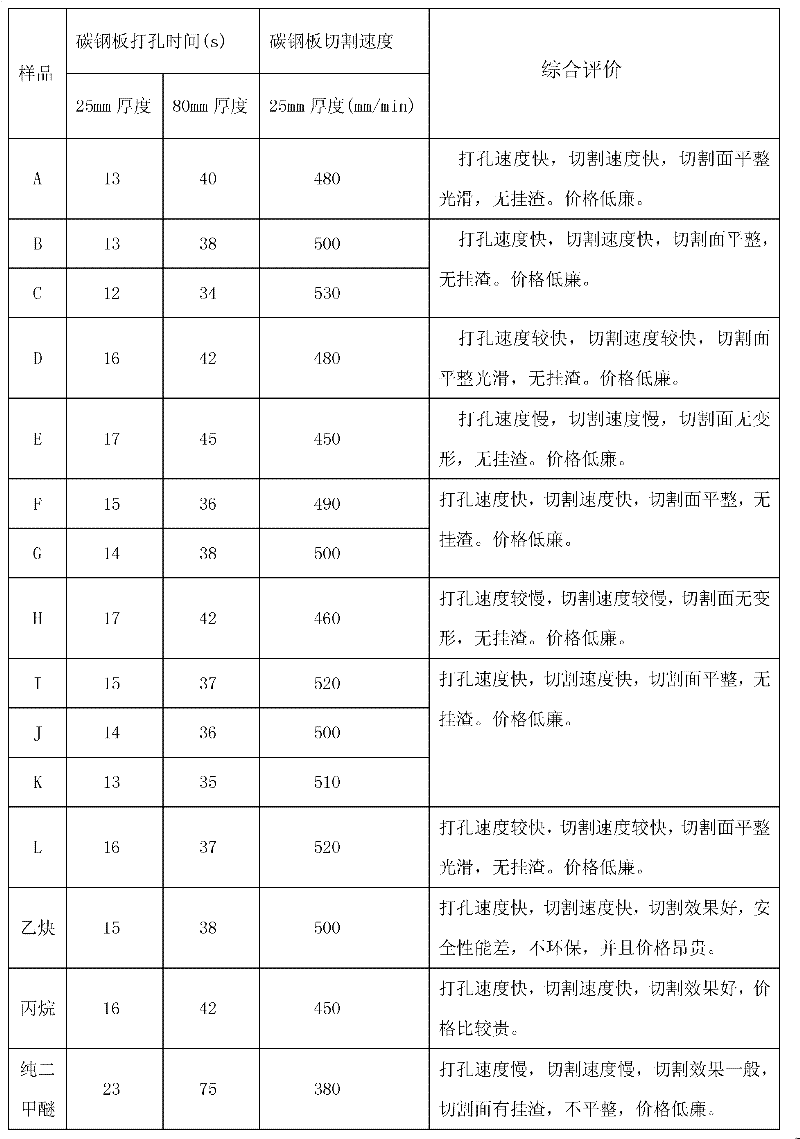

Image

Examples

Embodiment 1

[0046] The ratio of additive preparation is measured as follows: 10g of tert-butyl ferrocene, 800g of diethyl ether, 20g of aromatic oil (source: Beijing Haoker Chemical Co., Ltd.), 50g of 6# solvent oil (source: Beijing Haoker Chemical Co., Ltd.), 70g of tert-butanol and 50g of potassium permanganate were added to the preparation kettle, stirred continuously for 2 hours, and set aside. The additive sample is named a.

[0047] Press 20kg of additive a into a 50kg steel cylinder, then press 30kg of dimethyl ether into the cylinder, close the valve, and fully mix to obtain the cutting gas. The mass percent content of each component of the cutting gas is: dimethyl ether 60%, additive 40%. The cutting gas sample is named A.

Embodiment 2

[0049] The ratio of additive preparation is measured as follows: 300g of tert-butyl ferrocene, 100g of diethyl ether, 50g of aromatic oil, 150g of 6# solvent oil, 400g of tert-butanol, add to the preparation kettle, stir continuously for 2 hours, and set aside. The additive sample is named b.

[0050] Press 5g of additive b into a 50kg steel cylinder, then press 49.995kg of dimethyl ether into the cylinder, close the valve, and mix thoroughly to obtain the cutting gas. The mass percent content of each component of the cutting gas is: 99.99% of dimethyl ether and 0.01% of additives. The cutting gas sample is named B.

Embodiment 3

[0052] The ratio of additive preparation is measured as follows: 30g of tert-butyl ferrocene, 730g of diethyl ether, 10g of aromatic oil, 220g of 6# solvent oil, 10g of tert-butanol, add to the preparation kettle, stir continuously for 2 hours, and set aside. The additive sample is named c.

[0053] Press 0.5kg of additive c into a 50kg steel cylinder, then press 49.5kg of dimethyl ether into the cylinder, close the valve, and mix thoroughly to obtain cutting gas. The mass percent content of each component of the cutting gas is: 99% of dimethyl ether and 1% of additive. The cutting gas sample is named C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com