Oil-free honeycomb ceramic regenerator and preparation method thereof

A technology of honeycomb ceramics and regenerators, which is applied in the field of industrial ceramics, can solve the problems of lack of energy-saving and environmental protection production technology of ceramic regenerators, and the complex preparation process of adhesives, etc., to achieve short cycle, increase strength, increase stability and resistance The effect of compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

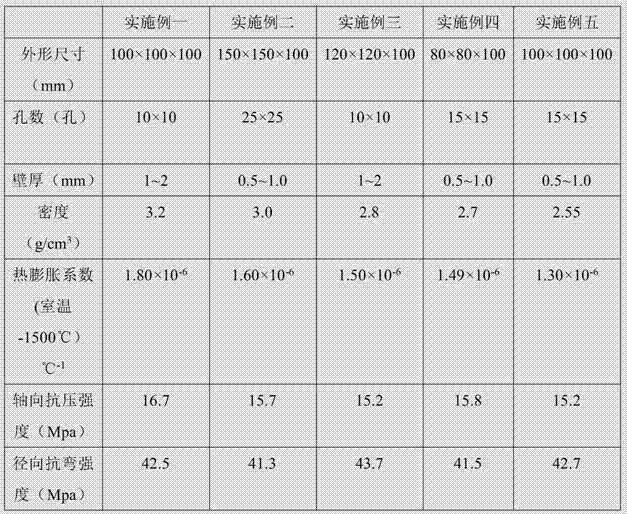

Examples

Embodiment 1

[0032] An oil-free honeycomb ceramic regenerator, which is prepared from the following components in parts by weight: 20 parts of extrusion aid mixed solution, 1 part of hydroxypropyl cellulose, 100 parts of mullite powder, 30 parts of tourmaline powder, 10 copies of Suzhou soil.

[0033] The extrusion aid mixed solution is composed of the following components in parts by weight: 100 parts of water, 1 part of polyethylene oxide, 1 part of polyacrylamide, and 15 parts of aluminum sol with a solid content of 15%.

[0034] A preparation method of oil-free honeycomb ceramic regenerator, it comprises the following steps:

[0035] 1) Preparation of extrusion aid mixed solution: heat 100kg of water to 65°C, slowly add 1kg of PEO to the aqueous solution, stir until the PEO is completely dissolved, then slowly add 1kg of PAM into the PEO solution, and stir until the PAM is completely flocculent viscous solution, then continue to add 15kg aluminum sol to the solution, stir and cool to ...

Embodiment 2

[0041] An oil-free honeycomb ceramic regenerator, which is prepared from the following components in parts by weight: 20 parts of extrusion aid mixed solution, 0.8 parts of hydroxypropyl cellulose, 100 parts of mullite powder, 25 parts of tourmaline powder, 10 copies of Suzhou soil.

[0042] The extrusion aid mixed solution is composed of the following components in parts by weight: 100 parts of water, 2 parts of polyethylene oxide, 2 parts of polyacrylamide, and 12 parts of aluminum sol with a solid content of 25%.

[0043] A preparation method of oil-free honeycomb ceramic regenerator, it comprises the following steps:

[0044] 1) Preparation of extrusion aid mixed solution: heat 100kg of water to 70°C, slowly add 2kg of PEO to the aqueous solution, stir until the PEO is completely dissolved, then slowly add 2kg of PAM into the PEO solution, and stir until the PAM is completely flocculent viscous solution, then continue to add 12kg aluminum sol to the solution, stir and coo...

Embodiment 3

[0050] An oil-free honeycomb ceramic regenerator, which is prepared from the following components in parts by weight: 20 parts of extrusion aid mixed solution, 0.8 parts of hydroxypropyl cellulose, 100 parts of mullite powder, 20 parts of tourmaline powder, 10 copies of Suzhou soil.

[0051] The extrusion aid mixed solution is composed of the following components in parts by weight: 100 parts of water, 3 parts of polyethylene oxide, 3 parts of polyacrylamide, and 10 parts of aluminum sol with a solid content of 15%.

[0052] A preparation method of oil-free honeycomb ceramic regenerator, it comprises the following steps:

[0053] 1) Preparation of extrusion aid mixed solution: heat 100kg of water to 75°C, slowly add 3kg of PEO to the aqueous solution, stir until the PEO is completely dissolved, then slowly add 3kg of PAM into the PEO solution, and stir until the PAM is completely flocculent Viscous solution, then continue to add 10kg aluminum sol to the solution, stir and cool ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com