Patents

Literature

250results about How to "Reduce the content of harmful substances" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tail gas-recycled sulfur recovery method

ActiveCN101274750AReduce emissionsImprove solvencyDispersed particle separationSulfur preparation/purificationChemistryNitrogen gas

The invention relates to a method for tail gas recycling sulphur recovery. The method of the invention comprises the steps that external acidic gas is blended with inert gas to reduce the concentration to 2 to 5 percent; after being treated with condensate separation, the mixed gas is heated to 200 to 220 DEG C and blended with air, the oxygen content of which is calculated and which is heated to 200 to 220 DEG C, to react after entering a catalytic oxidation reactor; the gas after the reaction enters a condenser to condense the sulphur; the condensed gas-liquid mixture is treated with the separation of liquid sulfur and gas by a sulphur separator and the gas is then discharged after being washed in a washing tower. In addition, the method for tail gas recycling sulphur recovery also comprises the steps that: 1) when a car is previously run and re-run after the system shutdown, the anoxic gas which is blended with the external acidic gas and dilutes and reduces the concentration of the external acidic gas to 2 to 5 percent is nitrogen gas, and after the car is normally run, the anoxic gas is the discharged gas which is pre-calculated and washed in the washing tower. Meanwhile, the method for tail gas recycling sulphur recovery can greatly reduce the exhaust emission amount of the treated tail gas and also reduce the content of surphur in the emitted tail gas.

Owner:江苏晟宜环保科技有限公司

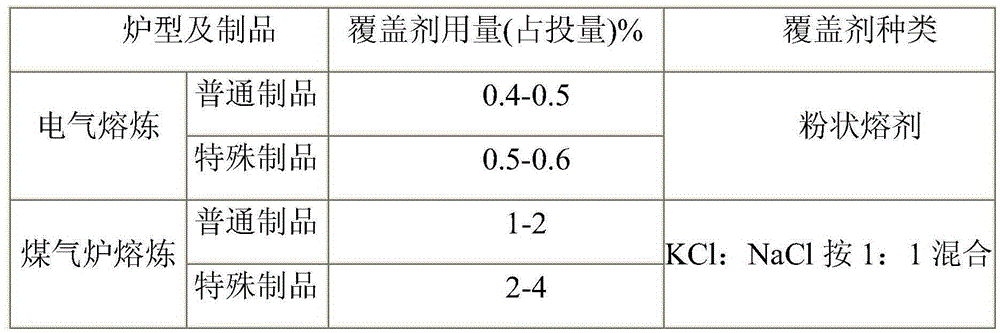

Environment friendly low-gas-content aluminum alloy ingot and production method thereof

The invention discloses an environment friendly low-gas-content aluminum alloy ingot which comprises the following components in percentage by weight: 1.6-3.3 percent of Cu, 9.8-11.8 percent of Si, 0-0.29 percent of Mg, 0-0.08 percent of Zn, 0-0.8 percent of Fe, 0-0.48 percent of Mn, 0-0.48 percent of Ni, 0-0.1 percent of Ti, 0-0.1 percent of Pb, 0-0.2 percent of Sn, 0-0.25 percent of other trace elements and the balance of aluminum. Meanwhile, the invention also discloses a production method of the environment friendly low-gas-content aluminum alloy ingot. The environment friendly low-gas-content aluminum alloy ingot has the advantages of low gas and dreg content, high aluminum liquid cleanness and good mechanical and machining properties. The production method has the advantages of low production cost and high efficiency and effectively solves the pollution problem of the secondary aluminum industry.

Owner:YE CHIU METAL RECYCLINGCHINALTD

Self-protecting flux-cored wire containing polyvinylidene resin

InactiveCN101279409AHigh and stable impact toughnessAdd a small proportionWelding/cutting media/materialsSoldering mediaSlagHazardous substance

The invention relates to a self-shielded flux-cored wire containing polyvinylidene fluoride resin, which comprises a shuck manufactured by adopting the home-made SPCC common mild-carbon steel strip. The invention is characterized in that flux core of the common mild-carbon steel strip consists of villaumite, carbonate, oxide, Manganese (Mn), Silicon (Si), Aluminum (Al), Magnesium (Mg), Nickel (Ni) and ferrous powder jointly; wherein, the components of the flux core include 20 percent to 45 percent of the villaumite, 4 percent to 13 percent of the carbonate, 4 percent to 15 percent of the oxide, 1 percent to 5 percent of Mn, 1 percent to 3 percent of Si, 3 percent to 8 percent of Al, 3 percent to 7 percent of Mg, 0 percent to 5 percent of Ni and ferrous powder serving as the rest. The invention has the advantages that the defects that the pore sensitivity of the self-shielded flux-cored wire is high and the impact toughness of the deposited metal is not excellent; when the multi-layer welding is carried out, the surface blowhole is not generated, the complete slag coverage is achieved, the slag can be easily detached, the weld can be formed well and the impact toughness of the deposited metal is high and stable; the concentration of the hazardous substances in the welding fume is lowered and the invention is beneficial to the health of the welder.

Owner:TIANJIN SAINTEAGLE WELDING CO LTD

Tail gas-recycled sulfur recovery method

ActiveCN101274750BReduce pollutionImprove solubilityDispersed particle separationSulfur preparation/purificationRecovery methodCatalytic oxidation

Owner:江苏晟宜环保科技有限公司

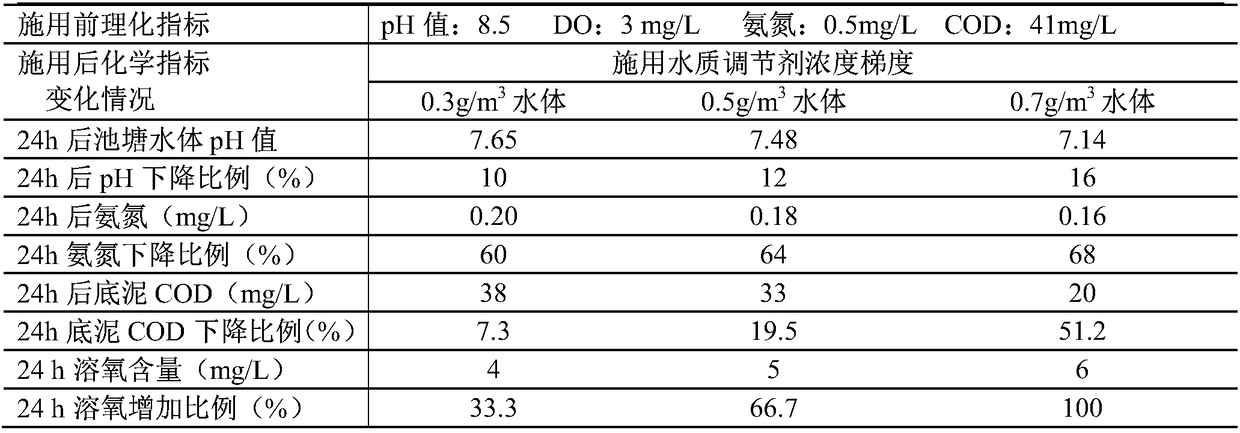

Water quality improvement agent for aquaculture and preparation method thereof

InactiveCN108328750AUnique mineral skeleton structureIncrease surface areaBiocideWater treatment parameter controlSodium bicarbonateCalcium peroxide

The invention discloses a water quality improvement agent for aquaculture and a preparation method thereof. The water quality improvement agent is prepared from the following raw materials in percentage by weight: 5 percent to 10 percent of lactobacillus, 5 percent to 10 percent of photosynthetic bacteria, 5 percent to 10 percent of bacillus, 5 percent to 10 percent of brown sugar, 10 percent to 20 percent of activated carbon, 25 percent to 35 percent of zeolite powder, 3 percent to 5 percent of citric acid, 2 percent to 5 percent of sodium bicarbonate and 10 percent to 15 percent of calcium peroxide. According to the water quality improvement agent disclosed by the invention, organic matters in a water body of water for the aquaculture can be reduced, and the content of ammonia-nitrogen and nitrite is greatly reduced; the chemical oxygen consumption of pond bottom sludge is improved and oxygen debt of the pond bottom is alleviated; growth and proliferation of beneficial microorganismsand decomposition of organic pollutants are accelerated and the circulation of pond substances is accelerated; the proliferation of beneficial algae in a pond is accelerated so that the pond dissolved oxygen is increased; a culture water region environment is improved, healthy growth of aquatic animals is promoted, the feed coefficient is reduced and the economic benefits are increased.

Owner:HENAN UNIV OF ANIMAL HUSBANDRY & ECONOMY

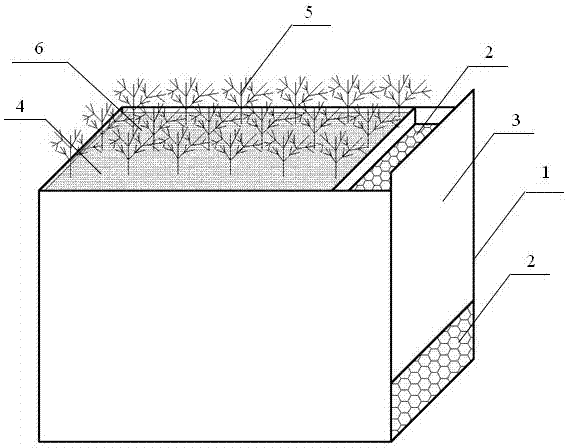

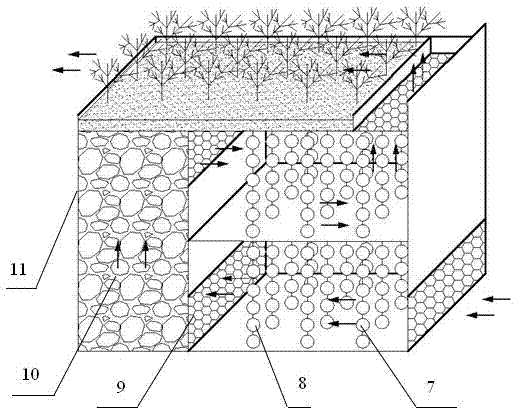

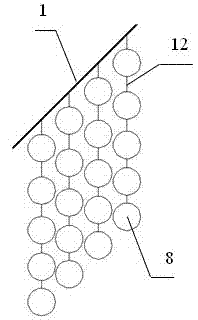

Portable combined constructed wetland purifying box for farmland drainage ditch

InactiveCN103288312AEasy to take outDoes not affect drainage capacityMultistage water/sewage treatmentWire gauzeConstructed wetland

The invention relates to a portable combined constructed wetland purifying box for a farmland drainage ditch. The portable combined constructed wetland purifying box is characterized in that a single portable combined constructed wetland purifying box frame is built through reinforcing steel bars, plastic plates and wire gauzes. The purifying box in the frame comprises a micro constructed wetland area, a biological cleaning ball area and an activated carbon adsorption area. Lateral sides of the single portable combined constructed wetland purifying box can be opened so as to facilitate regular replacing of fillers in the box. The portable combined constructed wetland purifying box is small in size, can be placed in the farmland drainage ditch conveniently and is convenient to move. A plurality of portable combined constructed wetland purifying boxes are connected in series and placed in the farmland drainage ditch, and farmland drainage water enters the boxes through water inlets of the purifying boxes and sequentially passes through the lower portions of the biological purifying ball areas, the activated carbon adsorption areas, the upper portions of the biological purifying ball areas and the micro constructed wetland areas to be purified and processed. The portable combined constructed wetland purifying box has the advantages of being capable of reducing the farmland non-point source pollution receiving water eutrophication degree and risks and reducing content of harmful substances such as heavy metal and pesticide residues in the farmland drainage so as to reduce damage of the harmful substances to receiving water aquatic organisms.

Owner:HOHAI UNIV

Method for preparing low-amine rubber anti-aging agent TMQ

The invention provides a method for preparing a low-amine rubber anti-aging agent TMQ. The method comprises the following steps: adding aniline and hydrochloric acid into a reactor, stirring, heating to 130 DEG C and stirring for 30min, wherein the using amount of the hydrochloric acid is 6-10% of the weight of the aniline; putting 2, 2, 4-trimethyl-1, 2-dihydroquinoline monomers into the reactor, wherein the adding quantity is 70-80% of the mass of the aniline; controlling the temperature at 120-125 DEG C, continuously dropping acetone, keeping the mass ratio of the aniline to the acetone at 1:(1-4), controlling the adding time to be 5-9 hours, controlling the adding temperature at 115-150 DEG C, keeping the temperature at 140 DEG C after the end of dropping, and maintaining the temperature for 4 hours; stopping heating, adding a sodium hydroxide water solution, stirring for 30 minutes, neutralizing, then controlling the pH value at 11, and then standing for 60 minutes; separating to remove a water phase and further obtaining an organic phase; and removing the monomers by distillation in a vacuum state, thus obtaining an anti-aging agent TMQ product. According to the method provided by the invention, the operation is simple, and the content of a primary amine compound is less than 2%.

Owner:KEMAI CHEM

Visible-light-curing vinyl ester resin composite prepreg, and preparation method and application method thereof

The invention particularly provides a visible-light-quick-curing vinyl ester resin composite prepreg, and a preparation method and application method thereof, belonging to the field of repair of a fiber-reinforced resin-base structure with certain thickness. A special vinyl ester resin is used as a matrix; the proper visible light initiator, thermal initiator and other aids are selected to constitute the light-thermal composite initiation system; magnesium oxide is used as a thickener; different types of fabrics are selected as fiber-reinforcing materials according to performance requirements; and a proper composite technique is utilized to prepare the composite prepreg with certain thickness. The visible-light-curing prepreg material can be cured within 5 minutes under the single-side irradiation of visible light, and the once-time photocuring thickness can reach 10mm or above, thereby basically solving the problems of poor operability, poor safety and insufficient film thickness under ultraviolet light. The visible-light-curing prepreg can be subjected to mass application in the field of structure repair.

Owner:四川远鸣科技有限公司

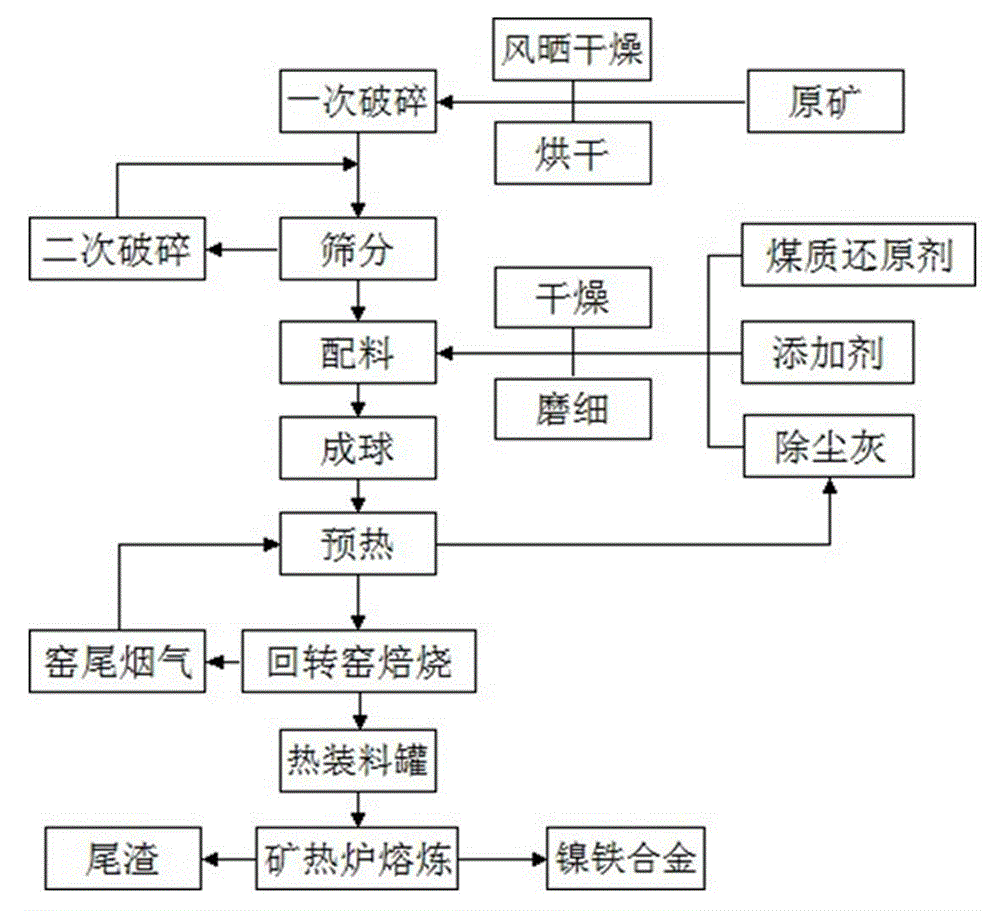

Production technology for smelting ferronickel from laterite-nickel ore

InactiveCN104451148AReduce the content of harmful substancesLow temperature requirementRotary kilnLaterite

The invention discloses a production technology for smelting ferronickel from laterite-nickel ore, belongs to the technical field of ferronickel smelting, and solves problems that existing technologies for smelting the ferronickel from the laterite-nickel ore are low in nickel recovery rate and higher in energy consumption. The production technology comprises steps as follows: (1) drying, crushing, screening and then mixing the laterite-nickel ore, additives and a reducing agent in the mass ratio of 100:(13-25):(10-20) respectively to obtain spheres with the particle size ranging from 30-50 mm; (2) preheating and then sending the spheres into a rotary kiln at the temperature of 1150-1250 DEG C for high-temperature reducing roasting for 4-8 h to obtain reduced roasted ore; (3) sending the reduced roasted ore and a smelting aid into an electric furnace for smelting at the temperature of 1500-1650 DEG C for 2-3 h to obtain a finished product, that is, the ferronickel. According to the production technology, RKEF (rotary kiln-electric furnace) and direct reduction are combined, multiple additives are used, the recovery rate is high, and the energy consumption is low.

Owner:偏关县晋电化工有限责任公司

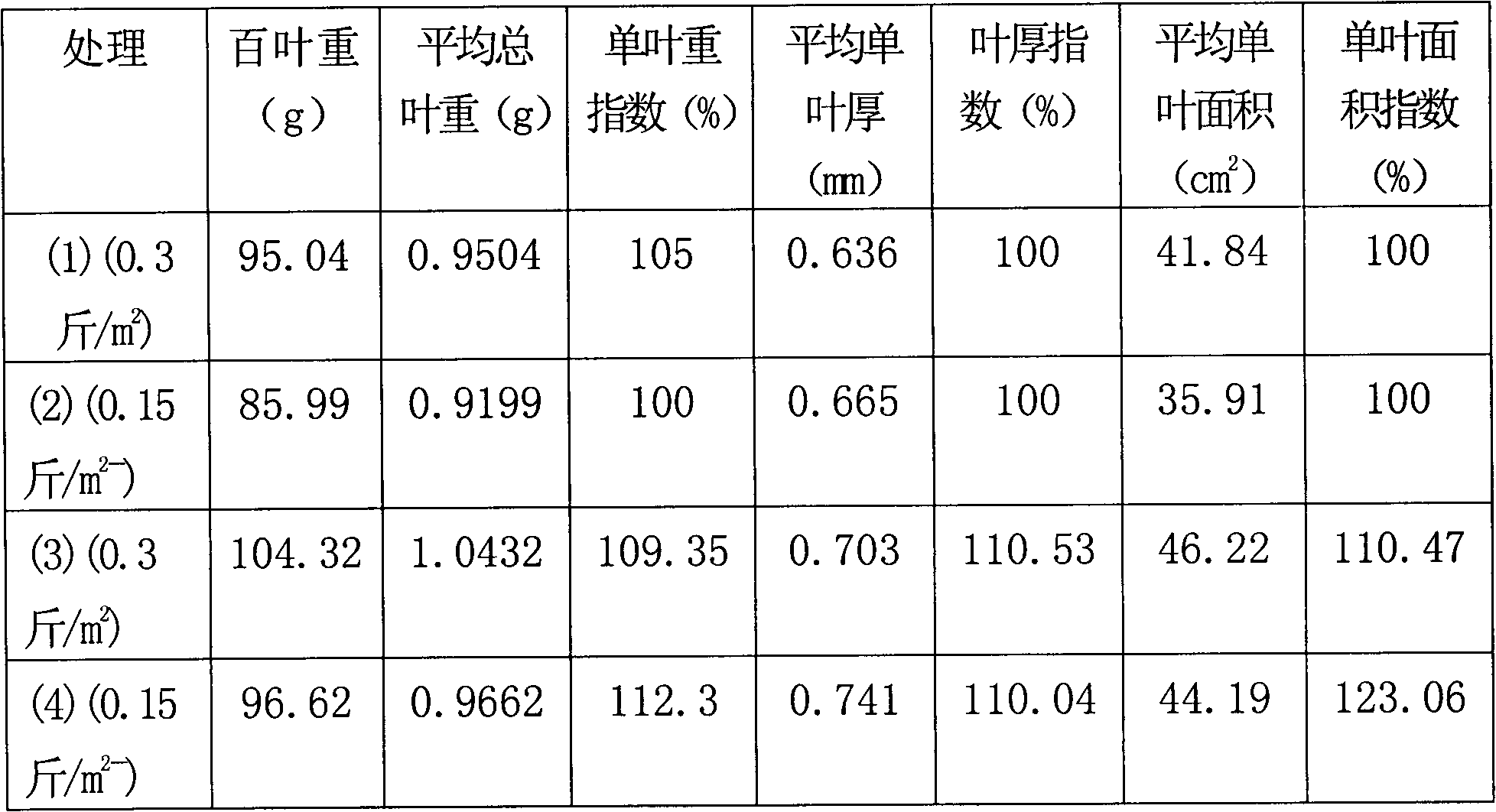

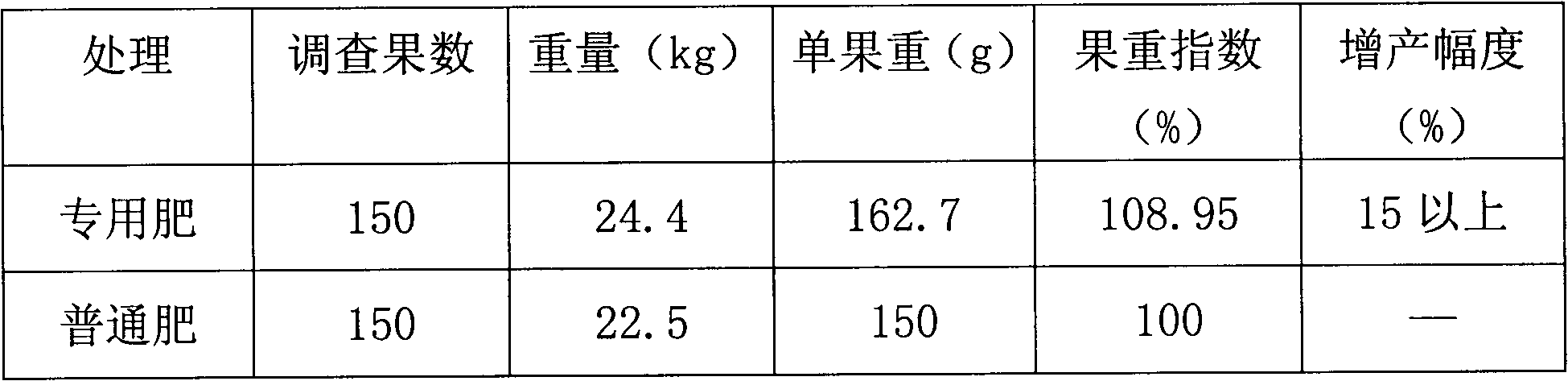

High-quality cultivation method for snakegourd fruit in northern Anhui province

InactiveCN105815083AStimulation and effectEnhancement and effectCalcareous fertilisersMagnesium fertilisersSoil treatmentPhacus

The invention discloses a high-quality cultivation method for a snakegourd fruit in the northern Anhui province. The method comprises the following steps: (1) root tuber treatment; (2) soil treatment; (3) seedling management; (4) final-period management; (5) harvesting and processing; and (6) overwinter management. The cultivation method is scientific and reasonable; the soil quality can be significantly improved; the seedling survival rate of the snakegourd fruit can be improved; the stress resistance of the snakegourd fruit plant is enhanced; the snakegourd fruit planted by the cultivation method can bear fruit in the same year; the requirements of the snakegourd fruit on the nutrients in the whole growth stage can be met only by applying a special fertilizer for the snakegourd fruit once a year; the quality and the yield of all snakegourd fruits are obviously improved; and good planting benefits can obtained.

Owner:杨立显

Volatile organic waste gas treatment process and treatment equipment used in treatment process

InactiveCN105709559AReduce the content of harmful substancesLow running costGas treatmentDispersed particle separationHazardous substanceDirect combustion

The invention discloses a volatile organic waste gas treatment process and treatment equipment used in the treatment process. Deep-cool nitrogen released from a liquid nitrogen storage tank exchanges heat with organic waste gas in a first treater and a second treater, the temperature of organic waste gas can be reduced to be lower than the freezing point due to low temperature of nitrogen, the organic waste gas is attached to the inside of condensing equipment, volatile organic compounds such as benzene, methylbenzene, xylene and the like in the organic waste gas are liquefied to flow out through switching of ventilation and heating and are combusted as fuel, and the purpose of removal of harmful substances in the organic waste gas is achieved. The treatment process has the advantages as follows: 1, the investment is small, and the operation cost is low; 2, the content of harmful substances in exhausted gas is reduced, and the effect of up-to-standard release is realized; 3, in combination of direct combustion, condensed substances can be combusted without other fuel, the energy is saved, and the operation cost is effectively reduced.

Owner:惠州市盛和化工有限公司

Biochemical fertilizer for organic crops and production method thereof

ActiveCN104311363ASimple processEasy to useAmmonium salt fertilisersOrganic fertilisersRare earthAmino acid

The invention discloses a biochemical fertilizer for organic crops and a production method thereof. The biochemical fertilizer for organic crops comprises the following components in parts by weight: 20-45 parts of carbon phosphorus potassium, 10-25 parts of organic fertilizer ferment, 25-35 parts of humic acid, 20-30 parts of polyaspartic amino acid, 15-25 parts of calcium magnesia phosphate fertilizer, 25-45 parts of dicyandiamide, 10-45 parts of ammonium molybdate heptahydrate, 10-35 parts of plant additive, 20-45 parts of soil conditioner, 10-15 parts of peptone, 20-35 parts of granular urea and 5-10 parts of rare earth additive. The biochemical fertilizer for organic crops solves problems of fertilizer selection, fertilizer matching, fertilizer application area, plant fertilizer application amount recalculation, control on fertilizer application amount and the like which are met by people, has the characteristics of simple technique, favorable use effect and the like, and is especially suitable for fertilizer application for organic crops. The biochemical fertilizer for organic crops is beneficial to upgrading soil organic matters, activating the original humus, enhancing the replacement amount of soil cations, enhancing the soil activity and improving the soil absorbability, and has obvious effect on shock-absorbing capacity.

Owner:赣州金秋农林开发有限公司

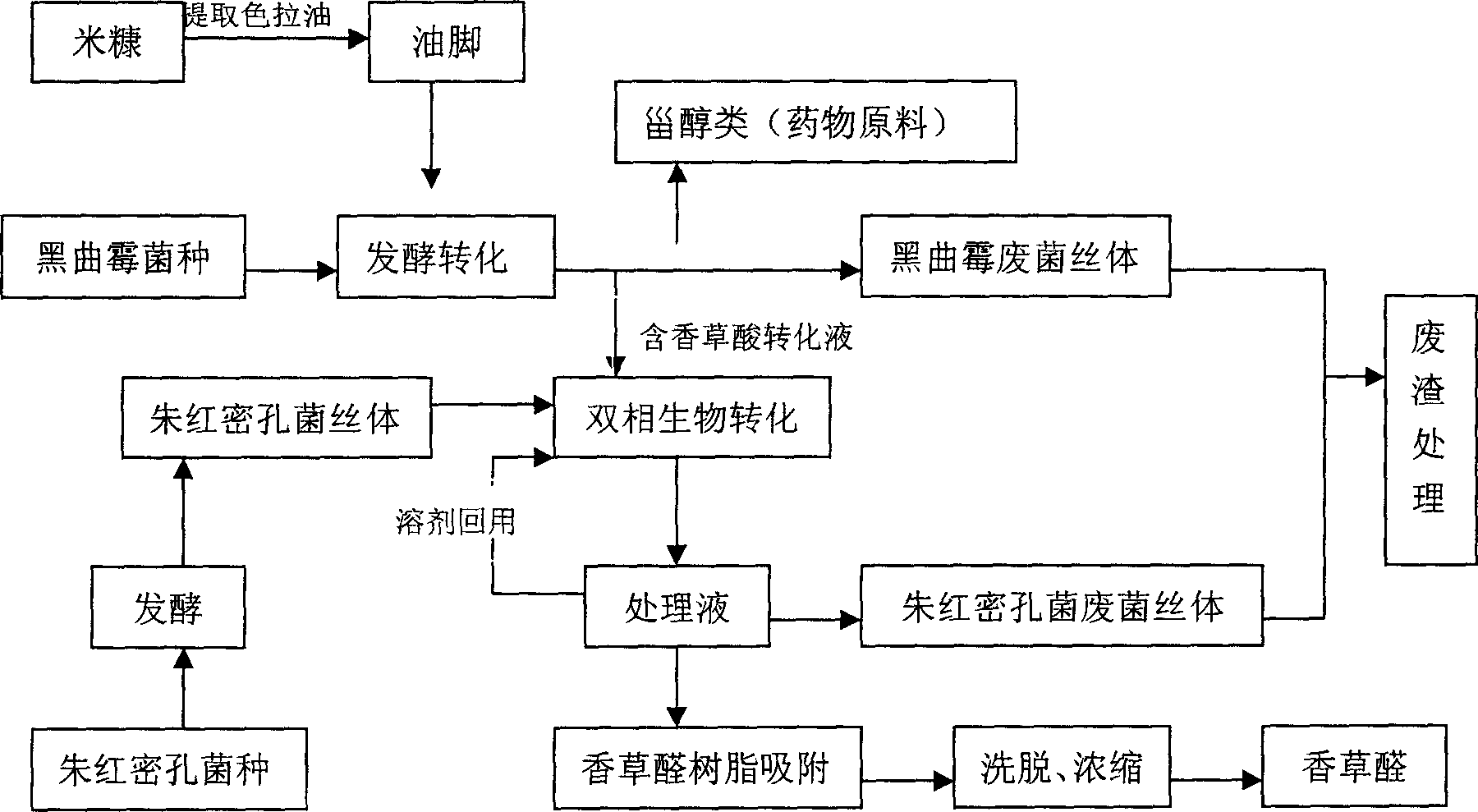

Process for producing vanillic acid and vanillic aldehyde by fermentation transforming bran foots

InactiveCN1824783AAlleviate the shortage of petrochemical resourcesReduce pollutionMicroorganism based processesFermentationChemical synthesisMicroorganism

The present invention provides a method capable of using wastes (oil foot) produced in the course of processing rice husk oil as raw material and utilizing microbial fermentation conversion process to produce vanillic acid and vanillic aldehyde. Said method is characterized by that it utilizes Aspergillus niger CGMCC 0774 to hydrolyze ferulic acid ester in rice husk oil foot to produce ferulic acid, and convert it into vanillic acid, then utilizes another Pycnoporuscinnabarinus CGMCC 1115 to convert the vanillic acid into vanillic aldehyde.

Owner:JIANGNAN UNIV +1

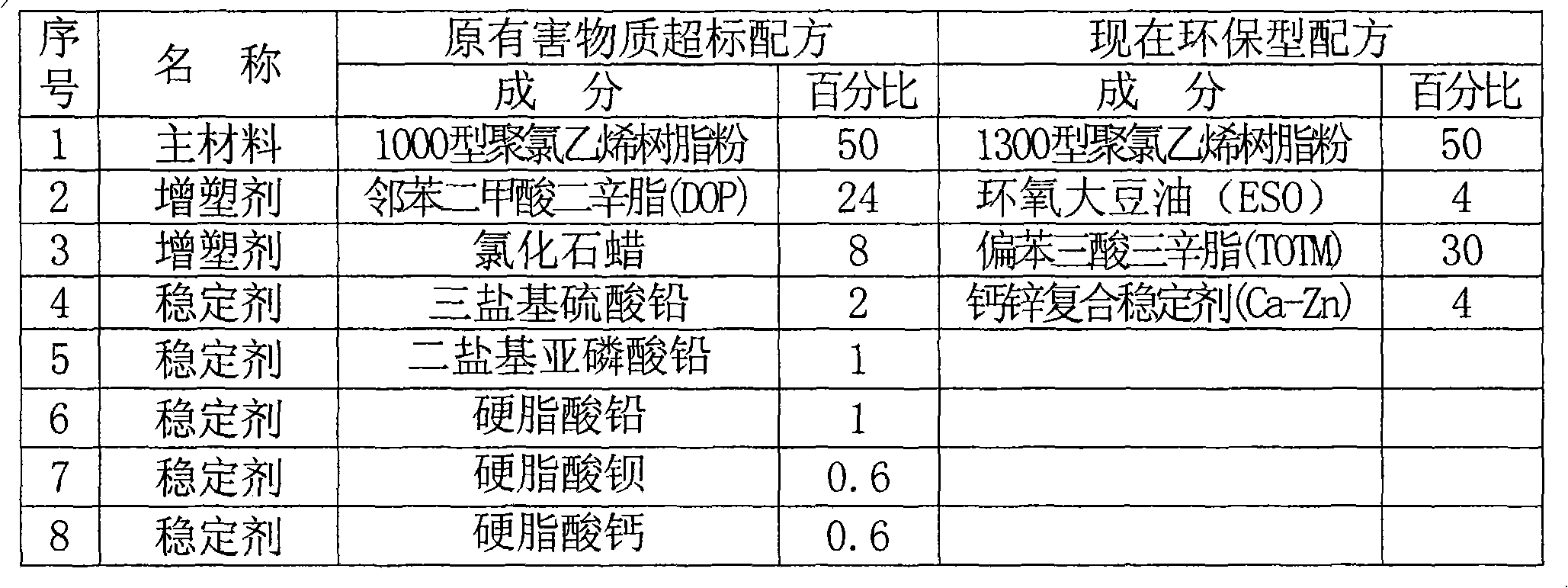

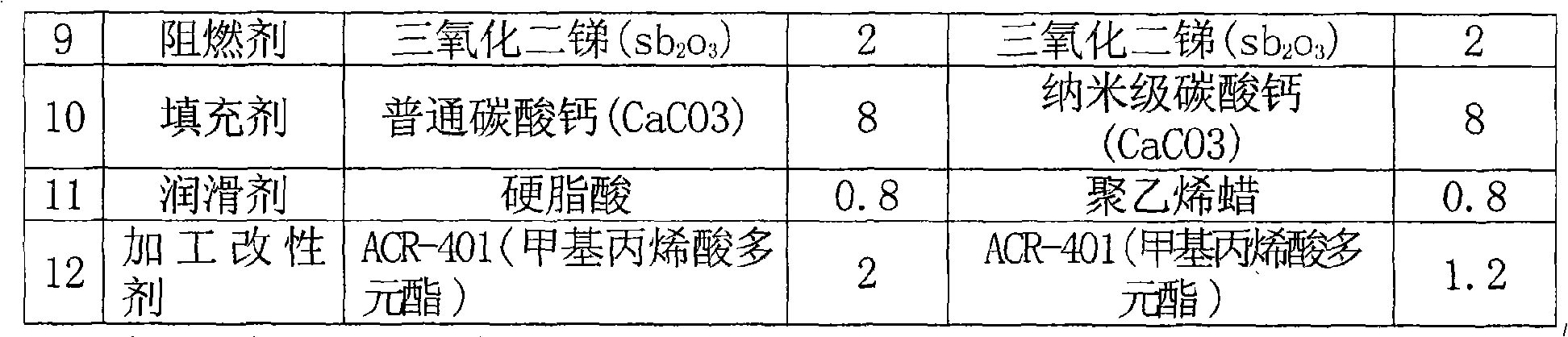

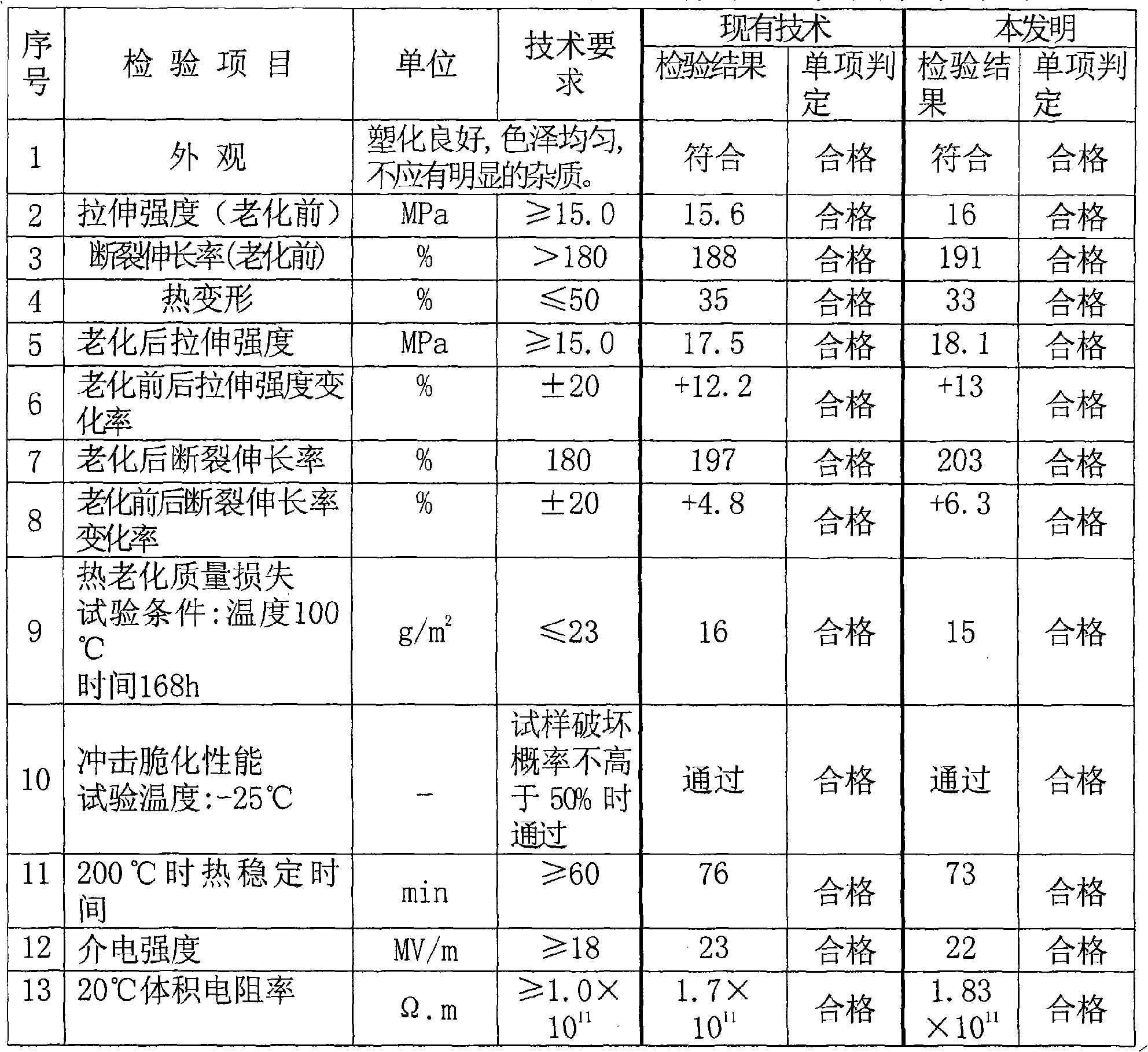

Polyvinyl chloride plastics specifically used for environment-friendly household power wire

InactiveCN101555338AMeet environmental protection requirementsGood physical propertiesPolyesterHazardous substance

The invention relates to a polyvinyl chloride plastics specifically used for an environment-friendly household power wire, which contains components with the following weight contents: 50 percent of 1300-type polyvinyl chloride resin powder, 4 percent of plasticizer-epoxidized soybean oil (ESO), 30 percent of plasticizer-trioctyl trimellitate (TOTM), 4 percent of Ca-Zn complex stabilizer (Ca-Zn), 2 percent of flame retardant-diantimony trioxide (Sb2O3), 8 percent of filling agent-nanoscale calcium carbonate (CaCO3), 0.8 percent of lubricant-polyethylene wax, and 1.2 percent of processing modifier-methacrylic acid polyester (ACR-401). On the premise of guaranteeing the excellent physical performance of the existing polyvinyl chloride plastics, the content of harmful substances thereof is in accordance with the latest rule of EU ROHS instruction and special environmental protection requirements of part top-ranking home-appliance producers in the world on the household power wire.

Owner:跃华控股集团有限公司

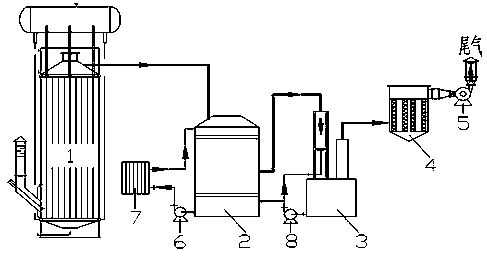

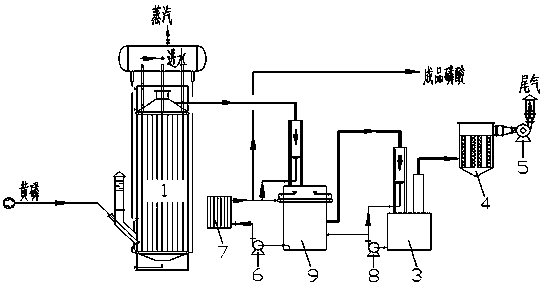

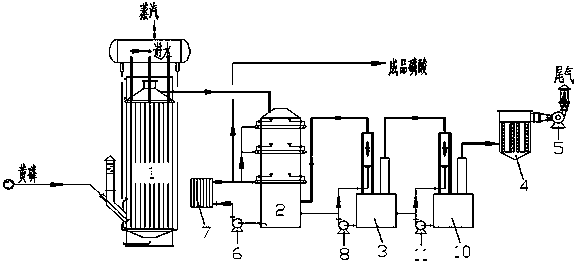

Phosphoric acid production device by employing hot method

ActiveCN104261370AReduce resistanceEmission reductionChemical industryCondensed phosphoric acidsVapor–liquid separatorCombustion

The invention discloses a phosphoric acid production device by employing a hot method, and belongs to the technical field of energy-saving technologies of phosphoric acid production by employing a hot method. The device comprises a combustion tower, an absorption tower, a dynamic wave demister, a gas-liquid separator and an induced draft fan, wherein the combustion tower is communicated with the inlet in the top of the absorption tower; the absorption tower is connected with the dynamic wave demister; the dynamic wave demister is communicated with the induced draft fan through the gas-liquid separator; meanwhile, the absorption tower is connected with a heat exchanger through an absorption tower circulating pump; the heat exchanger is communicated with the absorption tower to form a loop through a pipeline; and the dynamic wave demister and a demister circulating pump form a loop through a pipeline. According to the device, the resistance of the system is reduced, the dosage of circulating acid and circulating water is lowered, the installed capacity of the system is greatly lowered, energy conservation and consumption reduction are achieved, the production capacity of the system is improved, and the device has the characteristics of low investment cost, small floor area, low power consumption, low production cost, and low coal resource and water resource consumption.

Owner:KUNMING UNIV OF SCI & TECH

Method for rapid composting by combining sludge of different types

InactiveCN102649647AReasonable C/NOptimize composting conditionsBio-organic fraction processingOrganic fertiliser preparationEcological environmentMunicipal sewage

The invention relates to a novel method for rapid composting by combining sludge of different types. The method is realized by three main steps, namely mixed blending, aerobic fermentation and discharging and storing. According to the method, the aerobic composting is realized by combining sludge from urban sewage treatment plants, sludge from wastewater treatment plants of beer enterprises and furfural residue discharged by furfural enterprises and particularly parameters of initial composting are adjusted by using the characteristics of different sludge and acidic furfural residue. The novel method has the advantages of reducing the ecological environment risk, increasing nutritive substances of composting products, reducing the cost of the composting, realizing rapid composting without adding extra microbe consortium and the like.

Owner:JILIN NORMAL UNIV

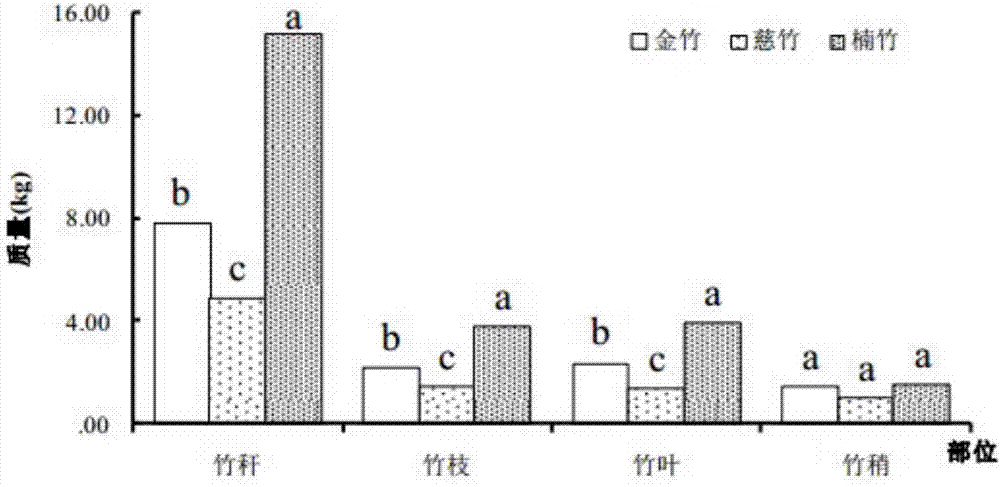

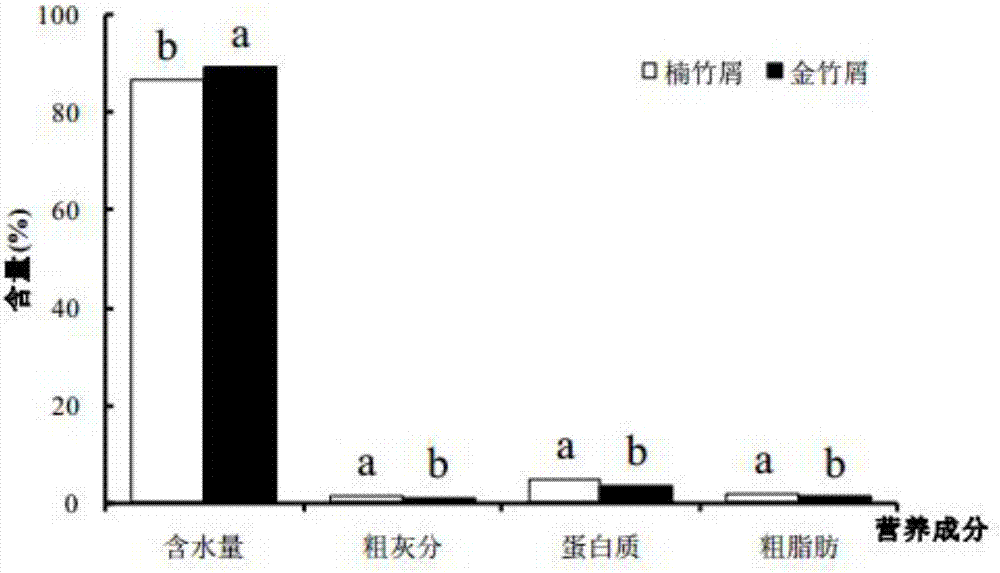

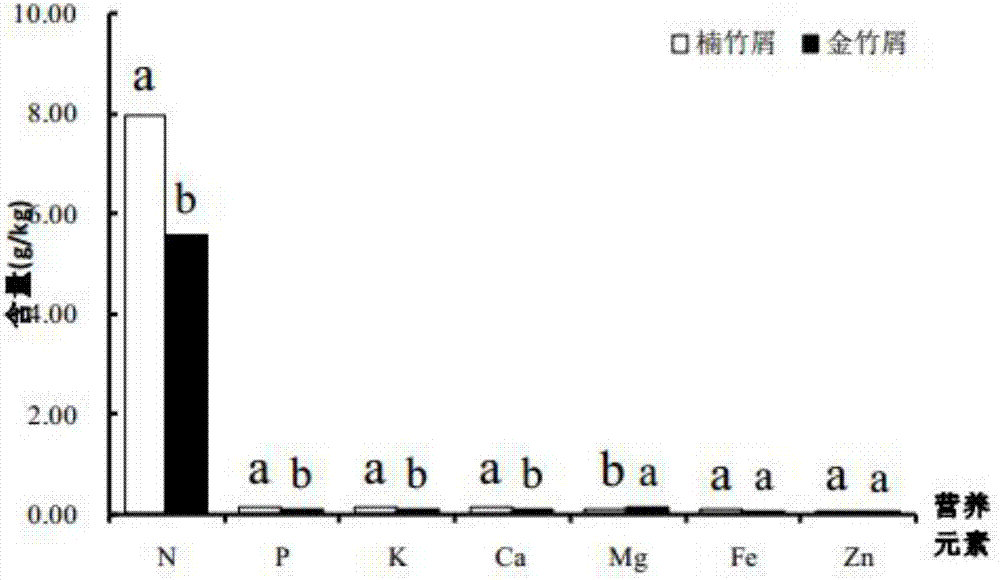

Method for utilizing bamboo forest waste to product edible mushrooms

InactiveCN106856992AIncrease profitReduce processing costsCalcareous fertilisersMagnesium fertilisersEdible mushroomOrganic fertilizer

The invention discloses a method for utilizing bamboo forest waste to product edible mushrooms. The method comprises the steps of choosing a strain mushroom, separating and purifying a strain, and conducting preparation to obtain a mother strain; preparing a mother strain culture medium, and inoculating the mother strain for culture without bacteria; conducting original strain culture; conducting cultivated strain culture; conducting spawn running period management; conducting mushroom producing period management; harvesting. The culture medium of the cultivated strain is obtained through preparation utilizing the bamboo forest waste. According to the method, the bamboo forest waste is utilized to produce the edible mushrooms, not only are bamboo forest resources fully utilized, but also the production cost of the edible mushrooms is lowered; meanwhile, edible mushroom cultivation waste materials can be converted into an organic fertilizer, the problem that the bamboo forest waste pollutes the environment is effectively solved, and circular and progressive development of bamboo industry economy is achieved.

Owner:SOUTHWEST UNIVERSITY

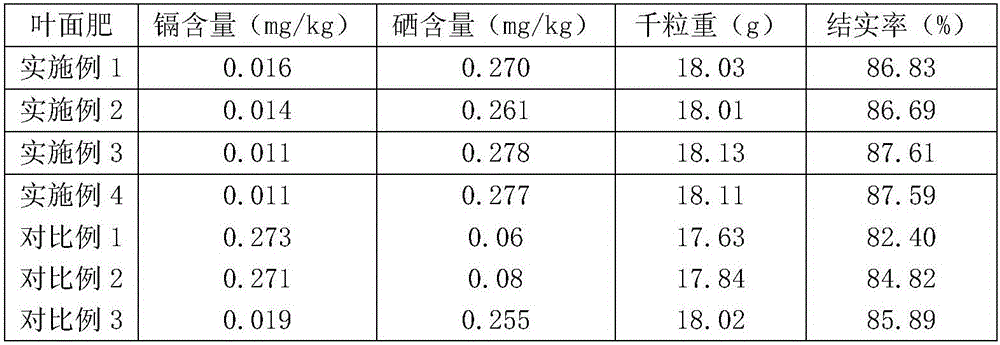

Selenium-rich cadmium-reducing leaf fertilizer special for paddy

ActiveCN106748274AIncrease selenium contentReduce the content of harmful substancesAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPotassiumMonopotassium phosphate

The invention belongs to the technical field of a paddy planting fertilizer and specifically relates to a selenium-rich cadmium-reducing leaf fertilizer special for paddy. The selenium-rich cadmium-reducing leaf fertilizer special for paddy is composed of citric acid monohydrate, sodium selenite, urea, potassium chloride, monopotassium phosphate, soluble microelement compound, momordica grosvenori and herb of alligator alternanthera. The leaf fertilizer can increase the absorbing conversion rate of the paddy for selenium, has an excellent cadmium-impeding performance, is rich in nutrition and is easily absorbed. After the fertilizer is applied to the paddy, the selenium-rich cadmium-reducing efficiency of the leaf fertilizer is higher, the effect is stable and the yield of the paddy is high.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

Rubber material for agriculture vehicle tire

InactiveCN104403140AHigh tensile strengthHigh tear strengthSpecial tyresRubber materialAluminium hydroxide

The invention discloses a rubber material for agriculture vehicle tires. The rubber material is prepared from the following raw materials in parts by weight: 40-50 parts of natural rubber, 10-14 parts of epoxy natural rubber, 15-20 parts of silicon dioxide, 2-4 parts of a silane coupling agent, 20-30 parts of brominated butyl rubber, 20-30 parts of superfine glass bead, 30-40 parts of carbon black N660, 20-30 parts of light calcium carbonate, 1-2 parts of tetramethyl thiuram disulfide, 1-2 parts of diisopropylbenzene peroxide, 2-3 parts of N-cyclohexyl-2-benzothiazole sulfonamide, 2-4 parts of zinc oxide, 1-2 parts of an accelerant DM, 0.5-1.0 part of an accelerant CZ, 1-2 parts of N-phenyl-N'-(1,3-dimethyl)-p-phenylenediamine, 1-2 parts of 2,2'-methylene-bi(4-methyl-6-tertiary butyl phenol), 1-2 parts of petroleum oil, 2-5 parts of stearic acid, 1-2 parts of protecting wax OK5194, 5-6 parts of rubber tackifying resin A-90, 5-8 parts of antimonous oxide, 5-10 parts of molybdenum trioxide and 20-30 parts of aluminium hydroxide.

Owner:QIAOJIAN NEW ENERGY TECH SUZHOU

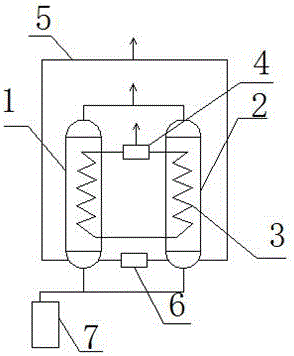

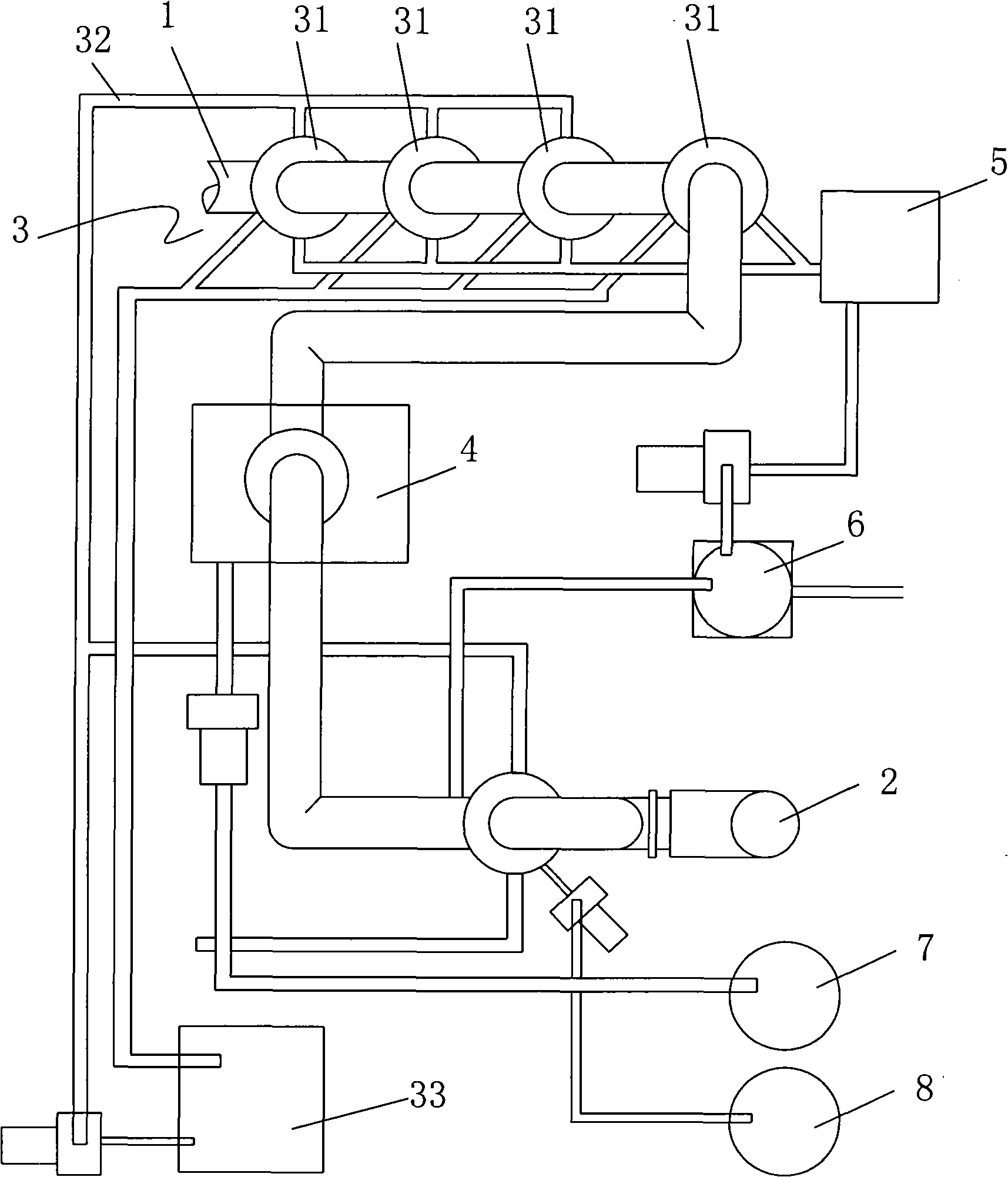

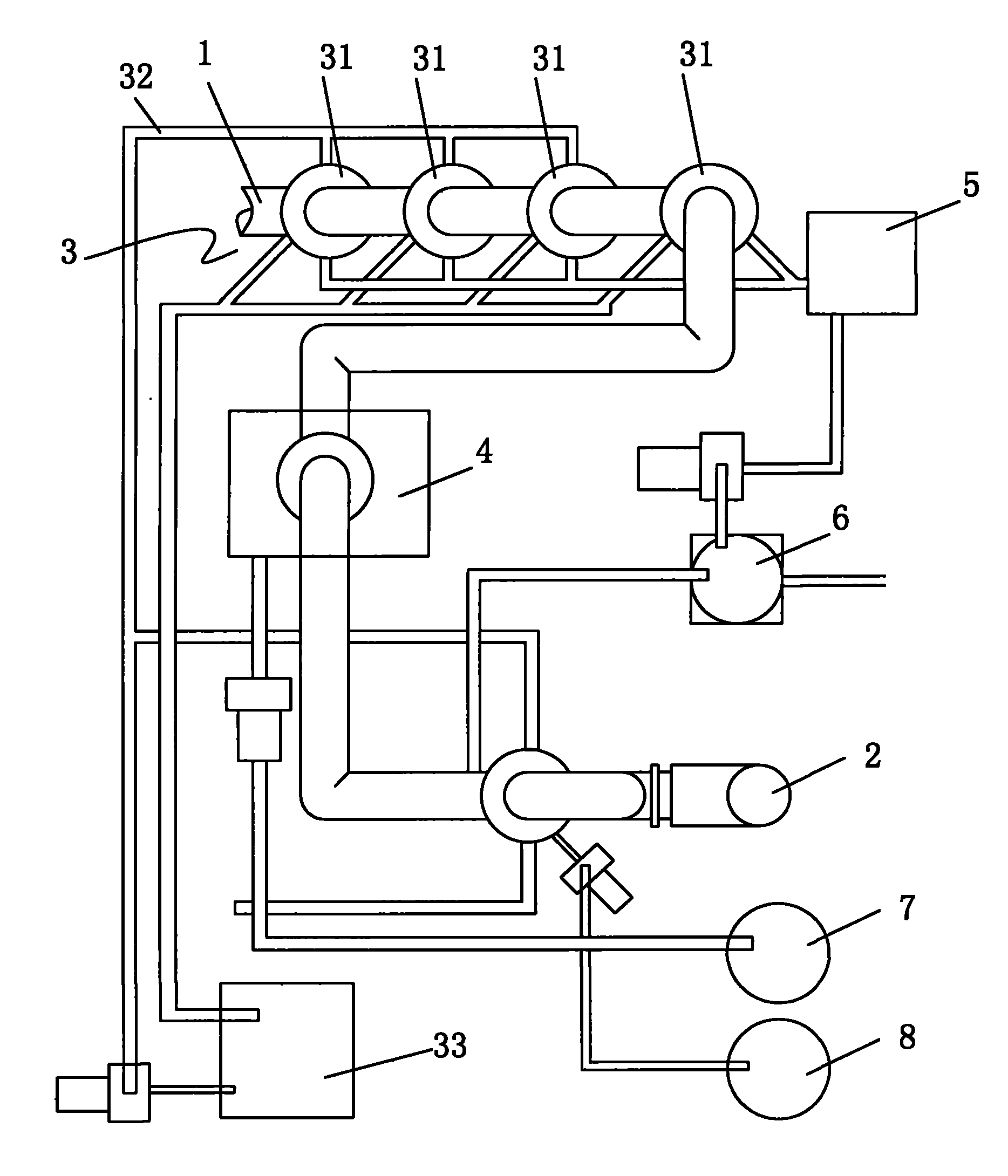

Treating and recycling method of tail gas generating in sulfonated naphthaldehyde water reducing agent production and special equipment

ActiveCN101797471ALow costImprove recycling ratesDispersed particle separationVapor condensationHazardous substanceDistillation

The invention discloses a treating and recycling method of tail gas generating in sulfonated naphthaldehyde water reducing agent production and special equipment thereof. The method comprises the steps of: a, condensation; b, neutralization; c, distillation; and d, recovery of condensed and uncollected gas after spraying. The equipment comprises an intake pipe and an air outlet, both of which are connected with an outlet of tail gas generating in the sulfonated naphthaldehyde water reducing agent production, wherein a condensation kettle and a spray tower are sequentially connected between the intake pipe and the air outlet, the condensation kettle is sequentially connected with a recovery liquid bath and a distillation kettle through a pipeline, the spray tower is communicated with a first regulating tank by a pipeline, and the distillation kettle is communicated with a second regulating tank by a pipeline. The invention more completely processes harmful materials in the tail gas, basically eliminates naphthalene and acidic harmful gases, and reduces the environment pollution caused by the tail gas; the recycled liquid can be reused in the sulfonated naphthaldehyde water reducing agent production, the recovery rate of the tail gas is higher, and the cost of the sulfonated naphthaldehyde water reducing agent production is further reduced.

Owner:广西红墙新材料有限公司

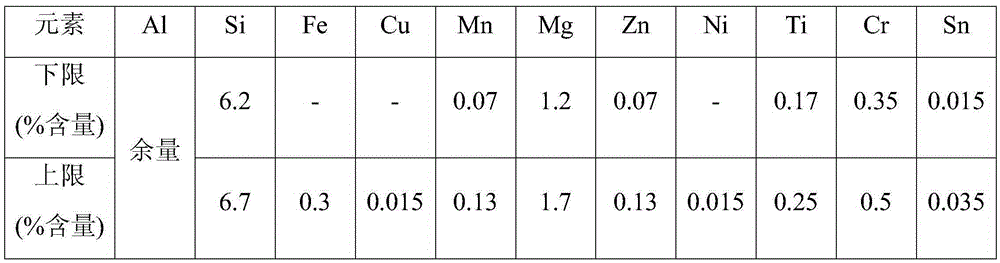

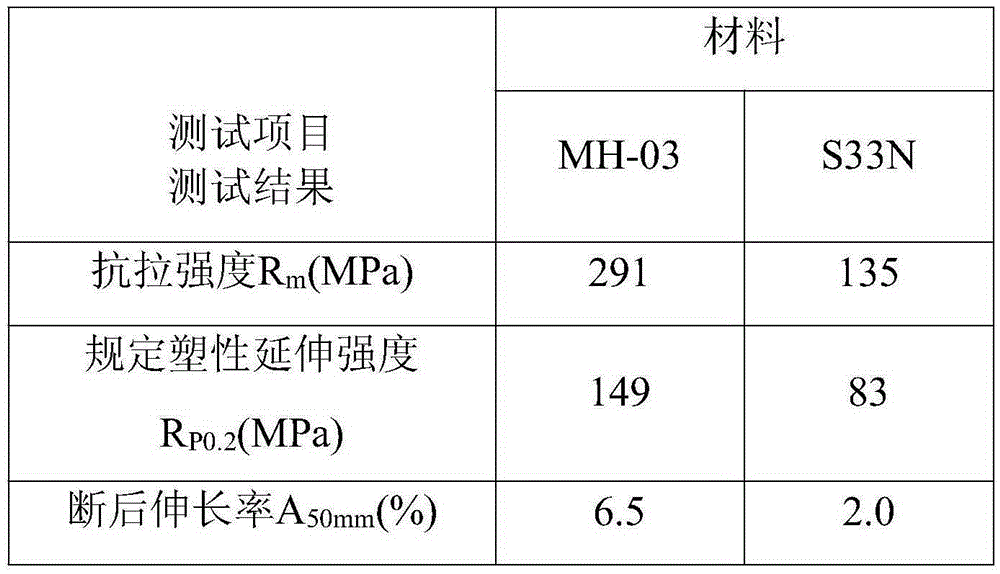

High-end aluminium alloy material MH-03 and preparation method thereof

The invention discloses a high-end aluminium alloy material MH-03. The high-end aluminium alloy material MH-03 comprises the following components: 89.0-91.0% of Al, 1.8-3.5% of Si, less than 0.50% of Fe, less than 0.2% of Cu, 0.55-1.0% of Mn, 4.8-6.5% of Mg, less than 0.3% of Cr, less than 0.07% of Ni, 0.05-0.1% of Zn, less than 0.2% of Ti, less than 0.005% of Bi, less than 0.002% of Ca, less than 0.1% of Pb, less than 0.05% of Sn, less than 0.005% of Bi, and less than 0.001% of Cd. The high-end aluminium alloy material MH-03 disclosed by the invention has higher tensile strength, specified plastic extension strength, percentage elongation after fracture, elasticity modulus and Brown hardness; the content of harmful substances is extremely low, and far lower than the limit value of 2001 / 65 / EU instructions; and the high-end aluminium alloy material MH-03 is simple in preparation process, and suitable for mass production.

Owner:深圳市鑫雅豪智能科技股份有限公司 +1

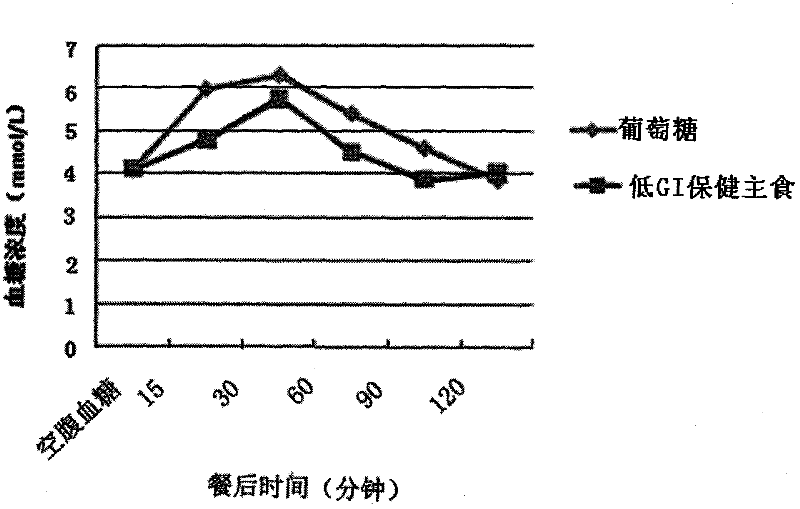

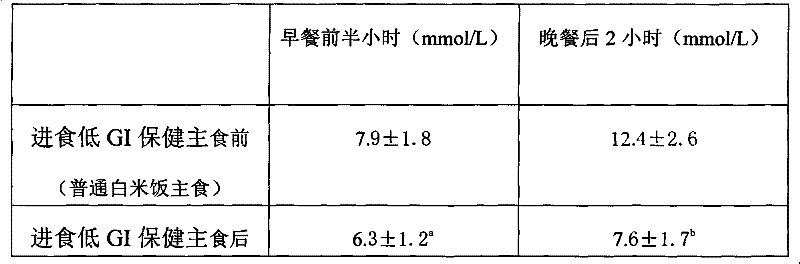

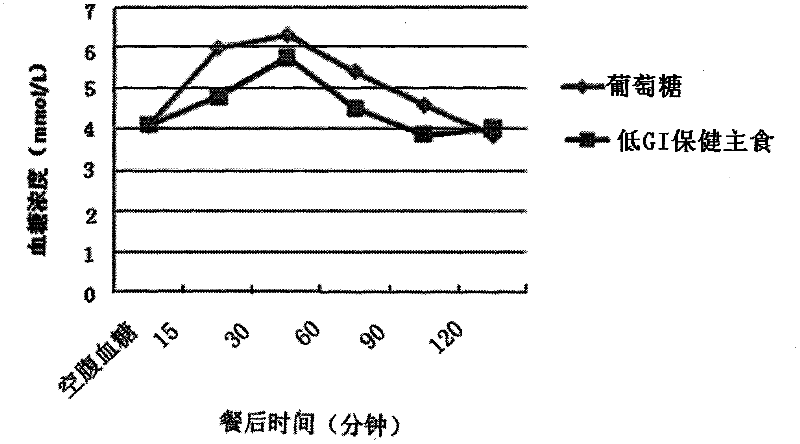

Health staple food with low glycemic index, its preparation method and application in blood sugar reduction

InactiveCN102204650AReduce the content of harmful substancesReduce secondary damageFood preparationDiseaseLow glucose

The invention relates to a health staple food capable of reducing postprandial blood sugar, and also relates to a preparation method of the health staple food and its application in reducing blood sugar. The health staple food with a low glycemic index comprises, by weight, 51-61% of rice, 16-26% of peanut kernel, and 18-28% of peeled mung bean. With organic food as the raw material, the health staple food of the invention is totally prepared with a physical processing method, without any harmful components added. No natural nutritious component in the raw material can be damaged. As a pollution-free green food, the health staple food of the invention integrates nutrition, diseases prevention and disease curing, thus ushering in the application prospect of coarse cereal food. And the application value of coarse cereals is enhanced, with remarkable economic benefit and social benefit. With a low glycemic index, the integrated staple food provided in the invention plays a role in reducing postprandial blood sugar, reducing glycated hemoglobin, and has certain effect on fat-reducing, thus being significant to diabetic patients.

Owner:胡任飞

Environmental-friendly waterborne coating for building inner wall decoration and preparation process of environmental-friendly waterborne coating

InactiveCN104263155AGood coating performanceReduce the content of harmful substancesAntifouling/underwater paintsCellulose coatingsCelluloseKaolin clay

The invention discloses an environmental-friendly waterborne coating for building inner wall decoration. The environmental-friendly waterborne coating is prepared from the raw materials in parts by weight: 20-40 parts of deionized water, 0.3-0.5 part of cellulose, 0.5-1.0 part of a wetting dispersant, 0.1-0.3 part of a defoamer, 0.1-0.2 part of a pH regulator, 2-8 parts of titanium dioxide, 5-8 parts of kaolin, 10-15 parts of light calcium carbonate, 5-10 parts of talc, 15-25 parts of heavy calcium carbonate, 8-12 parts of acrylic emulsion, 0.1-0.5 part of a fungicide, 1-2 parts of propanediol, 0.5-1.0 part of a film-forming additive and 0.3-0.5 part of a thickener. The environmental-friendly waterborne coating has the characteristics of good coating effect, low harmful matter content, soft smell, low production cost, good stability and long service life.

Owner:安徽铁创新材料科技有限公司

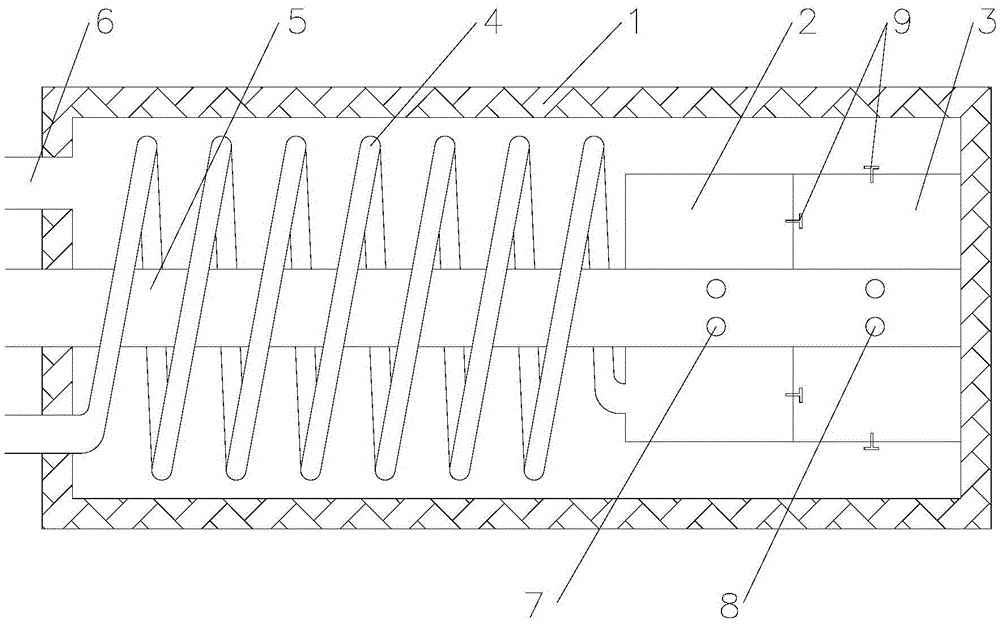

Efficient incinerator

InactiveCN105570909AAchieve preheatingIncreased preheating flow areaIncinerator apparatusCombustion chamberExhaust fumes

The invention relates to an efficient incinerator. A primary combustion chamber and a secondary combustion chamber are arranged at the back end of a furnace chamber; a check valve is arranged between the primary combustion chamber and the secondary combustion chamber; an air pipe is arranged in the center of an inner cavity of a furnace shell, enters the furnace chamber from the front end of the furnace shell and penetrates through the primary combustion chamber and the secondary combustion chamber; a first air inlet is formed in the pipe wall of the air pipe in the primary combustion chamber; a second air inlet is formed in the pipe wall of the air pipe in the secondary combustion chamber; the secondary combustion chamber is communicated with the furnace chamber through the check valve; a waste gas pipe enters the furnace chamber from the front end of the furnace shell, is communicated with the primary combustion chamber, is in a spiral shape and is arranged outsides the air pipe; and an exhaust hole is formed in the front end of the furnace shell. According to the efficient incinerator disclosed by the invention, with the arrangement of two combustion chambers, waste gas is fully combusted, so that content of harmful substances in the exhausted gas is lowered, and environmental pollution is reduced; and gas after being combusted flows through the exterior of the air pipe and the waste gas pipe, so that the waste gas and the air are preheated, the waste is avoided, and the cost is saved.

Owner:CHANGZHOU JINTAN HANGUANG TECH CO LTD

Quick-dissolving fertilizer and preparation method thereof

The invention relates to an organic and inorganic compound fertilizer applied to vegetable production, in particular to a quick-dissolving fertilizer and a preparation method thereof, wherein the quick-dissolving fertilizer comprises the following components in content by weight: 10-50 percent of ammonium nitro-humate, 0-40 percent of urea, 0-10 percent of ammonium nitrate or ammonium sulfate, 0-35 percent of monoammonium phosphate, 0-20 percent of potassium sulfate, 0-5 percent of magnesium sulfate, 0.5-1 percent of zinc sulfate and 0.3-0.8 percent of borax. The fertilizer disclosed by the invention has the effects of improving the structure and texture of soil, improving the soil fertility, improving the ventilation property and the water-retaining property, promoting the propagation and the growth of beneficial microorganisms, improving the stress resistance of crops and enhancing the drought-resisting (water-logging-resisting), cold-resisting and disease-resisting capabilities; and the quick-dissolving fertilizer is an ideal fertilizer for the production base of pollution-free foods.

Owner:施友刚

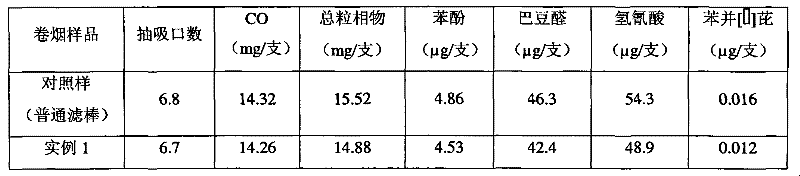

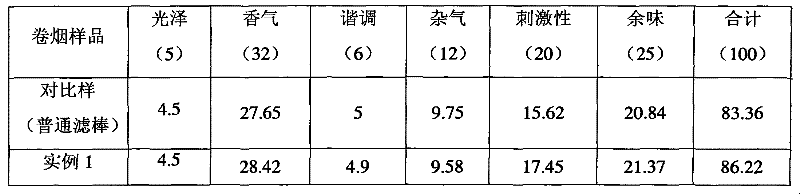

Mint tobacco filter stick and preparation method thereof

ActiveCN101912161BIncrease the amount of aromaImprove the taste of smokingTobacco smoke filtersFiberHazardous substance

The invention discloses a filter material of a cigarette filter stick and a composite filter stick made of the same. The filter material comprises a fiber base material and a plasticizer, wherein a Chinese herbal medicinal mixture of 3 to 4 weight parts of mint and 2 to 3 weight parts of blackberrykiky rhizome and 4 weight parts of tobacco leaf powder particles are added into the fiber base material; the granularity of the mixed particles is 40 to 80 meshes; and the additive amount is that each millimeter of filter stick contains 1.0 to 1.5mg of Chinese herbal medicinal mixed particles. The mint and blackberrykiky rhizome mixed particles are used as the adsorbing material of the functional composite filter stick, and factors such as the additive proportion and additive amount of the mint and the blackberrykiky rhizome, the granularity of the particles, the additive amount of the plasticizer and the like are determined. A cigarette finished product consists of the composite filter stick, cut tobacco and cigarette paper rolls and can effectively reduce harmful substances in smoke, cannot influence the flavor of cigarettes, and has the effects of moistening throat, hydrating, reducing the stimulation of the smoke to the throat and the like.

Owner:CHINA TOBACCO GUANGDONG IND

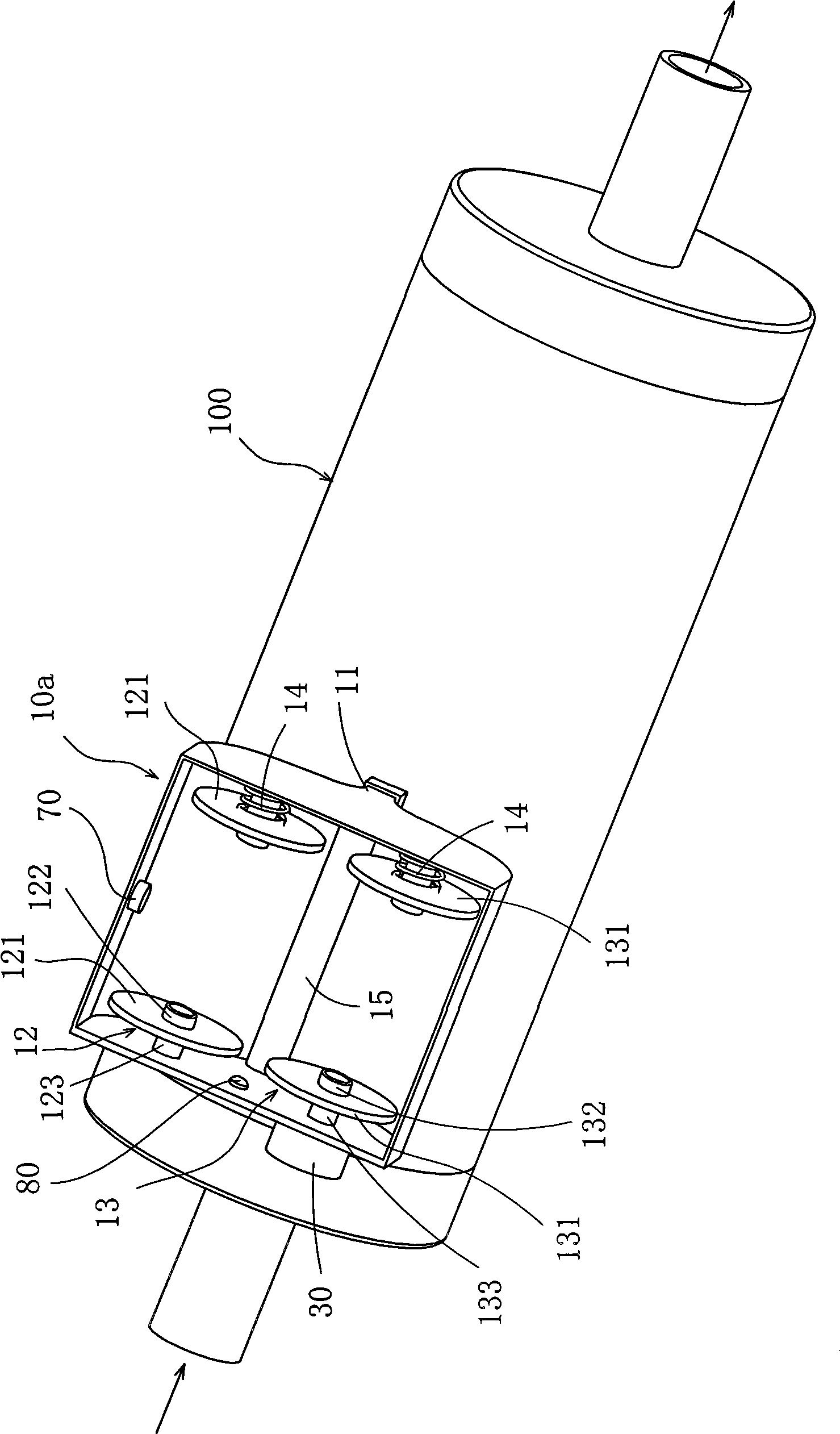

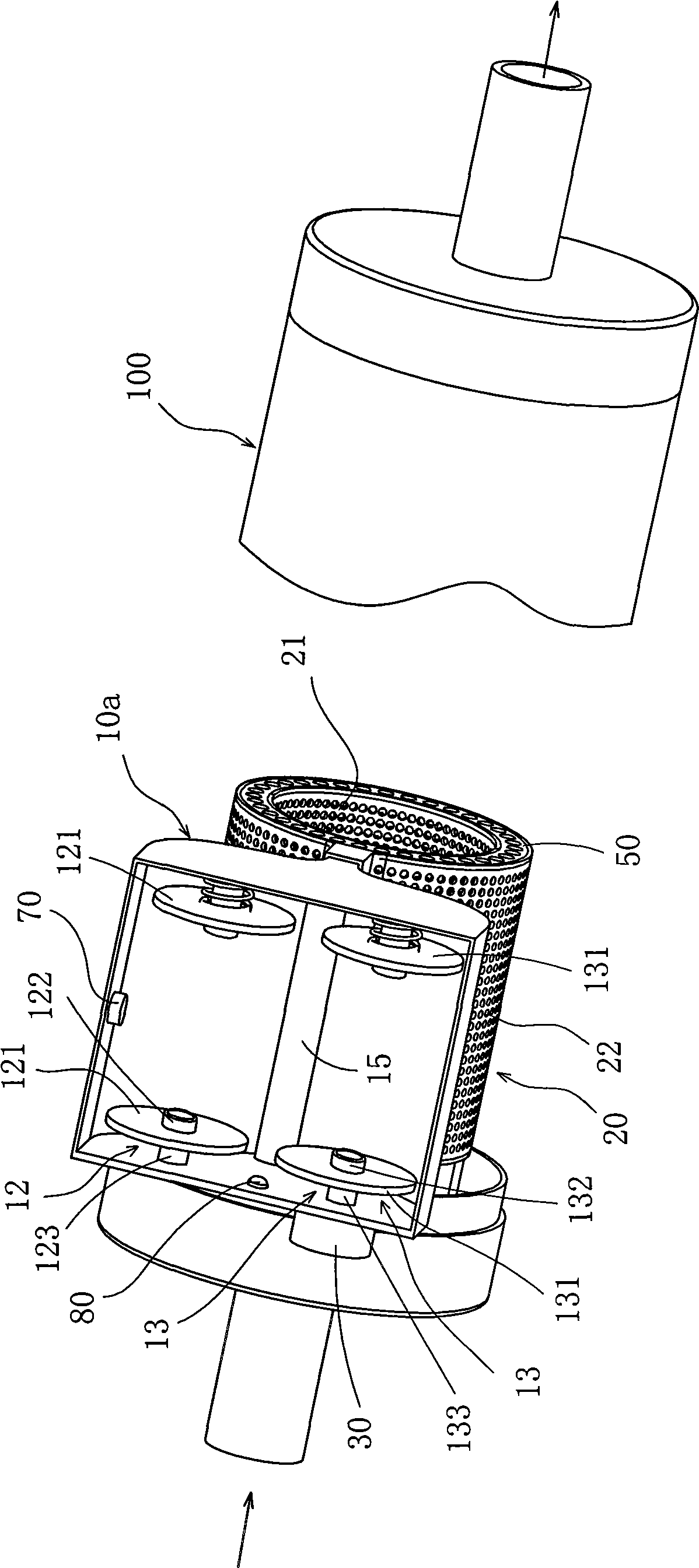

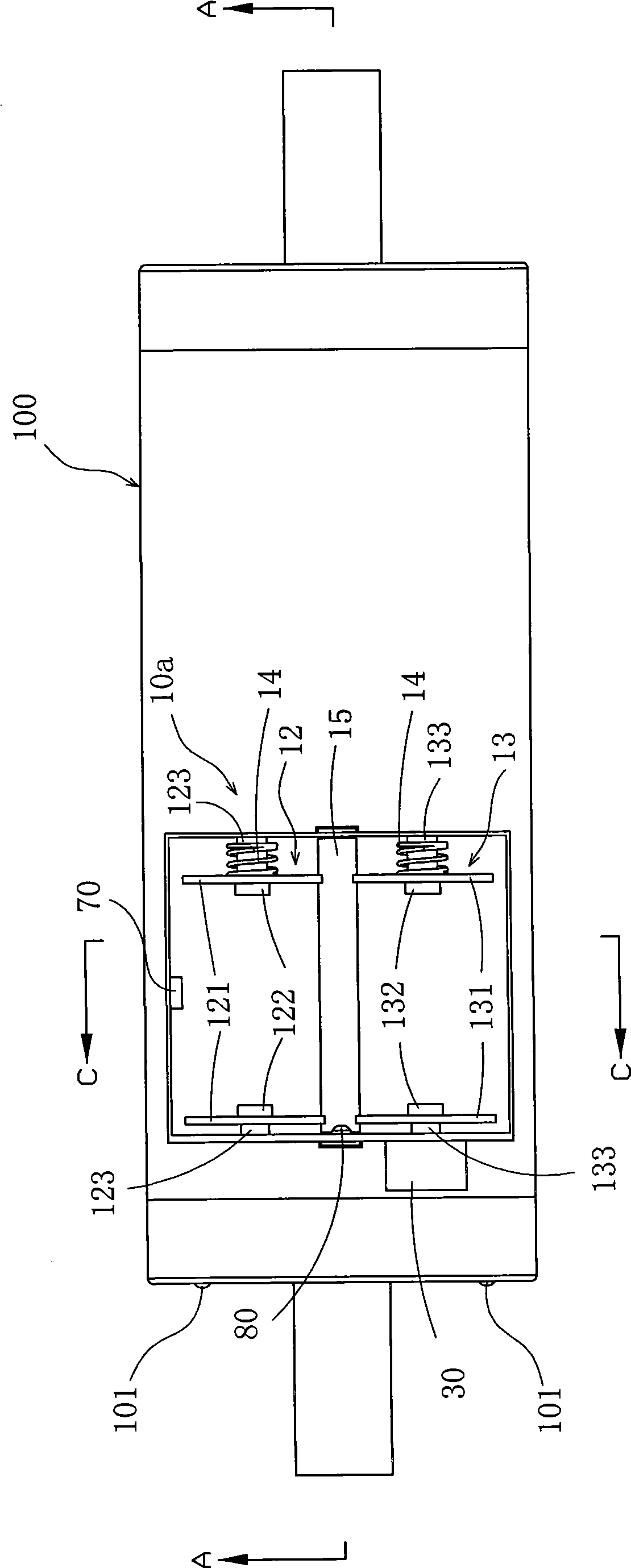

Automobile exhaust purification method and automobile exhaust purification system thereof

InactiveCN101532412AReduce the content of harmful substancesAchieve replacementExhaust apparatusSilencing apparatusActivated carbonPurification methods

The invention relates to an automobile exhaust purification method and an automobile exhaust purification system thereof. The automobile exhaust purification method comprises the following steps of winding one end of activated carbon paper (41) on active and passive carbon paper rolls (42) in tank bodies (10a, 10b), winding the other end thereof on the active carbon paper roll (43), and winding the part between the two ends on a paper tallying tube (20) on an exhaust channel in an automotive muffler tube (100); when the activated carbon paper adsorbs and is saturated with harmful substances, rotating the active carbon paper roll (43), correspondingly rolling the old activated carbon paper on the paper tallying tube (20) onto the active carbon paper roll, simultaneously driving the passive carbon paper roll (42) to rotate by the carbon paper, releasing and rewinding new activated carbon paper on the paper tallying tube, and stopping rotating when winding one circle of new carbon paper on the paper tallying tube; and when completely releasing the new carbon paper on the passive carbon paper roll, replacing the passive carbon paper rolls and the active carbon paper rolls. The invention utilizes the replaceable activated carbon paper to adsorb the harmful substances in exhaust with lasting effect, does not obstruct exhaust emission and noise damping, and the use of the carbon paper does not cause secondary pollution to environment.

Owner:王凯

Bamboo pellet fuel and manufacture method thereof

InactiveCN102120940AHigh combustion valueLow ash contentBiofuelsSolid fuelsHazardous substanceEngineering

The invention relates to a bamboo pellet fuel and a manufacture method thereof, belonging to the technical field of biomass energy utilization. The bamboo pellet fuel is characterized in that raw materials in the fuel at least comprise 60 percent of bamboo bits and the balance of wood bits or straw bits, wherein the water content of the bamboo fuel is less than 10 percent, the combustion value is4-50-4800kcal / kg, the ash content is 1.0-1.5 percent, the sulfur content is not more than 0.06 percent, the density is not less than 1.1g / cm<3> and the accumulation density is not less than 0.68g / cm<3>. The bamboo pellet fuel has the advantages of large combustion value, low ash content and low content of harmful materials. The bamboo pellet fuel has faint scent during the combustion and a function of refreshing and restoring consciousness.

Owner:吴谦

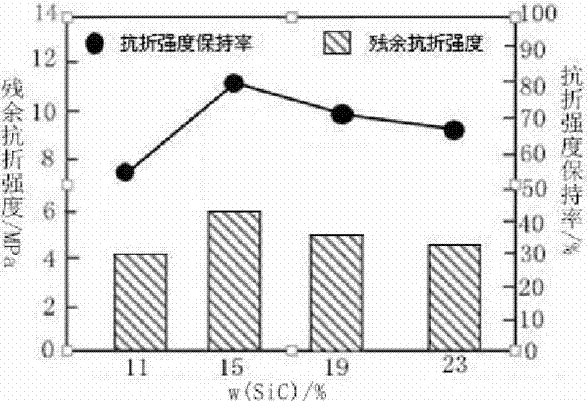

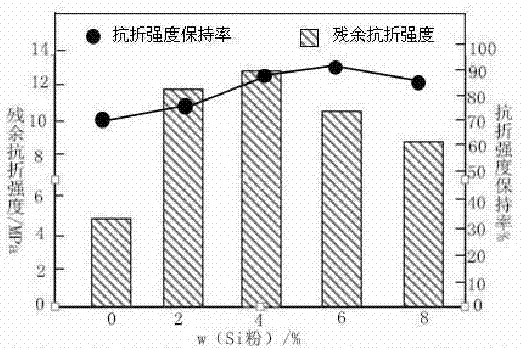

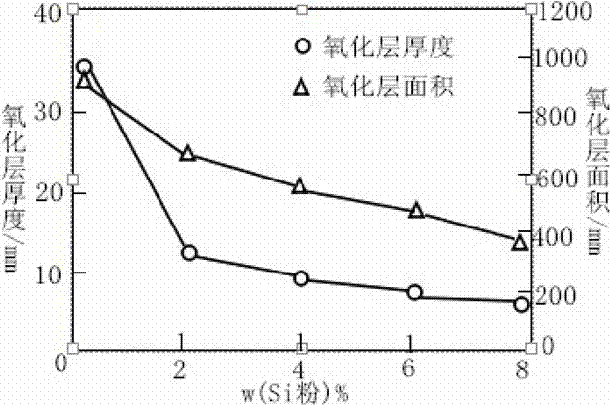

Environment-friendly high-iron-flux baking-free tapping channel ramming material and preparation method thereof

The invention relates to an environment-friendly high-iron-flux baking-free tapping channel ramming material and a preparation method thereof, belonging to the field of refractory materials. The environment-friendly high-iron-flux baking-free tapping channel ramming material is prepared from the following raw materials in parts by weight: 45-55 parts of brown corundum, 19-27 parts of dense corundum, 11-23 parts of SiC, 0-8 parts of Si powder, 0-12 parts of Si3N4, 3-6 parts of active alpha-Al2O3 powder, 1-5 parts of flake graphite and 3-8 parts of a bonding agent, wherein the total parts of all the other raw materials except the bonding agent is 100 parts; the bonding agent comprises the following components in parts by weight: 40-80 parts of carbon-containing resin, 10-40 parts of vegetable oil and fat, 5-15 parts of melamine urea-formaldehyde resin and 2-8 parts of carbon powder. An environment-friendly anhydrous tamping plug disclosed by the invention has the advantages that (1) the anhydrous tamping plug has small content of harmful substances, so that harms to the human body can not be caused; and (2) the anhydrous tamping plug does not have smoke and dust, so that the influence to the environment is small; (3) the anhydrous tamping plug has high iron flux and long service cycle, and can be used for reducing the labor intensity of workers.

Owner:渑池金华新材料有限公司

Method for manufacturing biological diesel oil

InactiveCN101153220ASimple processReduce manufacturing costLiquid hydrocarbon mixture productionBio-feedstockWaste oilPetrochemical

The present invention relates to a manufacturing method of biodiesel, aiming to provide a method used to convert the polluted waste of hogwash oil and waste oil into biodiesel. The steps are that: a. raw oil is deglued and dehydrated through acid cleaning to obtain pure fatty acid; b. the fatty acid is mixed together with sodium hydroxide, biological enzyme used as catalyst and methanol, c. the mixture is added into a reaction vessel, stirred ceaselessly and heated simultaneously, and when temperature rises to 70 DEG C, esterification reaction is completed and fatty acid methyl ester is generated; d. the material after reaction is taken out, and a plurality of bigger particles are filtered out by a filtering machine, thus the pure fatty acid methyl ester can be obtained; e. a part of petrochemical diesel is added into the fatty acid methyl ester extracted out, and the biodiesel can be obtained. The biodiesel manufactured by the present invention can be used for automobiles, steamship, generators and other machines.

Owner:ZHONGSHAN JINSHUANG TECH BIOLOGICAL FUEL DEV CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com