Patents

Literature

74results about How to "Increase stirring power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment friendly low-gas-content aluminum alloy ingot and production method thereof

The invention discloses an environment friendly low-gas-content aluminum alloy ingot which comprises the following components in percentage by weight: 1.6-3.3 percent of Cu, 9.8-11.8 percent of Si, 0-0.29 percent of Mg, 0-0.08 percent of Zn, 0-0.8 percent of Fe, 0-0.48 percent of Mn, 0-0.48 percent of Ni, 0-0.1 percent of Ti, 0-0.1 percent of Pb, 0-0.2 percent of Sn, 0-0.25 percent of other trace elements and the balance of aluminum. Meanwhile, the invention also discloses a production method of the environment friendly low-gas-content aluminum alloy ingot. The environment friendly low-gas-content aluminum alloy ingot has the advantages of low gas and dreg content, high aluminum liquid cleanness and good mechanical and machining properties. The production method has the advantages of low production cost and high efficiency and effectively solves the pollution problem of the secondary aluminum industry.

Owner:YE CHIU METAL RECYCLINGCHINALTD

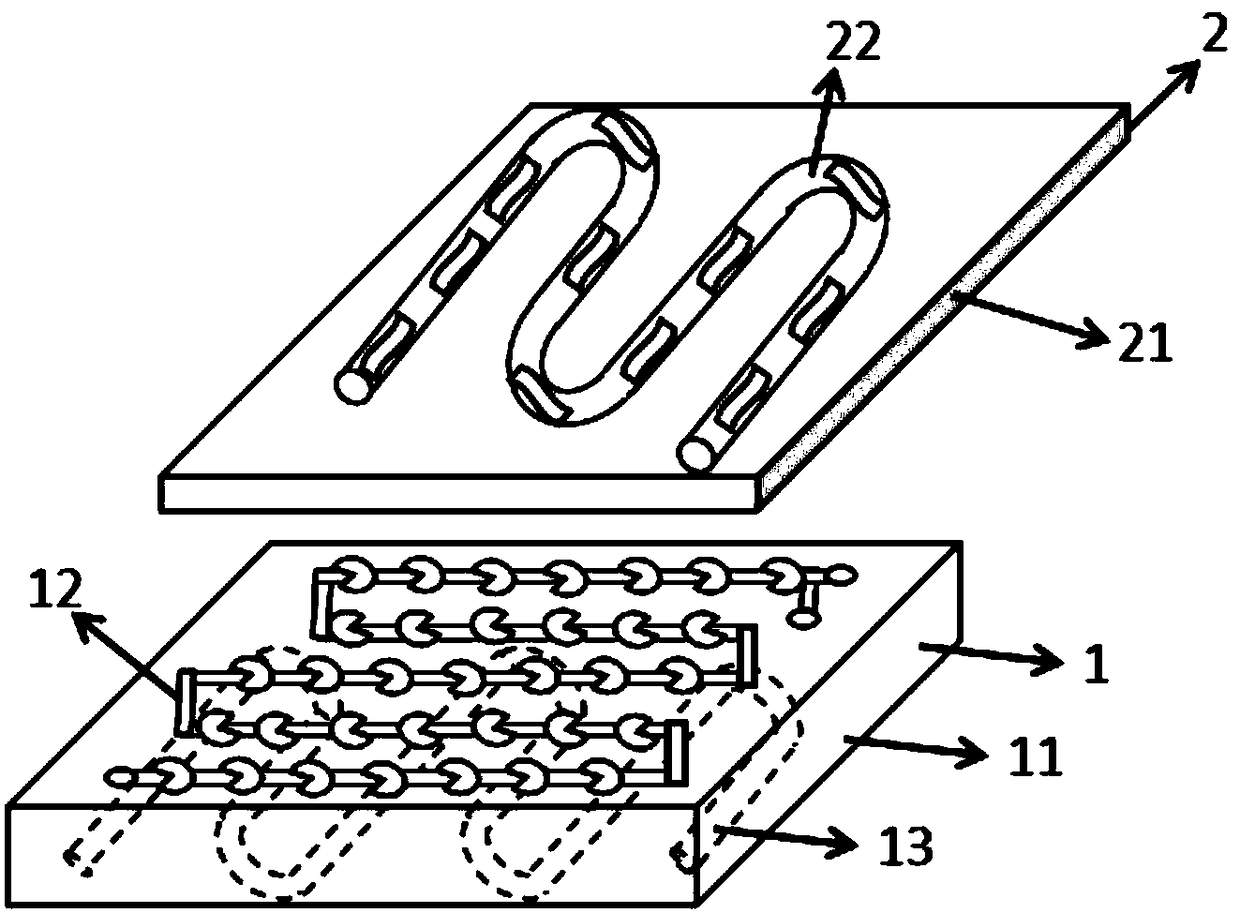

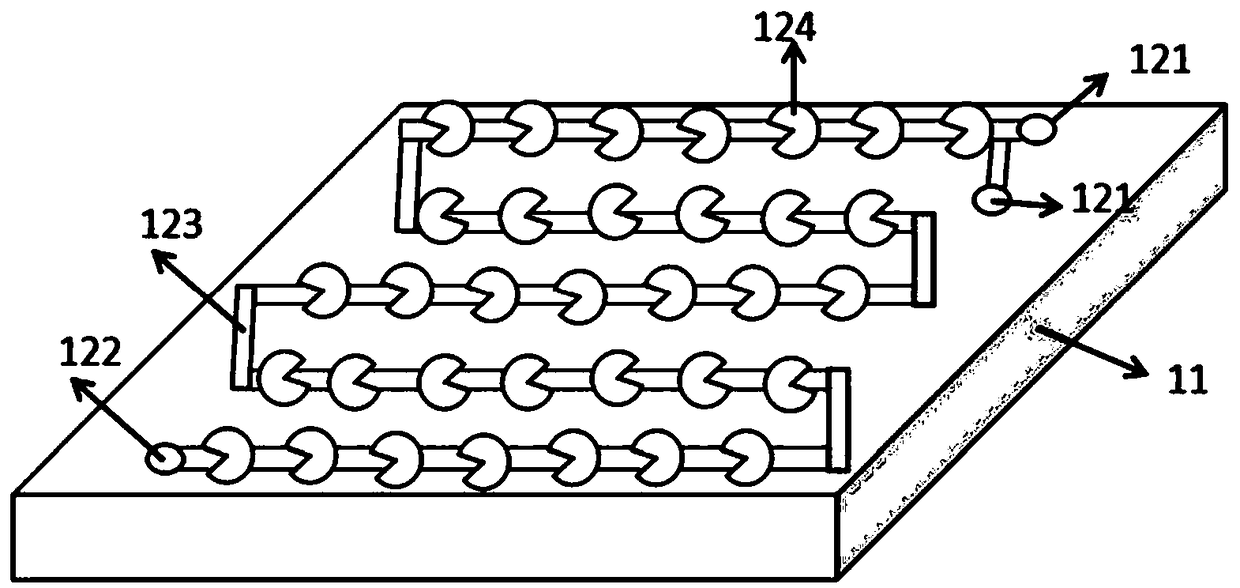

Heat collection and exchange system integrated silicon carbide micro-channel reactor

PendingCN108704591AWell mixedSpeed up chemical reactionsChemical/physical/physico-chemical microreactorsChemical reactionEngineering

The invention discloses a heat collection and exchange system integrated silicon carbide micro-channel reactor. The micro-channel reactor comprises a chip and a cover plate, wherein the cover plate ismounted on the chip; the chip comprises a first shell, a first heat exchange channel and a reaction channel; the cover plate comprises a second shell and a second heat exchange channel; and the reaction channel is formed in a contact surface between the first shell and the second shell, and the first heat exchange channel and the second exchange channel are respectively formed in the lower end surface of the first shell and the upper end surface of the second shell. According to the heat collection and exchange system integrated silicon carbide micro-channel reactor designed by the invention,the heat exchange of cooling liquid or heating liquid is realized by virtue of the first heat exchange channel and the second exchange channel, and the chemical reaction of reaction liquid is realized by virtue of the reaction channel, the structure is simple and efficient, and cold and hot mediums directly enter a reactor chip and are no longer conducted through metals, so that the conduction efficiency is greatly improved, and the cost is saved.

Owner:SHANDONG JINDE NEW MATERIAL CO LTD

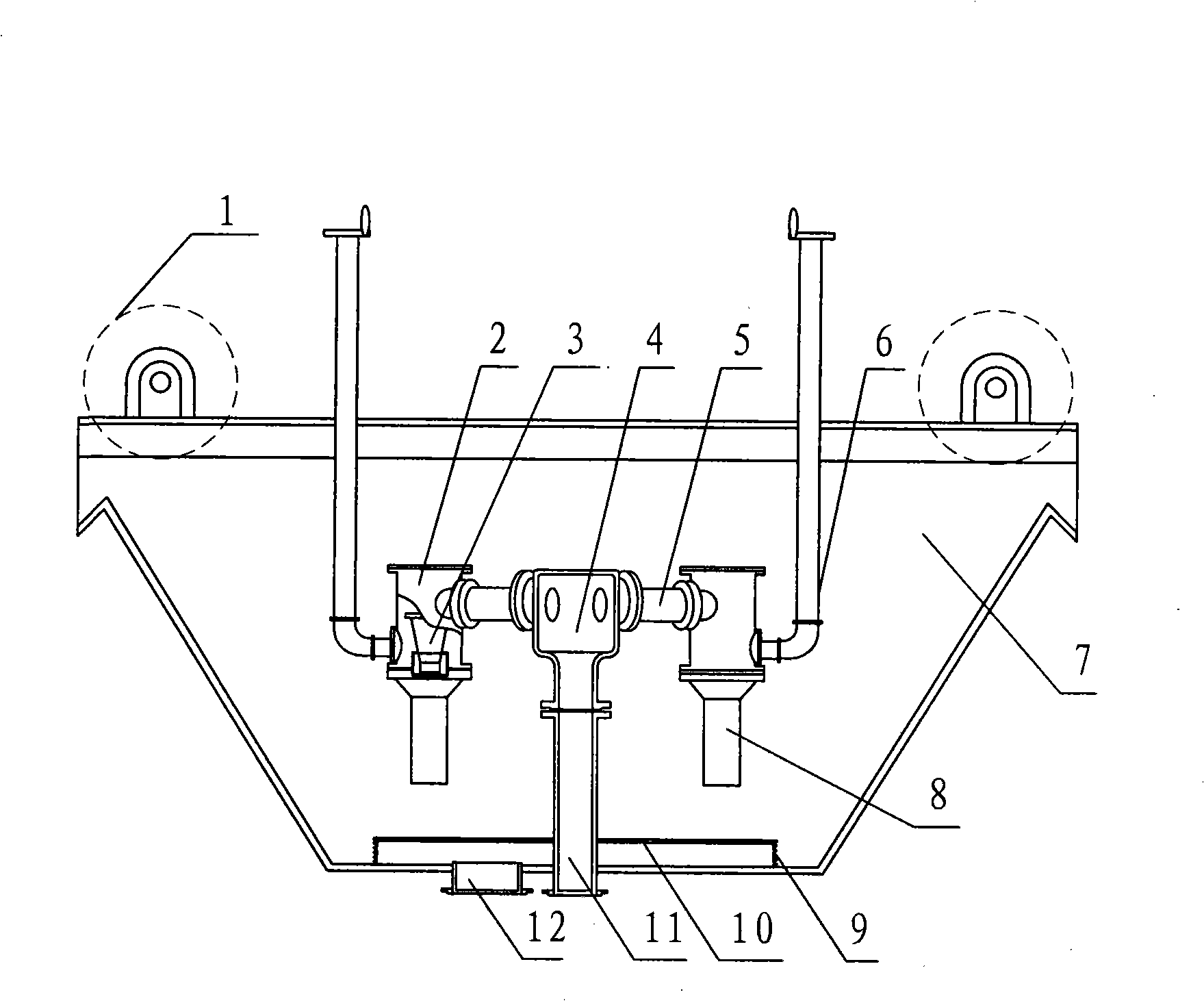

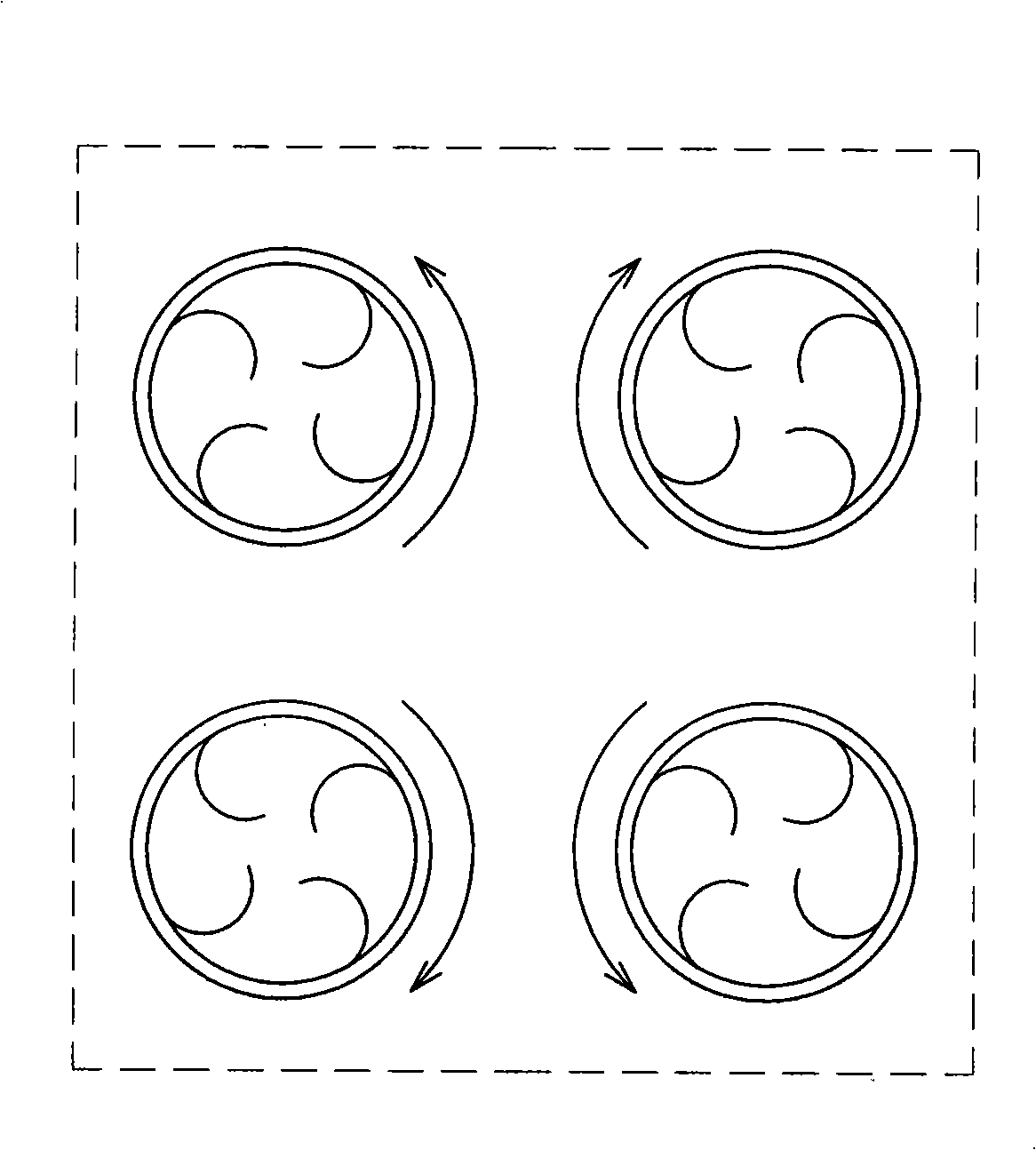

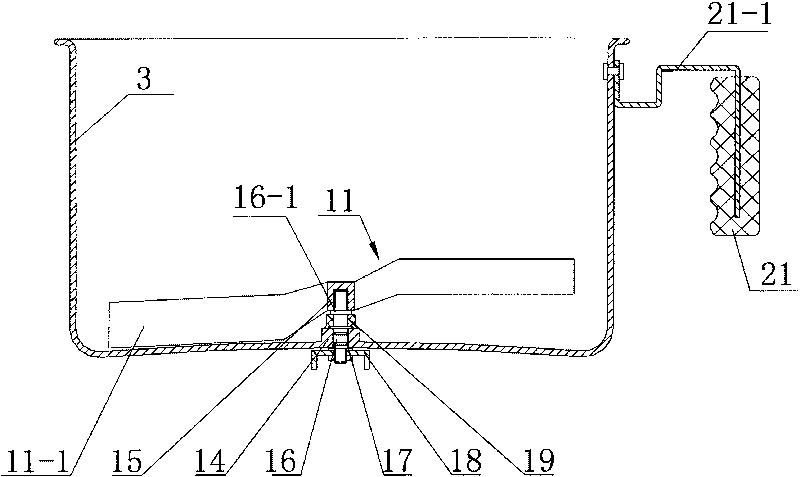

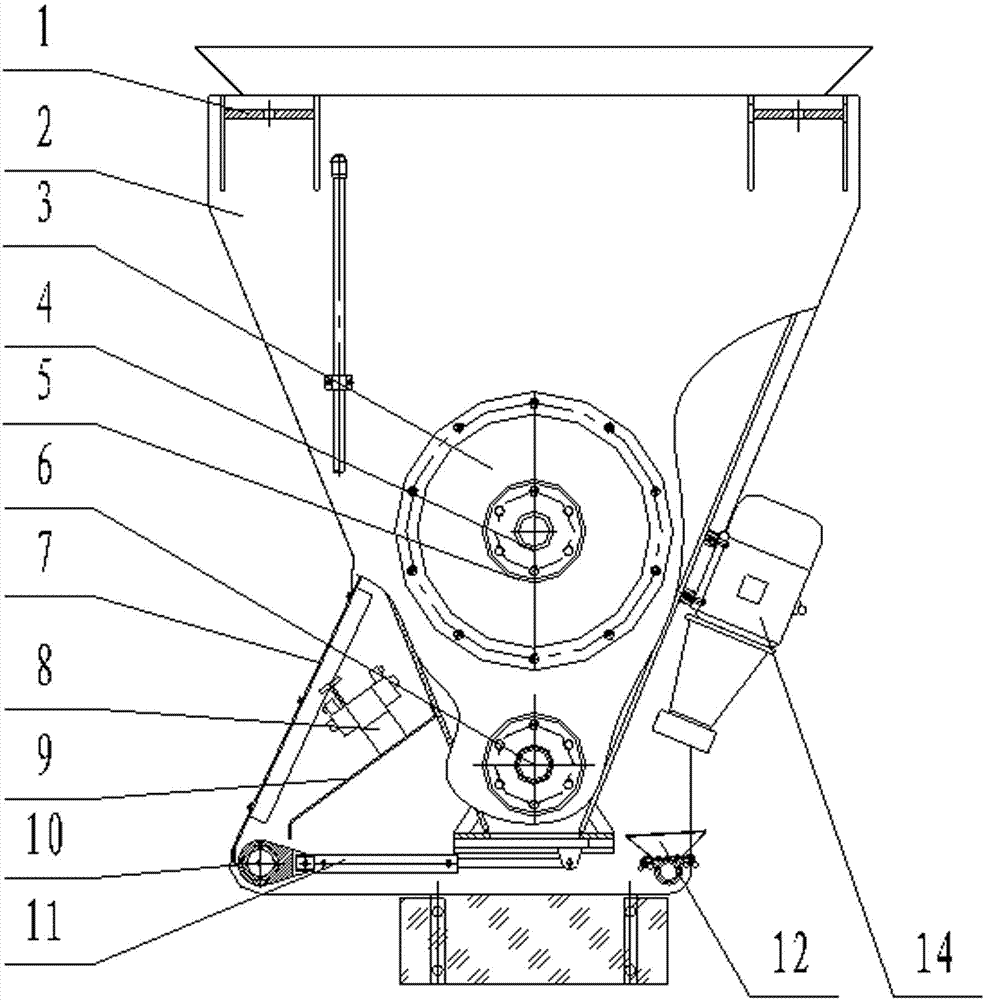

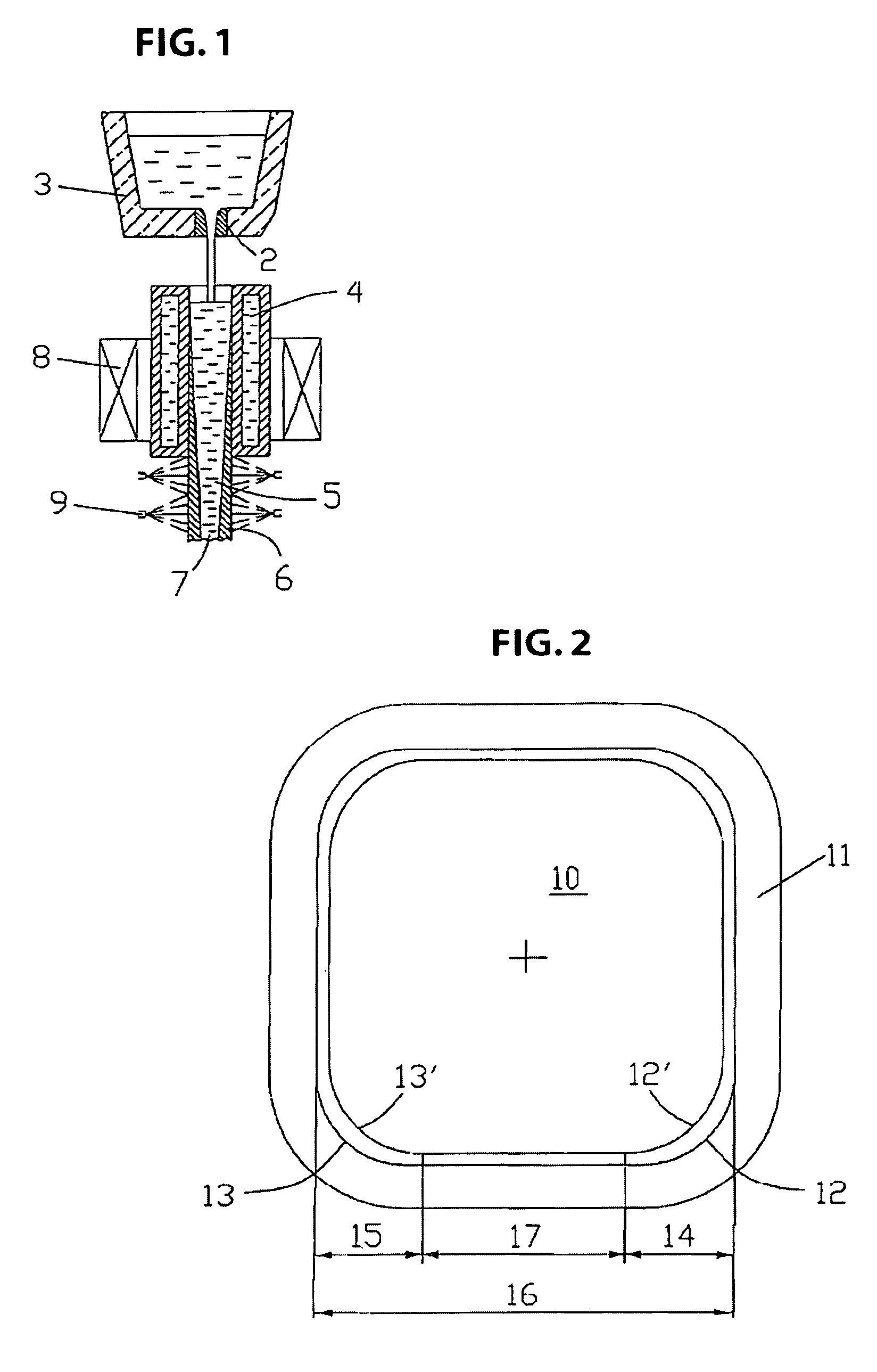

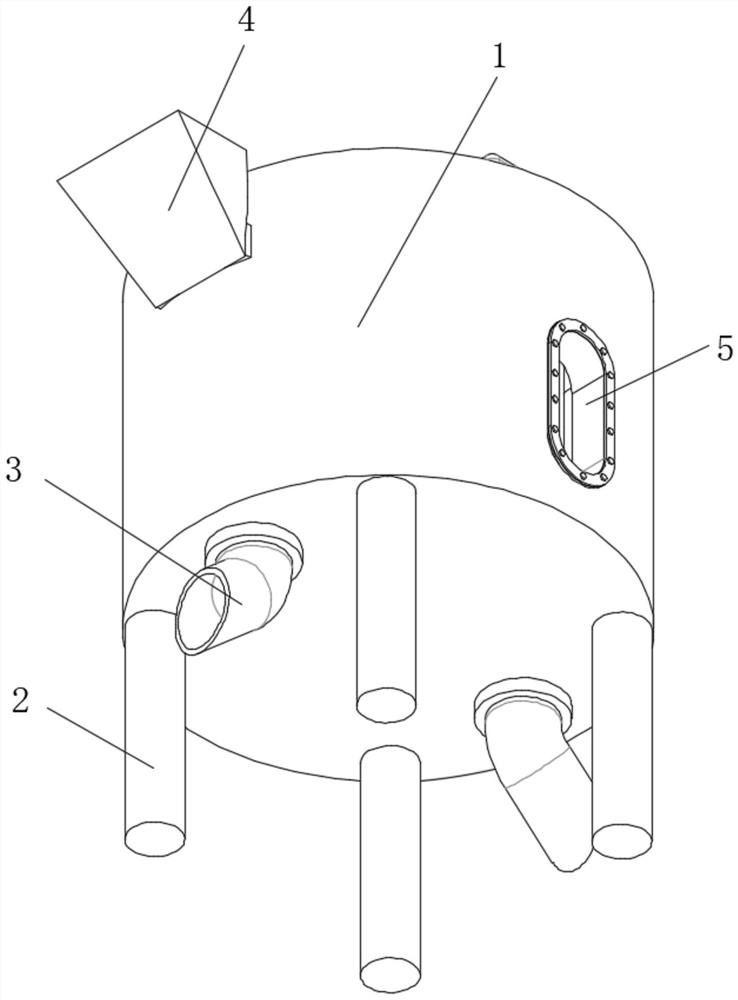

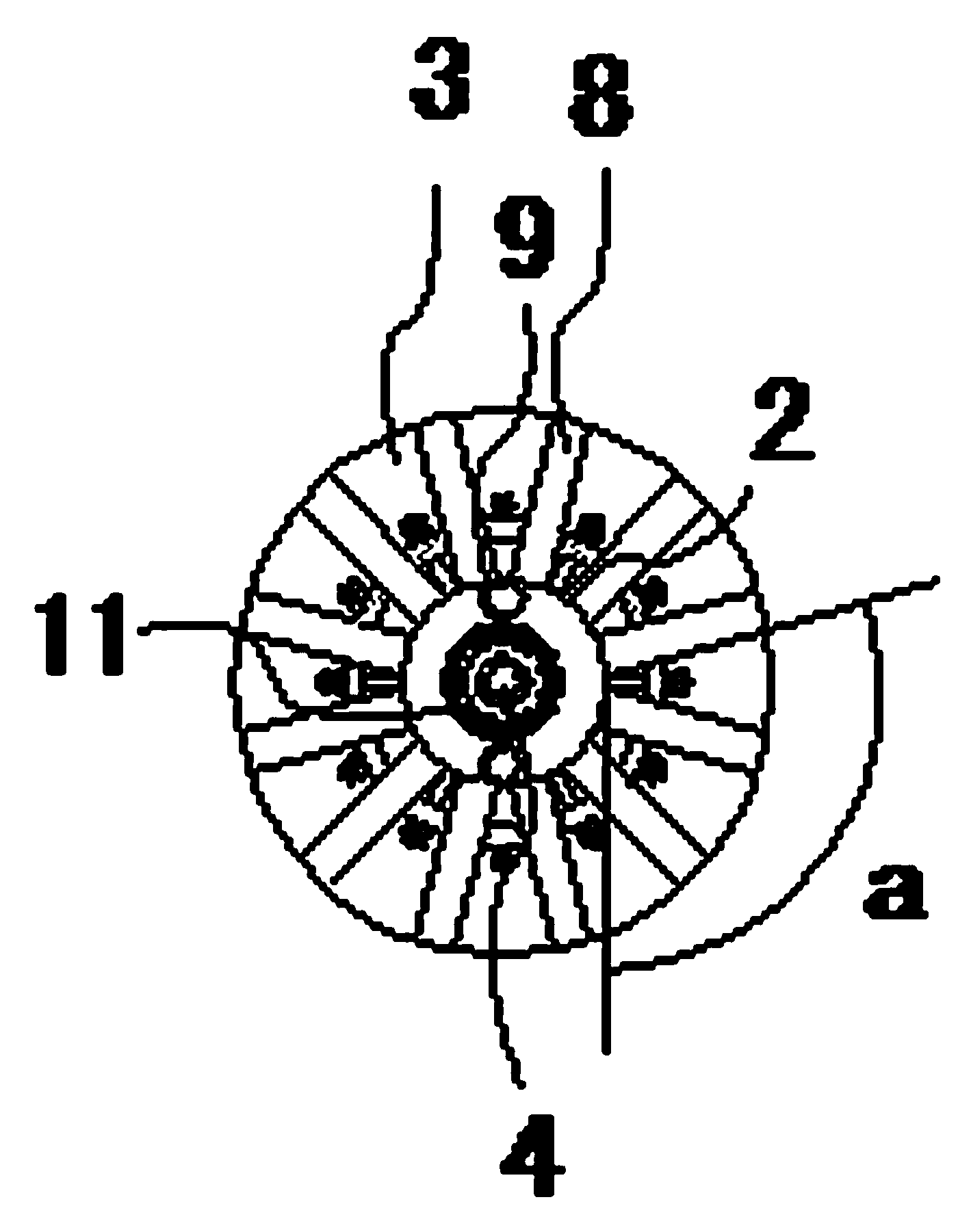

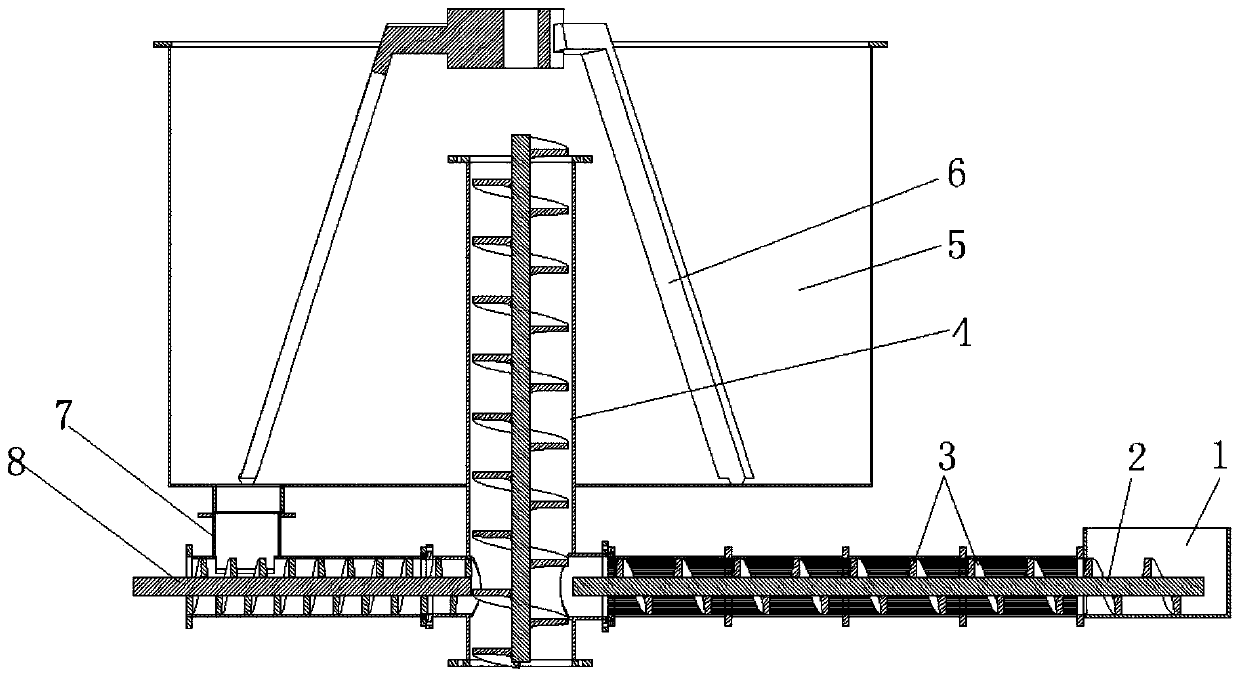

Immersed inflating and stirring device of injection type floatation cell for coal separation

The invention relates to a floatation machine applied to the coal dressing process, in particular to an immersion-typed aeration agitation device for jet flotation machine for coal dressing. The immersion-typed aeration agitation device comprises jet chambers, nozzles, hollow throats and air suction pipes. Arranged at the central part of a groove body of the floatation machine, connection pipes for distribution chamber are radially communicated with four jet chambers and the nozzles arranged in the jet chambers are fixedly connected with guide vanes; the external side of the jet chamber is communicated with the air suction pipe and the lower end of the jet chamber is connected with the hollow throat; the turning directions of the guide vanes of the nozzle arranged in the jet chamber at the same side of the axis of the distribution chamber are opposite; the hollow throat is a short one, the other end of which is suspended in the air; a wear-resistant liner is fixed connected with the internal wall of the short hollow throat; the upper end of the air suction pipe of the aeration agitation device extends from the liquid surface of coal paste and the remaining parts of the aeration agitation device are all immersed in the coal paste. The circulating coal paste is fed following tangent lines of different directions and a hydraulic stirring is carried out in each jet chamber to improve the aeration agitation effect. The immersion-typed aeration agitation device works reliably, has long service life, consumes less power and requires low maintenance cost.

Owner:BEIJING GUOHUA TECH GRP LTD

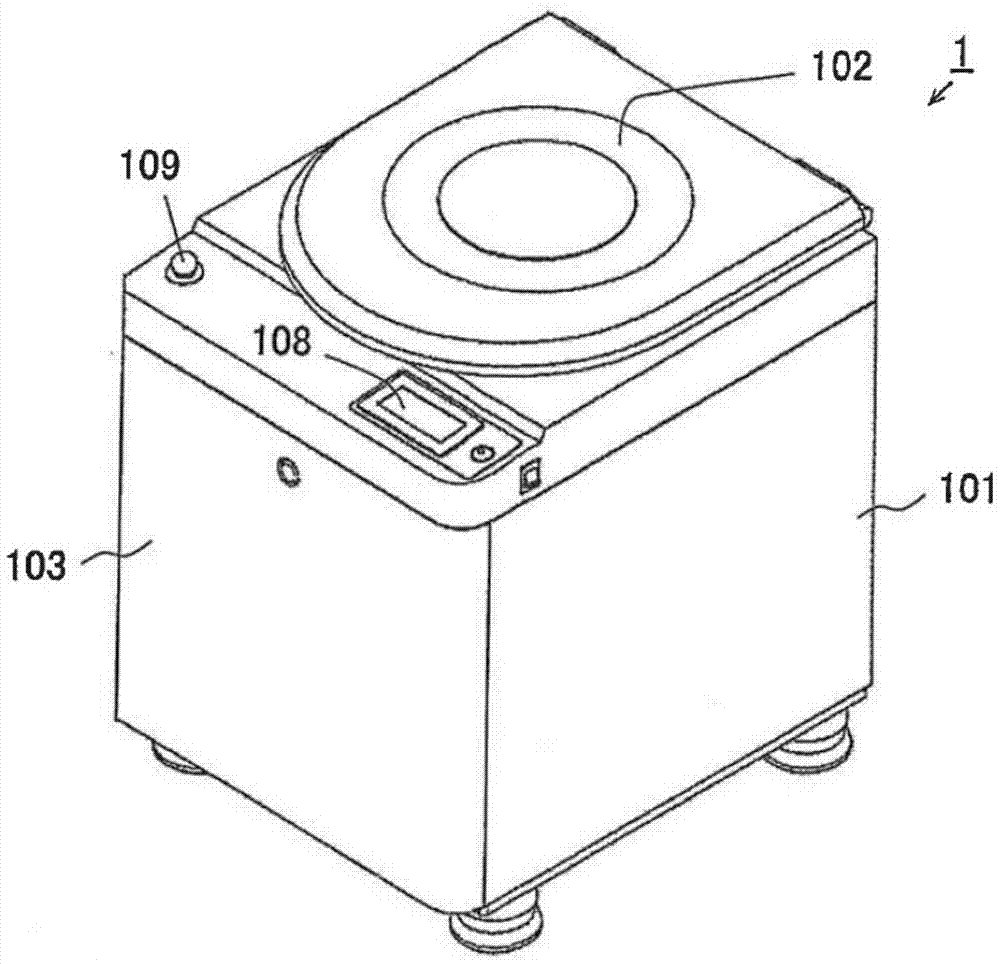

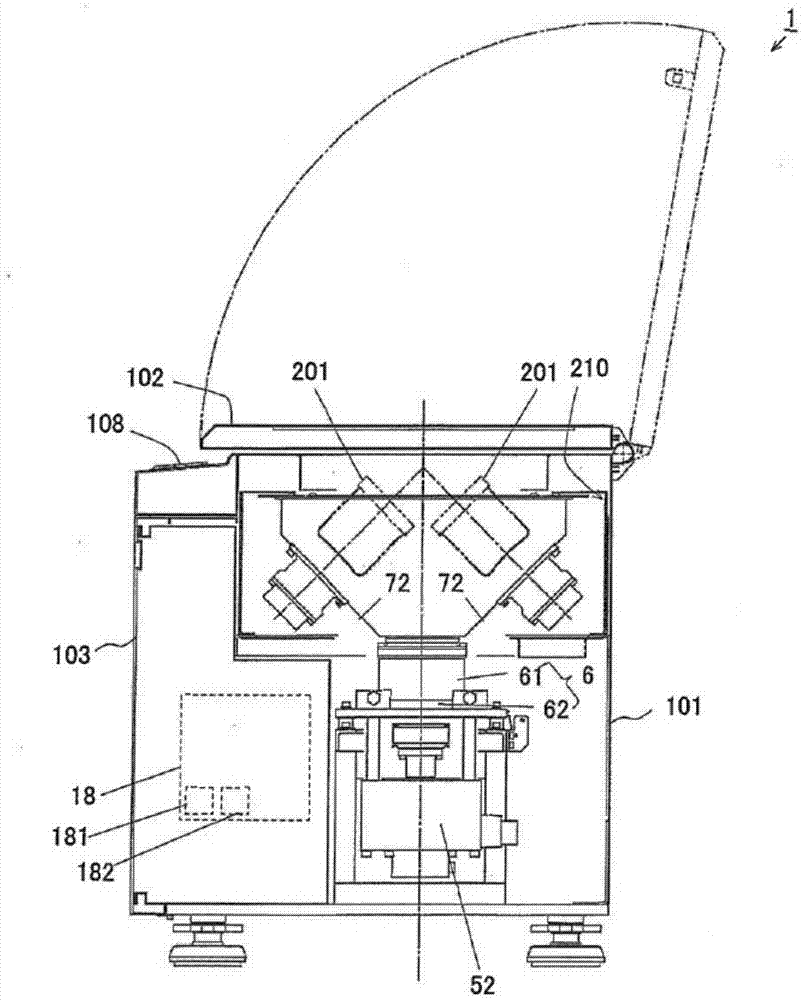

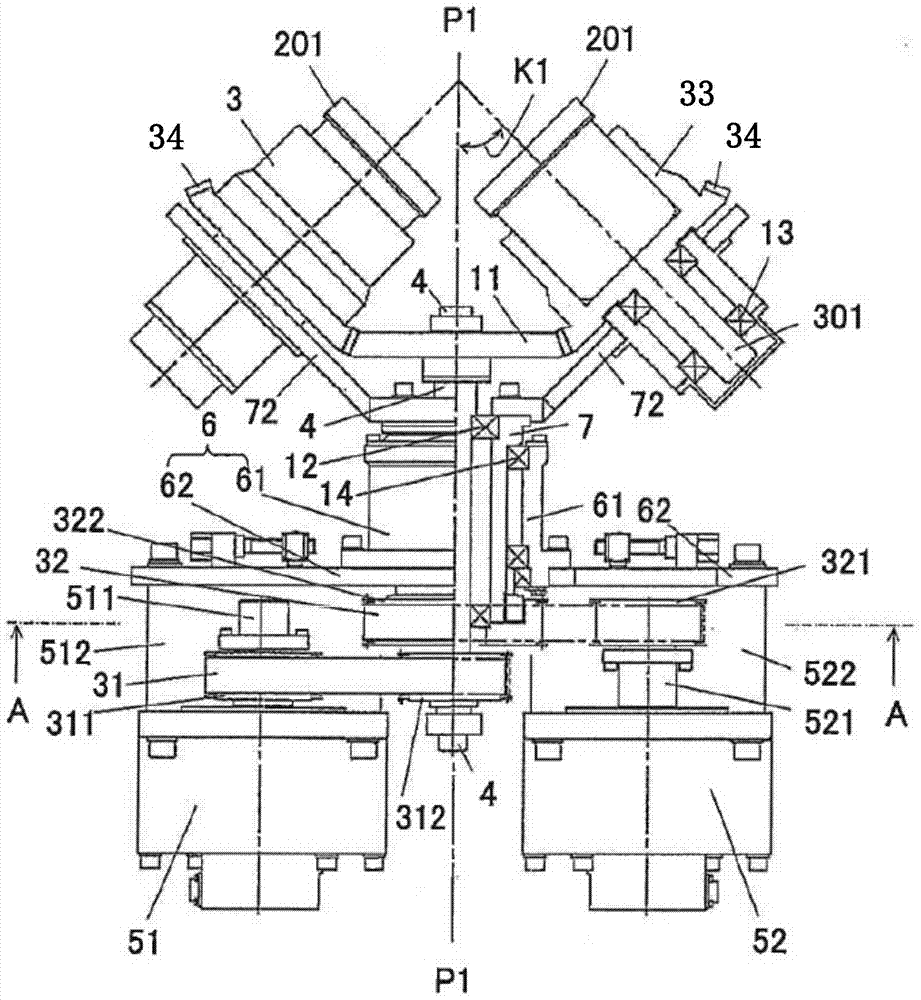

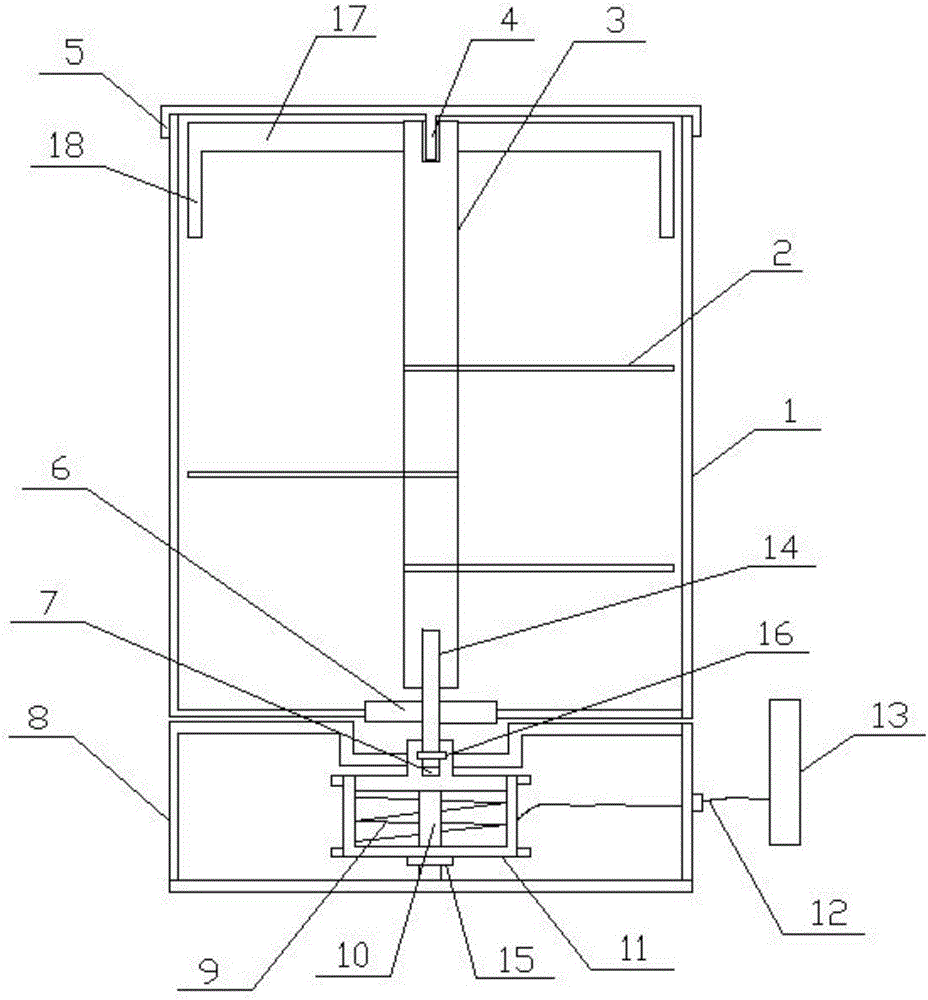

Stirring and defoaming device

InactiveCN104274997AGood reproducibilityRealize the number of rotationsRotating receptacle mixersLiquid degasificationCouplingDrive shaft

The present invention provides a stirring and defoaming device, and the rotation of the device can be controlled at a high accuracy. Meanwhile, the stirring and defoaming operation is conducted at a high reproducibility. The stirring and defoaming device comprises a container support used for holding a material receiving container; a self-rotation drive shaft coupled to the container support through a first coupling mechanism; a revolution drive shaft configured at the outer peripheral side of the self-rotation drive shaft, coupled to the self-rotation drive shaft through a second coupling mechanism and coupled to the container support through a third coupling mechanism; a base arranged at the outer peripheral side of the revolution drive shaft and coupled to the revolution drive shaft through a fourth coupling mechanism; a driven motor used for driving the self-rotation of the material receiving container; a driving motor used for driving the revolution of the revolution drive shaft; and a control device used for controlling the motors. The driven motor and the driving motor are fixed onto the base, and are of an independent structure respectively.

Owner:SUGINO MACHINE

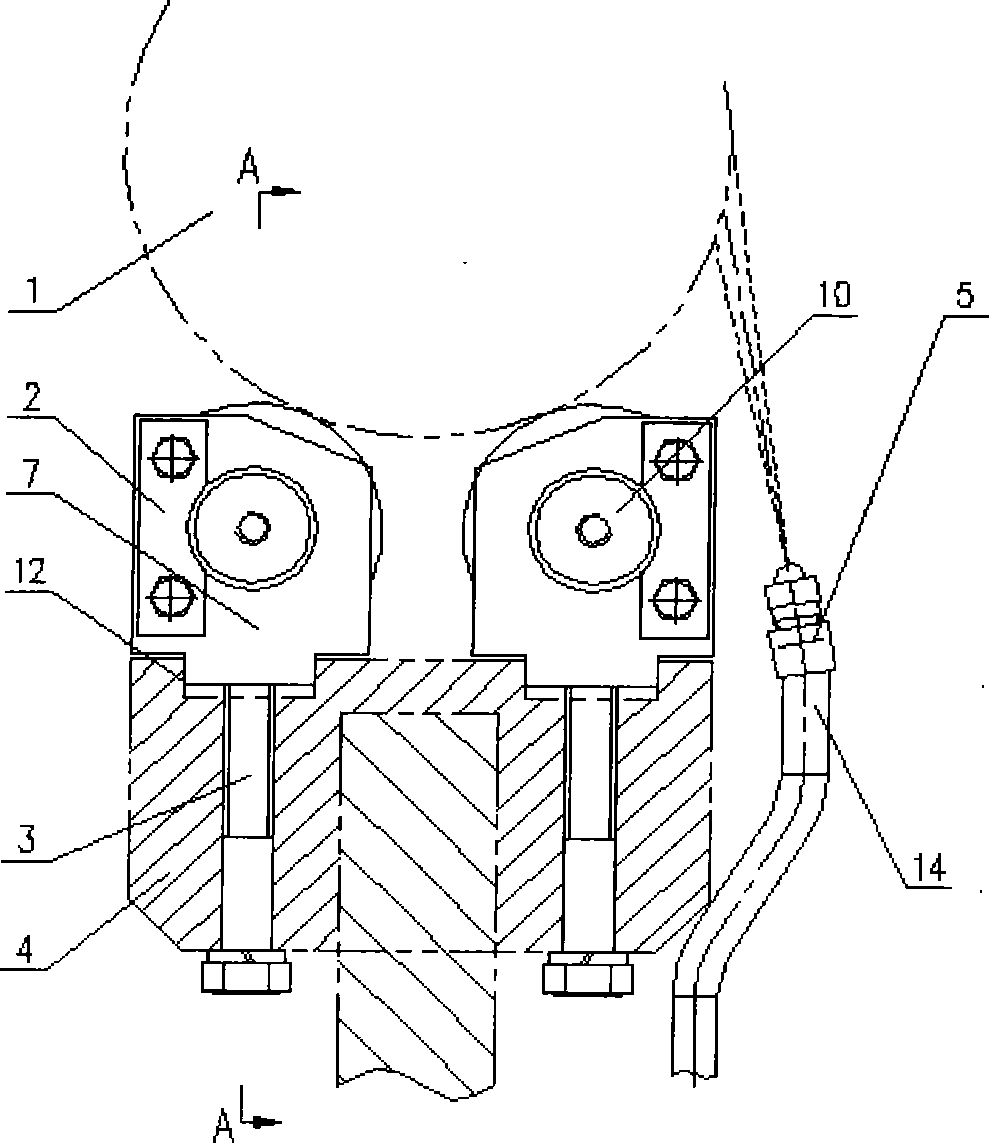

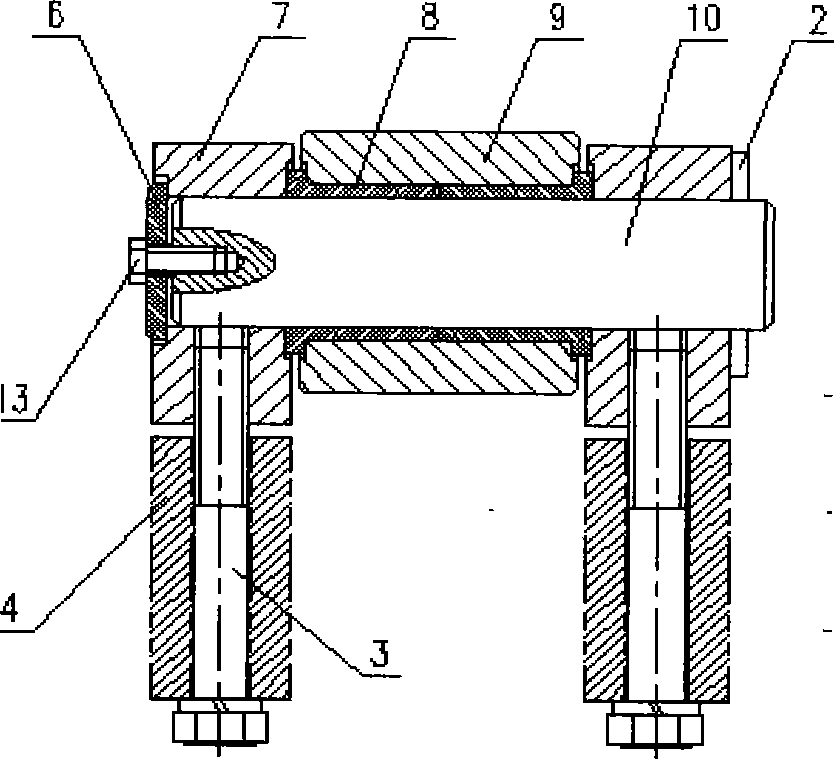

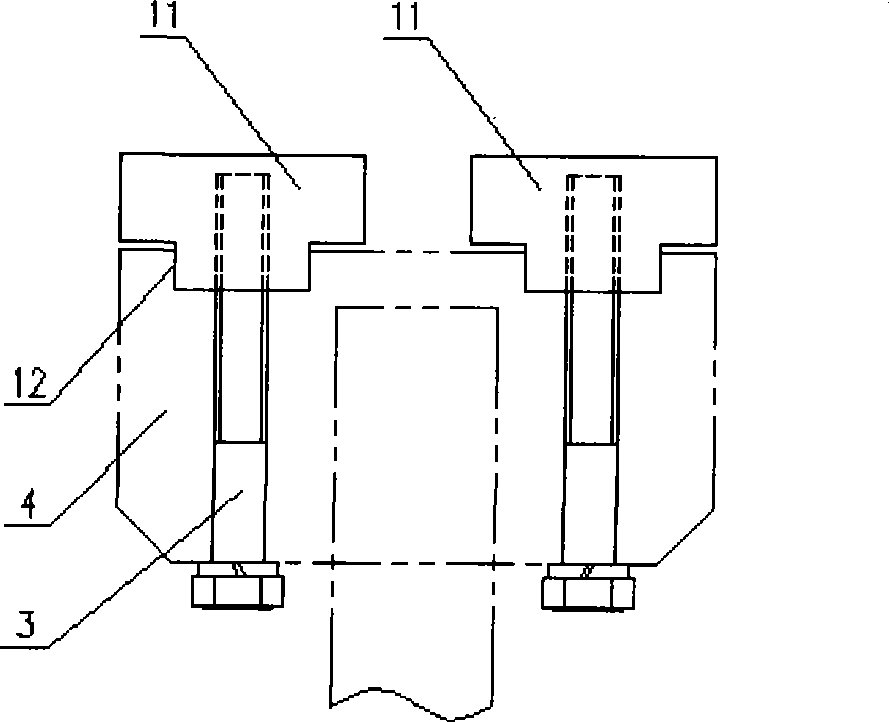

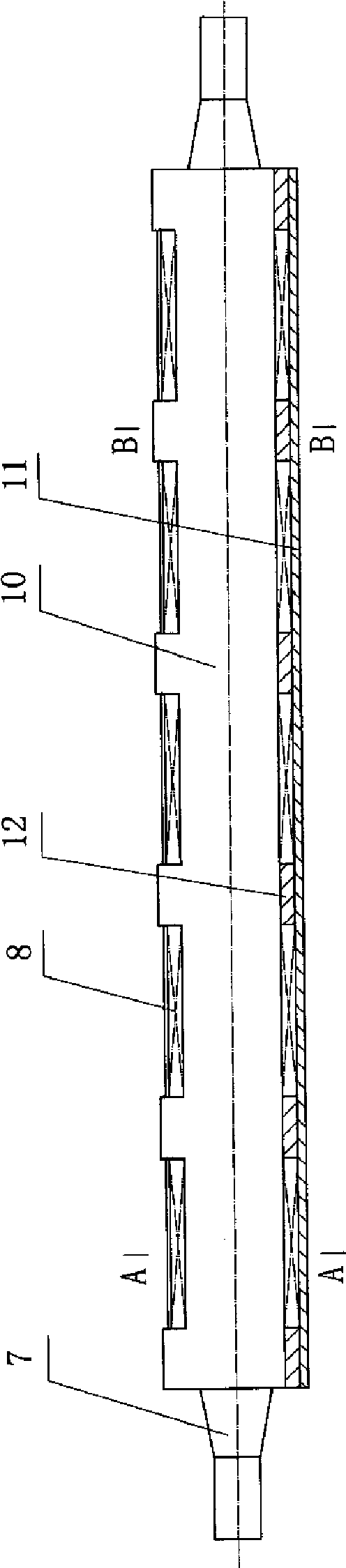

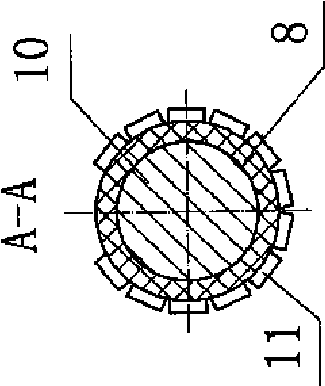

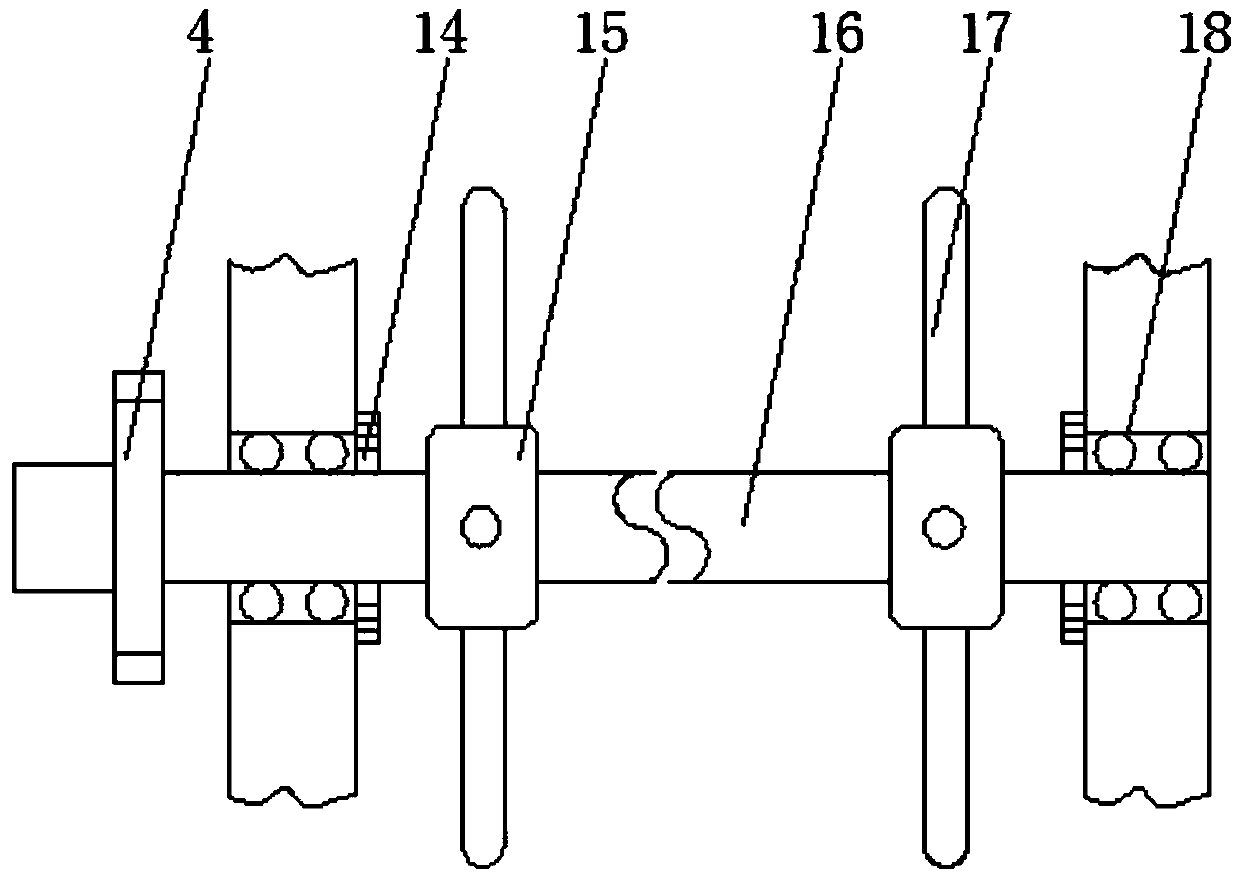

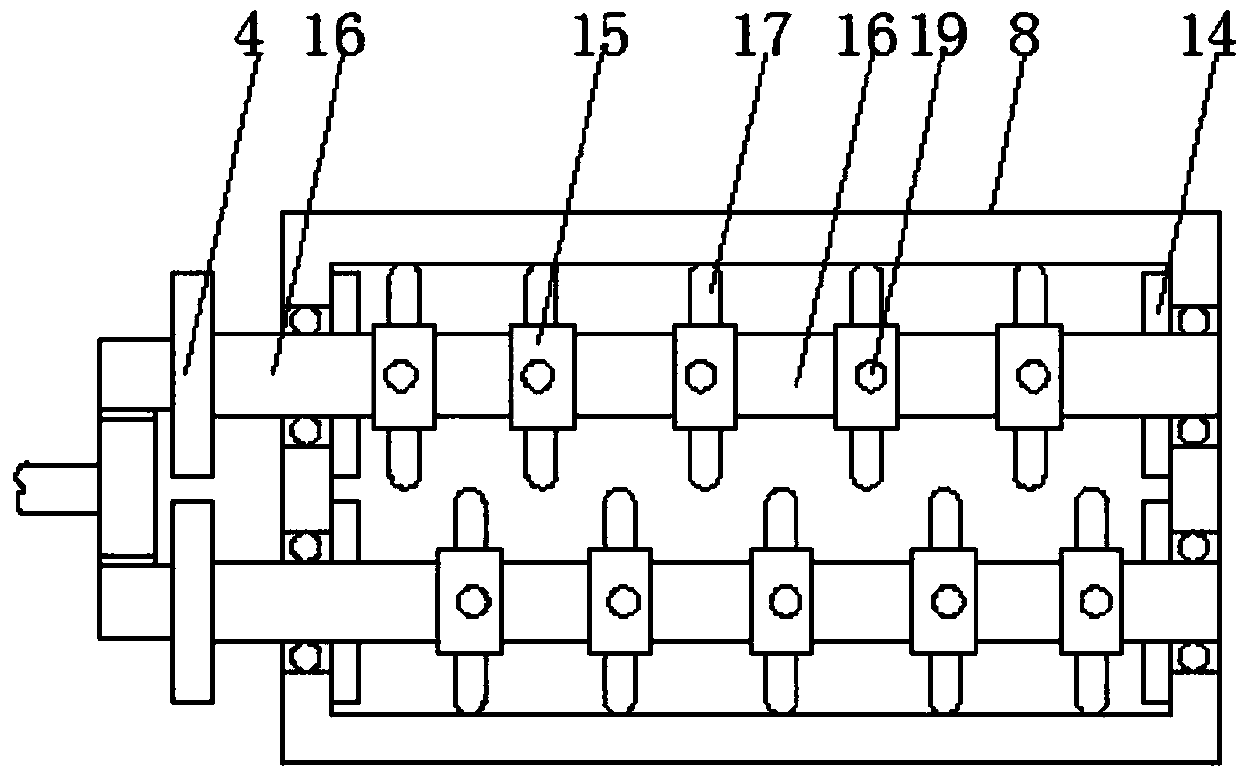

Eletromagnetic stirring supporting roller

The invention provides an electromagnetic stirring support roller device, which is arranged at the bottom of a stirring roller 1, and comprises a supporting roller 9 arranged in a notch 12, the notch 12 is in clearance fit with a bearing seat 7 and is fixed on a framework 4 through a high strength bolt 3, the middle of the support roller 9 is inserted with a mandril 10 and assembled together with the bearing seat 7, one end of the mandril 10 is connected with the bearing seat 7 through an end cover 6 and a bolt 13, and the other end of the mandril 10 is fixed with the mandril 10 through a shaft end baffle 2, a high-strength self-lubricating bearing 8 is arranged between the support roller 9 and the mandril 10, and a water spraying rack 14 on the inner and outer arc framework 4 is provided with a washing nozzle 5 specially. When the stirring roller 1 rotates, the support roller 9 is driven to rotate, then the washing nozzle 5 washes off iron scale on the stirring roller 1; when the stirring roller 1 is not used, a pressing plate 11 can be mounted in a mounting notch 12 of the support roller 9 for protection. The electromagnetic stirring support roller device has the characteristics of strengthening the rigidity, reducing the deflection deformation of the stirring roller, improving the stirring force, prolonging the service life of the stirring roller and reducing maintenance quantity.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

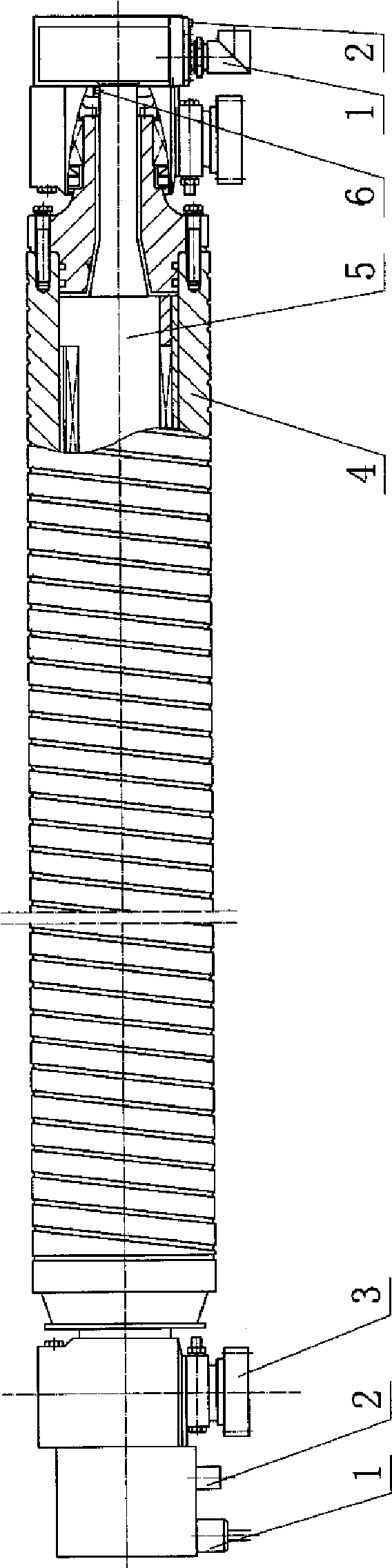

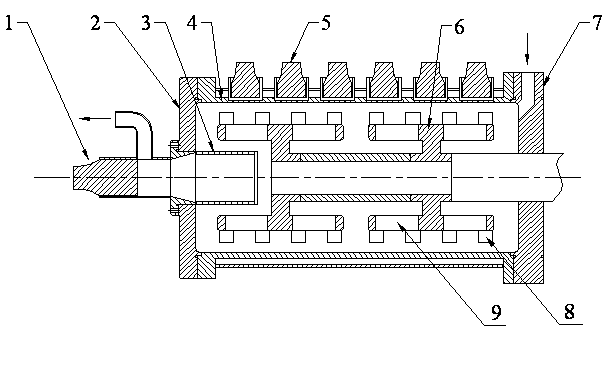

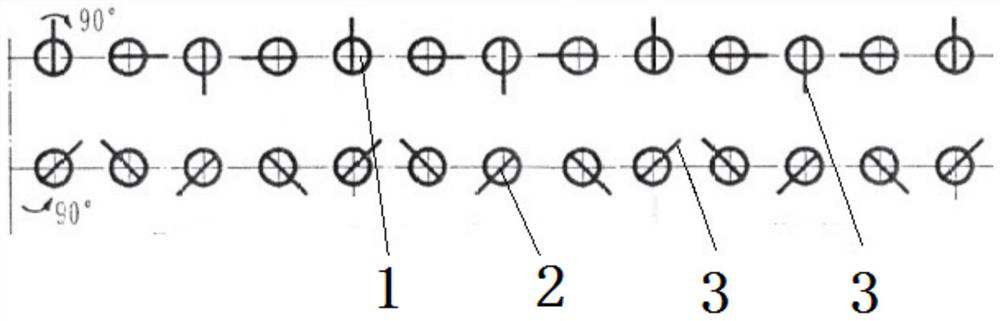

Roller type electromagnetic stirrer for block continuous-casting

The invention relates to a roll-type electromagnetic stirrer for continuously casting a plate blank, which comprises components such as coil windings, an iron core and the like, and is characterized in that the iron core is designed into a columnar elongated iron core with teeth, and tooth shaped parts protruded on a column are magnetic poles; the coil windings are arranged among the magnetic poles of the iron core at intervals; the peripheries of the iron core and the coil windings are provided with squirrel-cage components made of non-magnetic materials, wherein a stirrer body consisting of the iron core, the coil windings and the squirrel-cage components has a still structure; the stirrer body is arranged in a fully-closed rotating carrier roller; and a cooling water passage for cooling coils is arranged between the stirrer body and the rotating carrier roller. The rotating carrier roller is made of non-magnetic stainless steel with high temperature resistance and high strength, and a shell is provided with a spiral chute which is convenient for water flowing and heat dissipation. Because the formed copper squirrel-cage components cannot rotate, the current of the windings of the stirrer is increased under the same voltage; and relatively, the power for generating the same current is reduced, so the stirrer is easy to generate stronger stirring force.

Owner:岳阳鸿升电磁科技有限公司

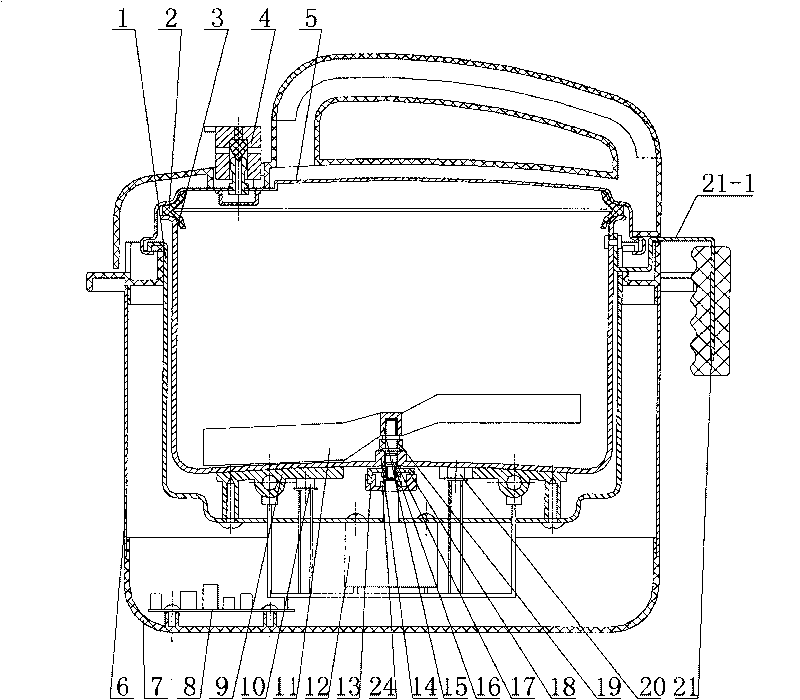

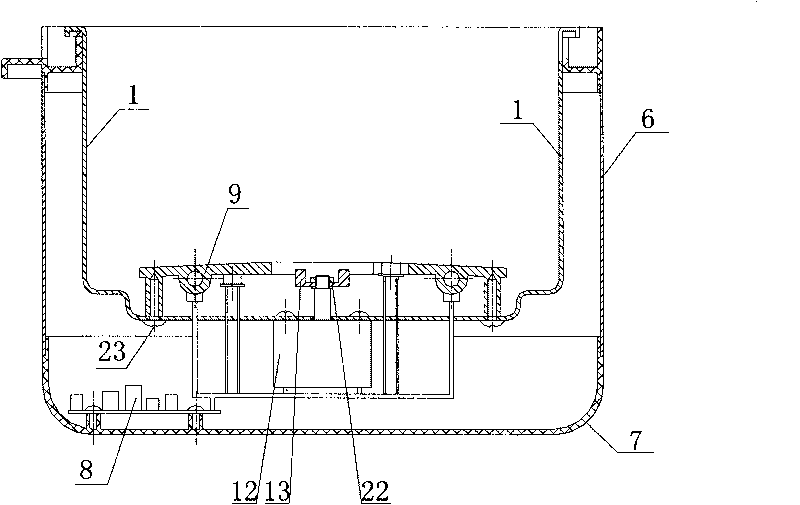

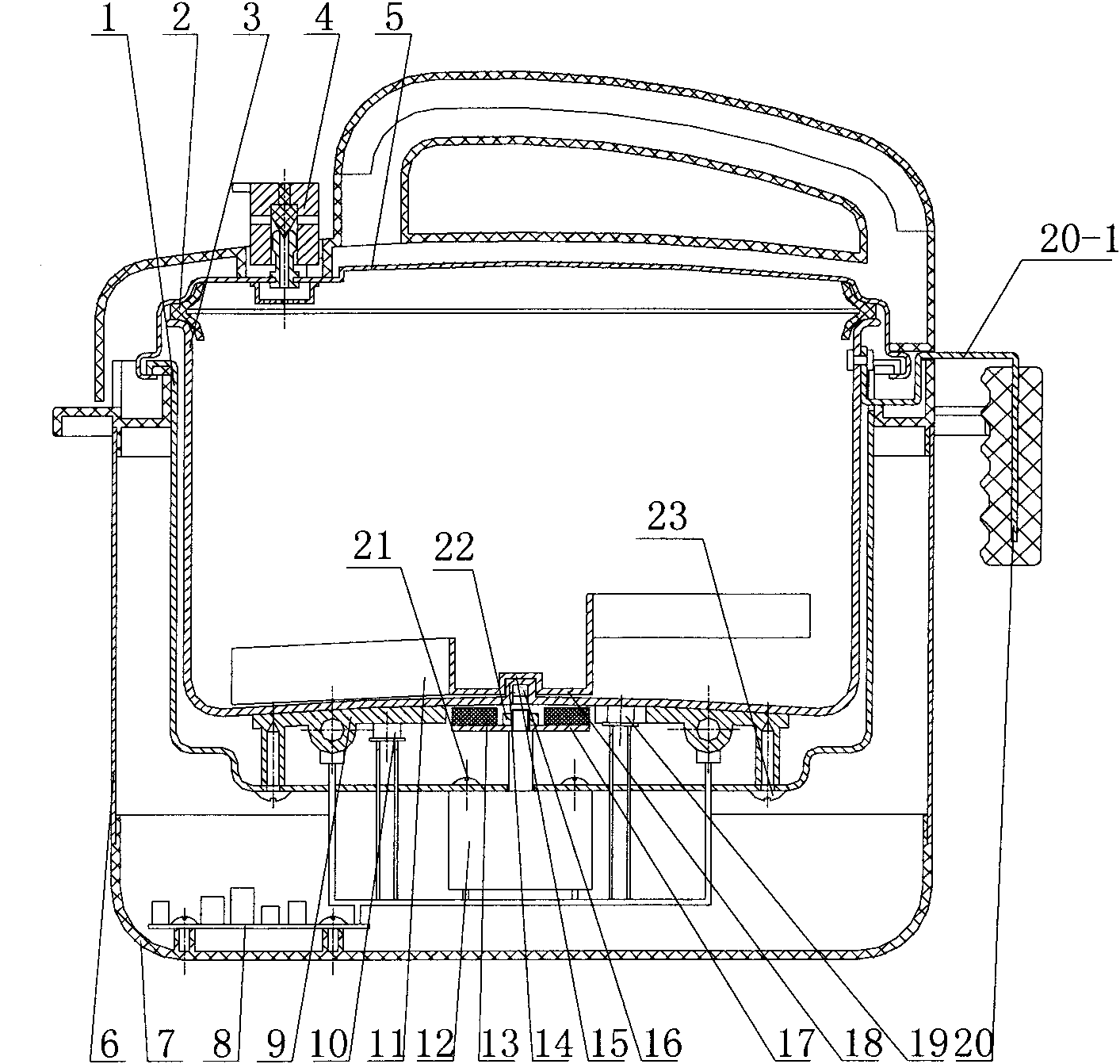

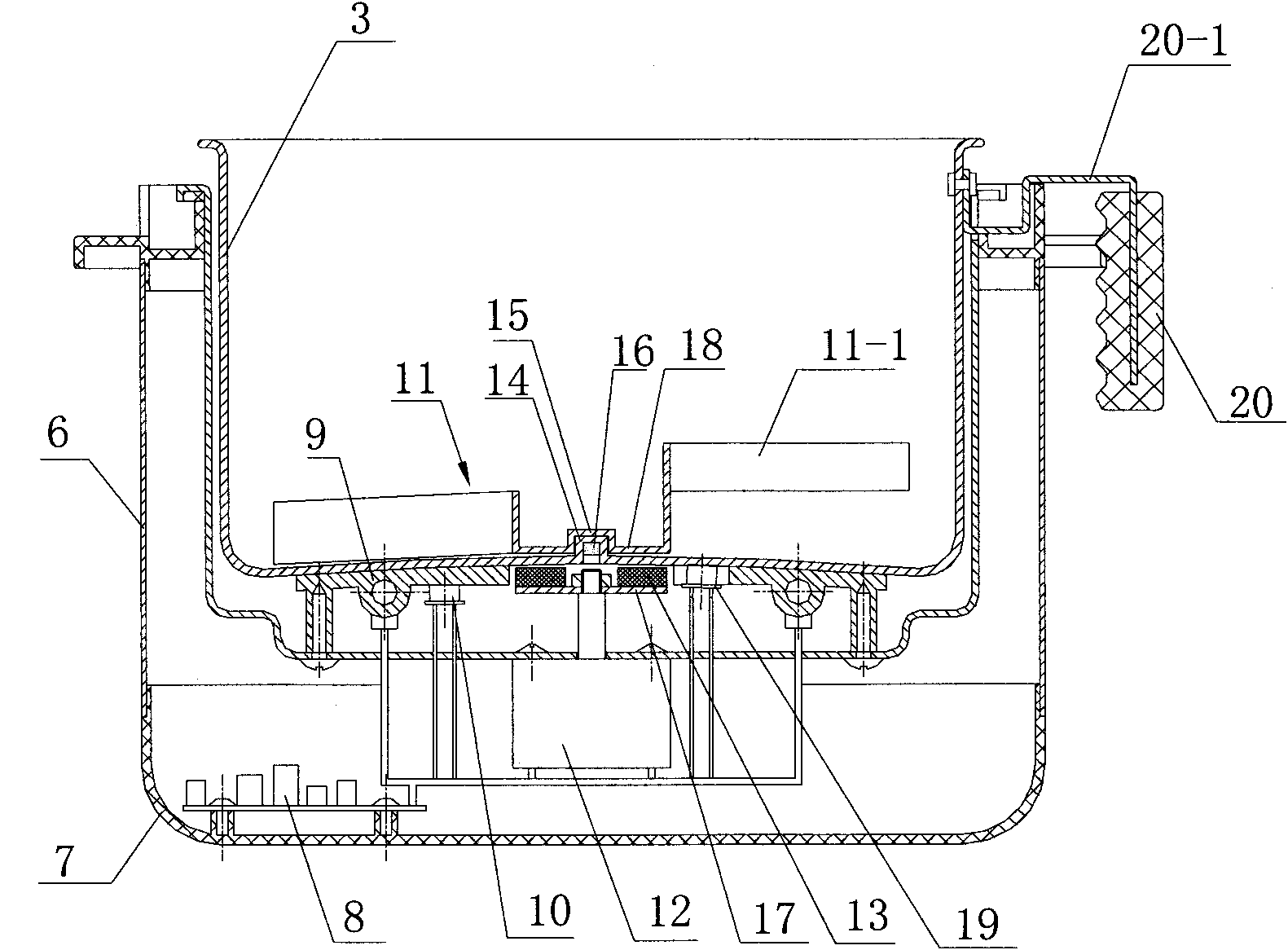

Electric pressure cooker

The invention provides an electric pressure cooker which can solve the problems caused by arranging an electrical motor on the cover of the cooker in the prior art. The technical scheme is as follows: the electric pressure cooker comprises an inner pot, an outer pot, a shell, a heating plate, the electrical motor and a stirrer, wherein the electrical motor is arranged in the lower part of the outer bottom surface of the inner pot, the motor shaft is connected with a main driving disc, the inner bottom surface of the inner pot is provided with a drive shaft sleeve, the inside of the drive shaft sleeve is provided with a drive shaft, the stirrer is fixedly connected with the upper end of the drive shaft through a stirrer sleeve, the lower end of the drive shaft passes through the bottom surface of the inner pot and is fixedly connected with an auxiliary driving disc, and the main driving disc and the auxiliary driving disc constitute a clutch. As the electrical motor and the motor shaft are arranged in the lower cavity of the outer bottom surface of the inner pot, the weight of the cover of the cooker is reduced, when the cover is opened, the motor shaft and a stirring blade are not needed to take out so as to avoid the phenomenon of taking soup or rice along with the motor shaft and the stirring blade out of the cooker, reduce the space occupied by the cover and ensure to conveniently and hygienically place the cover.

Owner:崔美娟

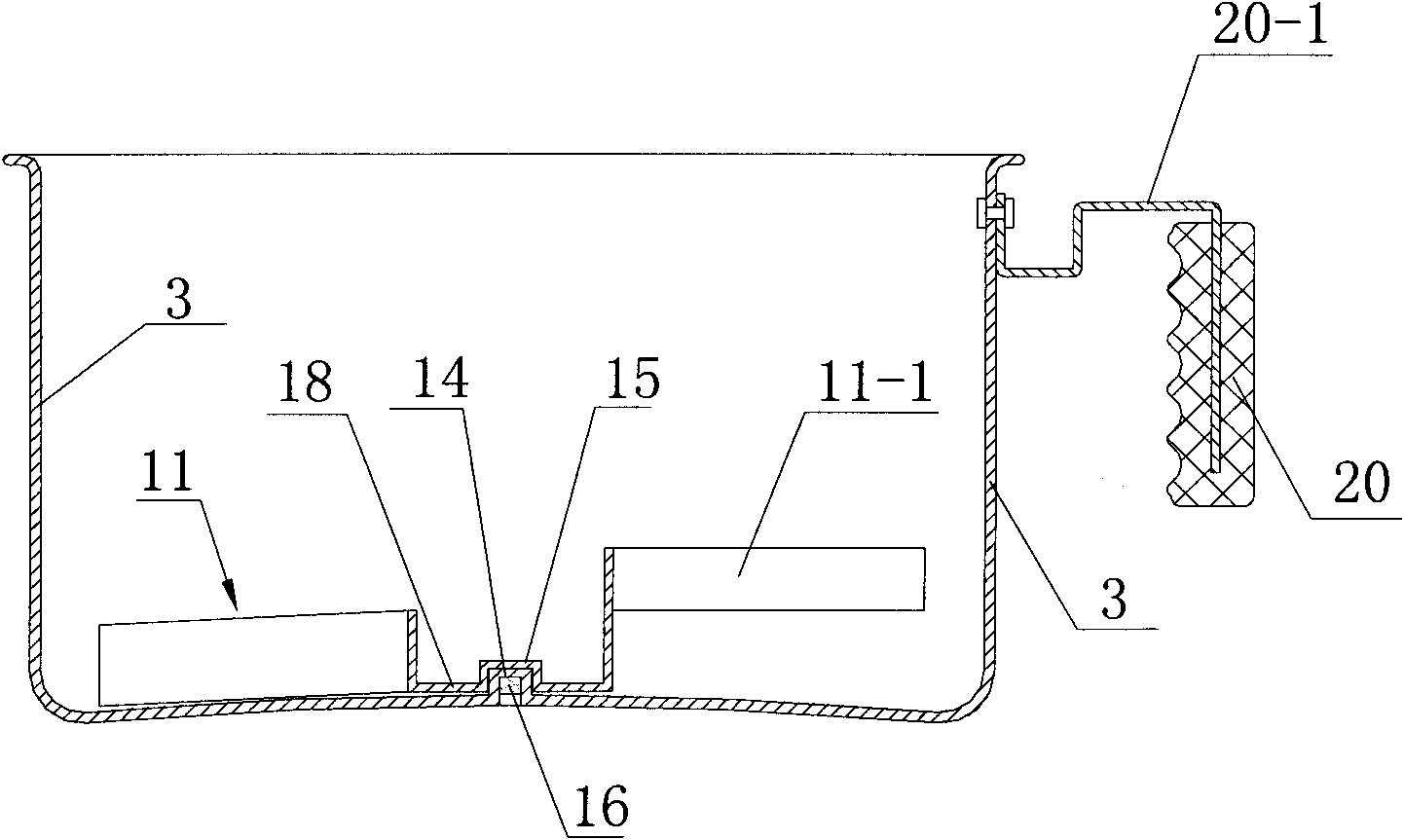

Electric pressure cooker

InactiveCN101773365AReduce weightSmall footprintPressure-cookersWarming devicesEngineeringKnife blades

The invention provides an electric pressure cooker which can solve the problem brought by the reason that a motor is arranged on a cooker cover in the prior art. The technical scheme is that a motor is arranged on the lower part on the outer bottom of an inner cooker, a motor shaft is connected with a master driving element which is made of magnet, or the magnet is arranged in the master driving element; the master driving element is arranged close to the outer bottom of the inner cooker; the inner bottom of the inner cooker is provided with a shaft head; a stirrer is sheathed on the shaft head and is provided with a slave driving element of which the position corresponds to that of the master driving element; the slave driving element is made of ferromagnetic material or magnetite. As the motor and the motor shaft are arranged in a lower cavity on the outer bottom of the inner cooker, the weight of the cooker cover is reduced; when the cooker cover is opened, the motor shaft and stirring blades do not need to be taken out, thus avoiding the phenomenon that soup and rice are taken out together, reducing cooker cover occupation space, and bringing convenience and cleanness to cooker cover placement.

Owner:崔美娟

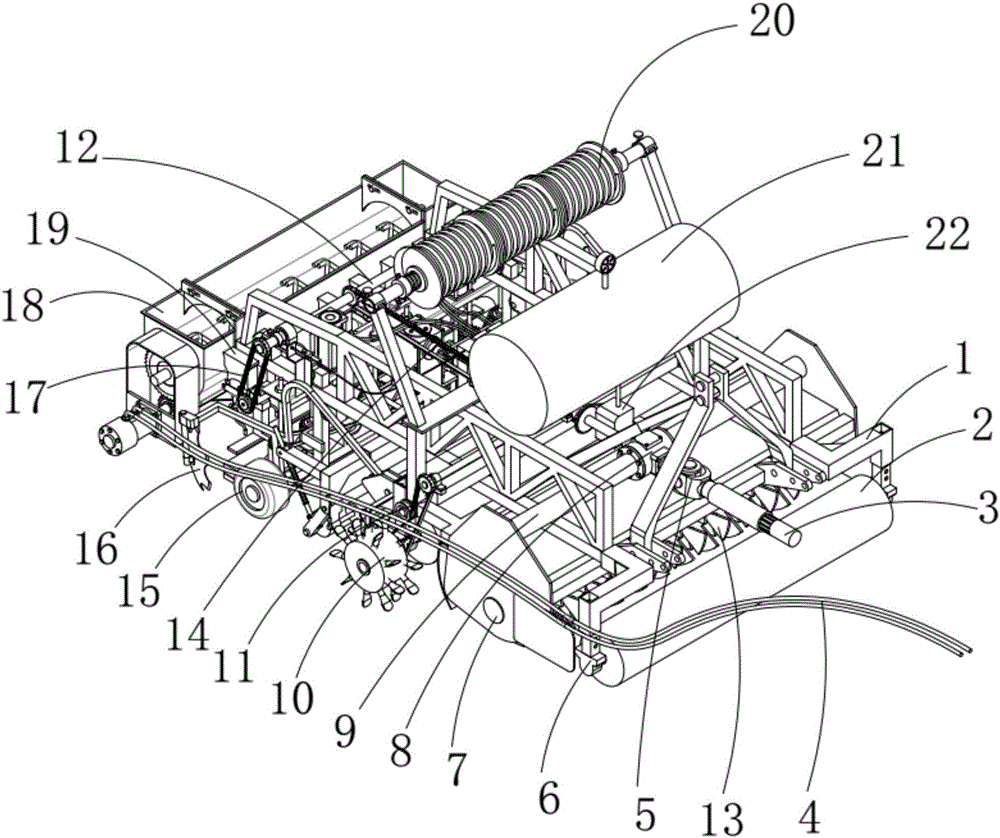

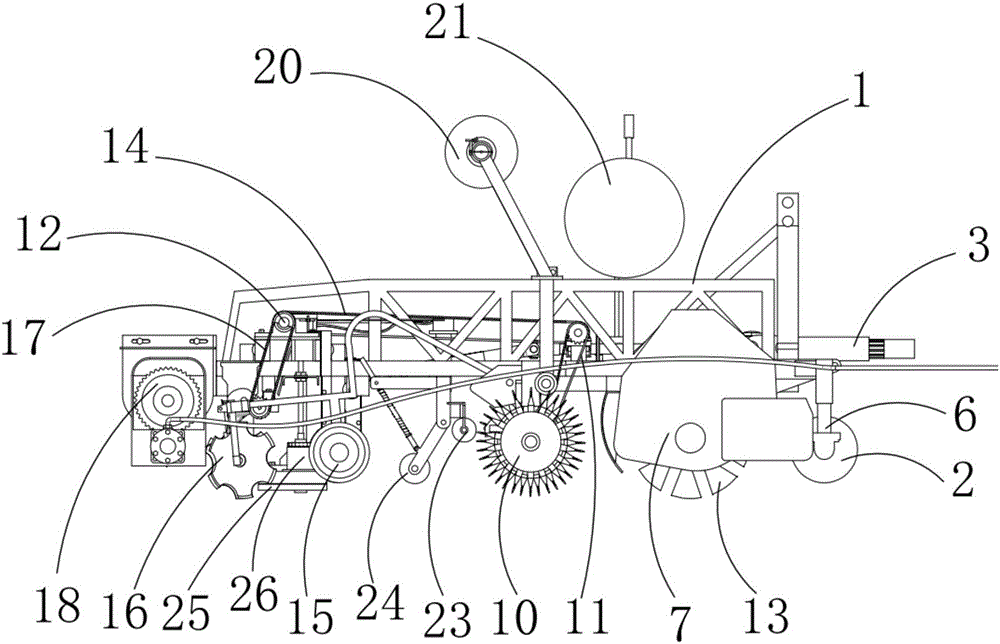

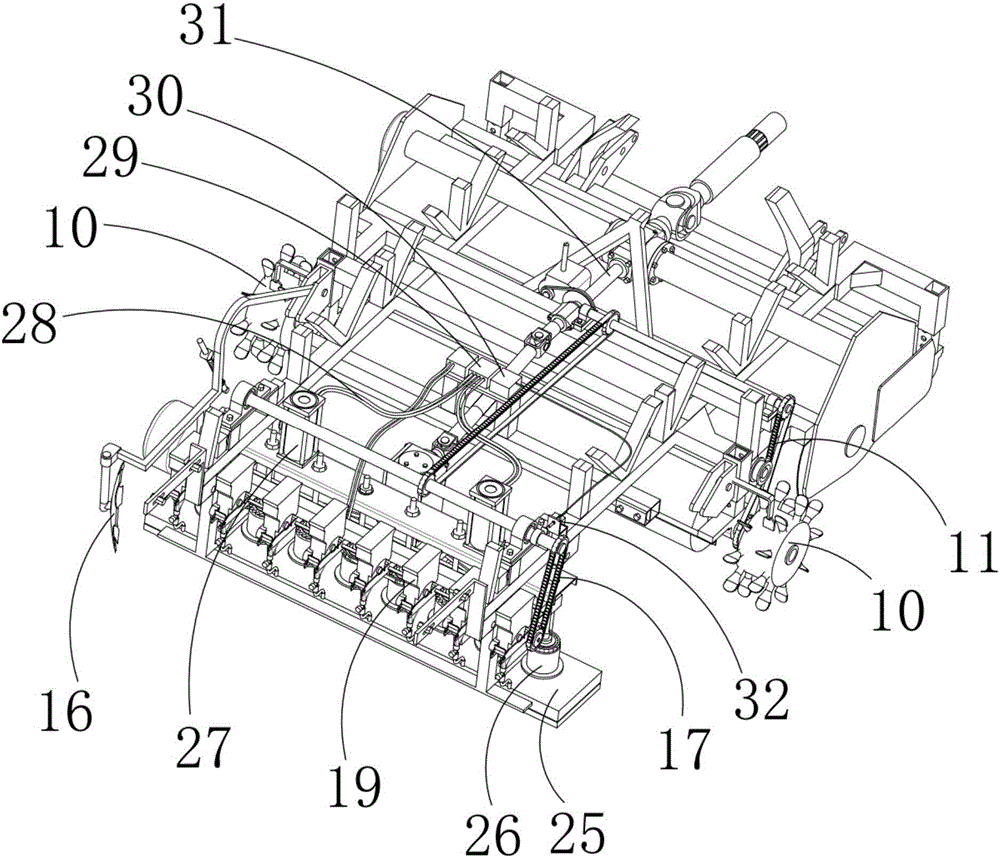

Multifunctional celery seeding all-in-one machine

InactiveCN106489325AGuarantee the quality of sowingKeep moistureSpadesPloughsSeederProduction effect

The invention discloses a multifunctional celery seeding all-in-one machine, and belongs to the field of agricultural machinery. The multifunctional celery seeding all-in-one machine comprises a rack, a pressing roller, a rotary tillage ridging device, a ground wheel device, a film laminating device, a sand pressing device and a seeder, wherein the pressing roller, the rotary tillage ridging device, the ground wheel device, the film laminating device and the seeder are fixedly mounted on the rack from front to back. The machine advances under the traction of a tractor or other agricultural machinery; rotation of ground wheels of the machine is realized through a first-stage chain in a transmission manner; and rotation of a film laminating shaft in the film laminating device and transmission of an output shaft of a speed change box of a perforation device are realized through second-stage and third-stage chains in a transmission manner. According to the multifunctional celery seeding all-in-one machine, the sand pressing device and the ground wheel device are improved, and a drop irrigation device is additionally arranged, so that the sand stirring and production effect is enhanced, the advancing resistance of the all-in-one machine is reduced, and the seeding precision is improved.

Owner:NINGXIA ACADEMY OF AGRI & FORESTRY SCI +1

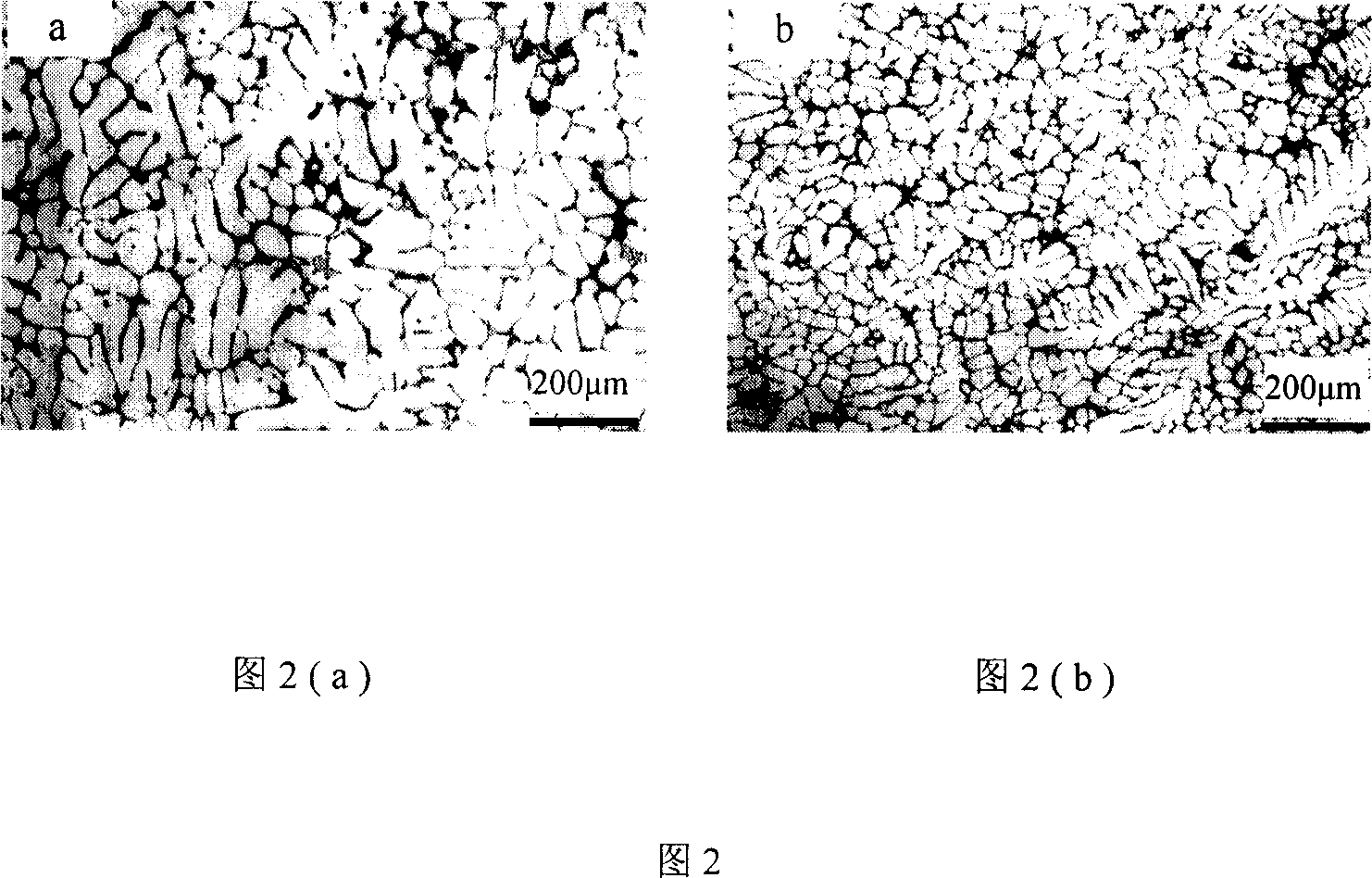

Composite shearing semi-solid state metal rheological slurry preparation method

The invention relates to a method for preparing composite shear semi-solid metal rheological slurry, wherein it comprises that: (1), controlling the alloy liquid at 0-100Deg. C above liquid temperature TL; (2), controlling the temperature of upper rubbing board at TL-40Deg. C to TL+20Deg. C, and controlling the upper end of lower rubbing board at TL-50Deg. C to TL+50Deg. C, the lower end at Tss-20Deg. C to Tss+20Deg. C, and the temperature difference from upper end to lower end is 0.03-1Deg. C / mm; (3), putting the alloy liquid on lower rubbing board, using compress cylinder to compress the lower rubbing board; (4), the upper rubbing board carries alloy liquid to the discharger; insulating temperature, the alloy liquid is solidified into semi-solid metal slurry in ball shape or particle shape. The invention can be used in aluminum base alloy, copper base alloy, etc.

Owner:有研金属复材技术有限公司

A flux-cored wire for gas-shielded welding

ActiveCN102267018AImprove organizationFast coolingWelding/cutting media/materialsSoldering mediaWeld seamImpurity

The invention discloses a flux-cored wire for gas shielded welding. The flux-cored wire comprises the following components by weight percentage: 80%-90% of carbon steel sheath and 10%-20% of flux core, wherein, the carbon content of the flux-cored wire is 0.06%-0.15%. The flux-cored wire is characterized in that the flux core comprises the following components by weight percentage: 2%-8% of TiO2, 1%-4% of SiO2, 0.1%-0.3% of Al2O3, 0.1%-0.8% of fluoride, 0.8%-3.2% of Mn, 0.4%-1.8% of ferrotitanium powder, 0.4%-2.4% of Fe2O3 and the balance of iron powder and unavoidable impurities. In the invention, by adding the ferrotitanium powder and the Fe2O3 to the flux core, fine and dispersedly distributed titanium-containing oxides or titanium-containing composite oxides are formed in welding seams, and the oxides induce generation of acicular ferrite; and due to faster welding cooling speed and greater mixing power, the inclusions are dispersedly distributed in the welding seams owing to no enough time for growth so that metal structures of the welding seams are refined.

Owner:ANGANG STEEL CO LTD

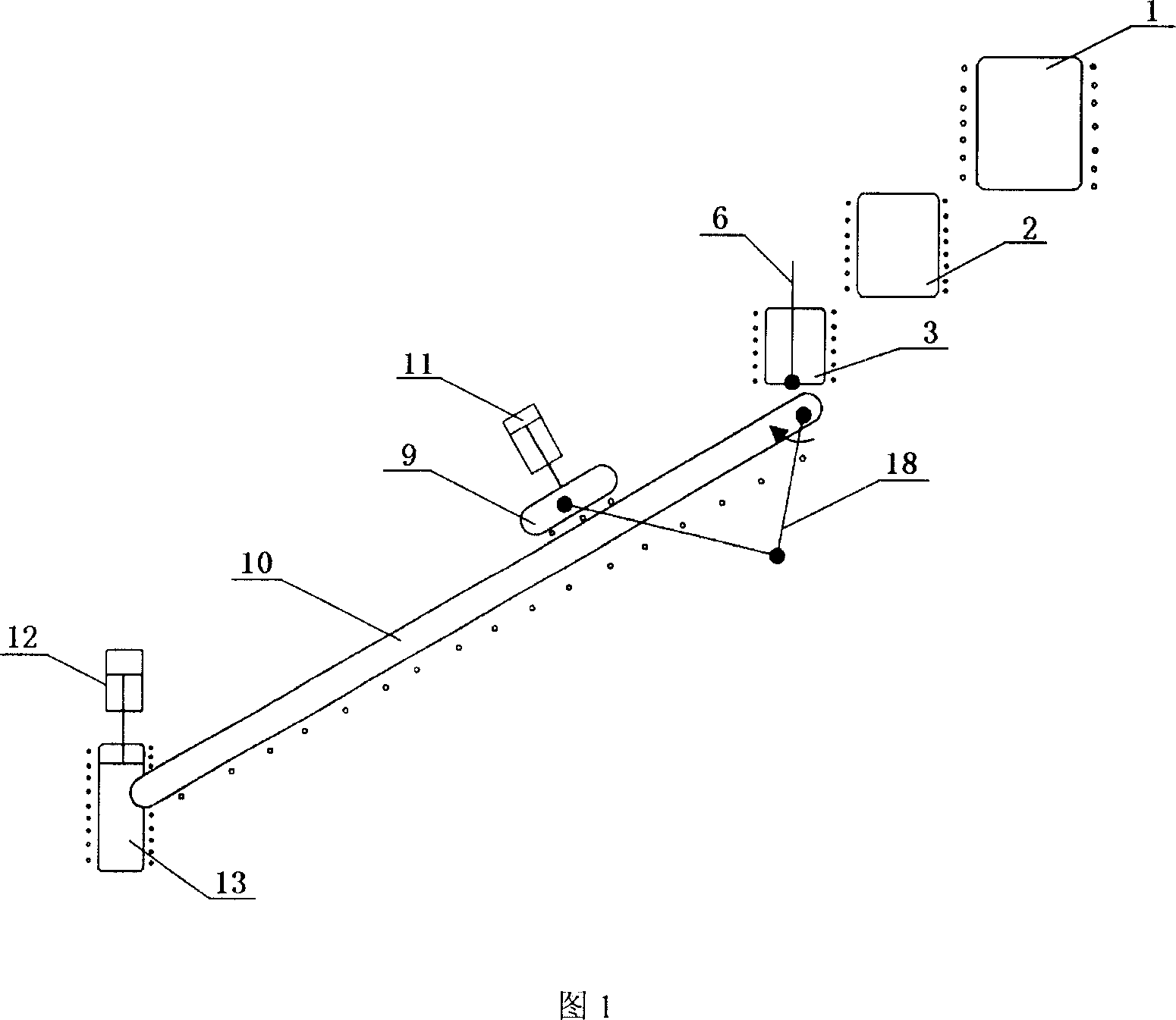

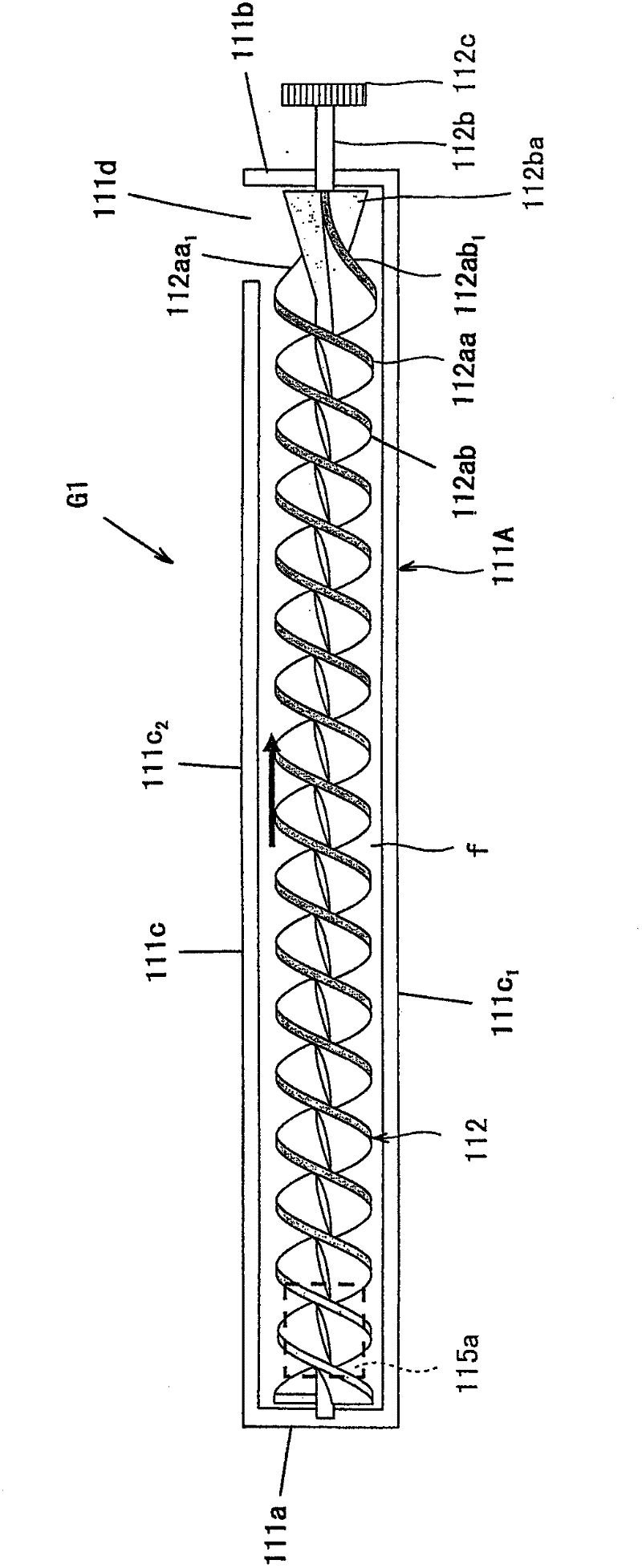

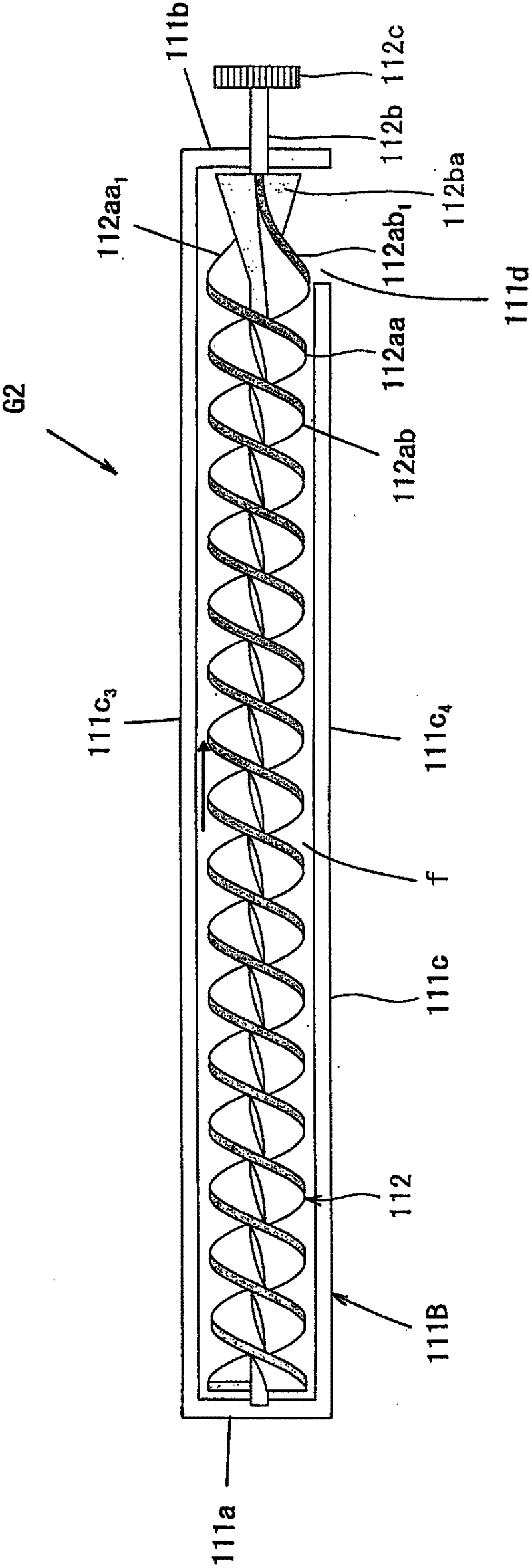

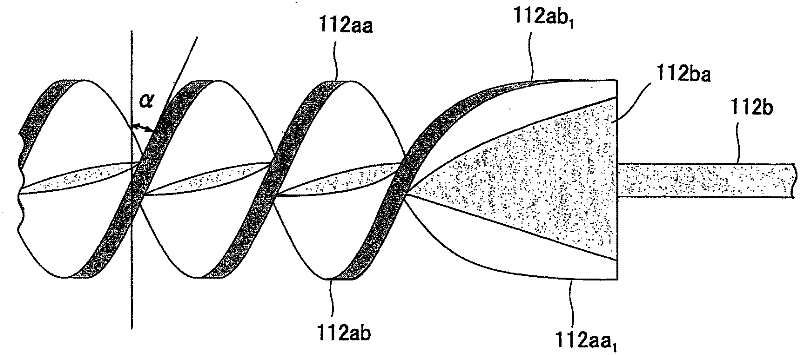

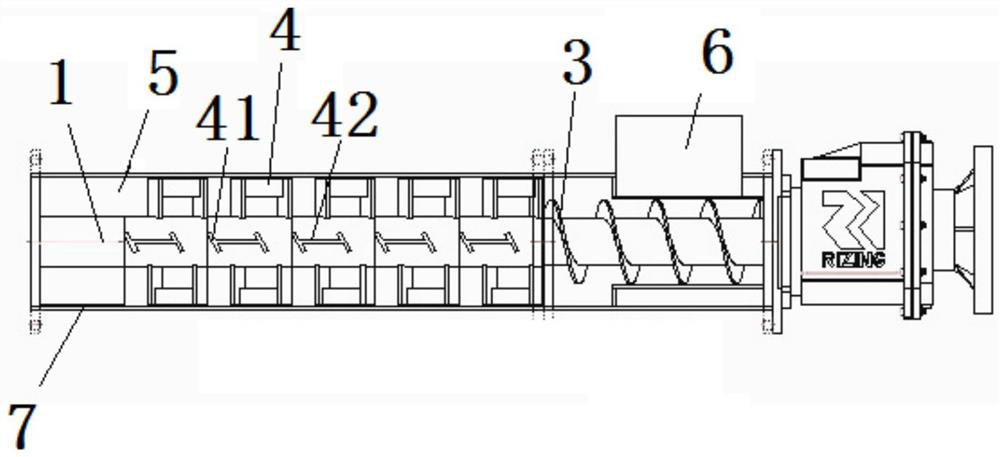

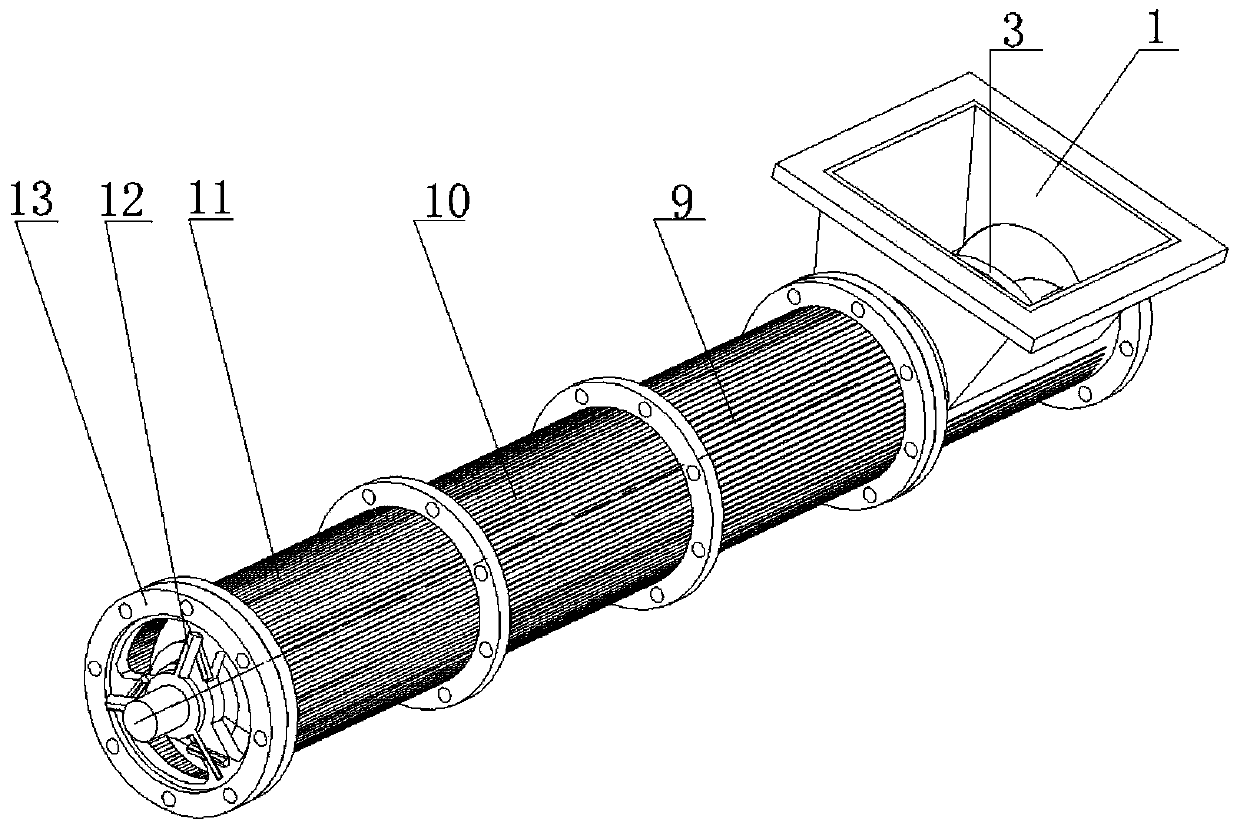

Developer conveying device and development device, toner cartridge, and cleaning unit that are provided with developer conveying device

ActiveCN102298292AReduced conveying capacityIncrease stirring powerElectrographic process apparatusSpiral bladeEngineering

The invention provides a developer conveying device and a development device, a toner cartridge, and a cleaning unit that are provided with the developer conveying device. The developer conveying device comprises a developer conveying cylinder and a screw-shaped shaft, wherein the screw-shaped shaft includes a rotating shaft that is journaled in an upstream wall portion and a downstream wall portion, which are included in the developer conveying cylinder, and a spiral blade that is mounted on an outer circumferential surface of the rotating shaft. The rotating shaft includes a conical portionthat thickens gradually toward the downstream side. And the spiral blade includes an agitating blade portion whose lead angle increases gradually toward the downstream side.

Owner:SHARP KK

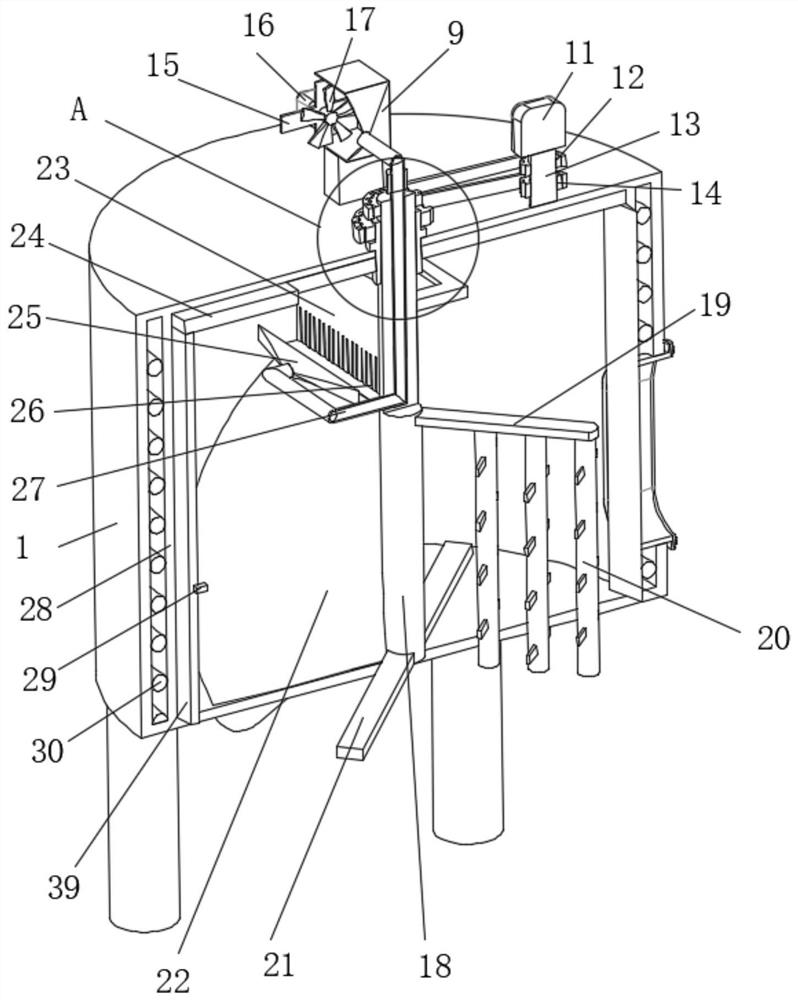

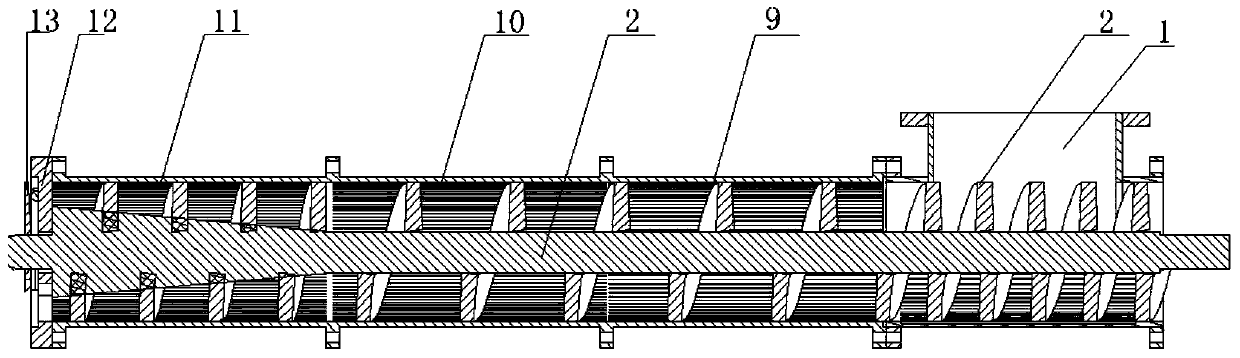

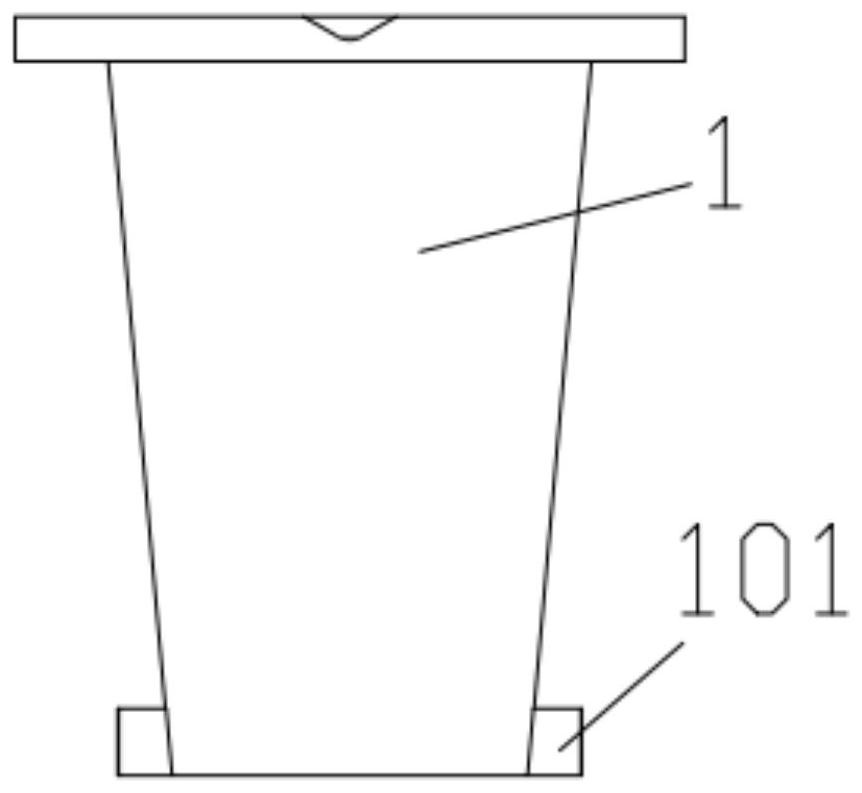

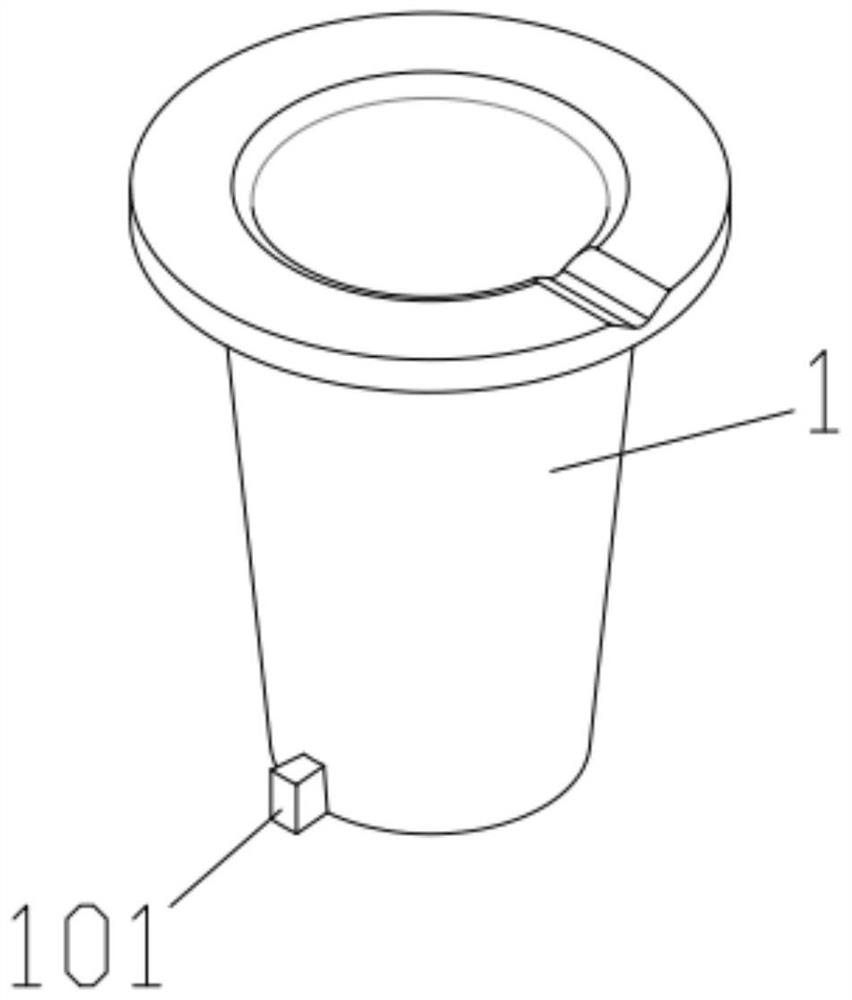

Distributing bucket

InactiveCN103114729AIncrease stirring powerEasy feedingBuilding material handlingSolenoid valveHydraulic pump

The invention discloses a distributing bucket. The distributing bucket comprises a box body, a motor accelerator-retarder, a hydraulic pump and a hydraulic solenoid valve. A stirring shaft and a discharging shaft are arranged in the box body. The stirring shaft and the discharging shaft are driven by the motor accelerator-retarder respectively. The distributing bucket is characterized in that a hopper type feeding opening is formed in the top of the box body, a weight support is arranged between the hopper type feeding opening and the inner portion of the box body, a box body purge pipe is arranged on one side of the box body, the box body purge pipe and the box body are fixed through a mounting clamp seat, multiple sets of stirring rods are arranged on the stirring shaft, two symmetrical surfaces of each stirring rod forms an angle, an end plate is arranged on a shaft head of the end portion of the feeding discharging opening, the end plate comprises a tubular shaft and vertical plates which are evenly arranged around the tubular shaft, and the end portions of the vertical plates are connected through arc plates. The distributing bucket has the advantages that feeding is convenient, washing labor intensity is reduced, manpower is saved, stirring force to the feeding is increased and side wall adhesion is reduced, materials and labor cost are reduced and the feeding shaft cannot be so heavy.

Owner:江苏中南模板科技有限公司

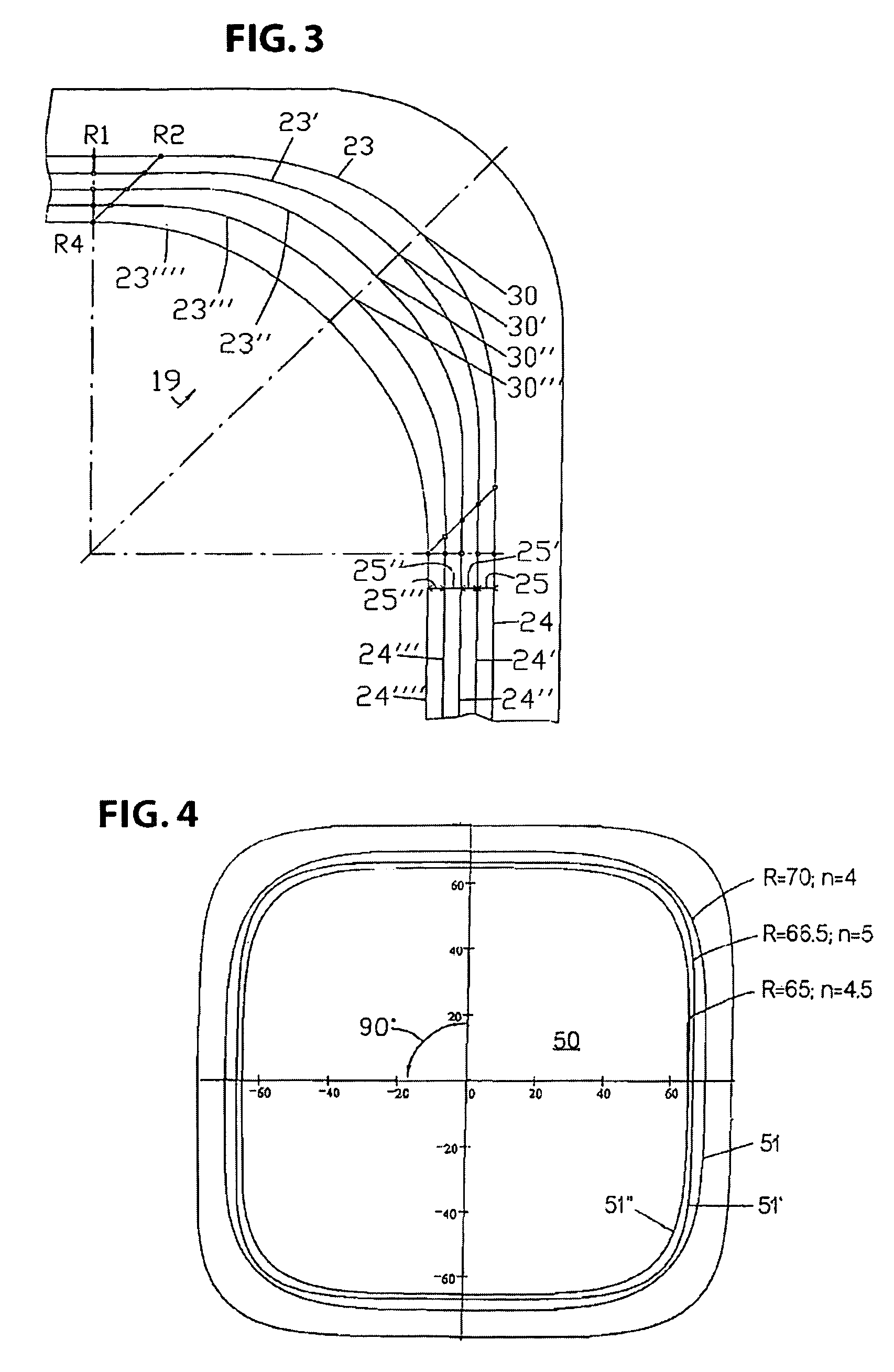

Continuous casting plant

InactiveUS20080230202A1Improve the mixing effectIncrease stirring powerCasting moldMaterials science

The invention relates to a continuous casting installation, for example for steel billet and bloom formats having substantially rectangular or circular cross-section. The invention improves the strand structure in the corner areas, to avoid rhomboidity, cracks and dimensional imperfections of the strand cross-section while achieving a high throughput capacity per strand and reducing investment and running costs. The fillets of the groove curvatures in the die cavity amount to a proportion of the length of the side of the strand cross-section. The degree of curvature 1 / R of the groove curvatures decreases in the direction of the strand at least along at least partial length of the entire casting die, thereby achieving gap elimination between the casting shell and the casting die wall and / or a targeted casting shell shaping in the area of the groove curvature. The continuous casting installation, directly downstream of the casting die, may thus be provided with a strand support-free secondary cooling zone or a supporting guide in the secondary cooling zone that is reduced in its supporting width and / or supporting length.

Owner:CONCAST AG

Ultrasonic high-energy density bead mill for biological cell wall breaking

The invention relates to an ultrasonic high-energy density bead mill used for biological cell wall breaking. The bead mill contains a breaking ultrasonic emission head, a plurality of cleaning ultrasonic emission heads, and several turbines with protruding pins. Vortex grooves of the turbine drive materials and milling beads to make strong radial circulating movement and the protruding pins to generate a strong stirring effect, so that a powerful shearing force can be generated among the milling beads and among the milling beads, the turbine and a cylinder wall so as to break cell walls rapidly. A small number of cell interleaved agglomerates that are still not broken after milling undergo concentrated ultrasonic radiation in a discharge channel, so that the cell agglomerates are dispersed and the walls are broken. In addition, ultrasonic waves can reduce the viscosity of cell fat-containing materials, mitigating adhesion wrapping of cell fat to the milling beads and a milling chamber, and have an excellent cleaning function. Due to the strengthening of the milling strength of the bead mill and the dispersion and breaking functions of auxiliary ultrasonic waves in the invention, the cell wall breaking rate is substantially increased, so that the ultrasonic high-energy density bead mill can be widely applied in the field of biological cell wall breaking.

Owner:威海叁星飞荣纳米科技有限公司

Glue making equipment with viscosity detection function

ActiveCN112705073AStir wellEasy to stir and mixRotary stirring mixersFlow propertiesGear driveElectric machinery

The invention discloses glue making equipment with a viscosity detection function in the field of glue making. The equipment comprises an outer shell, the bottom of the outer shell is connected with support legs, a discharge pipe is arranged at the bottom of the outer shell, the top of the outer shell is connected with a protective shell, an inner shell is arranged in the outer shell, and an electric heating wire is arranged between the inner shell and the outer shell. Raw materials enter the equipment through a feeding hopper, the raw materials are stirred through a stirring device, a first driving gear and a second driving gear are driven by a first motor to rotate, the second driving gear drives a second driven gear to rotate through a second gear belt so that a stirring shaft rotates, the stirring device on the stirring shaft can better stir and mix glue, and meanwhile, three uniformly arranged stirring rods on a second fixing plate rotate around the stirring shaft, the glue can be better stirred through stirring blades which are arranged on the stirring rods in a staggered manner, and the mixing efficiency is higher.

Owner:江西辰鑫科技有限公司

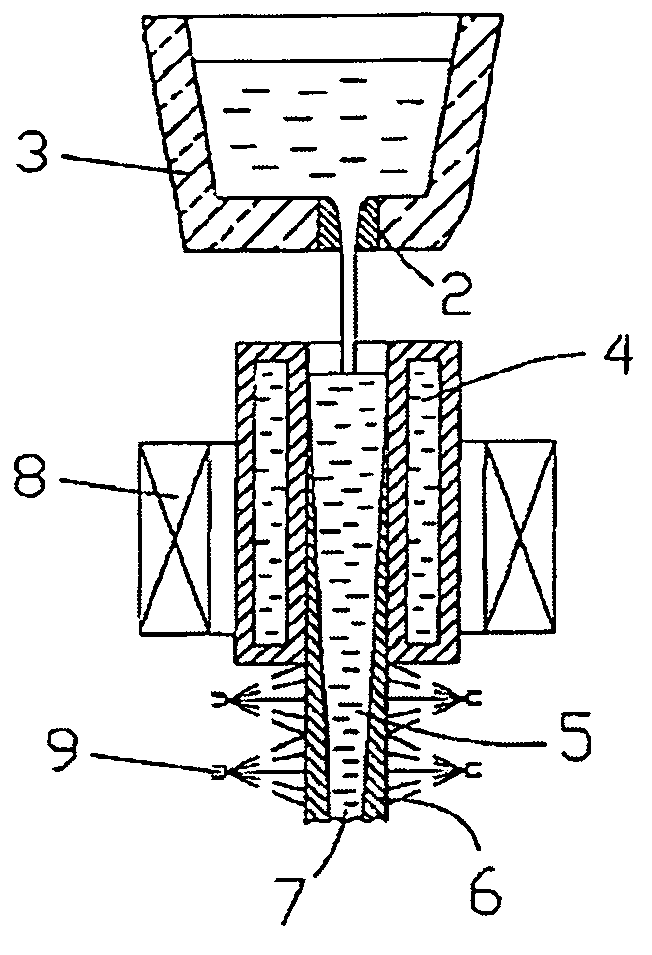

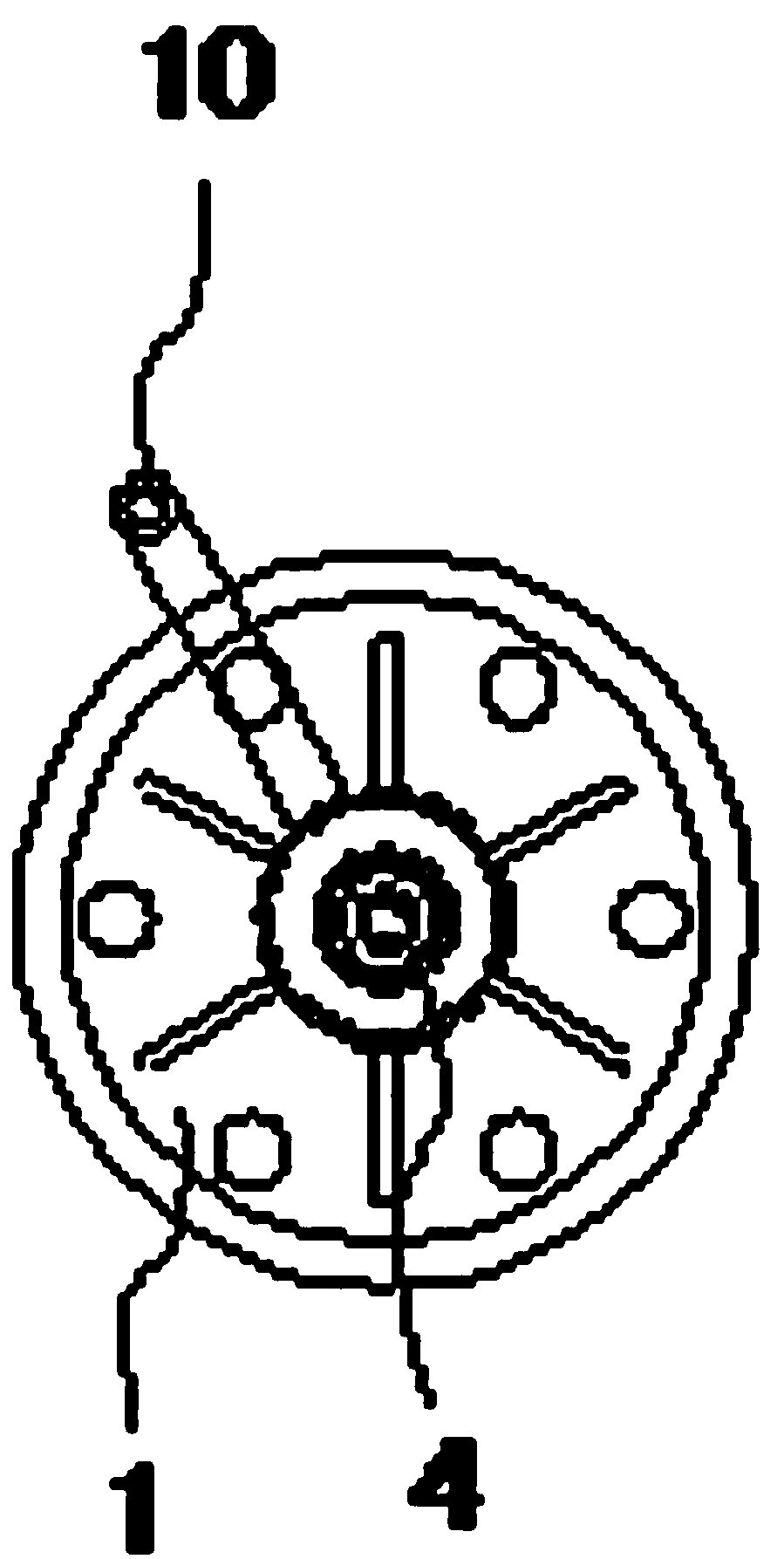

Efficient molten iron desulfurization spray gun

The invention belongs to the field of molten iron pretreatment desulfurization equipment, and particularly relates to an efficient molten iron desulfurization spray gun, which comprises a mounting flange (1), an outer protective pipe (2), a center desulfurizing agent nozzle pipe (4) and a refractory material protection layer (3); a blowing medium input pipe (10) is fixedly arranged in the mounting flange (1) region; a blowing medium gap (5) is arranged between the outer protective pipe (2) and the center desulfurizing agent nozzle pipe (4); one end port of the blowing medium input pipe (10) is communicated with the blowing medium gap (5) ; a blowing medium gas distribution mechanism (6) is horizontally fixedly arranged in the tail region of the outer protective pipe (2); the blowing medium gas distribution mechanism (6) comprises a gas supplying chamber (7) and a blowing medium nozzle (8); and the blowing medium gap (5) and the gas supplying chamber (7) are communicated. The efficient molten iron desulfurization spray gun is ideal in desulfurization effect, strong in stirring force, and fast in desulfurization reaction speed.

Owner:辽宁欣立耐火材料科技集团有限公司

Method of water-extraction-method ground sesame seed oil technology for adding water to extract oil

InactiveCN110747051AReduce labor intensityReduce vibration and oil outFatty-oils/fats productionEdible oils/fatsProcess engineeringBiology

The invention discloses a method of a water-extraction-method ground sesame seed oil technology for adding water to extract oil. The method comprises the six steps of (1) screening of a raw material,(2) rinsing of the raw material, (3) stir-frying, (4) blowing off of smoke, (5) grinding, and (6) water adding and stirring: adding hot water into slurry oil obtained through grinding at a low constant speed at once, and completing a high-speed stirring stage, a medium-speed stirring stage, a low-speed stirring stage and an oscillating oil extraction state through a stirring effect of a stirring blade. The method of the water-extraction-method ground sesame seed oil technology for adding the water to extract the oil is used for producing the ground sesame seed oil through a water extraction method.

Owner:HEZE BRANCH QILU UNIV OF TECH(SHANDONG ACAD OF SCI

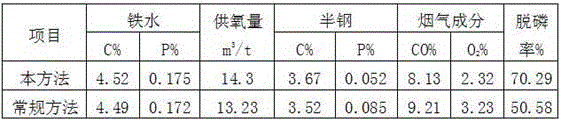

Combined blowing dephosphorization method of converter

InactiveCN105950816AOxygen for dephosphorizationSatisfy dephosphorylation powerManufacturing convertersSlagNitrogen gas

The invention discloses a combined blowing dephosphorization method of a converter. The method comprises the steps that (1) in the primary stage of combined blowing: combined blowing is carried out through adopting oxygen and nitrogen or an inert gas, the oxygen flow is controlled at 4 to 5 Nm<3> / s, after blowing for 1 to 3 min, nitrogen or the inert gas is batched, and the nitrogen flow or the inert gas flow is 20 to 30% that of oxygen; (2) in the middle stage of blowing: after slags are molten, the oxygen flow is increased to 5 to 6 Nm<3> / s, after the temperature is obviously increased, the nitrogen flow or the insert gas flow is adjusted to 1.1 to 2.2 Nm<3> / s, and the total gas mixture flow is controlled at 6 to 8 Nm<3> / s; and (3) in the later stage of blowing: the maximum total gas mixture flow is not larger than 8.33 Nm<3> / s, and the total oxygen supply is controlled at 12 to 16 m<3> / t during the blowing process. According to the method, high phosphorus molten iron is introduced into the converter, oxygen nitrogen combined blowing is adopted, small-large gas supplies are adopted, the oxygen nitrogen combined injection rate is adjusted, the oxygen supply intensity is guaranteed to meet the oxygen utilization requirement of dephosphorization, mixed gas pressure meets the requirement of dephosphorization power, and dephosphorization and carbon protection are achieved to the greatest extent.

Owner:HEBEI IRON AND STEEL

Multifunctional manually-operated fruit and vegetable shredder

The invention discloses a multifunctional manually-operated fruit and vegetable shredder. The multifunctional manually-operated fruit and vegetable shredder comprises a cup body and a cutter rack rotating shaft inside the cup body; a plurality of cutting blades are arranged on the cutter rack rotating shaft; a base is arranged at the bottom of the cup body; a wire winding wheel is arranged inside the base; a base rotating shaft is arranged inside the wire winding wheel, and the outer wall of the base rotating shaft is provided with a reset spring; winding wires are wound on the outer wall of the wire winding wheel; a metal shaft is embed into the bottom of the cutter rack rotating shaft; a plurality of scraper units are embedded at the top end of the cutter rack rotating shaft. During application, the cup body and the base are detachably connected through the metal shaft; a manual driving device is arranged inside the base, so that shredders in different sizes can share the same base, and further low use cost can be achieved also, the stirring force of the cutter rack rotating shaft can be large in the position close to the bottom of the cup body and good shredding effects can be achieved, and meanwhile, the stability of the cup body during stirring can be high.

Owner:GUANGDONG SHUNDE MINGYOU ELECTRIC CO LTD

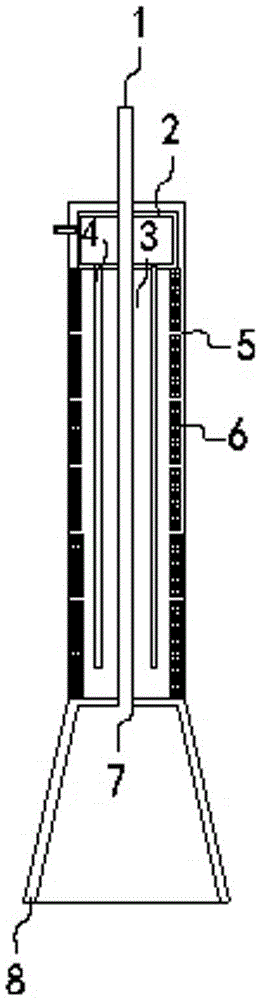

Molten-iron desulphurization spraying gun

The invention belongs to the field of molten iron pretreatment desulphurization devices, and particularly relates to an efficient molten-iron desulphurization spraying gun. The molten-iron desulphurization spraying gun comprises a spraying gun body. The spraying gun body comprises a central spraying pipe (1), a gas storage chamber (2) and a gas distribution bin (3). The central spraying pipe (1) penetrates through the gas storage chamber (2) and is fixedly connected with the gas storage chamber (2). A gas spraying and blowing pipe (4) is arranged in the gas distribution bin (3). An upper end opening of the gas spraying and blowing pipe (4) is communicated with the gas storage chamber (2), and a lower end opening of the gas spraying and blowing pipe (4) is communicated with the gas distribution bin (3). A plurality of gas spraying and blowing openings (5) are formed in the side wall of the gas distribution bin (3). A fireproof material protection layer (6) is fixedly arranged outside the gas distribution bin (3). The molten-iron desulphurization spraying gun is simple in structure, large in stirring force and high in desulphurization efficiency.

Owner:营口东邦环保科技股份有限公司

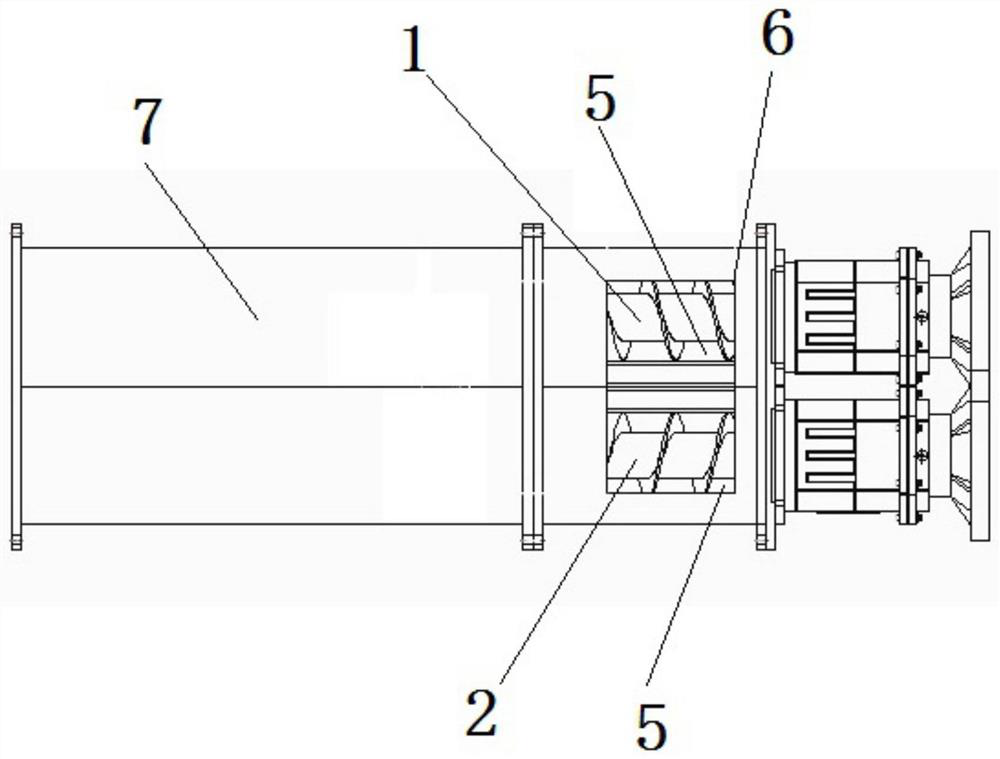

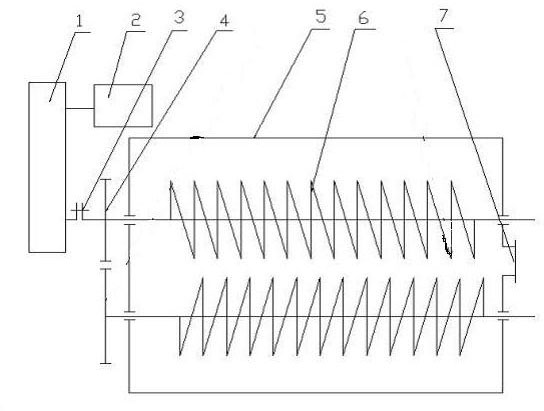

Double-shaft and double-cylinder pulping device

PendingCN113858431AQuality assurancePrecise and controllable ratioMixing operation control apparatusIngredients proportioning apparatusEngineeringSlurry

The invention belongs to the technical field of slurry preparation, and relates to a double-shaft and double-cylinder pulping device. The device comprises: a stirring cylinder, wherein the stirring cylinder is provided with two stirring cavities, a communication channel is formed between the two stirring cavities, and each stirring cavity is provided with a feed port and a discharge port; two stirring shafts; and stirring paddles. When the two stirring shafts rotate, the rotating directions of the two stirring shafts are opposite, so that materials in the first stirring cavity collide with materials in the second stirring cavity at a connecting channel, and the phase angle between the stirring paddle arranged on the first stirring shaft and the stirring paddle arranged on the second stirring shaft is 45 degrees; and the materials in the two stirring cavities spirally advance in the two stirring cavities corresponding to the communication channel according to the 8 shape. The double shafts rotate in opposite directions for stirring, so that collision among the materials is increased, and the pulping speed and the pulp quality are improved. The materials spirally advance in the two stirring cavities corresponding to the communicating channel according to the 8 shape, the motion path of the materials is long, and the quality of pulp is better guaranteed.

Owner:HENAN QIANGNAI NEW MATERIALS CO LTD

Continuous strengthened blender

InactiveCN102350242AOvercoming inadequate mixingOvercoming noiseRotary stirring mixersEngineeringBuilding construction

The invention discloses a continuous strengthened blender, overcoming the defects of insufficient material mixing, large noise during stirring and low stirring efficiency of the traditional blender. The continuous strengthened blender also can overcome the defects of low efficiency, big possibility of polluting environment and large equipment land occupation. In addition, the continuous strengthened blender has the advantage of regulating stirring efficiency and quality requirements according to material performances and construction requirements.

Owner:许西彪

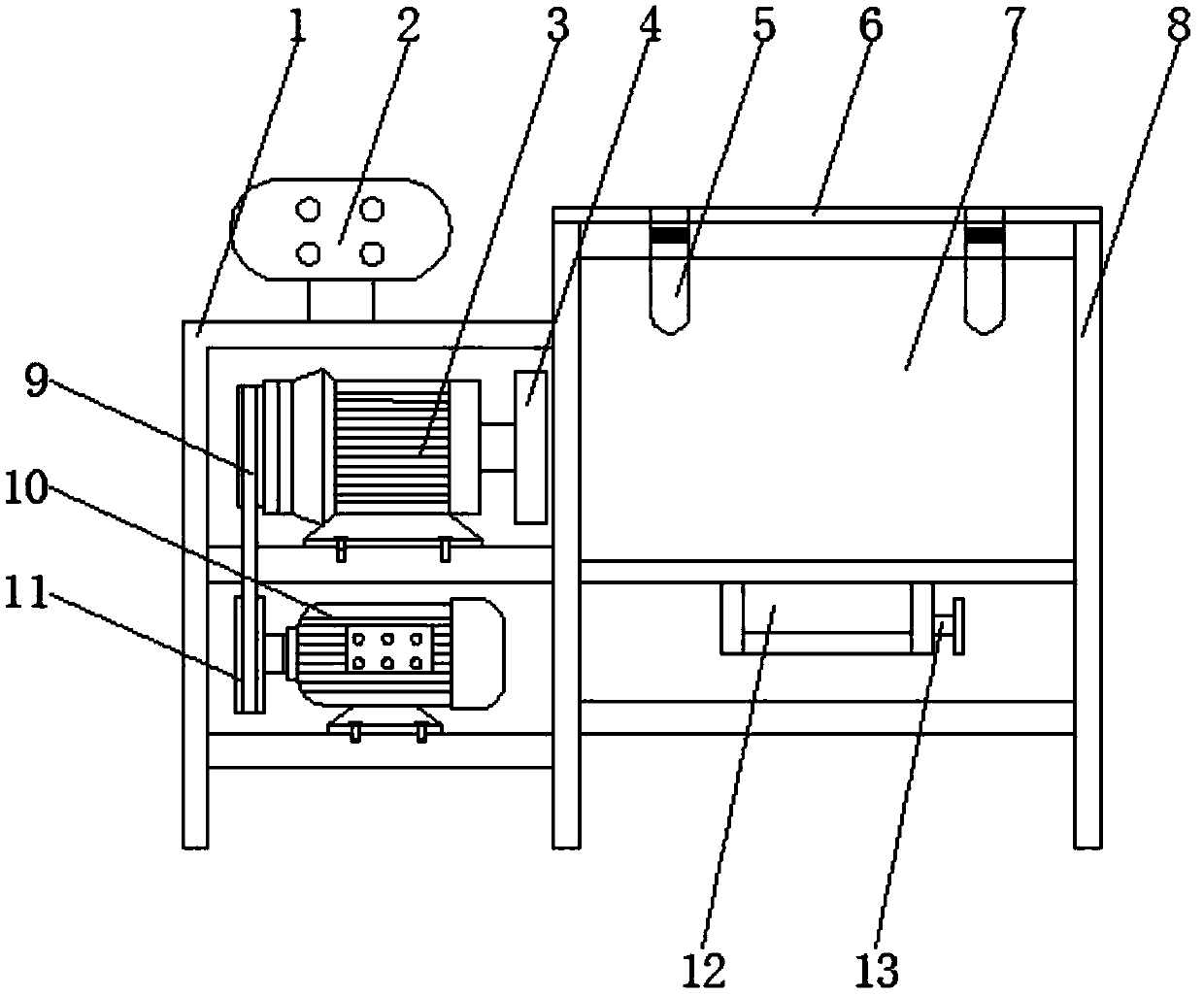

Double-roller feed stirring machine

InactiveCN109589818AIncrease stirring powerStir wellFeeding-stuffRotary stirring mixersReduction driveReducer

The invention discloses a double-roller feed stirring machine comprising a protection box, a machine body and a paddle mounting disk; an upper partition plate and a lower partition plate in the protection box are respectively provided with a speed reducer and an electric motor; the machine body is rotatably connected with a flip by using a hinge; the protection box is fixedly connected with one side surface of the machine body; the front side surface of the machine body is provided with a handlebar, and a discharging hole is formed in the lower end of a stirring box mounted inside the machinebody; a rotating gear arranged at one end of the speed reducer is engaged and connected with a rotating gear arranged at one end of two rotating rollers by wheel teeth; the paddle mounting disk is fixedly connected with the rotating rollers by using bolts and is provided with two paddles; and sealing rings are mounted at junctions of the rotating rollers and the stirring box. The double-roller feed stirring machine is provided with the two rotating rollers, so that a larger stirring force can be provided, and the double-roller feed stirring machine is suitable for stirring feed thick materials; and meanwhile, the paddles on the rotating rollers are designed to be of a staggered structure, so that a feed is stirred more uniformly.

Owner:天津一芳田农业科技发展有限公司

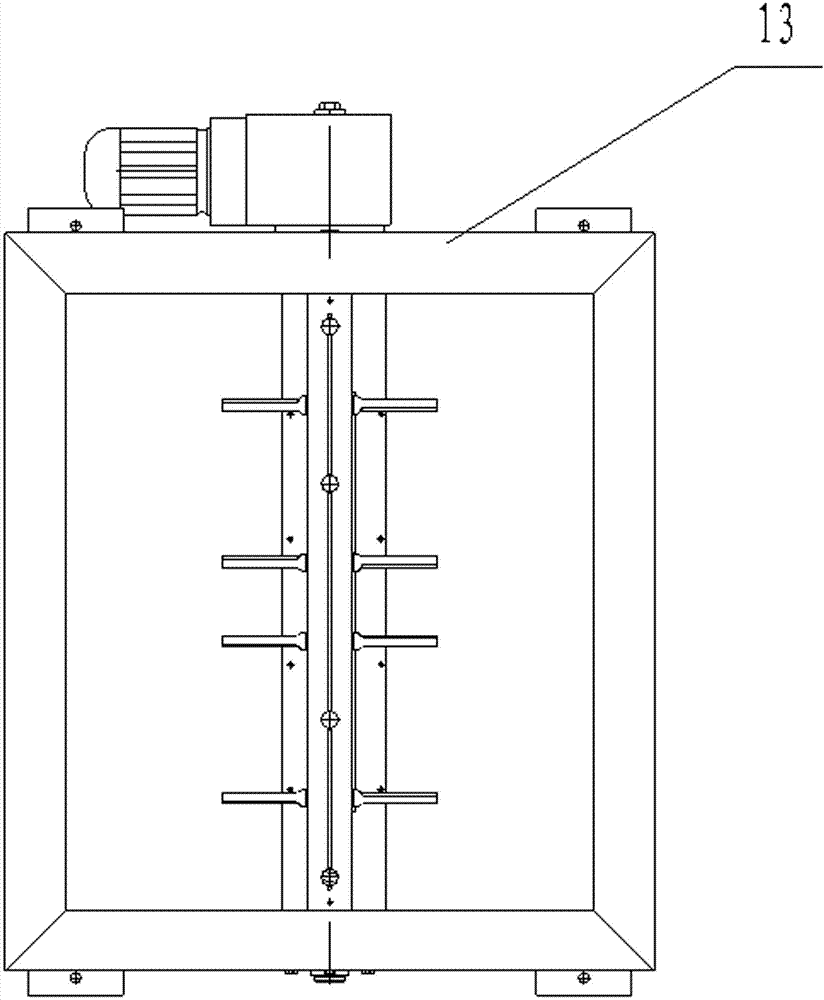

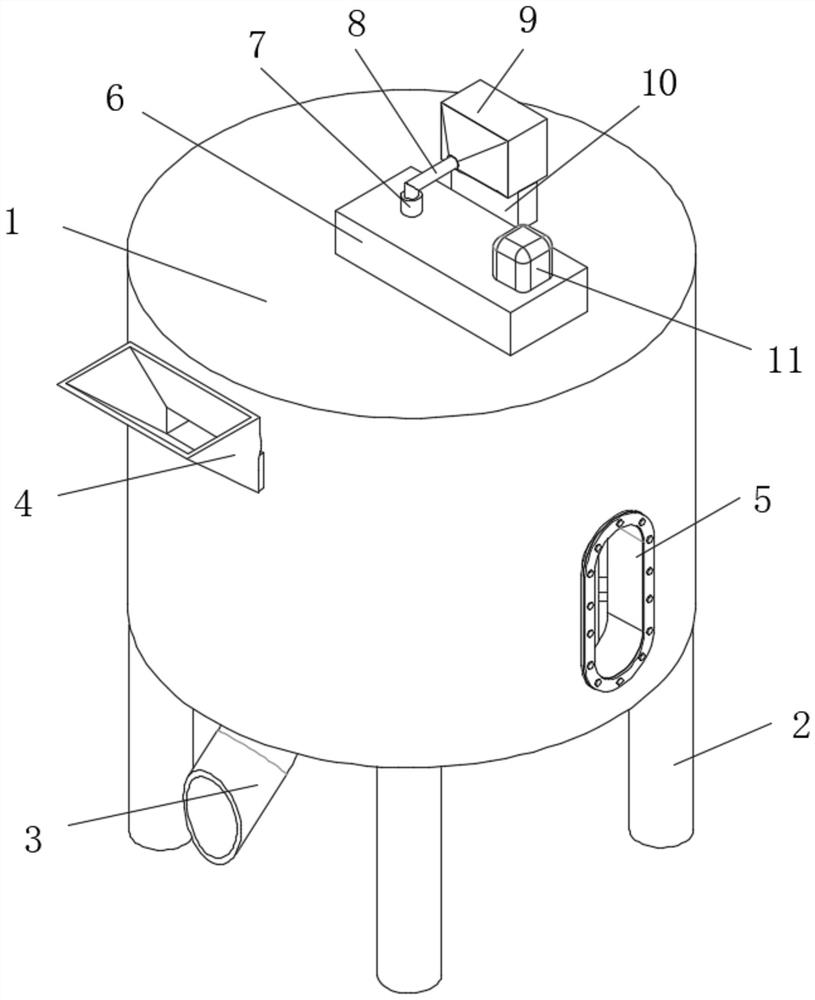

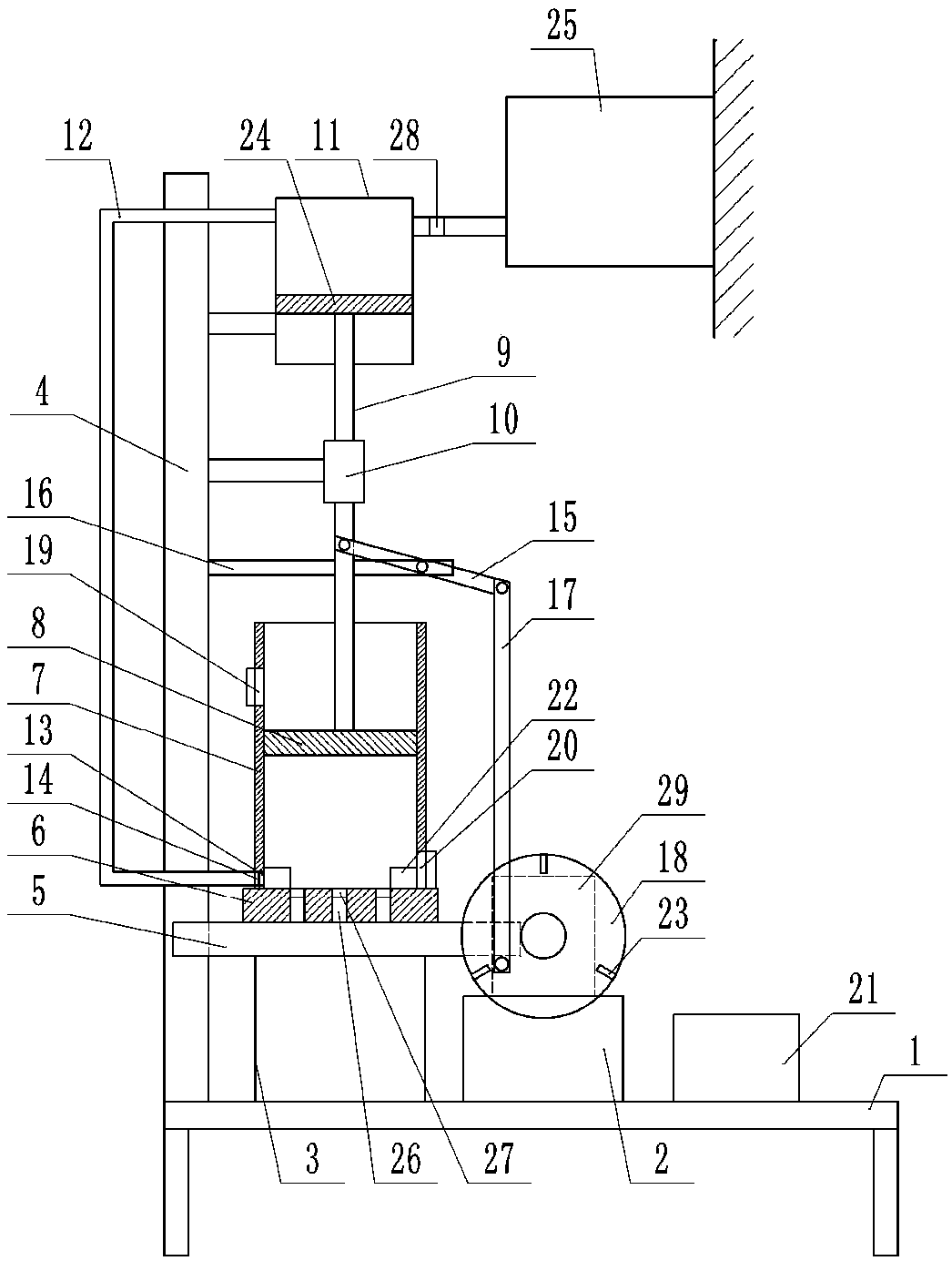

Garbage treatment fermentation device

PendingCN111452411AImprove delivery efficiencySmall footprintSolid waste disposalTransportation and packagingBiotechnologyEngineering

The invention relates to a garbage treatment fermentation device. The garbage treatment fermentation device comprises a dehydration feeding device, a vertical feeding device, a circulating stirring device, a fermentation bin and a circulating discharging device, wherein the vertical feeding device comprises a feeding cylinder body, the upper end of the feeding cylinder body is inserted into the fermentation bin, a transmission shaft penetrating through the cylinder body is arranged in the center of the feeding cylinder body, the transmission shaft is provided with auger blades from bottom to top, a feeding port is formed in one side of the lower part of the feeding cylinder body, the feeding port is in butt joint with an outlet of the dehydration feeding device, the circulating stirring device is arranged in the fermentation bin and comprises a central rotating shaft, the lower part of the central rotating shaft is connected with a plurality of stirring arms, the stirring arms are distributed in a multi-claw type structure, a discharging port is formed in the bottom of one side of the fermentation bin, and the discharging port is in butt joint with the circulating discharging device. The garbage treatment fermentation device is compact in overall equipment structure, the occupied area is reduced, the conveying is stable, and the dehydration and fermentation effects can be improved.

Owner:中环怡美环境科技(浙江)有限公司

Bamboo shoot washing device

ActiveCN108813669AAvoid damagePlay the role of turning materialFood treatmentEngineeringMechanical engineering

The invention belongs to the technical field of food processing equipment, and particularly discloses a bamboo shoot washing device. The bamboo shoot washing device comprises an operation table, a mounting frame, a supporting frame, a supporting rod, a worm wheel, a bottom disk, a washing barrel, a push plate, a sleeve pipe, a horizontal shaft, a push rod, a motor, a rotating disk and a worm, wherein the supporting rod is hinged to an eccentric position of the rotating disk; a horizontal rod is hinged to the horizontal shaft; a feeding opening and a discharging opening are formed in the washing barrel; baffle plates for opening and closing the feeding opening and the discharging opening are separately arranged at the feeding opening and the discharging opening; a sealing strip is arrangedon each baffle plate; a first one-way valve which is in one-way conduction to the inner part of the washing barrel is arranged at the bottom of the washing barrel; a plurality of water outlet holes are formed in the bottom disk; and a second one-way valve which is in one-way conduction to the outer part of the washing barrel is arranged in each water outlet hole. The bamboo shoot washing device disclosed by the invention is mainly used for washing bamboo shoots, and the problem that when the bamboo shoots are washed, impurities are left on the bamboo shoots easily, so that the washing effect is poor is solved.

Owner:徐琼华

Desulfurizing agent and desulfurizing method for converter

Owner:HEBEI XINDA IRON & STEEL GRP CO LTD

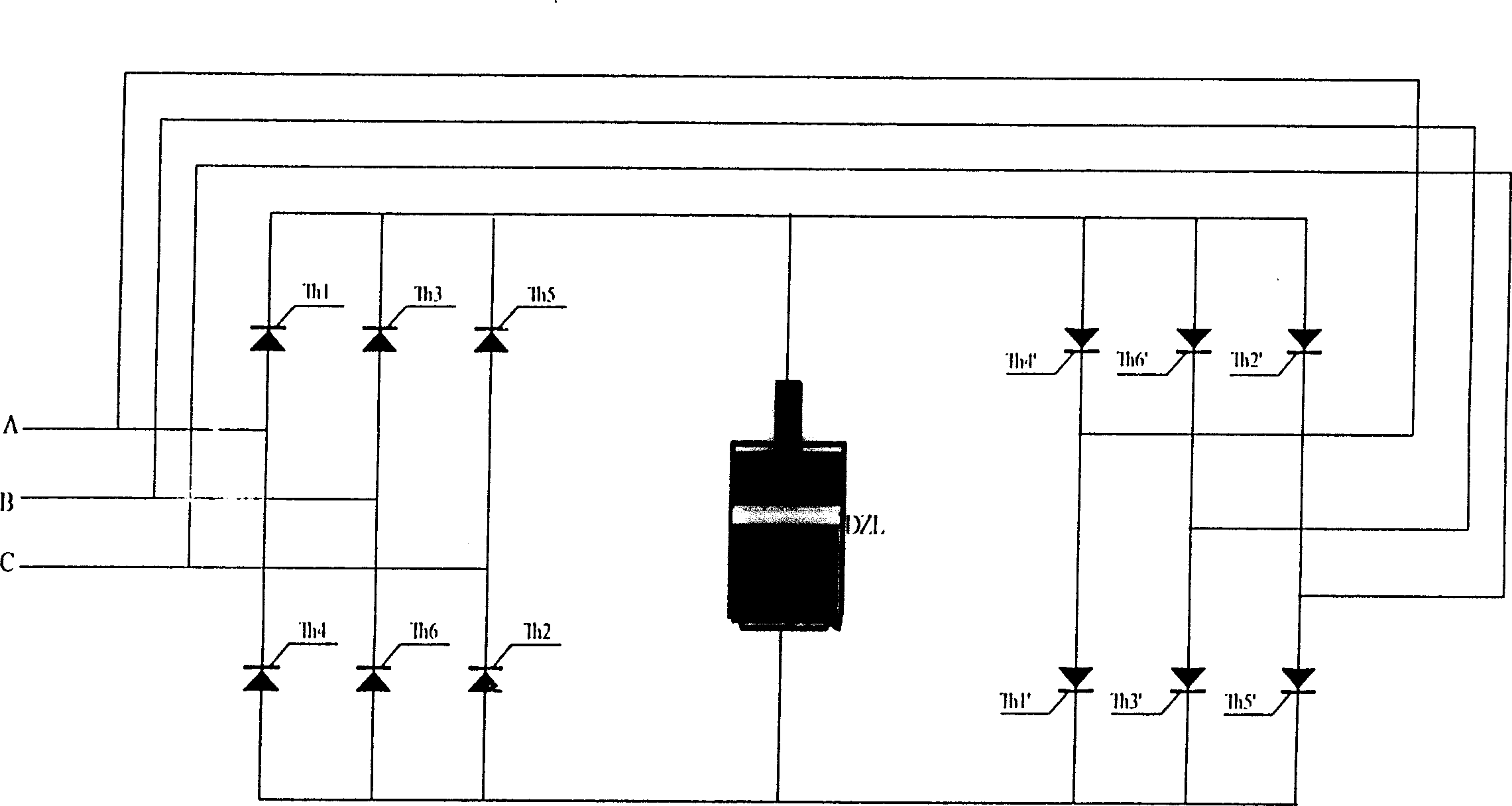

Electroslag furnace thyratron transistor low-frequency heating and smelting apparatus

This invention relates to a low frequency heating smelt device for a thyristor electroslag refining furnace, in which, an output end of a bridge full control commutating circuit composed of thyristors of Th1í»-Th6í»is parallel inversely on an output of a bridge full control commutating circuit composed of thyristors of Th1-Th6 to be parallel on a self-cost electrode and a crystallizer of a electroslag heavy melting furnace via a short net, which is advantaged that since the electroslag furnace uses the single phase load, if an electromagnetic transformer is used to change the three- phase to single or a single phase is used directly, the three phase voltages at the net side will be seriously unbalance to break the supply quality and the operation of low frequency supplier does not influence the three-phase voltage of the net side.

Owner:朱兴发 +1

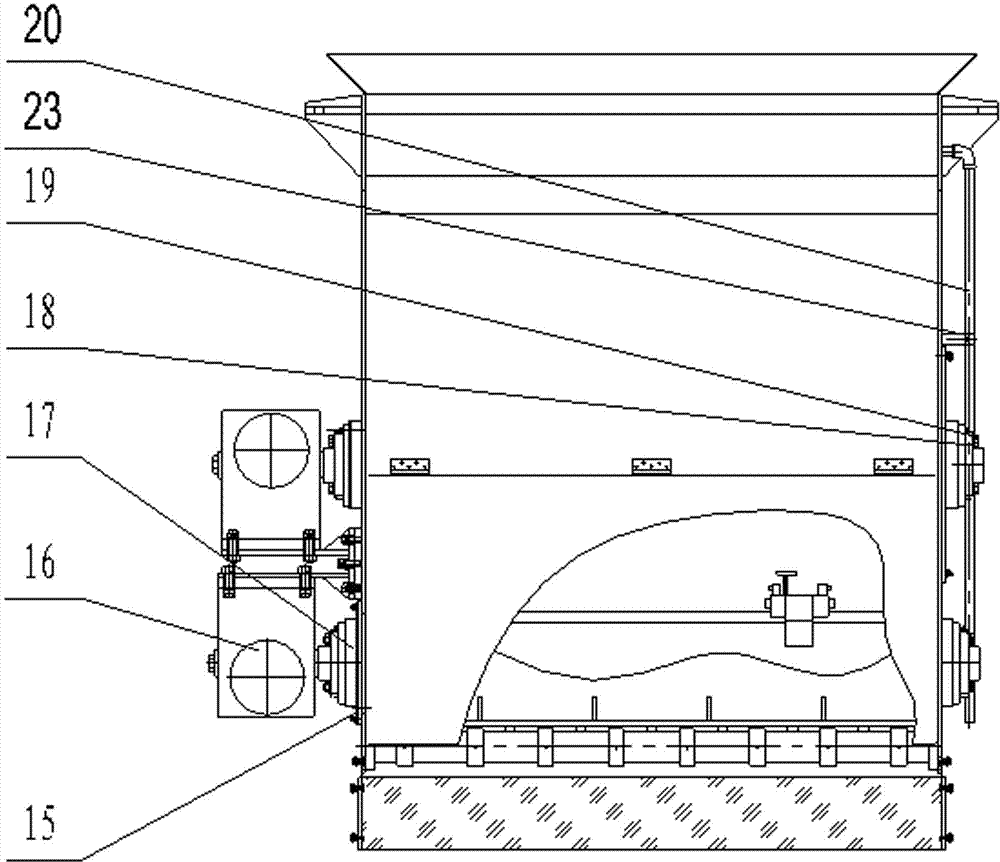

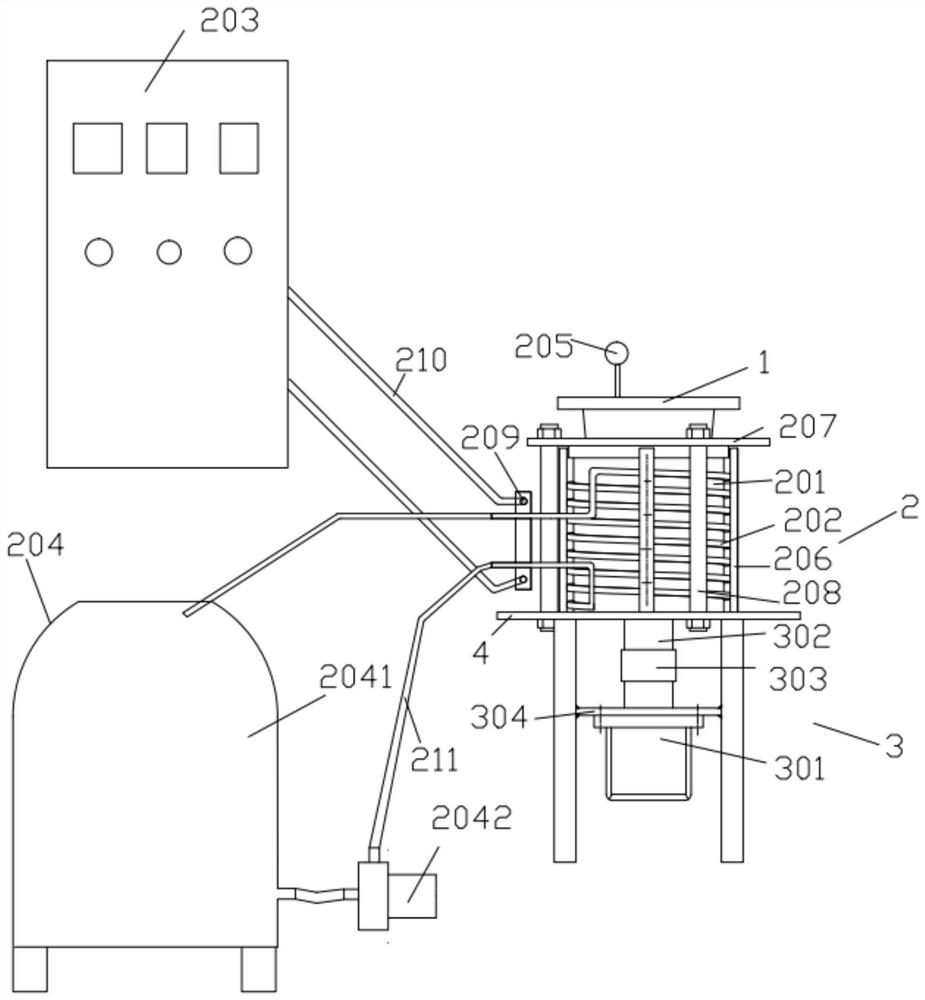

A composite preparation process and equipment for semi-solid metal paste

The invention discloses a composite preparation process and composite preparation equipment for semisolid metal slurry. A weak electromagnetic stirring device and a mechanical stirring device are compounded together to prepare the semisolid metal slurry. Compared with an existing semisolid metal slurry preparation technique, the compound preparation process has the advantages that 1, compared witha rotary magnetic field electromagnetic stirring method, the electromagnetic field can be fully covered to avoid a skin effect and the needed energy consumption is low; 2, compared with a weak electromagnetic stirring method, the stirring force of alloy slurry is enhanced, the time needed to obtain the semisolid metal slurry is shortened, and the efficiency is improved; 3, compared with a mechanical stirring method, no mechanical stirrers are available, so that the defects that the stirrer is corroded and the alloy slurry is polluted are overcome, and meanwhile, the temperature of the slurryis controllable; 4, the composite preparation equipment is simple in structure, low in cost, flexible to control process and convenient to operate; and 5, the composite preparation process solves theproblem of low preparation efficiency of the semisolid slurry in large structural part production in production of large structural parts, the weights of which are over 5 Kg.

Owner:XI AN JIAOTONG UNIV

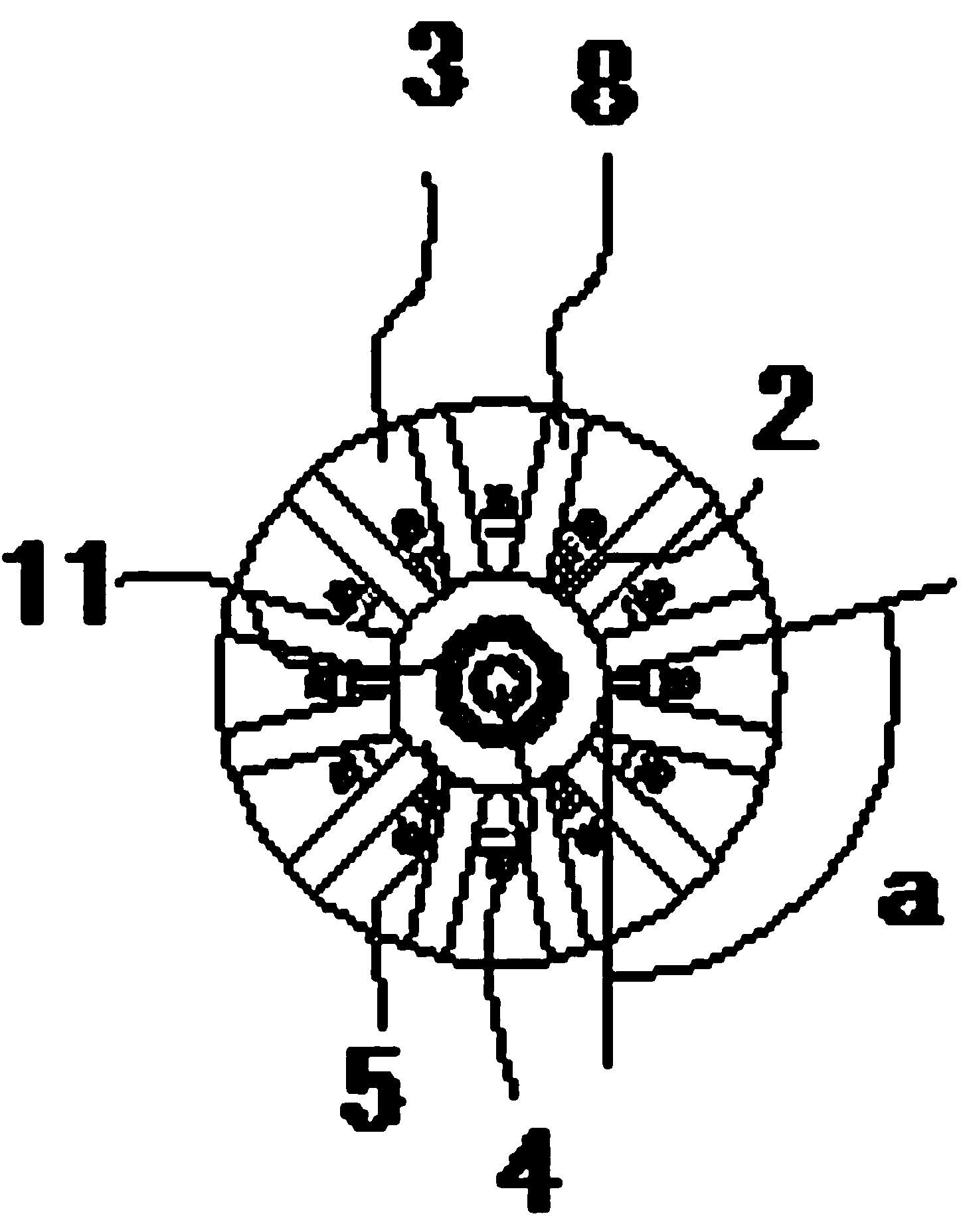

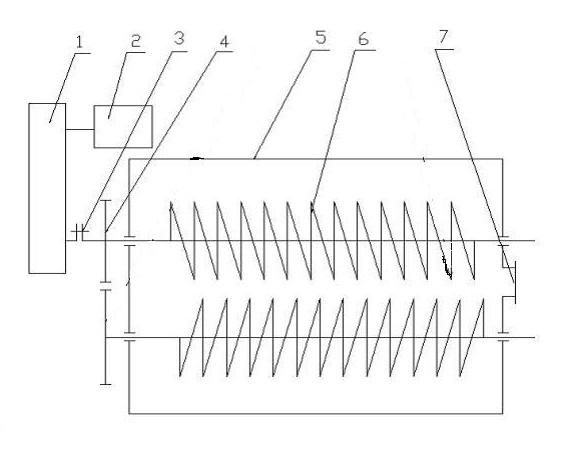

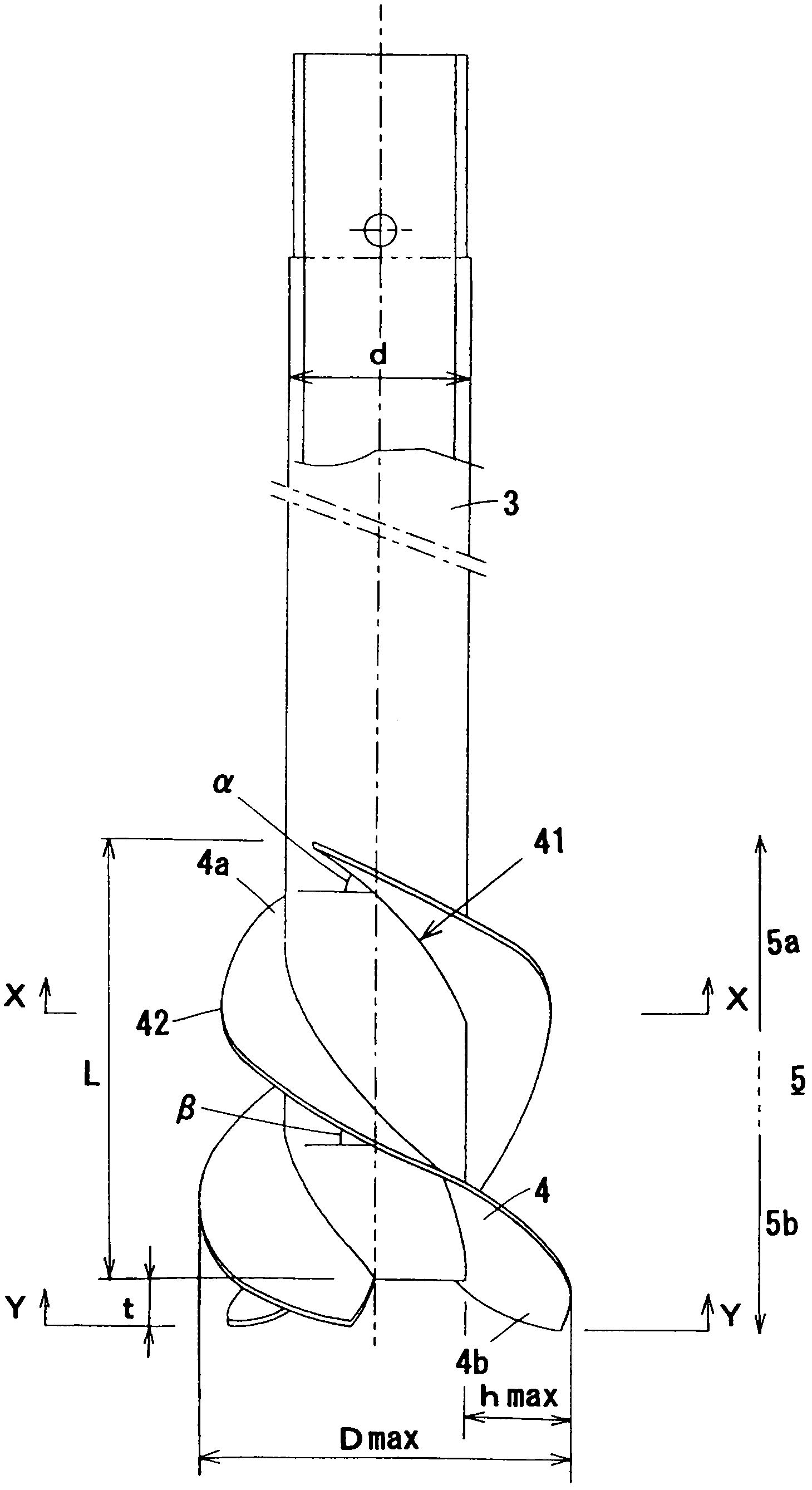

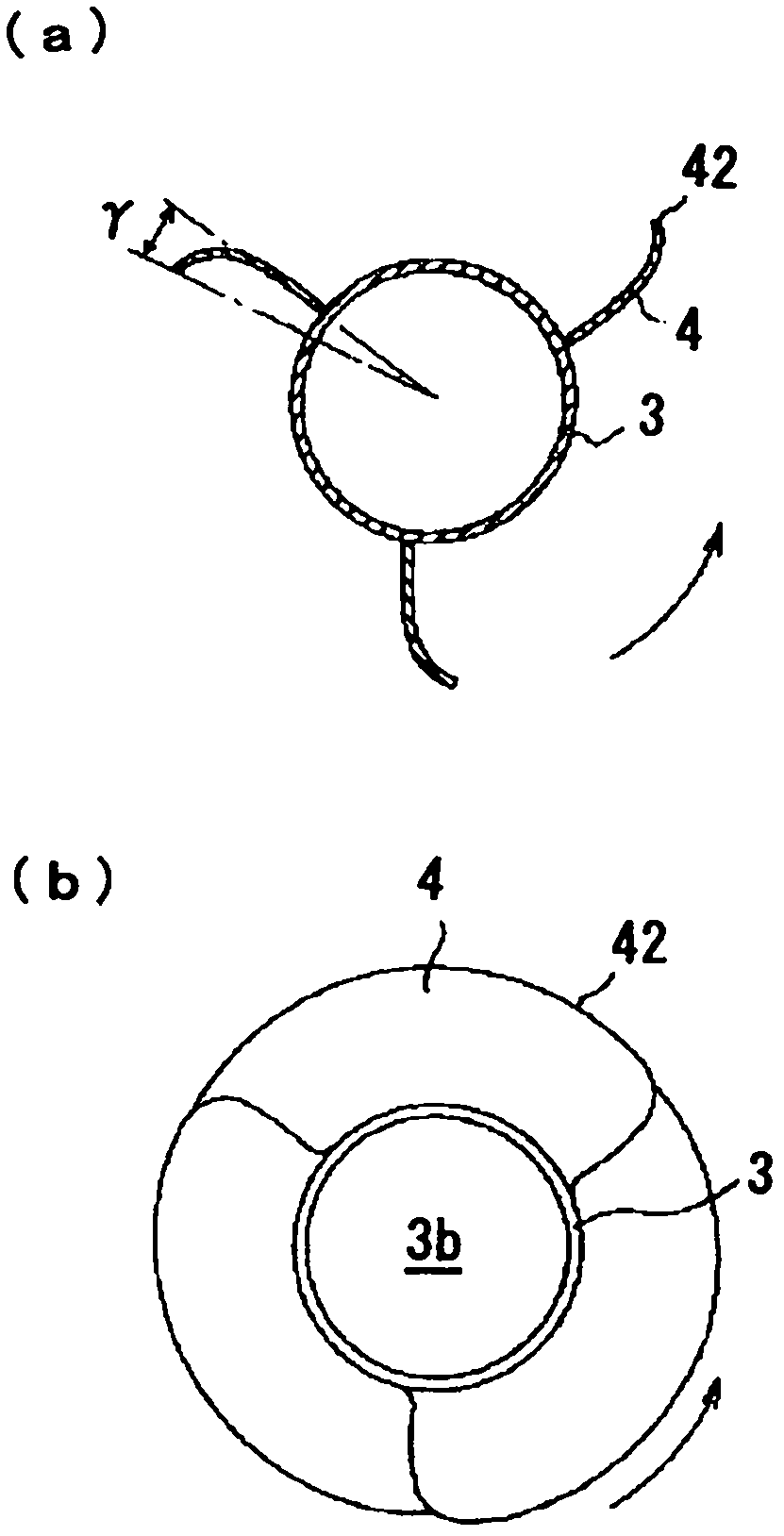

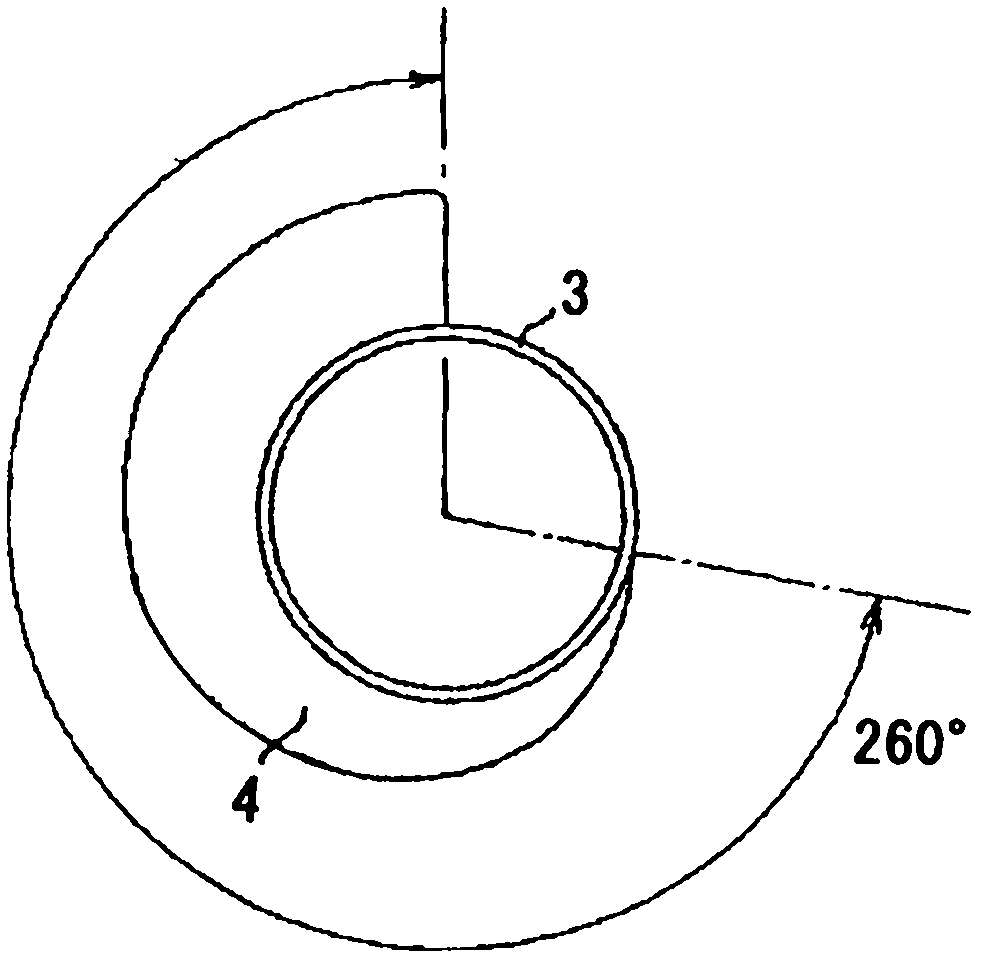

Screw propeller for aerator

ActiveCN102616948BIncrease absolute speedIncrease stirring powerWater aerationSustainable biological treatmentGreek letter betaMaximum diameter

Provided is a screw propeller for an aerator, featuring excellent aeration performance, simple structure, and easy making, capable of generating necessary bottom flow rate applicable to the groove with high depth of water without specially adding the power of each groove volume. In the invention, the length (L1) of the copula (41) between the blade (4) and the hollow shaft (3) is 1 to 1.5 times of the length of the blade (4) in winding direction; the angle beta, formed by the outer edge (42) of the blade upon the screw propeller outlet portion (5b) and the circumferential direction of the hollow shaft (3), is within the range of 30 to 100 degree; the winding angle (theta) of the blade (4) relative to the hollow shaft (3) is 360 degrees / the number of the blades to 360 degrees; and the ratio (d / Dmax) of the external diameter (d) of the hollow shaft (3) to the maximum diameter (Dmax) of the blades ranges from 0.30 to 0.55.

Owner:HITACHI LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com