Immersed inflating and stirring device of injection type floatation cell for coal separation

A technology of inflatable stirring and flotation machines, applied in the field of flotation machines, which can solve the problems of increased wear, energy loss, and short service time, and achieve the effect of reliable operation and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further introduced below in conjunction with the accompanying drawings and embodiments.

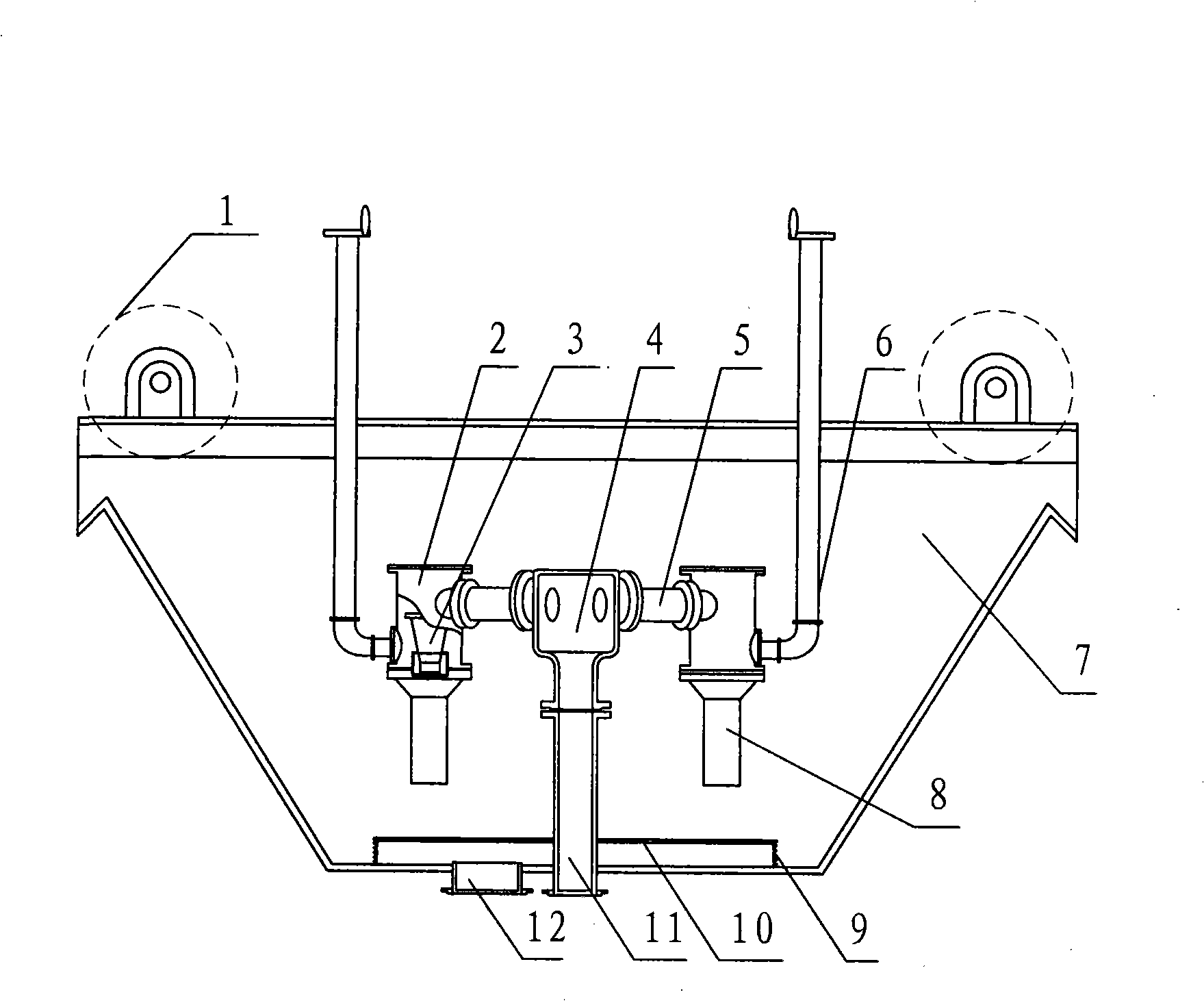

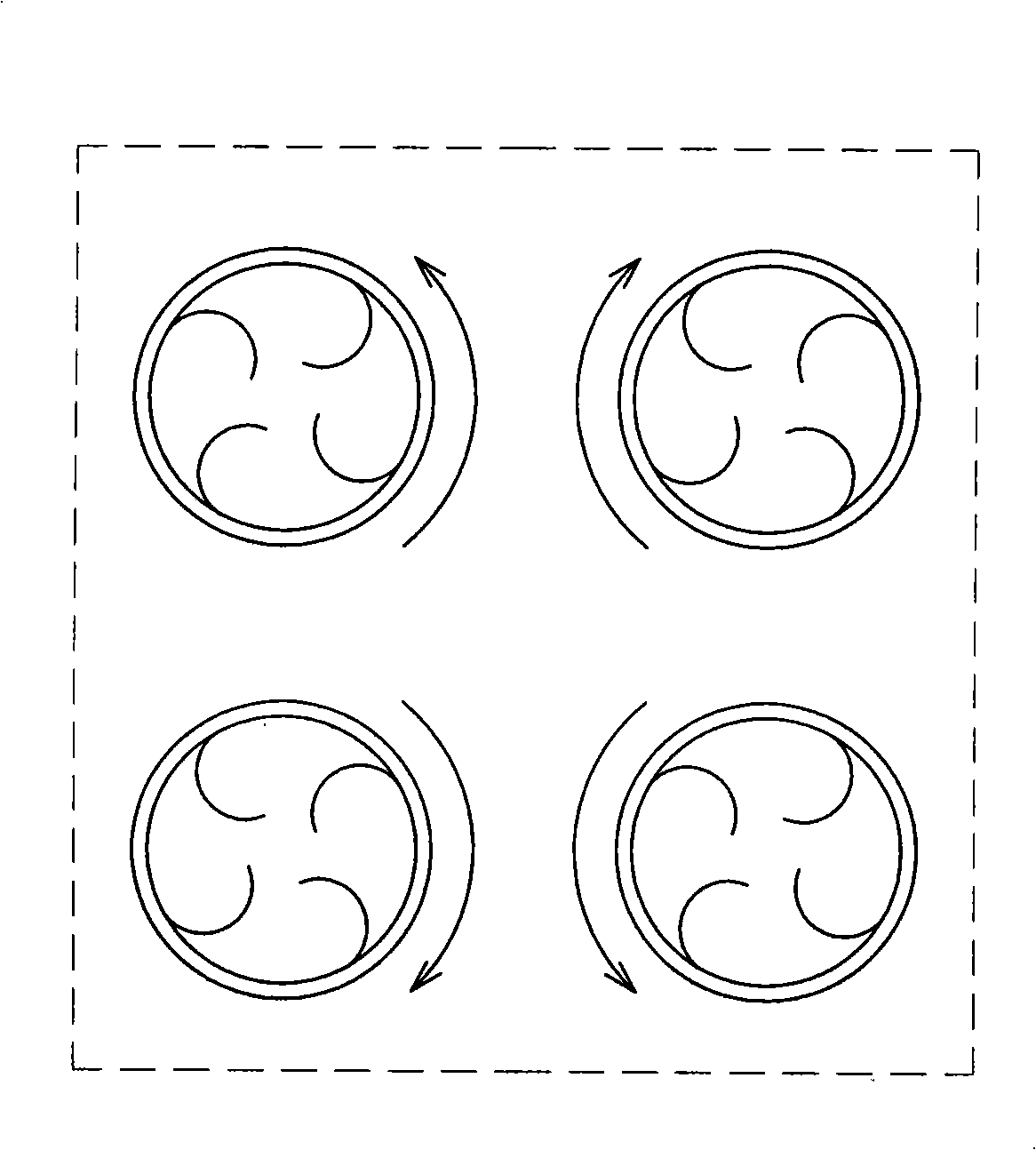

[0022] See attached Figure 1~2 , In this embodiment, the aeration stirring device is placed inside the flotation machine tank 7, and the device is composed of a spray chamber 2, a nozzle 3, a short throat 8 and a suction pipe 6 and the like. Wherein, the lower end of the distribution chamber 4 located in the center of the flotation machine tank is fastened with the upper end of the central feeding pipe 11, and the two are internally connected, and the lower end of the central feeding pipe 11 protrudes from the bottom of the tank body 7 The outer wall of the distribution chamber 4 is evenly equipped with four spray chambers 2 arranged in a radial pattern. The distribution chamber 4 communicates with each spray chamber 2 with a connecting short pipe 5. Connected with guide vanes, wherein the direction of rotation of the nozzle guide vanes in the two in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com