Distributing bucket

A hopper and material shaft technology, which is applied in the processing of building materials, construction, building structure, etc., can solve the problems of inconvenient feeding of the hopper, inconvenient cleaning, low work efficiency, etc., to reduce the cleaning labor intensity, The effect of convenient feeding and manpower saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

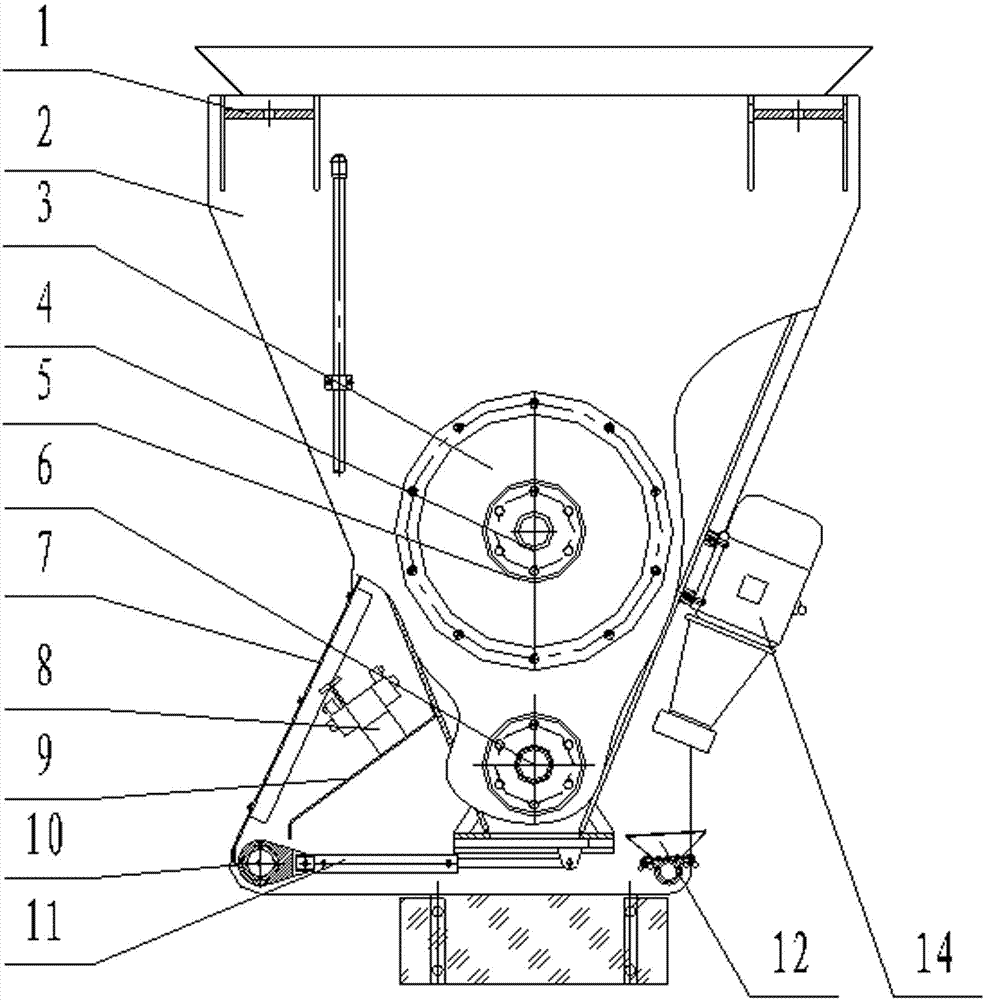

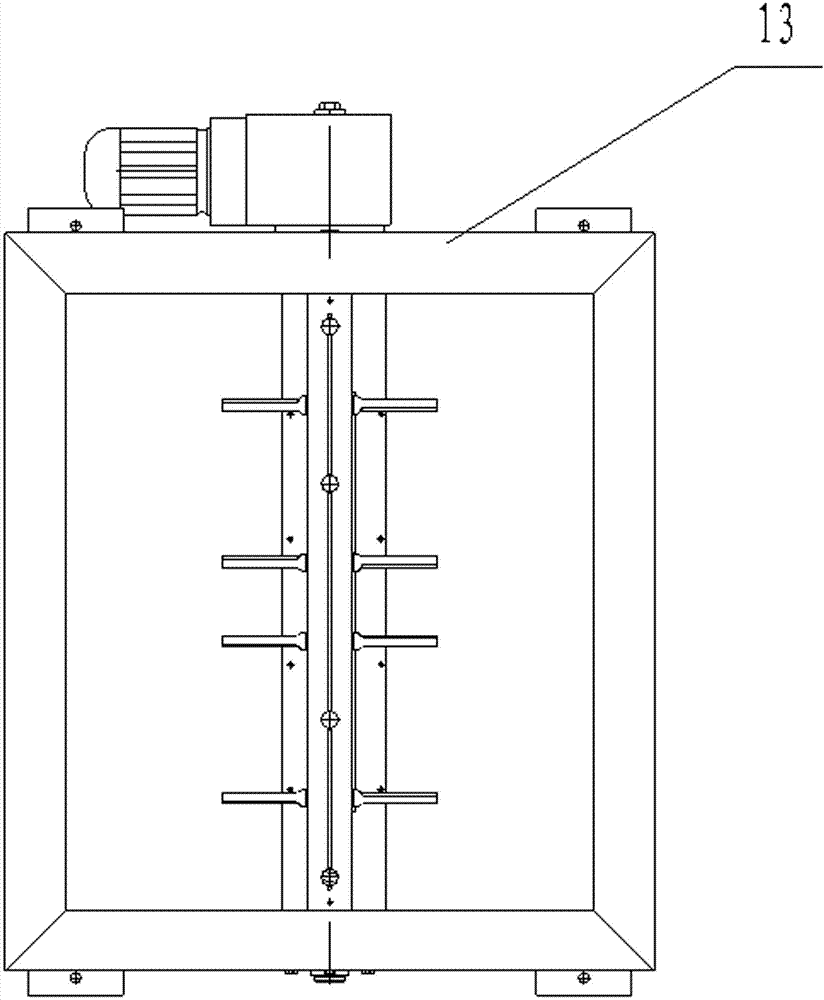

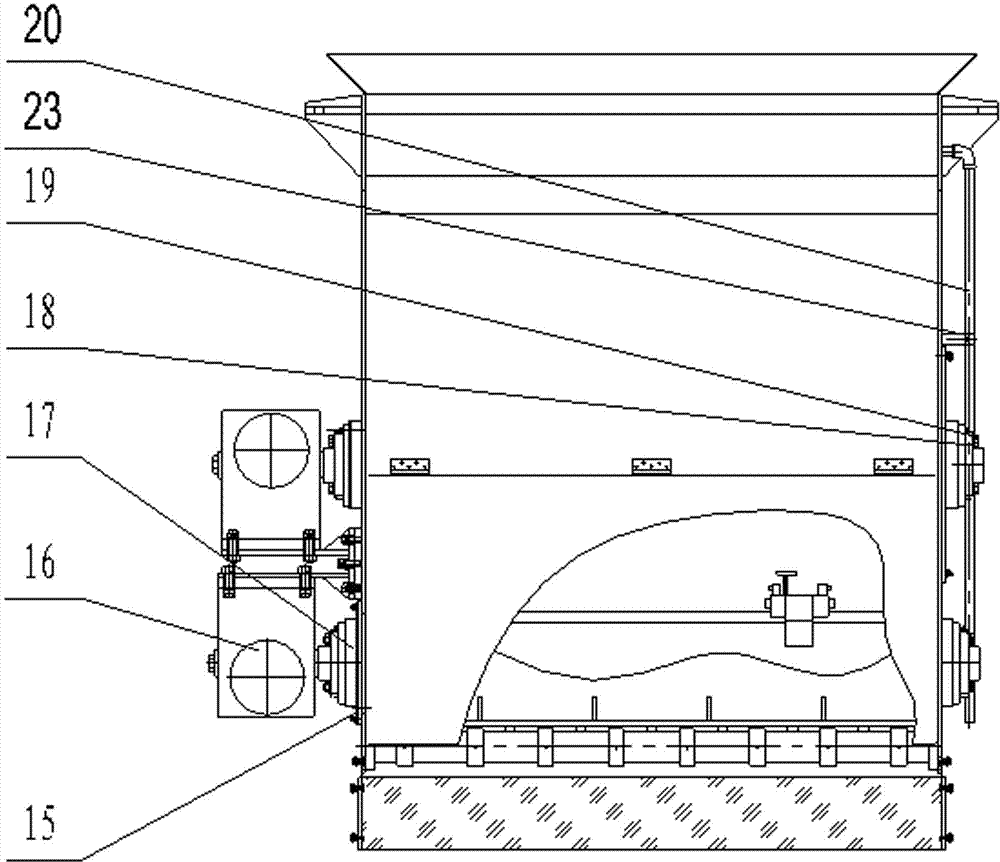

[0021] Such as Figure 1-6 As shown, the distribution hopper of the present invention includes a box body 2, a power motor acceleration and deceleration device 16, a hydraulic pump 14 and a hydraulic solenoid valve 8, and the power motor acceleration and deceleration device 16 is fixed on the motor acceleration and deceleration device mounting seat 13. The hydraulic pump 14 and the hydraulic solenoid valve 8 are respectively arranged on both sides of the bottom of the box body 2, the hydraulic solenoid valve 8 is fixed on the box body 2 through the hydraulic solenoid valve mounting plate 9, and the hydraulic solenoid valve 8 is provided with a cover plate 7. The box body 2 is provided with a stirring shaft 4 and a feeding shaft 6, and the stirring shaft 4 and the feeding shaft 6 are respectively driven by a power motor acceleration and deceleration device 16, and the stirring shaft 4 is connected to the box through a spherical bearing 21. The body 2 is connected, the upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com