Electroslag furnace thyratron transistor low-frequency heating and smelting apparatus

A low-frequency heating and thyristor technology, applied in the field of frequency conversion devices, can solve the problems of low efficiency, high energy consumption, and reduced power supply quality of the power grid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

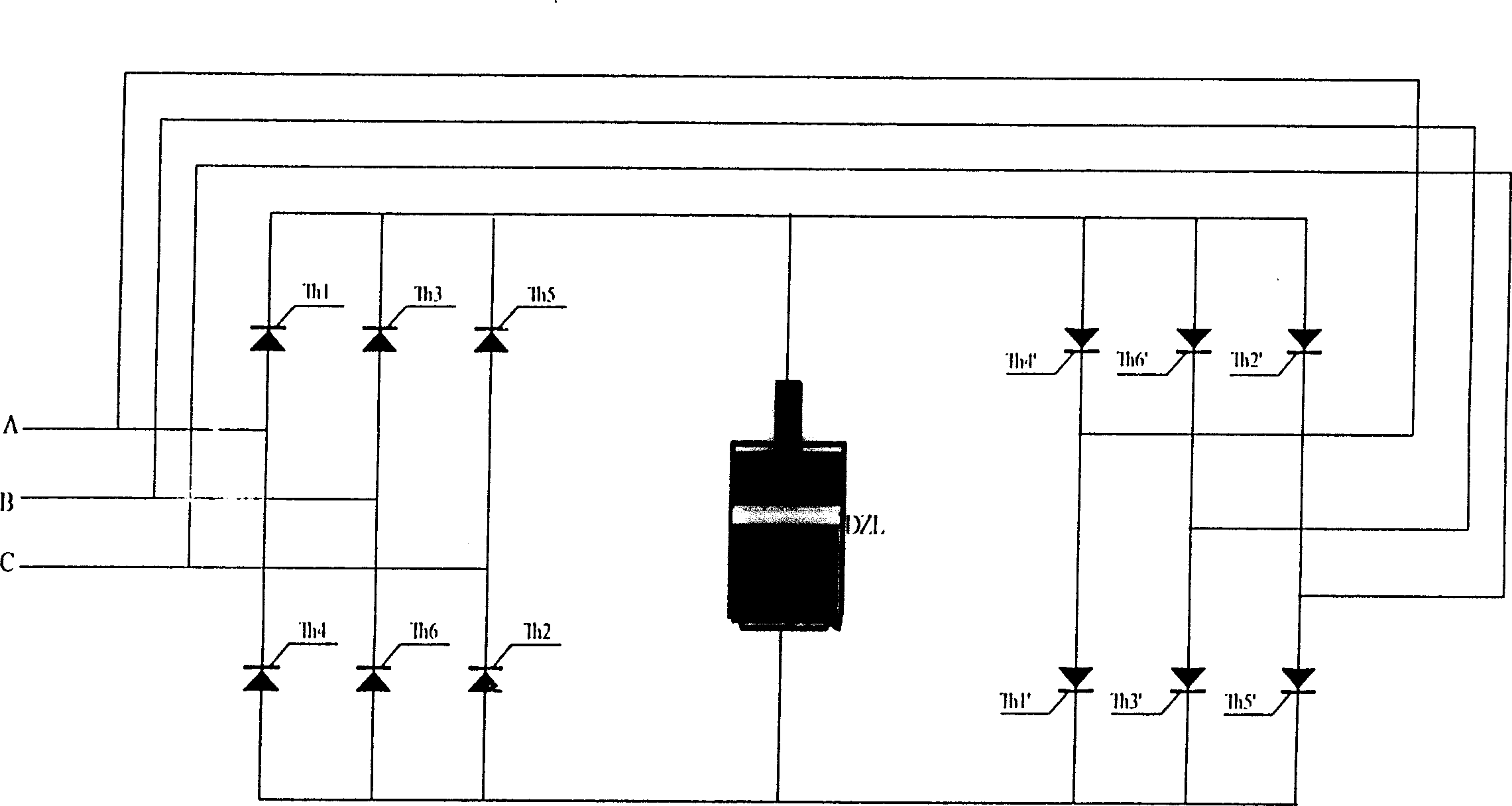

[0006] Referring to the accompanying drawings, its structure is to reversely connect a thyristor Th 1 ~Th6 1 The output end of the composed bridge type fully controlled rectification circuit is then connected to the consumable electrode and crystallizer of the electroslag remelting furnace through a short network.

[0007] The low-frequency power supply is low-voltage and high-current system, when the three-phase power frequency voltage U A , U B , U C When the power is 90V and the power is 3000KW, the output current of the secondary side of the electric furnace transformer is 27200A. It can be seen that the minimum electromagnetic induction design of the conductor and the optimal design of the short network are important ways to improve the electrical efficiency. The low-frequency conversion heating and smelting device of the utility model provides an energy-saving and environment-friendly product with low energy consumption and no grid pollution for the electroslag remelt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com