Patents

Literature

63results about How to "Reduce cleaning labor intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for continuously cooking rice

A technology for continuously cooking rice includes such steps as washing rice, immersing, quantitatively loading in boxes, microwave cooking and outputting rice in boxes. Its apparatus is composed of screw conveyer, high-position rice tank, rice washer, redox washer, jet-type sprayer, step impurities remover, rice immersing container, oblique rich dropper, quantitative loaders of rice and water, and continuous microwave cooker. Its advantages are high speed, high utilization rate of heat energy, and high productivity.

Owner:SOUTH CHINA UNIV OF TECH

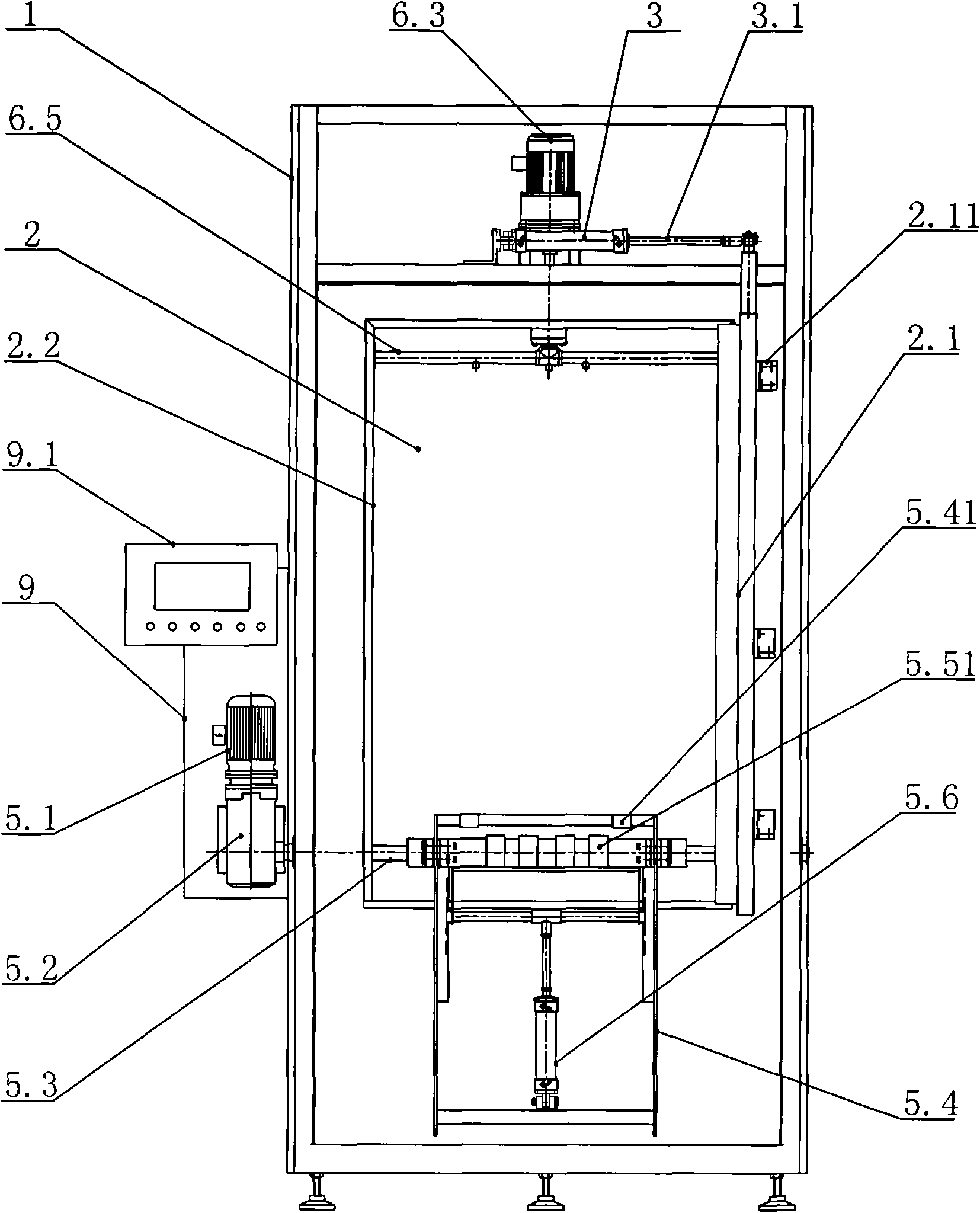

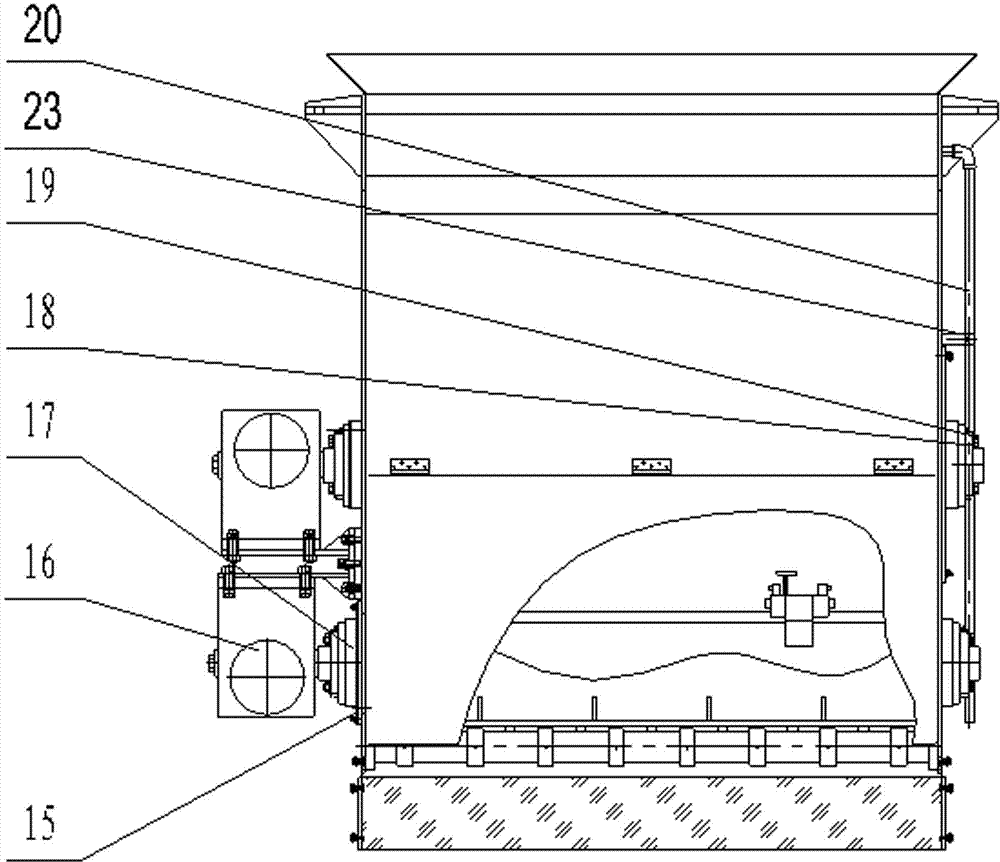

Method for cleaning environmental-friendly collecting box

ActiveCN102059238AProtect physical and mental healthDry fastHollow article cleaningEngineeringHigh pressure

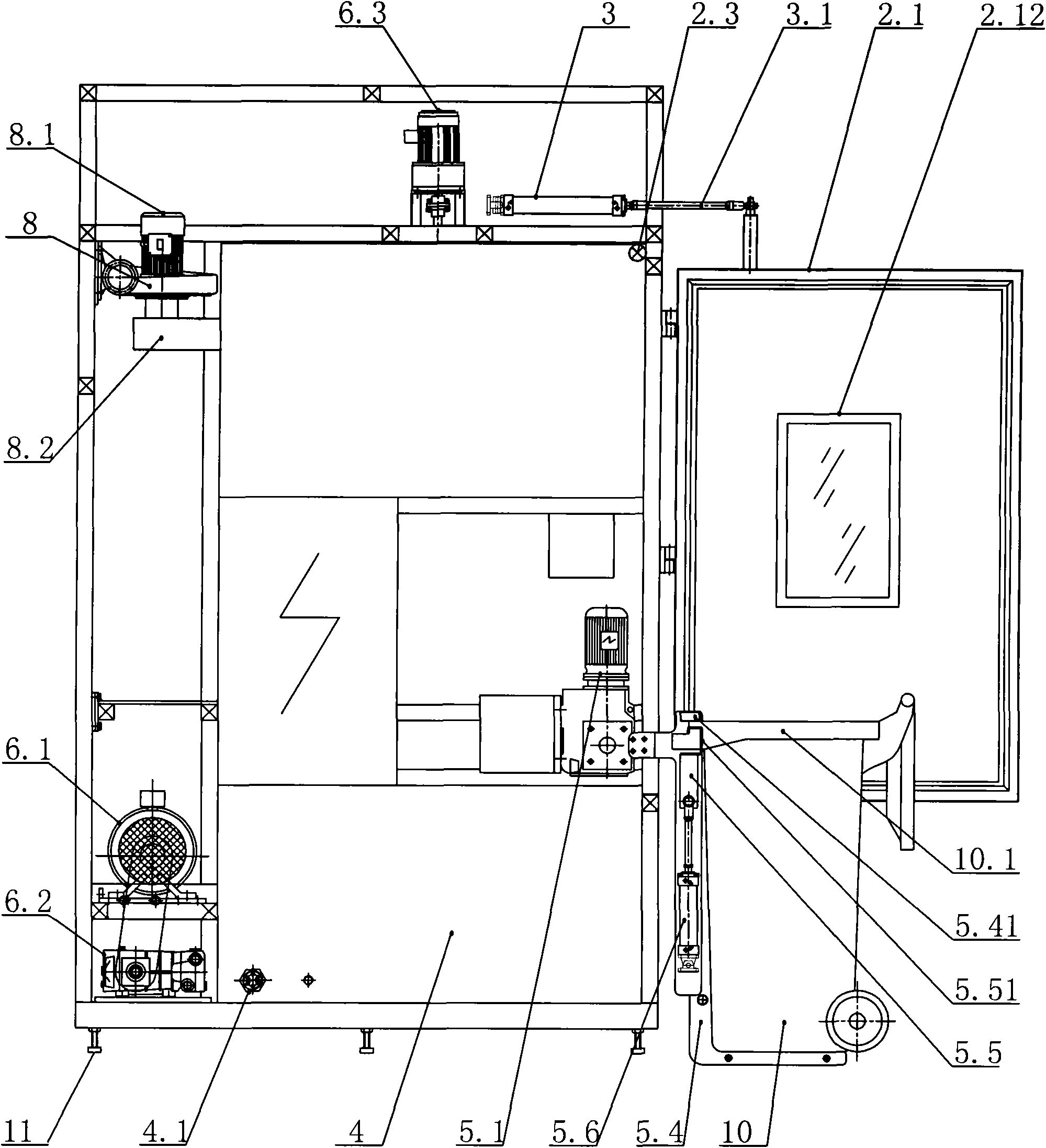

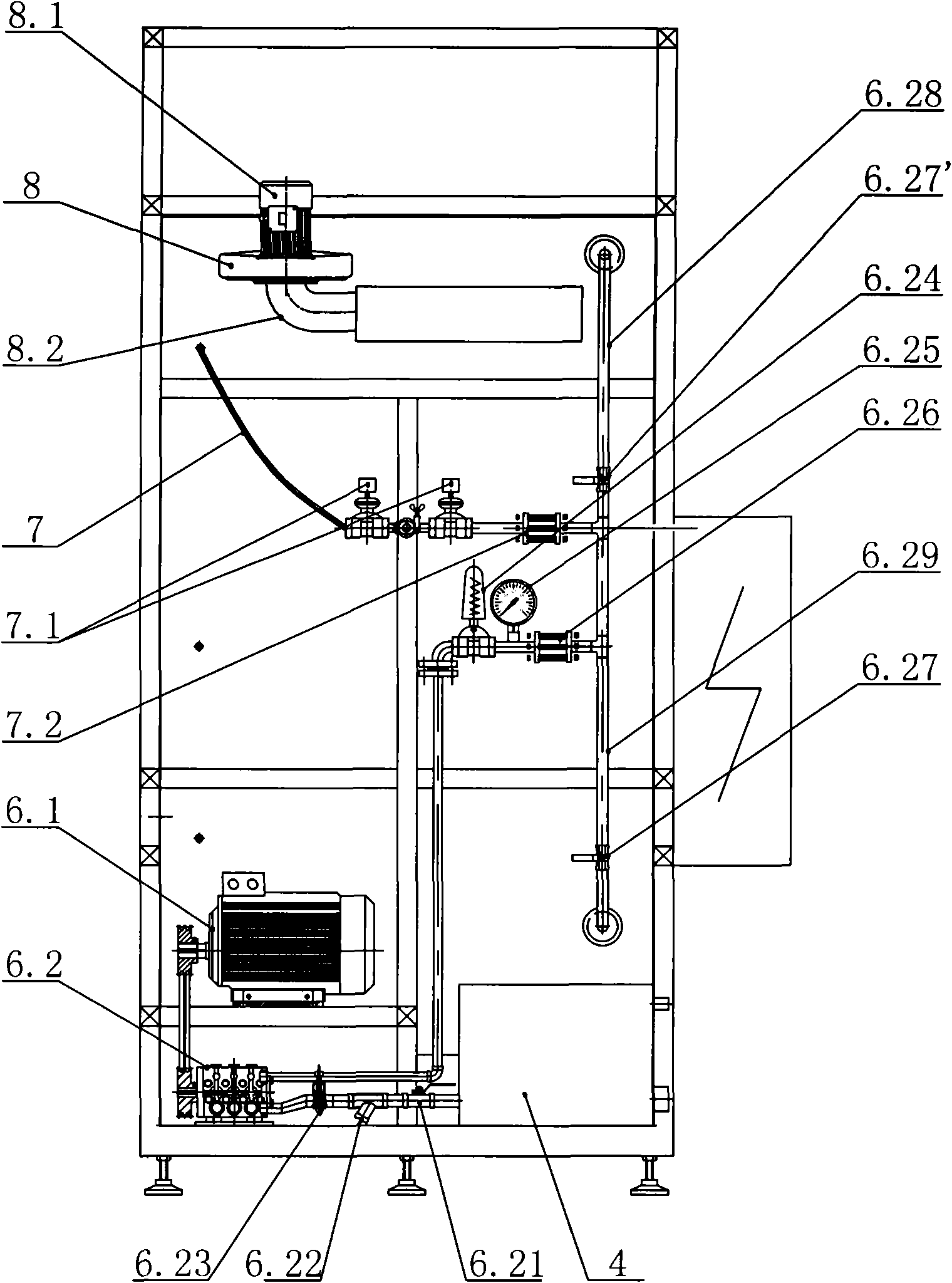

The invention discloses a method for cleaning an environmental-friendly collecting box by adopting a full-automatic environmental-friendly collecting box high-pressure cleaning machine. The method comprises the steps of: 1, opening a sealing door, clamping a turning frame and a moving frame of a turning mechanism to be turned outside a washing chamber; 2, enabling the box opening of the environmental-friendly collecting box to be upward and placing on the turning frame, clamping a barrel cylinder to act, pushing the moving frame to move upwards for firmly clamping the box opening of the environmental-friendly collecting box; 3, reversely turning a turning shaft for 180 degrees, turning the turning frame and the environmental-friendly collecting box into the washing chamber together; 4, opening a high-pressure plunger pump, cleaning the outer wall of the environmental-friendly collecting box by power rotation of an upper spraying mechanism, cleaning the inner wall of the environmental-friendly collecting box by powerless rotation of a lower spraying mechanism; 5, blowing and sweeping the environmental-friendly collecting box with compressed air; and 6, turning the environmental-friendly collecting box outdoors and taking out. The method for cleaning the environmental-friendly collecting box has the advantages of good cleaning effect and low cleaning labor intensity; and cleaning water can be recycled.

Owner:HYVA MECHANICS (CHINA) CO LTD

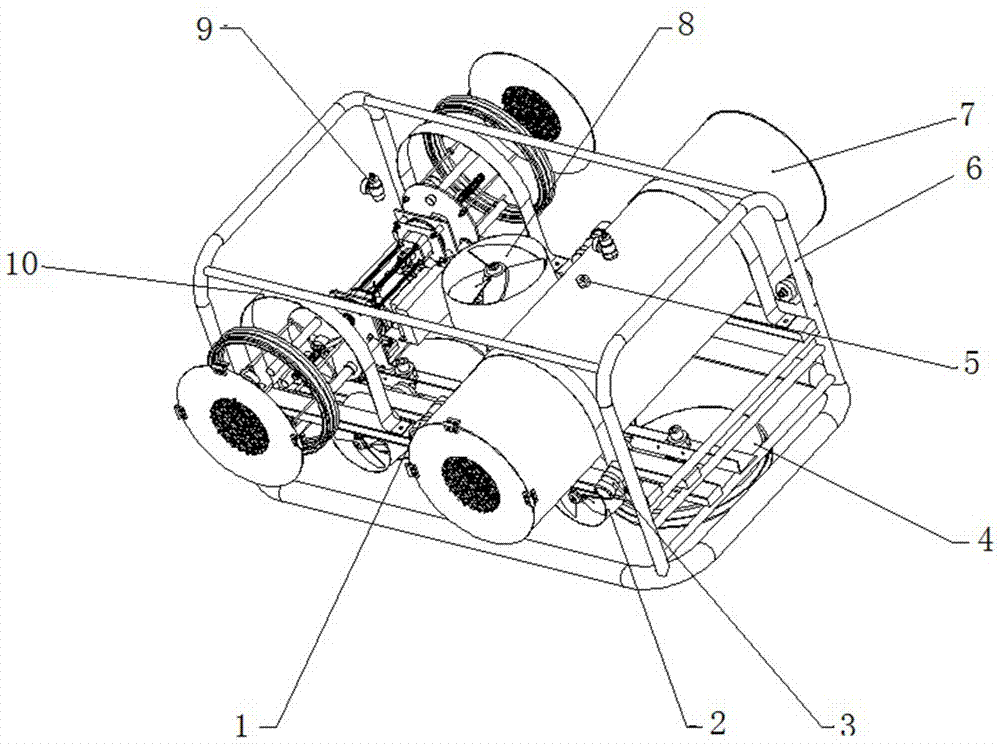

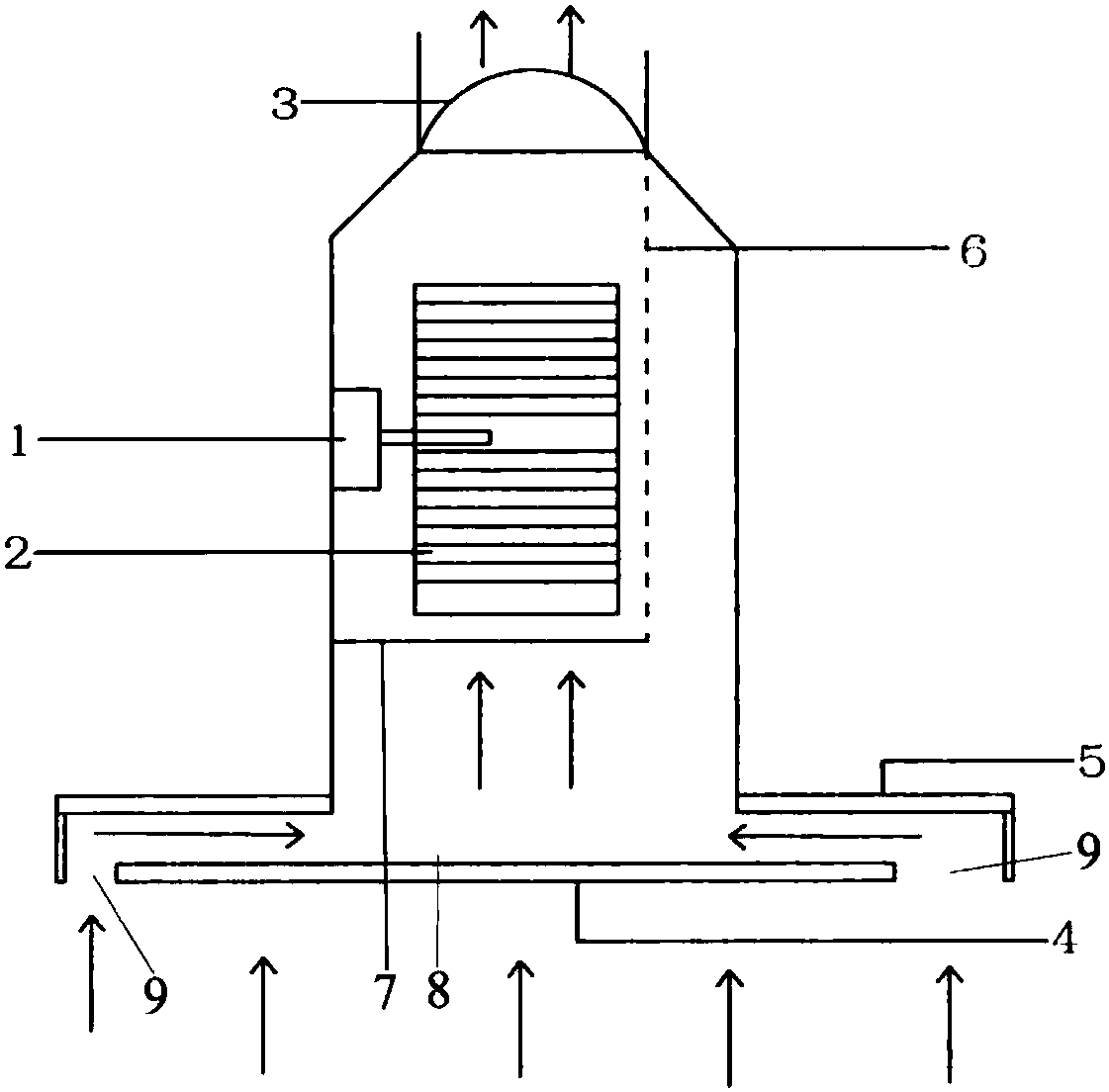

Novel deep sea net cage washing robot

The invention relates to a sea net cage culture auxiliary device, in particular to a novel deep sea net cage washing robot. The novel deep sea net cage washing robot comprises a rack, a high-pressure washing device connected with the rack, a snorkeling and posture control device arranged on the rack, an underwater camera device, an underwater lighting device and a spiral propeller fixedly connected to the rack, wherein the underwater camera device and the underwater lighting device are fixed to the rack. According to the novel deep sea net cage washing robot, high-pressure rotary water jet ejected by a divided manifold type spraying disk serves as a washing power source, the high-pressure water jet is circularly ejected to all points of a netting attachment, and the washing effect is obvious; and double flat bowls can freely adjust the underwater snorkeling postures and change running directions, it is guaranteed that washing of all corners of a net cage can be met, and the efficiency of washing the netting attachment and the cleanliness are high.

Owner:GUANGDONG OCEAN UNIVERSITY

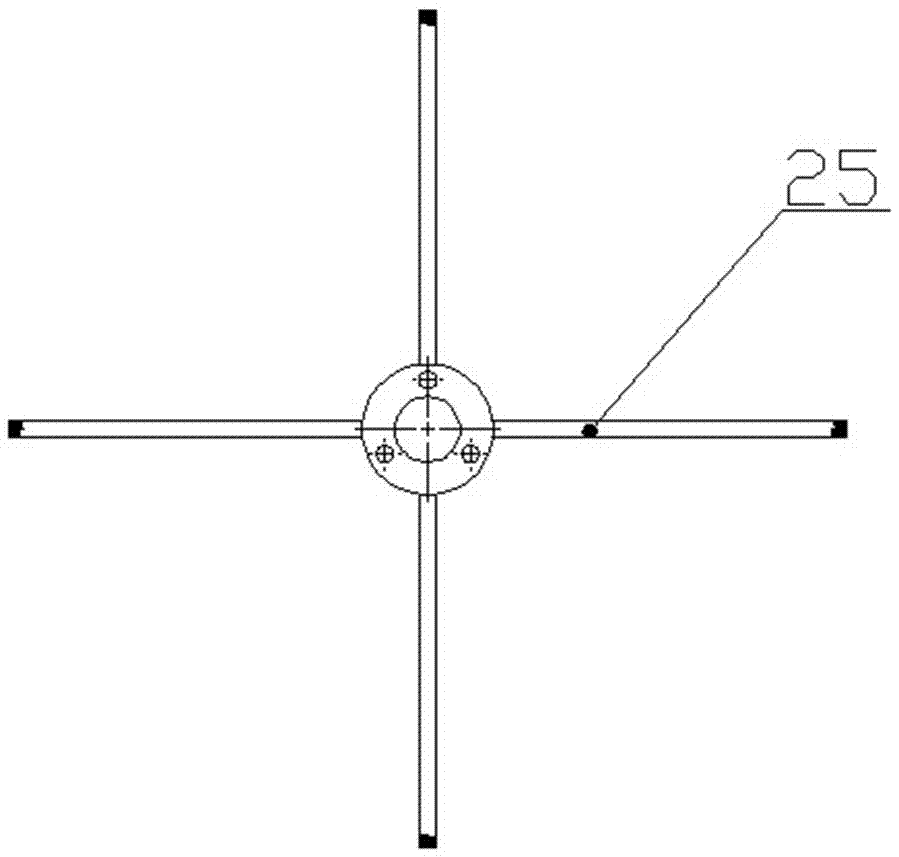

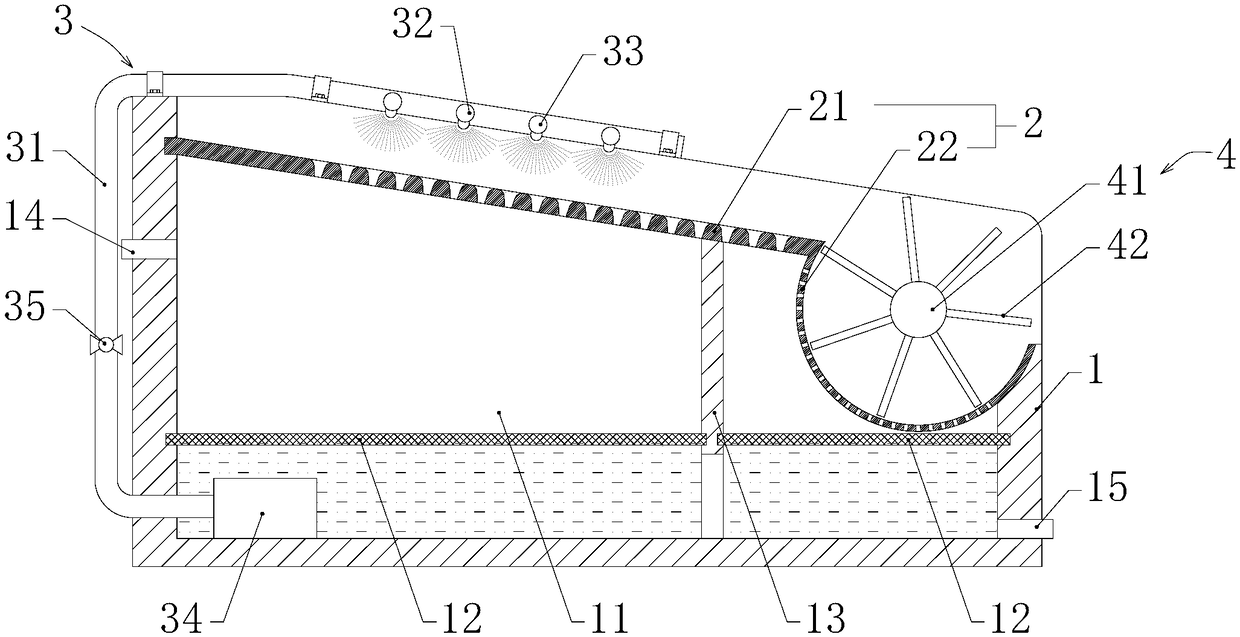

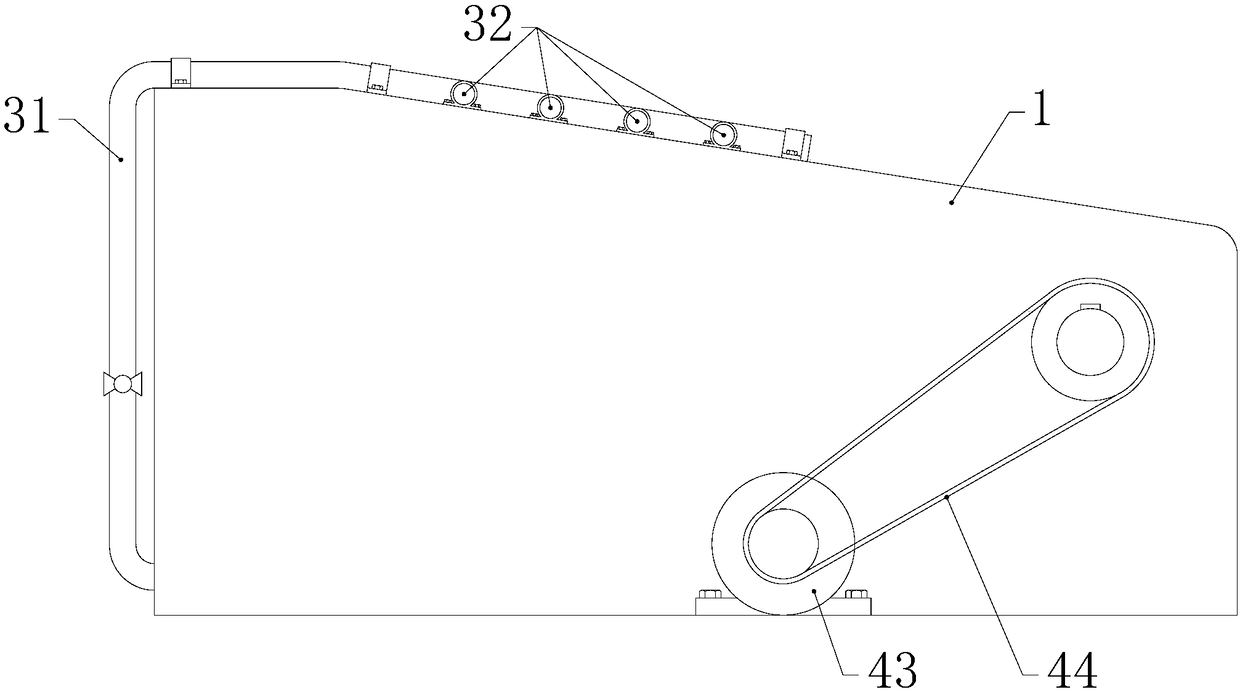

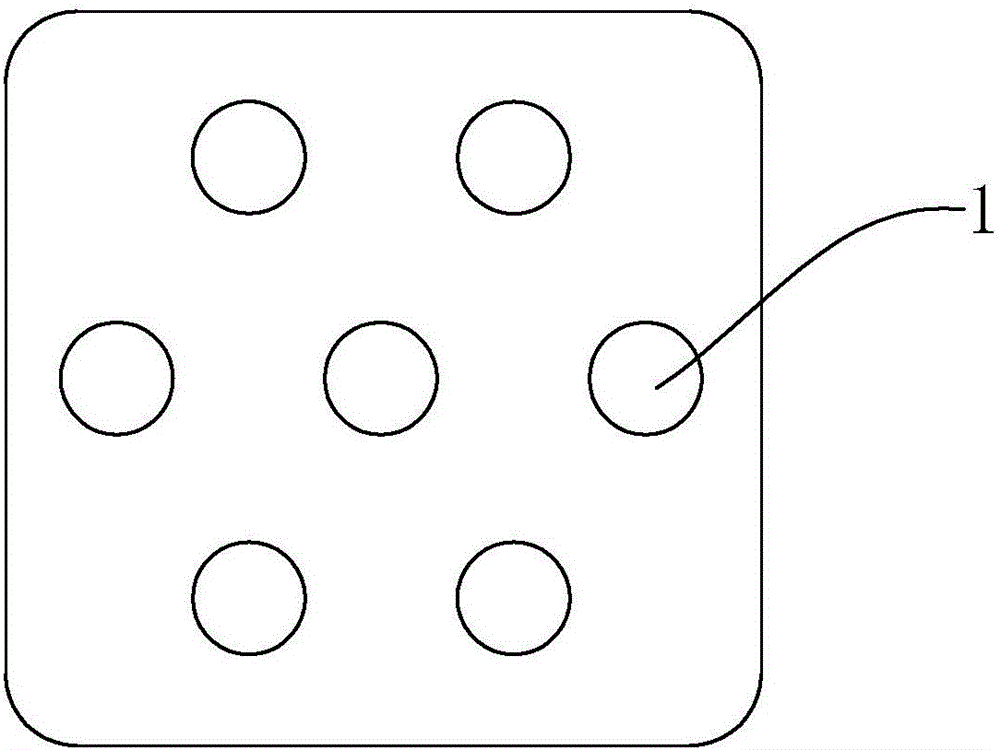

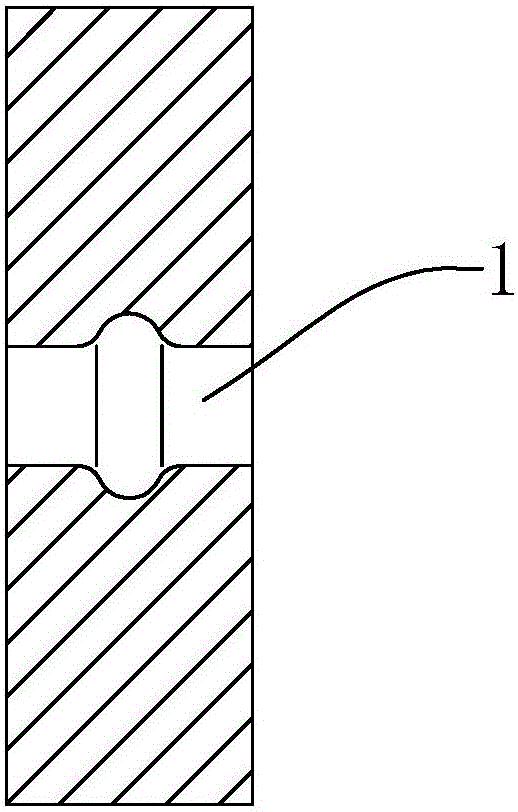

Cleaning device of bearing rolling body

PendingCN108097643AIncrease productivityReasonable structureCleaning using liquidsWater storageEngineering

The invention discloses a cleaning device of a bearing rolling body, which comprises a machine body, a hole plate, a spraying system and a discharging mechanism; the hole plate is arranged on the machine body and formed by connecting an oblique straight plate with an arc plate; the machine body is equipped with the discharging mechanism at the tail end of the hole plate, and the spraying system isfurther mounted on the machine body. The cleaning device is reasonable in structure, the processed bearing rolling body is poured from the front side of the machine body to the oblique straight plate, the rolling body is rolled downwards along the oblique straight plate, the cleaning fluid sprayed from a nozzle can spray the rolling body to remove impurities and oil stain on the rolling body; theimpurities and oil stain enter a filter plate along the open hole on the oblique straight plate into a water storage cavity to filter; the filtered clear liquid can be pumped into a general water transmission pipe through a circular pump to spray; the cleaned rolling body is rolled on a rotating baffle in the arc plate along the oblique straight plate; the rotation of the baffle drives the rolling body to discharge, thus the cleaning labor intensity is greatly reduced, and the cleaning device of the bearing rolling body is good for improving the production efficiency of the bearing.

Owner:XINCHANG JIANGBEI BEARING

Modified sodium silicate sand and making method thereof

InactiveCN103752762AGood collapsibilityImprove sand mold strengthFoundry mouldsFoundry coresSoluble glassHigh intensity

The invention relates to a modified sodium silicate sand and making method thereof, and belongs to the chemical field. The modified sodium silicate sand and making method thereof are characterized in that: 25% sodium polyacrylate solution whose weight is 5-8% of that of soluble glass is added into 50-52 baume degree soluble glass, the solution is stirred for producing the modified soluble glass, after uniform stirring, the sand mold with high intensity is obtained. The invention has the advantages that additive is added into common soluble glass with slightly increased cost, and the sand mold intensity is improved, and the sand mold collapsibility is improved, and the cleaning labor intensity is reduced, and the cleaning cost is saved.

Owner:周家欣

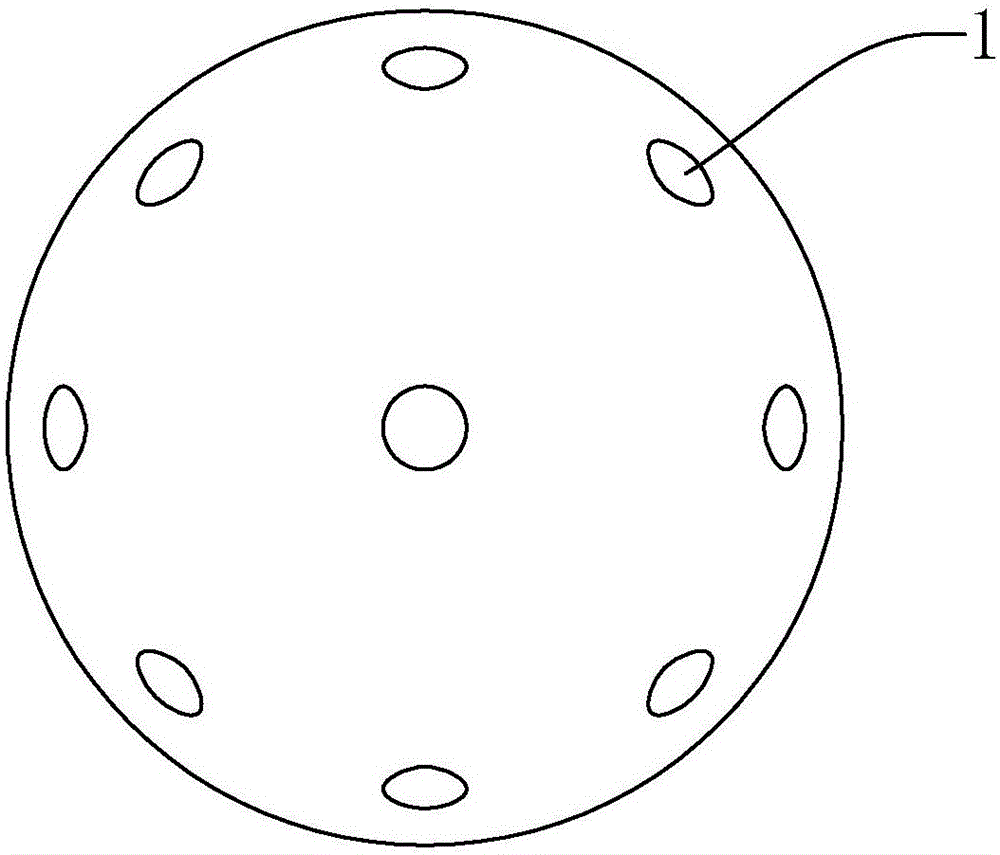

Honeycomb chilling block

The invention discloses a honeycomb chilling block. The honeycomb chilling block comprises a chilling block body, wherein the chilling block body comprises a cooling surface which is pressed close to a part, which is required to be cooled, of a casting; and a plurality of exhaust holes which penetrate through the chilling block body are formed in the cooling surface. By the exhaust holes, surface layer gas existing due to poor surface treatment of the chilling block or gas generated by decomposition of oxides at high temperature can be discharged effectively, pore defects of castings are eliminated effectively, the novel chilling block is used for casting production, and is convenient to treat and simple and convenient to arrange, the yield of the castings is improved, labor intensity for cleaning of the castings is reduced, traditional pore defects which are possibly caused by the chilling block can be eliminated, and therefore, the yield of the castings can be improved by above 5%. The novel honeycomb chilling block is suitable for various casting technologies for cast iron, cast steel and nonferrous materials. The production cost can be reduced by about 5%, and the economic benefit is obvious.

Owner:GUANGDONG HENGCHENG TECH

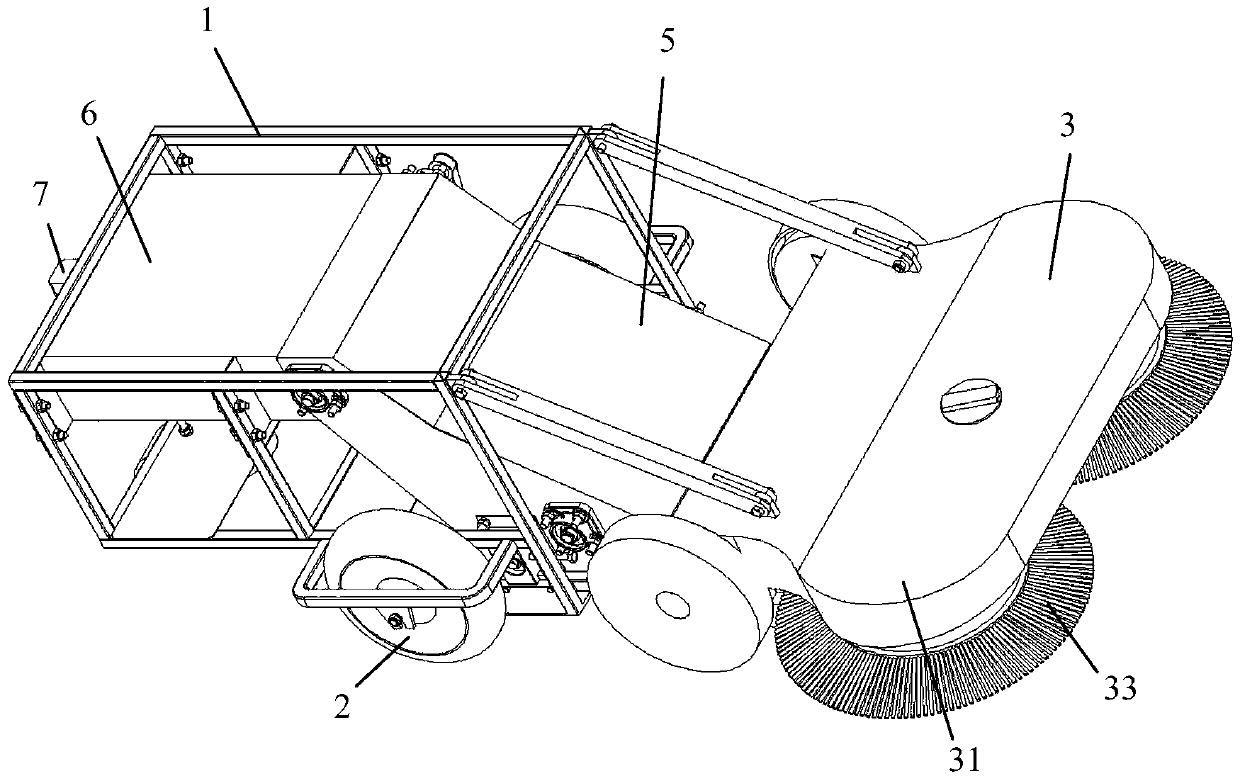

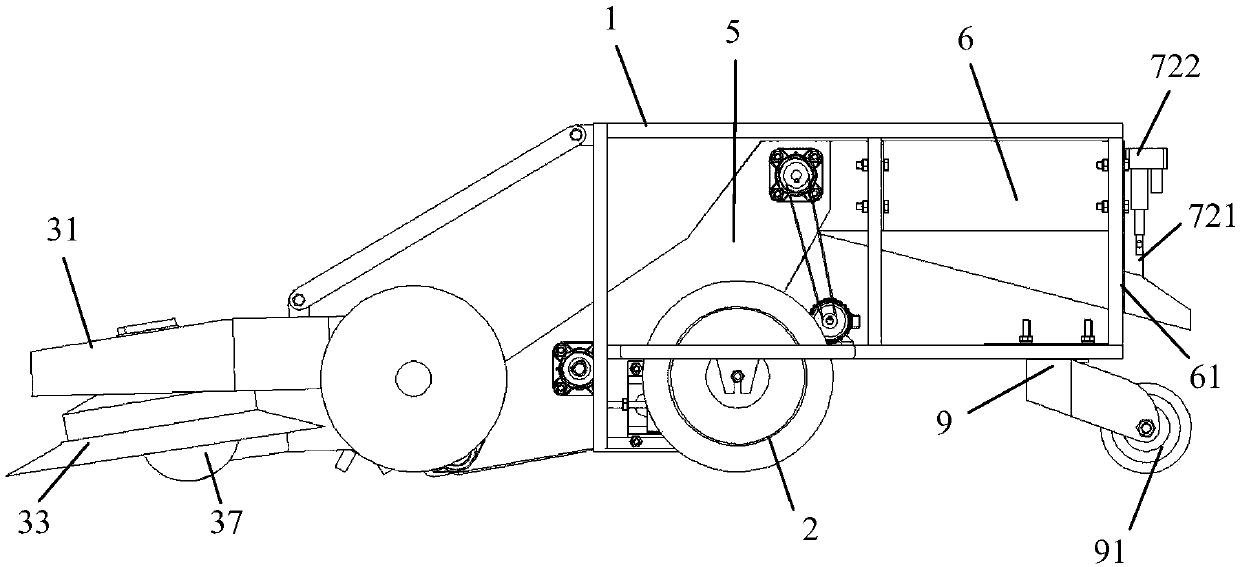

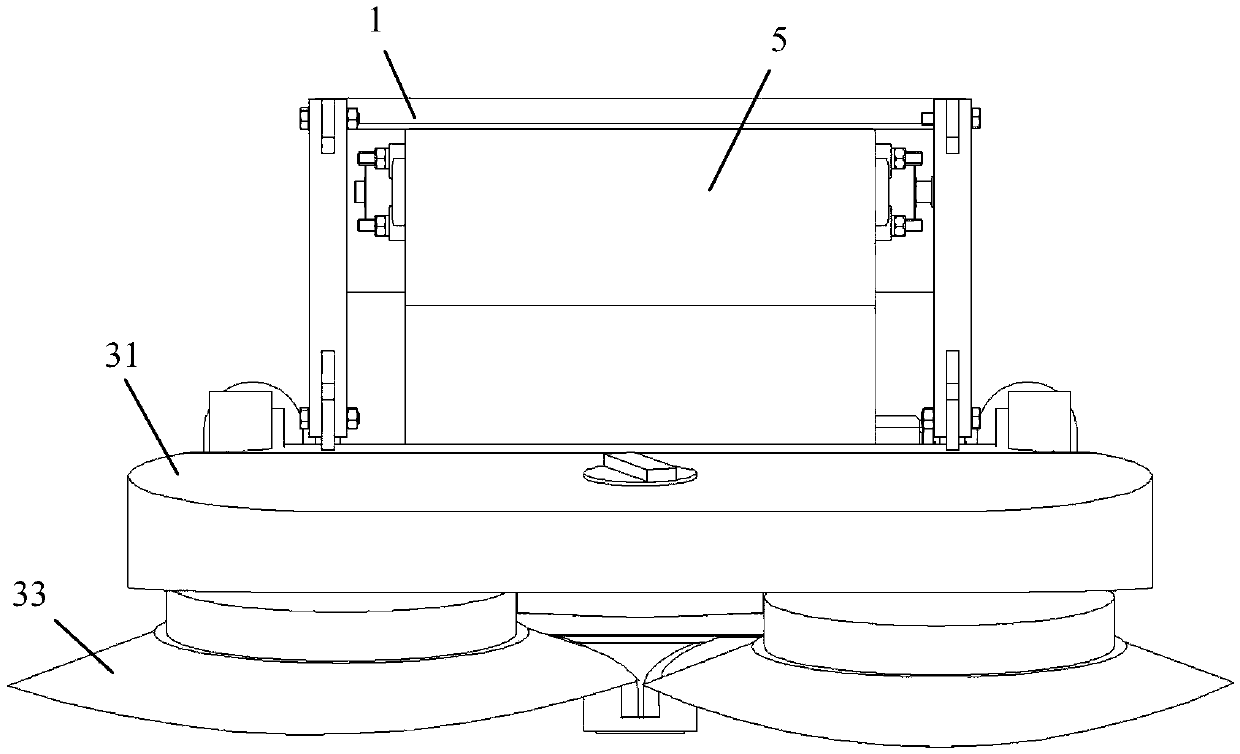

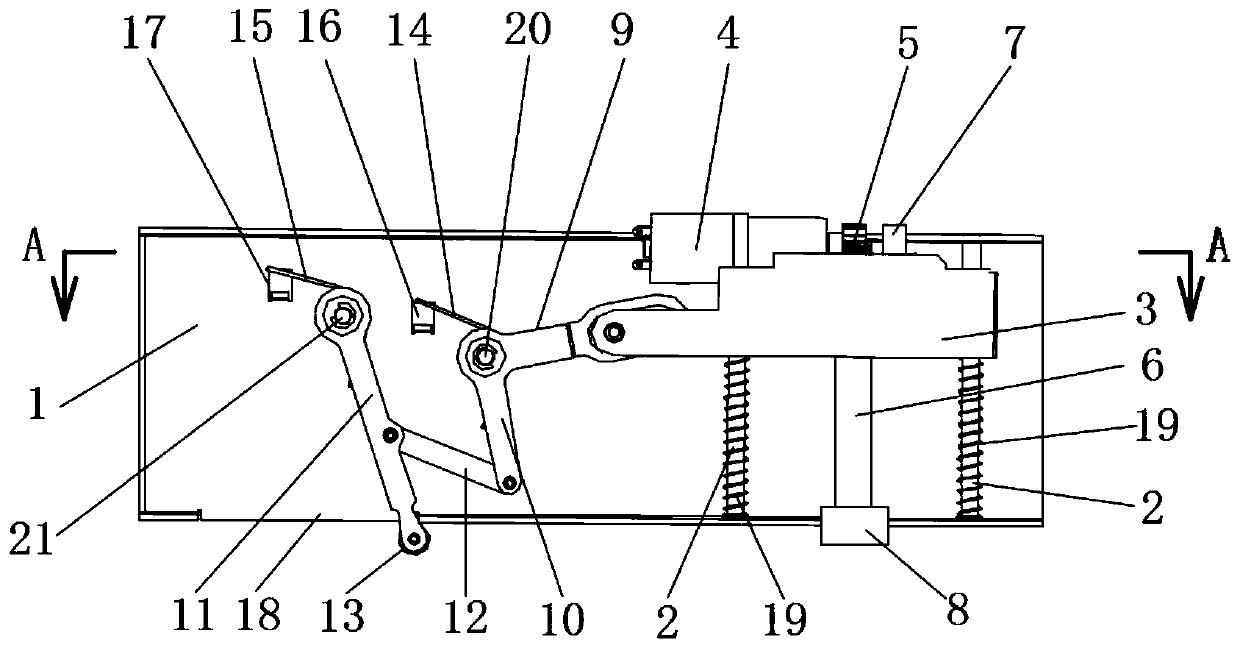

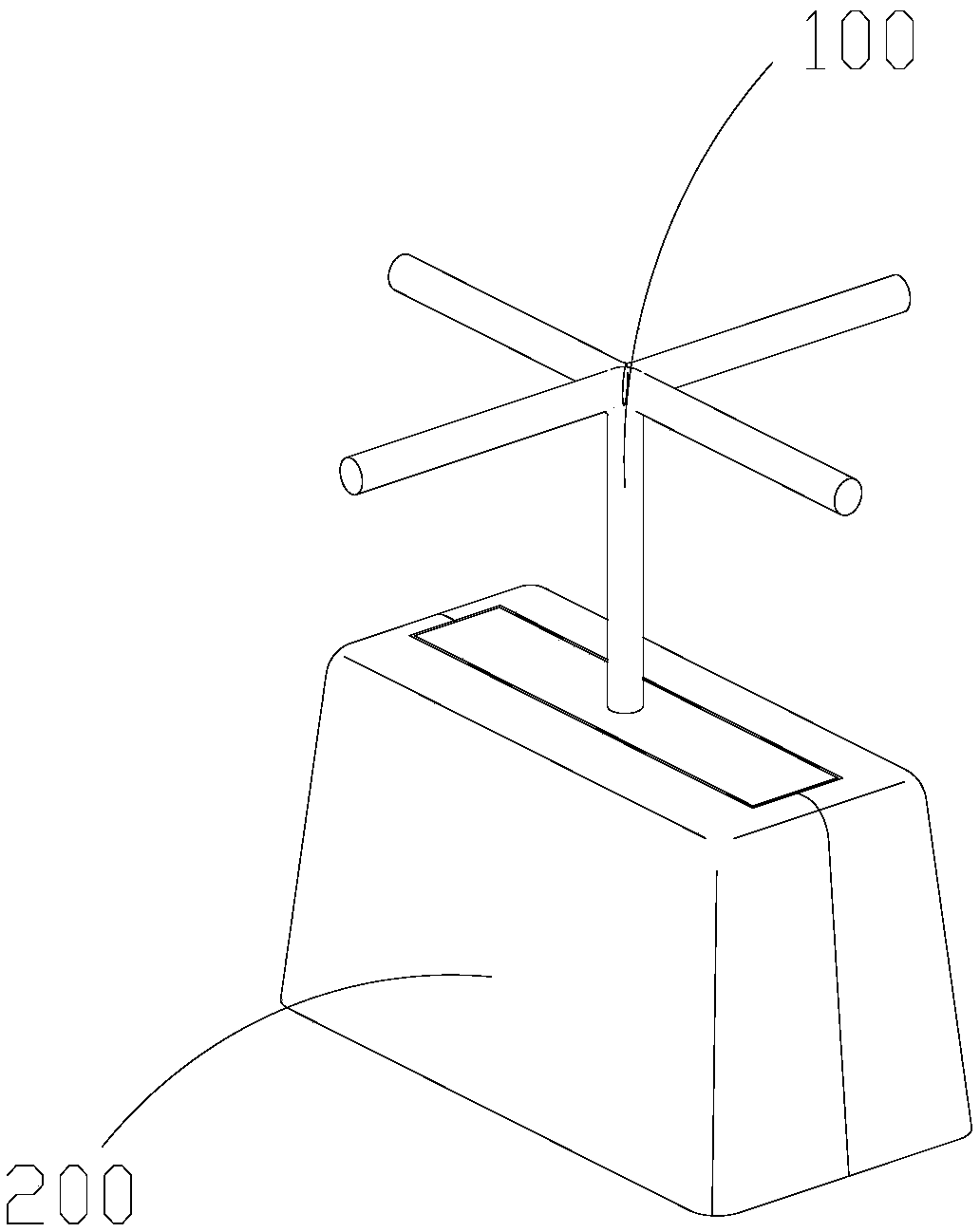

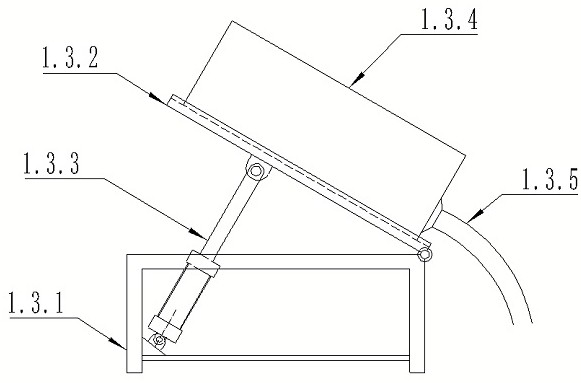

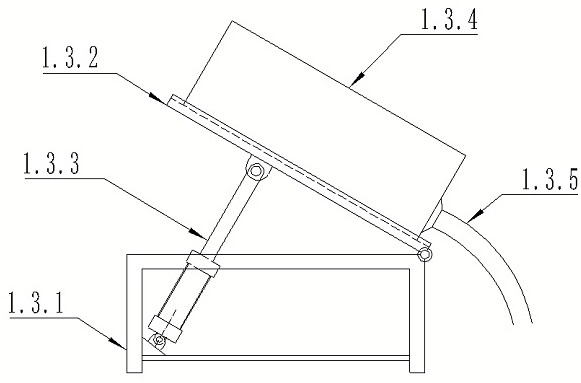

Intelligent granary bottom sweeping and collecting device

PendingCN109516144ASimple structureHigh degree of automationConveyorsHollow article cleaningDrive shaftEngineering

The invention discloses an intelligent granary bottom sweeping and collecting device. The intelligent granary bottom sweeping and collecting device comprises a frame, wheels for driving the frame to move, a rotary sweeping device, a rotary brush shaft, a conveying device, a receiving hopper and a discharging device, wherein the rotary sweeping device is used for rotatably sweeping and collecting bulk grain and conveying the bulk grain to the rotary brush shaft at the rear end of the rotary sweeping device; the rotary brush shaft is used for rotatably conveying the bulk grain to the conveying device; the conveying device comprises a driving shaft, a driven shaft and a conveyer belt; the two ends of the driving shaft and the driven shaft are rotatably connected to the frame; the conveyer belt is arranged on the driving shaft and the driven shaft in a sleeving manner, and conveys the bulk grain to the interior of the receiving hopper at the tail end of the frame through the rotation of the driving shaft; a discharge port is formed in the bottom of the tail end of the receiving hopper; and the discharging device comprises a control monitor for measuring the stacking height of the bulkgrain in the receiving hopper, and an automatic baffle plate mechanism for controlling the opening and closing of the discharge port. The Intelligent granary bottom sweeping and collecting device realizes the functions of automatically sweeping, collecting, transporting and discharging the bulk grain at the bottom of a granary, is simple in structure and has high intelligence.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Distributing bucket

InactiveCN103114729AIncrease stirring powerEasy feedingBuilding material handlingSolenoid valveHydraulic pump

The invention discloses a distributing bucket. The distributing bucket comprises a box body, a motor accelerator-retarder, a hydraulic pump and a hydraulic solenoid valve. A stirring shaft and a discharging shaft are arranged in the box body. The stirring shaft and the discharging shaft are driven by the motor accelerator-retarder respectively. The distributing bucket is characterized in that a hopper type feeding opening is formed in the top of the box body, a weight support is arranged between the hopper type feeding opening and the inner portion of the box body, a box body purge pipe is arranged on one side of the box body, the box body purge pipe and the box body are fixed through a mounting clamp seat, multiple sets of stirring rods are arranged on the stirring shaft, two symmetrical surfaces of each stirring rod forms an angle, an end plate is arranged on a shaft head of the end portion of the feeding discharging opening, the end plate comprises a tubular shaft and vertical plates which are evenly arranged around the tubular shaft, and the end portions of the vertical plates are connected through arc plates. The distributing bucket has the advantages that feeding is convenient, washing labor intensity is reduced, manpower is saved, stirring force to the feeding is increased and side wall adhesion is reduced, materials and labor cost are reduced and the feeding shaft cannot be so heavy.

Owner:江苏中南模板科技有限公司

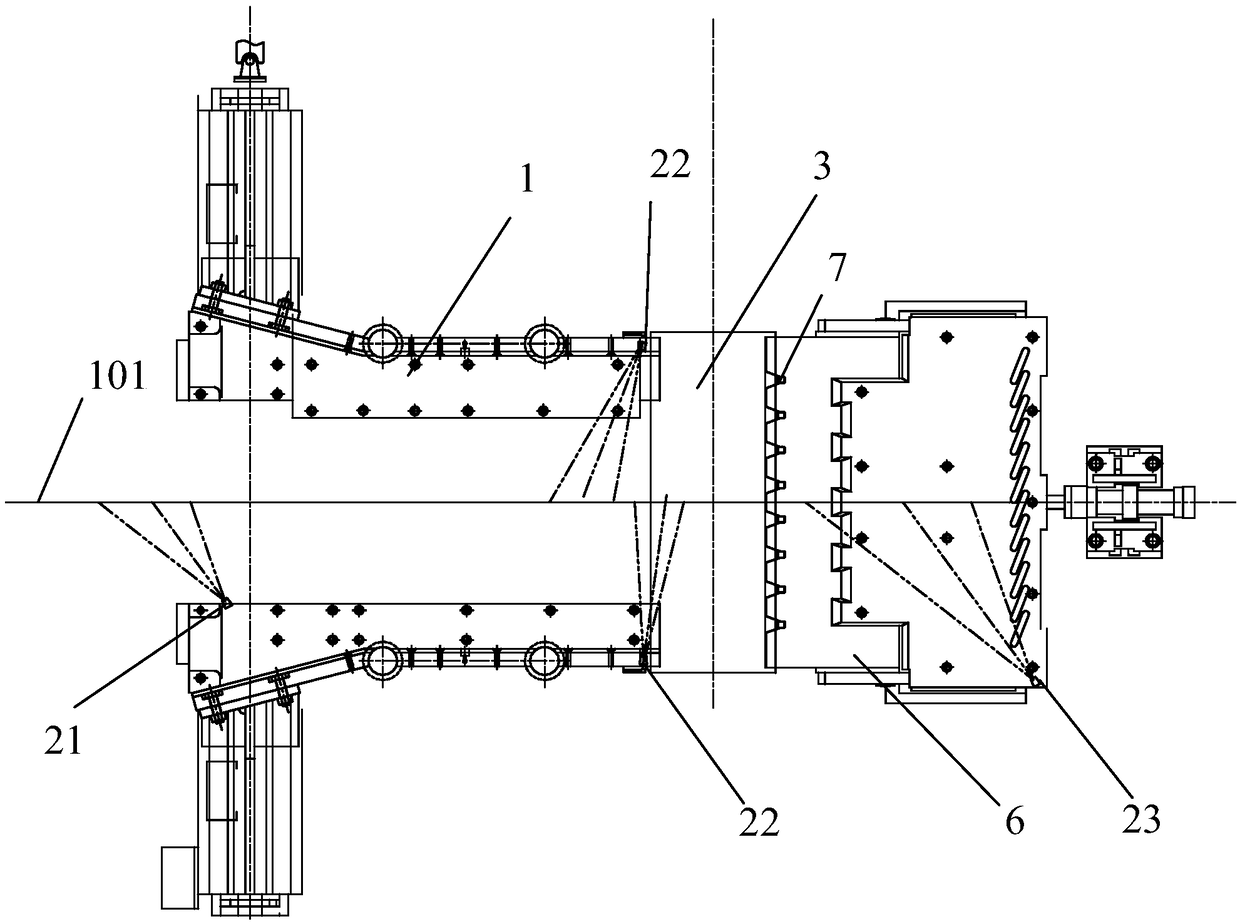

Device and method for reducing pressing-in of iron sheet ash during strip steel production through hot tandem rolling unit

ActiveCN108114994AReduce pushReduced press-in defectsWork cleaning devicesMetal rolling arrangementsForeign matterSpray nozzle

The invention relates to a device and method for reducing pressing-in of iron sheet ash during strip steel production through a hot tandem rolling unit. The device for reducing pressing-in of the ironsheet ash during strip steel production through the hot tandem rolling unit comprises two sets of inlet lateral water spraying devices arranged at an inlet of a finishing mill, one set of outlet lateral water spraying device arranged at an outlet of the finishing mill, a dust removal water spraying device, an ash blocking plate and an upper guide plate structure. The inlet lateral water sprayingdevices blow and sweep strip steel, and the outlet lateral water spraying device blows and sweeps the strip steel. The dust removal water spraying device is composed of a plurality of dust removal spray nozzles, and water sprayed by the dust removal water spraying device is sprayed on the lower surface of the strip steel. The ash blocking plate is welded to the front portion of an upper guide plate at the inlet of the finishing mill, a composite plate is welded to each of the lower portions of the upper guide plates at the outlet and the inlet of the finishing mill, and the anti-corrosion function is additionally achieved. According to the device and method for reducing pressing-in of the iron sheet ash during strip steel production through the hot tandem rolling unit, through blocking andblow-sweeping, pressing-in of foreign matter in the surface of the strip steel is reduced, rust generation is eliminated by additionally achieving the anti-corrosion function, the pressing-in defectof the iron sheet ash is further reduced, and the quality of a strip steel product is improved.

Owner:BAOSHAN IRON & STEEL CO LTD

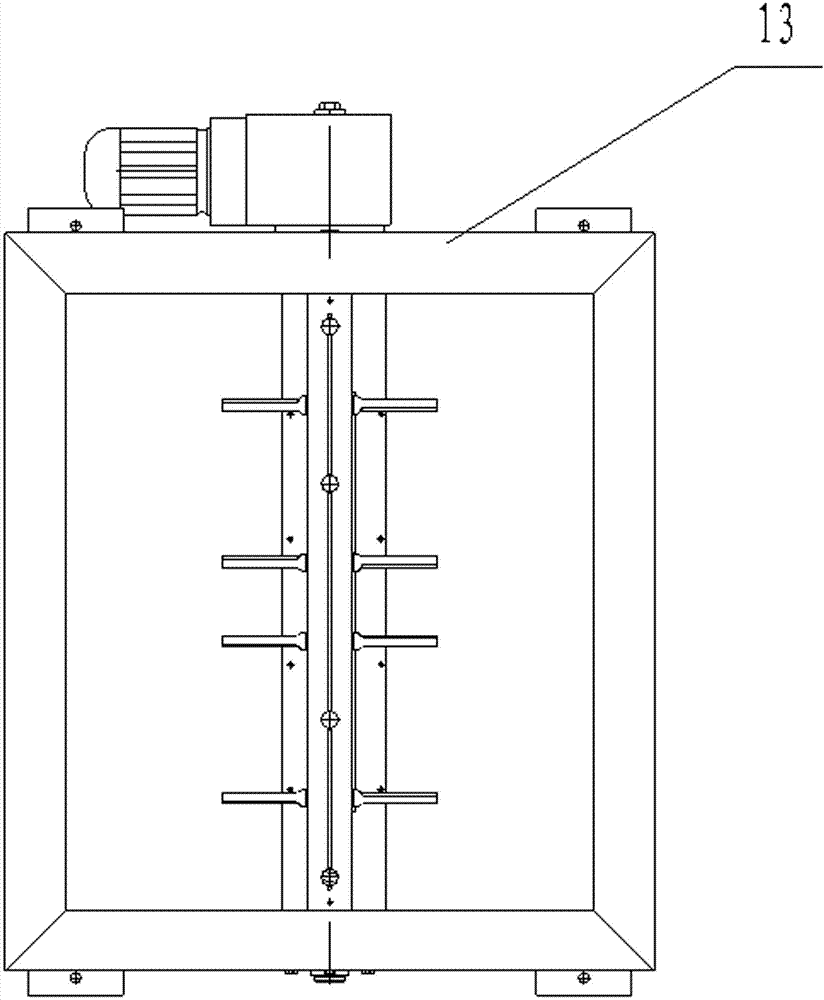

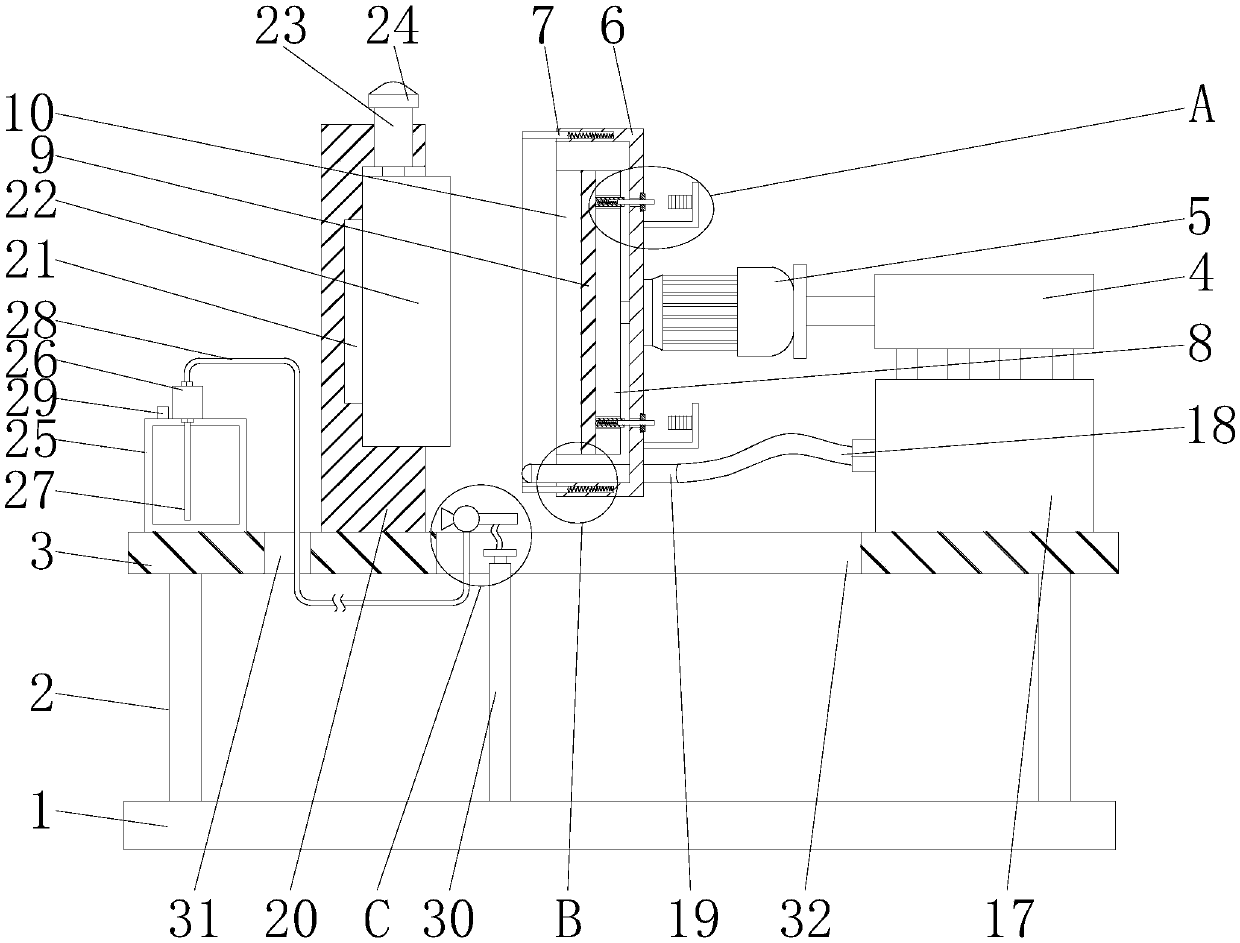

Soft capsule washing machine

InactiveCN106269677AAvoid secondary pollutionReduce cleaning labor intensityCleaning using liquidsAdditive ingredientPulp and paper industry

The invention discloses a soft capsule washing machine. The soft capsule washing machine comprises a box, an alcohol containing tank, a washing ingredient frame, rail grooves, supporting rods, rollers, an ultrasonic wave generating device, a controlling device, a motor, an eccentric wheel, a connecting rod and a connecting bar. The alcohol containing tank is arranged in the box; the washing ingredient frame is fixed above the alcohol containing tank through the rail grooves, the supporting rods and the rollers; the rollers are directly installed on the supporting rods correspondingly; the rail grooves are further formed in the box; the ultrasonic wave generating device is further installed in the alcohol containing groove; the motor and the eccentric wheel are directly connected; one end of the connecting rod and the eccentric wheel are directly connected; and the other end of the connecting rod and the connecting bar are directly connected. According to the soft capsule washing machine, a mechanical washing mode combining mechanical shaking and ultrasonic wave vibration is adopted, and therefore secondary pollution of manual washing is avoided, washing labor intensity is lowered, and soft capsule washing efficiency is largely improved.

Owner:ZHEJIANG YALIDA CAPSULES

Flue cleaning mechanism

ActiveCN110270561AAchieve cleanupRealize reciprocating cleaning workHollow article cleaningSolid removalUltimate tensile strengthFlue

The invention discloses a flue cleaning mechanism. The flue cleaning mechanism comprises a mounting plate, wherein a guide rod is arranged on the mounting plate, a power mounting seat is arranged on the guide rod in a sleeving mode, a power motor is arranged on the power mounting seat, a driving gear is arranged on a power output shaft of the power motor, the driving gear is meshed with a rack, and the rack is fixed with the mounting plate; an upper end and a lower end of the mounting plate are correspondingly provided with a first position switch and a second position switch which are used for controlling forward and reverse rotation of the power motor and correspond to the power mounting seat in position; and the power mounting seat is hinged to one end of the four-bar reciprocating mechanism, and a cleaning roller is arranged on the four-bar reciprocating mechanism. According to the flue cleaning mechanism, the reciprocating cleaning work of a flue can be realized, smoke dust in a certain plane can be cleaned, the cleaning labor intensity of workers is reduced, the ventilation efficiency of the flue is improved, the cleaning cost is reduced, and the service life of the flue is prolonged.

Owner:珠海美林达科技有限公司

Iron plate grinding device convenient for removing scrap scraps

InactiveCN109531307AEfficient suctionPrevent splashGrinding wheel securing apparatusGrinding drivesElectro hydraulicOil well

The invention discloses an iron plate grinding device convenient for removing scrap scraps. The device comprises a bottom plate, a supporting rod, a flat plate, an electro-hydraulic push rod, a motor,a protective cover, a cylinder, a first spring, a disc, a mounting plate, a mounting bolt, a grinding disc, a telescopic rod, a second spring, a sleeve, an iron rod, a through hole, a clamping groove, a limiting strip, a square hole, a connecting rod, an electromagnet, an industrial dust collector, a straight pipe, a straight pipe, a suction hole, a sealing cap, a fixing block, a permanent magnet, an iron plate, a threaded barrel, a locking bolt, an oil tank, an oil well pump, an oil pumping pipe, an oil outlet hose, an oil filling port, an electric push rod, a first through groove, a secondthrough groove, a gooseneck pipe, a connecting plate, an oil distributing pipe and a nozzle. The device is reasonable in structure and novel in design, through the arrangement of the protective cover,the cylinder and the first spring, the grinding disc and the iron plate can be covered when the grinding machine is used for grinding, the generated scraps can be effectively removed through the chipsuction structure, so that the scraps generated by grinding can be prevented from splashing to the outside, and the cleaning labor intensity is low.

Owner:南京壹久软件科技有限公司

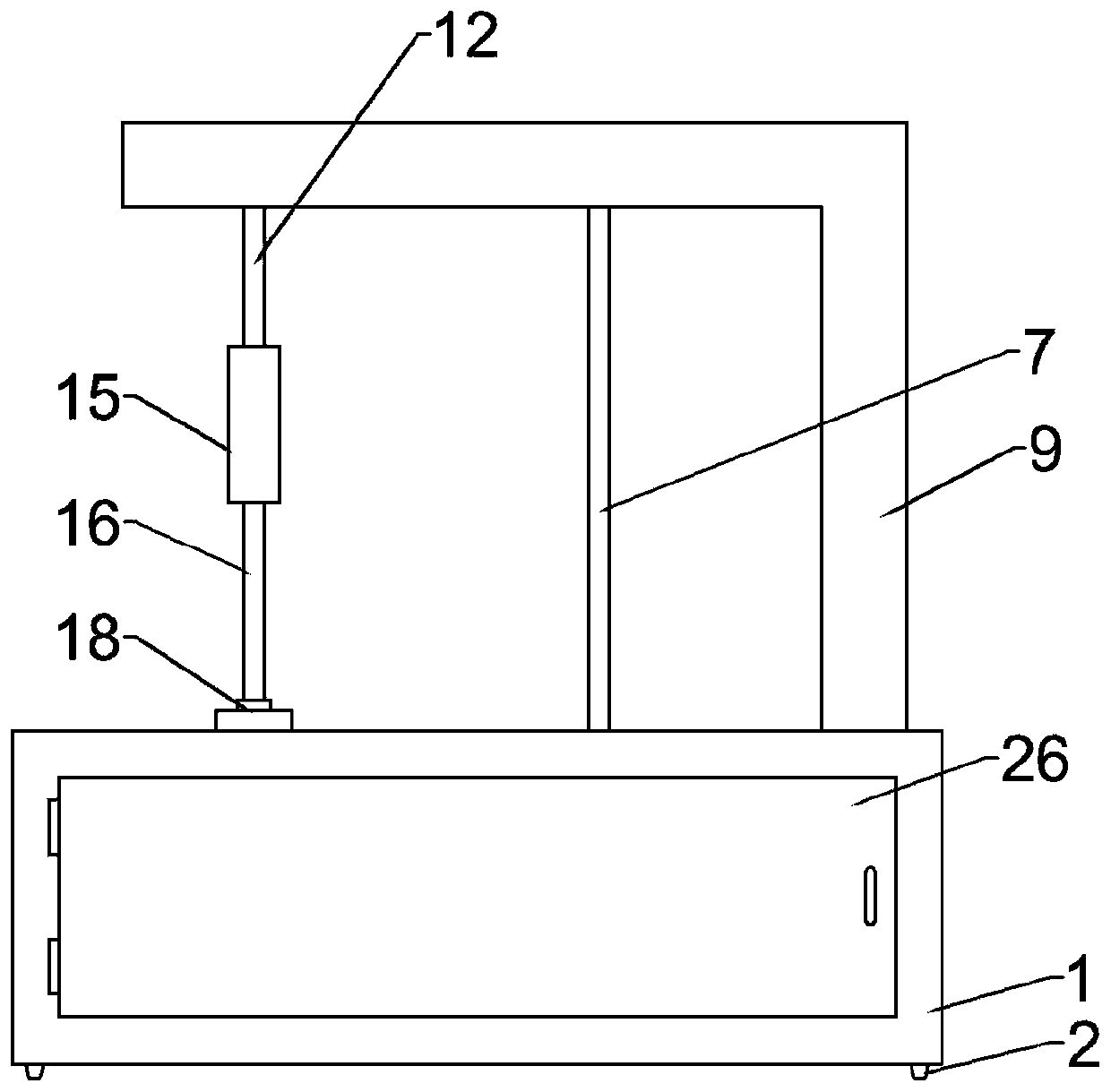

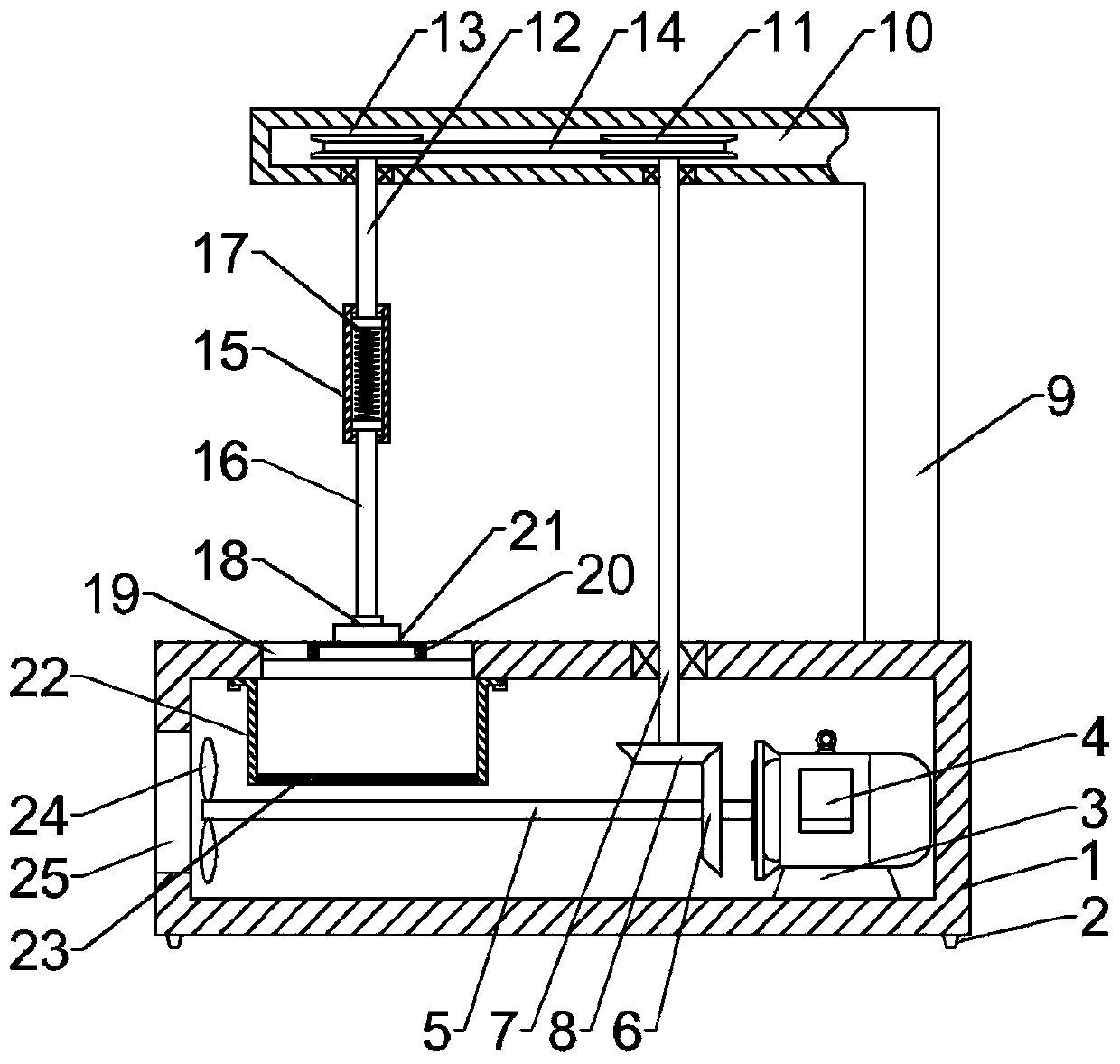

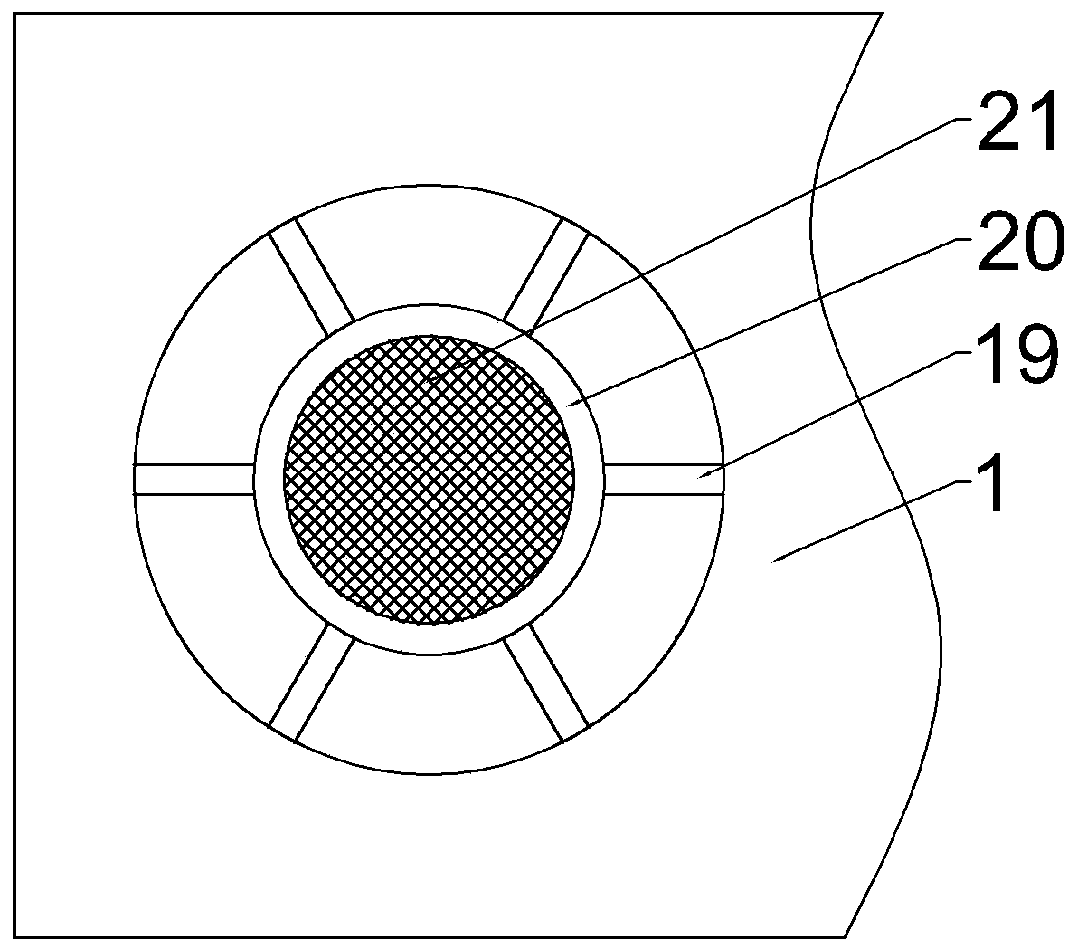

Cement barrel cleaning device for tunnel construction

InactiveCN107824584AGood for cleaning cement bucketsShorten the timeHollow article cleaningTunnel constructionCement

The invention relates to a cleaning device, in particular to a cement barrel cleaning device for tunnel construction. The cement barrel cleaning device for the tunnel construction is characterized bybeing time-saving, small in cleaning labor intensity and capable of cleaning a cement barrel cleanly and thoroughly enough. The cement barrel cleaning device for the tunnel construction comprises a cart and the like; a supporting plate is vertically installed on the left side of the top of a cart plate of the cart, a top plate is horizontally arranged at the top of the supporting plate, and a driving device is arranged in the middle of the bottom of the top plate; and a fixing device is arranged on a driving part of the driving device, the lower part of the supporting plate is provided with afirst cleaning device, and a cleaning part of the first cleaning device is positioned on the right side of the supporting plate. According to the cement barrel cleaning device for the tunnel construction, the fixing device is driven by the driving device to rotate, and the cement barrel is fixed on the fixing device, so that the cement barrel is driven to rotate, and therefore time is saved, the cleaning labor intensity is small and the cement barrel can be cleaned cleanly and thoroughly enough.

Owner:彭斌明

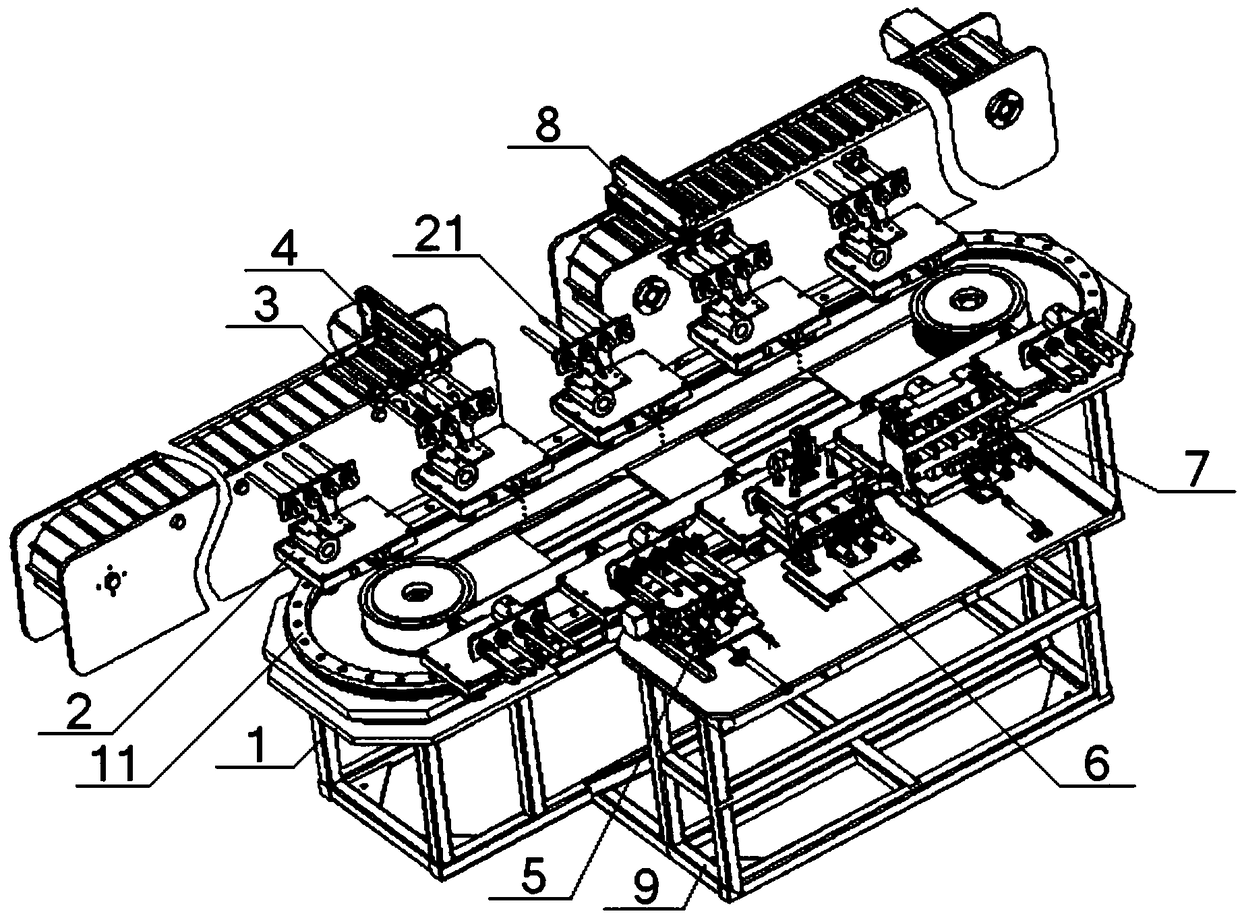

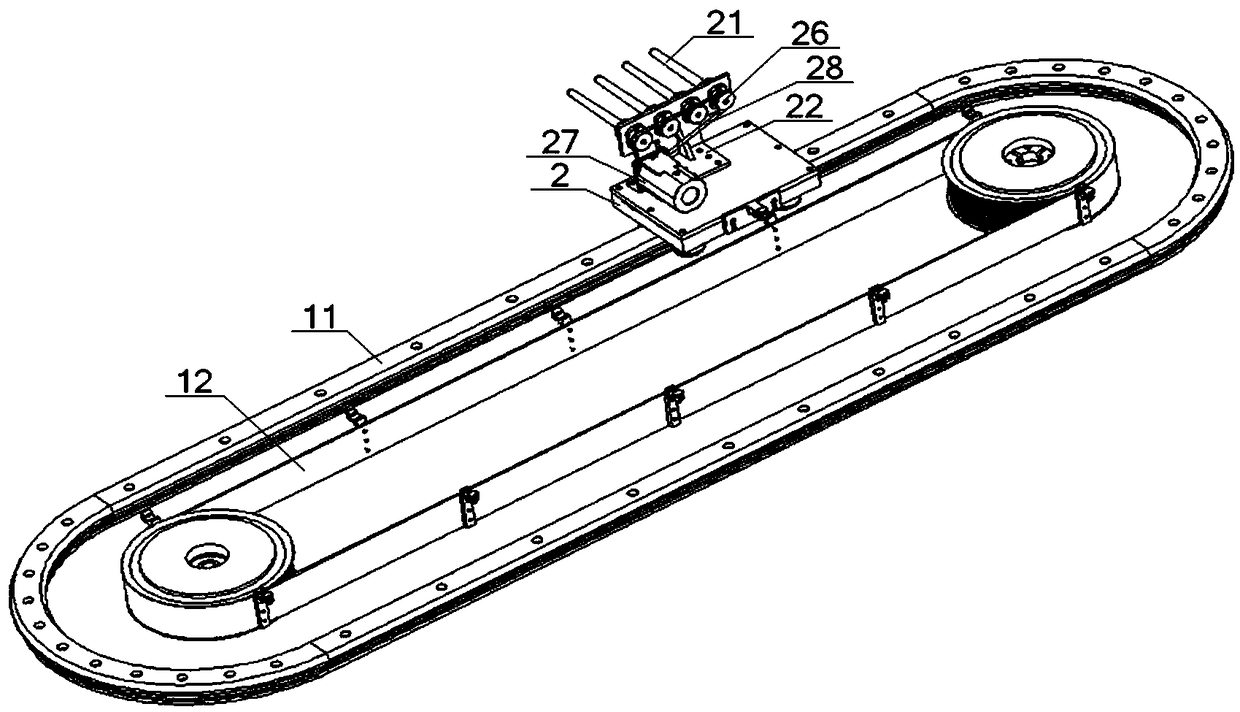

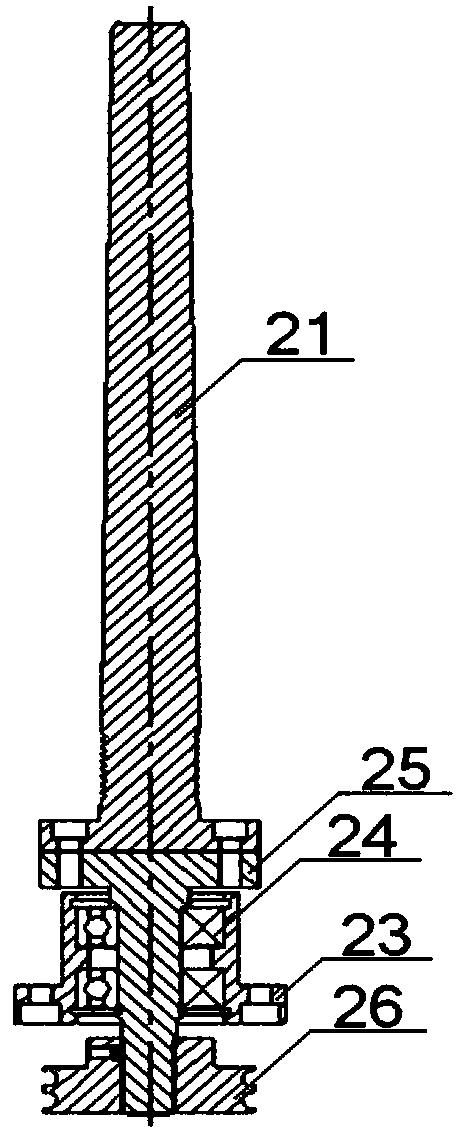

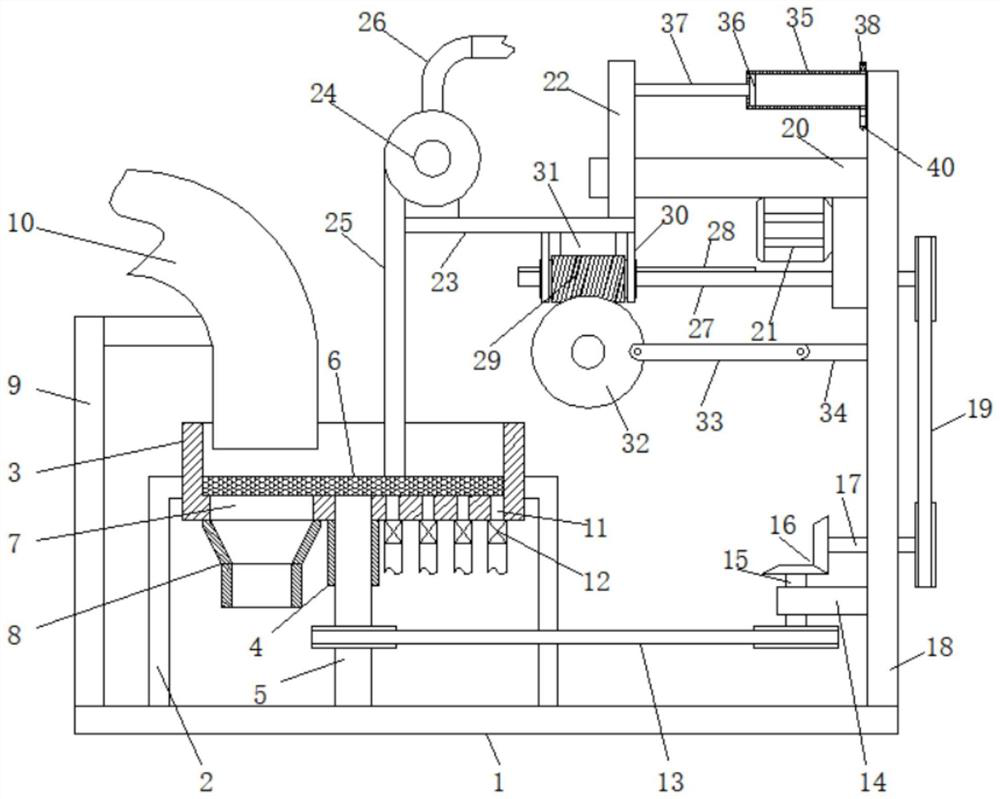

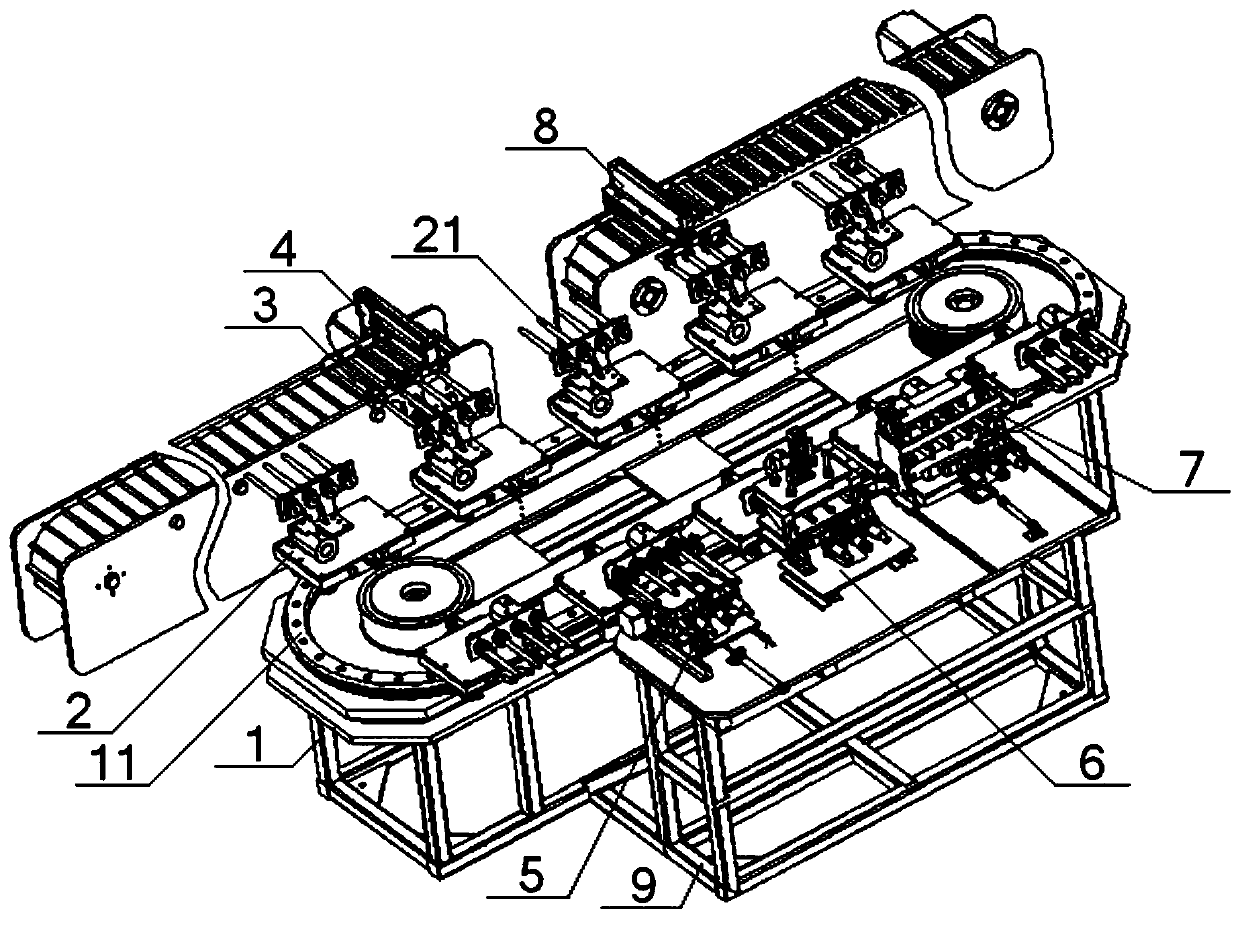

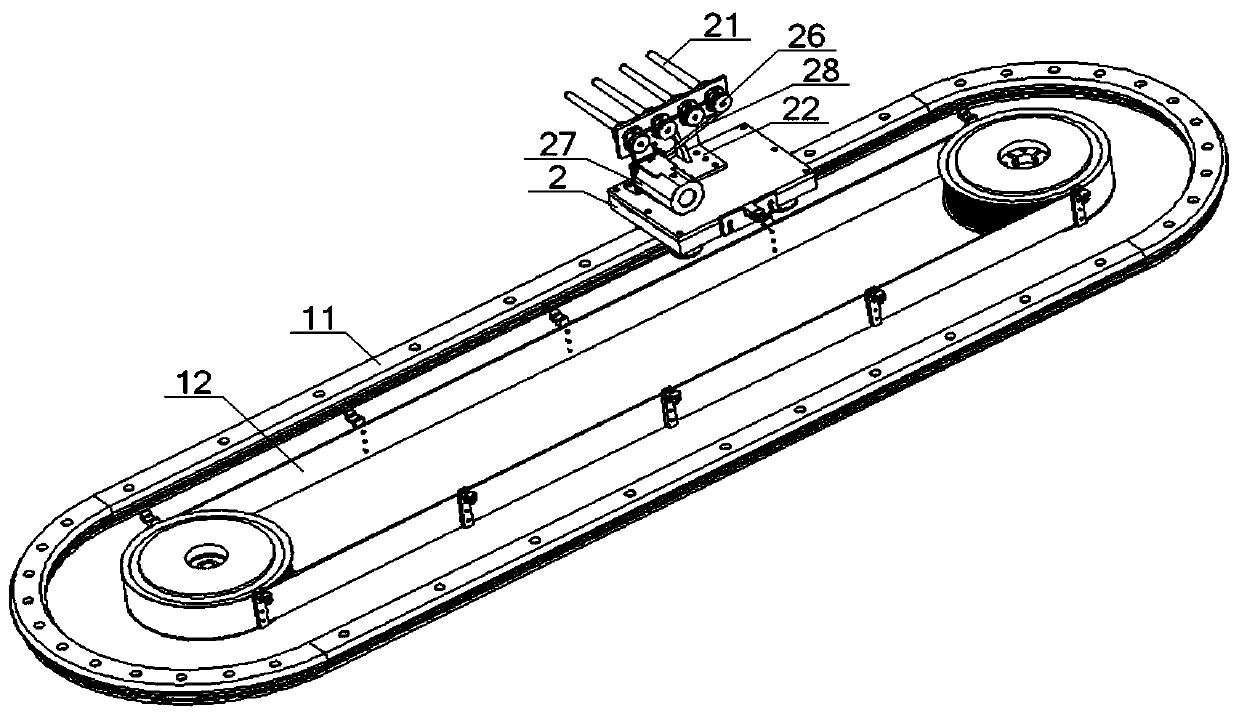

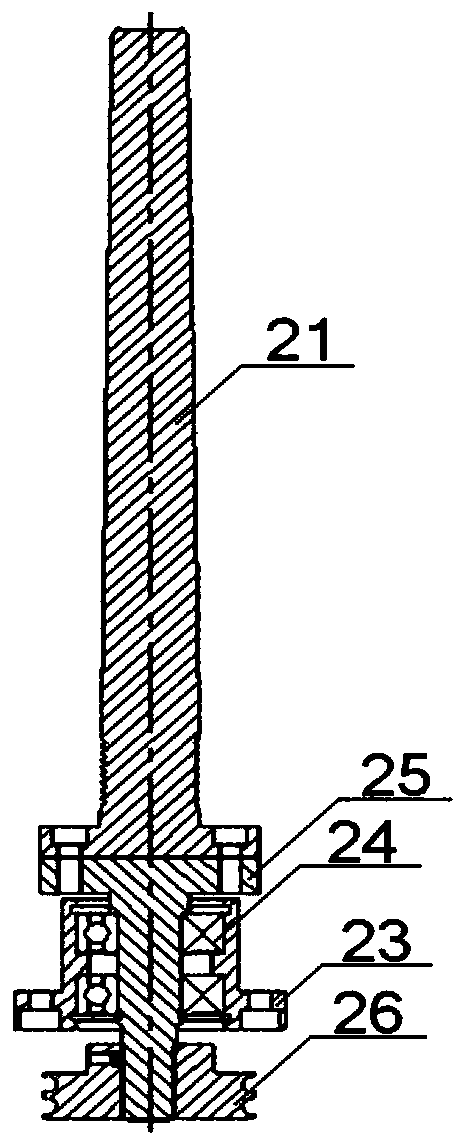

Automatic cleaning device for residual yarn on surfaces of fine yarn pipes

ActiveCN109399328AReduce labor intensityEasy to cleanFilament handlingConveyor partsYarnUltimate tensile strength

The invention discloses an automatic cleaning device for residual yarn on the surfaces of fine yarn pipes. The automatic cleaning device comprises a first machine frame and an annular guide rail arranged on the first machine frame, wherein a plurality of conveying trolleys are slidably connected to the annular guide rail, and a plurality of sleeves are horizontally arranged on the conveying trolleys; a discharging mechanism and a feeding mechanism are arranged on one side of the annular guide rail in sequence in the running direction of the conveying trolleys, and a cutting mechanism, a backing-off mechanism and a yarn scraping mechanism are arranged on the other side of the annular guiding rail in sequence in the running direction of the conveying trolleys; the feeding mechanism is used for installing the fine yarn pipes with residual yarn on the surfaces on the sleeves; the cutting mechanism is used for cutting the residual yarn on the surfaces of the fine yarn pipes; and the backing-off mechanism is used for backing-off the residual yarn on the surfaces of the fine yarn pipes; the yarn scraping mechanism is used for scraping the residual yarn on the surfaces of the fine yarn pipes; and the discharging mechanism is used for removing the cleaned fine yarn pipes from the sleeves. The automatic cleaning device not only reduces the labor intensity of cleaning of the residual yarn, but also improves the effect of cleaning of the residual yarn.

Owner:HUBEI TIANMEN TEXTILE MACHINERY

Oil fume cooling safe kitchen ventilator easy to disassemble and wash

PendingCN108286722AEasy to splitEasy to cleanDomestic stoves or rangesLighting and heating apparatusImpellerEngineering

The invention relates to improvement of an oil fume extraction technology, in particular to an oil fume cooling safe kitchen ventilator easy to disassemble and wash. A hollow angular fume collecting chamber is arranged in a fume collecting hood, a volute installing hole is formed in the missing portion of an angular prismatic shell wall located on the upper back portion of the fume collecting hood, a volute is vertically and fixedly installed in the volute installing hole, and an air outlet hole formed in the top end of the volute and the outer surface of a back shell are exposed out of the fume collecting hood; a motor is installed on the inner surface of the back shell of the volute, a power output shaft of the motor is horizontally arranged, and an impeller is fixedly installed on a shaft section, horizontally stretching out of a motor shell, of the power output shaft; a condensing plate is fixedly installed on a hood port of the fume collecting hood, an annular air inlet is formedbetween the condensing plate and the hood port, and the hollow portion of the condensing plate is filled with a solid or liquid condensing agent. According to the oil fume cooling safe kitchen ventilator easy to disassemble and wash, the oil stain retaining amount and the oil stain removing frequency which are caused by high-temperature oil fume to the interior can be significantly decreased, themanual oil stain removing labor intensity is reduced, the safe working reliability is further obviously improved, and the service life is further prolonged.

Owner:姚洪亮

Preparation method of modified sodium silicate-bonded sand

InactiveCN107671232AHigh strengthGood collapsibilityFoundry mouldsFoundry coresCarbon monofluorideSodium silicate

The invention discloses a preparation method of modified sodium silicate-bonded sand. The modified sodium silicate-bonded sand consists of the following raw materials including, by weight, 35-55 partsof quartz sand, 10-20 parts of sodium silicate, 6-12 parts of clay, 12-30 parts of gypsum, 3-8 parts of carbon monofluoride powder, 5-15 parts of nano calcium carbonate, 3-8 parts of a reinforcing agent, 3-8 parts of a collapsibility agent, 12-20 parts of resin powder, 3-8 parts of sodium tripolyphosphate, 5-12 parts of active silica powder and 20-30 parts of a sodium polyacrylate solution with the concentration being 25%. According to the preparation method, the active silica powder, the nano calcium carbonate and the carbon monofluoride powder are added into the common sodium silicate, andthe sodium polyacrylate solution with the concentration being 25% is used for replacing the water in the original sodium silicate, so that the sand mould strength is improved, the sand mould collapsibility is improved, the cleaning labor intensity is lightened and the cleaning expense is saved under the condition of increasing small cost.

Owner:JIANGSU MINJIANG MINING CO LTD

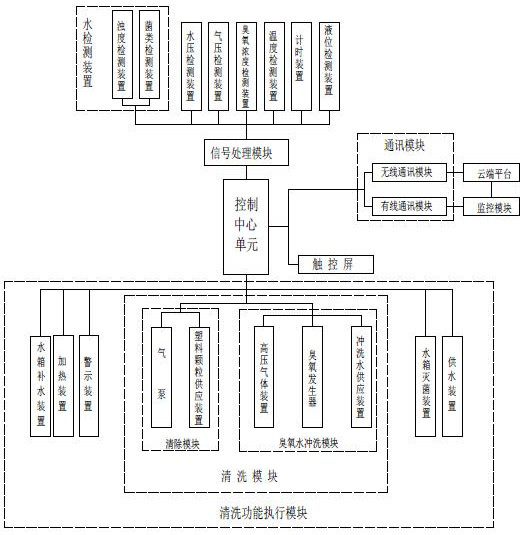

Intelligent cleaning control system for culture waterline

ActiveCN112394653ASmall content fluctuationsRealization of cleaning controlTransmissionProgramme control in sequence/logic controllersControl systemFishery

The invention discloses a culture waterline intelligent cleaning control system. The system comprises a control center unit, a signal processing module, a cleaning function execution module, a communication module and a touch screen, wherein the cleaning function execution module comprises a cleaning module, a water detection device is arranged on a culture waterline, and the culture waterline isconnected with a connecting cylinder through a pipeline; the cleaning module is connected with the connecting cylinder, the water detection device sends detected data signals to the signal processingmodule, the control center unit sends operation instructions to control all execution elements of the cleaning module to work, cleaning of the aquaculture water line is achieved, and cleaning work isobserved and controlled in real time through the touch screen; and the cleaning work is remotely monitored and controlled through the communication module. The system is advantaged in that real-time cleaning of the culture waterline and intelligent control over cleaning of the culture waterline are achieved, detection precision is high, cleaning labor intensity is small, cleaning is timely and thorough, cleaning control is intelligent, poultry can be flushed, and normal use of the culture waterline is guaranteed.

Owner:山东舍拜恩环保科技有限公司

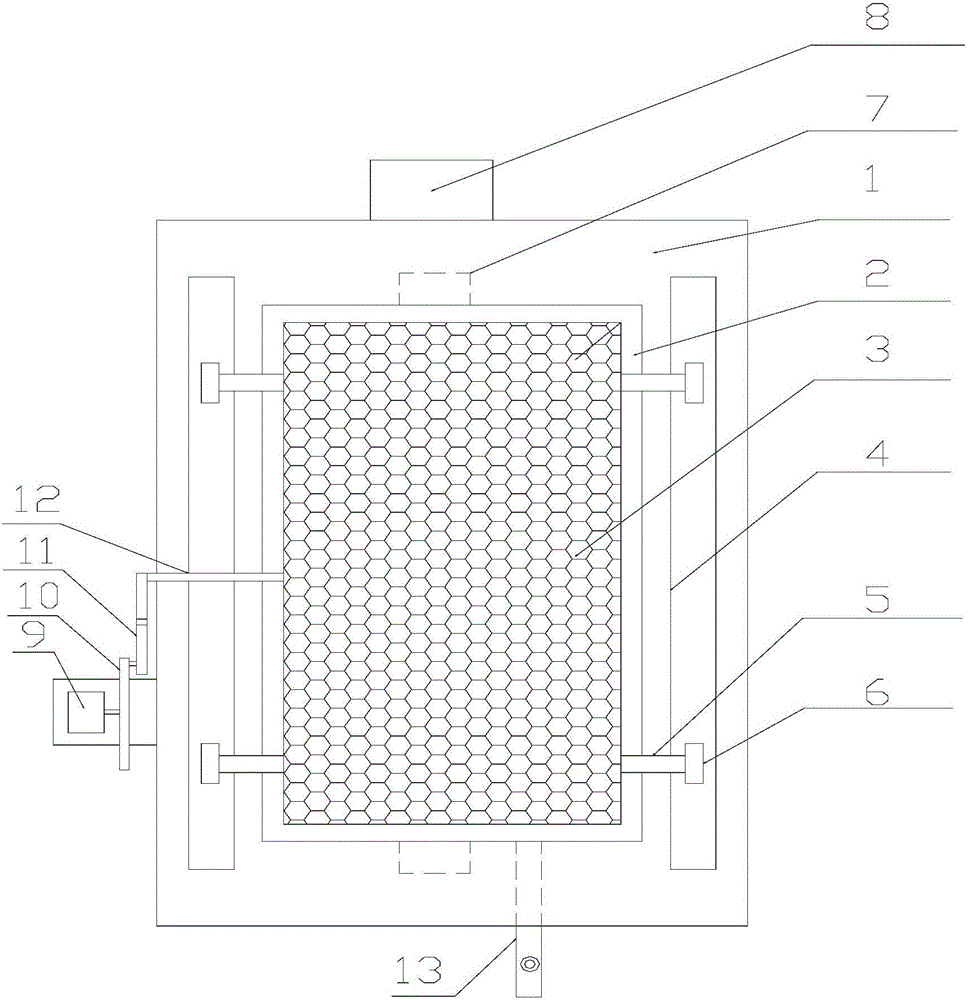

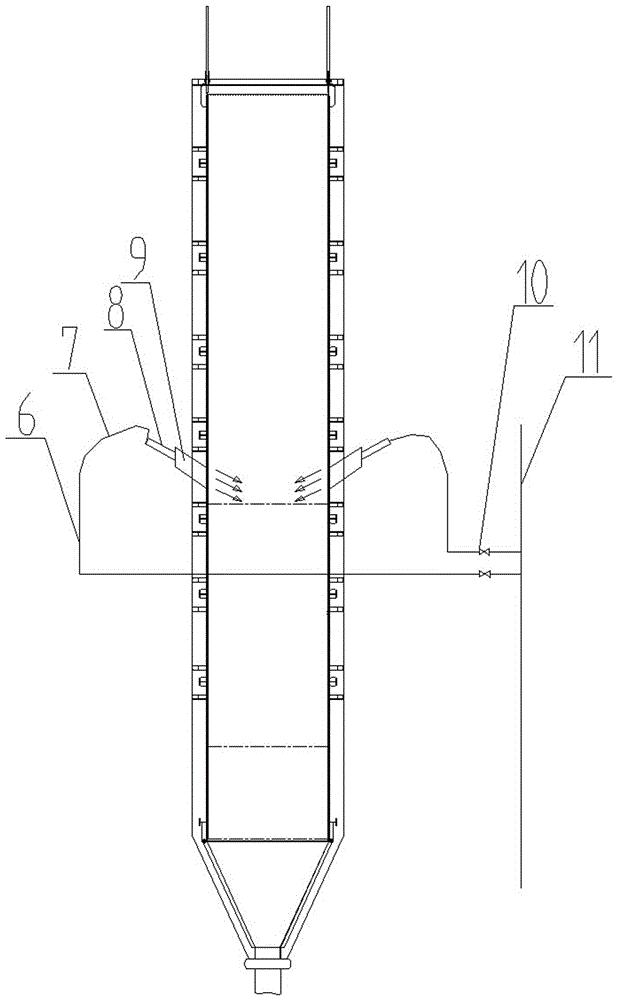

Filtering device for industrial wastewater purification and use method thereof

ActiveCN112973243AImprove processing efficiency and effectivenessImprove processing efficiencySpecific water treatment objectivesTreatment involving filtrationProcess engineeringSewage

The invention relates to the field of industrial wastewater purification equipment, in particular to a filtering device for industrial wastewater purification and a using method thereof. The filtering device comprises a base, wherein a filtering mechanism used for filtering flocculate in wastewater is arranged on the base, a sewage disposal mechanism is arranged on the base, is used for sucking and discharging the flocculate filtered on the filtering mechanism, and is in transmission connection with the filtering mechanism, an air pumping mechanism is arranged on the sewage disposal mechanism, and is used for cleaning and dredging the filtering mechanism in an air blowing mode, and the sewage disposal mechanism is in transmission connection with the air pumping mechanism. According to the filtering device for industrial wastewater purification and the use method thereof, the sewage disposal mechanism drives the filtering mechanism to filter wastewater subjected to flocculation treatment, so that efficient filtration of the wastewater is maintained, the wastewater treatment efficiency and effect are improved, shutdown is not needed, continuous work of the whole device is achieved, the wastewater treatment efficiency is improved, and the cleaning difficulty and the labor intensity of the flocculate are reduced.

Owner:浙江环森环境科技有限公司

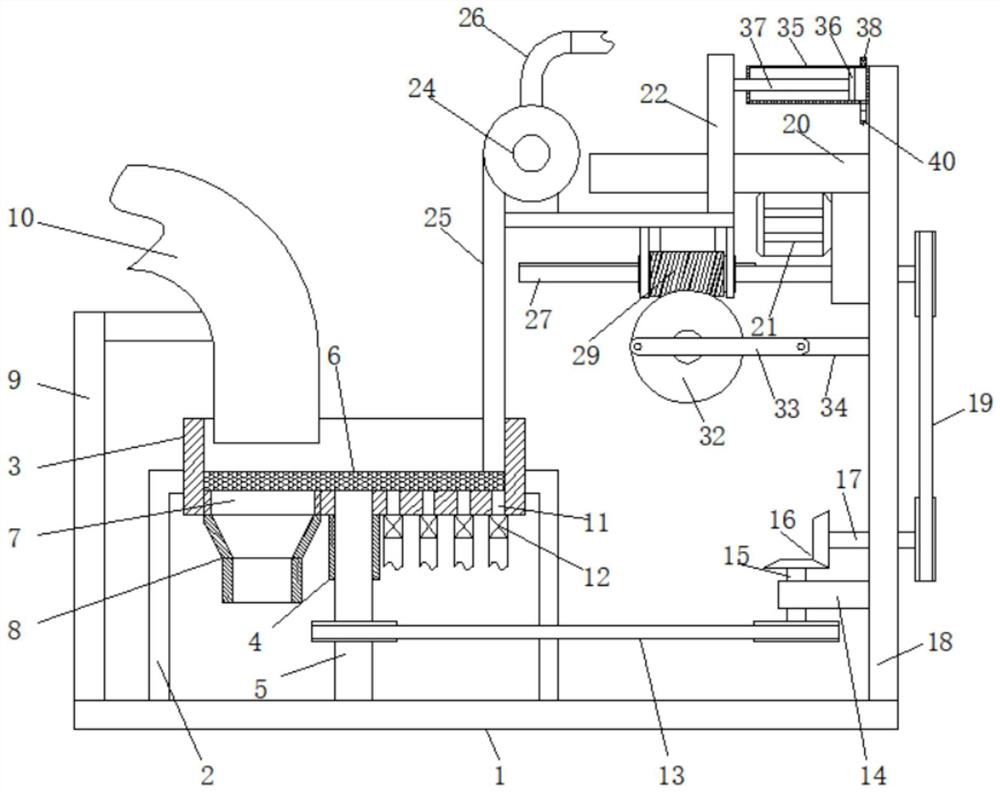

Tailing recycling device for cold-box core shooter and use method thereof

ActiveCN108637187AImprove cleaning efficiencyImprove efficiencyMoulding machine componentsMoulding machinesEngineeringTailings

The invention provides a tailing recycling device for a cold-box core shooter and a use method thereof, and aims at solving the problem of low efficiency and high working intensity in cleaning residual sand in a shooting barrel after core shooting and manufacturing of a product. The device comprises a main bone and an active material, wherein a sand hanging part for hanging sand is arranged at oneend of the main bone, and a sand core lug for carrying and recycling is arranged at the other end of the main bone; a clamping part which fits the active material is arranged in the middle part of the main bone; the active material is divided into a first active material and a second active material which can be buckled to form an integral active material; and the main function of the active material is to prevent the lug of the main bone from being buried. The device is directly positioned in a mold cavity of a core shooter die, so that core shooting and core manufacturing and continuous core shooting in tailing cleaning are achieved, and as a result, the efficiency in core shooting and core manufacturing of a product is improved, and meanwhile, the working intensity in tailing cleaningis reduced.

Owner:四川共享铸造有限公司

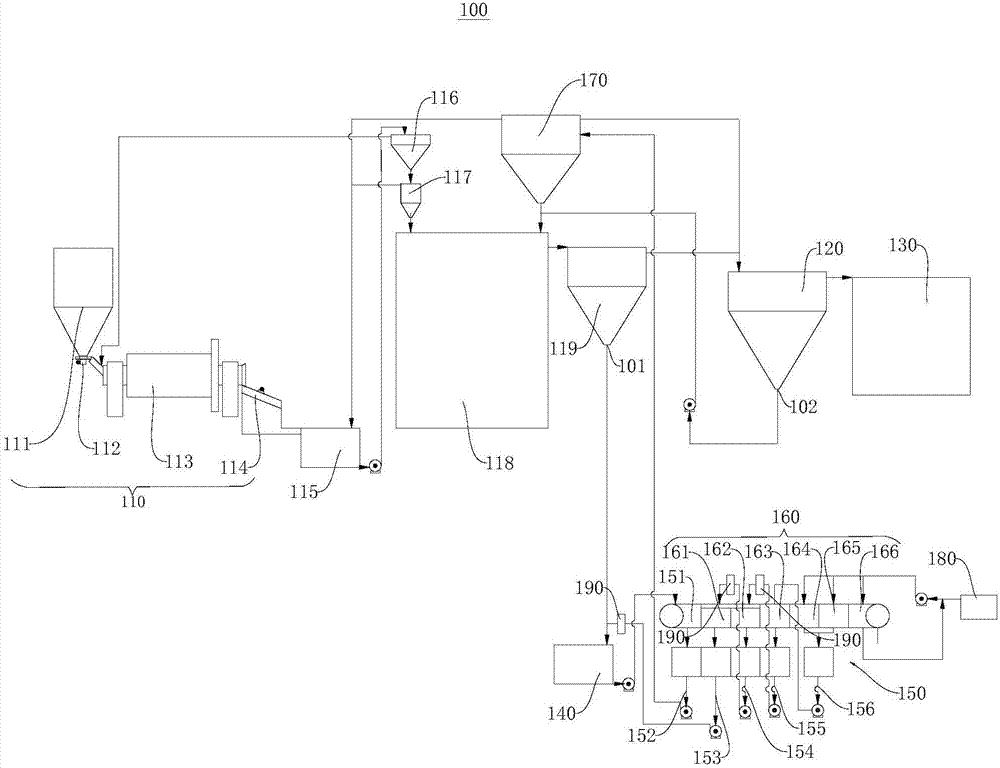

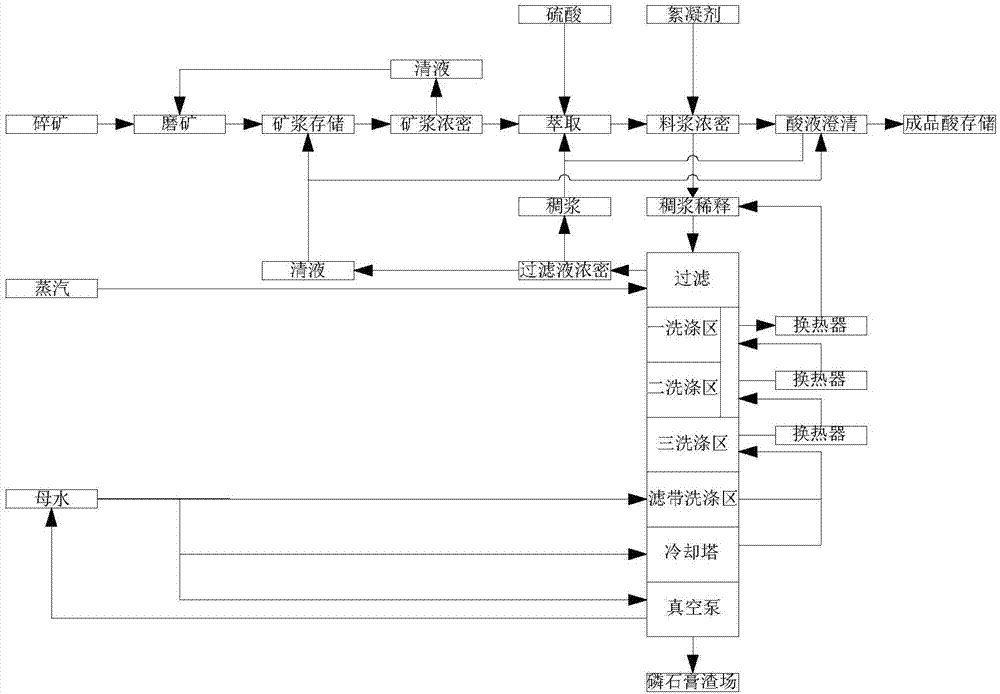

Wet phosphoric acid production system and wet phosphoric acid production method

ActiveCN106882776ASolve fouling and cloggingReduce damage ratePhosphoric acidProcess optimizationPhosphoric acid

The invention relates to the field of chemical engineering, and particularly discloses a wet phosphoric acid production system and a wet phosphoric acid production method. The wet phosphoric acid production system comprises mineral aggregate conveying equipment, an ore pulp storage tank, an ore pulp thickening tank, an ore pulp overhead tank, an extraction tank, a slurry thickening tank, a phosphoric acid clarification tank and a phosphoric acid storage tank. A thick slurry outlet of the slurry thickening tank is communicated to a material inlet of a thick slurry diluting tank, so that filtering and cleaning equipment does not participate in filtering of phosphoric acid stock solution, and only filters diluted slurry separated through a slurry thickener. The problems of scaling and blockage of a filter and relevant pipelines are effectively solved. By process optimization, the production efficiency is greatly improved, and the equipment utilization rate is increased; the production unit production of a product can be reduced. The wet phosphoric acid production method makes use of the wet phosphoric acid production system, so that during wet phosphoric acid production, the production efficiency is high.

Owner:胡士清

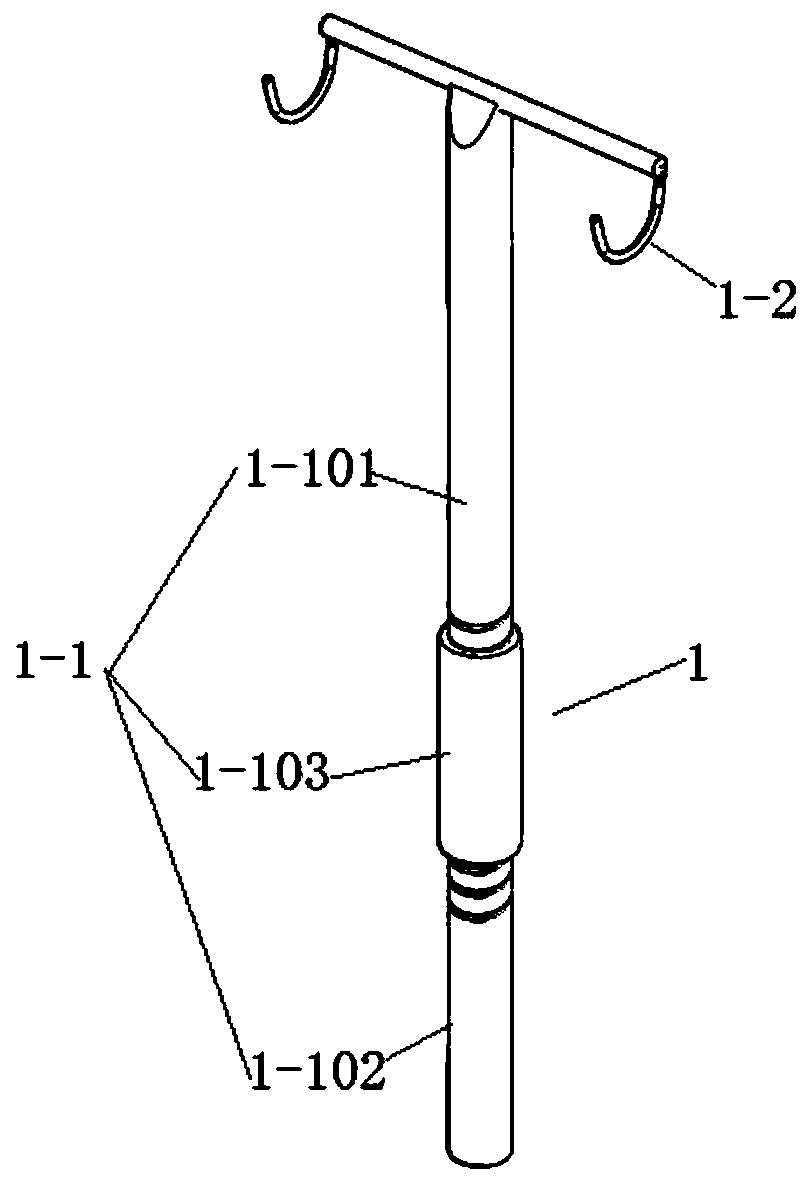

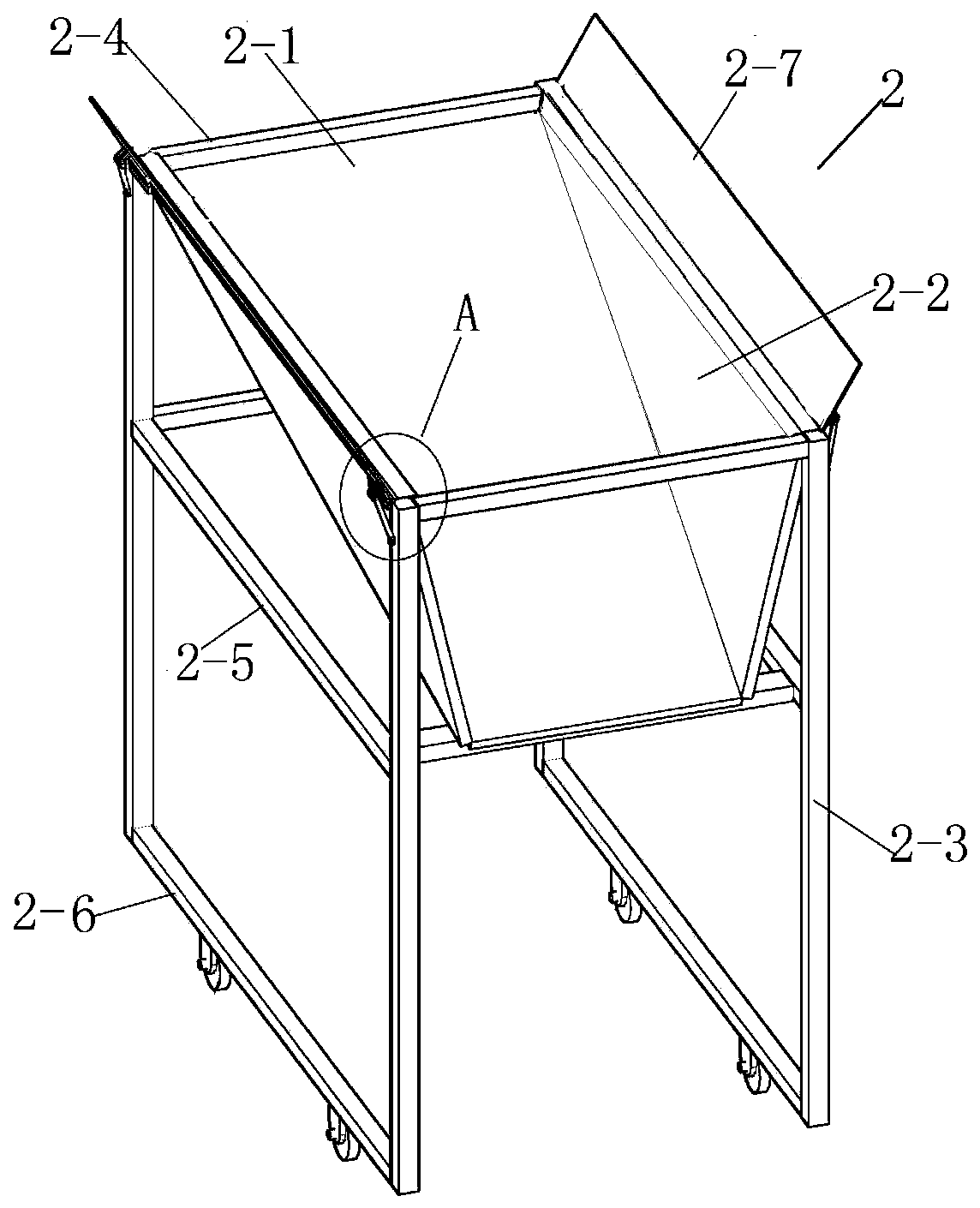

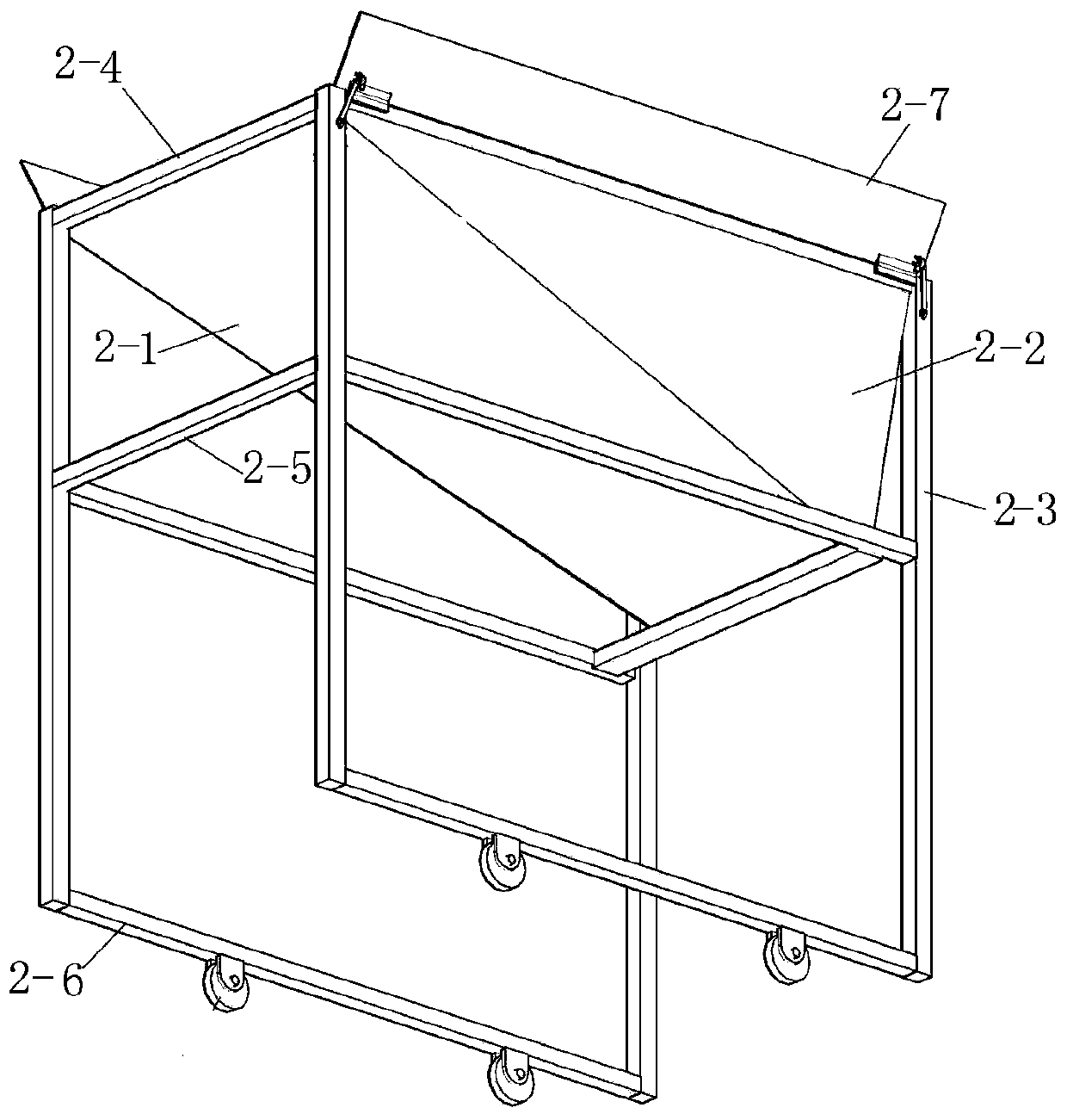

Safe and efficient duck catching method in duck shed

ActiveCN110352871AReduce cleaning labor intensityEasy to adjust the lengthAvicultureCage cultureEngineering

The invention relates to the technical field of meat duck cage culture, in particular to a safe and efficient duck catching method in a duck shed. According to the safe and efficient duck catching method for the duck shed, duck catching operation is realized through nondestructive cage door opening hooks, a duck-catching slow-down platform mechanism, a duck catching trolley for movement and a duckpushing plate, so that the duck catching time is greatly shortened; and meat ducks in duck cages on the left and right sides simultaneously slide down along a sliding plate of the duck-catching slow-down platform mechanism at the middle of the duck shed, and the time from opening the cage door to completing duck catching and closing the cage door is about 30-40s, so that the duck catching processis greatly shortened, and manpower and material resources are saved.

Owner:新泰市天信农牧发展有限公司

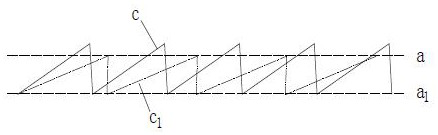

Belt scraper

PendingCN109230370AImprove scraping effectReduce the intensity of spare parts replacementCleaningEngineeringPulp and paper industry

The invention relates to the technical field of water slag conveying belt, in particular to a belt scraper, which comprises clamp plates with positioning holes arranged respectively at two ends, a scraping brush arranged between the clamping plates and adjusting plates which are vertically and movably arranged at the two ends of the clamping plates, wherein the material of the scraping brush is aconveying belt with the dipped canvas surface, the adjusting plates are provided with adjusting holes which are matched with the positioning holes, the adjusting plates can be fixedly connected with the clamping plates by bolts through the positioning holes in the clamping plates and the adjusting holes in the adjusting plates, the position of the clamping plates on the adjusting plates can be adjusted by the bolt, the belt scraper not only features good scraping effect and long service period, but also has the advantages of low cost, low maintenance rate and low maintenance cost.

Owner:SHANXI TONGCAI IND & TRADE

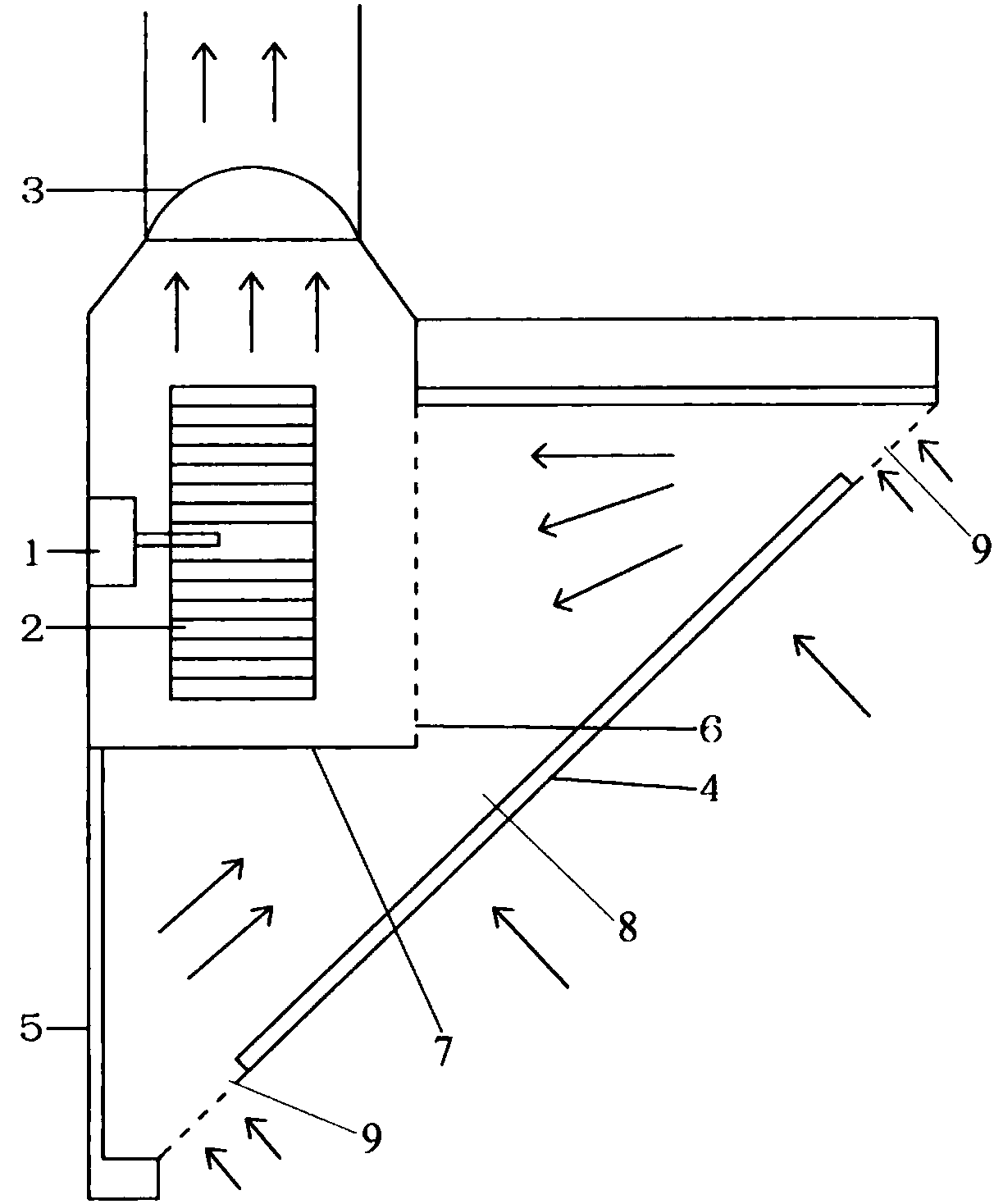

Air seal system capable of reducing dust deposition and adhering of water wall of waste heat boiler of silver copper smelting furnace

ActiveCN106288829AReduce ash formationReduce cleaning labor intensityIncreasing energy efficiencySolid removalEngineeringHigh pressure

The invention discloses an air seal system capable of reducing dust deposition and adhering of a water wall of a waste heat boiler of a silver copper smelting furnace. Air compression wind is conveyed to the position of a boiler uptake flue through a main pipeline. In the position of preset elevation of the boiler uptake flue, high-pressure controllable spray guns and spray gun holders are mounted in the centered positioned of two sides of the plate tubular type water wall. Two branch pipes are drawn out of the main pipeline and connected with the spray guns on the two sides of the boiler uptake flue through flexible metal tubes. During operation of the boiler under the normal working condition, a valve is opened for air feeding, the air amount of the main pipeline is adjusted, and the air seal system starts to work. The air seal system has the beneficial effects that high-pressure gas enters a descending flue and a radiation chamber through the uptake flue, the smoke content of a convection chamber is greatly lowered, the dust deposition degree of the water wall of the boiler can be effectively lowered, the dedusting labor intensity of firemen is relieved, and the production efficiency of a boiler system is improved.

Owner:BAIYIN NONFERROUS GROUP

Shoe sole edge-trimming device for slipper processing

InactiveCN109998231AAvoid scatterReduce cleaning labor intensityEdge grinding machinesShoemaking devicesMotor driveEngineering

The invention discloses a shoe sole edge-trimming device for slipper processing, and relates to an edge-trimming device. The shoe sole edge-trimming device comprises a lower box, the lower box is of ahollow structure, a motor bracket is fixedly connected to the right side of the inner bottom of the lower box, a motor is fixedly connected above the motor bracket, a horizontal rotation shaft is fixedly connected to the output end of the motor, a driving bevel gear is fixedly connected to the right side of the horizontal rotation shaft, a first longitudinal shaft is rotatably connected to the right side of the lower box, a driven bevel gear meshed with the driving bevel gear is fixedly connected to the bottom of the first longitudinal shaft, and a support vertical beam is fixedly connected on the right side of the upper side of the lower box. When the shoe sole edge-trimming device is used, the motor drives the horizontal rotation shaft to rotate, through the bevel gear group, the firstlongitudinal shaft, a transmission wheel, a transmission belt and a driven rotation shaft, grinding stone is driven to trim the shoe soles, during the trimming process, waste materials obtained aftergrinding can be directly discharged into a material collecting box, thus the phenomenon that the waste materials scatter around is avoided, and further, the labor intensity for cleaning of workers isalleviated.

Owner:台州市周芸鞋业有限公司

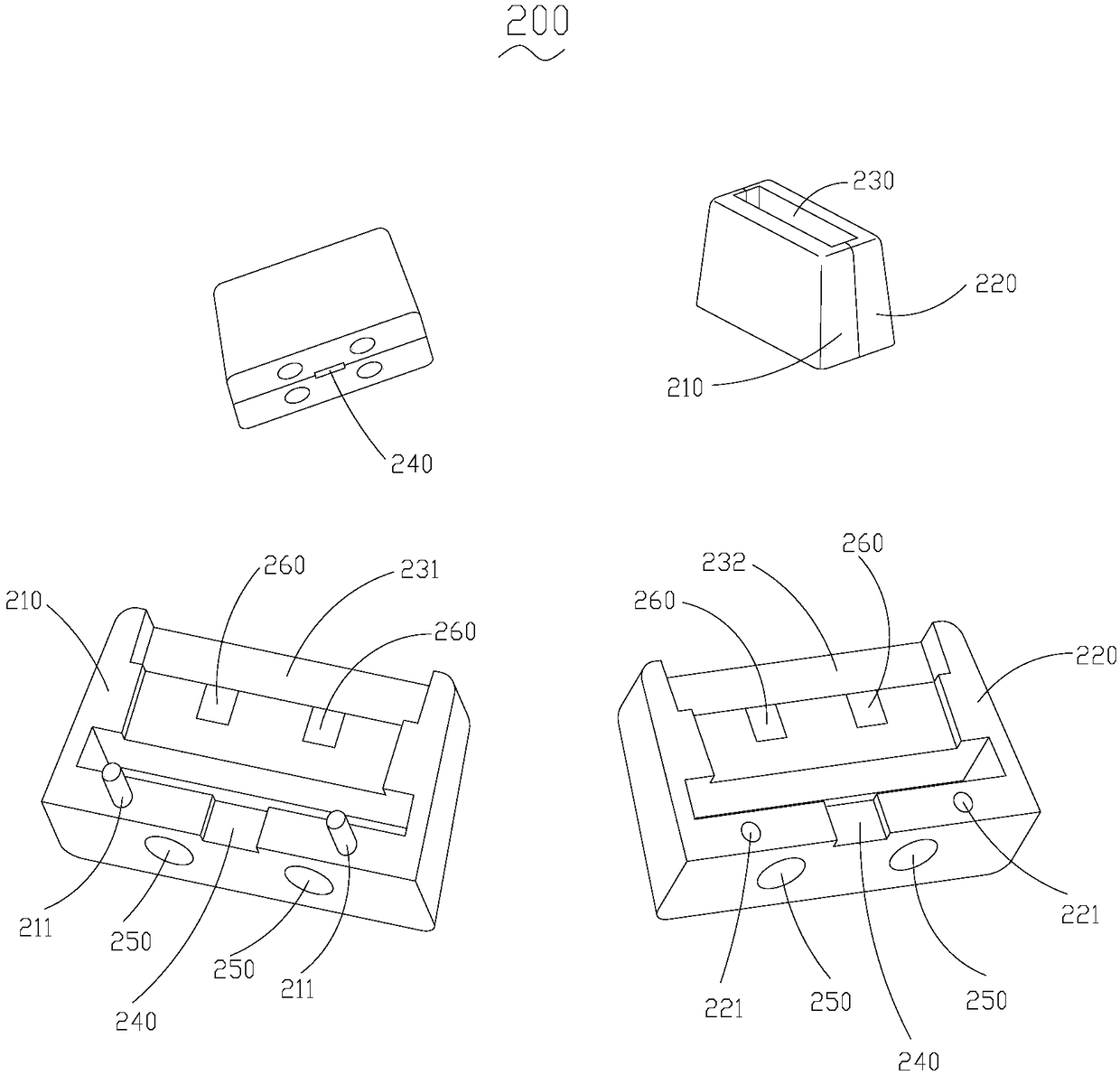

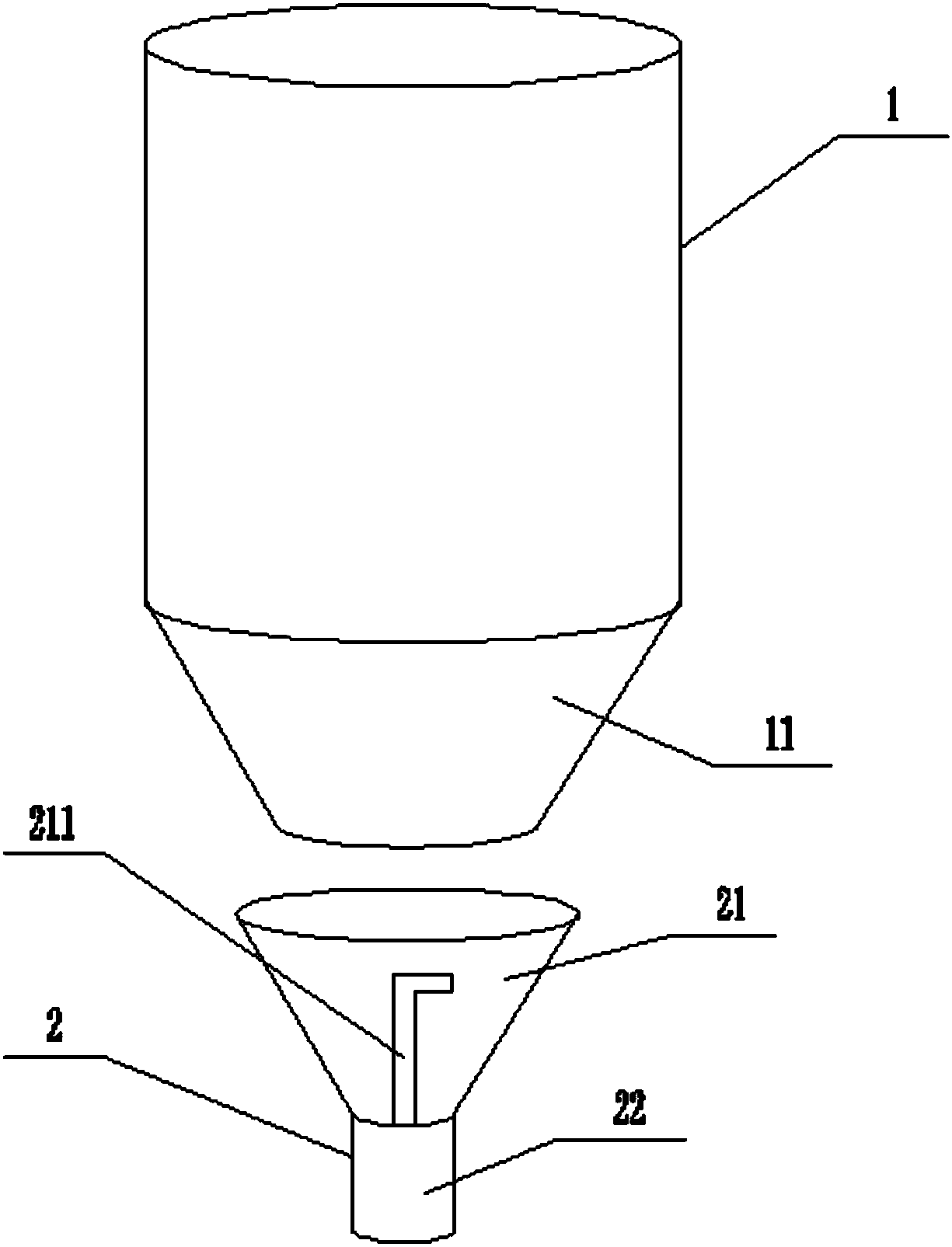

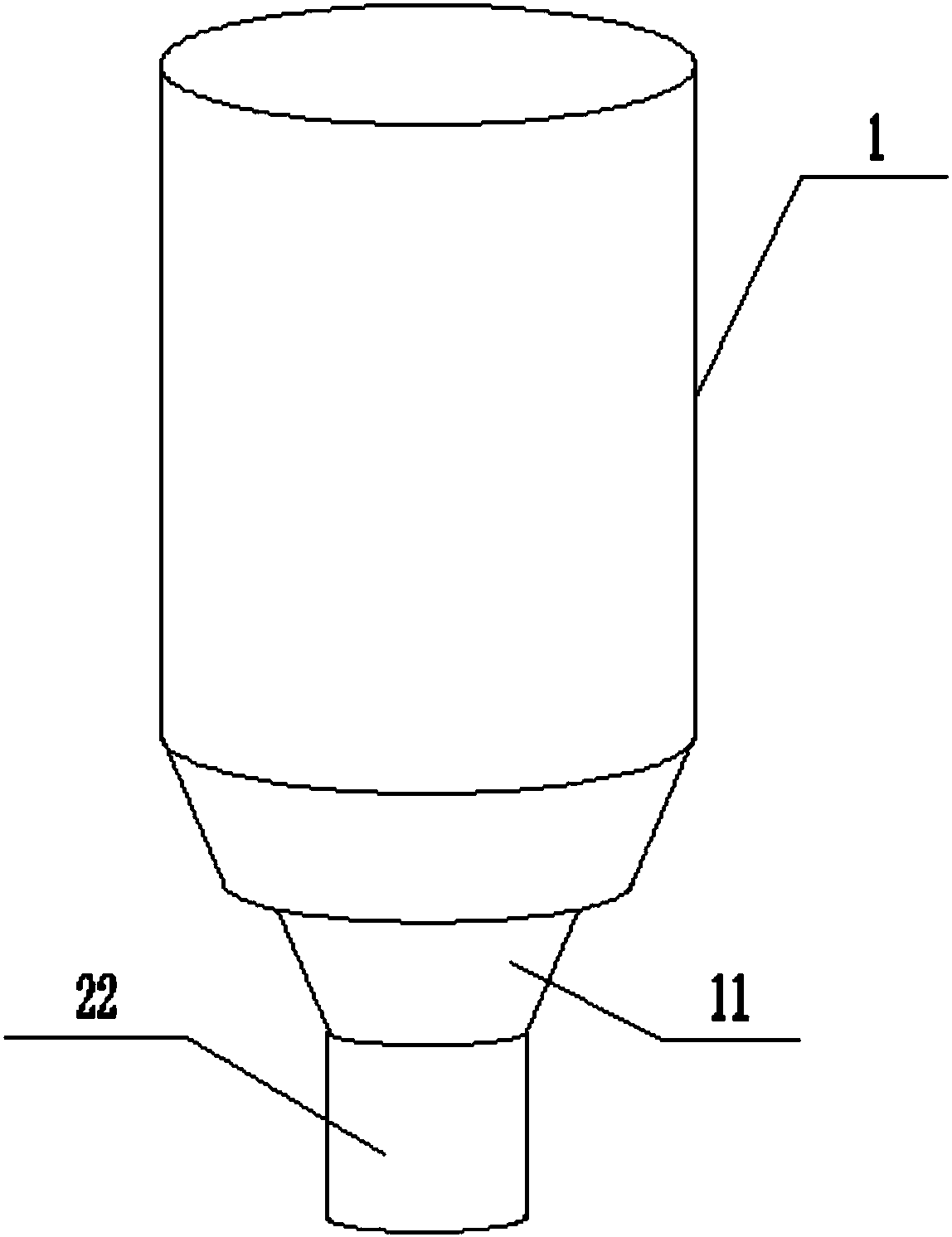

Combined storage hopper easy to clean

InactiveCN108216952AGuaranteed StrengthRapid positioningLarge containersEngineeringUltimate tensile strength

Owner:CHONGQING PINGWEI AUTO PARTS CO LTD

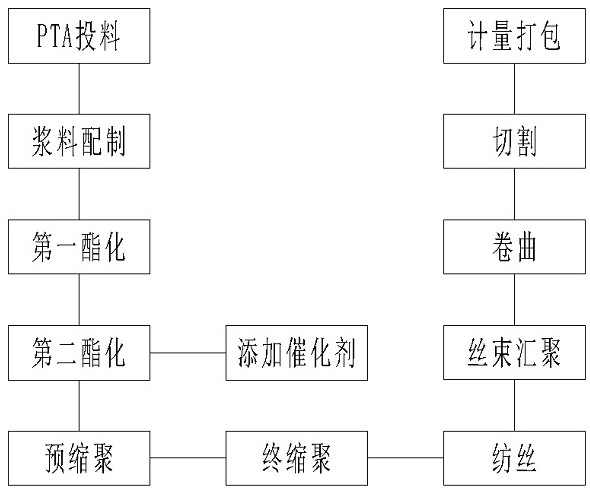

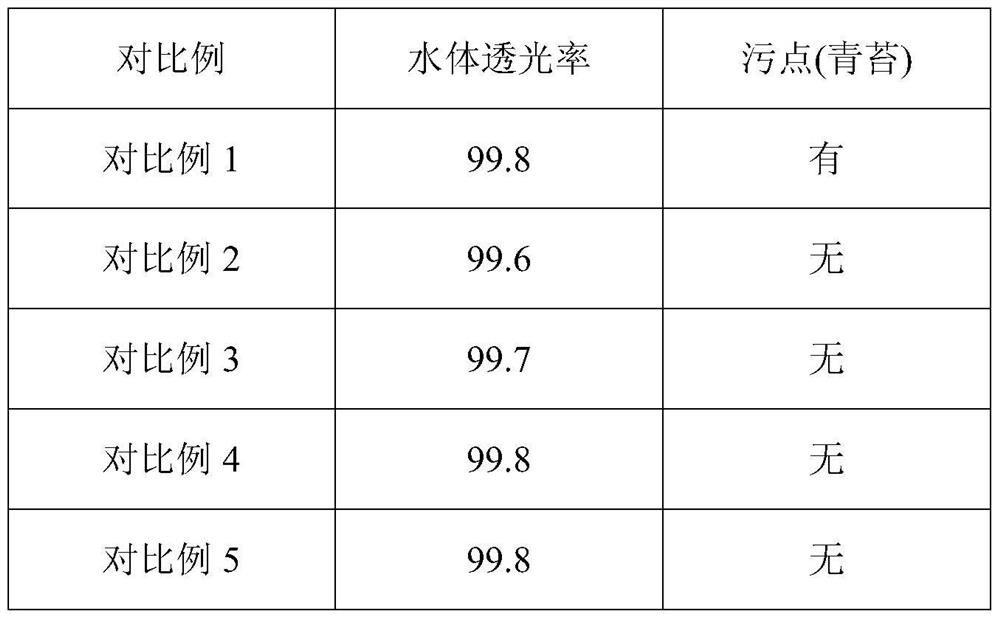

Production process of short fibers special for high-cleanness spunlace non-woven fabric

ActiveCN111910277AImprove processing efficiencyReduce processing costsSpinning solution de-aeratingNew-spun product collectionSpinningPtru catalyst

The invention relates to a production process of short fibers special for high-cleanness spunlace non-woven fabric. The production process comprises the steps of PTA feeding, slurry preparation, firstesterification, second esterification, pre-polycondensation, final polycondensation, spinning, tow gathering, curling, cutting, metering and packaging. Through the methods that various feeding modesare adopted, the adding mode of a catalyst is changed, process wastewater is subjected to pre-cooling treatment, a filter is adopted for automatic cleaning, an oil inlet of an oiling ring is improved,a tail filament alarm treatment device is arranged, a tow amplitude modulation device is adopted, a rotary standby cut-off mechanism is adopted, and a novel adjustable packaging briquetting method isadopted, the main problems in the production process of the short fibers special for the high-cleanness spunlace non-woven fabric at present are solved, and the production process of the short fibersspecial for the high-cleanness spunlace non-woven fabric is high in production efficiency, stable in product quality, flexible and controllable in production process, low in failure rate and low in production cost.

Owner:江苏华西村股份有限公司

Automatic cleaning device for residual yarn on the surface of spun bobbin

ActiveCN109399328BReduce labor intensityEasy to cleanFilament handlingConveyor partsYarnStructural engineering

The invention discloses an automatic cleaning device for residual yarn on the surfaces of fine yarn pipes. The automatic cleaning device comprises a first machine frame and an annular guide rail arranged on the first machine frame, wherein a plurality of conveying trolleys are slidably connected to the annular guide rail, and a plurality of sleeves are horizontally arranged on the conveying trolleys; a discharging mechanism and a feeding mechanism are arranged on one side of the annular guide rail in sequence in the running direction of the conveying trolleys, and a cutting mechanism, a backing-off mechanism and a yarn scraping mechanism are arranged on the other side of the annular guiding rail in sequence in the running direction of the conveying trolleys; the feeding mechanism is used for installing the fine yarn pipes with residual yarn on the surfaces on the sleeves; the cutting mechanism is used for cutting the residual yarn on the surfaces of the fine yarn pipes; and the backing-off mechanism is used for backing-off the residual yarn on the surfaces of the fine yarn pipes; the yarn scraping mechanism is used for scraping the residual yarn on the surfaces of the fine yarn pipes; and the discharging mechanism is used for removing the cleaned fine yarn pipes from the sleeves. The automatic cleaning device not only reduces the labor intensity of cleaning of the residual yarn, but also improves the effect of cleaning of the residual yarn.

Owner:HUBEI TIANMEN TEXTILE MACHINERY

Device for efficiently cleaning containers for machining

InactiveCN107744992AClose contactEasy to cleanHollow article cleaningCleaning using toolsEngineeringUltimate tensile strength

The present invention relates to a container cleaning device, and especially relates to a device for efficiently cleaning containers for machining. The technical problem to be solved is to provide a device for efficiently cleaning containers for machining, cleaning labor strength is little, both time and labor are saved, and the containers can be thoroughly cleaned. To solve the technical problem,the present invention provides a device for efficiently cleaning containers for machining. The device comprises a base plate, a support, a top plate, a transverse plate, a first hairbrush, a disposing plate and a rotary apparatus; the right side of the top of the base plate is connected with the support in a bolted connection manner; the top of the support is connected with the top plate in a bolted connection manner; and the bottom of the top plate is connected with the rotary apparatus in a bolted connection manner. The first hairbrush is driven by the rotary apparatus to clean inner wallsof the containers, a height adjusting apparatus is disposed, and operators can adjust the height of the disposing plate via sliding rails and sliding blocks according to different heights of the containers.

Owner:吴文英

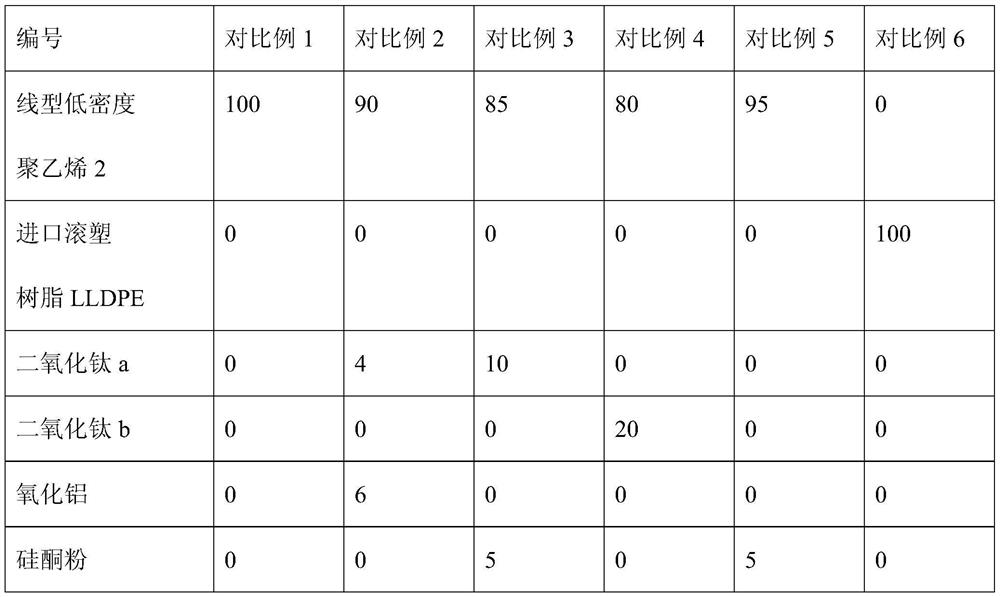

Polyolefin rotomolding composition, its preparation method and application

ActiveCN109627559BSolve pollutionPrevent mildewClimate change adaptationLow-density polyethylenePolymer science

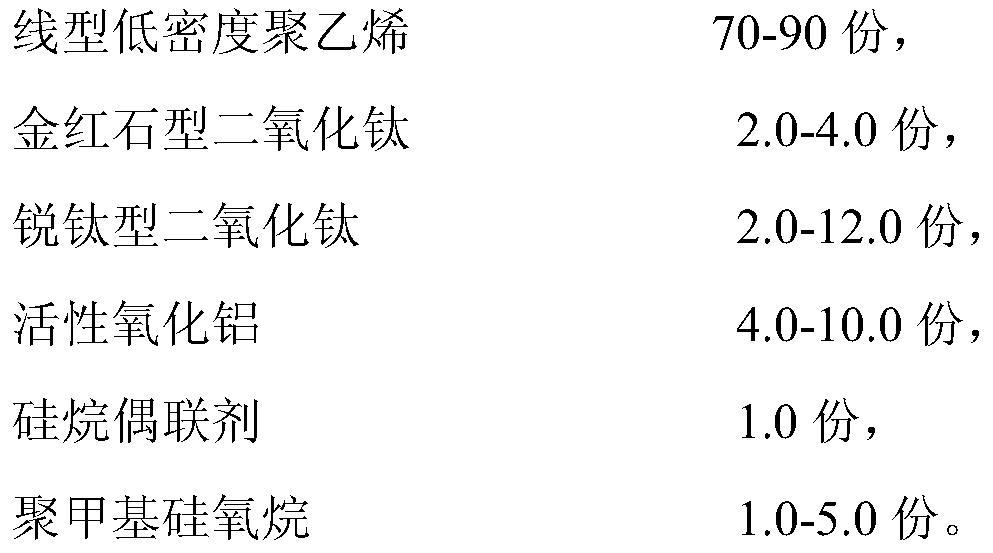

The present invention relates to a polyolefin composition, particularly to a polyolefin rotational molding composition, a preparation method and applications thereof, wherein the polyolefin rotationalmolding composition comprises, by weight, 70-90 parts of linear low-density polyethylene, 2.0-4.0 parts of rutile type titanium dioxide, 2.0-12.0 parts of anatase type titanium dioxide, 4.0-10.0 parts of active alumina, 1.0 part of a silane coupling agent, and 1.0-5.0 parts of polymethylsiloxane, wherein the linear low-density polyethylene has a density of 0.936-0.939 g / cm<3> and a melt mass flowrate of 6-12 g / 10 min. According to the present invention, with the polyolefin rotational molding composition, the problem of water pollution of the polyethylene water storage tank is solved, and thecondition that suspended matters and impurities in a water body are attached to the wall of the device to grow into moss and cause mildew can be effectively prevented. The invention further providesapplications of the polyolefin rotational molding composition, wherein the inner surface of the rotational molding product can be coated with the polyolefin rotational molding composition so as to prevent the moss in the water from the attached growth, such that the method is simple, and the effect is obvious.

Owner:CHINA PETROLEUM & CHEM CORP

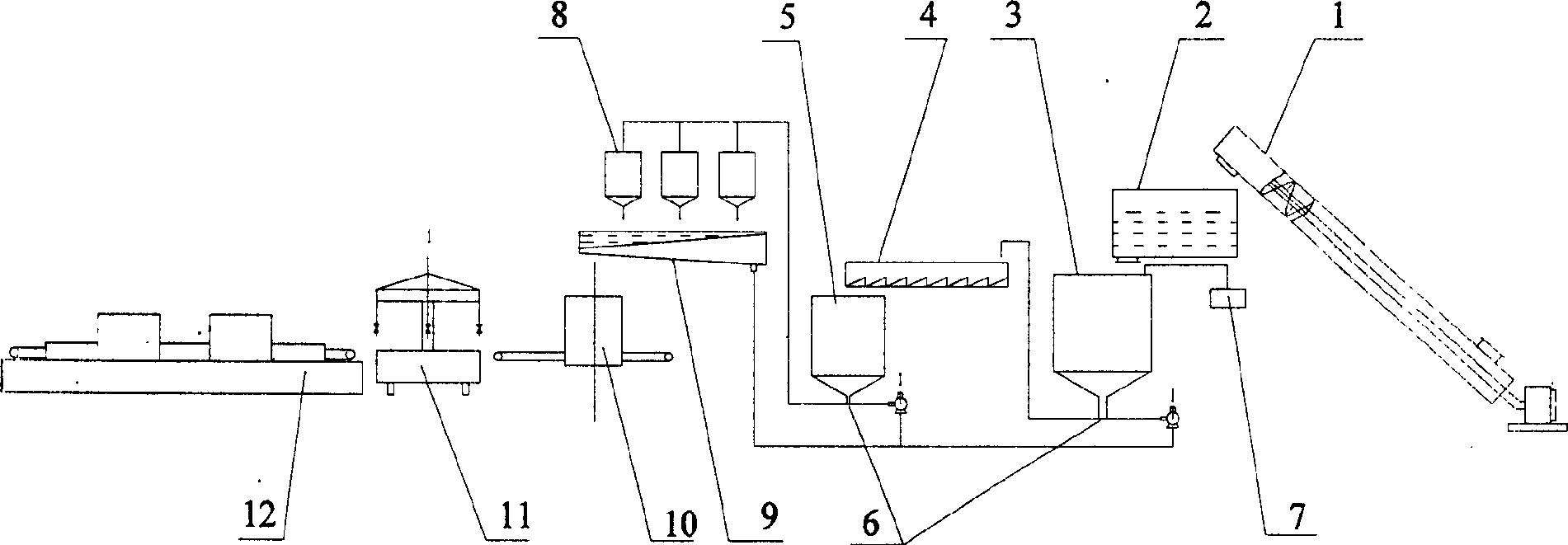

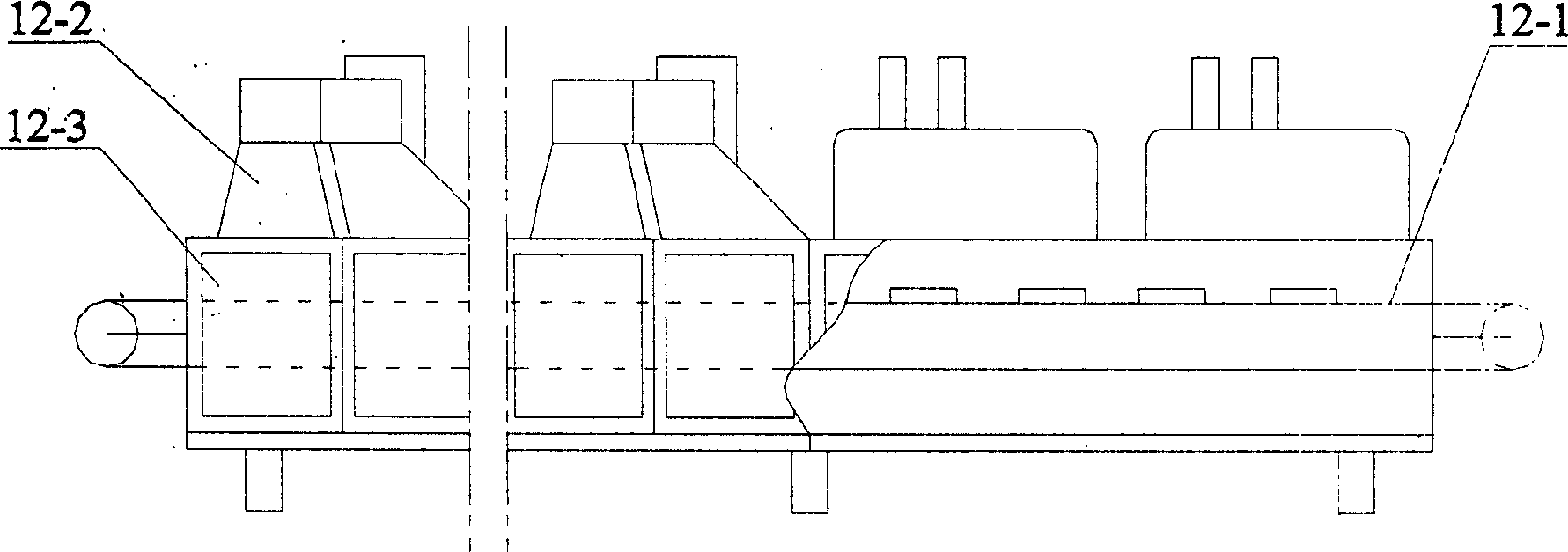

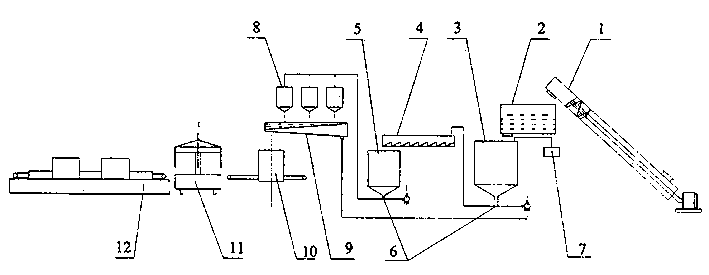

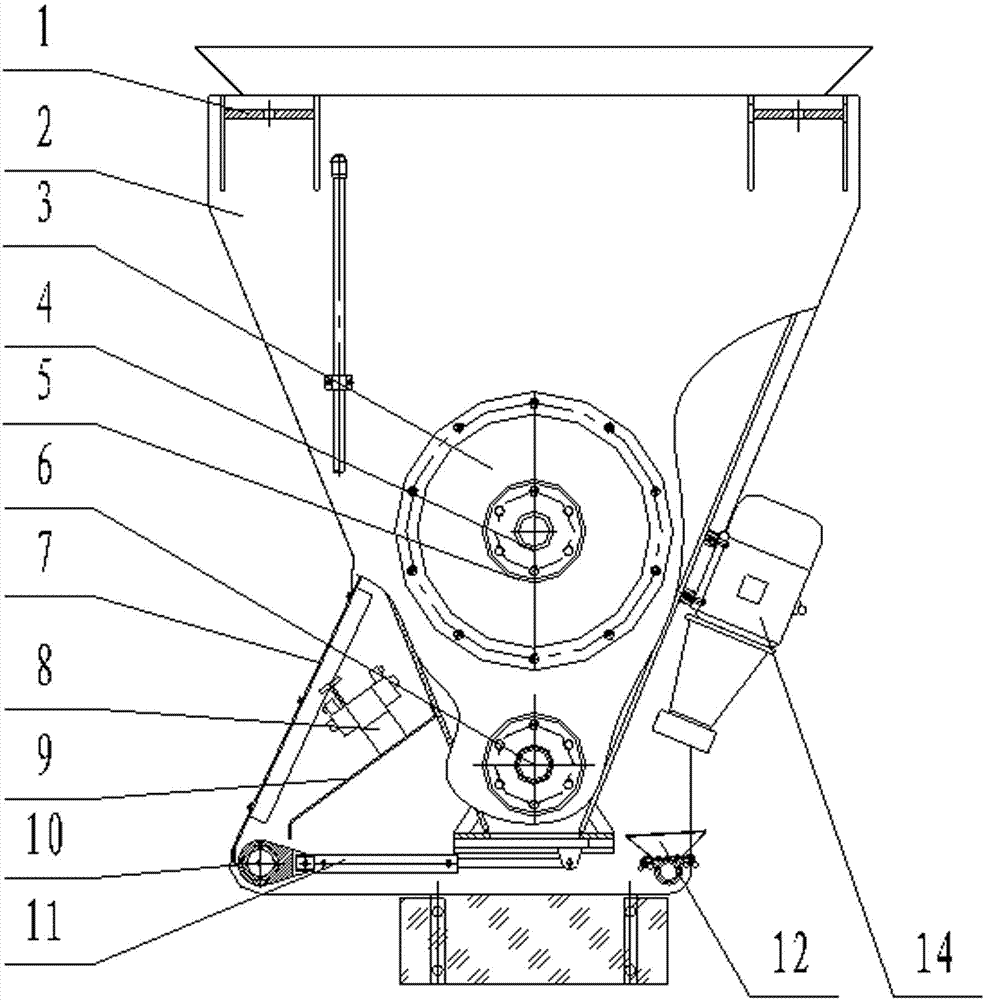

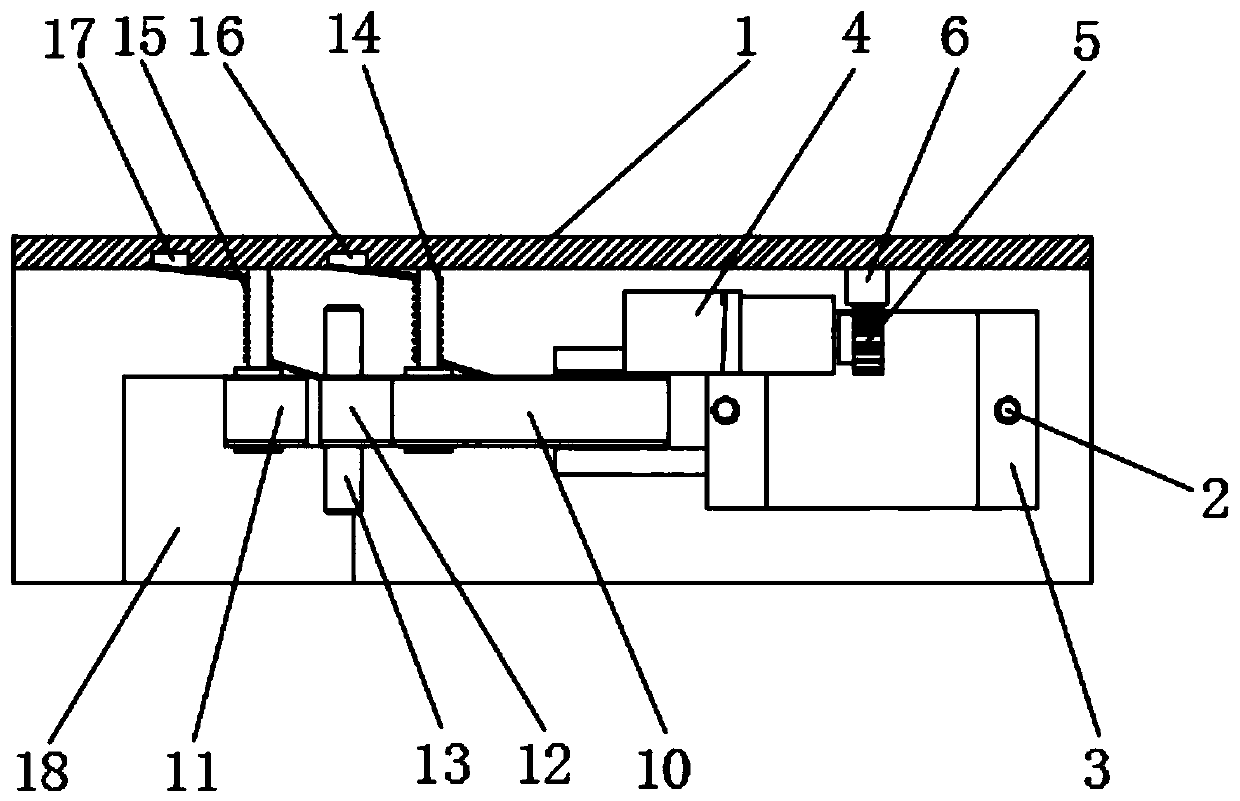

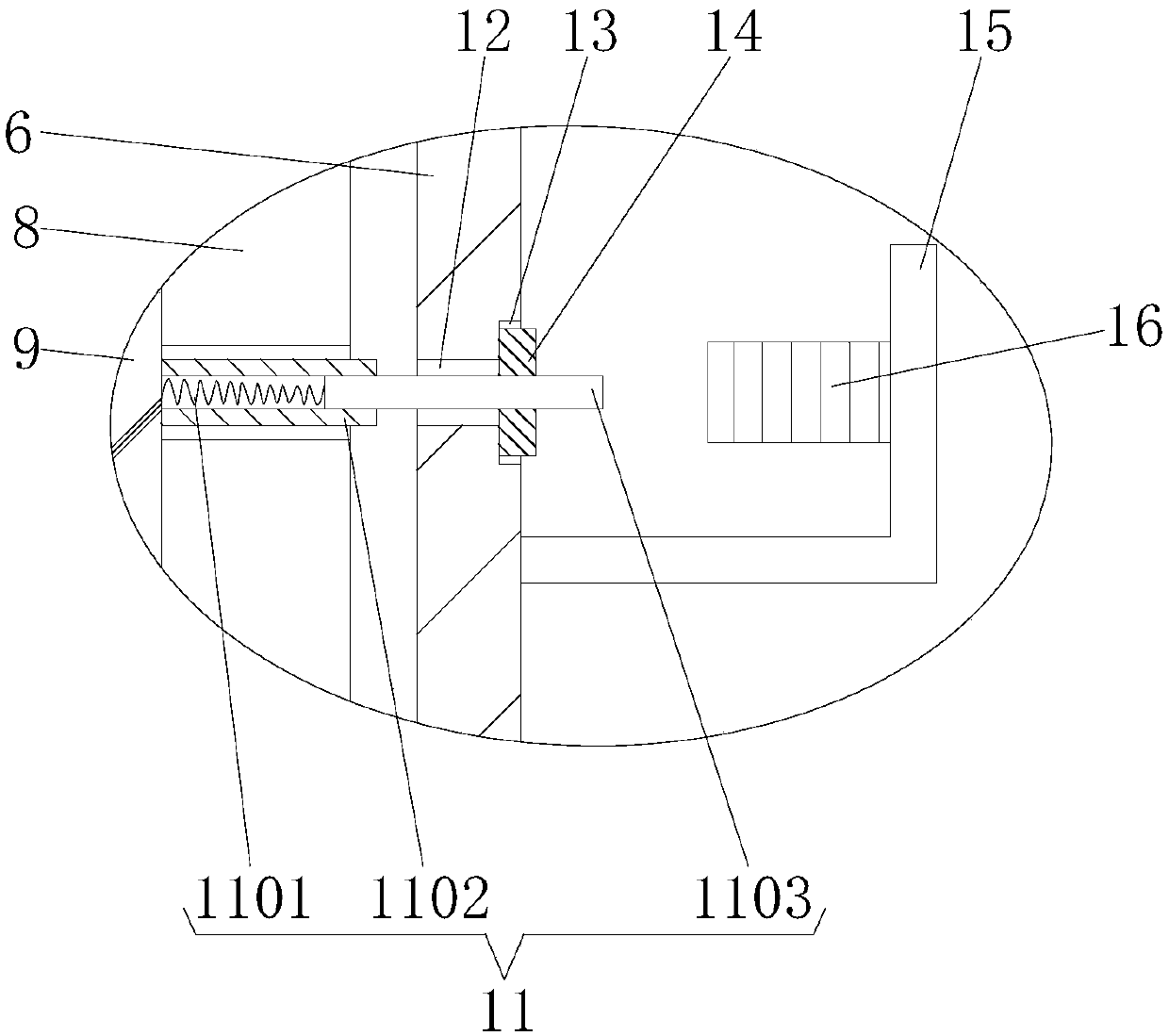

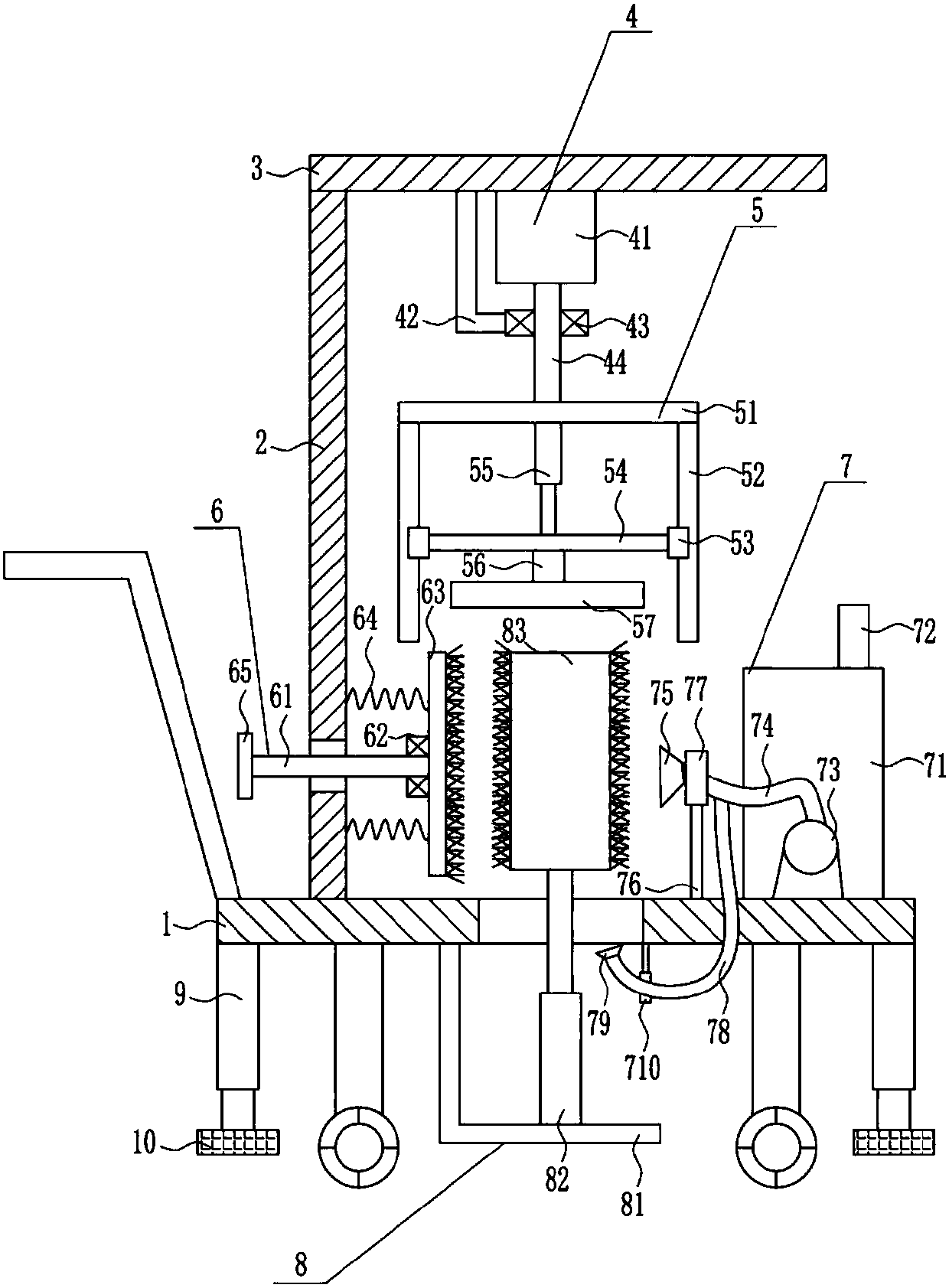

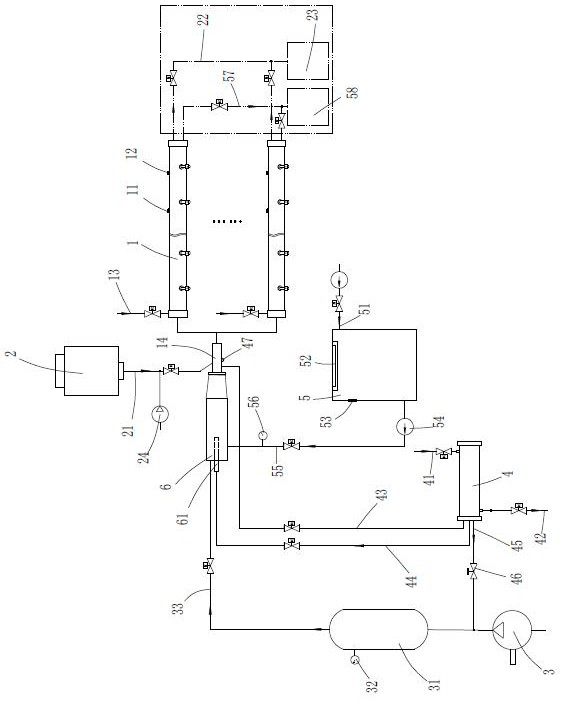

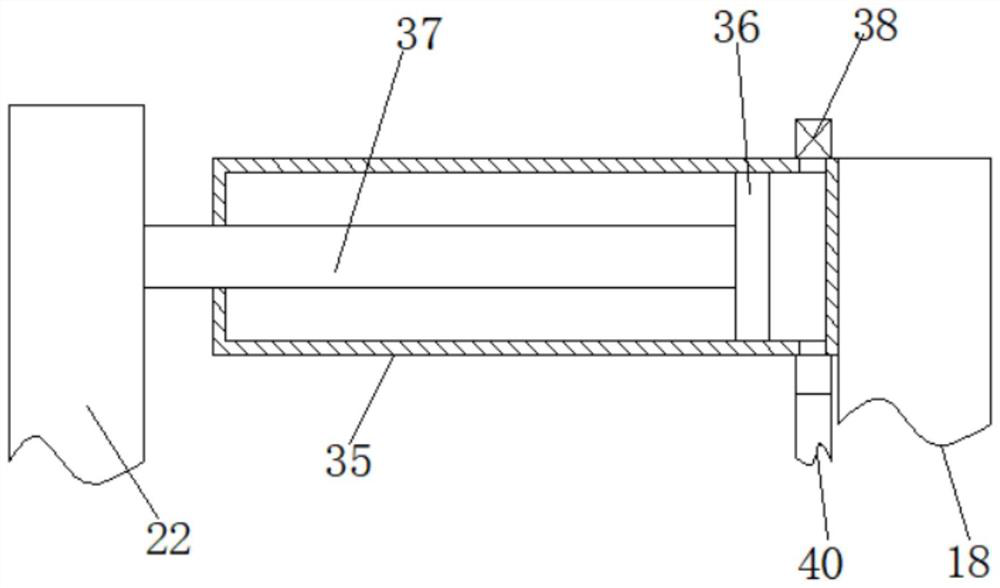

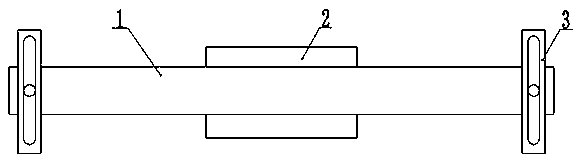

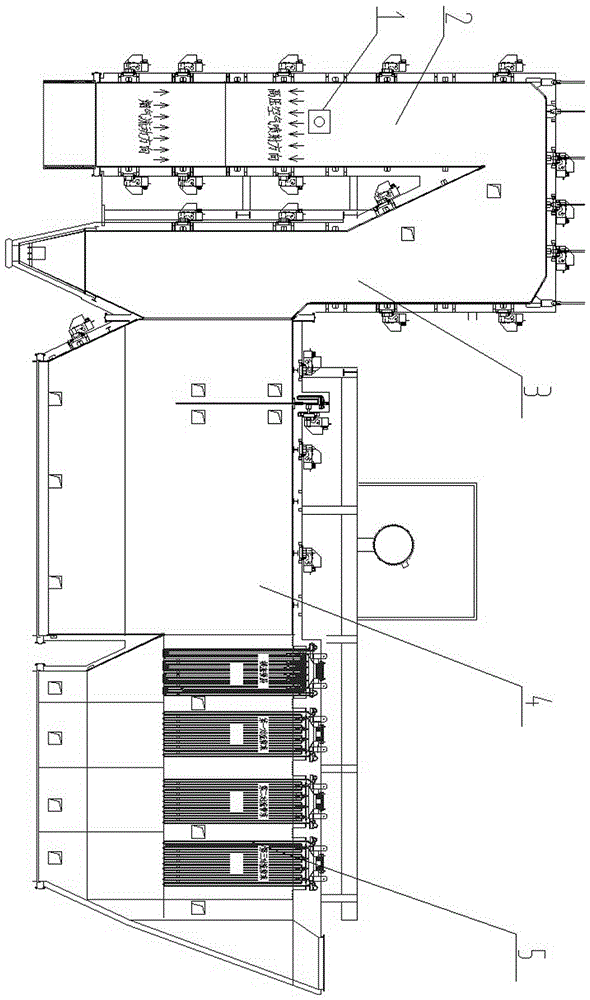

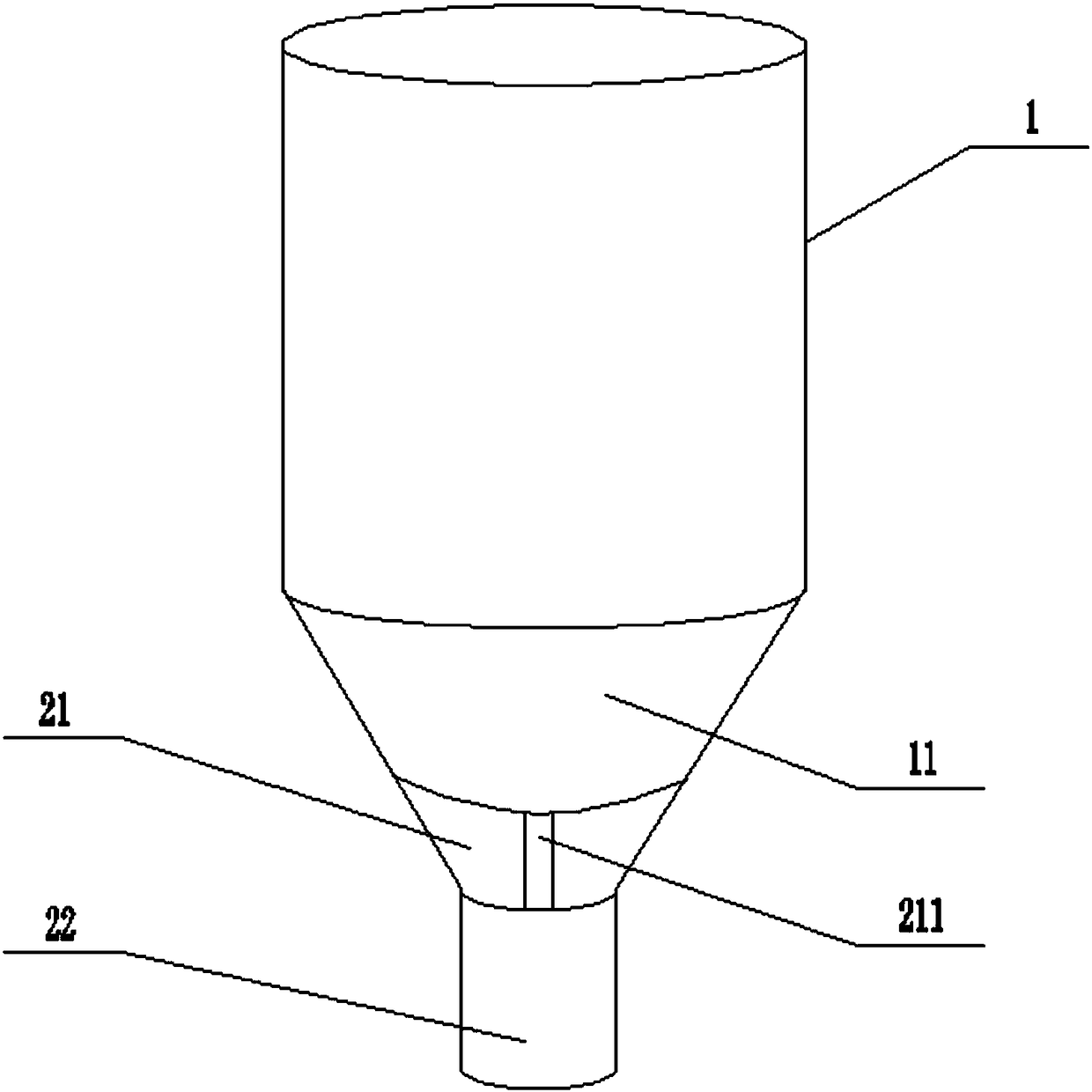

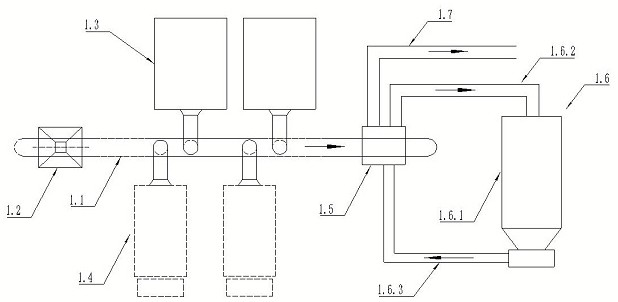

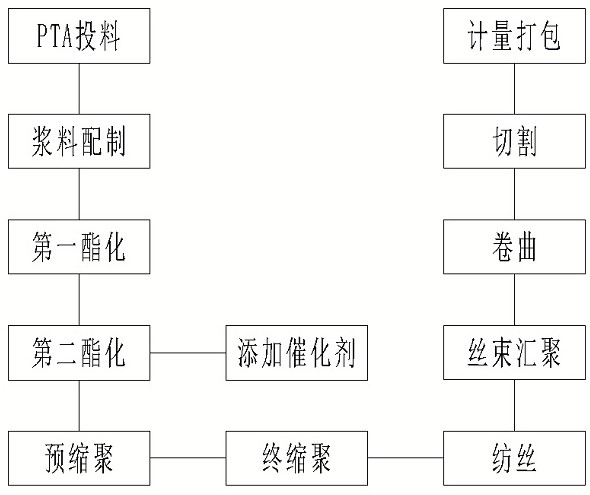

Special short fiber production line for high-cleaning spunlaced non-woven fabric

PendingCN111850721AImprove processing efficiencyReduce processing costsSpinning solution de-aeratingNew-spun product collectionWoven fabricYarn

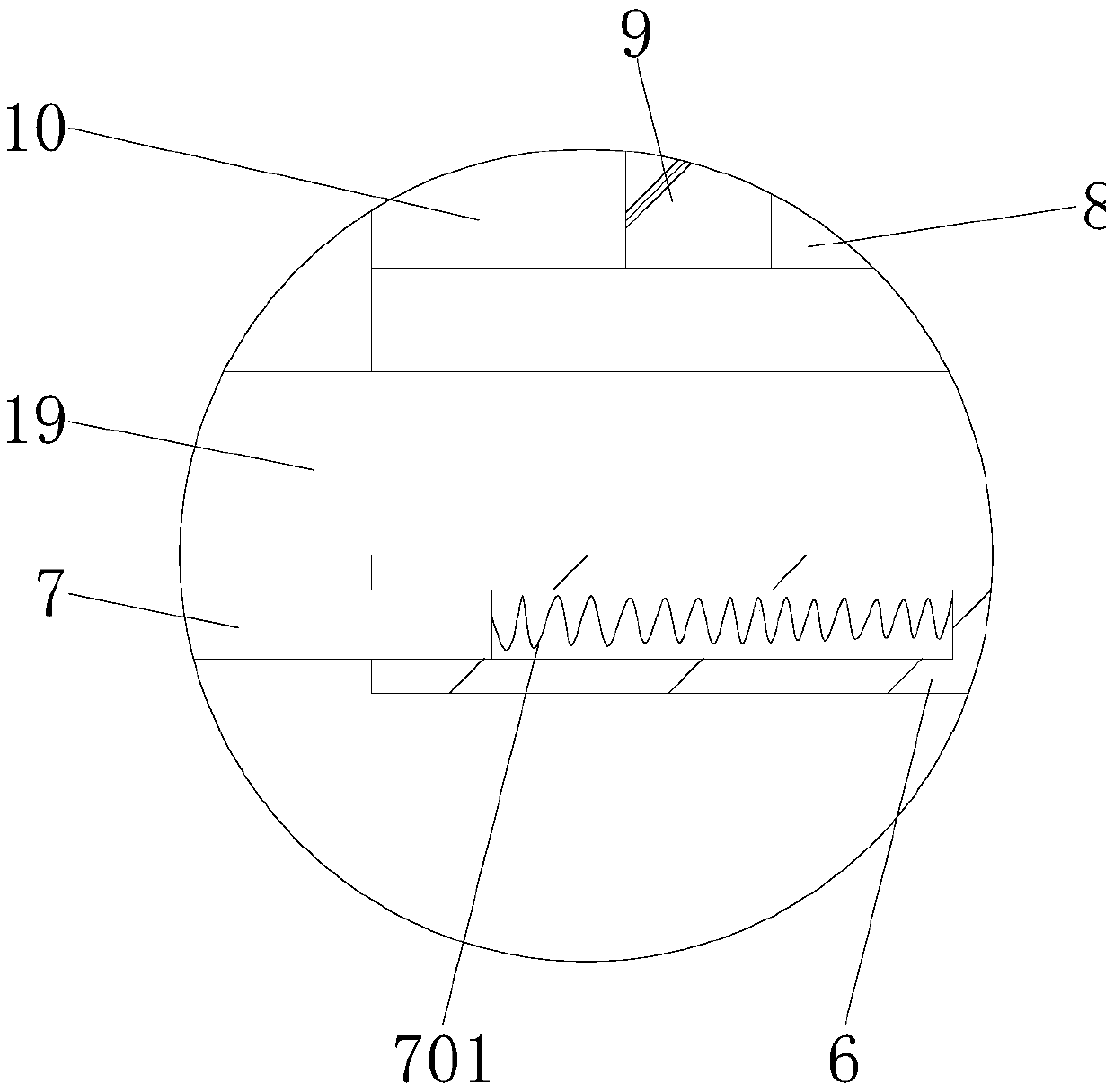

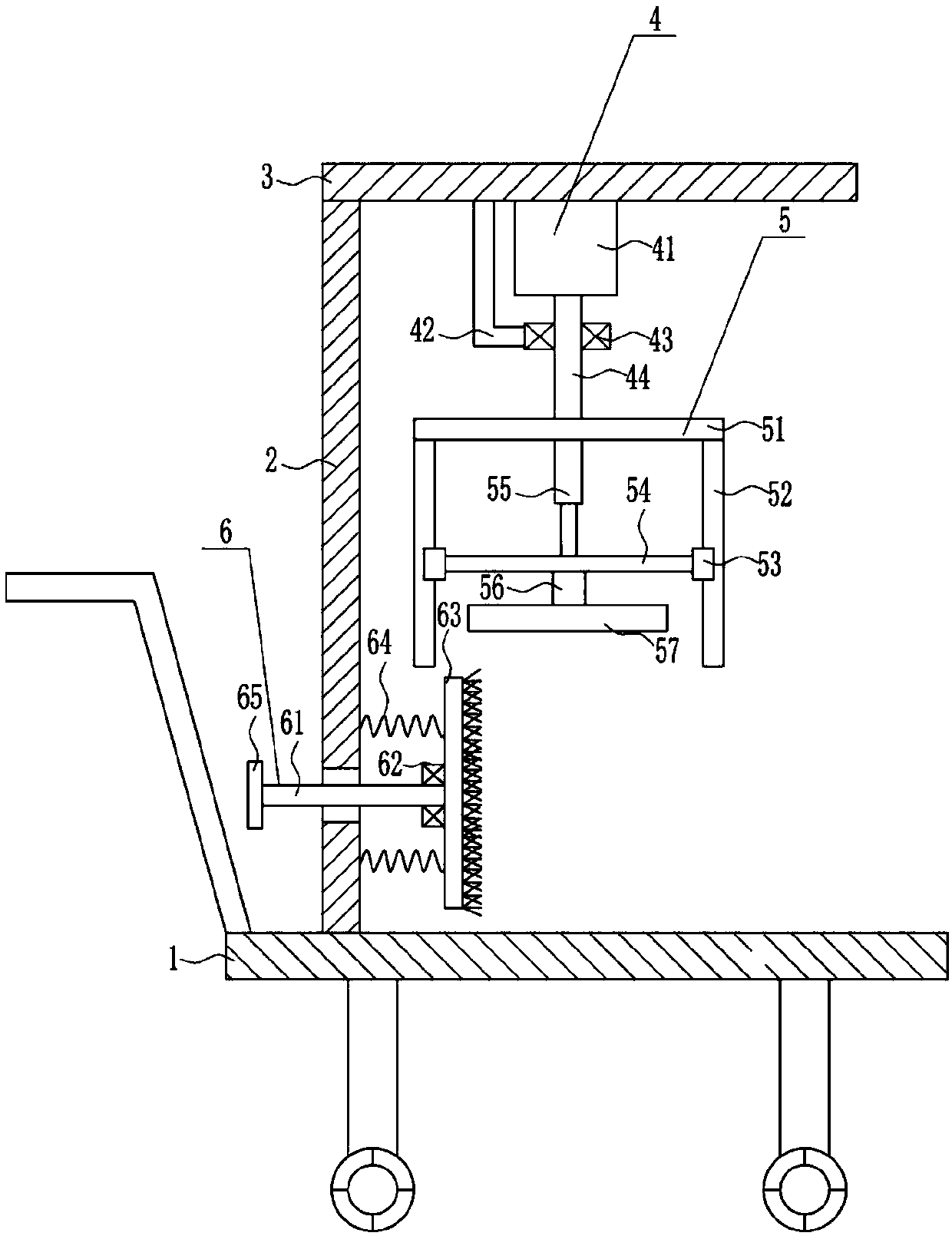

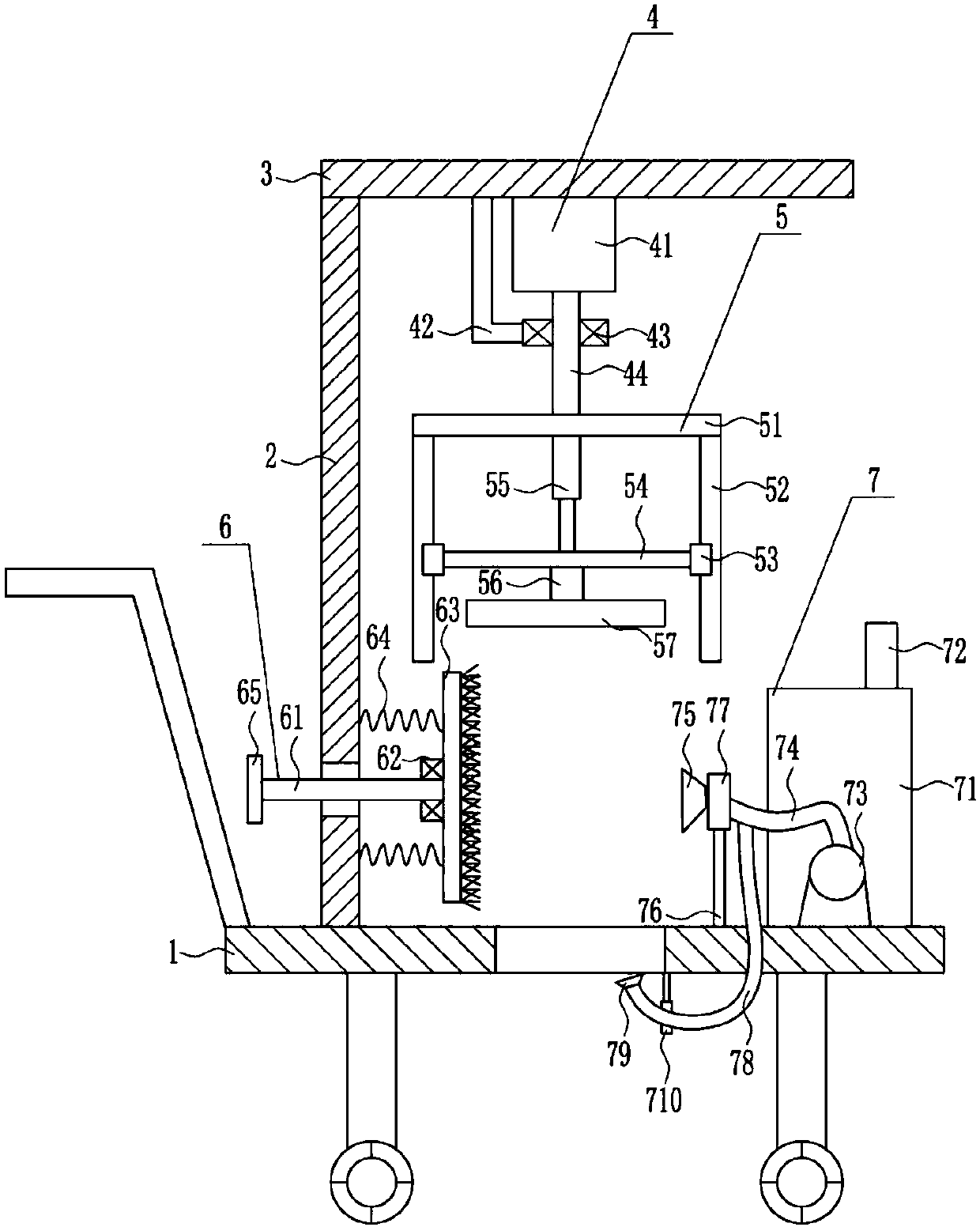

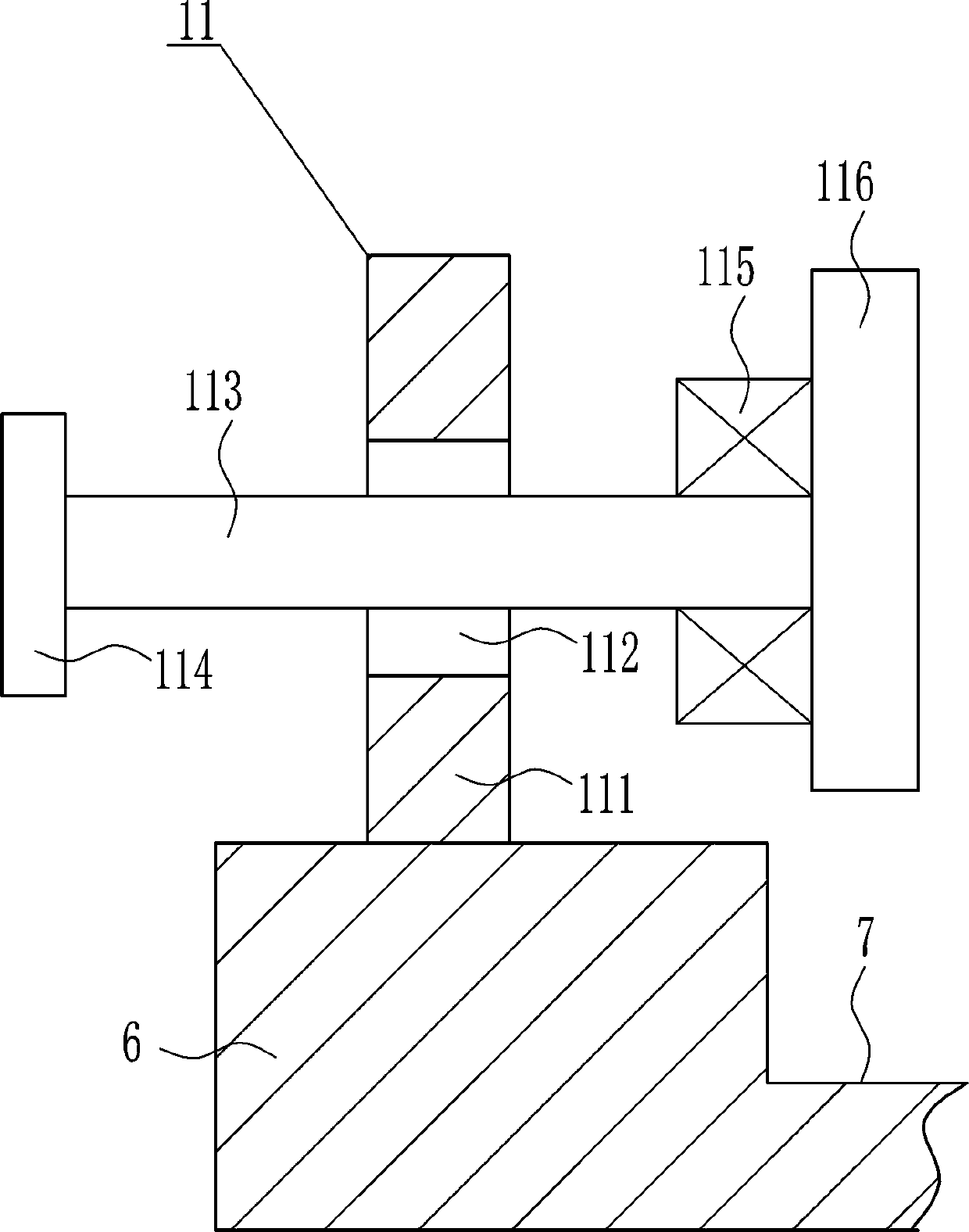

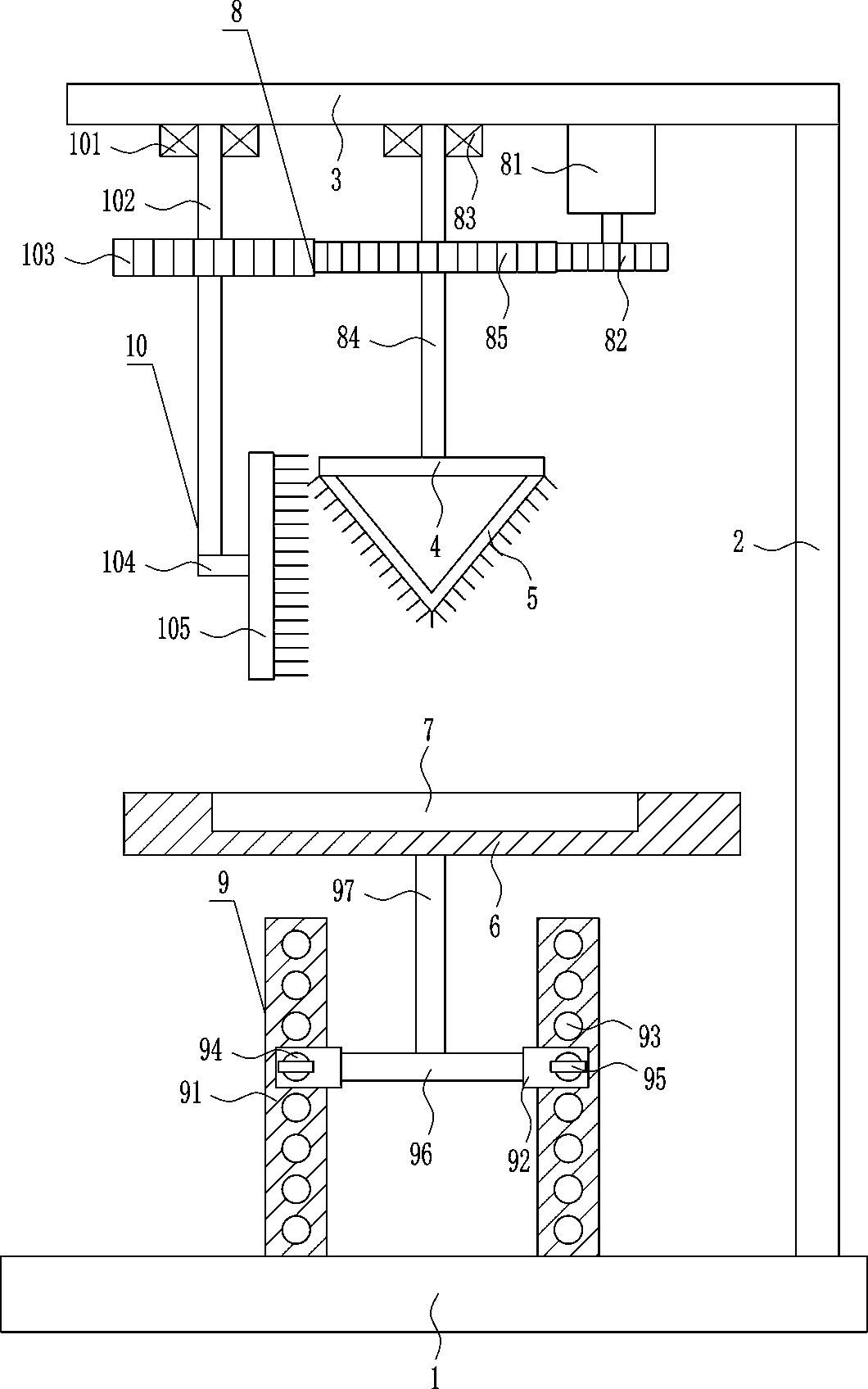

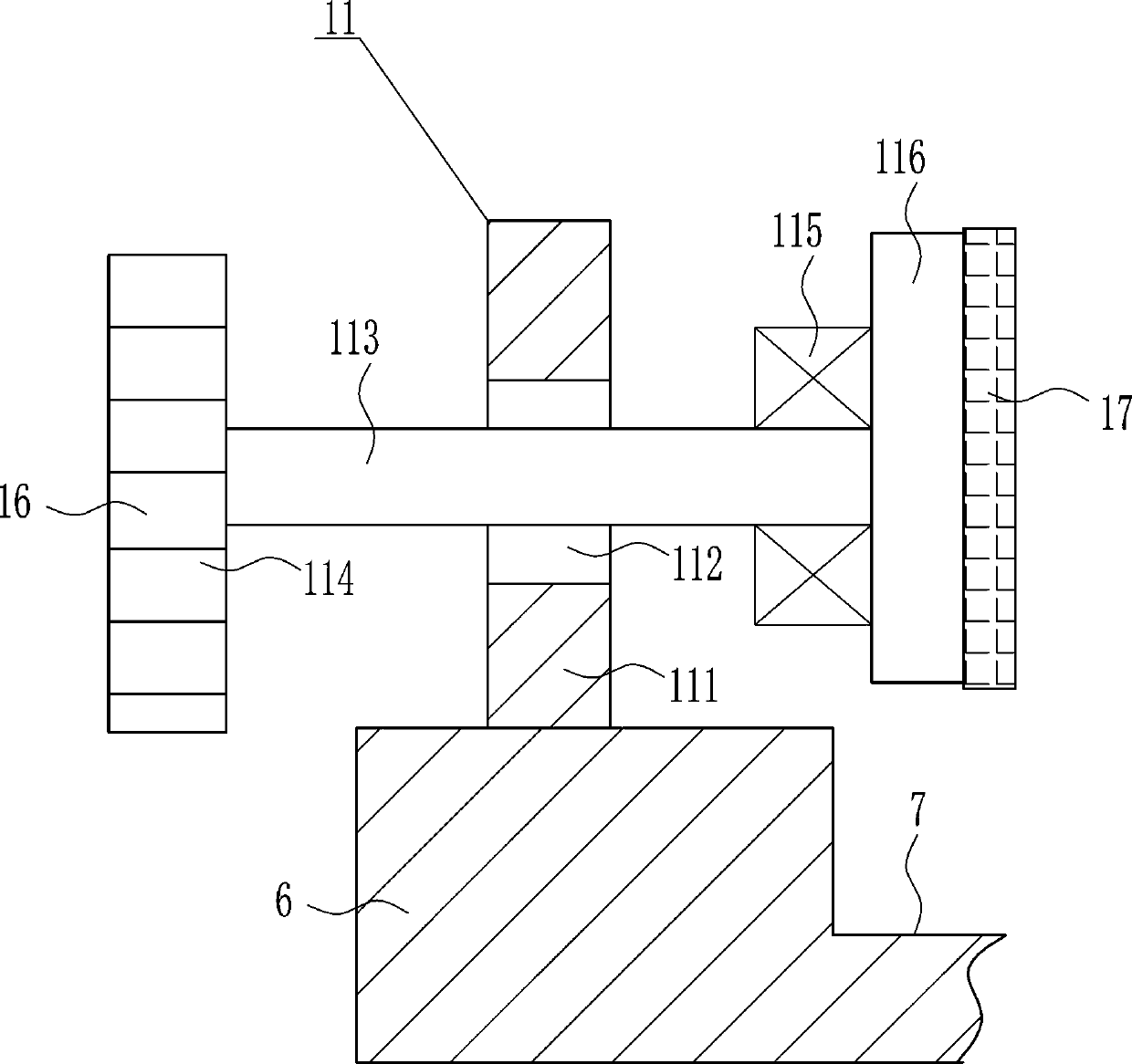

The invention relates to a special short fiber production line for high-cleaning spunlaced non-woven fabric. The special short fiber production line for the high-cleaning spunlaced non-woven fabric comprises a feeding system (1), a slurry preparation kettle (2), an esterification reaction kettle (3), a catalyst adding system (4), a polycondensation reaction kettle (5), a filter (6), a filter element cleaning device (7), a process wastewater pretreatment system (8), a spinning machine (9), an oiling ring (10), a yarn storage box (11), a yarn guide frame (12), a tail yarn alarm device (13), a crimper (14), a tow amplitude modulation device (15), a spinning cutter (16) and a packer (17). The feeding system (1), the slurry preparation kettle (2), the esterification reaction kettle (3), the polycondensation reaction kettle (5), the spinning machine (9), the oiling ring (10), the yarn storage box (11), the yarn guide frame (12), the crimper (14), the spinning cutter (16) and the packer (17)are sequentially arranged. The special short fiber production line for the high-cleaning spunlaced non-woven fabric has the advantages of high production efficiency, stable product quality, flexible and controllable production process and low production cost.

Owner:江苏华西村股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com